Ivoclar Vivadent EP 5010 User Manual

Programat® EP 5010

Operating Instructions

Valid |

from |

|

|

software |

|

V2.0

1

1

2

Table of Contents

List of parts |

4 |

1. Introduction / Signs and Symbols |

7 |

1.1Introduction

1.2Signs and symbols used in these Operating Instructions

1.3Notes regarding the Operating Instructions

1.4Notes on the different voltage versions

1.5Notes on the images in these Operating Instructions

2. |

Safety First |

9 |

2.1 |

Indications |

|

2.2 |

Health and safety instructions |

|

3. |

Product Description |

14 |

3.1 |

General |

|

3.2 |

Hazardous areas and safety equipment |

|

4. |

Installation and Initial Start-Up |

15 |

4.1Unpacking and checking the contents

4.2Selecting the location

4.3Assembly

4.4 Removing the furnace head

4.5Initial start-up

5. Operation and Configuration |

23 |

5.1Introduction to the operation

5.2Firing programs and programming options

5.3Press programs and programming options

5.4Advanced functions of the furnace (e.g. user code)

6. Practical Use |

68 |

6.1Firing procedure with an Ivoclar Vivadent program

6.2Firing procedure with an individual program

6.3Press procedure with an Ivoclar Vivadent program

6.4Press procedure with an individual program

7. Maintenance, Cleaning and Diagnosis |

77 |

7.1Monitoring and maintenance

7.2Cleaning

7.3Service note

7.4Idle mode

7.5Power-saving mode

7.6Replacing the press plunger

8. What if... |

81 |

8.1Error messages

8.2Additional error messages

8.3Technical malfunctions

8.4Repair

8.5Resetting to factory settings

9. Product Specifications |

88 |

9.1Delivery form

9.2Technical data

9.3Acceptable operating conditions

9.4Acceptable transportation and storage conditions

10. Appendix |

90 |

10.1 Firing program table 10.2 Press program table

3

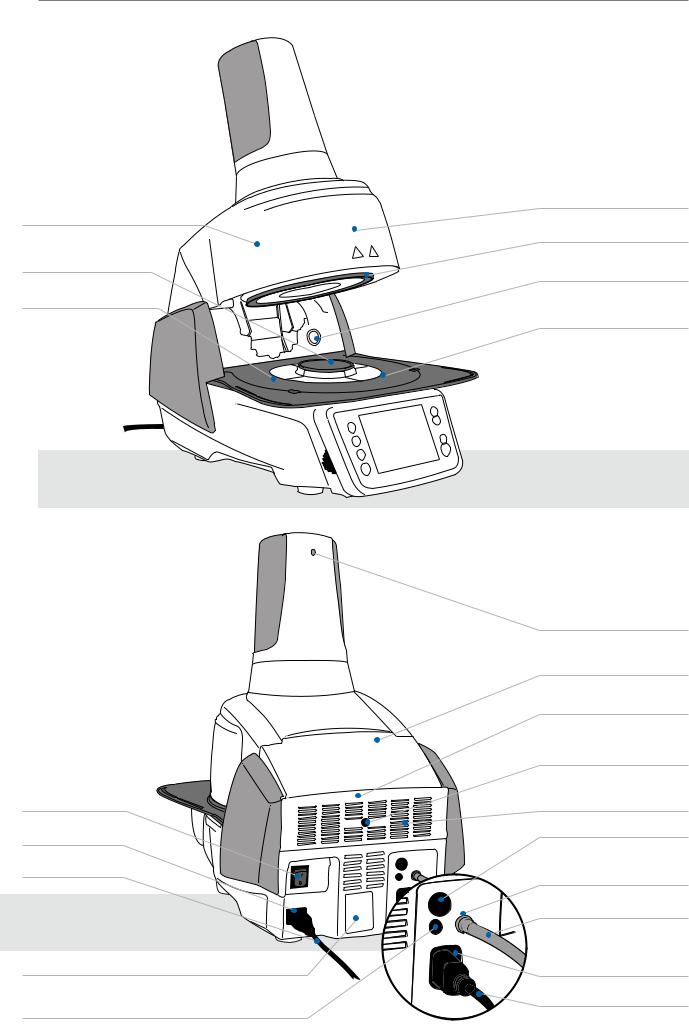

List of parts

B Ventilation grid press drive

1Screw for cooling tray

2Cooling tray

3Furnace base housing

4Audio ports

(in / out)

5Speaker

6Furnace feet 12b Progress display

13 Operating

unit fixture

14 USB connections

15 Card reader

A Press drive cover

7Air vents furnace head

8Furnace head housing

9Warnings

10Touch screen

11 Keypad

12a Optical Status Display

(OSD)

16Covering hood for

head opening mechanism

17Air vents furnace base

18USB connection

19USB device

20 Ethernet connection

4

21Insulation

22Firing plate

23Firing plate holder

24Frame plate

29On / Off switch

30Power socket

31Power cord

32Rating plate

33Vacuum pump fuse

List of parts

25QTK2 heating muffle

26Sealing rims of furnace head

27Infrared camera

28Sealing surface

CScrew for

press drive cover

36Covering hood for head opening mechanism

37Connection cover

38Screw for connection cover

39Air vents rear panel

40Heating element fuse

41Vacuum hose connection

42 Vacuum hose

34Vacuum pump socket

35Power cord for vacuum pump

5

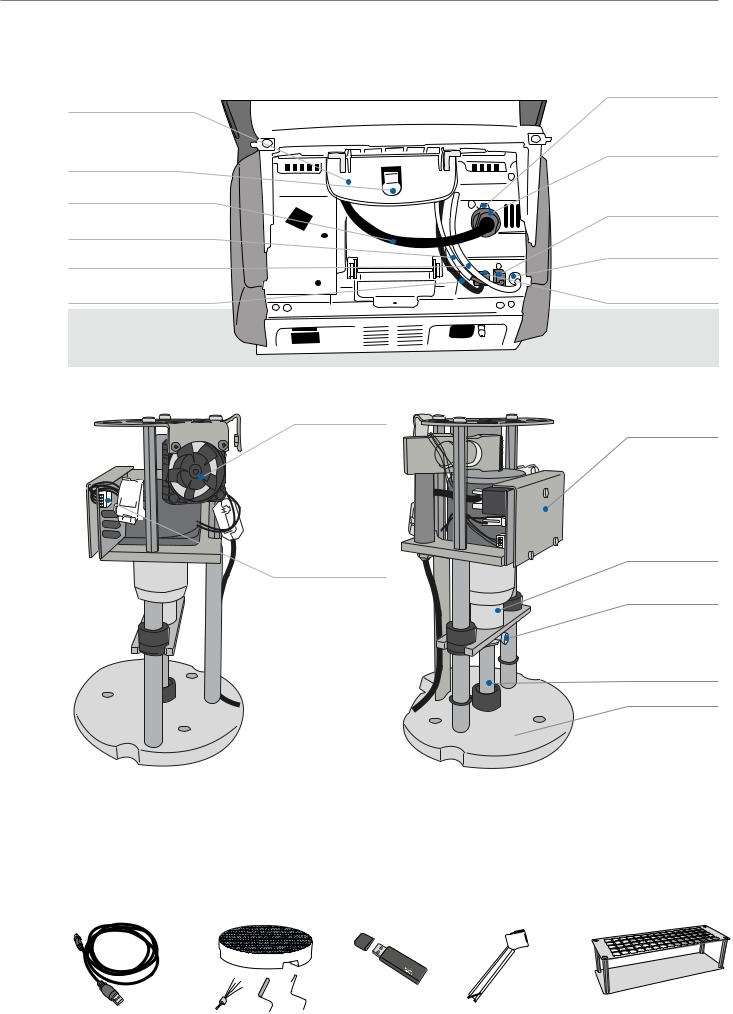

List of parts

43 |

Furnace head mounting |

48 |

Plug fuse |

|

|

||

|

|

49 |

Heater plug |

44 |

Furnace head |

50 |

Heater plug socket |

|

|

||

|

release |

|

|

|

|

51 |

Thermocouple plug |

45 |

Heater cable |

52 |

Thermocouple |

|

plug socket |

||

|

|

|

|

46 |

Thermocouple cable |

53 |

Furnace head vacuum |

|

|

||

47 |

Furnace head vacuum hose |

|

connection |

|

|

||

|

|

54 |

Press drive plug |

56 |

Press drive cable |

55 |

Press drive socket |

|

|

60 Fan |

62 Cover for press |

|

electronics |

63 Split taper socket

for press plunger

61 Press electronics

64 Terminal screw for press plunger

65 Press plunger

66 Head insulation

|

|

|

|

67 USB download cable |

68 Programat Firing Tray |

69 Programat USB |

70 Automatic Temperature 71 Cooling grid |

|

Kit 2 |

stick |

Checking Set ATK2 (test set) |

|

|

|

|

|

|

|

|

6

1. Introduction / Signs and Symbols

1.1 Introduction

Dear Customer

Thank you for having purchased the Programat® EP 5010. It is a state-of-the-art press and ceramic furnace for dental applications. The furnace has been designed according to the latest industry standards. Inappropriate use may result in certain risks. Please observe the relevant safety instructions and read these Operating Instructions carefully.

We hope that you will enjoy working with the Programat EP 5010.

1.2 Signs and symbols used in these Operating Instructions

The signs and symbols used in these Operating Instructions facilitate the finding of important points and have the following meanings:

Symbol Note

Risks and dangers

Important information

Contraindication

Burn hazard

Risk of crushing

The Operating Instructions must be read.

1.3 Notes regarding the Operating Instructions

Furnace concerned: |

Programat EP 5010 |

Target group: |

Dental technicians, dental professionals |

These Operating Instructions facilitate the correct, safe and economic use of the furnace. Should you lose these Operating Instructions, extra copies can be ordered at a nominal fee from your local Ivoclar Vivadent Service Center or downloaded from www.ivoclarvivadent.com.

7

1. Introduction / Signs and Symbols

1.4 Notes on the different voltage versions

The furnace is available in different voltage versions:

–110 – 120 V / 50 – 60 Hz

–200 – 240 V / 50 – 60 Hz

In the Operating Instructions, the furnace is described in the 200 – 240 V voltage version. Please note that the voltage range shown on the images (e.g. rating plate) may differ depending on the voltage version of your furnace.

1.5 Notes on the images in these Operating Instructions

All images and illustrations in these Operating Instructions are used for exemplification and the details are not authoritative for the construction of the furnace. They are symbols which may slightly differ from the original, e.g. due to simplification.

8

2. Safety First

This chapter is especially important for individuals who work with the Programat EP 5010 or who have to carry out maintenance or repair work. This chapter must be read and the corresponding instructions followed!

2.1 Indications

The Programat EP 5010 must only be used to press and fire dental ceramic materials and it should be used for this purpose only. Other uses than the ones stipulated, e.g. cooking of food, firing of other materials etc., are contraindicated. The manufacturer does not assume any liability for damage resulting from misuse. The user is solely responsible for any risk resulting from failure to observe these Instructions.

Further instructions to assure proper use of the furnace:

–The instructions, regulations and notes in these Operating Instructions must be observed.

–The instructions, regulations and notes in the material’s Instructions for Use must be observed.

–The system must be operated under the indicated environmental and operating conditions (Chapter 9.3).

–The Programat EP 5010 must be properly maintained.

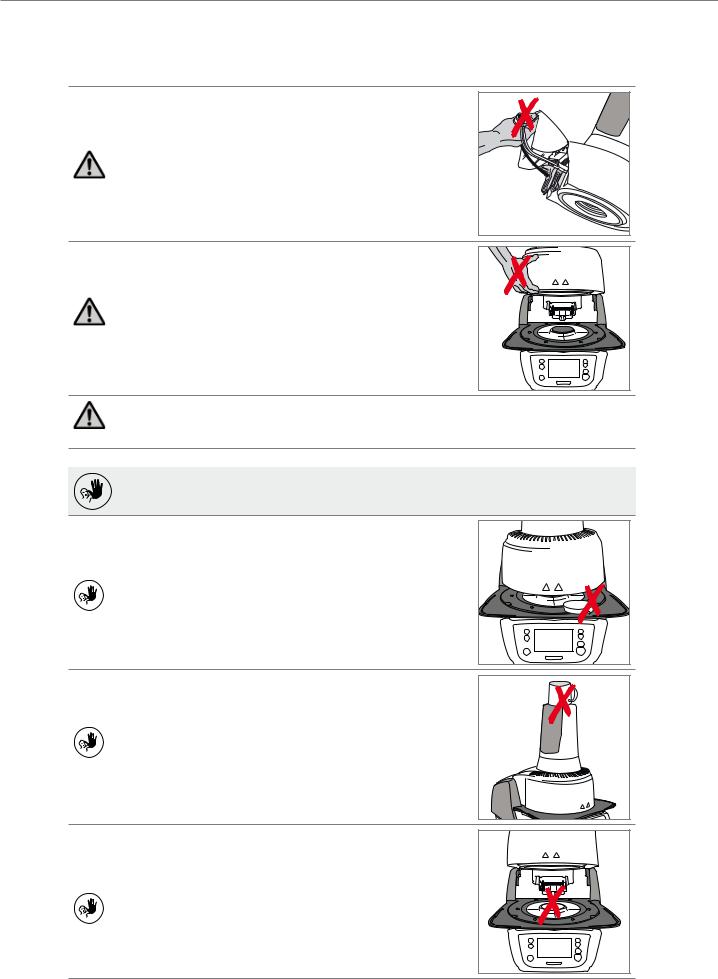

Risks and dangers

The furnace head should not be removed from the furnace base as long as the furnace head is connected by means of the heater cable.

Make sure that no liquids or other foreign substances enter the furnace.

Burn hazard: Never place objects in the firing chamber by hand, since there is a burn hazard. Always use the tongs (accessories) supplied for this purpose.  Never touch the hot surface of the furnace head, as there is a burn hazard.

Never touch the hot surface of the furnace head, as there is a burn hazard.

Do not carry the furnace by the cooling tray.

9

2. Safety First

The furnace head must not be carried by holding the cables, as there is a risk of damaging the cables and the corresponding connections.

The furnace head has an electric drive and must be operated by means of the electronic controls. Never open the furnace head by hand, since the mechanism will be damaged.

The furnace must not be operated if the quartz tube or the insulation in the firing chamber is damaged. There is a risk of electric shock upon contact with the heating wire. Avoid damage of the insulation by contact with the investment tongs or firing tongs.

Contraindications

Firing trays must not be placed in the area surrounding the firing plate, since this will obstruct the closing of the furnace head.

Foreign objects must not be placed on the furnace head or the air vents. Make sure that no liquids or other foreign objects enter the air vents, since this may result in an electric shock.

Never use the furnace without a firing plate.

10

2. Safety First

Do not touch the thermocouple or the quartz tube in the firing chamber. Avoid contact with the skin (grease contamination), as the parts will be prematurely damaged.

Do not insert any foreign objects into the air vents. There is a risk of electric shock.

This product contains ceramic fibres and may release fibre dust. Do not use compressed air thus distributing the dust in the environment and observe the additional notes on page 13.

Risk of crushing / burn hazard

Never reach under the furnace head with the hand or other parts of the body during operation. There is a risk of burning and crushing.

Never reach inside the rear cover with the hand or particularly with the fingers. There is a risk of crushing.

11

2. Safety First

2.2Health and safety instructions

This furnace has been designed according to EN 61010-1 and has been shipped from the manufacturer in excellent condition as far as safety regulations are concerned. To maintain this condition and to ensure risk-free operation, the user must observe the notes and warnings contained in these Operating Instructions.

–It is important that the user becomes familiar with the warnings and operating conditions to prevent injury to personnel or damage to materials. The manufacturer is not responsible for damage resulting from misuse or failure to observe the Operating Instructions. Warranty claims cannot be accepted in such cases.

–Before switching the furnace on, make sure that the voltage indicated on the rating plate complies with your local power supply.

–The mains socket must be equipped with a residual current operated device (FI).

–The power plug acts as a circuit breaker and may only be connected with an easy-to-access power socket with protective contact.

–Only use the supplied original power cord. Do not use an inadequately measured replacement.

–Place the furnace on a fire-proof table: Observe local regulations (e.g. distance to combustible substances or objects, etc.).

–Always keep the air vents at the rear of the furnace free from obstruction.

–Do not touch any parts that become hot during operation. Burn hazard!

–When removing hot components from the firing chamber (e.g. firing plate, firing tray), make sure not to place them on a flammable surface!

–Clean furnace only with a soft, dry cloth. Do not use solvents! Disconnect the power plug before cleaning and allow the furnace to cool down!

–The furnace must be cool before it is packed for transportation.

–Use original packaging for transportation purposes.

–Before calibration, maintenance, repair or change of parts, the power must be disconnected and the furnace has to be cool if it has to be opened.

–If calibration, maintenance or repair has to be carried out with the power connected and the furnace open, only qualified personnel who are familiar with the risks and dangers may perform the procedures.

–After maintenance, the required safety tests (high voltage resistance, protective conductor) must be carried out.

–Make sure that only fuses of the indicated type and rated current are used as replacements.

–If it is assumed that safe operation is no longer possible, the power must be disconnected to avoid accidental operation. Safe operation is no longer possible if

–the furnace is visibly damaged;

–the furnace does not work;

–the furnace has been stored under unfavourable conditions over an extended period of time.

–Use only original spare parts.

–The temperature range for faultless operation is +5 °C to +40 °C.

–If the furnace has been stored at very low temperatures or high atmospheric humidity, it must be dried or left to adjust to the room temperature for approx. 4 hours prior to connecting power.

–The furnace is tested for use at altitudes of up to 2,000 m above sea level.

–The furnace may only be used indoors.

–Before leaving the factory, the furnace functions were tested for several hours. It is therefore possible that these tests have caused slight discolouration of the insulation. Nevertheless, your Programat EP 5010 is still a brand new furnace.

12

2. Safety First

Any disruption of the protective conductor either inside or outside the furnace or any loosening of the protective conductor may lead to danger for the user in case of a malfunction. Deliberate interruptions are not permissible.

Materials developing harmful gases must not be fired.

Warnings regarding the removal of the heating muffle

This product contains ceramic fibres and may release fibre dust. Fibre dust has proved to be carcinogenic in animal experiments. The heating muffle may only be dismounted by a qualified After Sales Service Center. Information regarding the Safety Data Sheet is also available from your After Sales Service Center.

Disposal:

The furnace must not be disposed with the common domestic waste. Please correctly dispose of old furnaces according to the corresponding EU council directive. Information regarding disposal can be found on the respective national Ivoclar Vivadent website.

13

3. Product Description

3.1 General

The Programat EP 5010 is a state-of-the-art press and ceramic furnace for dental applications. The firing chamber may be heated up to max. 1200 °C by means of a heating element. The pressure for the press procedure is generated by a press drive. Furthermore, the firing chamber has been designed in such a way that a vacuum may be created with a vacuum pump. The firing / press programs are controlled with the corresponding electronic controls and software. Additionally, the set and actual temperatures are continuously compared.

The Programat EP 5010 consists of the following components:

–furnace base with electronic controls

–furnace head with firing chamber and press drive

–cooling tray

–firing plate

–power cord and hose for vacuum pump.

3.2 Hazardous areas and safety equipment

Description of the risk areas of the furnace: |

|

|

Hazardous area |

|

Type of risk |

|

||

|

|

|

Firing chamber |

|

Burn hazard |

|

|

|

Opening / closing mechanism |

|

Risk of crushing |

|

|

|

Electric components |

|

Risk of electric shock |

|

|

|

Description of the safety equipment of the furnace: |

|

|

Safety equipment |

|

Protective effect |

|

||

|

|

|

Protective conductor |

|

Protection from electric shock |

|

|

|

Electric fuses |

|

Protection from electric shock |

|

|

|

Furnace housing and covers |

|

Protection from electric shock, burning and crushing |

|

|

|

14

4. Installation and Initial Start-Up

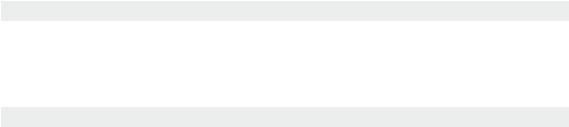

4.1Unpacking and checking the contents

Remove the furnace components from their packaging and place the unit on a suitable table. Please observe the instructions on the outer packaging.

There are no special transportation grips on the furnace. Support the bottom of the furnace to carry it. Check the delivery for completeness (see delivery form in Chapter 9) and transportation damage. If parts are damaged or missing, contact your local Ivoclar Vivadent Service Center.

We recommend keeping the original packaging for future service and transportation purposes.

4.2Selecting the location

Place the furnace on a flat table using the rubber feet. Make sure that the furnace is not placed in the immediate vicinity of heaters or other sources of heat. Make sure that air may properly circulate between the wall and the furnace. Also ensure that there is enough space between the furnace and the user, as the furnace releases heat during the opening of the furnace head.

The unit should neither be placed nor operated in areas where there is an explosion hazard.

15

4. Installation and Initial Start-Up

4.3 Assembly

Assembling the furnace is very easy and involves only few steps. Before you start assembling the furnace, make sure that the voltage indicated on the rating plate (32) complies with the local power supply. If this is not the case, the furnace must not be connected!

Step 1:

Mount the cooling tray (2).

Remove the two screws for the cooling tray and the transport protection for the infrared camera.

Place the cooling tray (2) on the frame plate (24). Make sure that the cooling tray is correctly positioned on the frame plate.

Secure the cooling tray with the two screws (1).

Step 2:

Place the firing plate.

Place the firing plate (22) on the firing plate holder (23). If placed correctly, the bottom of the firing plate is automatically centred in the firing plate holder.

1 |

1 |

2

|

24 |

1 |

2 |

22

23

16

4. Installation and Initial Start-Up

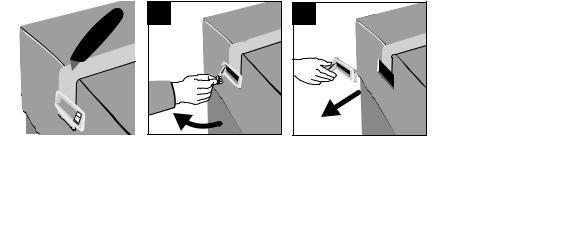

Step 3:

Mount the furnace head.

The furnace head is best mounted with the rear panel of the furnace pointing towards the user. Lift the furnace head with both hands (see picture) and carefully position it on the furnace head mounting.

Position the furnace head mounting as shown in the picture until the furnace head audibly snaps into place. Make sure that the firing plate and the insulation are not damaged by mounting the furnace head.

Step 4:

Connect the cables.

Connect the cables of the furnace head with the furnace base. Proceed as follows:

–Connect the vacuum hose.

–Insert the thermocouple plug (make sure that the polarity of the plug is correct).

–Insert the press drive plug.

–Insert the heater plug.

1.Insert the heater plug into the intended connector.

2.Secure the heater plug by rotating it 45° until it snaps into place.

49

54

51 |

53 |

2 |

|

1 |

|

17

4. Installation and Initial Start-Up

Step 5:

Close the covering hood.

Once all cables are properly connected to the furnace base, close the covering hood over the connections.

Step 6:

Mount the connection cover.

Mount the connection cover and secure it with the fastening screw. Make sure that the lateral catch springs snap into place when mounting the connection cover.

The furnace must only be operated with the covering hood closed and the connection cover mounted!

Step 7:

Establish additional connections.

Connecting the power

Please make sure that the voltage indicated on the rating plate complies with the local power supply. Subsequently, connect the power cord with the power socket of the furnace.

The furnace must only be operated with the supplied power cord!

Connecting the vacuum pump

Connect the vacuum pump plug with the vacuum pump socket. We recommend using only a vacuum pump from Ivoclar Vivadent (VP4 / VP5), since these pumps are especially coordinated with the press furnace. If other pumps are used, please observe and do not exceed the maximum power consumption.

Do not shorten the vacuum hose! The minimum length of the vacuum hose is 1.6 m.

32

33

25

26

29

30

18

4. Installation and Initial Start-Up

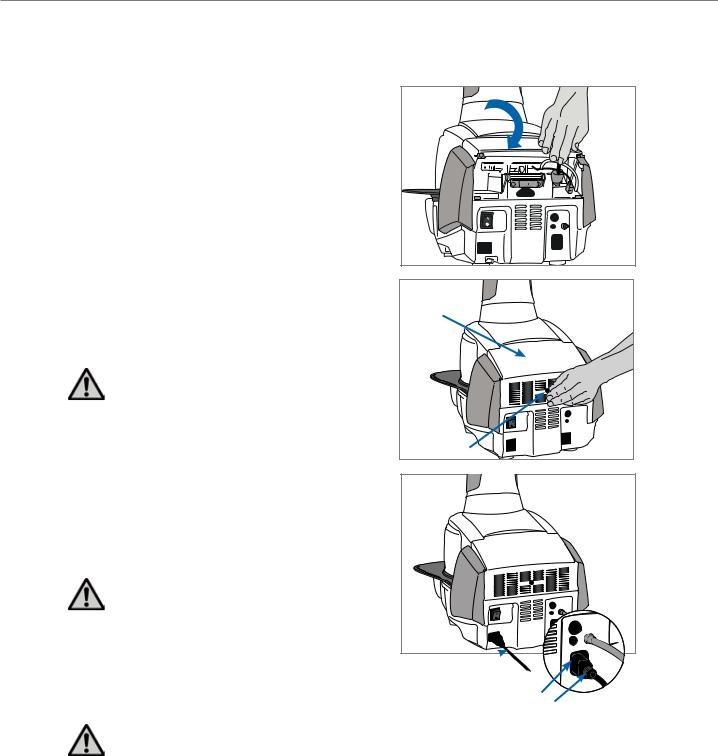

4.4 Removing the furnace head

Before the connection cover and the covering hood are removed, the furnace has to be switched off and the power cord disconnected from the power socket.

1.Loosen and remove the knurled screw of the connection cover.

2.Dismount the connection cover.

3.Open the covering hood.

4.Release the heater plug and disconnect it with a 45° anti- clockwise rotation.

5.Disconnect the press drive plug.

6.Disconnect the thermocouple plug.

7.Disconnect the vacuum hose.

8.Press the leaf spring with a finger, lift off the furnace head at the same time and remove it.

Make sure that the furnace head has completely cooled down before it is removed (fire hazard).

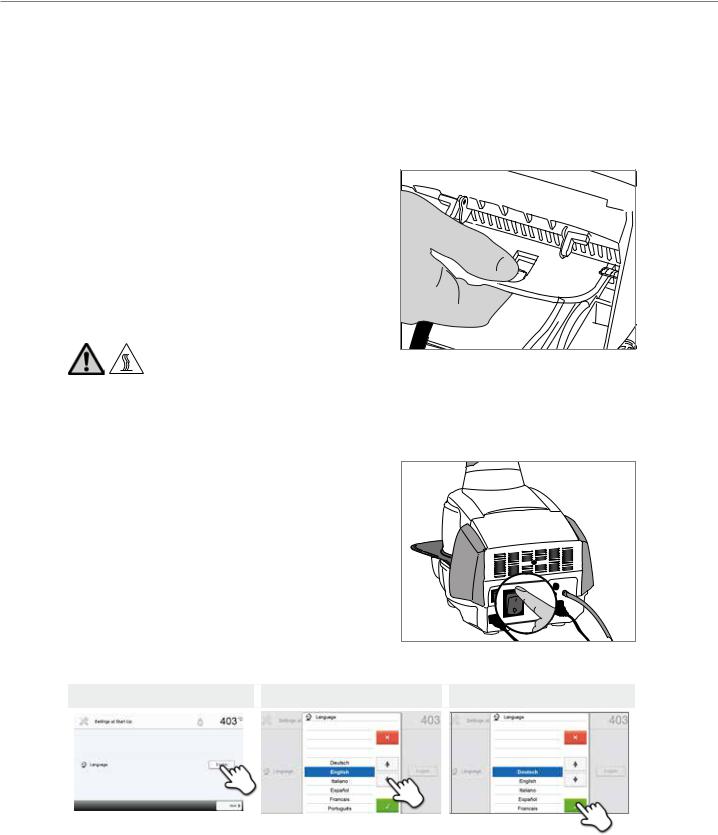

4.5 Initial start-up

1.Connect the power cord with the wall socket.

2.Switch the On / Off button at the rear of the furnace to position I.

4.5.1 Basic settings upon initial start-up

Upon the initial start-up of the new furnace, a number of basic settings are required. These settings will be stored and will not appear anymore upon the following starting procedure.

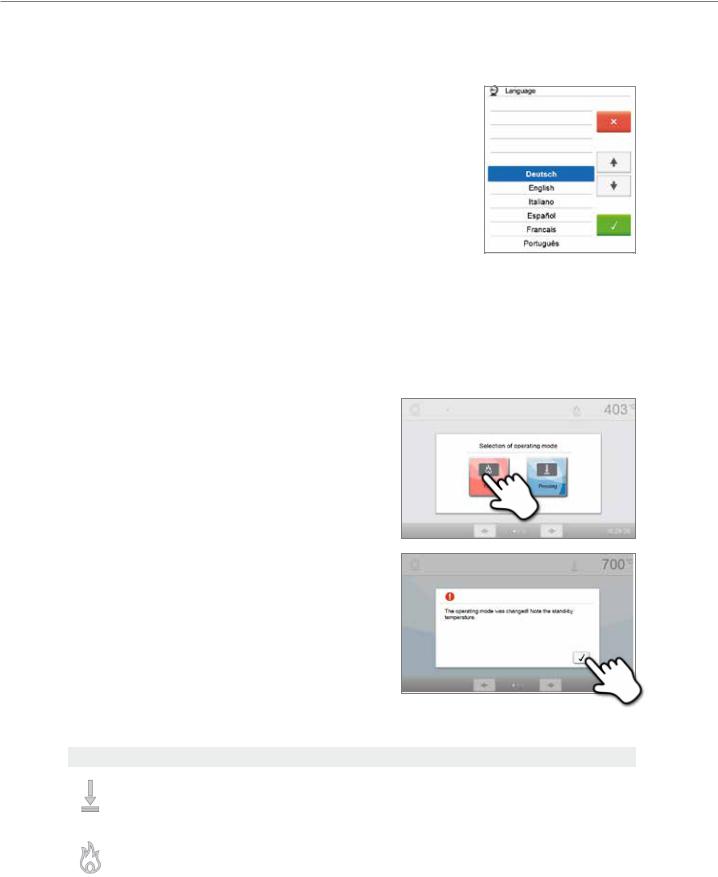

Step 1:

Select the language.

The touch buttons (display keys) can be operated by tapping the display.

Step 1 |

|

Step 2 |

|

|

|

|

|

|

Step 3

Select the desired language using the [Arrow up / down] buttons. Confirm the entry with the green button. The [Next] button is used to reach the next entry screen.

19

4. Installation and Initial Start-Up

Step 2:

Select the desired temperature unit.

The [Next] button is used to reach the next entry screen.

Step 3:

Select the date format.

Confirm the entry with the green button. The [Next] button is used to reach the next entry screen.

Step 4:

Set the date (day, month, year).

Confirm the entry with the green button. The [Next] button is used to reach the next entry screen.

Step 5:

Set the time (hours, minutes, seconds).

Confirm the entry with the green button. The [Next] button is used to reach the next entry screen.

The initial start-up and entry of the basic settings are now complete. The furnace will now automatically conduct a selftest.

20

4. Installation and Initial Start-Up

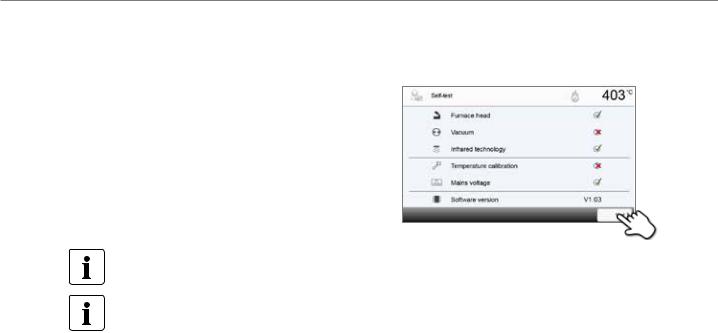

4.5.2 Start screen and self-test

Immediately after switching on, the display briefly shows the start screen. Subsequently, the furnace conducts an automatic self-test. The performance of all furnace components is automatically checked.

The following functions are checked:

Function

|

|

The furnace head test is in progress. |

|

|

|

Furnace head test |

The furnace head test was successful. |

|

|

|

|

|

|

The furnace head test failed. Please note the error message on the |

|

|

display. |

|

|

|

|

|

The vacuum test is in progress. |

|

|

|

Vacuum test |

The vacuum test was successful. |

|

|

|

|

|

|

The vacuum test failed. Please note the error message on the display. |

|

|

|

|

|

The IRT test is in progress. |

|

|

|

IRT test |

The IRT test was successful. |

|

|

|

|

|

|

The IRT test failed. Please note the error message on the display. |

|

|

|

The following information is displayed: |

|

|

Information |

|

|

|

|

|

|

|

Temperature calibration of the furnace is not required. |

Temperature calibration |

|

|

|

Some time has passed since the last calibration. |

|

|

|

|

|

|

Please conduct a calibration procedure. |

|

|

|

|

|

The power supply voltage is in the acceptable range. |

Power supply |

|

|

|

The power supply is outside the acceptable range. |

|

|

|

|

|

|

|

Software version |

The currently installed software version is displayed. |

|

|

|

|

If the self-test has been successful, the furnace will automatically display the screen to select the desired operating mode (firing / pressing).

If the program recognizes a malfunction during the test, a corresponding error message with the corresponding rectification information appears on the display.

The acoustic signal and the error message can be acknowledged with the corresponding buttons.

21

4. Installation and Initial Start-Up

Press the [Next] button to confirm the self-test.

Before the first firing, the firing chamber should be dehumidified using the dehumidification program (see Chapter 5.4 for details).

Please note that the furnace may require a certain acclimation time after having been set-up. Particularly if the furnace was exposed to considerable temperature changes (water condensation).

22

5. Operation and Configuration

5.1 Introduction to the operation

5.1.1 Control unit

The Programat EP 5010 is equipped with a wide-screen colour display. The furnace can be intuitively operated by means of the membrane-sealed keypad and the touch screen. The touch buttons can be actuated by slightly tapping the display with the fingertip and the furnace runs the desired function.

The user interface in the display is divided into three sections:

1.Information bar (e.g. indication of the current furnace temperature, selected program type, etc.)

2.Main screen (e.g. editing firing programs, changing the settings, etc.)

3.Navigation bar (e.g. scrolling, scrolling to higher levels, opening favourite programs, etc.)

5.1.2 Explanation of the key functions

Key |

Function |

HOME key

Switch to home screen (main menu).

PROGRAM key

Press once: Display of the currently selected program.

Press twice: Switch to the program selection via number entry.

CHANGE OPERATING MODE key

By pressing this key, you can switch between the firing and the press mode.

IRT key

With this key, the infrared image of the object can be displayed during the closing process.

POWER SAVING key

By pressing this key, the power-saving function is activated (only possible with the furnace head closed and the furnace on idle). The display shows the power-saving icon. Pressing any key ends the automatically activated power-saving function.

OPEN FURNACE HEAD key

Quick cooling with the furnace head open:

If the furnace head is completely open and the OPEN FURNACE HEAD key is pressed again, the quick cooling function is activated. I.e. the vacuum pump is switched on for 5 minutes. This function can be stopped at any time by pressing the STOP, CLOSE FURNACE HEAD or START key. This function can be activated any time when the furnace head is open.

CLOSE FURNACE HEAD key

23

5. Operation and Configuration

STOP key

A program in progress can be paused by pressing the STOP key and stopped by pressing

STOP twice. Movement of the furnace head can be stopped at any time by pressing

STOP. Acoustic signals can be confirmed by pressing the STOP key.

START key (Start LED)

Starts the selected program. The green LED indicates that a program is active. If the program is paused (1x STOP), the Start LED flashes until renewed pressing of START results in the program being resumed.

5.1.3 Explanation of the most important touch buttons

Button |

Function |

Scroll left / Scroll right

With these buttons, you can e.g. scroll to page 2 of the home screen.

Back with note

With this button, you can change to the "next higher" menu level. The button indicates to which screen you change, e.g. to the home screen.

Close

With this button, you can leave sub-menus.

Confirm entry

This button is used to confirm an entry. If the button appears pale green, no entry has been made yet or the value entered is not in the acceptable range.

Cancel entry

This button is used to cancel an entry. Changed values are not saved.

Program parameters

Pressing these buttons allows you to change program parameters. A selection list or numeric pad for entering the values appears.

The upper half of the button itself shows the parameter in question (e.g. closing time), while the lower half shows the entered value (e.g. 00:18).

On / Off button

This button is used to switch functions on or off.

Parameters

By pressing these buttons, a selection list or numeric pad for entering the values appears.

5.1.4 Explanation of the numeric pad and selection list

–Numeric pad

The numeric pad enables the entering and changing of parameters, e.g. in firing programs or setting menus. Additionally, the currently set value as well as the minimum and maximum values are indicated.

An entry must be confirmed with the green button. As soon as the entry has been confirmed, the numeric pad is closed. If the button appears pale green, the value is not in the acceptable range.

The numeric pad can be closed with the red button, without any parameters being changed.

24

5. Operation and Configuration

–Selection list

In the selection list, the desired parameter can be selected by using the up / down arrows. An entry must be confirmed with the green button. After that, the selection list is closed.

The selection list can be closed with the red button, without any parameters being changed.

5.1.5 Selecting the operating mode

The furnace can be operated in two different modes:

–Pressing:

Only press programs can be selected. The stand-by temperature of the furnace is set to 700 °C.

–Firing:

Only firing programs can be selected. For Ivoclar Vivadent programs, the stand-by temperature of the furnace is set to 403 °C.

In order to switch between the press and the firing modes, you must press the CHANGE OPERATING MODE key to change the operating mode (Chapter 5.1.2).

Once the CHANGE OPERATING MODE key has been pressed, the operating mode can be selected.

1. Select the desired operating mode.

2. After the operating mode is selected, a note is displayed indicating the different stand-by temperatures of the respective operating modes.

Switching from "Firing" to "Pressing": Make sure that the furnace has heated up to 700 °C before starting the press program.

Switching from "Pressing" to "Firing": Make sure that the furnace has cooled down to 403 °C before starting the firing program.

In the information bar, the operating mode is displayed in addition to the temperature.

Icon |

Meaning |

|

|

|

Operating mode "Pressing" |

|

If this icon is displayed in the information bar, the operating mode "Pressing" is active. |

|

In this operating mode, only press programs are available and the stand-by temperature |

|

is set to 700 °C. |

|

Operating mode "Firing" |

|

If this icon is displayed in the information bar, the operating mode "Firing" is active. In |

|

this operating mode, only firing programs are available and the stand-by temperature is |

|

set to 403 °C. |

25

5. Operation and Configuration

5.1.6 Explanation of the home screen

After the furnace is switched on, the display shows the home screen. All functions of the Programat can be selected from this screen. You can switch back to the home screen with the HOME key.

By pressing a selection button, you will reach the corresponding menu (e.g. firing programs, settings, calibration, etc.).

By pressing the [Arrow] buttons, the next page of the home screen is accessed, where additional functions are available.

The circles between the arrows indicate the number of pages. The current page is marked with a light dot.

5.1.7 Explanation of the speaker signals

– Upon closing the furnace head below 100 °C

There is a risk of crushing when closing the furnace head. If the furnace head is closed below 100 °C, the user is alerted to the hazard by an acoustic signal.

–Upon completion of the self-test

To inform the user that the automatic self-test has been successfully completed, a pre-set, not modifiable melody is played.

–Furnace head open and temperature below 560 °C

To inform the user that the temperature in the open furnace head has dropped below 560 °C the selected melody is played (5 seconds). Thus, the furnace head has sufficiently cooled down for the next program start. The acoustic signal can be stopped by pressing the STOP key.

–Furnace head open and temperature below 360 °C

To inform the user that the temperature in the open furnace head has dropped below 360 °C, the selected melody is played. If the first playback (10 seconds) is not acknowledged with the STOP key, a second playback sounds after

5 minutes (for 5 minutes) to signal that the furnace head is cooling down. After that, no further signal is played.

If one of the two playbacks is acknowledged with the STOP key, the signal transmitter is switched off and no further signals will be sounded.

–For error messages

Error messages are acoustically supported with the 'error melody' (endless beep). The acoustic signal can be confirmed by pressing the STOP key, while the error message still remains visible. If the error message is acknowledged with the corresponding button, the signal transmitter is also switched off.

–For active press cycle

To inform the user that the press cycle has been started, a pre-set, not modifiable melody is played.

–Upon completion of the press program

To inform the user that the press program has been completed, the selected melody is played continuously.

26

5. Operation and Configuration

5.1.8 Optical status and progress display (OSD)

The Optical Status Display (12a) shows the most important statuses of the furnace. The following activities are shown:

Colour |

Activity |

|

|

|

|

Yellow |

The furnace is performing a self-test or is not ready for use, as the recommended |

|

temperature range for a program start has not yet been reached. |

||

|

||

|

|

|

Yellow (flashing) |

Information, notification or error message |

|

|

|

|

Green |

The furnace is ready for use; the currently selected program can be started. |

|

|

|

|

Orange |

Program is closing the furnace head or is in predrying mode. |

|

|

|

|

Red |

Program is heating up or is in holding time mode. |

|

|

|

|

Blue |

Program is in long-term cooling or is opening the furnace head. |

|

|

|

Progress display:

During an active process, the progress of the program is also shown by the OSD. This is done by stage-to-stage lighting up of the lateral OSD (12b).

5.1.9 User code

For safety reasons, a user code is required for certain settings. The user code ex factory is as follows:

1234

The user code can be individually changed. See Chapter 5.4 Settings for details.

5.2 Firing programs and programming options

5.2.1 Program structure

The furnace offers several types of programs:

a.programs for Ivoclar Vivadent materials

b.500 free, individually adjustable programs

c.500 free, individually adjustable programs on a USB stick.

The program types are subdivided into program groups. Each program group consists of 20 programs. All programs are equivalent and therefore full-fledged programs. All the parameters can be individually set in each program.

a) Programs for Ivoclar Vivadent materials (see enclosed Program Table)

When the furnace is delivered ex factory, the Ivoclar Vivadent programs already contain the recommended material parameter settings and are write-protected. Consequently, it is not possible to accidentally overwrite these programs.

If required, the parameters can be changed and overwritten at any time, if the programs are to be used for other purposes. Therefore, these programs are also available as individual programs.

In case of software updates, individually changed parameters in Ivoclar Vivadent programs might be reset to the factory settings or changed!

b) 500 free, individually adjustable programs

The programs are designed in such a way that they can be either used as conventional, one-stage programs or as twostage programs, if required. The programs and program groups can be individually named.

In case of software updates, individually changed parameters in free programs are NOT reset to the factory settings or changed!

27

5. Operation and Configuration

c) 500 free, individually adjustable programs on a USB stick

In a first step, a USB stick must be prepared as program memory (see Chapter 5.4). The programs are designed in such a way that they can be either used as conventional, one-stage programs or as two-stage programs, if required. The programs and program groups can be individually named.

In case of software updates, individually changed parameters in free programs are NOT reset to the factory settings or changed!

5.2.2 Program selection

The program selection requires only few steps:

1. Select the program type.

2. Select the program group.

3. Select the program.

4. Start the program or edit the program parameters.

The firing program can now be started or, as an alternative, the program parameters can be changed.

Quick program selection

Pressing the P key switches to the program screen of the current program. When the program screen is shown, pressing the P key again switches to the quick program selection by means of number entry.

28

Loading...

Loading...