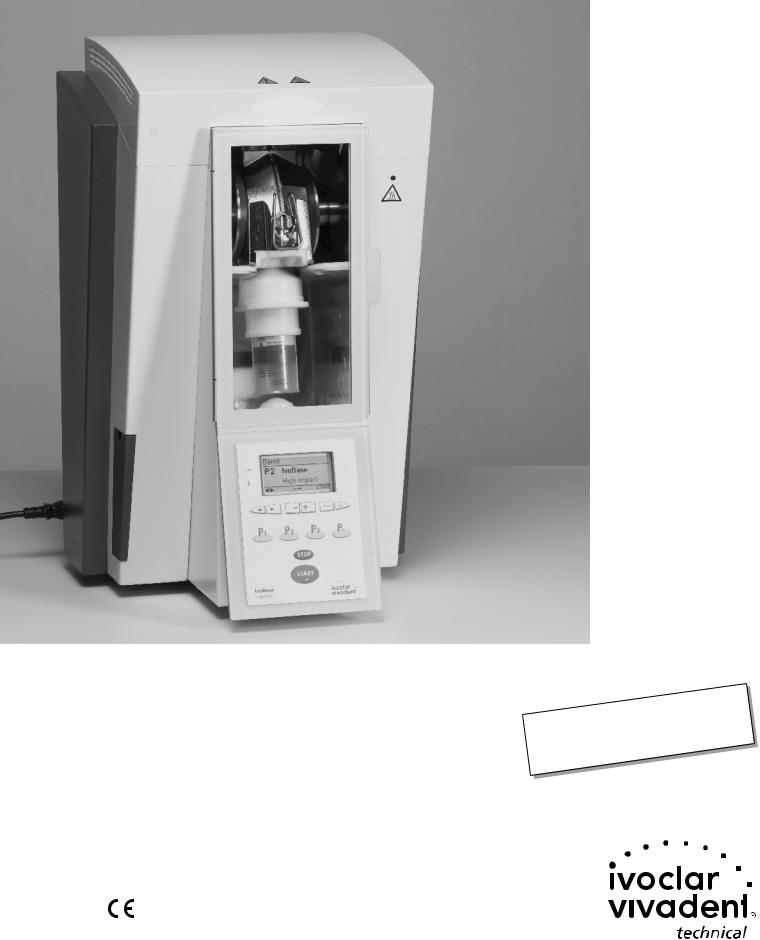

Ivoclar Vivadent IvoBase Injector User Manual

IvoBase® Injector

IvoBase® Injector

Operating Instructions

Valid |

as of |

.0 |

|

|

|

|

|

||

Software |

Version |

2 |

|

|

|

|

|||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Table of Contents

List of parts |

3 |

|

1. |

Introduction / Signs and Symbols |

6 |

1.1 |

Preface |

|

1.2 |

Introduction |

|

1.3 |

Notes regarding the Operating Instructions |

|

1.4 |

Note on the different voltage versions |

|

2. |

Safety First |

7 |

2.1 |

Indications |

|

2.2 |

Health and safety instructions |

|

3. |

Product Description |

10 |

3.1 |

Components |

|

3.2 |

Hazardous areas and safety equipment |

|

3.3 |

Functional description |

|

4. |

Installation and Initial Start-Up |

11 |

4.1 |

Unpacking and checking the contents |

|

4.2 |

Selecting the location |

|

4.3 |

Removing the transport protection |

|

4.4 |

Establishing the connections |

|

4.5 |

Initial start-up |

|

5. |

Operation and Configuration |

14 |

5.1 |

Introduction to the operation |

|

5.2 |

Explanation of key functions |

|

5.3 |

Basic meaning of the screens |

|

5.4 |

Settings and information |

|

5.5 |

Explanation of the symbols on the display |

|

5.6 |

Description of the beeper sounds |

|

5.7 |

Operating status display |

|

6. |

Practical Use |

17 |

6.1 |

Switching on the injector |

|

6.2 |

Loading |

|

6.3 |

Starting the injection process |

|

6.4 |

Further possibilities and special features of the injector |

|

7. |

Maintenance, Cleaning and Diagnosis |

19 |

7.1 |

Monitoring and maintenance |

|

7.2 |

Emptying the waste water container |

|

7.3 |

Replacing the heating |

|

7.4Replacing the temperature sensor

7.5Cleaning

7.6Heater test

7.7Service Hint

7.8Information about transport protection

8. |

What if...? |

23 |

8.1 |

Error messages |

|

8.2 |

Resin leaks from the flask |

|

8.3 |

Resin leaks from the injection head |

|

8.4Technical malfunctions

8.5Repair

9. |

Product Specifications |

26 |

9.1 |

Delivery form |

|

9.2 |

Technical data |

|

9.3 |

Acceptable operating conditions |

|

9.4 |

Acceptable transportation and storage conditions |

|

10. Appendix |

27 |

10.1 Program structure |

|

2

List of Parts

1 2 3

17

16

15

14

13

12

11

Injector:

1Temperature sensor

2Heater

3Warnings

4Operating Status Display (OSD)

5Warning light

6Clasps

7Door handle

8Polymerization chamber

9Injection head

10Operating panel

11Rubber feet

12Waste water container

13Power cord

14Housing

15Capsule

16Safety door

17Flask

18Knurled screw for hood

19Air vents

20On/Off switch

21Power socket

22Recessed grip

23USB connection

24Rating plate

25Flask holder

26Discharge opening

4

5

3

6

6

7

8

9

10

18

19

20

21

18

22

23

24

3

2

17

25 |

1 |

26 9

15 |

6 |

Flask: |

|

|

|

|

40 |

Isolating shoulder |

45 |

Locking clasp |

|

41 |

Centering peg |

46 |

Recess for the aeration filter |

|

42 |

Flask lid |

47 |

Screws |

|

43 |

Flask housing |

48 |

Heating surface |

|

44 |

Locking clasp attachment |

49 |

Sensor surface |

|

|

43 |

|

46 |

47 |

|

|

|

||

|

|

|

|

|

|

|

41 |

|

|

|

|

|

44 |

48 |

|

|

|

|

|

45 |

40 |

40 |

45 |

|

|

42 |

|

44 |

49 |

|

61 Access former half |

62 Access former full |

63 Centring insert |

64 Deflasking aid |

4

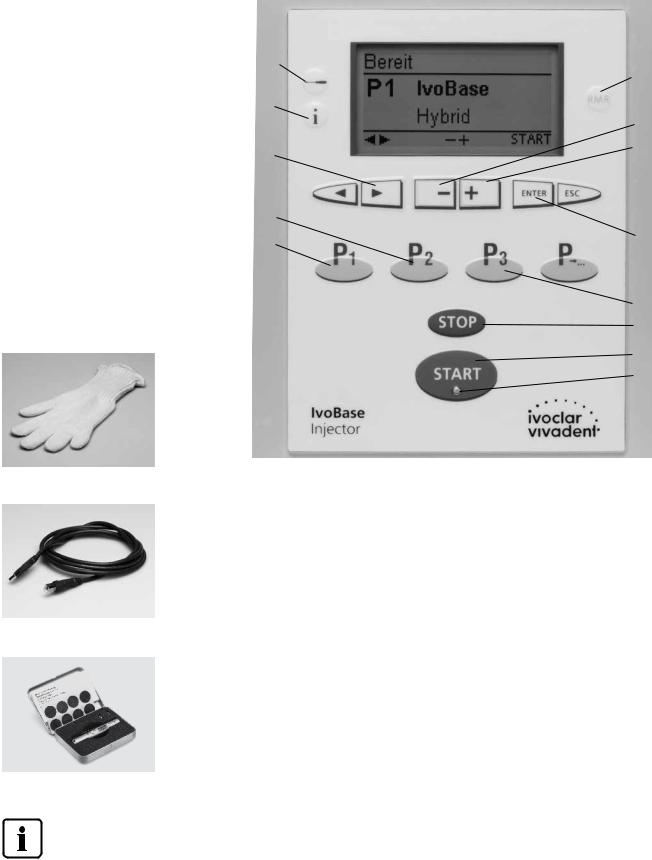

Operating panel

71Settings key

72Information key

73Right cursor key

74Left cursor key

75Program 2 key

76Program 1 key

77RMR key

78– key

79+ key

80ESC key

81ENTER key

82Next Program Number key

83Program 3 key

84STOP key

85START key

86Start LED

100 Thermal glove

101 USB download cable

102 Temperature Checking Set

71

72

73

74

75

76

Please note that the list of parts applies to the entire Operating Instructions. References are made to the parts and/ or the numbering in later chapters.

77

78

79

80

80

81

82 83 84

82 83 84

85

86

5

1. Introduction / Signs and Symbols

1.1Preface

Dear Customer

Thank you for having purchased the IvoBase Injector. It is a modern injection device for dental applications. The injector has been designed according to the latest industry standards. Inappropriate use may damage the equipment and be harmful to personnel. Please observe the relevant safety instructions and read the Operating Instructions carefully.

Enjoy working with the IvoBase Injector.

1.3 Notes regarding the Operating Instructions

– |

Device concerned: |

IvoBase Injector |

– |

Target group: |

Dental technologists |

These Operating Instructions facilitate the correct, safe and economic use of the IvoBase Injector. Should you lose the Operating Instructions, extra copies can be ordered at a nominal fee from your local Ivoclar Vivadent Service Centre or downloaded in the Download Center at www.ivoclarvivadent.com/downloadcenter.

1.2 Introduction

The signs and symbols in these Operating Instructions and on the injector facilitate the finding of important information and have the following meanings:

Risks and dangers

Important information

Contraindication

1.4 Note on the different voltage versions

The injector is suitable for the following voltage range:

100 – 120 V / 50 Hz – 60 Hz

200 – 240 V / 50 Hz – 60 Hz

No manual switch-over is necessary to use the individual voltage versions. Please make sure that the voltage indicated on the rating plate complies with the local power supply before setting the injector into operation.

Burn hazard

Risk of crushing

Fire hazard

The Operating Instructions must be read.

6

2. Safety First

This chapter is especially important for individuals who |

2.1.1 |

work with the IvoBase Injector or who have to carry out |

|

maintenance or repair work. This chapter must be read |

Risks and dangers |

and the corresponding instructions followed! |

|

2.1 Indications |

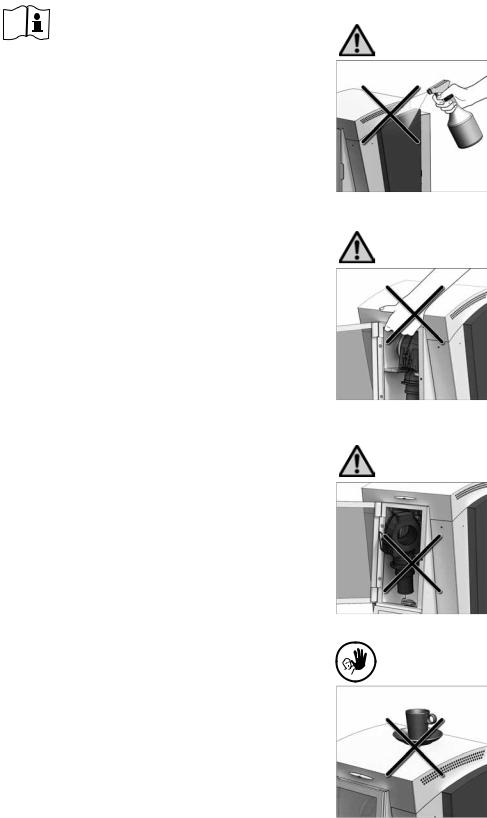

Make sure that no liquids or other |

||

foreign substances enter the |

|||

|

|

injector during cleaning. |

|

The IvoBase Injector is solely intended for the processing of special |

|

||

resins for dental applications. It should be used for this purpose |

|

||

only. Uses other than the ones stipulated, e.g. injection of other |

|

||

materials, etc., are contraindicated. The manufacturer does not |

|

||

assume any liability for damage resulting from misuse. The user is |

|

||

solely responsible for any risk resulting from failure to observe these |

|

||

Instructions. |

|

||

Further instructions to assure proper use of the injector: |

2.1.2 |

||

|

|||

– |

The instructions, regulations and notes in these Operating |

Risks and dangers |

|

|

Instructions must be observed. |

||

|

|

||

– |

The instructions, regulations and notes in the material's Instruc- |

|

|

|

tions for Use must be observed. |

The injector may only be carried |

|

– |

The injector must be operated under the indicated environmental |

||

by supporting the bottom under |

|||

|

and operating conditions (see Chapter 9). |

||

|

the operating field and by the |

||

– |

The IvoBase Injector must be properly maintained. |

||

recessed grip at the rear of the |

|||

|

|

||

injector.

2.1.3

Risks and dangers

Make sure that the flask is correctly positioned.

The injection program must not be started if the flask is incorrectly positioned.

2.1.4

Contraindication

Foreign objects must not be placed on the injector.

7

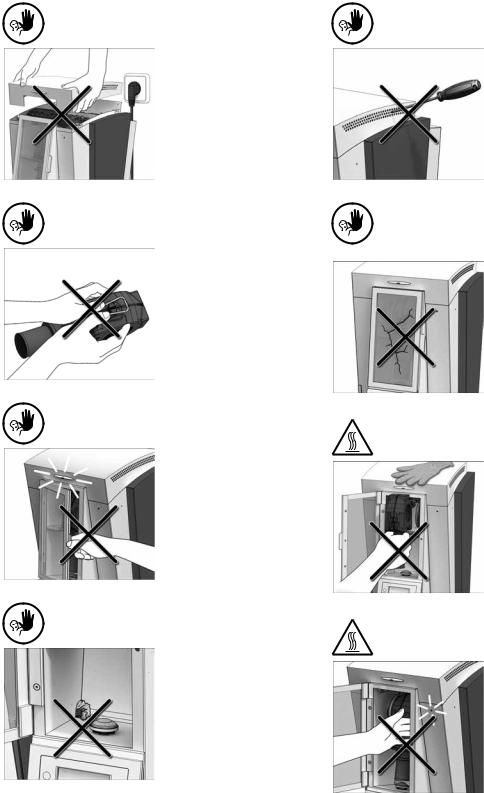

2.1.5 |

2.1.9 |

Contraindication |

Contraindication |

The hood may only be removed while the injector is switched off and the power plug disconnected.

Foreign objects must not enter the air vents.

2.1.6 |

2.1.10 |

Contraindication |

Contraindication |

The locking clasp may only be removed from the flask by rotating, rather than pushing it.

The injector must not be operated if it shows visible damage, for example, at the heater, safety door or clasps, etc.

2.1.7

2.1.11

Contraindication

Burn hazard

The safety door must not be opened while a program is in progress.

The flask must not be loaded or removed from the injector without thermal glove.

2.1.8

2.1.12

Contraindication

Burn hazard

If the discharge outlet is clogged, the injector must not be operated.

Do not reach into the hot injector!

Do not reach into the injector while the red warning light is still on. When switched off, the injector may still be hot even if the warning light is not on.

8

2.2 Health and safety instructions

This injector has been designed according to EN 61010-1 and has been shipped from the manufacturer in excellent condition as far as safety regulations are concerned. To maintain this condition and to ensure risk-free operation, the user must observe the notes and warnings contained in these Operating Instructions.

–It is important that the user becomes familiar with the warnings and operating conditions to prevent injury to personnel or damage to materials. The manufacturer is not responsible for damage resulting from misuse or failure to observe the Operating Instructions. Warranty claims cannot be accepted in such cases.

–Before switching on the injector, make sure that the voltage indicated on the rating plate complies with your local power supply.

–The mains socket must be equipped with a residual current operated device (FI).

–The power plug may only be inserted into sockets with protected contacts.

–Place injector on a fire-proof table. Observe local regulations (e.g. distance to combustible substances or objects, etc.).

–Always keep the air vents unobstructed.

–Do not touch any parts that become hot during operation of the injector. Burn hazard!

–Clean injector only with a dry, soft cloth. Do not use any solvents! Disconnect power before cleaning and allow the injector to cool down!

–The injector must be cool before it is packed for transportation.

–Use original packaging for transportation purposes.

–Before calibration, maintenance, repair or change of parts, the power must be disconnected and the injector has to be cool if it has to be opened.

–If calibration, maintenance or repair has to be carried out with the power connected and injector open, only qualified personnel who are familiar with the risks and dangers may perform the procedures.

–After maintenance, the required safety tests (high voltage resistance, protective conductor, etc.) must be carried out.

–Make sure that only fuses of the indicated type and rated current are used.

–If it is assumed that safe operation is no longer possible, the power must be disconnected to avoid accidental operation

–if the injector is visibly damaged.

–if the injector does not work.

–if the injector has been stored under unfavourable conditions over an extended period of time.

–Use only original spare parts.

–Observe the correct temperature range to ensure faultless operation (see section 9.2 Technical data).

–If the injector has been stored at very low temperatures or high atmospheric humidity, it must be dried or left to adjust to the room temperature for approx. 4 hours prior to connecting power.

–The injector is tested for use at altitudes of up to 2000 m (6562 ft) above sea level.

–The injector may only be used indoors.

Any disruption of the protective conductor either inside or outside the injector or any loosening of the protective conductor may lead to danger for the user in case of a malfunction. Deliberate interruptions are not permissible.

Material developing harmful gases must not be processed.

Monomer is used in the processing of denture base material in the IvoBase Injector. This substance contains methyl methacrylate (MMA), which is highly flammable. Please handle this substance with care and avoid direct skin contact. Please observe the detailed health and safety instructions contained in the Instructions for Use of the respective material.

Disposal:

The apparatus must not be disposed of in the normal domestic waste. Please correctly dispose of old devices according to the corresponding EU council directive. Information regarding disposal can be found on the respective national Ivoclar Vivadent website.

9

Loading...

Loading...