Page 1

Page 2

Page 3

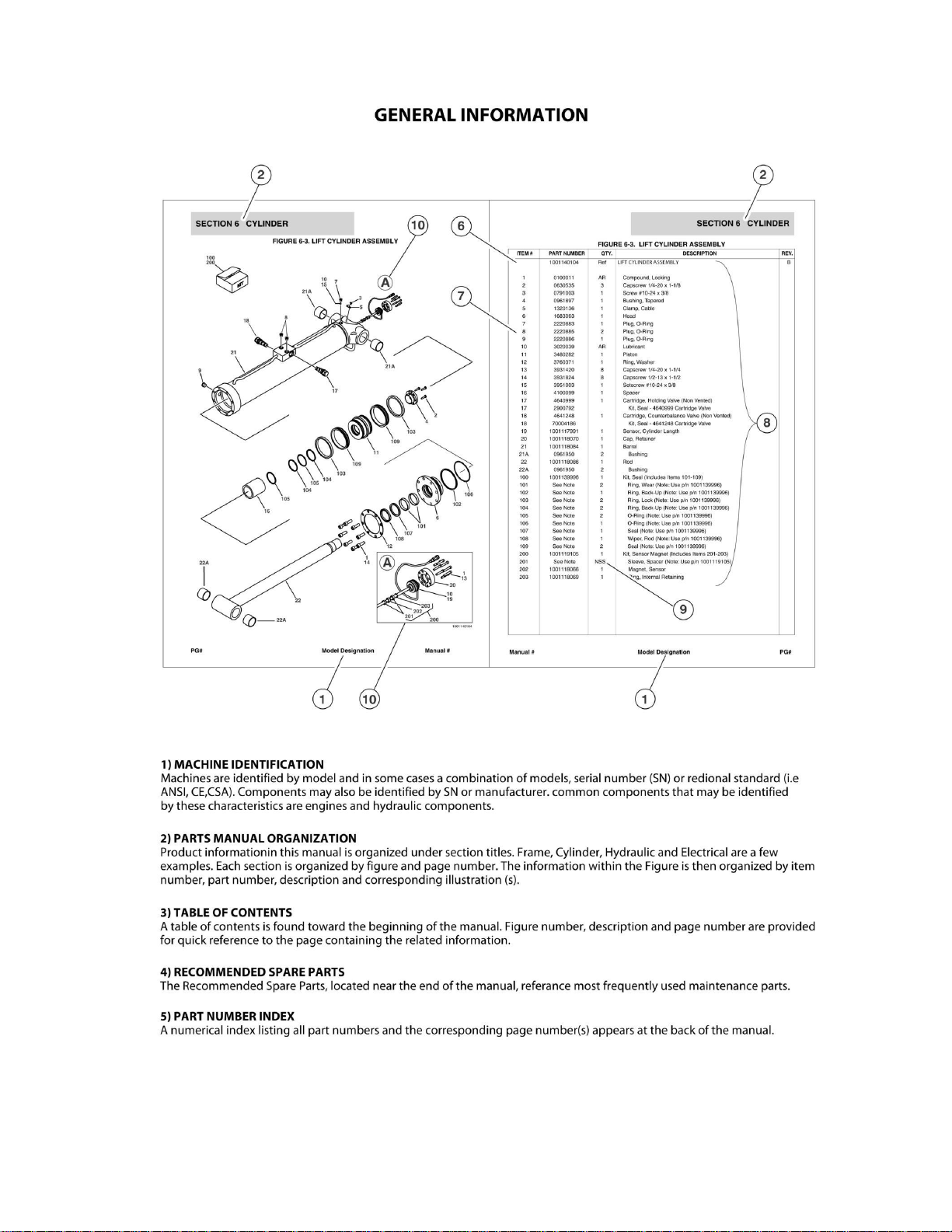

3121182 510AJ 3

Page 4

4 510AJ 3121182

Page 5

3121182 510AJ 5

Page 6

6 510AJ 3121182

Page 7

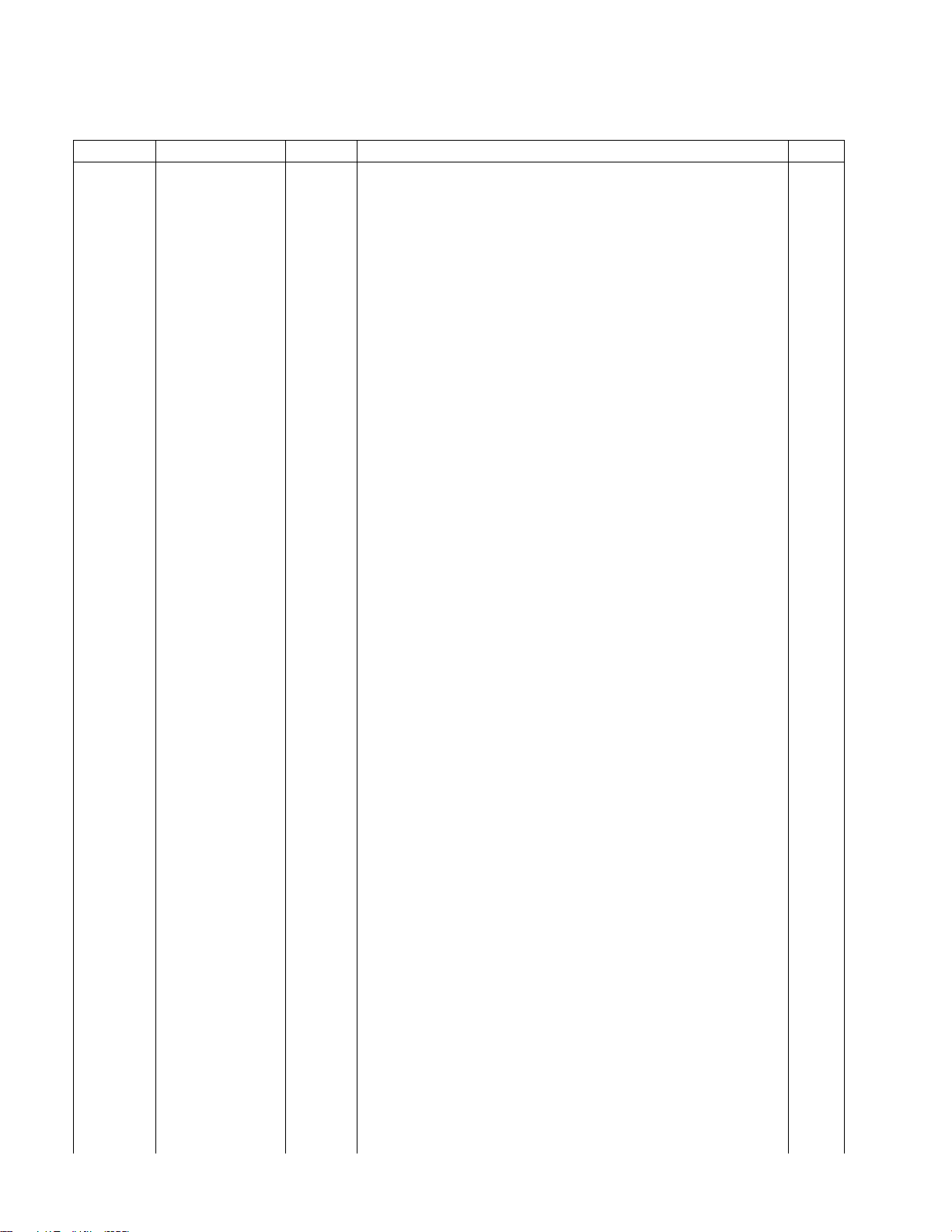

TABLE OF CONTENTS

SECTION 1 - FRAME ........................................................................................................................................................................... 9

FIGURE 1-1. AXLE AND STEERING INSTALLATION ................................................................................................................... 10

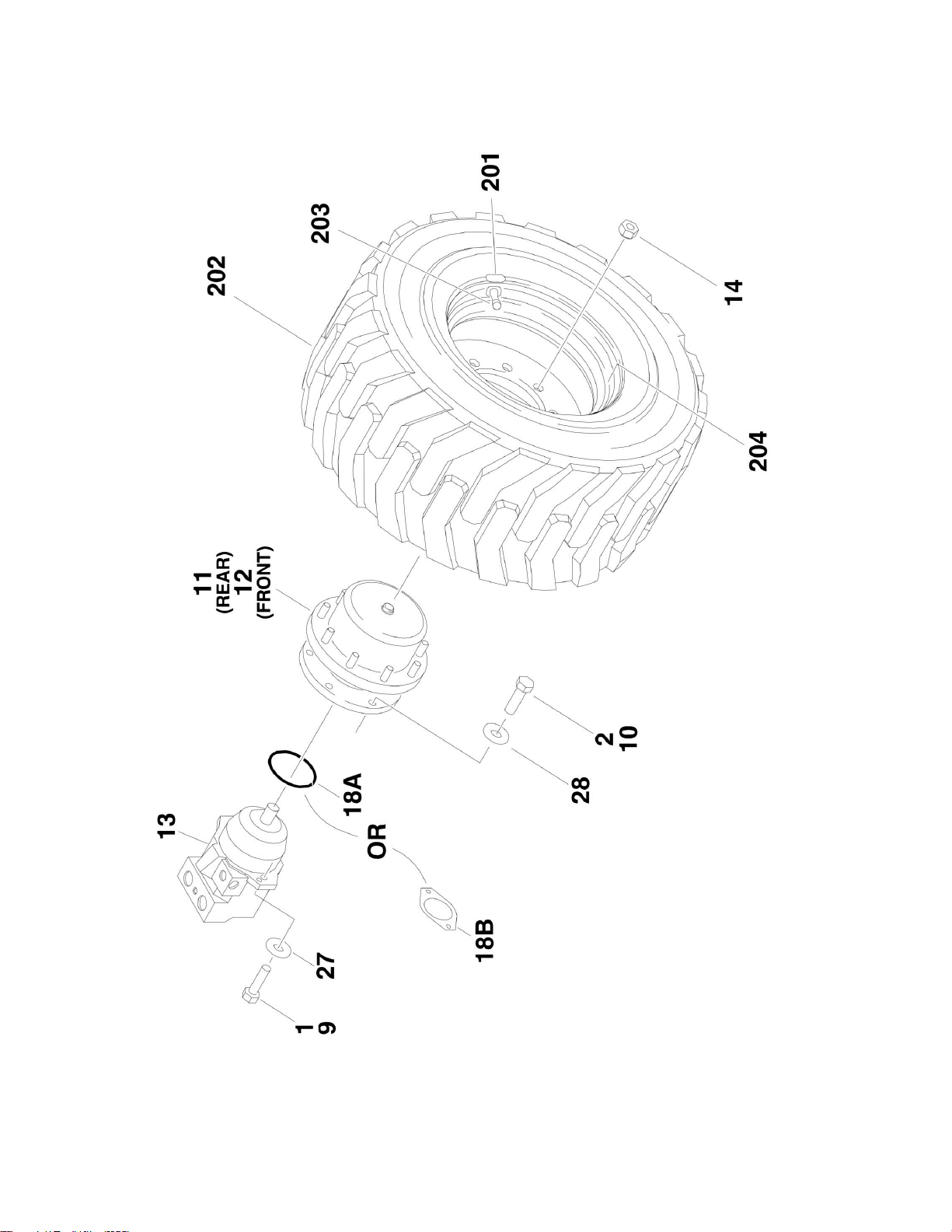

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS ........................................................................................................... 14

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR) ................................................................................................ ................ 18

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR) ................................................................................................ ................ 22

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)........................................................................................................................... 26

FIGURE 1-6. DRIVE HUB ASSEMBLY (FRONT)........................................................................................................................... 30

FIGURE 1-7. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300002249) ........................................ 34

FIGURE 1-8. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300002249 to Present, SN E300000100 through E300001114) ................................................................................................... 36

FIGURE 1-9. DRIVE VALVES INSTALLATIONS ........................................................................................................................... 38

SECTION 2 - TURNTABLE ................................................................................................................................................................ 41

FIGURE 2-1. CONTROL VALVE INSTALLATION.......................................................................................................................... 42

FIGURE 2-2. MAIN CONTROL VALVE ASSEMBLY ...................................................................................................................... 44

FIGURE 2-3. TURNTABLE AND SWING DRIVE INSTALLATIONS .............................................................................................. 46

FIGURE 2-4. SWING MOTOR ASSEMBLY (ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES) (Prior to SN

1300006701) .................................................................................................................................................................................. 50

FIGURE 2-5. SWING MOTOR ASSEMBLY (SERVICE REPLACEMENT FOR BELGIUM BUILT MACHINES AND ORIGINAL

EQUIPMENT FOR BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (Prior to SN 1300006701, SN

1300006701 to Present, SN E300000100 through E300001114) ................................................................................................... 52

FIGURE 2-6. SWING BEARING AND ROTATION BOX ASSEMBLY ............................................................................................ 54

FIGURE 2-7. CATERPILLAR ENGINE INSTALLATION (WITH UGM) ........................................................................................... 58

FIGURE 2-8. 2500W GENERATOR INSTALLATION - CATERPILLAR MACHINES (WITH UGM) (OPTIONAL) .......................... 66

FIGURE 2-9. DEUTZ ENGINE INSTALLATION (BELGIUM BUILT MACHINES) (Prior to SN 1300000981) ................................. 70

FIGURE 2-10. DEUTZ ENGINE INSTALLATION (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300000981 to Present, SN E300000100 through E300001114) ................................................................................................... 76

FIGURE 2-11. 2500W GENERATOR INSTALLATION - DEUTZ MACHINES (OPTIONAL) .......................................................... 84

FIGURE 2-12. PERKINS ENGINE INSTALLATION (WITH ELECTRICAL DRIVEN COOLING FAN) (WITHOUT UGM) .............. 88

FIGURE 2-13. PERKINS ENGINE INSTALLATION (WITH ENGINE DRIVEN COOLING FAN) (WITHOUT UGM) ...................... 96

FIGURE 2-14. PERKINS ENGINE INSTALLATION (WITH UGM) ............................................................................................... 104

FIGURE 2-15. 2500W GENERATOR INSTALLATION - PERKINS MACHINES (OPTIONAL) .................................................... 112

FIGURE 2-16. PISTON PUMP ASSEMBLY ................................................................................................................................. 116

FIGURE 2-17. AUXILIARY PUMP ASSEMBLY ............................................................................................................................ 120

FIGURE 2-18. TANK INSTALLATIONS ........................................................................................................................................ 124

FIGURE 2-19. GROUND CONTROL BOX ASSEMBLY (WITHOUT UGM) ................................................................................. 128

FIGURE 2-20. GROUND CONTROL BOX ASSEMBLY (WITH UGM) ......................................................................................... 132

FIGURE 2-21. ELECTRICAL OPTIONS INSTALLATION (TURNTABLE MOUNTED) ................................................................. 136

FIGURE 2-22. HOODS INSTALLATION (BELGIUM BUILT MACHINES) (Prior to SN 1300006659) .......................................... 140

FIGURE 2-23. HOODS INSTALLATION (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN 1300006659

to Present, SN E300000100 through E300001114)...................................................................................................................... 144

SECTION 3 - BOOM ........................................................................................................................................................................ 149

FIGURE 3-1. TOWER/MID BOOMS AND CYLINDERS INSTALLATION .................................................................................... 150

FIGURE 3-2. MAIN BOOM INSTALLATION ................................................................................................................................. 154

FIGURE 3-3. MAIN BOOM ASSEMBLY ....................................................................................................................................... 158

FIGURE 3-4. ROTATOR ASSEMBLY .......................................................................................................................................... 162

FIGURE 3-5. PLATFORM SUPPORT AND CONTROL VALVES INSTALLATIONS.................................................................... 164

SECTION 4 - PLATFORM ................................................................................................................................................................ 167

FIGURE 4-1. PLATFORM INSTALLATION .................................................................................................................................. 168

FIGURE 4-2. PLATFORM CONSOLE ASSEMBLY ...................................................................................................................... 172

FIGURE 4-3. CONTROLLER ASSEMBLY (LIFT AND SWING) ................................................................................................... 178

FIGURE 4-4. CONTROLLER ASSEMBLY (DRIVE AND STEER)................................................................................................ 182

FIGURE 4-5. SOFT TOUCH SYSTEM INSTALLATION (OPTIONAL) ......................................................................................... 186

SECTION 5 - CYLINDER ................................................................................................................................................................. 189

FIGURE 5-1. AXLE LOCKOUT CYLINDER ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300003223) ................. 190

FIGURE 5-2. AXLE LOCKOUT CYLINDER ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES)

(SN 1300003223 to Present, SN E300000100 through E300001114) ......................................................................................... 192

FIGURE 5-3. LEVEL (PLATFORM) CYLINDER ASSEMBLY ....................................................................................................... 194

3121182 510AJ 7

Page 8

TABLE OF CONTENTS

FIGURE 5-4. LIFT (JIB) CYLINDER ASSEMBLY ......................................................................................................................... 196

FIGURE 5-5. LIFT (MAIN BOOM) CYLINDER ASSEMBLY .......................................................................................................... 198

FIGURE 5-6. LIFT (TOWER BOOM) CYLINDER ASSEMBLY ..................................................................................................... 200

FIGURE 5-7. MASTER CYLINDER ASSEMBLY .......................................................................................................................... 202

FIGURE 5-8. STEER CYLINDER ASSEMBLY ............................................................................................................................. 204

FIGURE 5-9. TELESCOPE CYLINDER ASSEMBLY .................................................................................................................... 206

SECTION 6 - HYDRAULIC ............................................................................................................................................................... 209

FIGURE 6-1. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (Prior to SN 1300000353) .................. 210

FIGURE 6-2. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (SN 1300000353 through 1300003222)

................................................................................................................................................................................................ ...... 212

FIGURE 6-3. AXLE LOCKOUT HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES)

(SN 1300003223 to Present, SN E300000100 through E300001114) ................................................................ .......................... 214

FIGURE 6-4. DRIVE HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES) (Prior to SN 1300003476) .................................. 216

FIGURE 6-5. DRIVE HYDRAULIC DIAGRAM (BELGIUM BUILT MACHINES AND ROMANIAN BUILT MACHINES) (SN

1300003476 to Present, SN E300000100 through E300001114) ................................................................................................. 220

FIGURE 6-6. STANDARD HYDRAULIC DIAGRAM...................................................................................................................... 222

FIGURE 6-7. HYDRAULIC DIAGRAM LIST .................................................................................................................................. 226

SECTION 7 - ELECTRICAL .............................................................................................................................................................. 227

FIGURE 7-1. ELECTRICAL DIAGRAM LIST ................................................................................................................................ 228

FIGURE 7-2. HARNESS COMPONENTS INSTALLATION (WITHOUT UGM) ............................................................................. 230

FIGURE 7-3. HARNESS COMPONENTS INSTALLATION (WITH UGM) .................................................................................... 244

SECTION 8 - DECALS ..................................................................................................................................................................... 257

FIGURE 8-1. DECALS INSTALLATION - ANSI SPEC .................................................................................................................. 258

FIGURE 8-2. DECALS INSTALLATION - ANSI EXPORT SPECS................................................................................................ 262

FIGURE 8-3. DECALS INSTALLATION - CE AND AUSTRALIAN SPECS ................................................................................... 268

SECTION 9 - RECOMMENDED SERVICE PARTS STOCK ............................................................................................................ 273

FIGURE 9-1. MODEL 510AJ STANDARD PARTS ....................................................................................................................... 274

FIGURE 9-2. MODEL 510AJ VARIABLE PARTS ......................................................................................................................... 276

SECTION 10 - SPECIAL OPTIONS ................................................................................................................................................. 277

FIGURE 10-1. SPECIAL OPTIONS .............................................................................................................................................. 278

PART NUMBER INDEX .................................................................................................................................................................... 283

8 510AJ 3121182

Page 9

SECTION 1 - FRAME

SECTION 1 - FRAME

3121182 510AJ 9

Page 10

SECTION 1 - FRAME

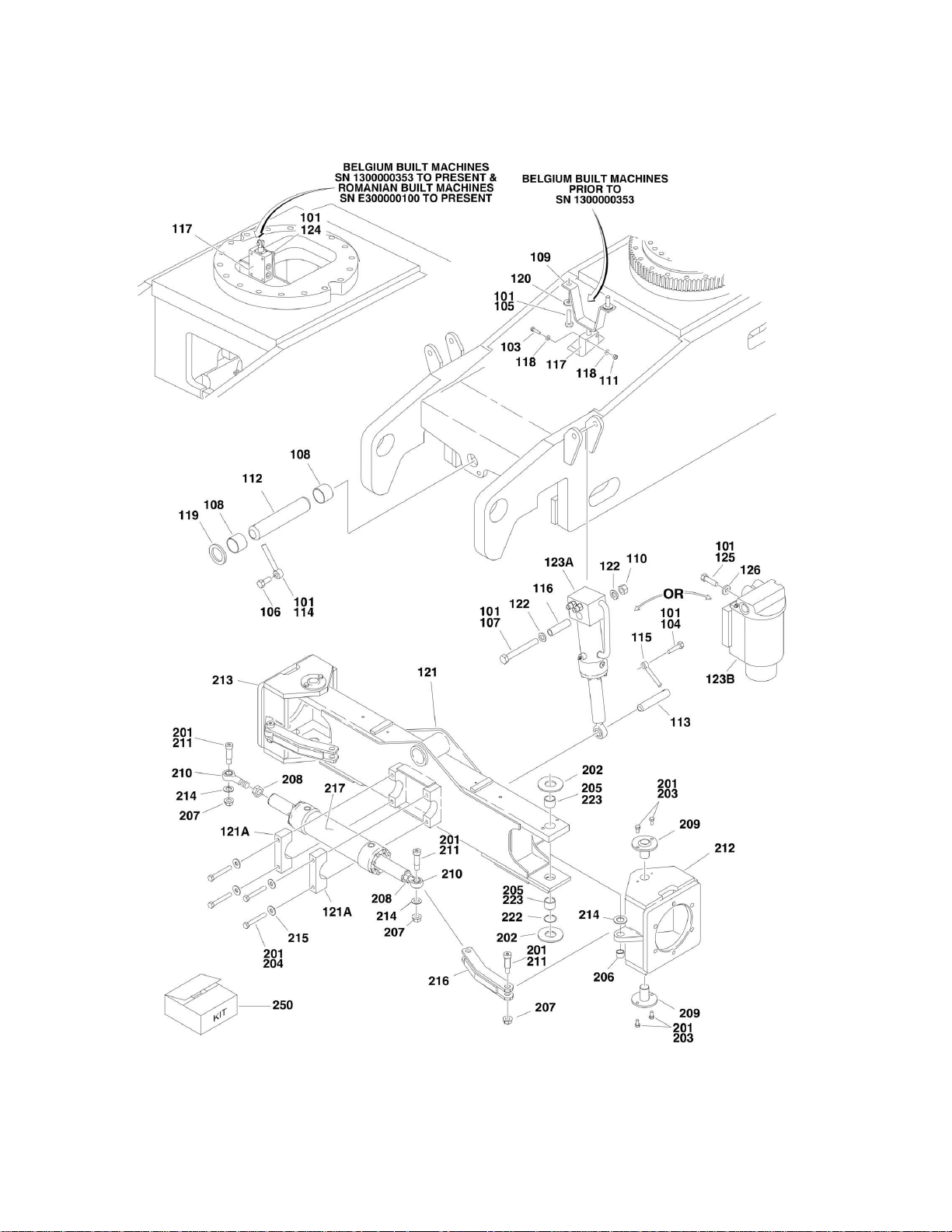

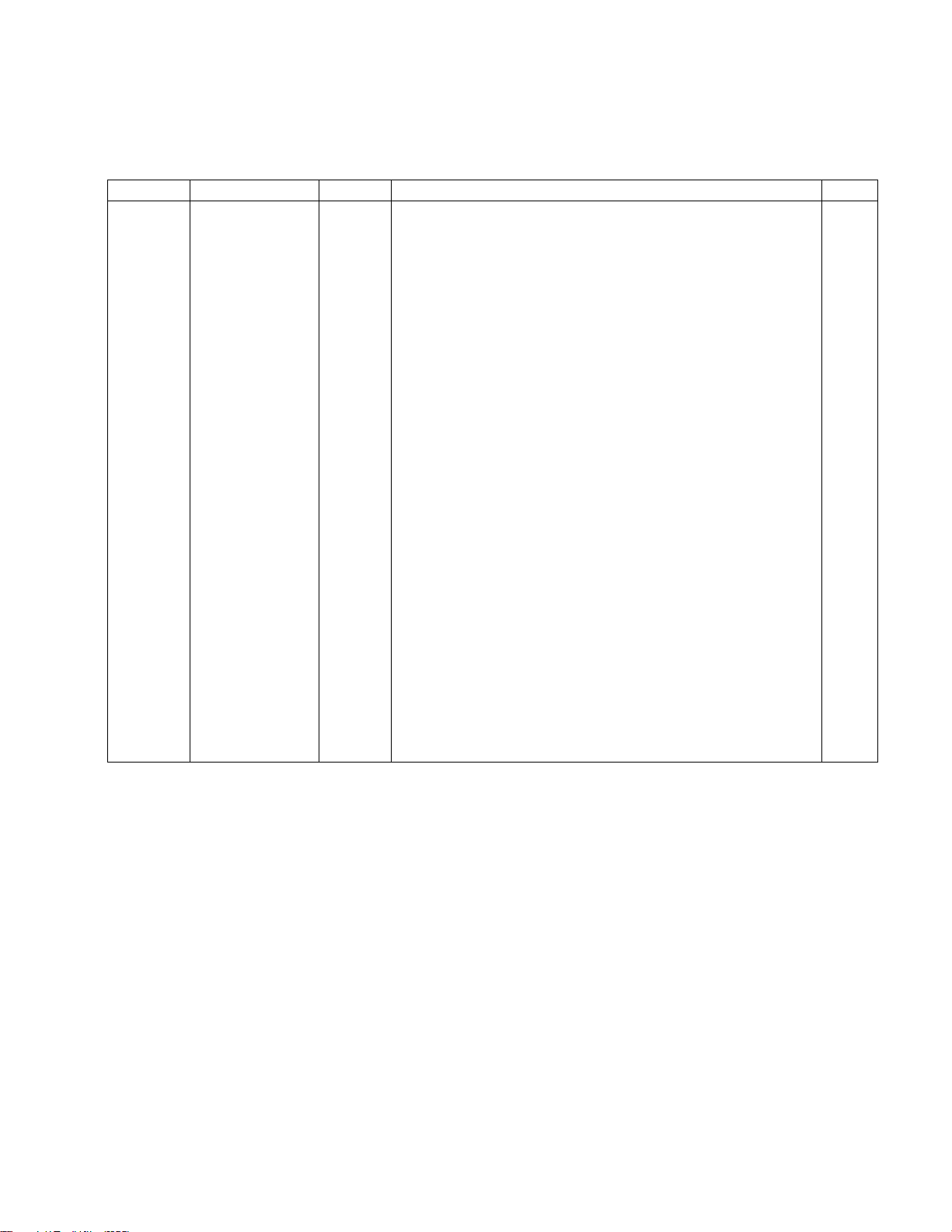

FIGURE 1-1. AXLE AND STEERING INSTALLATION

10 510AJ 3121182

Page 11

SECTION 1 - FRAME

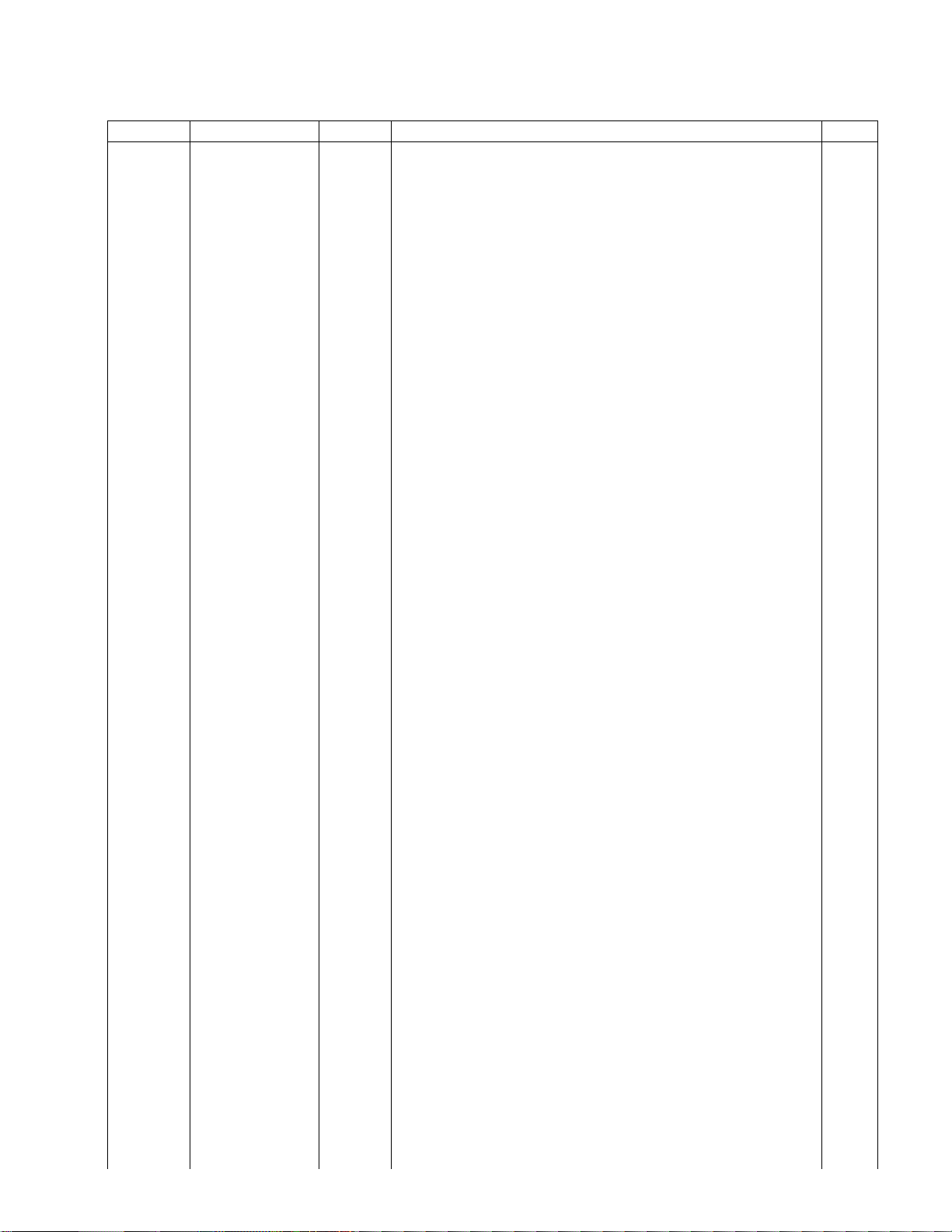

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

OSCILLATING AXLE INSTALLATIONS

0272424

Ref

Belgium Built Machines (Prior to SN 1300000353)

E 0273497

Ref

Belgium Built Machines (SN 1300000353 through 1300003222)

C 0274753

Ref

Belgium Built Machines (SN 1300003223 to Present)

A

0274753

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

A

101

0100011

AR

Compound, Locking

101

0100019

AR

Compound, Locking

102

0100038

AR

Primer, Locking #7471

103

0641416

4

Bolt 1/4in-20NC x 2in (Belgium Built Machines) (Prior to SN

1300000353)

104

0641607

2

Bolt 3/8in-16NC x 3/4in (Belgium Built Machines) (Prior to SN

1300003223)

105

0641810

2

Bolt 1/2in-13NC x 1-1/4in (Belgium Built Machines) (Prior to SN

1300000353)

106

0642012

1

Bolt 5/8in-11NC x 1-1/2in

107

0682248

2

Bolt 3/4in-10NC x 6in (Belgium Built Machines) (Prior to SN

1300003223)

108

0961950

2

Bushing

109

1100134

1

Cam, Lockout (Belgium Built Machines) (Prior to SN

1300000353)

110

3272201

2

Nut 3/4in-10NC (Belgium Built Machines) (Prior to SN

1300003223)

111

3311405

4

Locknut 1/4in-20NC (Belgium Built Machines) (Prior to SN

1300000353)

112

3422592

1

Pin, Axle Pivot

113

3422520

2

Pin (Belgium Built Machines) (Prior to SN 1300003223)

114

3841258

1

Keeper, Pin

115

3841520

2

Keeper, Pin (Belgium Built Machines) (Prior to SN 1300003223)

116

4567462

2

Tube, Mounting (Belgium Built Machines) (Prior to SN

1300003223)

117

Ref

Lockout Valve Assembly Options:

117

4640871

1

Valve used on Belgium Built Machines (Prior to SN

1300000353)

117

7012693

1

Seal Kit - 4640871 Valve

117

7002840

1

Anti-Rotation Pin Removal Tool

117

4641265

1

Valve used on Belgium Built Machines (SN 1300000353 to

Present)

117

4641265

1

Valve used on Romanian Built Machines (SN E300000100

through E300001114)

118

4711400

4

Flatwasher 1/4in Thin (Belgium Built Machines) (Prior to SN

1300000353)

119

4740158

1

Thrustwasher

120

4752000

4

Flatwasher 5/8in Regular (Belgium Built Machines) (Prior to SN

1300000353)

121

Ref

Axle Weldment Options:

Ref

Note: If kingpin holes in the axle measure 1.503in diameter

or larger in any direction, axle weldment must be replaced.

Ref

Note: See Kit Item 250 and additional notes at end of parts

list before ordering parts.

121

4846660

1

Belgium Built Machines (Prior to SN 1300003223)

121

0280203

1

Belgium Built Machines (SN 1300003223 to Present)

121

0280203

1

Romanian Built Machines (SN E300000100 through

FIGURE 1-1. AXLE AND STEERING INSTALLATION

3121182 510AJ 11

Page 12

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

E300001114)

121A

0561511

2

Steer Cylinder Mounting Block Assembly

122

4892200

4

Flatwasher 3/4in Hardened (Belgium Built Machines) (Prior to

SN 1300003223)

123

Ref

Lockout Cylinder Assembly Options (See CYLINDER SECTION

for Breakdown):

123A

1684243

2

Belgium Built Machines (Prior to SN 1300003223)

123B

1684465

2

Belgium Built Machines (SN 1300003223 to Present)

123B

1684465

2

Romanian Built Machines (SN E300000100 through

E300001114)

124

0791506

4

Screw 5/16in-18NC x 3/4in (Belgium Built Machines) (SN

1300000353 to Present)

125

0641814

8

Bolt 1/2in-13NC x 1-3/4in (Belgium Built Machines) (SN

1300003223 to Present)

126

4891800

8

Flatwasher 1/2in Hardened (Belgium Built Machines) (SN

1300003223 to Present)

126

4891800

8

Flatwasher 1/2in Hardened (Romanian Built Machines) (SN

E300000100 through E300001114)

0272428

Ref

STEERING INSTALLATION

F

201

0100011

AR

Compound, Locking

202

Ref

Thrustwasher Options:

202

0440161

AR

Belgium Built Machines (Top and Bottom Kingpin Location)

(Note: See Kit Item 250 and additional notes at end of parts list

before ordering parts) (Prior to SN 1300000441)

202

4740537

AR

Belgium Built Machines (.0625) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740537

AR

Romanian Built Machines (.0625) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740538

AR

Belgium Built Machines (.125) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740538

AR

Romanian Built Machines (.125) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740539

AR

Belgium Built Machines (.188) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740539

AR

Romanian Built Machines(.188) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

4740540

AR

Belgium Built Machines (.250) (Top Kingpin Location) (SN

1300000441 to Present)

202

4740540

AR

Romanian Built Machines (.250) (Top Kingpin Location) (SN

E300000100 through E300001114)

202

0440271

AR

Belgium Built Machines (Bottom Kingpin Location) (SN

1300000441 to Present)

202

0440271

AR

Romanian Built Machines (Bottom Kingpin Location) (SN

E300000100 through E300001114)

203

0641606

16

Bolt 3/8in-16NC x 3/4in

204

0641824

4

Bolt 1/2in-13NC x 3in

205

Ref

Bushing / Bearing Options:

205

0961951

2

Belgium Built Machines (Top and Bottom Kingpin Location)

(Note: See Kit Item 250 and additional notes at end of parts list

before ordering parts) (Prior to SN 1300000441)

205

0961951

2

Belgium Built Machines (SN 1300000441 to Present)

205

0961951

2

Romanian Built Machines Options: (SN E300000100 through

E300001114)

205

0440291

2

Bushing / Bearing (Top Kingpin Location)

205

0440274

2

Bushing / Bearing (Bottom Kingpin Location)

206

0962140

2

Bearing, Garmax

SECTION 1 - FRAME

12 510AJ 3121182

Page 13

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

207

3312008

4

Nut 5/8in-11NC

208

3322201

2

Nut 3/4in-16NC

209

Ref

Kingpin Options:

209

3422716

4

Belgium Built Machines (2 Bolt Mounting) (Note: See Kit Item 250

and additional notes at end of parts (Prior to SN 1300000441)

209

3423081

4

Belgium Built Machines (4 Bolt Mounting) (SN 1300000441 to

Present)

209

3423081

4

Romanian Built Machines (SN E300000100 through

E300001114)

210

Ref

Rod-End with Grease Fitting

210

3841367

2

Belgium Built Machines (Prior to SN 130005313)

210

3841517

2

Belgium Built Machines (SN 130005313 to Present)

210

3841517

2

Romanian Built Machines (SN E300000100 through

E300001114)

211

3900109

4

Screw, Shoulder

212

Ref

Spindle (Left Side) Options:

212

4130391

1

Belgium Built Machines (Prior to SN 1300000441)

212

4130408

1

Belgium Built Machines (SN 1300000441 to Present)

212

4130408

1

Romanian Built Machines (SN E300000100 through

E300001114)

213

Ref

Spindle (Right Side) Options:

213

4130392

1

Belgium Built Machines (Prior to SN 1300000441)

213

4130407

1

Belgium Built Machines (SN 1300000441 to Present)

213

4130407

1

Romanian Built Machines (SN E300000100 through

E300001114)

214

4740086

4

Thrustwasher

215

4751800

4

Flatwasher 1/2in Regular

216

4846666

2

Tie-Rod

217

1684246

1

Steer Cylinder Assembly (See CYLINDER SECTION for

Breakdown)

222

3780182

2

O-Ring (Belgium Built Machines) (SN 1300003223 to Present)

222

3780182

2

O-Ring (Romanian Built Machines) (SN E300000100 through

E300001114)

223

3020029

AR

Grease, Bearing

250

2902400

1

Kingpin & Bushings Update Kit for Belgium Built Machines Built

Prior to SN 1300000441 (Includes Newer “Belgium Built Machines

SN 1300000441 to Present” Design Items 202, 205, 210 & 222).

Refer to Field Service Bulletin AWP-04-11.

Ref

Note: Newer bushings will fit in "Belgium Built Machines Prior

to SN 1300000441" axles however if kingpin holes measure

1.503in diameter or larger in any direction, axle weldment

must be replaced before installation of kit.

Ref

Note: Spindles require drilling and tapping for 8 additional

kingpin mtg bolts. Newer design kingpins require 4 mtg bolts

each.

Ref

Note: All Romanian Built Machines have the newer design

axle.

3121182 510AJ 13

Page 14

SECTION 1 - FRAME

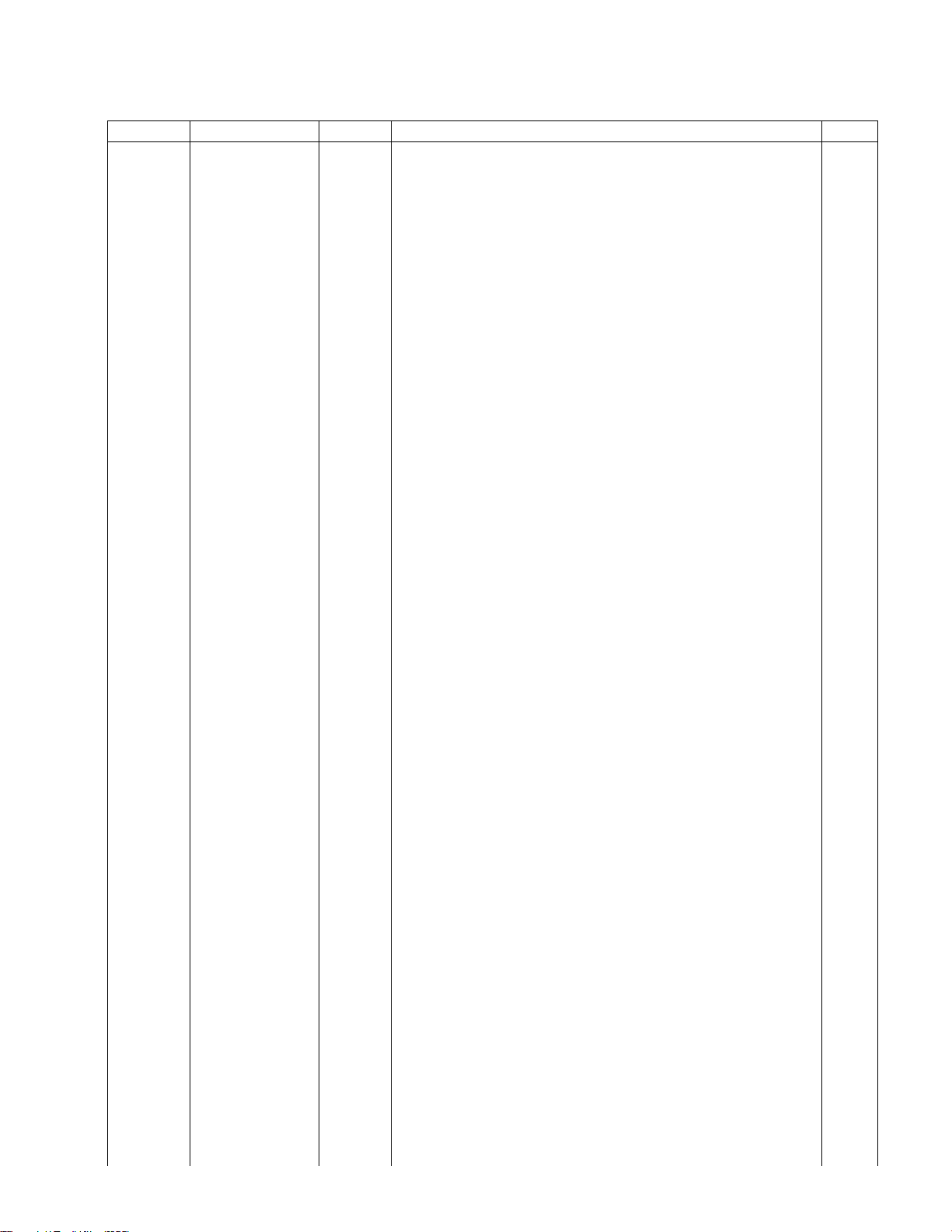

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS

14 510AJ 3121182

Page 15

SECTION 1 - FRAME

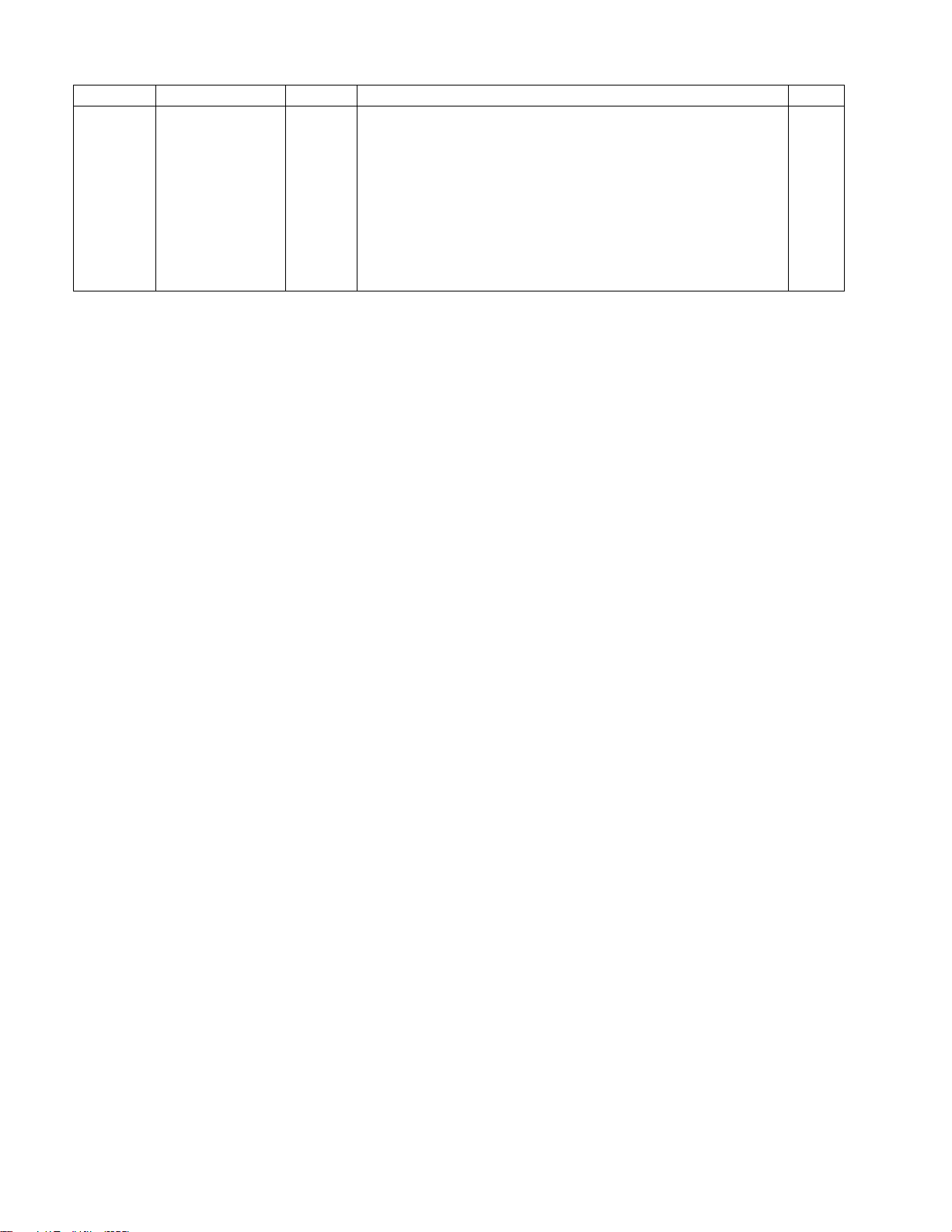

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

WHEEL DRIVE INSTALLATIONS

0272320

Ref

Wheel Drive Installations (Prior to SN 1300000159)

C

0272895

Ref

Wheel Drive Installations (SN 1300000159 through

1300003222)

G

0275854

Ref

Wheel Drive Installations (SN 1300003223 through

E300001114)

C

1

0100011

AR

Compound, Locking

2 0100019

AR

Compound, Locking

9 Ref

Hardware Options:

9

0681810

8

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Both Front and Rear Axle)

(Belgium Built Machines) (Prior to SN 1300000162)

9

0681810

4

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Front Axle) (Belgium Built

Machines) (SN 1300000162 to Present)

9 0681810

4

Bolt 1/2in-13NC x 1-1/4in (Grade 8) (Front Axle) (Romanian

Built Machines) (SN E300000100 through E300001114)

9

3311801

4

Nut 1/2in-13NC (Not Shown) (Rear Axle) (Belgium Built

Machines) (SN 1300000162 to Present)

9 3311801

4

Nut 1/2in-13NC (Not Shown) (Rear Axle) (Romanian Built

Machines) (SN E300000100 through E300001114)

10

0682014

24

Bolt 5/8in-11NC x 1-3/4in (Grade 8)

11 Ref

Drive Hub/Brake Assembly (Rear) Options:

11

2780256

2

Belgium Built Machines (See DRIVE HUB/BRAKE ASSEMBLY

(REAR) for Breakdown) (Prior to SN 1300000159)

11

2780267

2

Belgium Built Machines (See DRIVE HUB/BRAKE ASSEMBLY

(REAR) for Breakdown) (SN 1300000159 to Present)

11

2780267

2

Romanian Built Machines (See DRIVE HUB/BRAKE

ASSEMBLY (REAR) for Breakdown) (SN E300000100 through

E300001114)

12 Ref

Drive Hub Assembly (Front) Options:

12

2780257

2

Belgium Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (Prior to SN 1300000159)

12

2780268

2

Belgium Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (SN 1300000159 to Present)

12

2780268

2

Romanian Built Machines (See DRIVE HUB ASSEMBLY

(FRONT) for Breakdown) (SN E300000100 through

E300001114)

13 Ref

Drive Motor Assembly Options:

13

3160266

4

Belgium Built Machines (Use p/n 3160348 - See DRIVE

MOTOR ASSEMBLY for Breakdown) (For 3160348 Motor - See

DRIVE MOTOR ASSEMBLY for Breakdown) (Prior to SN

1300002249)

13

3160348

4

Belgium Built Machines (See DRIVE MOTOR ASSEMBLY for

Breakdown) (SN 1300002249 to Present)

13

3160348

4

Romanian Built Machines (See DRIVE MOTOR ASSEMBLY for

Breakdown) (SN E300000100 through E300001114)

14

3300106

36

Lugnut

18 Ref

Seal Options:

18A

3790045

2

O-Ring Belgium Built Machines (Prior to SN 1300002638)

18B

3960526

4

Gasket Belgium Built Machines (SN 1300002638 to Present)

18B

3960526

4

Gasket Romanian Built Machines (SN E300000100 through

E300001114)

27

4891800

8

Flatwasher 1/2in Hardened

28

4892000

24

Flatwasher 5/8in Hardened

31

2300016

AR

Fluid, Hydraulic (Not Shown)

FIGURE 1-2. TIRE AND WHEEL DRIVE INSTALLATIONS

3121182 510AJ 15

Page 16

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

32

3020008

AR

Lubricant, Mobilube HD 80W - 90 (Not Shown)

Ref

TIRE AND WHEEL INSTALLATION OPTIONS

0258028

Ref

12 x 16.5 Pneumatic (ANSI/ANSI Export/CSA/Japanese Specs

Only. Not Available on CE/Australian Specs)

A

0258030

Ref

12 x 16.5 Foam-Filled (Available on all Specs)

A 0270674

Ref

12 x 16.5 Foam-Filled, Non-Marking (Available on all Specs)

B 0258031

Ref

33/1550 x 16.5 Foam-Filled

B

0258831

Ref

33/16LL x 16.1 Pneumatic (ANSI/ANSI Export/CSA/Japanese

Specs Only. Not Available on CE/Australian Specs) (Requires

special counterweighting)

A

0257740

2

12 x 16.5 Pneumatic Right Side (Not Available on CE/Australian

Specs)

C

0257746

2

12 x 16.5 Pneumatic Left Side (Not Available on CE/Australian

Specs) C

0258009

2

12 x 16.5 Foam-Filled Right Side

C 0258010

2

12 x 16.5 Foam-Filled Left Side

C 0270675

2

12 x 16.5 Foam-Filled Non-Marking Right Side

A 0270676

2

12 x 16.5 Foam-Filled Non-Marking Left Side

A 0258011

2

33/1550 x 16.5 Foam-Filled Right Side

D 0258012

2

33/1550 x 16.5 Foam-Filled Left Side

D

0258830

4

33/16LL x 16.1 Pneumatic (Not Available on CE/Australian

Specs) (Requires special counterweighting)

Ref

Note: Assemblies may require ballast/foam filling to

manufacture's specifications prior to installing on a

machine. Refer to Operation and Safety or Service and

Maintenance Manuals. Purchase individual tire and/or rim

only if able to foam fill tire and wheel assembly, otherwise,

purchase complete assembly.

201

Ref

Decal Options (Pneumatic Only):

201

1702740

1

Decal - 90PSI

201

1703067

1

Decal - 40PSI

202

Ref

Tire Options:

202

4520216

1

12 x 16.5 NHS (OTR Brand)

202

4520240

1

12 x 16.5 Non-Marking (OTR Brand)

202

4520217

1

33/1550 x 16.5 NHS (OTR Brand)

202

4520212

1

33/16LL x 16.1 (Galaxy Brand)

203

Ref

Valve Stem Options:, Air (Pneumatic Only)

203

4640113

1

All except 33/1550 x 16.5 Foam-Filled Tire and Wheel Assy

203

8786514

1

33/1550 x 16.5 Foam-Filled Tire and Wheel Assy Only

204

Ref

Rim, Wheel Options:

204

4860178

1

16.5 x 12 (Use with 12 x 16.5 Tires)

204

4860179

1

16.5 x 12 (Use with 33/1550 x 16.5 Tires)

204

4860193

1

16.1 x 14 (Use with 33/16LL x 16.1 Tires)

SECTION 1 - FRAME

16 510AJ 3121182

Page 17

Page 18

SECTION 1 - FRAME

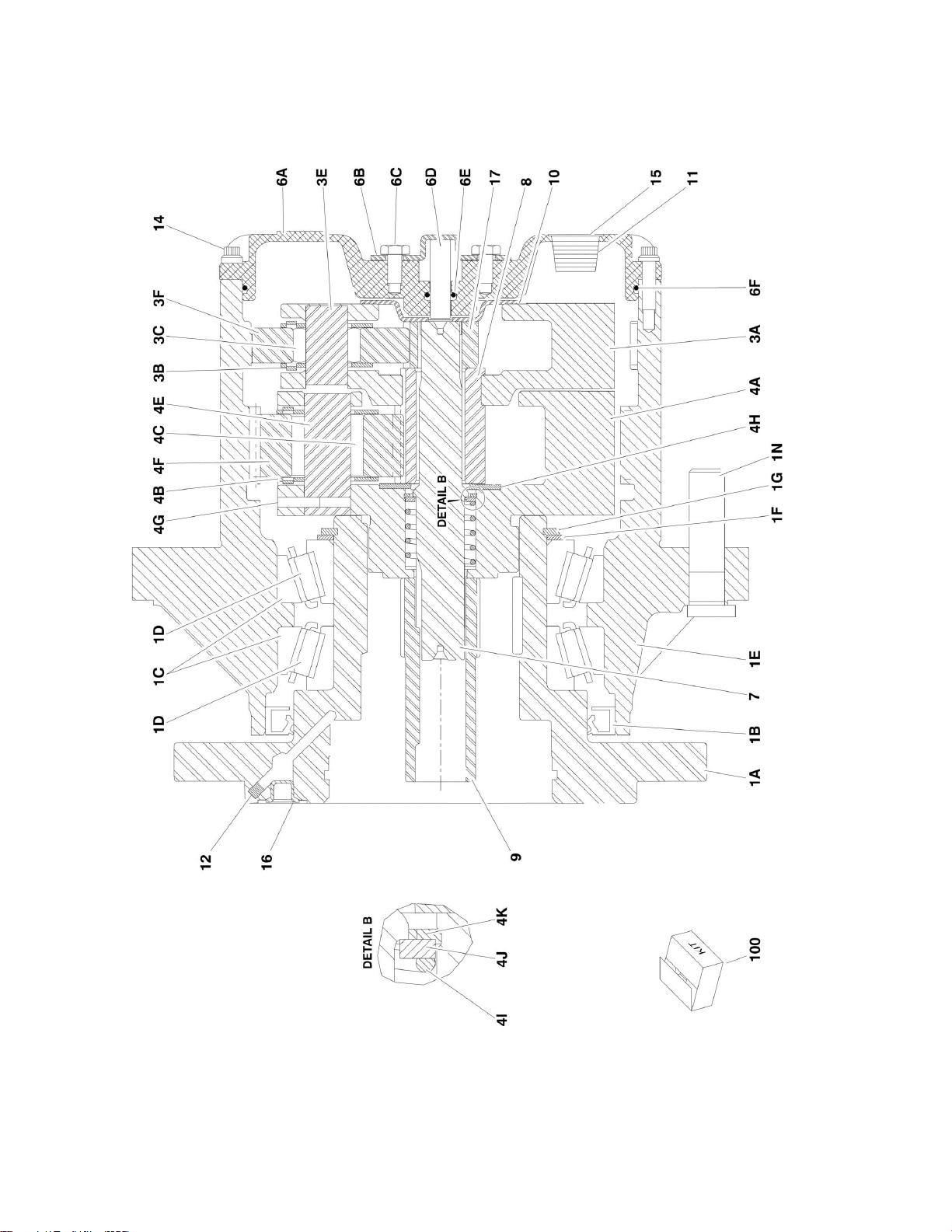

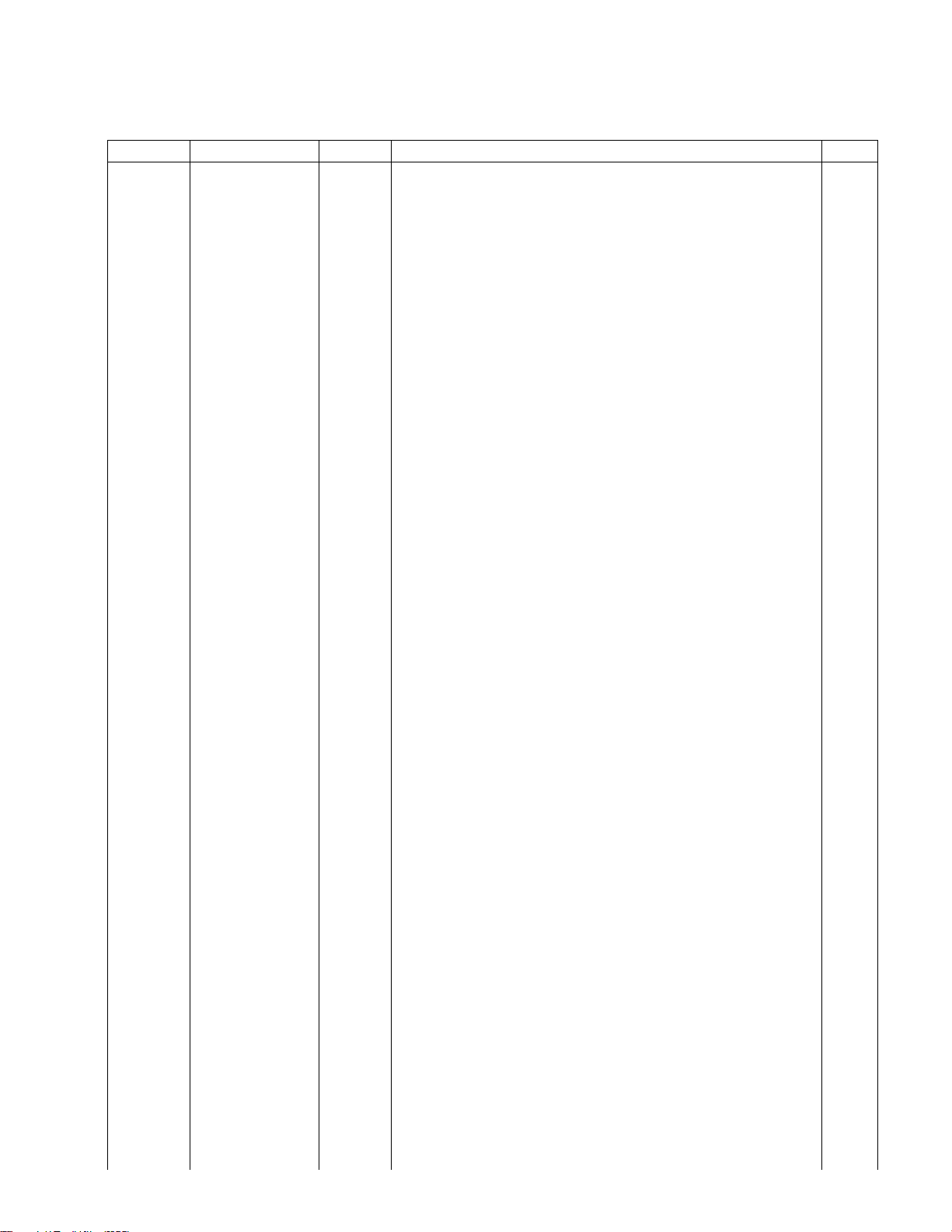

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR)

18 510AJ 3121182

Page 19

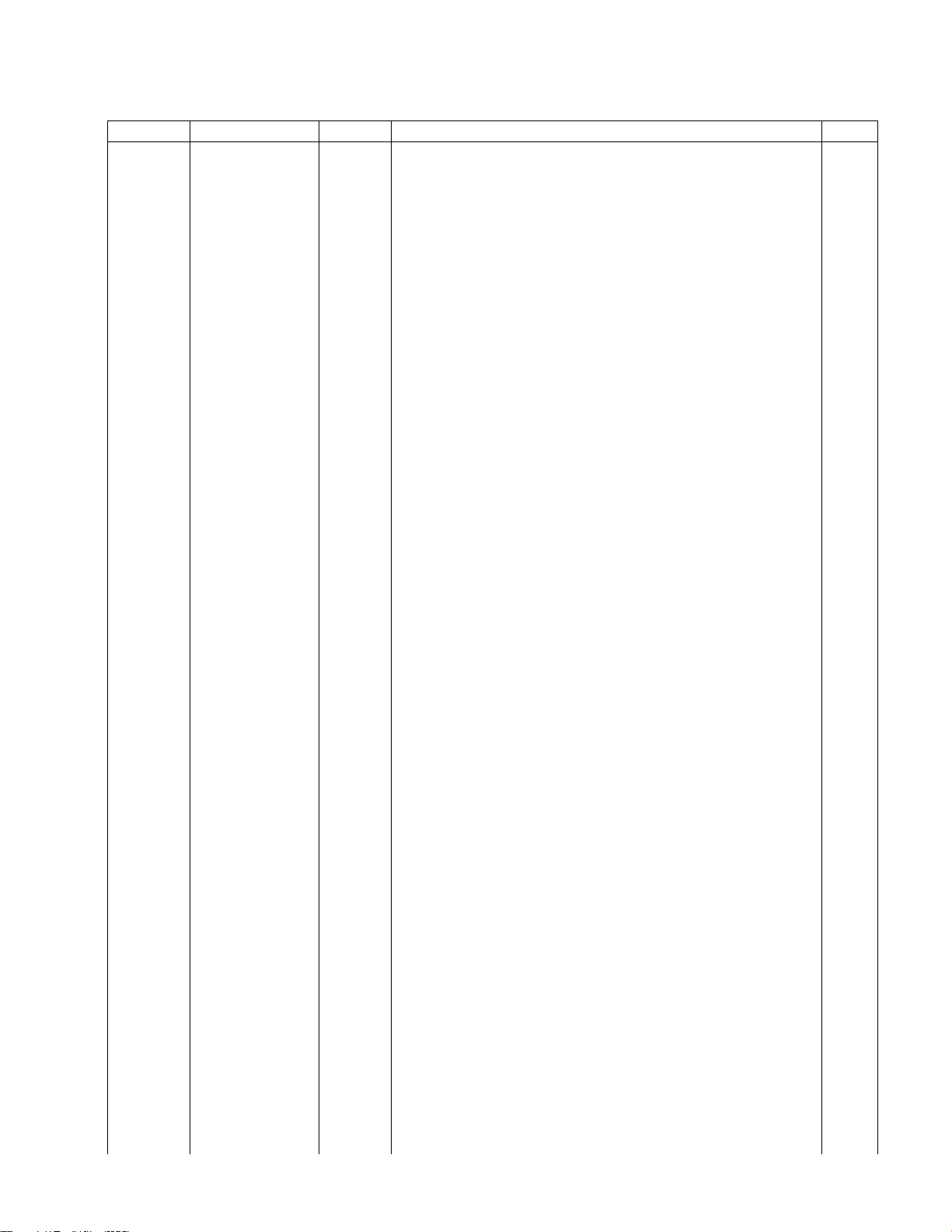

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: USED BELGIUM BUILT MACHINES (Prior to SN

1300000159)

Ref

NOTE: Hub may have been replaced with Service Kit p/n

1001178138. Kit uses hub p/n 2780267. See next figure for

service parts.

2780256

Ref

DRIVE HUB/BRAKE ASSEMBLY

G

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7024105

1

Spindle

1B

7024113

1

Seal 1C

7007006

2

Cone, Bearing

1D

7024112

2

Cup, Bearing

1E

7024110

1

Housing/Ring Gear

1F

7024109

1

Thrustwasher

1G

7024107

1

Ring, Retaining

1N

7024111

9

Stud, Wheel

2 7024106

1

Brake, Input

2A

7024710

1

Kit, Brake Lining (Includes Qty 8 Outer Plates and Qty 7 Inner

Plates)

2B

7024709

1

Kit, Brake O-Ring (Includes Qty 2 O-Rings and Back-up Rings)

2C

7024711

1

Kit, Brake Spring (Includes Qty 12 Springs)

2D

7024719

1

Kit, Brake Hardware (Includes End Plate, Spacer and Qty 2 EClips)

3 See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

3A

7024116

1

Carrier

3B

7024127

6

Thrustwasher

3C

7024123

42

Bearing, Needle

3E

7024120

3

Shaft, Planet

3F

7024118

3

Gear, Planet

4

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

4A

7024117

1

Carrier

4B

7024126

6

Thrustwasher

4C

7024122

45

Bearing, Needle

4E

7024121

3

Shaft, Planet

4F

7024119

3

Gear, Planet

4G

7001913

3

Rollpin

4H

7024128

1

Thrustwasher

4I

7024124

1

Spring

4J

7024129

1

Thrustwasher

4K

7024125

1

Thrustwasher

6

See Note

1

Cover Assembly (Note: Not Available - Purchase Individual

Components)

6A

7024132

1

Plate, Cover

6B

7017093

1

Cap, Disengage

6C

0641404

2

Bolt 1/2in-20NC x 1/2in

6D

7017092

1

Pin, Dowel

6E

7017095

1

O-Ring

6F

7024134

1

O-Ring

7 7024130

1

Shaft, Input

8 7024115

1

Gear, Sun

FIGURE 1-3. DRIVE HUB/BRAKE ASSEMBLY (REAR)

3121182 510AJ 19

Page 20

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

9

7024131

1

Coupling

10

7017097

1

Spacer, Thrust

11

7017094

2

Plug, Pipe

12

7024108

1

Plug, Pressure

14

7024133

12

Bolt 1/4in-20NC x 7/8in (Grade 8)

15

See Note

1

Plate, ID (Not Shown) (Note: Not Available for Purchase)

16

7017082

1

Plug, O-Ring

17

7024114

1

Gear, Sun

100

7024198

1

Seal Kit (Includes Items 1B, 1G & 6F)

SECTION 1 - FRAME

20 510AJ 3121182

Page 21

Page 22

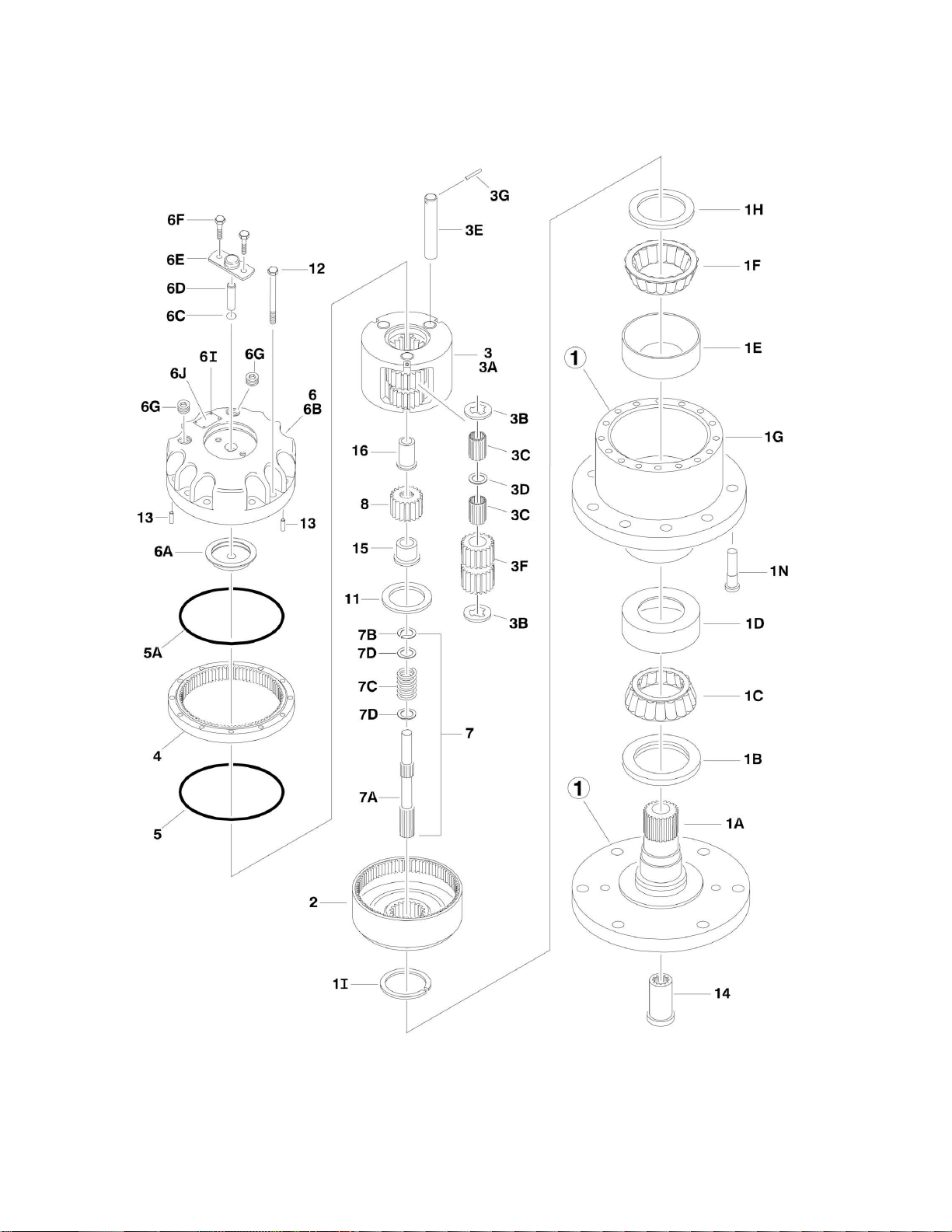

SECTION 1 - FRAME

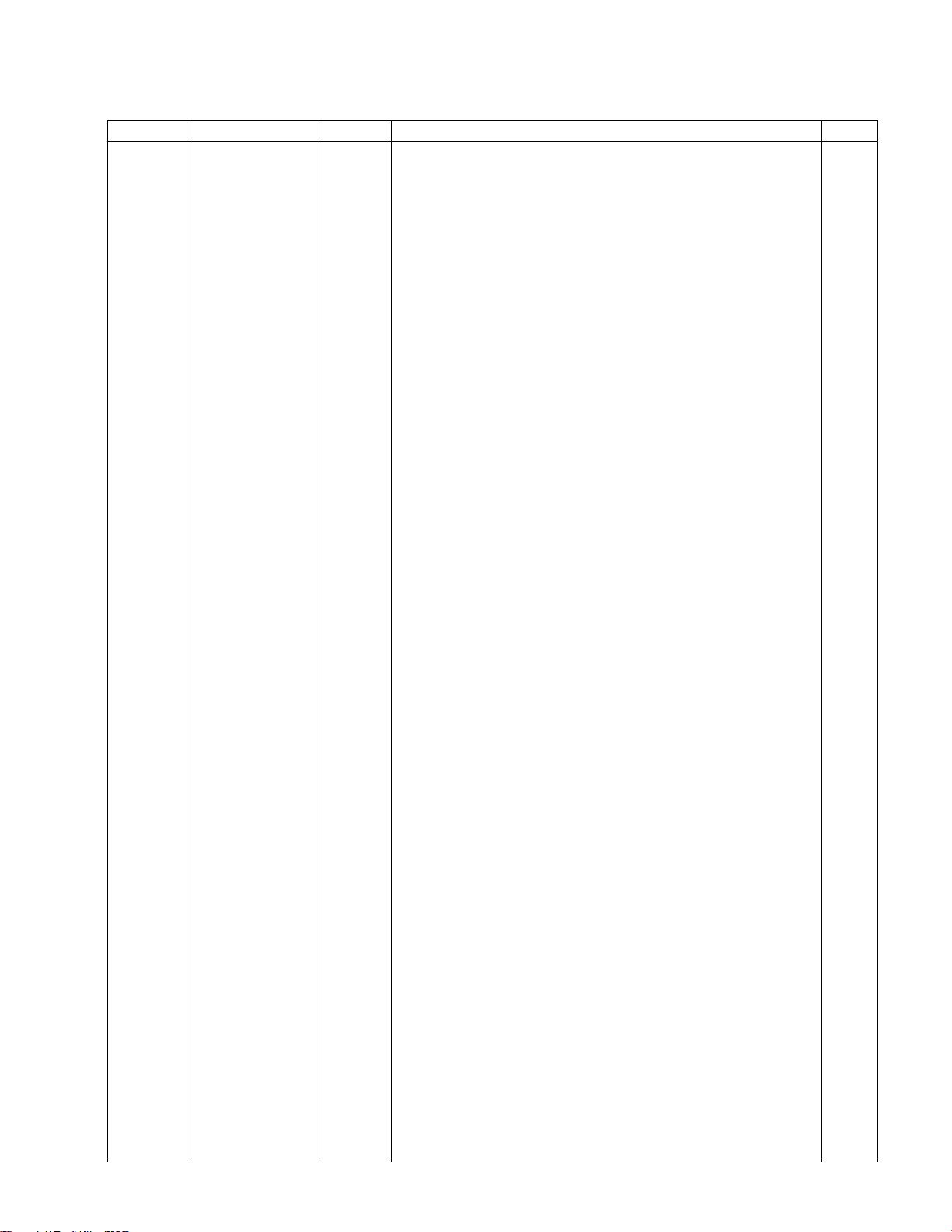

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR)

22 510AJ 3121182

Page 23

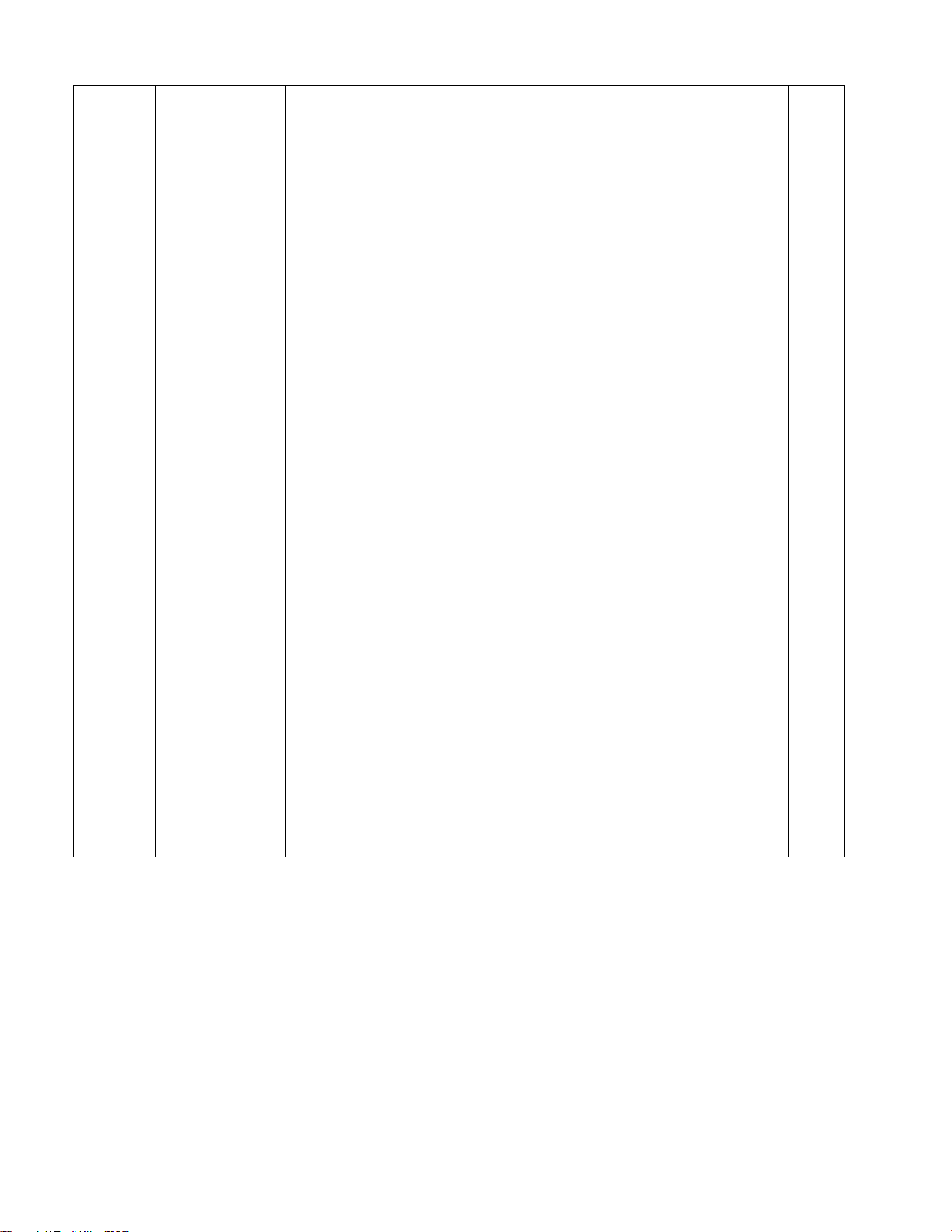

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: USED BELGIUM BUILT MACHINES (SN 1300000159 to

Present)

Ref

USAGE: USED ROMANIAN BUILT MACHINES (SN E300000100

through E300001114)

2780267

Ref

DRIVE HUB/BRAKE ASSEMBLY

D

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7017059

1

Spindle

1B

7001998

1

Seal 1C

7010429

1

Cone, Bearing (Includes Item 1D)

1D

7010429

1

Cup, Bearing (Includes Item 1C)

1E

7000257

1

Cup, Bearing

1F

7000258

1

Cone, Bearing

1G

7007601

1

Housing/Ring Gear

1H

7000232

1

Thrustwasher

1I

7000229

1

Ring, Retaining

1N

7007640

9

Stud, Wheel

2 7000246

1

Gear, Internal

3 7024712

1

Carrier Assembly

3A

7024712

1

Carrier

3B

7024712

6

Ring, Retaining

3C

7024712

AR

Bearing, Needle

3D

7024712

3

Thrustwasher

3E

7024712

3

Shaft, Planet

3F

7024712

3

Gear, Planet

3G

7024712

3

Rollpin

4 7000248

1

Ring Gear

5 7000230

1

O-Ring 5A

7017070

1

O-Ring 6

70001349

1

Cover Assembly (was p/n 7017090)

6A

70001349

1

Spacer, Thrust (was p/n 7017097)

6B

70001349

1

Plate, Cover (was p/n 7017091)

6C

70001349

1

O-Ring (was p/n 7017095)

6D

70001349

1

Rod, Disconnect (was p/n 7017092)

6E

70001349

1

Cap, Disengage (was p/n 7017093)

6F

70001349

2

Bolt (was p/n 0641404)

6G

7017094

1

Plug, Pipe

6I

See Note

4

Rivet (Note: Not Available - Purchase Locally)

6J

See Note

1

Plate, ID (Note: Not Available for Purchase)

7 Ref

Input Shaft Assembly

7A

7024714

1

Shaft 7B

7000261

1

Ring, Retaining

7C

7000262

1

Spring

7D

7000263

2

Spacer, Thrust

8 7024713

1

Gear, Sun

11

7000253

1

Thrustwasher

12

7017067

12

Bolt 13

7017080

4

Pin, Dowell

14

7000206

1

Coupling

15

7024715

1

Spacer, Input

FIGURE 1-4. DRIVE HUB/BRAKE ASSEMBLY (REAR)

3121182 510AJ 23

Page 24

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

16

7024716

1

Spacer, Input

17

7024182

1

Brake Assembly (See Items 101-123 for Breakdown)

27

7024705

1

O-Ring 28

7024717

2

Rod, Threaded

29

7024718

2

Nut 1/2in-13NC

30

7000731

1

Gasket

7024182

Ref

BRAKE ASSEMBLY

101

7024189

1

Shaft 102

7024182

1

Housing

103

I7024193

2

Plate, Friction

104

7024193

1

Plate, Pressure

105

7000731

1

Gasket

106

7024193

2

Plate, Outer

107

See Note

1

Gasket (Note: Use Item 150, 153 or 154.)

108

7024191

1

Cylinder

109

7024192

1

Piston 110

7024197

1

Bearing, Ball

111

7024197

1

Ring, Retaining

112

7024197

1

Seal, Shaft

113

See Note

6

Capscrew (Note: Not Available - Purchase Locally)

114

See Note

6

Lockwasher (Note: Not Available - Purchase Locally)

115

7024194

1

O-Ring

116

7024194

1

Ring, Back-up

117

7024194

1

O-Ring

118

7024194

1

Ring, Back-up

119

7024190

2

Pin, Dowel

120

See Note

1

Plug (Note: Not Available - Purchase Locally)

121

See Note

2

Plug (Note: Not Available - Purchase Locally)

122

7024196

10

Spring Kit (Natural)

123

7024196

2

Spring Kit (Blue)

150

7024194

1

Seal Kit, Brake (Includes Items 105, 107 & 115-118)

151

7024196

1

Spring Kit, Brake (Includes 12 Natural Colored Springs Item 122)

(was p/n 7024195)

152

7024196

1

Spring Kit, Brake (Includes 12 Natural Colored Springs Item 122 &

2 Blue Springs Colored Springs Item 123)

153

7024193

1

Friction Disc Kit, Brake (Includes Items 103, 104, 106 & 107)

154

7024197

1

Bearing Kit, Brake (Includes Items 107 & 110-112)

SECTION 1 - FRAME

24 510AJ 3121182

Page 25

Page 26

SECTION 1 - FRAME

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)

26 510AJ 3121182

Page 27

FIGURE 1-5. DRIVE HUB ASSEMBLY (FRONT)

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: BELGIUM BUILT MACHINES USED (Prior to SN

1300000064)

Ref

NOTE: Hub may have been replaced with Service Kit p/n

1001178136. Kit uses hub p/n 2780268. See next figure for

service parts.

2780257

Ref

DRIVE HUB ASSEMBLY

F

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7024105

1

Spindle

1B

7024113

1

Seal 1C

7007006

2

Cone, Bearing

1D

7024112

2

Cup, Bearing

1E

7024110

1

Housing/Ring Gear

1F

7024109

1

Thrustwasher

1G

7024107

1

Ring, Retaining

1N

7024111

9

Stud, Wheel

3

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

3A

7024116

1

Carrier

3B

7024127

6

Thrustwasher

3C

7024123

42

Bearing, Needle

3E

7024120

3

Shaft, Planet

3F

7024118

3

Gear, Planet

4

See Note

1

Carrier Assembly (Note: Not Available - Purchase Individual

Components)

4A

7024117

1

Carrier

4B

7024126

6

Thrustwasher

4C

7024122

45

Bearing, Needle

4E

7024121

3

Shaft, Planet

4F

7024119

3

Gear, Planet

4G

7001913

3

Rollpin

4H

7024128

1

Thrustwasher

4I

7024124

1

Spring

4J

7024129

1

Thrustwasher

4K

7024125

1

Thrustwasher

6

See Note

1

Cover Assembly (Note: Not Available - Purchase Individual

Components)

6A

7024132

1

Plate, Cover

6B

7017093

1

Cap, Disengage

6C

0641404

2

Bolt 1/2in-20NC x 1/2in

6D

7017092

1

Pin, Dowel

6E

7017095

1

O-Ring

6F

7024134

1

O-Ring

7 7024130

1

Shaft, Input

8 7024115

1

Gear, Sun

9 7024131

1

Coupling

10

7017097

1

Spacer, Thrust

11

7017094

2

Plug, Pipe

12

7024108

1

Plug, Pressure

14

7024133

12

Bolt 1/4in-20NC x 7/8in (Grade 8)

15

See Note

1

Plate, ID (Not Shown) (Note: Not Available For Purchase)

SECTION 1 - FRAME

3121182 510AJ 27

Page 28

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

16

7017082

1

Plug, O-Ring

17

7024114

1

Gear, Sun

100

7024198

1

Seal Kit (Includes Items 1B, 1G & 6F)

SECTION 1 - FRAME

28 510AJ 3121182

Page 29

Page 30

SECTION 1 - FRAME

FIGURE 1-6. DRIVE HUB ASSEMBLY (FRONT)

30 510AJ 3121182

Page 31

FIGURE 1-6. DRIVE HUB ASSEMBLY (FRONT)

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

USAGE: USED ON BELGIUM BUILT MACHINES (SN 1300000064

to Present)

Ref

USAGE: USED ON ROMANIAN BUILT MACHINES (SN

E300000100 through E300001114)

2780268

Ref

DRIVE HUB ASSEMBLY

C

1

See Note

1

Spindle/Housing Assembly (Note: Not Available - Purchase

Individual Components)

1A

7017059

1

Spindle

1B

7001998

1

Seal 1C

7010429

1

Cone, Bearing (Includes Item 1D)

1D

7010429

1

Cup, Bearing (Includes Item 1C)

1E

7000257

1

Cup, Bearing

1F

7000258

1

Cone, Bearing

1G

7007601

1

Housing/Ring Gear

1H

7000232

1

Thrustwasher

1I

7000229

1

Ring, Retaining

1N

7007640

9

Stud, Wheel

2 7000246

1

Gear, Internal

3 7024712

1

Carrier Assembly

3A

7024712

1

Carrier

3B

7024712

6

Ring, Retaining

3C

7024712

AR

Bearing, Needle

3D

7024712

3

Thrustwasher

3E

7024712

3

Shaft, Planet

3F

7024712

3

Gear, Planet

3G

7024712

3

Rollpin

4 7000248

1

Ring Gear

5 7000230

1

O-Ring 5A

7017070

1

O-Ring 6

70001349

1

Cover Assembly (was p/n 7017090)

6A

70001349

1

Spacer, Thrust (was p/n 7017097)

6B

70001349

1

Plate, Cover (was p/n 7017091)

6C

70001349

1

O-Ring (was p/n 7017095)

6D

70001349

1

Rod, Disconnect (was p/n 7017092)

6E

70001349

1

Cap, Disengage (was p/n 7017093)

6F

70001349

2

Bolt (was p/n 0641404)

6G

7017094

1

Plug, Pipe

6I

See Note

4

Rivet (Note: Not Available - Purchase Locally)

6J

See Note

1

Plate, ID (Note: Not Available for Purchase)

7 Ref

Input Shaft Assembly

7A

7024714

1

Shaft 7B

7000261

1

Ring, Retaining

7C

7000262

1

Spring

7D

7000263

2

Spacer, Thrust

8 7024713

1

Gear, Sun

11

7000253

1

Thrustwasher

12

7017067

12

Bolt 13

7017080

4

Pin, Dowel

14

7000206

1

Coupling

15

7024715

1

Spacer, Input

SECTION 1 - FRAME

3121182 510AJ 31

Page 32

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

16

7024716

1

Spacer, Input

SECTION 1 - FRAME

32 510AJ 3121182

Page 33

Page 34

SECTION 1 - FRAME

FIGURE 1-7. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300002249)

34 510AJ 3121182

Page 35

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

3160266

Ref

DRIVE MOTOR ASSEMBLY

D

Ref

Note: Original Equipment Motor p/n 3160266 uses 4 bolts to

assemble the motor. Service Replacement Motor p/n 3160348

motors use 5 bolts to assemble the motor. Visually identify

component before ordering parts. If equipped with 3160348

refer to next illustration.

1

7022302

2

Bearing, Journal

2 7022328

1

O-Ring

3 7022328

1

O-Ring

4 7007446

1

Pin 5

7007438

2

Ring, Retaining

6 7022305

1

Swashplate

7 7022328

1

O-Ring

8 7023907

1

Cylinder Block Kit (Includes Items 10-19)

9 7023908

1

Plate, Valve

10

7023907

1

Block, Cylinder

11

7021277

1

Guide, Slipper Retainer

12

7021275

3

Pin, Slipper Hold Down

13

7023907

9

Piston Assembly

14

7021276

1

Retainer, Hold Down Pin

15

7022310

1

Retainer, Slipper

16

7022311

1

Ring, Retaining

17

7022312

1

Spring

18

7022313

1

Washer

19

7022314

1

Retainer, Spring

20

7023910

1

Shaft 21

7007439

1

Ring, Retaining

22

7022367

1

Cap, End - Axial

23

7022368

4

Screw

24

7021249

1

Bearing, Needle

25

7022321

1

Plug (Includes Item 26)

26

7022328

1

O-Ring

27

7022318

1

Plug (Includes Item 28)

28

7022328

1

O-Ring

29

7007419

2

Plug (Includes Item 30)

30

7022328

2

O-Ring

31

7022372

1

Seat, Spring

32

7022370

1

Housing

33

7022318

2

Plug (Items Item 34)

34

7022328

2

O-Ring

35

7022321

1

Plug (Items Item 36)

36

7022328

1

O-Ring

37

7022323

1

Piston, Servo (Includes Items 38 & 39)

38

7022328

1

O-Ring

39

7022328

1

Ring, Seal

40

7007437

1

Bearing

41

7022326

1

Spring

42

7022328

1

Seal, Lip

43

7022371

1

Washer, Support

45

7022328

1

Seal Kit (Includes Items 2, 3, 7, 26, 28, 30, 34, 36, 38, 39 & 42)

FIGURE 1-7. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES) (Prior to SN 1300002249)

3121182 510AJ 35

Page 36

SECTION 1 - FRAME

FIGURE 1-8. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT

MACHINES) (SN 1300002249 to Present, SN E300000100 through E300001114)

36 510AJ 3121182

Page 37

SECTION 1 - FRAME

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

DRIVE MOTOR ASSEMBLY

3160348

Ref

Original Equipment Motor for Belgium Built Machines (SN

1300002249 to Present)

B

3160348

Ref

Original Equipment Motor for Romanian Built Machines (SN

E300000100 through E300001114)

B

3160348

Ref

Service Replacement Motor for p/n 3160266

B 1 7022302

2

Bearing, Journal

2 7007446

1

Pin 3

7007438

2

Ring, Retaining

4 7022305

1

Swashplate

5 See Note

2

Pin (Note: Not Available for Purchase)

6 7022328

1

Gasket

7 7023907

1

Cylinder Block Kit (Includes Items 7A & 9-17)

7A

7023907

1

Block, Cylinder

8 7023908

1

Plate, Valve

9 7021277

1

Guide, Slipper Retainer

10

7021275

3

Pin, Slipper Hold Down

11

7023907

9

Piston Assembly

12

7021276

1

Retainer, Hold Down Pin

13

7022310

1

Retainer, Slipper

14

7022311

1

Ring, Retaining

15

7022312

1

Spring

16

7024868

1

Washer

17

7022314

1

Retainer, Spring

18

7023910

1

Shaft 19

7007439

1

Ring, Retaining

20

70000797

1

Cap, End - Axial

21

7022368

5

Screw

22

7021249

1

Bearing, Needle

23

2220886

1

Plug (Includes Item 24)

24

7022328

1

O-Ring

25

2220883

1

Plug (Includes Item 26)

26

7022328

1

O-Ring

27

2220888

2

Plug (Includes Item 28)

28

7022328

2

O-Ring

29

7022372

1

Seat, Spring

30

3160348

1

Housing

31

2220883

2

Plug (Items Item 32)

32

7022328

2

O-Ring

33

2220886

1

Plug (Items Item 34)

34

7022328

1

O-Ring

35

7022328

1

O-Ring

36

7022328

1

Ring, Seal

37

7024854

1

Piston, Servo (Includes Items 35 & 36)

38

7007437

1

Bearing

39

7022326

1

Spring

40

7022328

1

Seal, Lip

41

7022371

1

Washer, Support

45

7022328

1

Seal Kit (Includes Items 6, 24, 26, 28, 32, 34, 35, 36 & 40)

FIGURE 1-8. DRIVE MOTOR ASSEMBLY (BELGIUM BUILT MACHINES AND ROMANIAN BUILT

MACHINES) (SN 1300002249 to Present, SN E300000100 through E300001114)

3121182 510AJ 37

Page 38

SECTION 1 - FRAME

FIGURE 1-9. DRIVE VALVES INSTALLATIONS

38 510AJ 3121182

Page 39

FIGURE 1-9. DRIVE VALVES INSTALLATIONS

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

DRIVE VALVES INSTALLATION

0272320

Ref

Belgium Built Machines (Prior to SN 1300000064)

C 0272895

Ref

Belgium Built Machines (SN 1300000064 through 1300003222)

G 0275854

Ref

Belgium Built Machines (SN 1300003223 to Present)

C

0275854

Ref

Romanian Built Machines (SN 1300003223 through

E300001114)

C

103

0363012

2

Bar, Clamping

104

0641420

2

Bolt 1/4in-20NC x 2-1/2in

105

0641618

4

Bolt 3/8in-16NC x 2-1/4in

106

0641530

2

Bolt 5/16in-18NC x 3-3/4in (Belgium Built Machines) (Prior to SN

1300003223)

106

0641560

3

Bolt 5/16in-18NC x 7-1/2in (Belgium Built Machines) (SN

1300003223 to Present)

106

0641560

3

Bolt 5/16in-18NC x 7-1/2in (Romanian Built Machines) (SN

E300000100 through E300001114)

107

0641538

2

Bolt 5/16in-18NC x 4-3/4in (Belgium Built Machines Only) (Prior

to SN 1300003223)

115

3311505

AR

Locknut 5/16in-18NC

117

3340911

4

Rubber, Clamp

121

4641208

1

Flow Divider Valve Assembly (Belgium Built Machines Only)

(Prior to SN 1300003223)

A

121A

7023934

2

Valve, Cartridge (Flow Divider) (4641208 Valve)

121A

7021655

2

Seal Kit - 7023934 Flow Divider Cartridge

121B

7023935

4

Valve, Cartridge (Check) (4641208 Valve)

121B

7023936

4

Seal Kit - 7023935 Check Cartridge

122

Ref

Flow Divider Valve Assembly Options:

122A

4641207

1

Flow Divider Valve Assembly (Belgium Built Machines) (Prior

to SN 1300003223)

A

122B

7023917

1

Valve, Cartridge (Flow Divider) (Used on 4641207 Valve)

122B

7021625

1

Seal Kit - 7021625 Flow Divider Cartridge

122C

7022397

1

Valve, Cartridge (Check) (4641207 Valve)

122C

7022399

1

Seal Kit - 7022397 Check Cartridge

122D

7010542

2

Valve, Cartridge (Load Shuttle) (4641207 Valve)

122D

7010543

2

Seal Kit - 7010542 Load Shuttle Cartridge

122E

4641510

1

Flow Divider Valve Assembly (Belgium Built Machines) (SN

1300003223 to Present)

D

122E

4641510

1

Flow Divider Valve Assembly (Romanian Built Machines) (SN

E300000100 through E300001114)

D

122F

7023917

1

Valve, Cartridge (Flow Divider) (4641510 Valve)

122F

7021625

1

Seal Kit - 7023917 Flow Divider Cartridge

122F

70002962

1

Lock Kit

122G

7023934

2

Valve, Cartridge (Flow Divider) (4641510 Valve)

122G

7021655

2

Seal Kit - 7023934 Flow Divider Cartridge

122G

70000781

2

Lock Kit

122H

7022397

5

Valve, Cartridge (Check) (4641510 Valve)

122H

7022399

5

Seal Kit - 7022397 Check Cartridge

122J

7021639

2

Valve, Cartridge (Check) (4641510 Valve)

122J

7017496

2

Seal Kit - 7021639 Check Cartridge (was p/n 2900756)

122K

7024881

1

Piston, Pilot (4641510 Valve)

123

4641155

1

Valve, Junction Manifold

B

124

4711400

2

Flatwasher 1/4in Thin

125

4751500

8

Flatwasher 5/16in Regular

SECTION 1 - FRAME

3121182 510AJ 39

Page 40

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

126

4751600

AR

Flatwasher 3/8in Regular

Ref

FRAME SHIELDS INSTALLATION OPTIONS:

0272600

Ref

Belgium Built Machines (Prior to SN 1300000353)

B 0273499

Ref

Belgium Built Machines (SN 1300000353 through 1300003222)

C 0275858

Ref

Belgium Built Machines (SN 1300003223 to Present)

A

0275858

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

A

201

0100011

AR

Compound, Locking

202

0641606

10

Bolt 3/8in-16NC x 3/4in

203

Ref

Cover (Front) Options:

203

4061046

1

Belgium Built Machines (Prior to SN 1300000353)

203

3380504

1

Belgium Built Machines (SN 1300000353 through

1300003222)

203

3380764

1

Belgium Built Machines (SN 1300003223 to Present)

203

3380764

1

Romanian Built Machines (SN E300000100 through

E300001114)

204

4061047

1

Shield (Rear)

205

4751600

10

Flatwasher 3/8in Regular

SECTION 1 - FRAME

40 510AJ 3121182

Page 41

SECTION 2 - TURNTABLE

SECTION 2 - TURNTABLE

3121182 510AJ 41

Page 42

SECTION 2 - TURNTABLE

FIGURE 2-1. CONTROL VALVE INSTALLATION

42 510AJ 3121182

Page 43

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

VALVES INSTALLATIONS

0271197

Ref

Belgium Built Machines (Prior to SN 1300001243)

F 0274616

Ref

Belgium Built Machines (SN 1300001243 to Present)

A

0274616

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

A

1

0100011

AR

Compound, Locking

2 0140001

1

Horn 4

0641404

1

Bolt 1/4in-20NC x 1/2in

5 0651405

4

Bolt 1/4in-24NF x 5/8in

7 0641607

4

Bolt 3/8in-16NC x 7/8in

9 Ref

Pressure Filter Assembly Options:

9 2120163

1

Belgium Built Machines (Prior to SN 1300001243)

9 2120150

1

Element, Filter

9 7020020

1

Indicator

9 7023206

1

O-Ring, Filter

9 7023207

1

Ring, Back-up

9 2120209

1

Belgium Built Machines (SN 1300001243 to Present)

9

2120209

1

Romanian Built Machines (SN E300000100 through

E300001114)

9

2120210

1

Element, Filter

9 7020020

1

Indicator

9 70000934

1

O-Ring, Filter Bowl

11

4641176

1

Main Control Valve Assembly (See MAIN CONTROL VALVE

ASSEMBLY for Breakdown)

14

4711600

10

Flatwasher 3/8in Thin

15

4751400

1

Flatwasher 1/4in Regular

20

4711400

4

Flatwasher 1/4in Thin

21

4791400

1

Starwasher 1/4in

FIGURE 2-1. CONTROL VALVE INSTALLATION

3121182 510AJ 43

Page 44

SECTION 2 - TURNTABLE

FIGURE 2-2. MAIN CONTROL VALVE ASSEMBLY

44 510AJ 3121182

Page 45

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

4641176

Ref

PROPORTIONAL VALVE ASSEMBLY

E 1 7012975

1

Cartridge, Check

1 7012540

1

Seal Kit - 7012975 Cartridge

2 7017482

2

Cartridge

2 7012518

2

Seal Kit - 7017482 Cartridge

3 7023970

1

Cartridge, Flow Regulator

3 7012953

1

Seal Kit - 7023970 Cartridge

4 7017440

3

Cartridge, Load Shuttle

4 7017441

3

Seal Kit - 7017440 Cartridge

5 7010542

2

Cartridge, Load Shuttle

5 7010543

2

Seal Kit - 7010542 Cartridge

6 7021611

1

Cartridge (Proportional Dump)

6 7012518

1

Seal Kit - 7021611 Cartridge

7 7023913

2

Cartridge, Relief (Telescope and Lower Lift)

7 7012998

2

Seal Kit - 7023913 Cartridge

8 7017422

1

Cartridge, Relief (Steer)

8 7012998

1

Seal Kit - 7017422 Cartridge

9 7017421

1

Cartridge, Relief (Upper Lift)

9 7012998

1

Seal Kit - 7017421 Cartridge

10

7017428

1

Cartridge, Relief (Swing)

10

7012998

1

Seal Kit - 7017428 Cartridge

11

7023922

1

Cartridge without Coil (Upper Lift)

11

7017402

1

Seal Kit - 7023922 Cartridge

12

7023914

1

Cartridge without Coil (Swing)

12

7017402

1

Seal Kit - 7023914 Cartridge

13

7017410

1

Cartridge without Coil (Main Dump)

13

7012967

1

Seal Kit - 7017410 Cartridge

14

7017433

1

Cartridge without Coil (Steer)

14

7017402

1

Seal Kit - 7017433 Cartridge

15

7017454

2

Cartridge without Coil (Lower Lift and Telescope)

15

7012903

2

Seal Kit - 7017454 Cartridge

16

7012944

7

Coil 17

7012943

4

Coil 18

7017451

1

Coil

FIGURE 2-2. MAIN CONTROL VALVE ASSEMBLY

3121182 510AJ 45

Page 46

SECTION 2 - TURNTABLE

FIGURE 2-3. TURNTABLE AND SWING DRIVE INSTALLATIONS

46 510AJ 3121182

Page 47

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

SWING DRIVE INSTALLATION OPTIONS:

0272167

Ref

Belgium Built Machines (Prior to SN 1300000353)

D 0273358

Ref

Belgium Built Machines (SN 1300000353 to Present)

0273358

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

D

1

0100019

AR

Compound, Locking

2 Ref

Swing Bearing and Rotation Box Assembly Options (See SWING

BEARING AND ROTATION BOX ASSEMBLY for Breakdown):

2

0440255

1

Belgium Built Machines (Prior to SN 1300000353)

2 0440272

1

Belgium Built Machines (SN 1300000353 to Present)

2

0440272

1

Romanian Built Machines (SN E300000100 through

E300001114)

3 Ref

Bolt 1/2in-13NC Options:

3

0641818

2

2-1/4in Length (Belgium Built Machines) (Prior to SN

1300006701)

3 3931832

2

2in Length (Belgium Built Machines) (SN 1300006701 to

Present)

3

3931832

2

2in Length (Romanian Built Machines) (SN E300000100

through E300001114)

4

0682040

18

Bolt 5/8in-11NC x 5in (Grade 8)

5 0682048

24

Bolt 5/8in-11NC x 6in

6 Ref

Swing Motor Assembly Options:

6

3160287

1

Motor for Belgium Built Machines (See SWING MOTOR

ASSEMBLY for Breakdown - Use p/n 1001105455) (Prior to

SN 1300006701)

6

1001104850

1

Motor for Belgium Built Machines (See SWING MOTOR

ASSEMBLY for Breakdown) (SN 1300006701 to Present)

6

1001104850

1

Motor for Romanian Built Machines (See SWING MOTOR

ASSEMBLY for Breakdown) (SN E300000100 through

E300001114)

7 Ref

Flatwasher 1/2in Hardened Options:

7 4891800

2

Belgium Built Machines (Prior to SN 1300006701)

7 4740171

2

Belgium Built Machines (SN 1300006701 to Present)

7

4740171

2

Romanian Built Machines (SN E300000100 through

E300001114)

8

4892000

42

Flatwasher 5/8in Hardened

9 Ref

Grease, Bearing (Not Shown) Options:

9 Not Required

0

Belgium Built Machines (Prior to SN 1300000353)

9 2160001

AR

Belgium Built Machines (SN 1300000353 to Present)

9

2160001

AR

Romanian Built Machines (SN E300000100 through

E300001114)

0258400

Ref

REMOTE BEARING LUBE INSTALLATION

B

101

0641609

2

Bolt 3/8in-16NC x 1-1/8in

102

0902520

1

Bracket

103

2160002

1

Fitting, Grease

104

2180344

1

Fitting, Bulkhead

105

2180822

1

Fitting, Tee

106

2200261

1

Fitting, Coupling

107

2220001

1

Fitting, Straight

108

2220124

2

Fitting, Elbow

109

2750529

2

Hose 110

2750807

1

Hose

FIGURE 2-3. TURNTABLE AND SWING DRIVE INSTALLATIONS

3121182 510AJ 47

Page 48

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

111

3311605

2

Locknut 3/8in-16NC

112

4751600

4

Flatwasher 3/8in Regular

1001102695

Ref

DRIVE ORIENTATION INSTALLATION (BELGIUM BUILT

MACHINES) (SN 1300006701 to Present)

D

1001102695

Ref

DRIVE ORIENTATION INSTALLATION (ROMANIAN BUILT

MACHINES) (SN E300000100 through E300001114)

D

201

0100011

AR

Compound, Locking

202

0641406

1

Bolt 1/4in-20NC x 3/4in

203

0641606

2

Bolt 3/8in-16NC x 3/4in

204

0641614

2

Bolt 3/8in-16NC x 1-3/4in

205

1320041

1

Clamp 206

3311005

2

Locknut #10

207

3311405

1

Locknut 1/4in

208

3931010

2

Screw #10-24 x 5/8in

209

4360517

1

Switch, Proximity

209

4460320

1

Connector, Male

209

4460227

2

Pin, Male

210

4711000

2

Flatwasher #10 Thin

211

4711400

1

Flatwasher 1/4in Thin

212

4711600

4

Flatwasher 3/8in Thin

213

1001145163

2

Spacer (was p/n 7116691 & 1001114757)

214

1001102526

1

Cam 215

1001102527

1

Bracket, Switch

216

4740120

2

Flatwasher, Special

SECTION 2 - TURNTABLE

48 510AJ 3121182

Page 49

Page 50

SECTION 2 - TURNTABLE

FIGURE 2-4. SWING MOTOR ASSEMBLY (ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES)

(Prior to SN 1300006701)

50 510AJ 3121182

Page 51

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

3160287

Ref

SWING MOTOR ASSEMBLY

B

Ref

Note: Original Equipment motor p/n 3120287 may have been

replaced with Service Replacement motor p/n 1001105455.

Visually identify component before ordering parts. Service

Replacement motor shown on next illustration

1

2900477

1

Seal, Dust

2 2900477

1

Ring, Retaining

3 2900477

1

Shim, Metal Back-Up

4 2900477

1

Seal, High Pressure

5 2900477

1

Shim, Metal Back-Up

6 2900477

1

Shim, Teflon Back-Up

7 2900477

1

Seal, Shaft

8 2900477

3

Seal, Body

9 2900477

1

Washer, Carrier

10

2900477

1

Thrustwasher

11

See Note

1

Bearing, Thrust (Note: Not Available - Replace Complete Motor)

12

7005889

1

Link, Drive

13

See Note

1

Plate, Wear (Note: Not Available - Replace Complete Motor)

14

7016432

1

Rotor Set Assembly

15

7016433

1

Pin, Drive Link

16

See Note

1

Ball (Note: Not Available - Replace Complete Motor)

17

See Note

1

Cover, End (Note: Not Available - Replace Complete Motor)

18

See Note

1

Nameplate (Note: Not Available for Purchase)

19

7016434

1

Bolt Set (Includes 4 Bolts)

20

7016435

1

Housing

21

7016435

1

Plug, Cooling

22

7005843

1

Shaft 23

7005887

1

Key 25

2900477

1

Seal Kit (Includes Items 1-10)

26

7016435

1

Housing/Shaft Kit (Includes Items 20-23)

FIGURE 2-4. SWING MOTOR ASSEMBLY (ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES)

(Prior to SN 1300006701)

3121182 510AJ 51

Page 52

SECTION 2 - TURNTABLE

FIGURE 2-5. SWING MOTOR ASSEMBLY (SERVICE REPLACEMENT FOR BELGIUM BUILT

MACHINES AND ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES AND ROMANIAN BUILT

MACHINES) (Prior to SN 1300006701, SN 1300006701 to Present, SN E300000100 through

E300001114)

52 510AJ 3121182

Page 53

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

SWING MOTOR ASSEMBLY

1001105455

Ref

Service Replacement for Belgium Built Machines (Prior to SN

1300006701)

A 1001104850

Ref

Original Equipment for Belgium Built Machines (SN

1300006701 to Present)

A

1001104850

Ref

Original Equipment for Romanian Built Machines (SN

E300000100 through E300001114)

A

1

See Note

5

Bolt (Note: Not Available - Replace Complete Motor)

2 7004035

1

Cover, End

3 7023318

1

Seal, Commutator

4 7004036

5

O-Ring

5 7024453

1

Commutator

6 7024453

1

Commutator and Ring Assembly (Includes Items 5)

7 7024379

1

Manifold

8 70002206

1

Rotor Set

9 7024380

1

Plate, Wear

10

70002207

1

Link, Drive

12

70000088

1

Shaft, Coupling

12A

70000089

1

Key 13

7024381

1

Bushing, Inner

14

7004043

1

Thrustwasher

15

7004044

1

Bearing, Thrust

16

7004049

1

Seal, Inner Shaft

17

7004045

1

Ring, Backup

18

See Note

1

Housing (Note: Not Available - Replace Complete Motor)

19

7024390

1

Bearing

20

7004047

1

Seal, Outer Shaft

25

7024389

1

Seal Kit (Includes Items 3, 4, 16, 17 & 20)

FIGURE 2-5. SWING MOTOR ASSEMBLY (SERVICE REPLACEMENT FOR BELGIUM BUILT

MACHINES AND ORIGINAL EQUIPMENT FOR BELGIUM BUILT MACHINES AND ROMANIAN BUILT

MACHINES) (Prior to SN 1300006701, SN 1300006701 to Present, SN E300000100 through

E300001114)

3121182 510AJ 53

Page 54

SECTION 2 - TURNTABLE

FIGURE 2-6. SWING BEARING AND ROTATION BOX ASSEMBLY

54 510AJ 3121182

Page 55

SECTION 2 - TURNTABLE

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

SWING BEARING AND ROTATION BOX ASSEMBLY

0440255

Ref

Belgium Built Machines (SN 1300000001 through 1300000352)

B 0440272

Ref

Belgium Built Machines (SN 1300000353 to Present)

C

0440272

Ref

Romanian Built Machines (SN E300000100 through

E300001114)

C

101

4891500

2

Flatwasher 5/16in Hardened

102

7026042

2

Cup, Bearing

103

7026043

2

Cone, Bearing

104

0681610

8

Bolt 3/8in-16NC x 1-1/4in (Grade 8)

105

0641808

2

Bolt 1/2in-13NC x 1in

106

0641810

2

Bolt 1/2in-13NC x 1-1/4in

107

0641520

2

Bolt 5/16in-18NC x 2-1/2in

108

See Note

1

Plug 1/8in (Note: Not Available - Purchase Locally)

109

See Note

1

Plug (Note: Not Available - Purchase Locally)

110

7026060

1

Seal, Oil

111

See Note

1

Plug 1/4in (0440255 Bearing Only) (Note: Not Available Purchase Locally)

112

See Note

2

Cap (Note: Not Available - Purchase Complete Assembly)

113

See Note

1

Fitting, Grease (Note: Not Available - Purchase Locally)

114

7026044

1

Bushing, Reducer

115

7027358

1

Fitting, Grease

116

See Note

2

Fitting, Grease Elbow (0440255 Bearing Only) (Note: Not

Available - Purchase Locally)

117

7026045

1

Cup, Bearing

118

7026046

1

Ring, Grease

119

7026047

1

Cone, Bearing

120

7026048

1

Cup, Bearing

121

7026049

1

Cone, Bearing

122

7026050

1

Worm-Gear

123

7026051

1

Pinion, Output

124

7026052

1

Spacer, Washer

125

See Note

1

Housing (Note: Not Available - Purchase Complete Assy)

126

7026053

1

Cover, Gear Options:

127

7026059

AR

Shim, Brown (.010)

127

Ref

0440255 Bearing

127

Ref

0440272 Bearing

128

7026059

AR

Shim, Clear (.0075) Options:

128

Ref

0440255 Bearing

128

Ref

0440272 Bearing

129

7026059

AR

Shim, Blue (.005) Options:

129

Ref

0440255 Bearing

129

Ref

0440272 Bearing

130

7026059

AR

Shim, Yellow (.020) Options:

130

Ref

0440255 Bearing

130

Ref

0440272 Bearing

131

Ref

Bearing, Turntable Options:

131

7026054

1

0440255 Bearing

131

1001104627

1

0440272 Bearing (Bearing Kit, Turntable p/n 1001104627

includes bearing and hardware to mount bearing/rotation box

assembly to machine) (was p/n 70000042)

132

7026060

1

O-Ring

FIGURE 2-6. SWING BEARING AND ROTATION BOX ASSEMBLY

3121182 510AJ 55

Page 56

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

133

7026055

1

Cap, Gear

134

Ref

Cap, Worm Options:

134

7026056

1

0440255 Bearing

134

7027354

1

0440272 Bearing

135

70000681

8

Screw #6-32NC x 3/8in

136

7026059

AR

Shim, Natural (.0075in) Options:

136

Ref

0440255 Bearing

136

Ref

0440272 Bearing

137

7026059

AR

Shim, Blue (.005in) Options:

137

Ref

0440255 Bearing

137

Ref

0440272 Bearing

138

7026059

AR

Shim, Green (.003in) Options:

138

Ref

0440255 Bearing

138

Ref

0440272 Bearing

139

7026057

1

Worm, Ground

140

7026059

AR

Shim, Blue (.005in) Options:

140

Ref

0440255 Bearing

140

Ref

0440272 Bearing

141

7026059

AR

Shim, Yellow (.020in) Options:

141

Ref

0440255 Bearing

141

Ref

0440272 Bearing

142

Ref

Adapter, Motor Options:

142

7026058

2

0440255 Bearing

142

7027356

AR

0440272 Bearing

143

7026060

1

Seal, Face

144

7026059

AR

Shim, Green (.003in) Options:

144

Ref

0440255 Bearing

144

Ref

0440272 Bearing

150

7026060

1

Seal Kit (Includes Items 110, 132 & 143)

151

7026059

1

Shim Kit (Includes Items 127-130, 136-138, 140-141 & 144)

SECTION 2 - TURNTABLE

56 510AJ 3121182

Page 57

Page 58

SECTION 2 - TURNTABLE

FIGURE 2-7. CATERPILLAR ENGINE INSTALLATION (WITH UGM)

58 510AJ 3121182

Page 59

SECTION 2 - TURNTABLE

3121182 510AJ 59

Page 60

ITEM

PART NUMBER

QTY

DESCRIPTION

REV

Ref

Belgium Built Machines use SNs 13xxxxxxxx. Romanian Built

Machines use SNs E3xxxxxxxx.

Ref

Note: For Module (with/without UGM) Identification, refer to

Revision Log page A.

1001108389

Ref

CATERPILLAR ENGINE ASSEMBLY

D 1 0080181

1

Adapter, Pump Mounting Plate

2 0080201

1

Adapter, Elbow Air Intake

3 0100011

AR

Compound, Locking

4 0641812

2

Bolt 1/2in-13NC x 1-1/2in

5 0340041

2

Band, Air Cleaner Mounting

6 0340046

2

Band, Muffler Mounting

7 2111010

1

Fitting, Straight

8 2111612

1

Fitting, Straight

9 0630569

9

Bolt M14 x 30mm

10

0641406

8

Bolt 1/4in-20NC x 3/4in

11