Karcher BD530 User Manual [en, es, fr]

BD 530 Bp Classic

FOR U. S. USE ONLY

English |

3 |

Español |

19 |

Français |

37 |

Registerwww . kaercherand . win! com!

5.963-660.0 03/10

2

IMPORTANT SAFETY IN-

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

WARNING

To reduce the risk of fire, electric shock, or injury:

–Do not leave the unit when plugged in. Unplug from outlet when not in use and before servicing.

WARNING

–TO REDUCE THE RISK OF ELECTRIC SHOCK-USE INDOORS ONLY

–Do not allow to be used as a toy. Close attention is necessary when used near children.

–Use only as discribed in this manual. Use only manufacturer’s recommended attachments.

–Do not use with damaged cord or plug. If the unit is not working as it should, has been dropped, damaged, left outdoors, or dropped into water, return it to a service center.

–Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners. Do not run the unit over cord.

Keep cord away from heated surfaces.

–Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

–Do not handle plug or appliance with wet hands.

–Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair,

and anything that may reduce air flow.

–Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

–Turn off all controls before unplugging.

–Do not use to pick up flammable or combustible liquids, such as gasoline, or use in areas where they may be present.

SAVE THESE INSTRUCTIONS

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility of the operator.

The operator shall be familiar with the operation and function of all controls and instruments before undertaking to operate the unit.

Before operating the unit, operators shall have read and be familiar with the operator’s manual for the particular unit being operated and they shall also abide by the safety rules and practices in the following paragraphs.

Before operating any unit, the operator shall be familiar with unusual operating conditions which may require additional safety precautions or special operating instructions.

General

Before starting to operate the unit be in operating position.

Do not start or operate the unit, any of its functions or attachments, from any place other than from the designated operators position.

Before leaving the operator’s position:

English 3

Abring the unit to a complete stop;

Bif the unit must be on an incline, block the wheels.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Travelling

Yield the right of way to pedestrians and emergency vehicles such as ambulances and fire trucks.

Cross railroad tracks at an angle wherever possible. Do not park closer than 6 ft (1800 mm) to the nearest rail of a railroad track.

Keep a clear view of the path of travel and observe for other traffic, personnel, and safe clearances.

Under all travel conditions, operate the unit at a speed that will permit it to be brought to a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors. Before driving over a dockboard or bridge plate, be sure that it is properly secured. Drive carefully and slowly across the dockboard or bridge plate, and never exceed its rated capacity. When negotiating turns, reduce speed to a safe level consistent with the operating environment. Make the turns smoothly.

Operator care of the unit

If the unit is found to be in need of repair or in any way unsafe, or contributes to an unsafe condition, the matter shall be reported immediately to the user’s designated authority, and the unit shall not be operated until it has been restored to safe operating condition.

If during operation the unit becomes unsafe in any way, the matter shall be re-

ported immediately to the user’s designated authority, and the unit shall not be operated until it has been restored to safe operating condition.

Do not make repairs or adjustments unless specifically authorized to do so. Do not use open flames when checking electrolyte level in storage batteries.

MAINTENANCE AND REBUILD PRACTICES

Operation of the unit may be hazardous if maintenance is neglected or repairs, rebuilds, or adjustments are not performed in accordance with the manufacturer’s design criteria. Therefore, maintenance facilities (on or off premises), trained personnel, and detailed procedures shall be provided. Maintenance and inspection of the unit shall be performed in conformance with the following practices:

Aa schedules planned maintenance, lubrication, and inspection system shall be followed; consult the manufacturer’s recommendations.

Bonly tranined and authorized personnel shall be permitted to maintain, repair, adjust, and inspect the unit, and in accordance with manufacturer’s specifications.

Avoid fire hazards and have fire protection equipment present in the work area. Do not use an open flame to check the level of any fluid, especially battery electrolyte. Do not use open pans of fuel or flammable cleaning fluids for cleaning parts.

FIRE SAFETY STANDARD

Any unit not in safe operating condition shall be removed from service. Repairs shall not be made in Class I, Class II, and Class III locations.

4 English

Fire Prevention.The unit shall be kept in a clean condition and reasonably free of lint, excess oil, and grease. Noncombustible agents are preferred for cleaning the unit. Flammable liquids [those having flash points at or above 100°F (37,8°C)] are not allowed. Precautions regarding toxicity, ventilation, and fire hazard shall be appropriate for the agent or solvent used.

Nameplate Visibility. The unit type designations as shown on the nameplate and the type markers shall not be covered over with paint so that their identification information is obscured. The unit shall not be used in classified areas.

Please read and comply with

Please read and comply with  these original instructions pri-

these original instructions pri-

or to the initial operation of your appliance and store them for later use or subsequent owners.

Contents

Safety instructions |

5 |

Function |

6 |

Proper use |

6 |

Environmental protection |

6 |

Control elements |

7 |

Before Startup |

8 |

Operation |

11 |

Maintenance and care |

14 |

Faults |

15 |

Technical specifications |

18 |

Warranty |

18 |

Spare parts |

18 |

Safety instructions

Before using the appliance for the first time, read and observe these operating instructions and the accompanying brochure: Safety information for brush cleaning units and spray-extraction units, 5.956-251.

The machine has been approved for use on surfaces with gradients of up to 2%.

The appliance may only be operated when the container and all lids are closed.

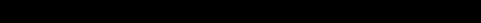

Symbols

The following symbols are used in this operating manual:

Danger

Indicates an immediate threat of danger. Failure to observe the instruction may result in death or serious injuries.

English 5

Warning

Indicates a possibly dangerous situation. Failure to observe the instruction may result in light injuries or damage to property.

Note

Indicates useful tips and important information about the product.

Function

The appliance is used for the wet cleaning of level floors. It can be easily adjusted to the cleaning task by setting the water quantity and the dirt water suction.

A working width of 460 mm and a capacity of 40 l each of the fresh and dirt water reservoirs enable an effective cleaning even when the machine is used for long duration.

Proper use

Use this appliance only as directed in these operating instructions.

–The appliance should only be used for cleaning level floors that are not affected by moisture.

–The appliance is not suited for the cleaning of frozen grounds (e.g. in cold stores).

–The appliance may only be equipped with original accessories and spare parts.

Environmental protection

The packaging material can be recycled. Please do not place the packaging into the ordinary refuse for disposal, but arrange for the proper recycling.

Old appliances contain valuable materials that can be re-

cycled. Please arrange for the proper recycling of old appliances. Batteries, oil, and similar substances must not enter the environment. Please dispose of your old appliances using appropriate collection systems.

Notes about the ingredients (REACH)

You will find current information about the ingredients at: http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

6 English

Control elements

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Push handle |

13 |

Vacuum bar (not included in the de- |

||||||||||||||||

2 |

Control handle |

|

|

livery) |

|||||||||||||||

3 |

Operator console |

14 |

Connecting the suction hose to the |

||||||||||||||||

4 |

Electronics and fuses |

|

|

suction turbine |

|||||||||||||||

|

|

(under the operations panel) |

15 |

Nameplate |

|||||||||||||||

5 |

Vacuum bar lowering lever |

16 |

Disc brush |

||||||||||||||||

6 |

Dirt water discharge hose |

17 |

Cleaning head |

||||||||||||||||

7 |

Suction hose |

18 |

Chassis |

||||||||||||||||

8 |

Battery (BD 530 Bp only) |

19 |

Locking |

||||||||||||||||

9 |

Star grips to exchange the vacuum |

20 |

Handle |

||||||||||||||||

|

|

lips |

21 |

Cover dirt water reservoir |

|||||||||||||||

10 |

Vacuum bar suspension |

22 |

Screw for locking the container; in |

||||||||||||||||

11 |

Cross handles for fastening and |

|

|

the container. Batteries * |

|||||||||||||||

|

|

slanting the vacuum bar |

Under the lid of the dirt water tank: |

||||||||||||||||

12 |

Wing nuts for tilting the vacuum bar |

23 |

Fresh water reservoir filler neck |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

24 |

Lint sieve (suction) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

25 |

Dirt water reservoir |

|||||||

English 7

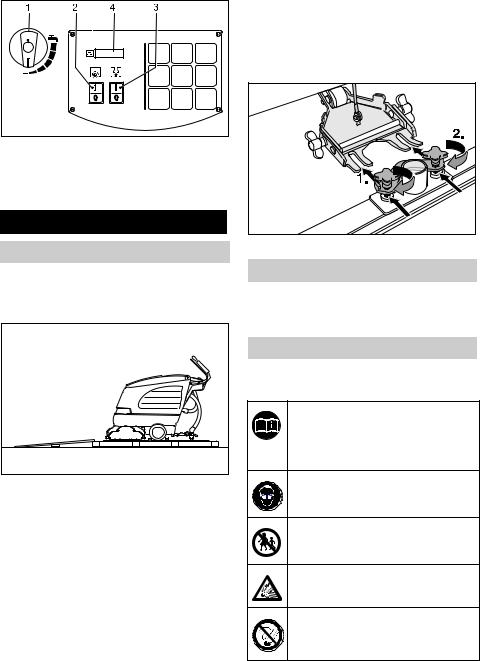

Operator console |

|

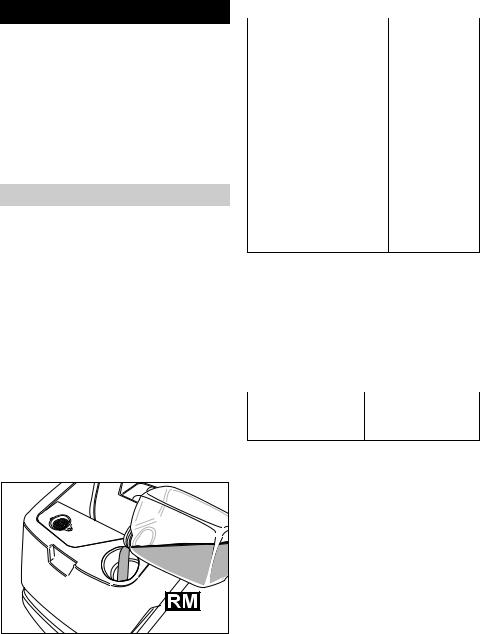

Installing the Vacuum Bar |

1Water quantity regulator

2Switch for brush operations

3Switch of suction turbine

4Display

Before Startup

Unloading

ÎFasten the pushing handle using the four screws that have been delivered and fit the protective caps.

ÎInsert the vacuum bar into the vacuum bar suspension in such a manner that the profiled sheet is positioned above the suspension.

ÎTighten the cross-handles.

Î Insert the suction hose.

Install the brush

The disc brush must be installed before the initial operation (see "Maintenance work").

Batteries

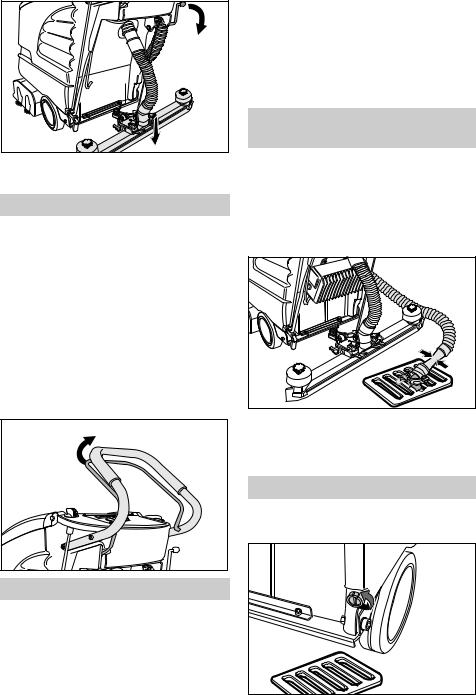

ÎPlace long lateral boards of the packaging as a ramp next to the pallet.

ÎFix the ramp on the pallet with nails.

ÎPlace short boards as a support underneath the ramp.

ÎRemove the wooden bars in front of the wheels.

ÎRaise the cleaning head and remove the cartonage.

ÎPush down the appliance through the ramp from the pallet.

8 English

Please observe the following warning notes when handling batteries:

Observe the directions on the battery, in the instructions for use and in the vehicle operating instructions

Wear eye protection

Keep children away from acid and batteries

Danger of explosion

Fire, sparks, naked flames and smoking must be strictly avoided

Danger of chemical burns

First aid

Warning note

Disposal

Do not throw the battery into the regular waste

Danger

Danger of explosion. Do not put tools or similar on the battery, i.e. on the terminal poles and cell connectors.

Risk of injury. Ensure that wounds never come into contact with lead. Always clean your hands after having worked with batteries.

Insert batteries and connect

ÎRelease the lock screw for the container and open the container.

ÎPlace the batteries facing the cleaning head closely in the trough.

ÎLubricate the battery pole with pole grease.

ÎConnect pole using the enclosed connecting cable.

Caution

Risk of damage during repoling the connecting cable. Connect the red cable to the plus pole and the black cable to the minus pole of the battery. The battery model can easily be recognised by the casing color of the batteries: EXIDE: grey, HOPPECKE: green.

ÎConnect the connection cable to the free battery poles (+) and (-).

ÎClose the container and tighten the screw.

ÎScrew in the the lock screw for the container and tighten it.

Warning

Charge the battery before commissioning the machine.

Charging battery

Danger

Danger of explosion. Wet batteries can only be charged with opened battery cover.

Note

The device is equipped with a safety mechanism to prevent total discharge, i.e. when the permissible minimum capacity is reached, then the brush motor and the turbine are switched off. The message "LOW BAT“ is displayed on the operations panel.

Note

Average charging time is approx. 10 -15 hours.

The recommended chargers (matching the batteries used) are regulated electronically and will automatically switch off the charging process.

All functions of the machine are automatically interrupted during the charging process.

English 9

ÎMove the machine directly to the charging station.

Charging process

ÎPull out the suction hose from the vacuum bar.

ÎRelease the lock screw for the container and open the container.

ÎRemove battery plug and join it to the charging cable.

ÎConnect the charger to the mains and turn it on.

Low maintenance batteries (wet batteries)

ÎAdd distilled water one hour before the charging process comes to an end; follow the correct acid level.

There are corresponding indicators on the battery.

Danger

Danger of causticization!

–Adding water to the battery in its discharged state can cause the acid to leak.

–Use safety glasses while handling battery acid and follow the safety instructions to avoid personal injury or damage to clothes.

–Should the acid spray on to the skin or clothes, rinse immediately with lots of water.

Warning

Risk of damage!

–Use only distilled or desalinated water (EN 50272-T3) for filling the battery.

–Do not add any substances (socalled performance improving agents), else warranty claims will not be entertained.

Recommended batteries

Manufactur- |

Description |

er, Kärcher |

|

order no. |

|

|

|

EXIDE |

12 V, 80 Ah, low main- |

6.654-097.0 |

tenance |

|

|

Recommended chargers

Manufactur- |

Description |

er, Kärcher |

|

order no. |

|

|

|

KÄRCHER |

Separate charger for |

6.654-179.0 |

battery 6.654-097.0 |

Batteries and chargers are available in specialised stores.

Battery control display

The charging status of the battery is shown in the display on the operations panel:

–After switching on the button for brush operations or suction turbine, the operating hours are displayed for 5 seconds.

–A bar diagram is then displayed to show the charging status of the battery.

10 English

Operation

Warning!

Risk of damage. Raise the vacuum bar before reversing.

Note

The appliance is designed and built in such a way that the brush head is projecting towards the right. This enables working in a comfortable way close to the edges.

Filling in detergents

Warning

Risk of damage. Only use the recommended detergents. With respect to different detergents the operator bears the increased risk regarding the operational safety and danger of accident. Only use detergents that are free from solvents, hydrochloric acid and hydrofluoric acid.

Note

Do not use highly foaming detergents. Observe the dosing notes.

ÎOpen the cover of the fresh water reservoir.

ÎFill in fresh water (maximum 60 °C).

ÎAdd detergent. Follow dosing instructions for detergent.

Recommended detergents:

Application |

Detergent |

Regular cleaning |

RM 745 |

(even for floors sensi- |

RM 746 |

tive to alkalies) |

|

Cleaning dirt from |

RM 69 ES |

grease |

ASF |

|

RM 69 ASF |

Basic cleaning (strip- |

RM 752 |

ping) of alkali-resis- |

|

tant hard coatings |

|

Basic cleaning (strip- |

RM 754 |

ping) linoleum |

|

Sanitary cleaning |

RM 25 ASF |

Disinfection cleaning |

RM 732 |

Detergents are available in specialised stores.

ÎClose the cover of the dirt water reservoir.

|

Cleaning |

|

Chassis |

|

|

|

|

|

Down |

Transport |

|

|

|

|

Up |

Cleaning |

|

ÎRaise the device slightly at the handle.

ÎPull out the lock.

ÎTilt the chassis to the desired position.

ÎPut the lock.

Driving to the Place of Use

ÎTilt the chassis downward and lock it.

ÎPush the machine to the place where it is to be used.

Cleaning

ÎTilt the chassis upward and lock it.

ÎSwitch on the button for brush operations and suction turbine

English 11

Î Press control switch.

Note

If the brush motor does not run when switched on, then brush motor is to be released by pulling the machine backward.

Î Perform the cleaning operation.

Setting the advance speed

ÎReducing the speed: Turn the button in "–" direction.

ÎIncreasing the speed: Turn the button in "+" direction.

Setting the water quantity

ÎSet the water quantity at the regulation knob according to the dirt level and the type of flooring.

Note

Carry out initial cleaning attempts with low quantity of water. Slowly increase the water quantity till the desired cleaning result is achieved.

Setting the Vacuum Bar

Oblique position

To improve the vacuuming result on tiled floors the vacuum bar can be turned to an oblique position of up to 5°.

ÎLoosen cross-handles.

ÎTurn the vacuum bar.

Î Tighten the cross-handles.

Inclination

If the vacuum result is unsatisfactory the inclination of the straight vacuum bar can be modified.

ÎRelease the wing nuts.

ÎTilt the vacuum bar.

ÎTighten the wing nuts.

Lower the vacuum bar

ÎTurn the lever downwards; the vacuum bar is lowered.

12 English

ÎSwitch on the suction turbine using the switch.

Switching on the cleaning head

Warning!

Risk of damage to the floor covering. Do not operate the appliance on the spot.

ÎSwitch on the button for brush operations.

ÎActivate the control handle; the brush motor starts up.

Note

First turn on the switch for brush operation, then use the control handle. If you do this in reverse order, there will an error message on the display.

Shutting Down the Appliance

ÎClose the water quantity regulator.

ÎDrive the appliance forward for another 1-2 m to draw off residual water.

ÎRelease the control handle.

ÎSwitch off the button for brush operations and suction turbine

ÎRaise the vacuum bar.

ÎTilt the chassis downward and lock it.

Warning!

Danger of deformation of the brush(es). When shutting down the appliance relieve the brush(es) by lowering the running gear.

Emptying the Dirt Water Reser-

voir

Warning

Please observe the local provisions regarding the wastewater treatment.

ÎTake the dirt water discharge hose from the support and lower above a suited collection device.

ÎLet off water by opening the dosage device at the discharge hose.

ÎThe rinse the dirt water reservoir with clear water.

Emptying the Fresh Water Tank

ÎOpen the lock of the fresh water tank using a suitable tool (such as a coin).

English 13

Maintenance and care

Danger

Risk of injury!

Before carrying out any tasks on the device, switch off the button for brush operations and suction turbine and pull out the charger plug.

Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt water and the remaining free water before wokring at the machine.

Maintenance schedule

After the work

Warning

Risk of damage. Do not wash down the appliance with water and do not use aggressive detergents.

ÎDrain off dirt water.

ÎRinse the dirt water reservoir with clear water.

ÎClean the outside of the appliance with a damp cloth which has been soaked in mild detergent.

ÎCheck the fluff filter, clean if required

ÎClean the vacuum lips and the wiping lips, check for wear and replace if required.

ÎCheck the brushes for wear, replace if required.

ÎCharge battery if required.

Monthly

ÎCheck the condition of the seals between dirt water reservoir and cover, replace if required.

ÎCheck battery pole for oxidation; brush it if required and lubricate it using pole grease. Ensure that the connection cable sits firmly.

14 English

ÎCheck the acid density of the cells if the batteries are not maintenancefree batteries.

Yearly

ÎHave the prescribed inspection carried out by the customer service.

Maintenance Works

Turn or replace vacuum lips

ÎRemove the vacuum bar.

ÎUnscrew the star grips.

ÎRemove the plastic parts.

ÎRemove the vacuum lips.

ÎTurn the vacuum lips or insert new ones.

ÎInsert the plastic parts.

ÎScrew in and tighten the star grips.

Replacing the disk brushes

ÎTurn the button for the setting of the advance speed in "– " direction.

ÎRaise the disk brush.

ÎTurn the disk brush by approx. 45° in anti-clock-wise direction.

ÎRemove the disk brush at the bottom.

ÎInsert new disk brush in reverse sequence.

ÎSet the advance speed.

Maintenance contract

To ensure a reliable operation of the appliance maintenance contracts can be concluded with the competent Kärcher sales office.

Frost protection

In case of danger of frost:

ÎEmpty the fresh and dirt water reservoirs.

ÎStore the appliance in a frost-pro- tected room.

Transport

ÎRemove brushes to avoid damage to the brushes.

ÎIf you want to transport the machine on a vehicle secure it from slipping using belts/ ropes.

Faults

Danger

Risk of injury!

Before carrying out any tasks on the device, switch off the button for brush operations and suction turbine and pull out the charger plug.

Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt water and the remaining free water before wokring at the machine.

|

Faults with display |

|

|

Display |

Remedy |

|

|

ERR B |

Check if foreign matters block the brushes; remove for- |

|

eign matter if required. |

|

|

ERR T |

Call customer service. |

|

|

LOW BAT |

Charging battery |

|

|

ERR TEMP |

Allow device to cool down. |

|

Reduce brush contact pressure, if necessary. |

|

|

HandsOff |

Release the control handle and wait until the operating |

|

hours or the battery status is shown in the display. After |

|

that, activate the control handle again. |

|

|

ERR REL |

Turn off the switch for brush operation, turn off the switch |

|

for the vacuum turbine, release the control handle, wait 3 |

|

seconds and turn back on. |

|

If the event recurs, call Customer Service. |

|

|

English 15

Faults without display on the console

Fault |

Remedy |

|

|

|

|

Appliance cannot be start- |

Press control switch. |

|

ed |

|

|

Check battery; replace, if needed. |

||

|

||

|

|

|

|

Check if the mains plug is connected. |

|

|

|

|

Insufficient water quantity |

Check fresh water level, refill tank if necessary. |

|

|

|

|

|

Check hoses for blockages; clean if required. |

|

|

|

|

Insufficient vacuum perfor- |

Clean the seals between dirt water reservoir and |

|

mance |

cover and check for tightness, replace if required. |

|

|

|

|

|

Clean the fluff filter. |

|

|

|

|

|

Clean the vacuum lips on the vacuum bar, turn or |

|

|

replace if required |

|

|

|

|

|

Check if the suction hose and vacuum bar are |

|

|

chocked, clean if required |

|

|

|

|

|

Check the suction hose for tightness; replace if re- |

|

|

quired. |

|

|

|

|

|

Check if the cover on the dirt water discharge hose |

|

|

is closed |

|

|

|

|

|

Check the setting of the vacuum bar. |

|

|

|

|

Insufficient cleaning result |

Check the brushes for wear, replace if required. |

|

|

|

|

Brushes do not turn |

Press control switch. |

|

|

Check if foreign matters block the brushes; remove |

|

|

foreign matter if required. |

|

|

|

16 English

Accessories

The appliance can be equipped with various accessories depending on the cleaning task. Please request our cata-

logue or visit us on the Internet at www.kaercher.com.

Description |

Part no.: BD 530 |

Description |

Each/packaging |

Machine requires piece |

|

|

|

|

|

Disk brush, natural |

6.906-056.0 |

For polishing floors. |

1 |

1 |

(white) |

|

|

|

|

|

|

|

|

|

Disk brush, red (me- |

6.906-054.0 |

For cleaning slightly dirtied |

1 |

1 |

dium, standard) |

|

or sensitive floors. |

|

|

|

|

|

|

|

Disk brush, black |

6.906-055.0 |

For cleaning heavily dirtied |

1 |

1 |

(hard) |

|

floors. |

|

|

|

|

|

|

|

Driver plate |

6.906-332.0 |

For intake of pads. |

1 |

1 |

|

|

|

|

|

Disc pad, red (medi- |

6.369-024.0 |

For cleaning slightly dirtied |

5 |

1 |

um) |

|

floors. |

|

|

|

|

|

|

|

Disc pad, green |

6.369-023.0 |

For cleaning normal dirtied |

5 |

1 |

(hard) |

|

floors. |

|

|

|

|

|

|

|

Disc pad, black |

6.369-022.0 |

For cleaning heavily dirtied |

5 |

1 |

(very hard) |

|

floors. |

|

|

|

|

|

|

|

Vacuum bar, |

4.777-047.0 |

Standard |

1 |

1 |

straight |

|

|

|

|

|

|

|

|

|

Vacuum bar, bent |

4.777-054.0 |

Standard |

1 |

1 |

|

|

|

|

|

Rubber lip, blue |

6.273-204.0 |

Standard |

1 |

1 |

|

|

|

|

|

Rubber lip, brown |

6.273-207.0 |

oil-resistant |

1 |

1 |

|

|

|

|

|

English 17

Loading...

Loading...