Ivoclar Vivadent P300 User Manual

Programat® P300/G2

Programat® P300/G2

Operating Instructions

|

|

|

|

|

|

|

|

f |

|

|

|

|

|

|

|

|

|

|

s |

o |

|

|

|

|

|

|

|

d |

a |

|

|

|

|

||

|

|

|

li |

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

.0 |

|

|

|

|

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s |

|

|

n |

5 |

|

|

|

|

|

|

|

|

|

io |

|

|

|

|

|

|

|

|

|

|

rs |

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

re |

V |

|

|

|

|

|

||

|

|

a |

|

|

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

ft |

|

|

|

|

|

|

|

|

|

|

|

so |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

Table of Contents

Views of the Furnace, List of Parts |

4 |

1. Introduction / Signs and Symbols |

8 |

1.1Preface

1.2Introduction

1.3Notes regarding the Operating Instructions

1.4Notes on the different voltage versions

2. |

Safety First |

9 |

2.1 |

Indications |

|

2.2 |

Health and safety instructions |

|

3. |

Product Description |

12 |

3.1Components

3.2Hazardous areas and safety equipment

3.3Functional description

3.4Accessories

4. Installation and Initial Start-Up |

13 |

4.1Unpacking and checking the contents

4.2Selecting the location

4.3Assembly

4.4Dismounting the furnace head

4.5Initial start-up

4.6Dehumidification

5. Operation and Configuration |

18 |

5.1Introduction to the operation

5.2Explanation of the key functions

5.3Program structure

5.4Adjustable parameters and possible value ranges

5.5Settings / test programs and information

5.6Explanation of the symbols on the display

5.7Explanation of the beeper signals

6. Practical Use |

23 |

6.1Switching on/off

6.2Firing using an Ivoclar Vivadent program

6.3Firing using an individual program

6.4Other options and special features of the furnace

7. Maintenance, Cleaning and Diagnosis |

25 |

7.1Monitoring and maintenance

7.2Cleaning

7.3Special programs

7.4Temperature calibration

7.5Service note

7.6Stand-by

8. What if ... |

27 |

8.1Error messages

8.2Technical malfunctions

8.3Repair

9. Product Specifications |

30 |

9.1Delivery form

9.2Technical data

9.3Acceptable operating conditions

9.4Acceptable transportation and storage conditions

10. Appendix |

31 |

10.1Program table

10.2Menue structure

10.3Firing curves

3

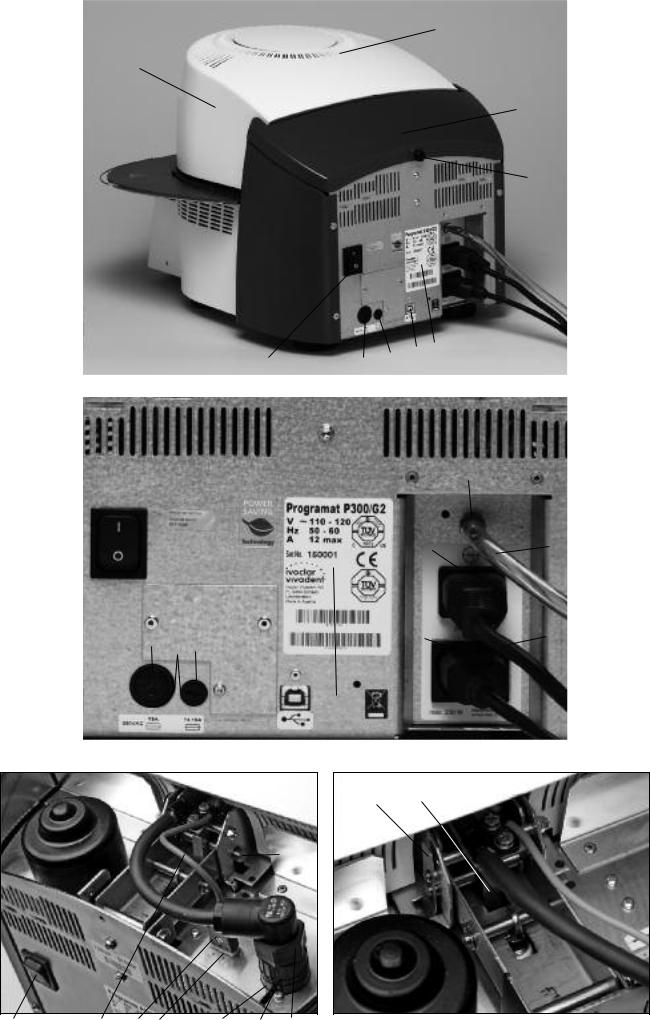

List of parts

Front view:

1Sealing surface

2Furnace head sealing ring

3Insulation

4Thermocouple

5Firing plate

6Display

7Frame plate

8QTK heating muffle

9Furnace housing

10Keypad

11On/Off switch

12Heating element fuse

13Vacuum pump fuse

15Fuse holder

16Power cord

17Power socket

18Vacuum pump socket

19Rating plate

21 Vacuum hose connection

23 Rubber feet

25Furnace head housing

26Thermocouple plug

27Plug fuse

28Heater plug

29Heater plug socket

30Thermocouple plug socket

32Leaf spring

33Air vents (base)

34Cooling tray

35Screw for cooling tray

36Hood

37Knurled screw for hood

38Air vents furnace head

39Air vents rear panel

40Warnings

41Furnace head mounting mark

42Furnace base mounting mark

43Furnace head mounting

44Quartz-glass tube

46Vacuum hose

47Silicone washer

48Firing plate holder

49Thermocouple cable

50Connecting rod

51Plug-in console

53USB interface

Please note that the list of parts applies to the entire Operating Instructions. These parts and their numbers are often referred to in later chapters.

4

25

40

6 |

|

|

47 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

||

10 |

|

|

35 |

|

||

|

|

|

|

|

||

|

|

|

|

|

34 |

|

|

|

|

|

|

||

33 |

23 |

|||||

|

||||||

|

|

|

||||

4 |

8 |

3

2

5

7

1

9

5

38

25

36

37

39

39

11 |

12 |

13 |

53 |

19 |

|

|

21

17 |

46 |

12 |

18 |

16 |

15 |

13 |

|

|

19 |

|

32 43

51 50

51 50

11 |

49 |

26 |

30 |

29 |

27 |

28 |

6

8

4

44

Control unit:

70Program key

71ESC key

72ENTER key

73START key

74Start LED

75STOP key

76+ key

77– key

78Information / Settings

79Cursor key right

80Cursor key left

81Stand-by temperature

82Closing time

83Temperature increase

84Holding temperature

85Holding time

86Vacuum on

87Vacuum off

88Long-term cooling

89Power saving key

90Open furnace head

91Close furnace head

92Numeric keys

93Home key

100 Programat firing tray

101 Metal pin A

100

102Metal pin B

103Metal pin C

3

84

78

93

89

87

86

83

81

82

51

51

50

41

41

42

90

90

91

91

88

75

75

73

74

80 |

79 |

85 |

70 |

71 |

77 |

76 |

72 |

92 |

102 |

103 |

101 |

7

1. Introduction / Signs and Symbols

1.1 Preface

Dear Customer

Thank you for having purchased the Programat P300/G2. It is a state-of-the-art furnace for dental applications.

The furnace has been designed according to the latest industry standards. Inappropriate use may damage the equipment and be harmful to personnel. Please observe the relevant safety instructions and read these Operating Instructions carefully.

Enjoy working with the

P300/G2.

1.2 Introduction

The signs and symbols in these Operating Instructions facilitate the finding of important points and have the following meanings:

Risks and dangers

Important information

Contraindication

Burn hazard

Risk of crushing

The Operating Instructions must be read.

1.3Notes regarding the Operating Instructions

Furnace concerned:

Programat P300/G2

Target group:

Dental technologists

These Operating Instructions facilitate the correct, safe and economical use of the Programat P300/G2 furnace.

Should you lose the Operating Instructions, extra copies can be ordered at a nominal fee from your local Ivoclar Vivadent Service Centre or downladed from www.ivoclarvivadent.com.

1.4Notes on the different voltage versions

The furnace is available with different voltage versions.

–110–120 V / 50–60 Hz

–200–240 V / 50–60 Hz

In the Operating Instructions, the furnace is described in the 200-240 V voltage version.

Please note that the voltage range shown on the images (e.g. rating plate) may differ depending on the voltage version of your furnace.

8

2. Safety First

This chapter is especially important for personnel who work with the |

2.1.1 |

|

|

Programat P300/G2 or who have to carry out maintenance or repair |

|

|

|

work. This chapter must be read and the corresponding instructions |

|

|

|

followed. |

Risks and dangers |

||

|

|

|

|

2.1 Indications

The Programat P300/G2 must only be used to fire dental ceramic |

|

materials and it should be used for this purpose only. Other uses |

|

than the ones stipulated, e.g. cooking of food, firing of other |

|

materials, etc. are contraindicated. The manufacturer does not |

|

assume any liability for damage resulting from misuse. The user is |

2.1.2 |

solely responsible for any risk resulting from failure to observe these |

|

Instructions. |

|

The furnace head should not be removed from the furnace base as long as the furnace head is connected by means of the heater cable.

Further instructions to assure proper use of the furnace:

–The instructions, regulations and notes in these Operating Instructions must be observed.

–The instructions, regulations and notes in the material’s Instructions for Use must be observed.

–The furnace must be operated under the indicated environmental and operating conditions (Chapter 9).

–The Programat P300/G2 must be properly maintained.

Risks and dangers

Make sure that no liquids or other foreign objects enter the furnace.

2.1.3

Contraindication

Firing trays must not be placed in the area surrounding the firing table, since this will obstruct the closing of the furnace head.

2.1.4

Contraindication

Foreign objects must not be placed on the furnace head or the air vents. Make sure that no liquids or other foreign objects enter the air vents, since this may result in an electrical shock.

2.1.5

Risks and dangers

Never place objects in the firing chamber by hand, since there is a burn hazard. Always use the tongs (accessories) supplied for this purpose. Never touch the hot surface of the furnace head, as there is a burn hazard. Please also refer to the warnings on the furnace.

9

2.1.6 |

2.1.11 |

Risk of crushing and burn hazard

Risks and dangers

2.1.7

Risks and dangers

Risks and dangers

Do not carry the furnace by the |

Never reach under the furnace |

|

cooling tray. |

||

head with the hand or other parts |

||

|

||

|

of the body during operation, |

|

|

since there is a risk of crushing |

|

|

and a burn hazard. |

2.1.12

Contraindication

Do not carry the furnace head by

Do not insert any foreign objects

the cables, since the cables and

into the air vents. There is a risk of

connections may be damaged.

electrical shock.

2.1.13

2.1.8

Contraindication

Risks and dangers

The furnace has an electric drive and must be operated by means of the electronic controls. Never open the furnace head by hand, since the mechanism will be damaged.

This product contains ceramic fibres and may release fibre dust. Do not use compressed air on the furnace, thus distributing the dust in the environment, and observe the additional notes on page 11.

2.1.9

2.1.14

Contraindication

Never use the furnace without a firing table.

2.1.10

Contraindication

Do not touch the thermocouple and the quartz tube in the firing chamber. Avoid contact with the

skin (grease contamination), as the parts will be prematurely damaged.

Risks and dangers

The furnace must not be operated if the quartz tube in the firing chamber is damaged. There is a risk of electric shock upon contact with the heating wire.

Avoid damage of the insulation by contact with the investment tongs or firing tongs.

10

2.2 Health and safety instructions

This furnace has been designed according to EN 61010-1 and has been shipped from the manufacturer in excellent condition as far as safety regulations are concerned. To maintain this condition and to assure risk-free operation, the user must observe the notes and warnings contained in these Operating Instructions.

–Place furnace on a fire-proof table (observe local regulations, e.g. distance to combustible substances or objects, etc.).

–Always keep the air vents at the rear and the side of the furnace free from obstruction.

–Do not touch any parts that become hot during the operation of the furnace. There is a burn hazard!

–Clean furnace only with a dry or slightly moist cloth. Do not use any solvents! Disconnect power before cleaning.

–Use original packaging for transportation purposes.

–The furnace must be cool before it is packed for transportation purposes.

–The user must especially become familiar with the warnings and the operating conditions to prevent injury to personnel or damage to materials. The manufacturer is not responsible for damage resulting from misuse or failure to observe the Operating Instructions. Warranty claims cannot be accepted in such cases.

–Before switching on the furnace, make sure that the voltage indicated on the rating plate complies with your local power supply.

–The power socket must be equipped with a residual current circuit breaker.

–The furnace must be plugged into a socket with protected contacts.

–Before calibration, maintenance, repair or exchange of parts, the power must be disconnected if the furnace is to be opened.

–If calibration, maintenance, or repair has to be carried out with the power connected and the furnace open, only qualified personnel who are familiar with the risks and dangers may perform these procedures.

–After maintenance, the required safety tests (high voltage resistance, protective conductor, etc.) have to be carried out.

–Ensure that only fuses of the indicated type and rated current are used.

–If it is assumed that safe operation is no longer possible, the power must be disconnected to avoid accidental operation. Safe operation is no longer possible if

–the furnace is visibly damaged;

–the furnace does not work;

–the furnace has been stored under;

unfavourable conditions over an extended period of time.

–Use only original spare parts.

–The temperature range for faultless operation is +5 °C to +40 °C (+41 °F to +104 °F).

–If the furnace has been stored at very low temperatures or high atmospheric humidity the head has to be opened and the unit dried or left to adjust to room temperature for approx. 1 hour (do not connect the power yet).

–The furnace has been tested for use at altitudes of up to 2000 m above sea level.

–The furnace may only be used indoors.

Any disruption of the protective conductor either inside or outside the furnace or any loosening of the protective conductor connection may lead to danger for the user in case of malfunction. Deliberate interruptions are not tolerated. Materials developing harmful gases must not be fired.

Warnings regarding the dismounting of the heating muffle

This product contains ceramic fibres and may release fibre dust. Fibre dust has proved to be carcinogenic in animal experiments. The corresponding EU Safety Data Sheet must be observed.

The heat insulation of the firing chamber in the Programat P300/G2 consists of ceramic fibres. After prolonged use of ceramic fibres at temperatures of over 900 °C (1652 °F), silicogenic substances (Cristobalite) may be produced. In certain cases, e.g. upon changing of the heating muffle, the possible resulting dust exposure may cause irritation of the skin, eyes, and respiratory organs. Therefore, proceed as follows when changing the heating muffle:

–Make sure the corresponding staff wears long-sleeved clothing as well as headgear, goggles and gloves.

–Place suction equipment at the source of the dust or, if not possible, provide the staff with FFP3 facemasks or similar items.

–Once the procedure has been completed, any dust possibly adhering to exposed skin must first be rinsed off with cold water. Only after that should soap and warm water be used.

–The corresponding work clothes should be washed separately.

Warning

The insulation on this product contains refractory ceramic fibres (RCF) which pose a possible cancer hazard, if agitated and inhaled. May be irritating to the skin, eyes or respiratory tract if insulation is cracked or corrupted.

California Proposition 65

Warning: ”This product contains Refractory Ceramic Fibres, a substance known to the State of California to cause cancer.”

Disposal:

The furnaces must not be disposed of in the normal domestic waste. Please correctly dispose of old furnaces according to the corresponding EU council directive. Information on the correct disposal may also be found on your local Ivoclar Vivadent homepage.

11

Loading...

Loading...