Ivoclar Vivadent EP 600 User Manual

EP 600

Press Furnace

Valid |

as of |

.0 |

|

Software |

Version |

V4 |

|

|

|||

|

|

|

|

Operating Instructions

2

Table of Contents

|

|

Page |

Views of the Furnace, List of Parts |

4 |

|

1 |

Introduction / Signs and Symbols |

8 |

1.1 |

Preface |

|

1.2 |

Signs and Symbols |

|

1.3 |

Notes regarding the Operating Instructions |

|

2 |

Safety First |

9 |

2.1 |

Indications |

|

2.2 |

Health and safety instructions |

|

3 |

Product Description |

13 |

3.1Components

3.2Hazardous areas and safety equipment

3.3Functional description

3.4Accessories

4 |

Installation and Initial Start-Up |

14 |

4.1 |

Unpacking and checking the contents |

|

4.2 |

Selecting the location |

|

5 |

Operation and Standard Settings |

18 |

5.1Starting the furnace

5.2Introduction to the operation 'Pressing'

5.3Introduction to the operation 'Miscellaneous'

5.4Operating the menu / key functions

5.5Help function

5.6Protocol

6 |

Practical Use |

23 |

6.1 |

Switching on/off |

|

6.2 |

Standard programs |

|

7 |

Maintenance, Cleaning, and Diagnosis |

24 |

7.1Monitoring and maintenance

7.2Cleaning

7.3'Access alarm table' menu

7.4'Diagnostic programs' menu

7.5Temperature calibration

7.6Changing the press plunger

8 What If… |

27 |

8.1Error messages and notifications (alarm)

8.2Technical malfunctions

8.3Repair

9 Product Specifications |

30 |

9.1Delivery form

9.2Technical data

9.3Acceptable operating conditions

9.4Acceptable transportation and storage conditions

10 Miscellaneous |

32 |

10.1Press table

10.2Menu structure of the EP 600

3

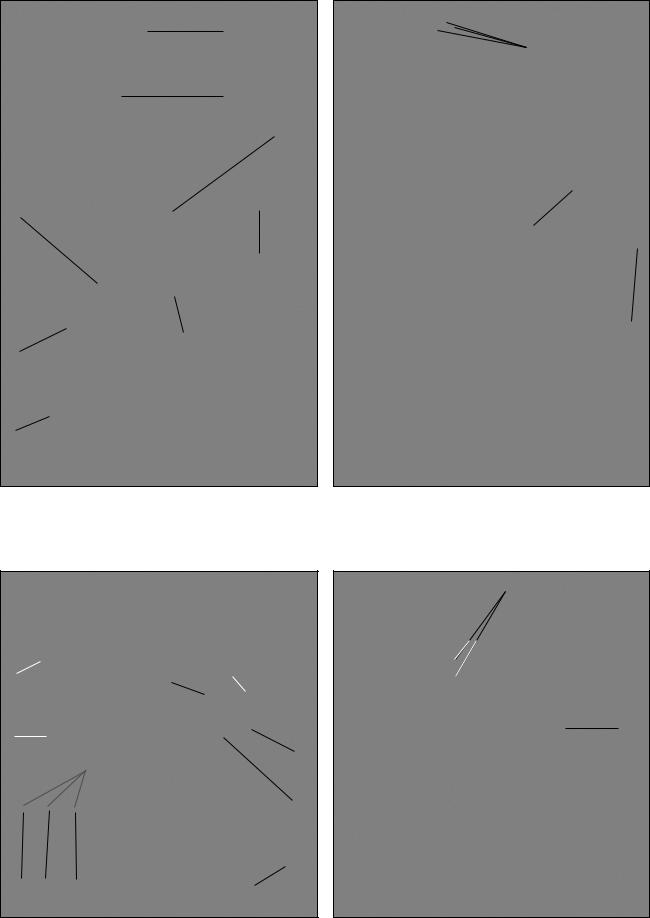

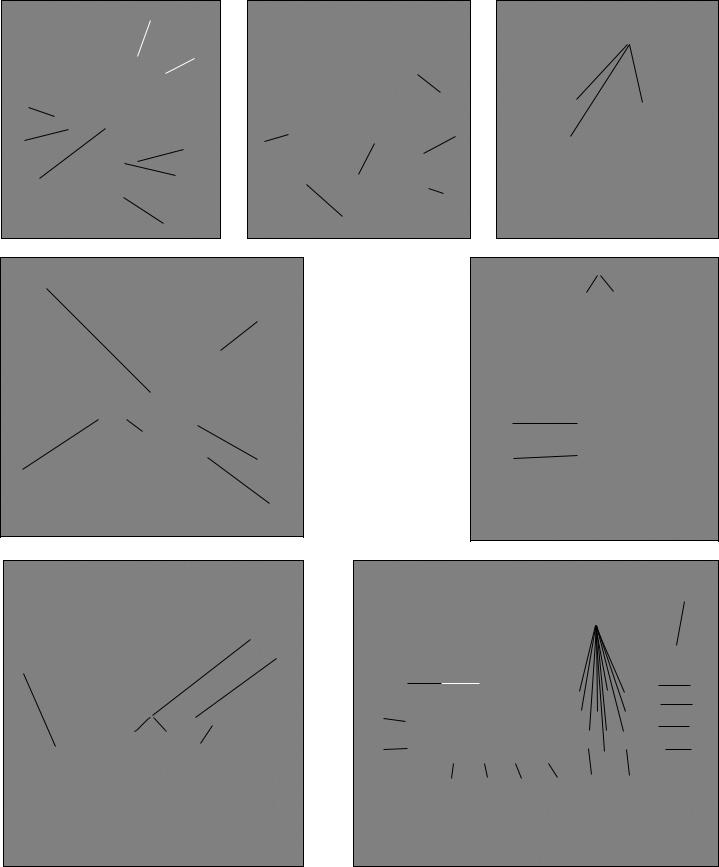

List of Parts

A = Furnace Base

1Sagger tray BP1

2Screws for sagger tray

3Rubber foot

4Air vents

5On/Off switch

6Power socket

7Vacuum pump socket

8External vacuum pump fuse

9Heater fuse

10Controls fuse

11Rating plate

12Vacuum hose connection

13Vacuum hose

14PC printer connection (RS-232)

15Opening for the operating pin

16Press drive socket

17Heater plug socket

18Thermocouple socket

19Sealing surface

20Fuse holder

21Power cord

22Plug for power cord

23Plug-in for ground connection

24Recess for ATK1

25Support for tray

B = Furnace Head with Press Mechanism

50Firing plate

51Screws for furnace head connections cover

52Press drive cover

53Furnace head cover

54Furnace head connections cover

55Screws for press drive cover

56Press plunger EP600 (red)

57Terminal screw for press plunger

58Cover for press electronics

59Press electronics

60Split taper socket for press plunger

61Press drive cable

62Thermocouple cable

63Heater cable

64Thermocouple plug

65Press drive plug

66Heater plug

67Heater plug retention screw

68Snap ring

69Stone lining

70Heating muffle

71Sheathed thermocouple

72Seal (O-ring)

73Warnings

74Recess for removal of firing plate (50)

75Pegs for plug-on console

76Leaf spring

77Plug-on console

78Grounding band

79Socket for Pager 1

80Operating pin

81Motion rod

C = Control Unit

100LC Display

101Contrast key

102HELP key

103Foil

104Function key 1

105Function key 2

106Function key 3

107Function key 4

108ESC key

109ENTER key

110START key

111STOP key

112Open furnace head key

113Close furnace head key

114Numerical keys (0-9)

D = Automatic

Temperature

Checking Set (ATK 1)

121Ceramic base block

122Melting sample

123Contact pins

E = Investment Ring

Cooling Grid (complete)

140 Investment ring cooling grid

4

4

52

53

1

73

2

4

3

6 |

|

|

|

11 |

|

7 |

14 |

79 |

|

||

|

|

|

|

20 |

|

55

54

4

51

54

8 |

9 |

10 |

12 |

5

59

55

58

62

61

62 |

|

66 |

64 |

57 |

|

||

|

|

|

|

81 |

60 |

|

63 |

|

|

65 |

|

|

|

|

|

|

56 |

|

67 |

73

56

68

80

71

69 |

15 |

70

72

|

|

|

|

|

|

103 |

|

|

|

|

|

114 |

|

|

24 |

|

|

|

|

|

|

50 |

|

|

|

|

|

19 |

|

|

|

|

|

|

|

100 |

|

|

|

|

112 |

|

|

|

|

|

|

113 |

|

101 |

|

|

|

|

111 |

|

|

|

|

|

|

|

74 |

102 |

|

|

|

|

110 |

|

104 |

105 |

106 |

107 |

108 |

109 |

6

5 |

75 |

11

22

54

79

|

|

73 |

7 |

|

|

|

|

18 |

21 |

13 |

23 |

|

||

|

17 |

16 |

1

25

140

76

77

78

E

122

121

123

D

7

1. Introduction / Signs and Symbols

1.1 Preface |

1.2 Signs and symbols |

Display |

Dear Customer,

Thank you for having purchased the EP 600 Press Furnace. This furnace with the intelligent press drive has been especially developed for the Ivoclar Vivadent all-ceramic systems (IPS e.max®, IPS Empress®). It is the latest of our technical highquality products. Inappropriate use may damage the equipment and be harmful to personnel. Please observe the relevant safety instructions in Chapter 2.

The EP 600 is designed according to EN61010-1 and thus complies with the relevant EU regulations.

The signs and symbols in these Operating Instructions and on the furnace facilitate the finding of important points and have the following meanings:

Risks and dangers

This symbol marks

safety instructions that must be followed to

prevent injury or death. Furthermore, damage to the furnace and/or laboratory may be avoided.

Important information

This symbol marks additional information for correct and economic use of the EP 600.

Contraindication

Burn hazard

Risk of crushing

Furnace

Printer

V ~ 110-120

A max. 2.1 Fuses

Ableitstrom / Leakage current

max. 0.75 mA

T5A T12A T2A

250VAC

250VAC

Vacuum

K-Module

(Communication

module)

Alternating current

(IEC 417)

Burn hazard

(IEC 417)

PRESSING

Mode

IPS e.max

IPS Empress Esthetic

IPS Empress Layering

Technique

IPS Empress 2

Layering Technique

IPS Empress Cosmo

IPS Empress

Staining Technique

Note

Technical malfunction

Operating error

Saving active; do not switch off the furnace

Timer active, programs cannot be started

Energy-saving mode active

|

Risk of crushing |

|

Outlet |

RS 232 |

(SELV, max. 24 VDC/A1) |

|

PC printer connection |

1.3Notes regarding the Operating Instructions

These Operating Instructions facilitate the correct, safe, and economic use of the EP 600 Press Furnace. They are divided into several, clearly structured chapters. This should enable you to locate specific topics quickly and easily.

You must read these

Operating Instructions

To inform you about risks, dangers, important information, and contraindications, these Instructions contain corresponding signs/symbols to mark important paragraphs.

We recommend keeping the Instructions in a safe place near the furnace to have immediate access to the information if necessary.

Should you lose the Operating Instructions, extra copies can be ordered at a normal fee from your local Ivoclar Vivadent Service Center.

Furnace concerned:

EP 600 Press Furnace

Target group:

Dental technicians and technologists

8

2. Safety First

This chapter is especially important for individuals who work with the EP 600 or who have to carry out maintenance or repair work. This chapter must be read and the corresponding instructions followed!

2.1 Indications

The EP 600 has been designed for pressing

IPS e.max and IPS Empress ingots and should be used for this purpose only. Uses other than the ones stipulated, e.g. cooking of food, firing of other materials, etc., are contraindicated. The manufacturer does not assume any liability for damage resulting from misuse. The user is solely responsible for any risk resulting from failure to observe these instructions.

Further instructions to assure proper use of the furnace:

–The instructions, regulations, and notes in these Operating Instructions must be observed.

–The instructions, regulations, and notes in the vacuum pump Operating Instructions must be observed.

–The furnace must be operated under the indicated environmental and operating conditions (see Chapter 9)

–The EP 600 must be properly maintained.

2.1.1 |

|

Make sure that no liquids or |

|

other foreign objects enter the |

|

|

|

|

|

|

furnace or the air vents, since |

|

Risks and dangers |

this may result in an electrical |

|

shock. |

|

|

|

2.1.2

Burn hazard

2.1.3

Risks and dangers

The furnace head should not be removed from the furnace and placed on a working surface or packaging material while it is still hot, as there is a burn hazard.

Never touch the electronic components, since a static discharge may damage them.

9

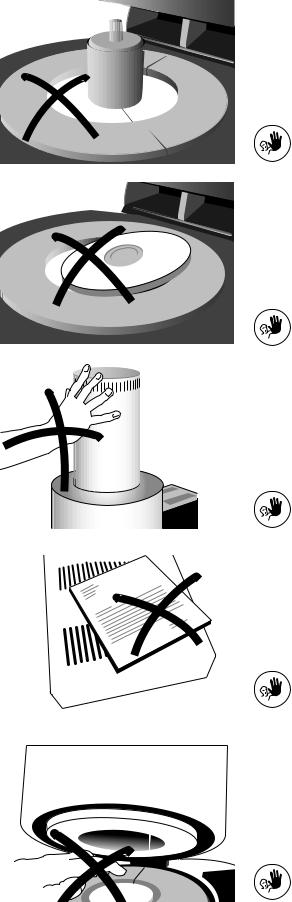

2.1.4

Risk of crushing / burn hazard

2.1.5

Risk of crushing

2.1.6

Contraindication

2.1.7

Contraindication

2.1.8

Contraindication

10

Never reach under the furnace head during operation. There is a risk of crushing and a burn hazard.

Never touch the press drive during operation. There is a risk of crushing.

Investment rings or firing trays must not be placed in the area surrounding the firing table, since they may get stuck under the furnace head. Use the sagger tray for firing trays or the cooling grid for fired investment rings.

Fired investment rings must not be placed on the sagger tray to cool. Please use the cooling grid especially designed for that purpose.

Do not place any objects on the furnace head. The opening process of the furnace head must not be obstructed.

2.1.9

Contraindication

2.1.10

Contraindication

2.1.11

Contraindication

2.1.12

Contraindication

2.1.13

Contraindication

Press cycles must not be conducted without the firing plate (50) in place.

The firing plate (50) must be correctly positioned in the firing chamber.

The furnace head is equipped with an electronic drive and must be operated with the corresponding keys. Never open or close the furnace head manually.

The air vents must be kept free from obstruction and clean at all times. If this is not done, there is a risk of overheating the furnace.

Do not bend the thermocouple (71). Do not touch the thermocouple with your fingers in order to prevent contamination (grease).

11

Loading...

Loading...