Karcher KM120-150R User Manual

KM 120/150 R G

KM 120/150 R D

KM 120/150 R LPG

59637740 09/14

2

Please read and comply with

these original instructions prior to the initial operation of your appliance and store them for later use or subsequent owners.

these original instructions prior to the initial operation of your appliance and store them for later use or subsequent owners.

Before first start-up it is definitely necessary to read the safety indications no. 5.956-250!

Contents

Appliance description . . . . . |

EN . . . 1 |

|

Safety instructions . . . . . . . |

EN . . . 1 |

|

General notes . . . . . . . . |

EN . . . 1 |

|

Symbols on the machine |

EN |

. . . 2 |

Symbols in the operating in- |

EN |

. . . 2 |

structions. . . . . . . . . . . . |

||

Safety Guidelines for liqui- |

|

|

fied gas vehicles (only KM |

EN . . . 2 |

|

120/150 R LPG) . . . . . . |

||

Function . . . . . . . . . . . . . . . |

EN . . . 3 |

|

Proper use . . . . . . . . . . . . . |

EN . . . 3 |

|

Suitable surfaces. . . . . . |

EN . . . 3 |

|

Environmental protection . . |

EN |

. . . 3 |

Operating and Functional Ele- |

EN |

. . . 4 |

ments . . . . . . . . . . . . . . . . . |

||

Machines without driver cab- |

EN . . . 4 |

|

in . . . . . . . . . . . . . . . . . . |

||

Machines with driver cabin |

EN . . . 4 |

|

Colour coding . . . . . . . . |

EN |

. . . 4 |

Opening/closing and secur- |

EN . . . 5 |

|

ing cover . . . . . . . . . . . . |

||

Operator console. . . . . . |

EN . . . 6 |

|

Before Startup. . . . . . . . . . . |

EN . . . 7 |

|

Unloading . . . . . . . . . . . |

EN |

. . . 7 |

Moving sweeper without en- |

EN |

. . . 7 |

gaging self-propulsion . . |

||

Moving sweeper by engag- |

EN . . . 7 |

|

ing self-propulsion . . . . . |

||

Start up . . . . . . . . . . . . . . . . |

EN . . . 7 |

|

General notes . . . . . . . . |

EN |

. . . 7 |

Refuelling (only KM 120/150 |

EN |

. . . 7 |

R G and R D) . . . . . . . . |

||

Connect/ change gas cylin- |

|

|

der (only KM 120/150 R |

EN |

. . . 7 |

LPG) . . . . . . . . . . . . . . . |

||

Inspection and maintenance |

EN . . . 8 |

|

work. . . . . . . . . . . . . . . . |

||

Operation . . . . . . . . . . . . . . |

EN . . . 8 |

|

Adjusting driver's seat . . |

EN |

. . . 8 |

Adjusting the external mirror |

|

|

(only KM 120/150 without |

EN |

. . . 8 |

driver cabin) . . . . . . . . . |

||

Switching on/off the wipers |

|

|

(only KM 120/150 without |

EN . . . 8 |

|

driver cabin) . . . . . . . . . |

||

Programme selection . . |

EN . . . 8 |

|

Starting the machine . . . |

EN . . . 8 |

|

Drive the machine . . . . . |

EN . . . 8 |

|

Sweeping mode . . . . . . |

EN . . . 8 |

|

Emptying waste container |

EN . . . 9 |

|

Turn off the appliance . . |

EN . . . 9 |

|

Shutdown . . . . . . . . . . . . . . |

EN |

. . . 9 |

Close fuel tap (only KM 120/ |

EN |

. . 10 |

150 R G and R D) . . . . . |

||

Close gas supply (only KM |

EN |

. . 10 |

120/150 R LPG) . . . . . . |

||

Transport. . . . . . . . . . . . . . . |

EN |

. . 10 |

Storing the device . . . . . . . . |

EN |

. . 10 |

Maintenance and care . . . . . |

EN |

. 10 |

General notes . . . . . . . . |

EN |

. 10 |

Cleaning the inside of the |

EN |

. 10 |

machine . . . . . . . . . . . . . |

||

External cleaning of the ap- |

EN |

. 10 |

pliance . . . . . . . . . . . . . . |

||

Maintenance intervals . . |

EN |

. 10 |

Maintenance Works . . . . |

EN |

. .11 |

Troubleshooting . . . . . . . . . . |

EN |

. 16 |

Technical specifications . . . . |

EN |

. 17 |

Accessories . . . . . . . . . . . . . |

EN |

. 18 |

Installation set suction hose |

EN |

. 18 |

EC Declaration of Conformity |

EN |

. 18 |

Warranty . . . . . . . . . . . . . . . |

EN |

. 18 |

Appliance description

–KM 120/150 R G = Petrol engine

–KM 120/150 R D = diesel engine

–KM 120/150 R LPG = gas engine

Safety instructions

–The machine (without driver cabin) has been approved for use on surfaces with gradients of up to 18%.

–The machine (with driver cabin) has been approved for use on surfaces with gradients of up to 10%.

General notes

Your sales outlet should be informed about any transit damage noted when unpacking the product.

–Warning and information plates on the machine provide important directions for safe operation.

–In addition to the information contained in the operating instructions, all statutory safety and accident prevention regulations must be observed.

Drive mode

Danger

Risk of injury!

Danger of tipping if gradient is too high.

–Drive up the slopes only with max. 18% gradient (without driver cabin) or 10% (with driver cabin).

Danger of tipping when driving round bends at high speed.

–Drive slowly when cornering. Danger of tipping on unstable ground.

–Only use the machine on sound surfaces.

Danger of tipping with excessive sideways tilt.

–The gradient perpendicular to the direction of travel should not exceed 10%.

–It is important to follow all safety instructions, rules and regulations applicable for driving motor vehicles.

–The operator must use the appliance properly. He must consider the local conditions and must pay attention to third parties, in particular children, when working with the appliance.

–The appliance may only be used by persons who have been instructed in han-

EN - 1

dling the appliance or have proven qualification and expertise in operating the appliance or have been explicitly assigned the task of handling the appliance.

–The appliance must not be operated by children, young persons or persons who have not been instructed accordingly.

–It is strictly prohibited to take co-pas- sengers.

–Ride-on appliances may only be started after the operator has occupied the driver's seat.

Please remove the ignition key, when not in use, to avoid unauthorised use of the appliance.

Never leave the machine unattended so long as the engine is running. The operator may leave the appliance only when the engine has come to a standstill, the appliance has been protected against accidental movement, if necessary, by applying the immobilization brake and the ignition key has been removed.

Appliances with combustion engine

Danger

Risk of injury!

–Do not close the exhaust.

–Do not bend over the exhaust or touch it (risk of burns).

–Do not touch the drive motor (risk of burns).

–Only KM 120/150 R LPG: Ensure that there is adequate ventilation or provision for diverting the exhaust gas while operating the appliance in closed rooms (risk of poisoning).

–Exhaust gases are poisonous and hazardous to health, do not inhale them.

–The engine requires approx. 3-4 seconds to come to a standstill once it has been switched off. During this time, stay well clear of the working area.

Machines with driver cabin

Note

The driver cabin only provides protection against weather; it is not a safety roof or a lock against overrolling!

Danger

The plastic sheet doors of the driver cabin have ventilation slots. Always leave these open to ensure adequate ventilation.

Risk of hearing impairment. Always use proper ear-protection aids while working with the appliance.

Accessories and Spare Parts

–Only use accessories and spare parts which have been approved by the manufacturer. The exclusive use of original accessories and original spare parts

3

ensures that the appliance can be operated safely and trouble free.

–At the end of the operating instructions you will find a selected list of spare parts that are often required.

–For additional information about spare parts, please go to the Service section at www.kaercher.com.

Symbols on the machine

Risk of burns on account of hot surfaces! Allow the exhaust to cool down sufficiently before starting work on the machine.

Symbols in the operating instructions

DANGER

Immediate danger that can cause severe injury or even death.

WARNING

Possible hazardous situation that could lead to severe injury or even death.

CAUTION

Possible hazardous situation that could lead to mild injury to persons or damage to property.

Safety Guidelines for liquified gas vehicles (only KM 120/150 R LPG)

Hauptverband der gewerblichen Berufsgenossenschaften e.V. (HVBG / Germany). Liquified gases (propellants) are butane and propane or a mixture of butane/ propane. They are available in special cylinders. The operating pressure of these gases depends on the outside temperature.

Danger

Risk of explosion! Do not handle liquified gas like petrol. Petrol evaporates slowly, liquified gas immediately turns into gas.

The risk of gas spreading in the room and getting ignited is thus higher in case of liquefied gas than in petrol.

Danger

Risk of injury! Use only liquefied gas cylinders with propellant filled according to DIN 51622 of A or B quality, depending on the surrounding temperature.

CAUTION

Use of cooking gas is strictly prohibited. For the gas engine, use only liquid gas mixtures of propane/ butane or their mixtures where the mixing ratio lies between 90/10 to 30/70. On account of better cold start behaviour even at low outside sub-zero temperatures (below 0° C / 32 °F) always prefer a mixture with a higher propane share because evaporation takes place even at low temperatures.

Liabilities of the factory management and the employee

–All persons handling liquid gases are liable to acquaint themselves with the special properties of the liquefied gases for hazard-free handling of operations. The current documentation is always to be kept with the sweeper.

Maintenance by expert

–Propellant-operated units are to be checked at regular intervals, at least once a year, by an expert against leaks (according to BGG 936) and ensure that the unit is functioning properly.

–The inspection must be certified and documented. The inspection guidelines are § 33 and § 37 UVV (occupation accident prevention regulations) "Use of liquid gas" (BGV D34).

–General applicable regulations are the guidelines for inspecting vehicles whose engines are driven by liquefied gases of the Federal Transportation Minister.

Commissioning/Operations

–Gas must always be drawn only from one cylinder. Drawing gas from multiple cylinders simultaneously can cause liquid gas from one cylinder flowing into the other. This causes the over-filled cylinder to be subjected to an unpermitted excess pressure when the cylinder valve is closed later (refer B.1 of these guidelines).

–Ensure the correct positioning of the cylinder with the "top" marking while connecting a full cylinder (the connection screw points vertically upward).

Perform the replacement of the gas cylinder carefully. During assembly and disassembly, the gas outlet nozzle of the cylinder valve must be sealed by means of a cap nut that is tightened using a wrench.

–Discontinue the use of leaky gas cylinders. Such cylinders are to be emptied by slowly letting out the gas in open spaces by conforming to all safety regulations and are to be indicated as leaky. Also inform the issuing company or its representative (the filling-station attendant) in writing about the damage to the cylinder while delivering or receiving the cylinders.

–Before connecting the gas cylinder, check that its connection neck is in a proper state.

–After connecting the cylinder, regularly check that it is not leaky by using a foaming agent.

–Open the valves slowly. Do not use hammers to open and close the cylinders.

–Use only dry fire extinguishers (with carbonic acid gas) in case of fire caused by liquefied gases.

–The entire LPG unit must be continuously checked to ensure that there are no leaks and the unit is functioning properly. Using the vehicle with a leaky gas unit is strictly prohibited.

–First close the cylinder valve before loosening the pipe or tube connection. Unscrew and loosen the connection nut of the gas cylinder slowly because otherwise the gas under pressure in the tube will flow out instantly.

–If the gas is refilled from a larger tank, then ask the sales agent of the LPG about the important regulations to be followed.

Danger

Risk of injury!

–LPG in a liquid state can cause frost bites on bare skin.

–After disconnecting the cylinder, tighten the closing nut firmly on the connecting threading of the cylinder.

–Use soap water or some such foaming agent to check whether the cylinder is leaking. The use of open flames to illuminate the LPG unit is strictly prohibited.

–Follow the manufacturer's installation specifications while changing individual parts of the LPG unit. Close all cylinder and locking valves while doing so.

–Regularly check the status of the electrical unit of the LPG vehicles . Sparks can cause explosions if the gas-carry- ing parts of the unit are leaky.

–If a LPG-driven vehicle has been idling for a long time, then first ventilate the

4 |

EN - 2 |

setting room before commissioning the vehicle or its electrical unit.

–Immediately inform the trade association and the concerned trade supervisory authority about accidents with gas cylinders or LPG units. Store the damaged parts carefully until all investigations have been completed.

In the installation and storage rooms as well as the workshops

–Propellants or LPG cylinders must always be stored according to the regulations of TRF 1996 (Technical Regulations for Liquid Gases, refer DA to BGV D34, Appendix 4).

–Always store the gas cylinders in a vertical position. Use of open flames and smoking at the installation site of the cylinders and during repairs is strictly prohibited. Protect the stored cylinders against unauthorised access. Close all empty cylinders properly.

–Close the cylinder and main locking valves immediately when you switch off the vehicle.

–Follow the regulations for garages and the construction guidelines of the respective State about the location and structure of the parking areas for LPGdriven vehicles.

–Gas cylinders are to be stored in separate rooms away from the parking areas (refer DA to BGV D34, Appendix 2).

–The electrical hand-held lamps used in the rooms are to be equipped with closed, sealed case and a strong protection cover.

–Close all cylinder and main valves before working in repair workshops and protect the gas cylinders against effect of external heat.

–A responsible person must check that all valves, especially the cylinder valves, are closed during operational breaks and before closing the factory. Do not carry out any jobs involving fire - such as cutting and welding jobs - in the vicinity of the gas cylinders. Do not store gas cylinders, not even empty ones, in the workshops.

–The parking and storage rooms and the repair workshops must be ventilated properly. Please note that liquefied gases are heavier than atmospheric air. They get collected on the floor, in recesses and other holes in the floors and form a gas-air mixture that can lead to explosions.

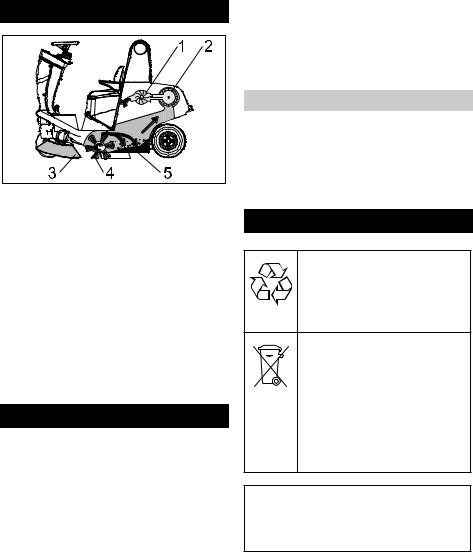

Function |

Figure 1 |

The sweeper operates using the overthrow principle.

–The side brushes (3) clean the corners and edges of the surface, moving dirt and debris into the path of the roller brush.

–The rotating roller brush (4) moves the dirt and debris directly into the waste container (5).

–The dust raised in the container is separated by the dust filter (2) and the filtered clean air is drawn off by the suction fan (1).

Proper use

Use this appliance only as directed in these operating instructions.

The machine with working equipment must be checked to ensure that it is in proper working order and is operating safely prior to use. Otherwise, the appliance must not be used.

–This sweeper has been designed to sweep dirt and debris from outdoor surfaces.

–Only KM 120/150 R LPG: This sweeper is also suitable for sweeping dirty floors in closed spaces provided the same are ventilated adequately.

–The machine can only be used on public highways with the StVZO extension kit.

–The machine is not suitable for vacuuming dust which endangers health.

–The machine may not be modified.

–Never vacuum up explosive liquids, combustible gases or undiluted acids and solvents. This includes petrol, paint thinner or heating oil which can generate explosive fumes or mixtures upon contact with the suction air. Acetone, undiluted acids and solvents must also be avoided as they can harm the materials on the machine.

–Do not sweep/vacuum up any burning or glowing objects.

–The machine is only suitable for use on the types of surfaces specified in the operating instructions.

–The machine may only be operated on the surfaces approved by the company or its authorised representatives.

–The machine may not be used or stored in hazardous areas. It is not allowed to

use the appliance in hazardous locations.

–The following applies in general: Keep highly-flammable substances away from the appliance (danger of explosion/fire).

Suitable surfaces

–Asphalt

–Industrial floor

–Screed

–Concrete

–Paving stones

Environmental protection

The packaging material can be recycled. Please do not throw the packaging material into household waste; please send it for recycling.

Old appliances contain valuable materials that can be recycled; these should be sent for recycling. Batteries, oil, and similar substances must not enter the environment. Please dispose of your old appliances using appropriate collection systems.

Please do not release engine oil, fuel oil, diesel and petrol into the environment Protect the ground and dispose of used oil in an environmentally-clean manner.

Notes about the ingredients (REACH)

You will find current information about the ingredients at: www.kaercher.com/REACH

EN - 3 |

5 |

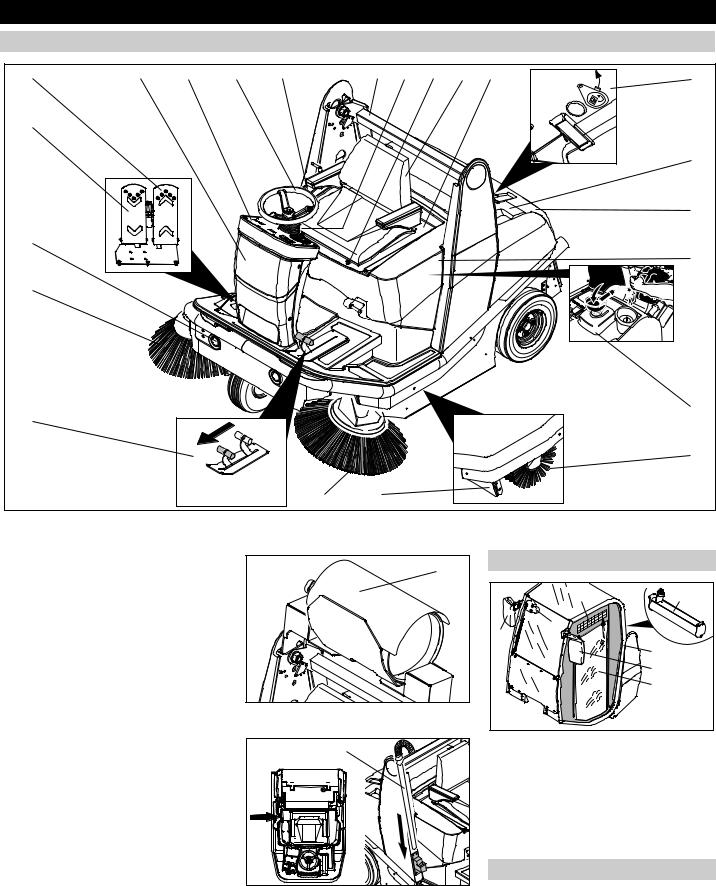

Operating and Functional Elements

Machines without driver cabin

5 |

4 |

3 |

2 |

1 |

12 |

13 |

14 |

15 |

16 |

17 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

19 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

|

|

|

9 |

10 |

|

|

|

|

|

Figure 2a

1Operator control unit for waste container and parking brake

2Steering wheel

3Operator console

4Fuses (behind front panel)

5Accelerator pedal, forwards

6Accelerator pedal, reverse

7Lights

8Right side brush

9Left side brush

10Bulk waste flap

11Pedal for raising/lowering bulk waste flap

12Lift/tilt emptying mechanism

13Lever for steering wheel adjustment

14Lever for seat adjustment

15Seat (with seat contact mat)

16Seat bracket

17Wet/dry flap

18Filter case

19Waste container

20Cover

21Tank

22Roller brush

23Gas cylinder (only KM 120/150 R LPG)

24Installation set suction hose (option)

|

23 |

|

Machines with driver cabin |

|

|

|

|

|

|

|

|

|

7 |

2 |

|

|

4 |

3 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

5 |

|

|

|

|

6 |

Figure 2b |

|

|

|

|

|

Figure 2d |

|

||

24 |

1 |

|

Driver cabin (optional) |

|

|

2 |

|

Tank |

|

|

3 |

|

Turn on/off the wipers |

|

|

4 |

|

Right exterior mirror |

|

|

5 |

|

Left exterior mirror |

|

|

6 |

|

Plastic sheet doors |

|

|

7 |

|

Ventilation slots |

|

|

|

Colour coding |

Figure 2c |

|

The operating elements for the cleaning |

|

|

process are yellow. |

|

|

The controls for the maintenance and |

|

|

service are light gray. |

6 |

EN - 4 |

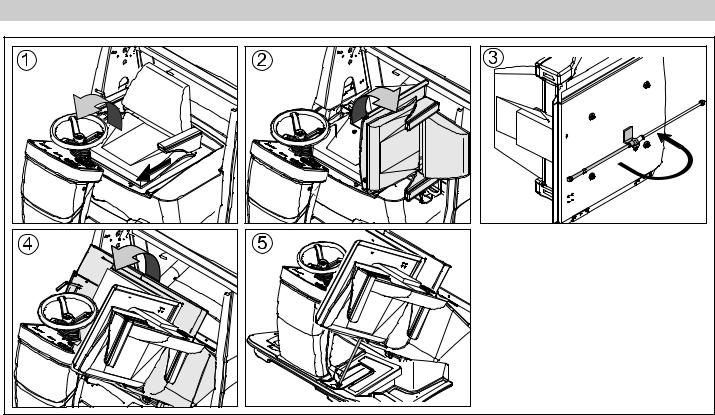

Opening/closing and securing cover

Figure 3

Danger

Risk of injury! When open, the cover must be propped up using the retaining rod.

Figure 1

Operate steering wheel adjustment lever and fold steering wheel forwards.

Operate seat adjustment lever and slide seat forwards.

Figure 2

Fold seat bracket to the side.

Figure 3

Fold out retaining rod.

(only 120/150 KM without driver cabin)

Figure 4

Fold cover forwards.

Figure 5

Insert retaining rod into the recess next to the bulk waste flap pedal.

(only 120/150 KM without driver cabin)

Follow this sequence in reverse order to close the cover.

EN - 5 |

7 |

Loading...

Loading...