Karcher KM70-30C User Manual [en, es, fr]

KM 70/30 C Bp Pack Adv.

English |

3 |

Français |

11 |

Español |

19 |

59659800 (12/12)

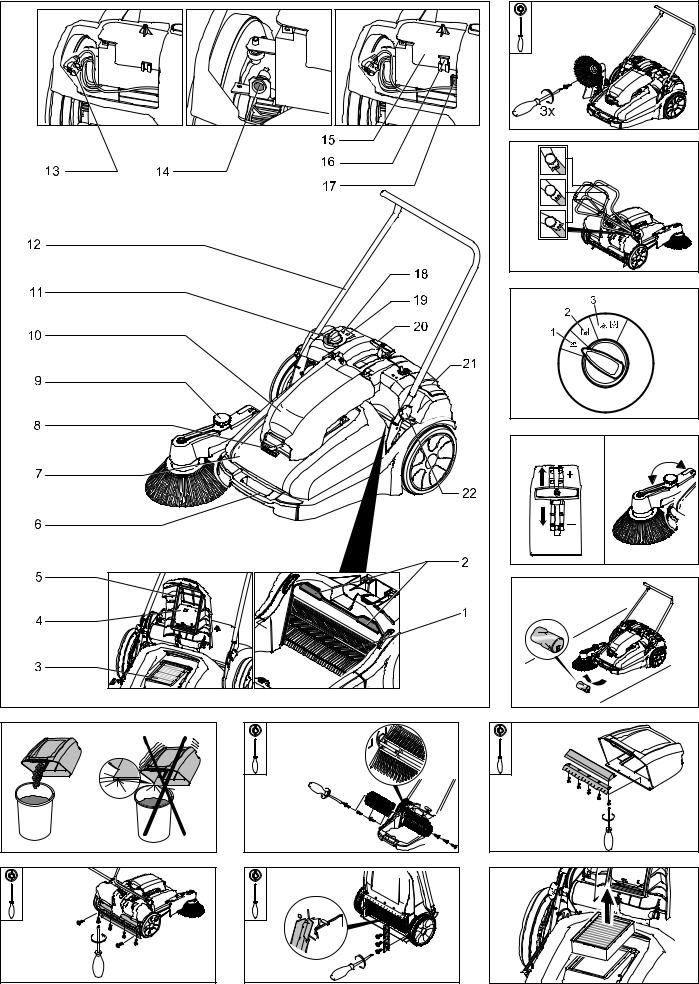

1 |

|

7 |

8 |

10 |

11 |

2 |

3 |

4

5 |

a |

b |

6 |

9 |

12

2

Operator Qualifications

Only trained and authorized persons shall be permitted to operate a powered unit. Operators of powered units shall be qualified as to visual, auditory, physical, and mental ability to operate the equipment safely according to the following points.

Operator Training

Personnel who have not been trained to operate powered units may operate a unit for the purposes of training only, and only under the direct supervision of the trainer. This training should be conducted in an area away from other units, obstacles, and pedestrians.

The operator training program should include the user s policies for the site where the trainee will operate the unit, the operating conditions for that location, and the specific unit the trainee will operate. The training program shall be presented to all new operators regardless of previous experience.

The training program shall inform the trainee that:

The primary responsibility of the operator is to use the unit safely following the instructions given in the training program.

The training program shall emphasize safe and proper operation to avoid injury to the operator and others and prevent property damage, and shall cover the following areas:

AFundamentals of the powered unit(s) the trainee will operate, including:

(1)characteristics of the powered unit(s), including varations between the units in the workplace;

(2)similarities and differences from automobiles;

(3)significance of nameplate data, warnings, and instructions affixed to the unit;

(4)operating instructions and warnings in the operating manual for the unit, and instructions for inspection and maintenance to be performed by the operator;

(5)type of motive power and its characteristics;

(6)method of steering;

(7)braking method and characteristics;

(8)visibility, forward and reverse;

(9)stability characteristics with and without load, with and without attachments;

(10)controls-location, function, method of operation, identification of symbols;

(11)battery charging;

(12)guards and protective devices for the specific type of unit;

(13)other characteristics of the specific

unit;

BOperating environment and its effect on unit operation, including:

(1)floor or ground conditions including temporary conditions;

(2)ramps and inclines;

(3)battery charging facilities;

(4)narrow aisles, doorways, overhead wires and piping, and other areas of limited clearance;

(5)areas where the unit may be operated near other powered units, other vehicles, or pedestrians;

(6)operation near edge of dock or edge of improved surface;

(7)other special operating conditions and hazards which may be encountered.

COperation of the powered unit, including:

(1)proper preshift inspection and approved method for removing from service a unit which is in need repair;

(2)parking and shutdown procedures;

(3)other special operating conditions for the specific application.

DOperating safety rules and practices, including:

(1)provisions of the section OPERATING SAFETY RULES AND PRACTICES in this document.

(2)other rules, regulations, or practices specified by the employer at the location where the unit will be used.

EOperational training practice, including:

(1)if feasible, practice in the operation of a powered unit shall be conducted in an area separate from other workplace activities and personnel:

(2)training practice shall be conducted under the supervision of the trainer;

(3)training practice shall include the actual operation or simulated performance of all operating tasks such as maneuvering, traveling, stopping, starting, and other activities under the conditions which will be encountered in the use of the unit.

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Safe operation is in the responsibility of the operator.

The operator shall develop safe working habits and also be aware of hazardous conditions in order to protect himself, other personnel, the unit, and other material.

The operator shall be familiar with the operation and function of all controls and instruments before undertaking to operate the unit.

Before operating the unit, operators shall have read and be familiar with the operator s manual for the particular unit being operated and they shall also abide by the safety rules and practices in the following paragraphs.

Before operating any unit, the operator shall be familiar with unusual operating conditions which may require additional safety precautions or special operating instructions.

General

Before starting to operate the unit: A be in operating position;

Bplace directional controls in neutral; C turn switch to ON position.

Do not start or operate the unit, any of its functions or attachments, from any place other than from the designated operator s position.

Keep hands and feet inside the operator s designated area.

Understand unit limitations and operate the unit in a safe manner so as not to cause injury to personnel. Safeguard pedestrians at all times.

A Do not drive a unit up to anyone standing in front of an object.

BEnsure that personnel stand clear of rear swing area before conducting turns and maneuvers.

CExercise particular care at cross aisles, doorways, and other locations where pedestrians may step into the path of travel of the unit.

Before leaving the operator s position: A bring the unit to a complete stop;

Bplace the directional controls in neutral; C apply the parking brake;

In addition, when leaving the unit unattended:

A stop the engine or turn off the controls;

Bif the unit must be on an incline, block the wheels.

Maintain a safe distance from the edge of ramps, platforms, and other similar working surfaces.

When powered units are driven on and off highway trucks or trailers, the brakes on the highway trucks or trailers shall be applied and wheel chocks or other positive mechanical means shall be used to prevent unintentional movement of highway trucks and trailers.

When powered units are driven on and off semitrailers that are not coupled to a tractor, supports may be needed to prevent upending or corner dipping.

Report all accidents involving personnel, building structures, and equipment to the supervisor or as directed.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Traveling

Observe all traffic regulations including authorized plant speed limits. Under normal traffic conditions, keep to the right. Maintain a safe distance, based on speed of travel, from the unit ahead; keep the unit under control all times.

Yield the right of way to pedestrians and emergency vehicles such as ambulances and fire trucks.

Do not pass another unit traveling in the same direction at intersections, blind spots, or at other dangerous locations.

EN - 1 |

3 |

Cross railroad tracks at an angle wherever possible. Do not park closer than 6 ft (1800 mm) to the nearest rail of a railroad track. Keep a clear view of the path of travel and observe for other traffic, personnel, and safe clearances.

Ascend or descend grades slowly, and with caution. Avoid turning, if possible, and use extreme caution on grades, ramps, or inclines; normally travel straight up and down.

Under all travel conditions, operate the unit at a speed that will permit it to be brought to a stop in a safe manner.

Make starts, stops, turns, or direction reversals in a smooth manner so as not shift load and/or overturn the unit.

Do not indulge in stunt driving or horseplay. Slow down for wet and slippery floors. Before driving over a dockboard or bridge plate, be sure that it is properly secured. Drive carefully and slowly across the dockboard or bridge plate, and never exceed its rated capacity.

Do not drive units onto any elevator unless specially authorized to do so. Do not exceed the capacity of the elevator. Approach elevators slowly, and then enter squarely after the elevator car is properly leveled. Once on the elevator, neutralize the controls, shut off power, and set brakes. It is advisable that all other presonnel leave the elevator before the unit is allowed to enter or leave.

When negotiating turns, reduce speed to a safe level consistent with the operating environment. Make the turns smoothly.

Motorized hand unit operation requires special safety considerations as follows:

A never operate with greasy hands; B foot protection is recommended; C do not ride on the unit;

Dkeep feet clear of unit frame while operating.

Ealways keep hands and fingers inside the protected area of the control handle;

Fbe cautious when traveling in reverse due to steering characteristics;

G use caution when turning into an aisle;

Hnever travel at a speed greater than normal walking speed (approximately 3.5 mph [5.6 km/h]);

Ialways place both hands on the control handle when operating;

Jalways operate with ohe hand on controls.

Operator care of the unit

At the beginning of each shift and before operating the unit, check its conditon, giving special attention to the following:

A condition of tires

Bif pneumatic tires, check inflation pressures

C warning and safety devices

D lights

E battery

F controls

G chains and cables

H limit switches

Isteering mechanism

Jadditional items or special equipment as specified by the user and/or manufacturer

If the unit is found to be in need of repair or in any way unsafe, or contributes to an unsafe condition, the matter shall be reported immediately to the user s designated authority, and the unit shall not be operated until it has been restored to safe operating condition.

If during operation the unit becomes unsafe in any way, the matter shall be reported immediately to the user s designated authority, and the unit shall not be operated until it has been restored to safe operating condition.

Do not use open flames when checking electrolyte level in storage batteries.

Do not make repairs or adjustments unless specifically authorized to do so.

MAINTENANCE AND REBUILD PRACTICES

Operation of the unit may be hazardous if maintenance is neglected or repairs, rebuilds, or adjustments are not performed in accordance with the manufacturer s design criteria. Therefore, maintenance facilities (on or off premises), trained personnel, and detailed procedures shall be provided. Parts manuals and maintenance manuals may be obtained from the unit manufacturer.

In unusual cases not covered by the manuals referred above, consult the unit manufacturer.

Maintenance and inspection of the unit shall be performed in conformance with the following practices:

Aa schedules planned maintenance, lubrication, and inspection system shall be followed; consult the manufacturer s recommendations;

Bonly trained and authorized personnel shall be permitted to maintain, repair, adjust, and inspect the unit, and in accordance with manufacturer s specifications.

Before starting inspection and repair of the unit:

Araise drive wheels free of floor or disconnect battery and use chocks or other positive unit positioning devices;

B block chassis before working on them;

Cdisconnect battery before working on the electrical system;

Dthe charger connector shall be plugged only into the battery connector and never into the unit connector.

Operation of the unit to check performance shall be conducted in an authorized area where safe clearance exists.

ABefore starting to operate the unit:

(1)be in operating position;

(2)place directional controls in neutral;

(3)turn switch to ON position;

(4) check function of steering, warning devices, and breaks;

BBefore leaving the unit:

(1)stop unit;

(2)place directional controls in neutral;

(3)stop the engine or turn off power;

(4)turn off the control circuit;

(5)if the unit must be left on an incline, block the wheels.

Avoid fire hazards and have fire protection equipment present in the work area. Do not use any open flame to check the level or to check for leakage of any fluid, especially battery electrolyte. Do not use open pans of fuel or flammable cleaning fluids for cleaning parts.

Properly ventilate work area, vent exhaust fumes, and keep shop clean and dry. Brakes, steering mechanisms, control mechanisms, warning devices, articulating axle stops, and frame members shall be carefully and regularly inspected and maintanined in safe operating condition.

FIRE SAFETY STANDARD

Maintenance

Any unit not in safe operating condition shall be removed from service. Precautions. Repairs shall not be made in Class I, Class II, and Class III locations. Repairs to the electrical system of batterypowered units shall be performed only after the battery has been disconnected.

Operating Temperature. Where temperature of any part of the unit is found to be in excess of its normal operating temperature and creates a hazardous condition, the unit shall be removed from service and shall not be returned to service until the cause for such overheating has been eliminated. Fire Prevention. The unit shall be kept in a clean condition and reasonably free of lint, excess oil, and grease. Noncombustible agents are preferred for cleaning the unit. Flammable liquids [those having flash points at or above 100°F (37,8°C)] are not allowed. Precautions regarding toxicity, ventilation, and fire hazard shall be appropriate for the agent or solvent used. Nameplate Visibility: The unit type designations as shown on the nameplate and the type markers shall not be covered over with paint so that their identification information is obscured.

4 |

EN - 2 |

Changing and Charging Storage

Batteries

This section shall apply to batteries used in electric units. The two types of batteries commonly used are lead and nickel-iron. They contain corrosive chemical solutions, either acid or alkali, and, therefore , present a chemical hazard. While being charged, they give off hydrogen and oxygen, which, in certain concentrates, are explosive. Battery-charging installations shall be located in areas designated for that purpose; such areas shall be kept free of extraneous combustible materials. Facilities shall be provided for the following:

A Flushing spilled electrolyte; B Fire protection;

CProtecting charging apparatus from damage by trucks; and

DAdequate ventilation for dispersal of fumes from gasing batteries.

Where on-board chargers are used, charging shall be accomplished at locations designated for that purpose, taking into account the electrical requirements of the charger and facilities for fire protection.

Exception: Flushing faclilties shall not be required if charging is accomplished without removing the battery from the vehicle.

Where handling acid concentrates greater than 50 percent acid (above 1.400 specific gravity), an eye-wash fountain shall be provided.

A conveyor, overhead hoist, or equivalent material handling equipment shall be provided for handling batteries.

Chain hoists shall be equipped with loadcabin containers. Where a hand hoist is used, uncovered battries shall be covered with a sheet of plywood or other nonconducting material to prevent the hand chain from shorting on cell connectors or terminals. A properly insulated spreader bar shall be used with any overhead hoist. Reinstalled or new batteries shall meet or exceed the battery type marked on the unit. Reinstalled batteries shall be positioned properly and secured in the unit.

A carboy tilter or siphon shall be provided where acid in carboys is used. When diluting concentrated sulfuric acid to make up electrolyte, the acid ALWAYS shall be added to the water - not the reverse. Battery maintenance personnel shall wear protective clothing such as eye protection, long sleeves, and gloves.

Exception: Removal and replacement of batteries shall not require the use of protective clothing.

Trained and authorized personnel shall change or charge batteries.

Electrical installations shall be in accordance with NFPA 70, National Electrical Code, and any local ordinances.

Units shall be positoned properly and brakes shall be applied before attempting to change or charge batteries.

Where charging batteries, the vent caps shall be kept in place to avoid electrolyte

spray. Care shall be taken to ensure that vent caps are functioning. The battery (or compartment cover(s) shall be open to dissipate heat and gas.

Smoking shall be prohibited in the charging area.

Precautions shall be taken to prevent open flames, sparks, or electric arcs in batterycharging areas.

Tools and other metallic objects shall be kept away from the tops of uncovered batteries.

EN - 3 |

5 |

Please read and comply with

these original instructions prior to the initial operation of your appliance and store them for later use or subsequent owners.

these original instructions prior to the initial operation of your appliance and store them for later use or subsequent owners.

Please read the safety instructions before start-up!

Contents

General notes . . . . . . . . . . . EN . . 4 Proper use . . . . . . . . . . . . . EN . . 4 Safety instructions . . . . . . . EN . . 4

Operating and Functional Ele-

ments . . . . . . . . . . . . . . . . . EN . . 5 Before Startup. . . . . . . . . . . EN . . 5 Start up . . . . . . . . . . . . . . . . EN . . 6 Operation . . . . . . . . . . . . . . EN . . 6 Shutdown . . . . . . . . . . . . . . EN . . 6 Transport. . . . . . . . . . . . . . . EN . . 6 Storage . . . . . . . . . . . . . . . . EN . . 6 Maintenance and care . . . . EN . . 6 Special accessories . . . . . . EN . . 7 Faults . . . . . . . . . . . . . . . . . EN . . 8 Technical specifications . . . EN . . 8

General notes

Your sales outlet should be informed about any transit damage noted when unpacking the product.

–Warning and information plates on the machine provide important directions for safe operation.

–In addition to the information contained in the operating instructions, all statutory safety and accident prevention regulations must be observed.

Environmental protection

The packaging material can be recy-

cled. Please do not place the packaging into the ordinary refuse for disposal, but arrange for the proper recycling.

cled. Please do not place the packaging into the ordinary refuse for disposal, but arrange for the proper recycling.

Old appliances contain valuable materials that can be recycled. Please

arrange for the proper recycling of old appliances. Batteries and accumulators contain substances that must not enter the environment. Please dispose of your old appliances, batteries and accumulators using appropriate collection systems.

arrange for the proper recycling of old appliances. Batteries and accumulators contain substances that must not enter the environment. Please dispose of your old appliances, batteries and accumulators using appropriate collection systems.

Notes about the ingredients (REACH)

You will find current information about the ingredients at: www.kaercher.com/REACH

Warranty

The warranty terms published by the relevant sales company are applicable in each country. We will repair potential failures of your appliance within the warranty period free of charge, provided that such failure is caused by faulty material or defects in manufacturing. In the event of a warranty claim please contact your dealer or the nearest authorized Customer Service centre. Please submit the proof of purchase.

6

Accessories and Spare Parts

Danger

To avoid risks, all repairs and replacement of spare parts may only be carried out by authorized customer service personnel.

–Only use accessories and spare parts which have been approved by the manufacturer. The exclusive use of original accessories and original spare parts ensures that the appliance can be operated safely and troublefree.

–At the end of the operating instructions you will find a selected list of spare parts that are often required.

–For additional information about spare parts, please go to the Service section at www.kaercher.com.

Symbols in the operating instructions

Danger

Warns about immediate danger which can lead to severe injuries or death.

Warning

Warns about possible danger which could lead to severe injuries or death.

Caution

Points out a possibly dangerous situation which can lead to light injuries or property damage.

Proper use

Use this sweeper only as directed in these operating instructions.

–This sweeper has been designed to sweep dirt and debris from indoor as well as outdoor surfaces.

–Any use extending beyond this is not considered as proper use. The manufacturer is not liable for any losses resulting from this; the user alone bears the risk for this.

–The machine is only suitable for use on the types of surfaces specified in the operating instructions.

Foreseeable misuse

–Never vacuum up explosive liquids, combustible gases or undiluted acids and solvents. This includes petrol, paint thinner or heating oil which can generate explosive fumes or mixtures upon contact with the suction air. Acetone, undiluted acids and solvents must also be avoided as they can harm the materials on the machine.

–Never sweep/vacuum up reactive metal dusts (e.g. aluminium, magnesium, zinc), as they form explosive gases when they come in contact with highly alkaline or acidic detergents.

–Do not sweep/vacuum up any burning or glowing objects.

–The appliance is not suitable for sweeping off liquids.

–The machine may not be used or stored in hazardous areas. It is not allowed to

EN - 4

use the appliance in hazardous locations.

–Pushing or transporting objects by means of this appliance is prohibited.

Suitable surfaces

–Asphalt

–Industrial floor

–Screed

–Concrete

–Paving stones

Safety instructions

–This device is not intended for use by persons (including children) with reduced physical, sensory or mental abilities or lacking experience and/or knowledge, unless they are supervised by a person responsible for their safety or are instructed by these persons on the use of the device. Children should be supervised, to ensure that they do not play with the device.

–The operator must use the appliance properly. The person must consider the local conditions and must pay attention to third parties, in particular children, when working with the appliance.

–The machine with working equipment must be checked to ensure that it is in proper working order and is operating safely prior to use. Otherwise, the appliance must not be used.

–The machine may not be modified.

–The following applies in general: Keep highly-flammable substances away from the appliance (danger of explosion/fire).

Danger

Risk of injury. Before performing any tasks at the machine, first turn the programme selection switch to "OFF“and clamp the cable at the minus pole of the battery.

Warning

Risk of being squeezed or hurt at the belts, side-brushes, containers, pushing handle.

Caution

Wear proper safety gloves while removing glass, metal or other sharp-edged materials from the dirt container.

Battery-operated machines

Note

Warranty claims will be entertained only if you use batteries and chargers recommended by Kärcher.

–Always follow the instructions of the battery manufacturer and the charger manufacturer. Please follow the statutory requirements for handling and disposing batteries.

–Never leave the batteries in a discharged state; recharge them as soon as possible.

–Always keep the batteries clean and dry to avoid creep currents. Protect the bat-

teries and avoid contact with impurities such as metal dust.

–Do not place tools or similar items on the battery. Risk of short-circuit and explosion.

–Do not work with open flames, generate sparks or smoke in the vicinity of a battery or a battery charging room. Danger of explosion.

–Used batteries are to be disposed according to the EC guideline 91/ 157 EWG in an environment-friendly manner.

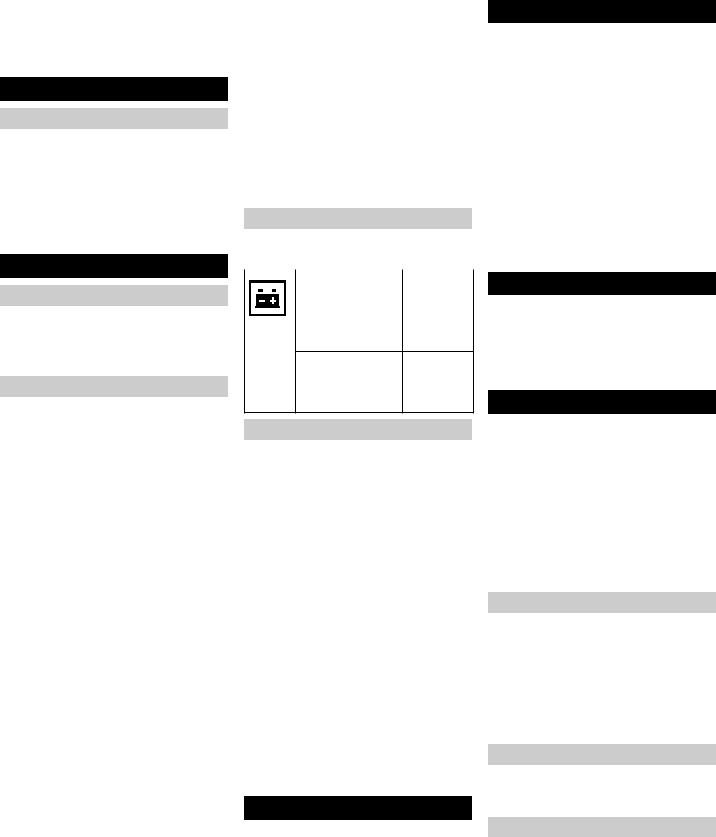

Operating and Functional

Elements

Figure 1, see cover page

1Roller brush

2Foam filter

3Flat fold filter

4Blower dust suction

5Washer dust suction

6Carrying handle

7Waste container

8Handle filter shake-off

9Pressing handle for contact pressure to the side brushes

10Dust suction

11Programme switch

12Push handle

13Mains cable with plug

14Charging box

15Battery cover

16Reserve fuse

17Fuse

18Fault display: Battery

19Battery display

20Lever for contact pressure to sweeping roller

21Mains cable storage/ battery compartment

22Star grip pushing handle fastening

Before Startup

Unpacking

Open the carton on the side and take out the appliance.

Your sales outlet should be informed about any transit damage noted when unpacking the product.

Assembly

Figure 2, see cover page

Fasten the side brushes with the 3 screws enclosed in the packet.

Batteries

Safety notes regarding the batteries

Please observe the following warning notes when handling batteries:

Observe the directions on the battery, in the instructions for use and in the vehicle operating instructions

Wear eye protection

Keep children away from acid and batteries

Danger of explosion

Fire, sparks, naked flames and smoking must be strictly avoided

Danger of chemical burns

First aid

Warning note

Disposal

Do not throw the battery into the regular waste

Please observe the following warning notes when handling batteries:

Danger

Risk of explosion! Do not put tools or similar on the battery, i.e. on the terminal poles and cell connectors.

Risk of injury! Ensure that wounds never come into contact with lead. Always clean your hands after having worked with batteries.

Installing and connecting the battery

Remove the lid of the battery compartment.

Turn out the screw and remove the battery cover.

Insert battery in battery mount.

Warning

Pay attention to correct poles.

Attach the connection cable provided with the pack.

Connect pole terminal (red cable) to positive pole (+).

Connect pole terminal to negative pole (-).

Replace the battery cover and fasten using screw.

Replace the lid of the battery compartment and lock it.

Note

Before removing the battery, make sure that the negative pole lead is disconnected.

EN - 5

Check that the battery pole and pole terminals are adequately protected with pole grease.

Warning

Charge the battery before commissioning the machine.

Charging battery

Danger

Risk of electric shock. Observe supply network and fuse protection - see "Charger". Only use the charger in dry rooms with sufficient ventilation!

Note

The charging time for an empty battery is approx. 12 hours.

Danger

Risk of injury! Comply with safety regulations on the handling of batteries. Observe the directions provided by the manufacturer of the charger.

Charging process

Danger

Risk of injury! The charger should be used only if the mains cable is in an undamaged state. Get the manufacturer, the customer service agent or a qualified person to immediately replace a damaged mains cable.

Note

Normally, the machine is equipped with a maintenance-free battery.

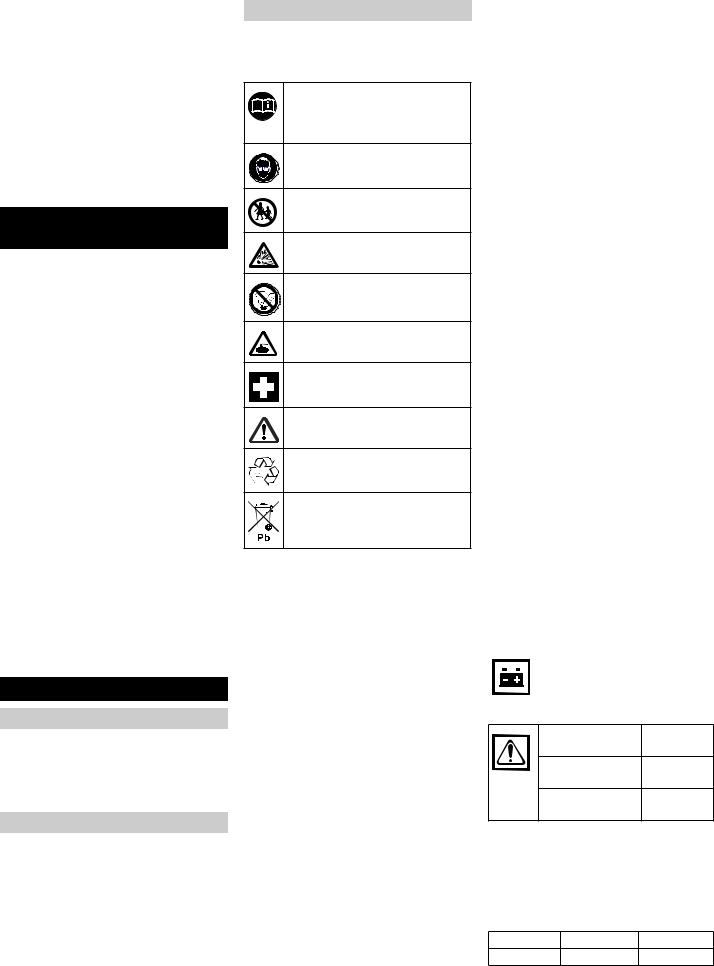

Insert the plug of the charger into the socket.

Note

The charger has electronic controls and automatically switches off the charging process. All functions of the machine are automatically interrupted during the charging process.

The battery display shows the progress of the charging process when the plug is inserted:

|

Battery is being |

glows yellow |

|

charged |

|

|

|

|

|

Battery is charged |

glows green |

|

|

|

Charger is defec- |

glows red |

tive |

|

Battery poled or is |

slowly blinks |

not connected |

red |

Battery defective |

blinks red |

|

fast |

After charging

Remove the mains cable and put it away:

–Insert the mains plug in the appliance hood.

Maximum battery dimensions

Length |

Width |

Height |

175 mm |

166 mm |

125 mm |

Removing the batteries

Remove the lid of the battery compartment.

7

Turn out the screw and remove the battery cover.

Clamp off the minus pole of the battery.

Disconnect pole terminal to positive pole (-).

Remove the battery.

Dispose of the used battery according to the local provisions.

Start up

Adjust the pushing handle

Figure 3, see cover page

Loosen both the star grips.

Pull the pushing handle backward and tilt it to the desired position.

Press the pushing handle forward and lock it in.

Tighten the star handles.

Operation

Programme selection

Figure 4, see cover page

1OFF - Appliance is switched off.

2Sweep.

3Sweep suction (only Adv. model).

Sweeping mode

Caution

Do not sweep up packing strips, wire or similar objects as this may damage the sweeping mechanism.

The drive belts of the side brushes can slip down. Tilt up the side brushes only when the appliance is switched off.

Note

To achieve an optimum cleaning result, the driving speed should be adjusted to take specific situations into account.

Note

During operation, the waste container should be emptied at regular intervals.

Note

Also lower side brush when cleaning along edges.

Tilt the side brushed upward or downward depending on the task.

Note

The dust blown up by the side brushes is not sucked in. Place the side brushes at the edge only while sweeping.

Set the programme switch to sweep or

sweep suction. |

|

|

|

Dry floor |

Sweep suction |

Wet floor |

Sweep |

Move the appliance over the surface to be swept.

Adjust the brush contact pressure Figure 5, see cover page

Lift, adjust and lower the lever for the contact pressure of the sweeping roller.

+ Increase contact pressure.

– Reduce contact pressure.

8

Adjust the pressure by turning the turning handle for the contact pressure of the side brushes.

+ Increase contact pressure.

– Reduce contact pressure.

Note

A very high contact pressure means increased power consumption and hence lesser usage time.

Collect dirt

Figure 6, see cover page

Slightly press the pushing handle downward so that the appliance lifts up slightly towards the front.

Move the appliance with the raised upper part over the dirt.

Now lower the appliance again.

Battery display

The battery display shows the charging status of the battery during operations:

|

full |

glows green |

|

30% capacity re- |

glows yel- |

|

maining |

low |

|

|

|

|

10% capacity re- |

blinks red |

|

maining |

|

Protection against glows red total discharge; the

appliance is switched off

Emptying waste container

Warning

Risk of injury on account of rotating roller brush.

Before removing the waste container please turn the programme selection to "OFF" and wait until the roller brush comes to a halt.

Note

Dust progress. As far as possible, shake off the filter and empty the waste container in open places.

Turn the program selection switch to "OFF".

Pull the handle of the filter shake-off many times and release it.

Tilt the dust suction upward.

Pull the waste container upward at the handle and remove it from the appliance.

Figure 7, see cover page

Dispose off the waste according to local regulations.

Shutdown

If the sweeper is going to be out of service for a longer time period, observe the following points:

Park the sweeper on an even surface.

Lock the sweeper to ensure that it does not roll off.

Clean the inside and outside of the sweeper.

Park the machine in a safe and dry place.

EN - 6

Disconnect battery.

Charge battery and recharge it approx. every 2 months.

Transport

Caution

Risk of injury and damage! Observe the weight of the appliance when you transport it.

Turn the program selection switch to "OFF".

Lift the appliance at the carrying handles when you want to transport it.

Secure the wheels of the machine with wheel chocks.

Secure the machine with tensioning straps or cables.

When transporting in vehicles, secure the appliance according to the guidelines from slipping and tipping over.

Storage

Caution

Risk of injury and damage! Note the weight of the appliance in case of storage.

This appliance must only be stored in interior rooms.

Maintenance and care

Danger

Risk of injury. Before performing any tasks at the machine, first turn the programme selection switch to "OFF“and clamp the cable at the minus pole of the battery.

Do not clean the appliance with a water hose or high-pressure water jet (danger of short circuits or other damage).

Note

Do not use aggressive and abrasive cleaning agents.

Cleaning the inside of the machine

Warning

Risk of injury! Wear dust mask and protective goggles.

Blow through machine with compressed air.

Clean the machine with a damp cloth which has been soaked in mild detergent.

External cleaning of the appliance

Clean the machine with a damp cloth which has been soaked in mild detergent.

Maintenance intervals

Daily maintenance:

Check the sweeping roller and the side brush for wear and wrapped belts.

Check function of all operator control elements.

Weekly maintenance:

Clean both the foam filters under flowing water.

Check the flat folded filter, clean if required

Check moving parts for freedom of movement.

Check the sealing strips in the sweeping area for wear.

Half-yearly maintenance:

Check tension, wear and tear and functioning of the drive belts.

Maintenance following wear:

Replace sealing strips.

Replace roller brush.

Replace side brush.

For description, see section on Maintenance work.

Maintenance Works

Note

Where maintenance is carried out by the customer, all service and maintenance work must be undertaken by a qualified specialist. If required, a specialised Archer dealer may be contacted at any time.

Park the sweeper on an even surface.

Turn the program selection switch to "OFF".

Replacing side brush

Loosen 3 fastening screws.

Replace side brushes and tighten the screws.

Replacing roller brush

It is necessary to replace them if the sweep results are visibly poorer due to wear and tear of the brushes and it is not possible to readjust them using "Lever contact pressure of sweep roller".

Remove the waste container.

Figure 8, see cover page

Pull the lever for contact pressure of sweep roller fully backwards.

Loosen 3 screws each on both the sides of the sweep roller.

Separate the roller halves and remove them.

Place new roller halfs on the sweep roller shaft. Ensure that the pins are sitting correctly.

Fix in the screws and tighten them.

Replace the sealing strips

Loosen the screws as shown in the respective diagram.

Remove the sealing strip and replace it with a new sealing strip.

Fix in the screws and tighten them. Front sealing strip (at the waste container)

Figure 9, see cover page

Rear sealing strip

Figure 10, see cover page

Side sealing strips

Figure 11, see cover page

Replace flat fold filter (only Adv. model).

Pull the handle of the filter shake-off many times and release it.

Tilt the dust suction upward.

Figure 12, see cover page

Lift out the flat-fold filter and insert a new flat-fold filter.

Cleaning the flat-fold filter

Remove both the foam filters.

Clean the foam filters under flowing water and let them dry.

Push in the foam filters into the casing. Ensure that the foam filters are gap-free on all sides.

EN - 7 |

9 |

Loading...

Loading...