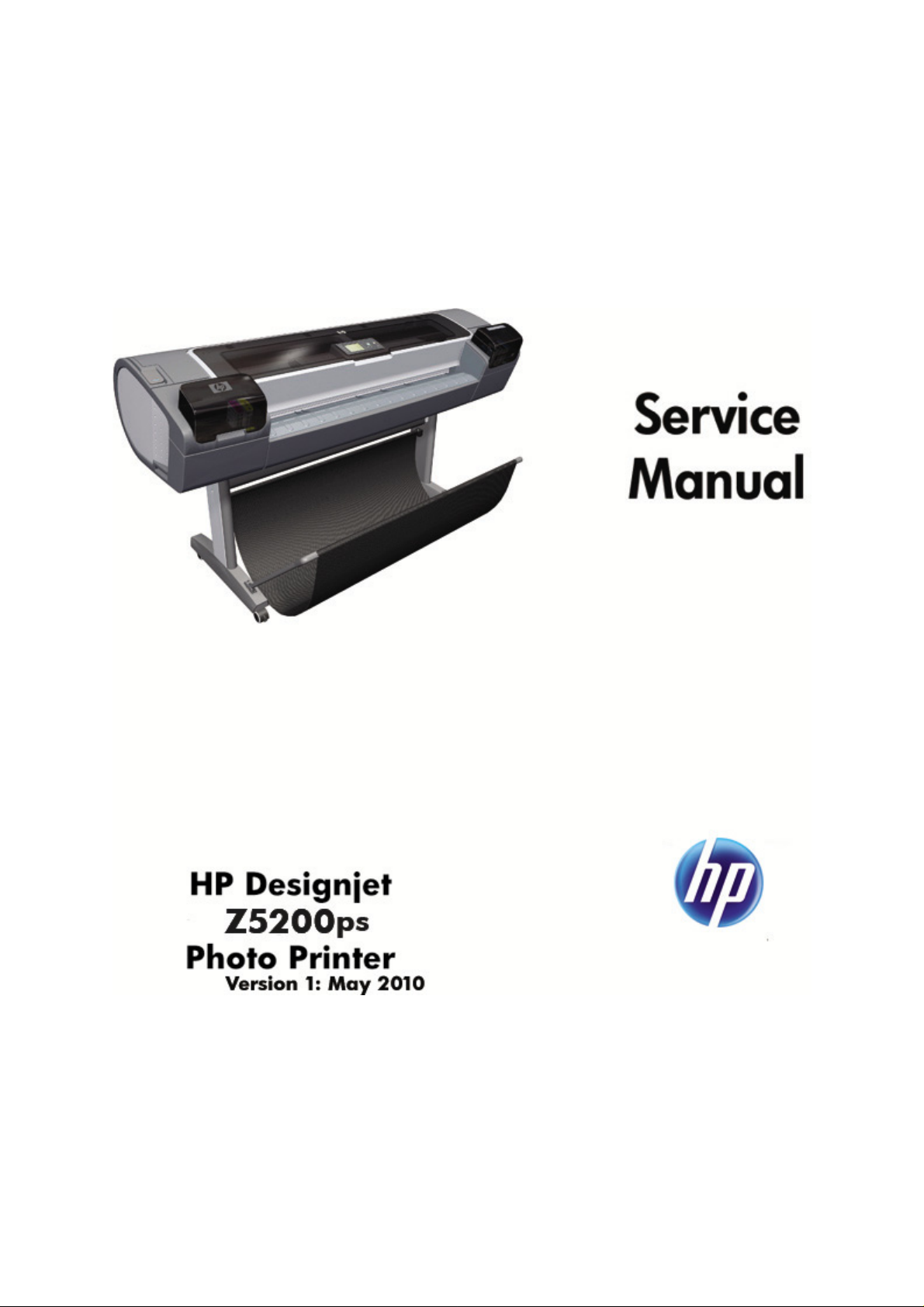

HP DesignJet Z5200ps Photo Service Manual

Notices

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

material, including, but not limited to,

the implied warranties of

merchantability and fitness for a

particular purpose.

Hewlett-Packard shall not be liable for

errors contained herein or for incidental

or consequential damages in connection

with the furnishing, performance, or use

of this material.

WARNING! The procedures described

in this manual are to be performed by

HP-qualified service personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or

injury may result if you do not take the

following precautions:

●

Ensure that the ac power outlet

(mains) has a protective earth

(ground) terminal.

●

Disconnect the Printer from the

power source prior to performing

any maintenance.

●

Prevent water or any other liquids

from running onto electrical

components or circuits, or through

openings in the enclosure.

Electrostatic Discharge

Refer to the beginning of

Diagnostic

Menu on page 73 of this manual, for

precautions you should take to prevent

damage to the Printer circuits from

electrostatic discharge.

Safety Symbols

General definitions of safety symbols are

given immediately after the table of

contents.

WARNING! The Warning symbol calls

attention to a procedure, practice, or the

like, which, if not correctly performed or

adhered to, could result in personal

injury. Do not proceed beyond a Warning

symbol until the indicated conditions are

fully understood and met.

CAUTION: The Caution symbol calls

attention to an operating procedure,

practice, or the like, which, if not correctly

performed or adhered to, could result in

damage to or destruction of part or all of

the product. Do not proceed beyond a

Caution symbol until the indicated

conditions are fully understood and met.

Content Management Department,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

ENWW iii

Using this Manual

Purpose

This Service Manual contains information necessary to test, calibrate and service:

●

HP Designjet Z5200 Photo Printer 44 inch (Model CQ 11 3A)

For information about using this product, refer to the corre sponding User a nd Quick Reference Gui des.

Readership

The procedures described in this Service Manual are to be performed by HP Certified service personnel

only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are located in

Parts and Diagrams

on page 151.

Conventions

A small arrow

indicates a link to other parts of the Service Manual where you can find in fo rmation

related to the topic you are consulting.

ENWW v

Table of contents

1 Ink Supplies Troubleshooting & Print Quality

Introduction ..................................................................... .................................... .................................. 2

Troubleshooting System Error Codes .................................................................................................. 2

Performing a Service Test on a failed Assembly ..................................... ................................... .......... 2

Performing the Necessary Service Calibrations ................................................................................... 2

Solving Ink Supplies Problems .................................. .. ..... ..... .. ..... ..... .. ..... ..... .. ..... ..... .. ..... ..... .. ............. 3

Solving Print Quality Problems ................................................ ............................. ................................ 3

Using the Front Panel ......................................................................... .................................................. 3

The Printer does not Power ON ........................................................................................................... 4

The Printer Continuously Rejects Printheads ........................... ................................... ......................... 4

What to do if the Front Panel is blank .................................................................................................. 5

Cover Sensors are not Working ........................................................................................................... 6

The Line Sensor has Problems Detecting Media ................................................................................. 6

Problems with Color Accuracy ............................................................................................................. 6

Troubleshooting Media Jams/Printhead Crashes ................................................................................ 6

Banding at variable extreme environmental conditions ........................................................................ 7

Worm marks on HP Coated media with light area fills ......................................................................... 7

Solving Media-Handling Problems ....................................................................................................... 7

What to do when plastic parts on the Media Basket become damaged during printer setup ............... 8

Solving Ink Supplies problems ............................................................................................................. 9

Ink Cartridges ...................................................................................................................... 9

Available Ink Cartridges ..................... ... .......................... ........................... .......................... 9

Printheads .......................................................................................................................... 10

Available Printheads .......................................................................................................... 10

General Information About the Ink Supplies ...................................................................... 10

General Precautions When Handling Ink Supplies ............................................................ 11

When Should You Replace the Ink Supplies? ................................................................... 11

Ink Cartridge Levels, Information, and Replacement ......................................................................... 11

Ink Cartridge Levels ............................ .... ... .... ..... .. ..... .... ... .... .... ... .... ..... .. ..... .... ... .... ..... .. .... 11

Obtaining Ink Cartridge Information ....................... .. .......................... ......................... ....... 12

Changing an Ink Cartridge .......................... ........................... ........................... ................. 13

Printhead Information, Replacement and Alignment ................................................................ .......... 15

Obtaining Printhead Information ........................................................................................ 15

Changing a Printhead ........................................................................................................ 16

Aligning Printheads ................................. ..... ....... ....... ..... ....... ....... .... ........ ...... .... ....... ........ 18

Ink Cartridge and Printhead Status Messages ................ .. ............................ ........................... .......... 20

Ink Cartridge Status Messages ............................................................... ........................... 20

ENWW vii

Printhead status messages ............................................................................................... 20

Solving Ink Supplies Problems ............................... ...... . ..... ..... .. ..... ..... .. ..... ..... .. ..... ..... .. ..... ..... ....... ... . 21

You Cannot Insert the Ink Cartridge Into the Printer .................................. ........................ 21

You Cannot Insert the Printhead Into the Printer ............................................................... 21

The front panel says to reset or replace a printhead ......................................................... 21

Maintaining and Cleaning the Printheads ................................................................ ........................... 22

Clean the printheads .......................................... ... ....... ..... ... ..... ....... .. ...... ..... .... ...... ..... .... .. 22

Flex Contacts Cleaning Tool ............................... ... .................................. .......................... 22

Print Quality ................................... .. ..... ..... ... ..... ...... . ..... ...... ... ..... ..... .. ..... ..... .. ..... ..... .......................... 23

Print Quality Troubleshooting Actions ........................................................ ........................ 23

The Service Image Quality Diagnostic Print ............................................... ............................ ............ 24

What is the Service Image Quality Diagnostic Print? ........................................................ 24

Considerations for Printing the Diagnostic Print ................................................................ 24

Printing the Diagnostic Print .............................................................................................. 24

Reading the Diagnostic Print Results ........................ ............................ ............................. ................ 25

Diagnostic Part 1: Printhead Reliability ......................................................... ..................... 25

Diagnostic Part 2: Printhead Alignment ............................................................................. 26

Diagnostic Part 3: Printheads & Paper Advance ............................................................... 28

No Printing Defects Found in the Diagnostic Print ................................ ............................. 29

The Advanced Diagnostic Prints ........................................................................................................ 29

What are the Advanced Diagnostic Prints? ....................................................................... 29

Printing the Advanced Diagnostics Print .............................................................. .............. 30

Reading the Advanced diagnostic Print Results ................................................................................ 30

Paper Advance .................................................................................................................. 30

Printhead Alignment .......................................................................................................... 33

Nozzle Health .................................................................................................................... 34

Force Drop Detection .......................................... .... ..... ...... .. ....... ..... ... ..... ....... .. ...... ..... .... .. 35

Troubleshooting Print Quality Problems .............................. ... .... .... .... ... ..... ... .... ..... .. ..... ..... .. ..... ......... 36

Print Quality General Advice .............................................................................................. 36

Horizontal Lines Across the Image (Banding) ................................................................... 36

Lines are Missing, Too Thin, or Too Thick ................................ ... ................................ ...... 37

Problems with Stepped Lines ............................................................................................ 37

Lines are Printed Double or in Wrong Colors .................................................................... 38

Lines are discontinuous ..................................................................................................... 38

Lines are Blurred (Ink Bleeds from Lines) ......................................................................... 39

Problems with Graininess .................................................................................................. 39

Paper is not Flat ................................................................... ................................... ........... 40

Print Scuffing or Scratching when Touched .............................. ..... ... ..... ..... .... ..... ...... .. ...... 41

Ink marks on the paper ...................................................................................................... 41

Problems with the Edges of objects ................................ .................................. ................. 42

Bronzing ............................................................................................................................. 42

Black and white prints do not look neutral ......................................................................... 43

Horizontal lines at the end of a cut sheet print ............................ .. ................................. .... 43

Vertical lines of different colors ................................................... .......................... ............. 43

White spots on the print ..................................................................................................... 43

Problems with Color Accuracy ................................................. .......................... ................ 43

Output Only Contains a Partial Print ................... .......................... .......................... ........... 44

viii ENWW

Problems with Image Clipping ........................................................................................... 44

Some objects are missing from the printed image ......................................... ... ... .............. 45

A PDF file is clipped or objects are missing ................................................................. ...... 45

2 System Error Codes

Introduction ..................................................................... .................................... ................................ 46

Continuable and Non-Continu abl e Erro r Codes ................................................................................. 47

System Error Code Brief Descriptions ................................................................................................ 47

System Error Codes - Full Descriptions ............................................................................................. 50

3 Diagnostic Menu

Introduction ..................................................................... .................................... ................................ 74

Diagnostics - Self Test .................. .. ........................... ........................... ............................ . 74

Service Tests (Diagnostics) ................................ ... ....... ...... .. ....... ....... . ....... ....... . ....... ....... .. ............. .. . 74

Entering the Service Tests Menu ............................................................. .......................... 76

1. Scan Axis ...................................................................................................... 76

2. Paper Drive .................................................................................... ............... 87

3. Electronics Module .......................................... ........................ ...................... 90

4. Carriage Assembly ........................................... ......................... .................... 95

5. Sensors ....................................................................................................... 101

6. Color Sensor (ESP) ............................ .. . .. .. .......................... .. .. . .. . .. .............. 104

7. Ink Delivery System (IDS) ........................................................................... 106

8. Service Station ............................................................................................ 110

9. I/O Information .................................................................... ........................ 117

10. Unit Information ......................................................................................... 117

11. EEROM Reset ........................................................................................... 119

12. Set Unit Configuration ............................................................................... 120

13. Error 71:19 Recovery ................................................................................ 120

.......................................................................................................................................................... 123

4 Service Menu

Entering the Service Utilities Menu .................................................................................................. 124

Introduction ...................................................................................................................... 125

......................................................................................................................... 126

1. Turn Drive Roller .......................................................................................................... 126

2. Purge Tubes ................................................................................................................ 128

3. Set SN ......................................................................................................................... 130

4. Reset Life Counters ..................................................................................................... 131

5. Diagnostic Print ............................................................................................................ 132

6. Set Date and Time ....................................................................................................... 132

7. Enable/Disable Firewall ............................................................................................... 133

8. Enable/Disable Sleep Mode ........................................................................................ 134

9. SNMP Language Write Access ................................................................................... 135

10 Borderless Cut Distance ............................................................................................. 137

Service Calibrations ......................................................................................................................... 138

Entering the Service Calibrations Menu .......................................................................... 139

ENWW ix

Scan Axis Calibration ....................................................................................................... 139

Service Station Calibration .............................................................................................. 140

Paper Advance Calibration .............................................................................................. 140

Drop Detector Calibration ................................................................................................ 145

Line Sensor Calibration ................................................................................................... 146

Carriage PCA .................................... ...... ..... .... ..... ....... . ....... ..... ... ..... ....... ... ...... ..... ... ....... 149

Color Sensor (ESP) Calibration ............................... ...... ... ... ...... ... ..... .... ... ..... .... ... ...... ... .. 149

5 Parts and Diagrams

Printer Support ................................................................................................................................. 152

Center Covers (Front) ...................................................................................................................... 153

Center Covers (Rear) ................... .. ......................... ........................ ......................... ........................ 154

Right Cover ...................................................................................................................................... 155

Left Cover ............................................................ ............................... .............................................. 156

Right Hand Assemblies ..................... ........................ .......................... ........................ ..................... 157

Left Hand Assemblies ...................................................................................................................... 158

Carriage Assembly .......................... .... ..... . .... ..... .. .... .... .. .... ..... . ..... .... .. ..... ... .. ..... .... .. ..... ... ............. ... 159

Scan-Axis Assemblies ............................... .... ........ ....... ..... ....... ........ .... ........ ....... ..... ....... ................. 160

Paper Path Assemblies (Front) ........................................................................................................ 161

Paper Path Assemblies (Rear) ................................ ..... ... .... ..... ... .... ..... ... .... .... .... .... .... .... .... .... ......... 162

Tools 1 ........................................................................ .................................... .................................. 163

Tools 2 ........................................................................ .................................... .................................. 164

Miscellaneous Parts ......................................................................................................................... 165

6 Removal and Installation

Introduction ....................................................................................................................................... 169

Safety Precautions ....................................... .. ....... ..... ... ..... ....... .. ...... ...... ... ..... ....... . ....... .. 169

Electrostatic Discharge (ESD) Precautions ..................................................................... 169

Required Tools ................................................................................................................ 169

Service Calibration Guide to Removal and Installation .................................................................... 170

Using the Service Calibration Guide ........................ .......................... ......................... ..... 170

The Service Calibration Matrix ................................ ................................ ......................... 171

Performing the Service Calibrations and Diagnostic Tests ............................. .. ............... 172

Window ............................................................................................................................................. 174

Front Cover ...................................................................................................................................... 177

Media Output Assembly ................................................................................................................... 178

Right Front Trim ............................................................................................................................... 179

Left Front Trim ......................................................... .............................. ........................................... 181

Right Ink Cartridge Door ................................................................................................................... 182

Left Ink Cartridge Door .............................................. ......................... ......................... ..................... 183

Right Cover ...................................................................................................................................... 185

Left Cover ............................................................ ............................... .............................................. 188

Rear Tray ......................................................................................................................................... 194

Rear Cover .......................... ..... .... ... .... .... ... ... ..... .. .... ..... . ..... .... .. ..... .... ... ... ..... .. .... ..... . ........... ............ 195

Media Lever ................................... ..................................... ..................................... ......................... 196

Media Lever Position Sensor ........................................................................................................... 198

x ENWW

Cutter Assembly ............................ .. ..... ... ... .... .... .. .... .... ... .... .... ... ... ..... .. ... ...... . .... ..... .. .... ................... 199

Right Rear Tray Support .................................................................................................................. 200

Left Rear Tray Support ..................................................................................................................... 201

Front Panel ....................................................................................................................................... 203

Top Cover .............................. .. ..... .... .. .... ..... .. .... .... .. ..... .... ... .... .... .. .... ..... .. ..... ... ... .... .... ......... ... ......... 205

Window Position Sensor .................................................................................................................. 208

Ink Supply Tubes Support Rail ......................................................................................................... 209

Service Station ................................................................................................................................. 214

Drop Detector ................................................................................................................................... 217

Aerosol Fan Assembly ..................................................................................................................... 219

PrintMech PCA ................................................................................................................................. 220

Pen to Paper Space (PPS) Solenoid ................................................................................................ 221

Spindle ..................... .......................................................... .............................................................. 223

Left Spindle Holder ........................................................................................................................... 224

Right Spindle Holder ........................................................................................................................ 224

Clean Out Assembly ................................................ ........................ .......................... ....................... 225

Out Of Paper Sensor ...................................................................................... .................................. 226

Left Roll Guide ......................... .. .......................... ......................... ......................... ........................... 229

Right Roll Guide ............................................................................................................................... 230

Encoder Strip (with spring and attachment nut) ............................................................................... 231

Clean Encoder Strip Procedure .............................................. ....................... ........................ ........... 234

Encoder Strip ................................................ ......................... .......................... ................................. 236

Trailing Cable ................................................................................................................................... 237

Carriage Assembly (with or without Trailing Cable) ......................................................................... 244

Carriage Rear Bushing ..................................................................................................................... 254

Belt Assembly ............................ .. .... ..... .. .... .... .. ..... .... . ..... .... .. ..... .... .. .... ..... .. .... ..... . .... ......... .............. 256

Scan-Axis Motor ............................................................................................................................... 257

Carriage Rail Oiler ............................................................................................................................ 260

Color Sensor (ESP) ......................... . .... .... . .... .... .. ... .... .. ... .... .. ... .... .. .... ... .. ... .... .. ... .... . .... ... .. ............... 262

Line Sensor ...................................................................................................................................... 267

Carriage Cover (includes Carriage Latch) ........................................................................................ 272

Carriage PCA ................................................................................................................................... 276

Right Ink Supply Station ................................................................................................................... 280

Left Ink Supply Station ..................................................................................................................... 284

Ink Supply Tubes ................................................. ......................... ......................... ........................... 288

Formatter ............................................................. ................................................... .......................... 296

Hard Disk Drive .................................... ..................................................... ....................................... 297

Electronics Module (Main PCA and PSU) ........................................................................................ 298

Starwheel Assembly ......................................................................................................................... 301

Print Zone Overdrive ........................................................................................................................ 302

Left Spittoon ..................................................................................................................................... 306

Encoder Disk and Encoder Sensor .................................................................................................. 308

Media Advance Drive ....................................................................................................................... 311

Pinchwheel Assembly ...................................................................................................................... 314

Pinch Roller .....................................................................................................................

................. 319

Left Starwheel Lifter ......................................................................................................................... 320

Right Starwheel Lifter ....................................................................................................................... 322

ENWW xi

Starwheel Motor ............................................................................................................................... 325

Full Bleed Foam ............................................................ ............................. ...................................... 326

7 Preventive Maintenance

Preventive Maintenance ................................... .. ..... ..... .. ..... ..... ... .... ..... ... ..... ..... .. ..... ..... .. ..... ............ 328

Moisture on the Printer .................................................................................................... 328

Noisy Carriage Bushing .................................... ....... ..... ... ..... ....... .. ...... ...... ... ..... ..... ... ...... 328

Belt Swelling ................................ .. ..... ..... . ...... ..... . ...... . ..... ..... .. ..... ..... .. ..... .... ... .... ..... ... .... 328

Cleaning the Printer ............................. ... ................................... .................................. .... 328

Carriage Assembly Lubrication ...................... ..... .... .. ..... ... ... .... ..... .. .... ..... . ..... .... .. ..... .... ... 328

General Cleaning ........................... ..... .... ... ..... ... ..... ... .... ..... .. ..... ..... .. ..... .... ... .... ..... .. .... .... 329

Cleaning the Drive Roller and Overdrive ............................. ............................. .. .. ........... 329

Level of Printer Usage ..................................................................................................... 329

Preventive Maintenance Kits .......................... ... ............................. ............................. ..................... 330

Preventive Maintenance Kit #1 ........................ ... .................................. ........................... 330

Preventive Maintenance Kit #2 ........................ ... .................................. ........................... 331

8 Printer menu Map

xii ENWW

1 Ink Supplies Troubleshooting & Print

Quality

●

Introduction

●

Troubleshooting System Error Codes

●

Performing a Service Test on a failed Assembly

●

Performing the Necessary Service Calibrations

●

Solving Ink Supplies Problems

●

Solving Print Quality Problems

●

Using the Front Panel

●

The Printer does not Power ON

●

The Printer Continuously Rejects Printheads

●

What to do if the Front Panel is blank

●

Cover Sensors are not Working

●

The Line Sensor has Problems Detecting Media

●

Problems with Color Accuracy

●

Troubleshooting Media Jams/Printhead Crashes

●

Banding at variable extreme environmental conditions

●

Worm marks on HP Coated media with light area fills

●

Solving Media-Handling Problems

●

What to do when plastic parts on the Media Basket become damaged during printer setup

●

Solving Ink Supplies problems

●

Ink Cartridge Levels, Information, and Replacement

●

Printhead Information, Replacement and Alignment

●

Ink Cartridge and Printhead Status Messages

●

Solving Ink Supplies Problems

●

Maintaining and Cleaning the Printheads

●

Print Quality

●

The Service Image Quality Diagnostic Print

ENWW 1

●

Reading the Diagnostic Print Results

●

The Advanced Diagnostic Prints

●

Reading the Advanced diagnostic Print Results

●

Troubleshooting Print Quality Problems

Introduction

This chapter will guide you through the relevant steps to take when troubleshooting the printer.

Troubleshooting System Error Codes

Chapter 2, System Error Codes on page 46 contains a list of system error codes and their respective

descriptions and recommended corrective actions. Only try one recommended action at a time and

check if the error code has disappeared.

If you have an error code which is not documented in this Service Manual or you have an error which

you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office.

When reporting the error, have the following information ready:

●

Model and Serial Number of the printer

●

Which firmware revision the printer is using (See Note below). Check firmware in Utilities/

Statistics/Code rev.

●

The complete error number (See Note below).

●

The Service Configuration Print.

●

The Current configuration sheet.

●

Which software application the customer is using (name, version, etc.).

NOTE: When reporting the System Error Code, make sure that you supply the full Error Code

and the firmware version. Without this information, HP Support Personnel cannot help you.

Performing a Service Test on a failed Assembly

If possible, always perform a Service Test on the component/assembly that you are about to replace,

just to make sure that is the component/assembly that has failed.

NOTE: If the test on that component/assembly passes, you should NOT replace it.

For information on the Service Tests and how to use them see Diagnostic Menu on page 73 & Service

Menu on page 124.

Performing the Necessary Service Calibrations

Is the printer calibrated correctly after replacing a component? For information on the Service

Calibrations and how to use them see Chapter 5, Service Calibrations.

NOTE: Remember that certain Calibrations are required even if an Assembly has been

disassembled to gain access to another Assembly or Component.

2 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

Solving Ink Supplies Problems

For information on solving Ink Supplies problems see Solving Ink Supplies problems on page 9 in

this section.

Solving Print Quality Problems

For information on solving Print Quality problems see Print Quality on page 23 in this section.

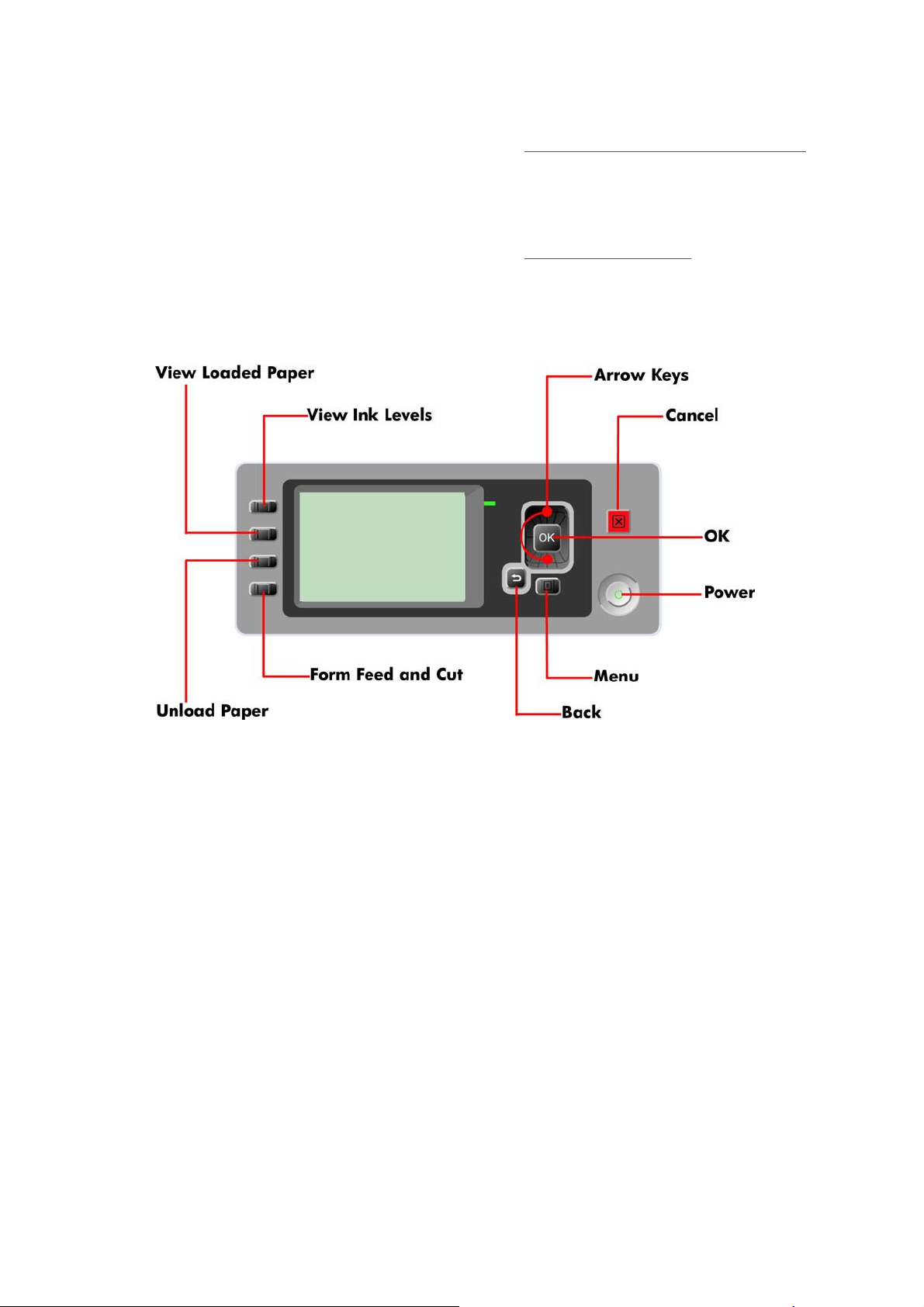

Using the Front Panel

Below is a diagram of the front panel.

Key Function

●

Arrow Keys

Use the Arrow keys to scroll through a menu or toggle between YES or NO when prompted.

●

Cancel

Use the Cancel key to abort or stop a procedure or reject test results.

●

OK

Use the OK key to select a menu option.

●

Power

Use the Power key to turn the printer ON and OFF.

●

Menu

Use the Menu key to enter the main menu.

●

Back

Use the Back key to go back to the previous menu or reject test results.

ENWW Solving Ink Supplies Problems 3

Service Key Combinations

●

Diagnostic mode

With the printer OFF, press and hold the UP and OK keys. While hol ding the Up and OK keys down,

press and hold the Power key to turn on the printer. Hold all three keys until the Power key stops

flashing, usually about 5 seconds.

●

Service Menu (Service Engineers Only)

From the main menu, press and hold the Up and Cancel keys.

●

Service Menu (For users)

From the main menu, press and hold the Down and Cancel keys.

The Printer does not Power ON

1. Check that the power cord is connected correctly to the Printer and to the Power Socket.

2. Check that the Power Switch on the BACK of the Printer is in the ON position.

3. Check to see the LED on the Front Panel Power Switch are On.

4. Check that the Front-Panel Cable is correctly connected to the Electronics Module. Also make sure

that the Front-Panel cable is not damaged.

5. Replace the Power Supply Unit

Refer Electronics Module (Main PCA and PSU) on page 298.

The Printer Continuously Rejects Printheads

1. Clean the flex contacts on the Printhead and in the Carriage Assembly using the Carriage

Interconnect Wiper (Refer to

Flex Contacts Cleaning Tool on page 22) and try again.

2. If ALL the Printheads are rejected (the status message on th e F ron t Pa ne l do es NOT show "OK"

for ALL the Printheads) then perform the Electronic Module Test

Refer 3. Electronics Module

on page 90.

4 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

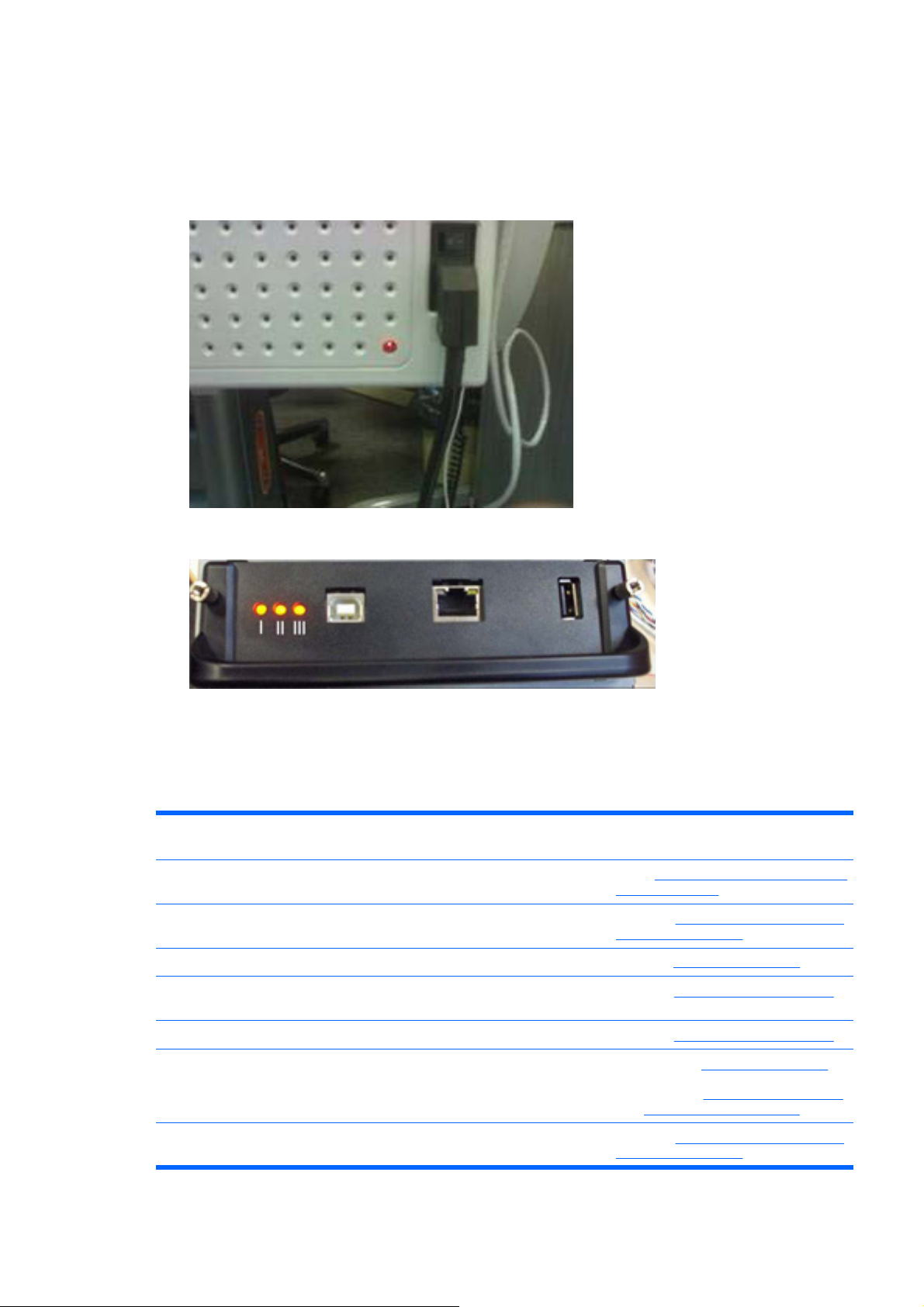

What to do if the Front Panel is blank

The LEDs of the formatter (visible through the cover) and the power supply can help you troubleshoot

a problem when the Front Panel is blank.

1. The following image shows the Power Supply LED, looking through the cover.

2. The following image shows the Formatter LEDs, which are marked I, II and III.

▲

Use the following table to interpret the LEDs and find the so urce of the problem. Remember that

you should read these LEDs when you push the Power button. Some combinations may require

the replacement of two or more components. In th is case, always replace one component at a time.

Test the printer to see if the problem has disappeared (ch eck the LEDs again). If the same LED

sequence continues, replace the next component indicated in the table.

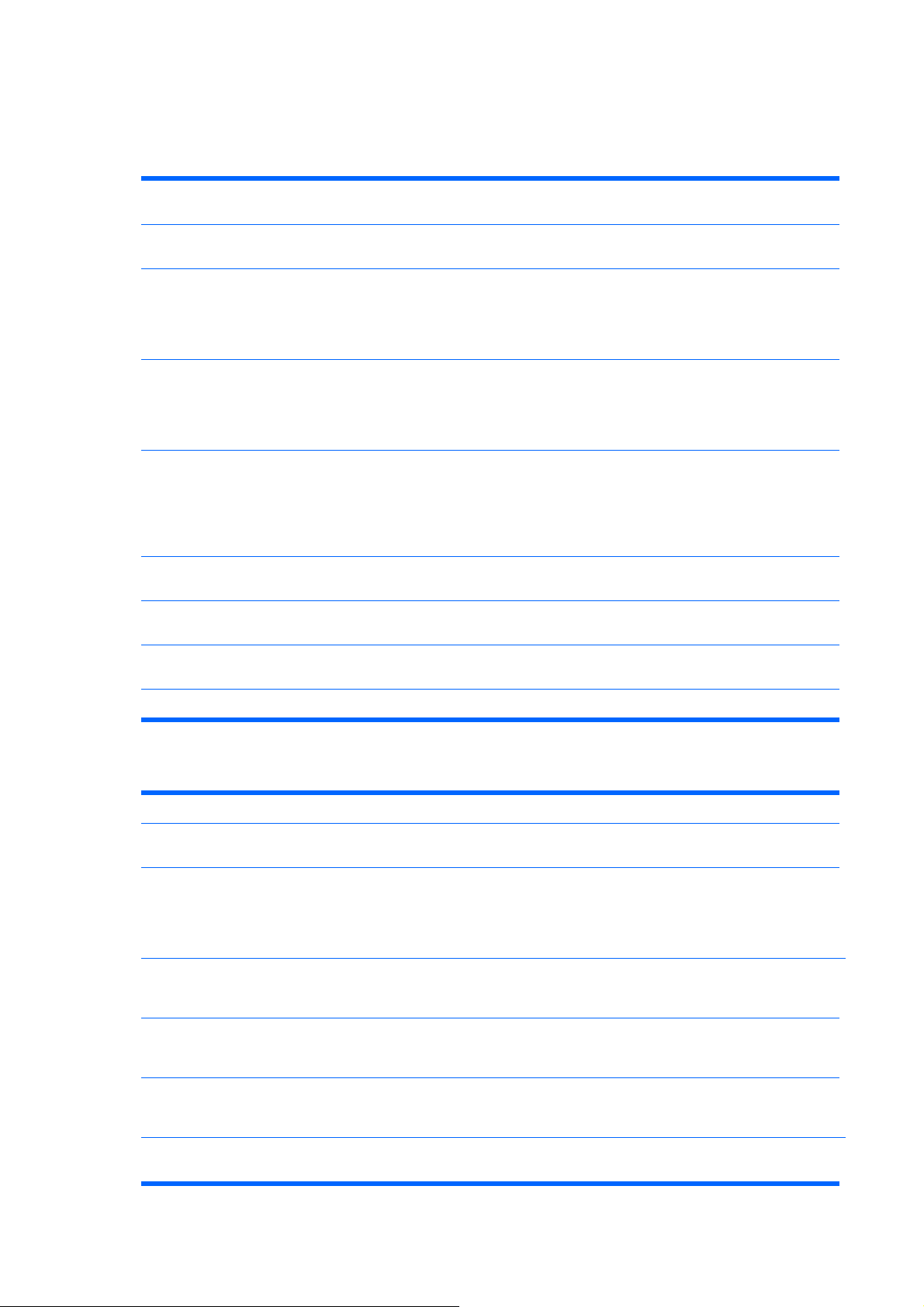

Power

Supply LED

Formatter

LED 1

Formatter

LED 2

Formatter

LED 3

Front Panel

Status

Solution (part replacement)

1 Off Off Off Off Off Power Electronics Module (Main PCA and

PSU) on page 298

2 On Off Off Off Off Main PCA Electronics Module (Main PCA

and PSU) on page 298

3 On On Off N/A N/A Formatter Formatter on page 296

4 On On

(Flashing)

Off Off N/A Hard Disk Hard Disk Drive on page 297

5 On On On (flashing) Off N/A Hard Disk Hard Disk Drive on page 297

6 On On On Off N/A 1. Formatter Formatter on page 296

2. Main PCA

Electronics Module (Main

PCA and PSU) on page 298

7 On On On On (flashing) N/A Main PCA Electronics Module (Main PCA

and PSU) on page 298

ENWW What to do if the Front Panel is blank 5

8 On On On On Front Panel

(Light on)

1. Front Panel Front Panel

on page 203

2. Formatter

Formatter on page 296

3. Main PCA

Electronics Module (Main

PCA and PSU) on page 298

4. Front Panel Cable

Front Panel

on page 203

9 On On On On Off Front Panel Front Panel on page 203

Cover Sensors are not Working

1. Perform the Sensors Test Refer 5. Sensors on page 101.

2. Check if the cable for the faulty sensor is not damaged and is connected correctly.

3. Replace the faulty Sensor.

The Line Sensor has Problems Detecting Media

1. Check the type of media that is being used since the Line sensor may have problems detecting

transparent media or some types of Non-HP media. Try loading white HP media in to the Printer

and check if the Line sensor detects it.

2. The Line Sensor is not calibrated correctly. Perform the Line Sensor Calibration

Refer Line

Sensor Calibration on page 146.

3. The Line Sensor is damaged or faulty. Replace the Line Sensor

Line Sensor on page 267.

Problems with Color Accuracy

The Color Sensor (ESP) is a powerful tool unique to the Z series printers to maintain color accuracy. If

you notice any problems with colors, perform the Color Sensor (ESP) calibration. Refer to

Color Sensor

(ESP) Calibration on page 149.

Troubleshooting Media Jams/Printhead Crashes

The failure modes "media jam" and "head crash" are grouped together because in many cases a media

jam causes the media to lift up into the Carriage path and cause a Printhead crash, thus causin g many

media jam failures to be reported as head crashes.

1. Did the media jam occur when loading media?

●

If the client has had media jams, it is common for pieces of media to get stuck in the media

path. Clear the media path.

NOTE: When clearing a media jam, sometimes media is stuck in the paper path. To clear this,

you must lift the Media Lever and insert thicker media into the p ap er pa th t o push ou t th e media

that is still stuck there.

2. Is the customer using non-HP media?

●

The use of non-HP media can easily be the cause of media jams and head crashes (espec ially

head crashes because HP media is specially formulated to avoid cockle, one of the primary

causes of head crashes). If the media is not HP approved, advise the customer to use HP

media and check to see if the problem is now solved.

6 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

Banding at variable extreme environmental conditions

Since the Accuracy Calibration has been done at normal environmental conditio ns, printing in extreme

environmental conditions will cause banding because the advan ce of th e Media Advance Roller does

not correspond to the same conditions that the calibra tio n was done in. To solve the problem, try the

following:

Perform the Accuracy Calibration in the new environmental conditions (Refer to the User’s Guide).

Worm marks on HP Coated media with light area fills

Light bands (S-shaped) in Paper axis direction where light area fills are printed, causing unacceptable

Image Quality defect.

●

Print the Service Configuration Print and check if the level of Humidity is very low (below 30%).

Increasing humidity may help in reducing the severity of th e p ro blem.

NOTE: The media is causing the problem and NOT the Printer. Do not attempt to try and replace

Printer parts to solve this problem.

Solving Media-Handling Problems

The Front Panel indicates that media is misalig ne d or incorrectly positioned.

Roll media

●

The roll may be loaded the wrong way. The paper should load over the roll toward you.

●

Check that the paper is correctly loaded onto the spindle.

●

The paper may be loaded at an angle. The right-hand edge must be aligned with the blue line on

the Print Platen.

NOTE: Ensure that the paper is wrapped tightly on the roll. This is a very imp ortant step to rememb er

because if this is not done, the media may be loaded at an angle, causing the media to be rejected.

Sheet media

●

Always load sheet media using the Rear Input Tray. Do NOT load the media as you would load

roll media.

●

It must be loaded with the right-hand edge against the blu e line on th e Prin t Platen.

●

The media may be crumpled or warped or may have irregular edges.

●

If hand-cut media is used, the edges may not form a right-angle or they may be rough. If possible,

hand-cut media should not be used. Only purchased sheet media should be used in the Printer.

●

If you have problems with paper jams, check that the Overdrive is not obstructed by bits of paper

or using the Turn Drive Roller Service Utility

1. Turn Drive Roller on page 126.

ENWW Banding at variable extreme environmental conditions 7

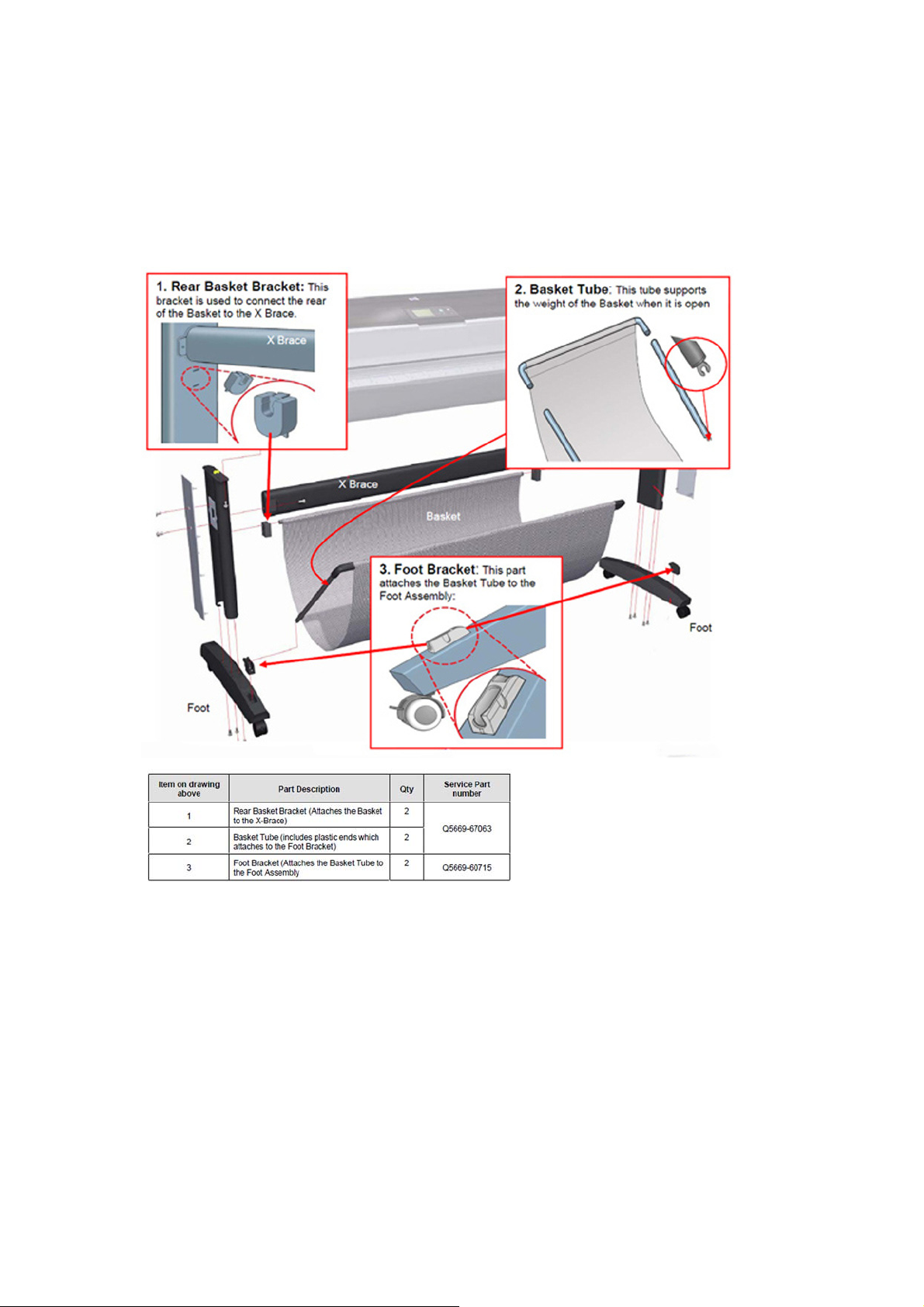

What to do when plastic parts on the Media Basket become

damaged during printer setup

The following information explains what to do if one or more of the back plastic brackets or the Basket

Tube becomes broken. The information helps to identify which service parts to order as replacements.

There are three plastic parts that could break during printer installation and need replacing. Use the

pictures below to identify with the customer which part needs replacing (numbers 1, 2 or 3).

8 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

Solving Ink Supplies problems

What are Ink Supplies?

For each of the ink colors used in the printer, there are two components, th e Printhead and Ink Cartridge.

These components are called Ink Supplies.

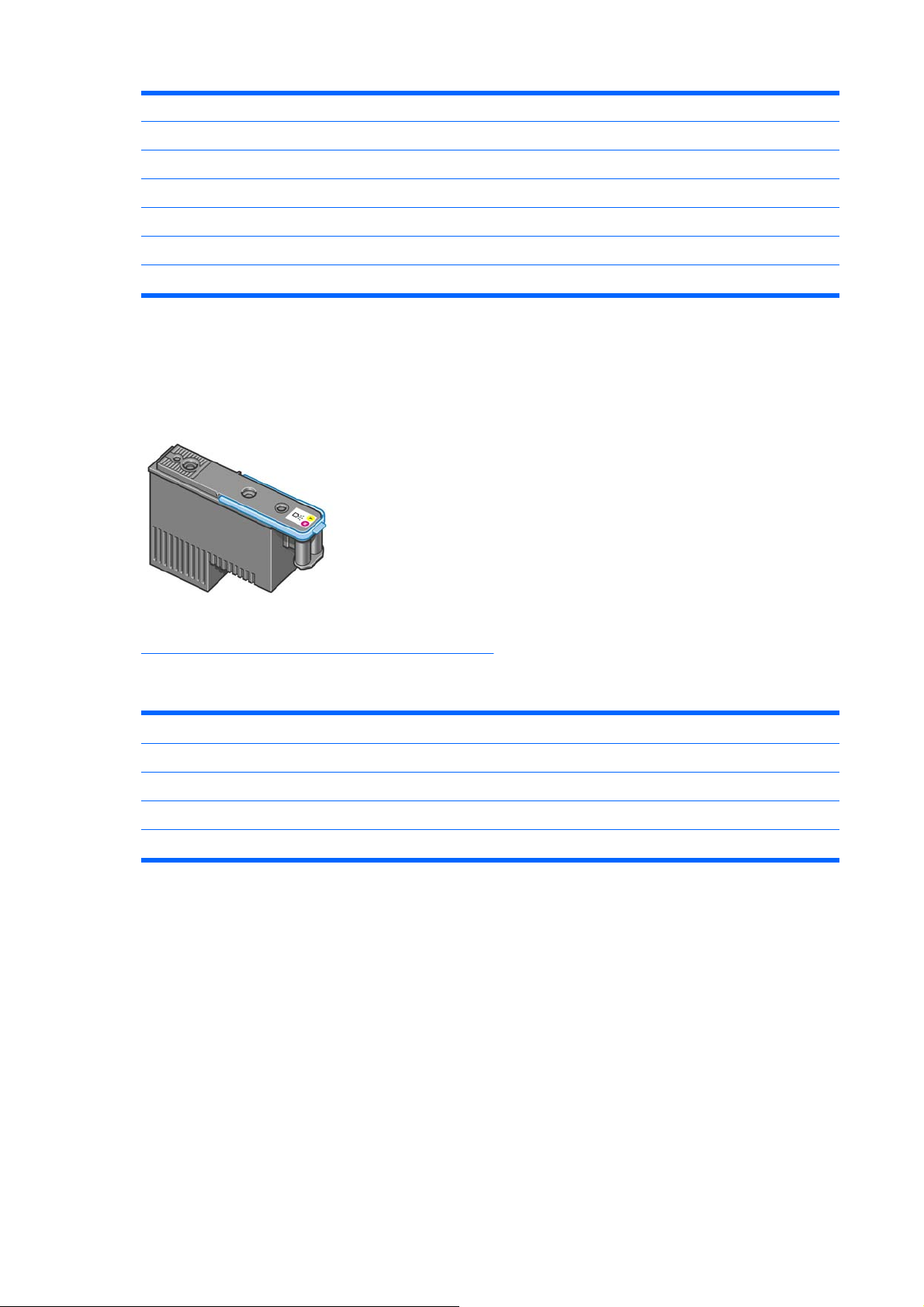

Ink Cartridges

The printer's Ink Cartridges provide ink to the Printheads. The color Ink Cartridges supplied with the

printer have a capacity of 69ml but optional 130 ml and 30 0 ml are also ava ilab l e.

The Ink Cartridges require no maintenance or cleaning. As long as each Ink Cartridge is inserted

correctly into its slot, the ink will flow to the Printheads. Because the Printheads control the amount of

ink transferred to the page, you will continue to see high quality printing results that require no

maintenance or cleaning. As long as each Ink Cartridge is inserted correctly into its slot, the ink will flow

to the Printheads. Because the Printheads control the amount of ink transferred to the page, you will

continue to see high quality printing results even when the ink levels are getting low.

The front panel displays the status of the Ink Cartridge. Using the front panel, detailed information can

be checked on the Ink Cartridges.

Available Ink Cartridges

Color Part number 69ml Part number 130ml Part number 300ml

HP 70 Matte Black C9436A C9448A CN635A

ENWW Solving Ink Supplies problems 9

HP 70 Photo Black C9437A C9449A CN633A

HP 70 Light Gray C9439A C9451A CN634A

HP 70 Cyan C9440A C9452A CN636A

HP 70 Magenta C9441A C9453A CN629A

HP 70 Yellow C9442A C9454A CN630A

HP 70 Light Magenta C9443A C9455A CN631A

HP 70 Light Cyan C9389A C9390A CN632A

Printheads

The Printheads are extremely durable an d d o n ot need to be replaced every time an Ink Cartridge is

replaced. They are independent of the Ink Cartridges and will continue giving excellent image quality

results even if the Ink Cartridges are low on ink.

If you notice a decline in print quality such as lines or dots missing from text/graphics, go to

Troubleshooting Print Quality Problems on page 36.

Available Printheads

Printhead Type Part number

HP 70 Matte Black & Cyan C9404A

HP 70 Light Magenta & Light Cyan C9405A

HP 70 Magenta & Yellow C9406A

HP 70 Photo Black & Light Gray C9407A

General Information About the Ink Supplies

For optimum results from the printer and modular ink delivery system always follow these guidelines

when handling the ink supplies:

●

Always install the Ink Cartridges and Printheads befo re t he exp ira tion da te , wh ich is o n the

packaging.

●

Install Ink Cartridges and Printheads in their color-coded slots.

●

Follow the instructions on the front panel of the Printer during installation.

●

Avoid unnecessary removal of the Ink Cartridges and Printheads.

10 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

●

When turning off the Printer always use the power Off button on the front panel. The Printheads

are then stored correctly which prevents them from drying out.

●

The Ink Cartridges should never be removed while the printer is printing. They should only be

removed when the printer is ready for you to replace them. The front panel will guide you through

the removal and installation procedure.

General Precautions When Handling Ink Supplies

Use the following precautions when handling Ink Supplies:

NOTE: Do not touch, wipe or attempt to clean the printhead nozzles. This can damage the printhead.

●

Handle the ink supplies with care. In particular the Printhead, which is a hi gh precision de vice and

must be handled carefully.

●

Do not touch the Printhead nozzles.

●

Do not put the Printhead down on the nozzles.

●

Do not be rough when handling the Printheads. Always set them down gently.

●

Do not drop the Printheads.

●

Proper handling will assure optimum performance throughout the Printhead life.

●

Do not touch the end of the Ink Cartridge which is inserted into the printer as there may be a small

amount of ink on the connection.

●

Avoid storing partially used Ink Cartridges on their ends.

When Should You Replace the Ink Supplies?

When to change the ink supplies is mostly determined by you with guidance from the front panel. In

conjunction with the messages displayed in the front panel and the message explanations in this

chapter, you will be able to choose for yourself when is the right time to change the ink supplies.

The Printer will also display the ink level and will tell you when the ink supply is low on ink. This means

you have constantly updated information about the ink supplies.

Ink Cartridge Levels, Information, and Replacement

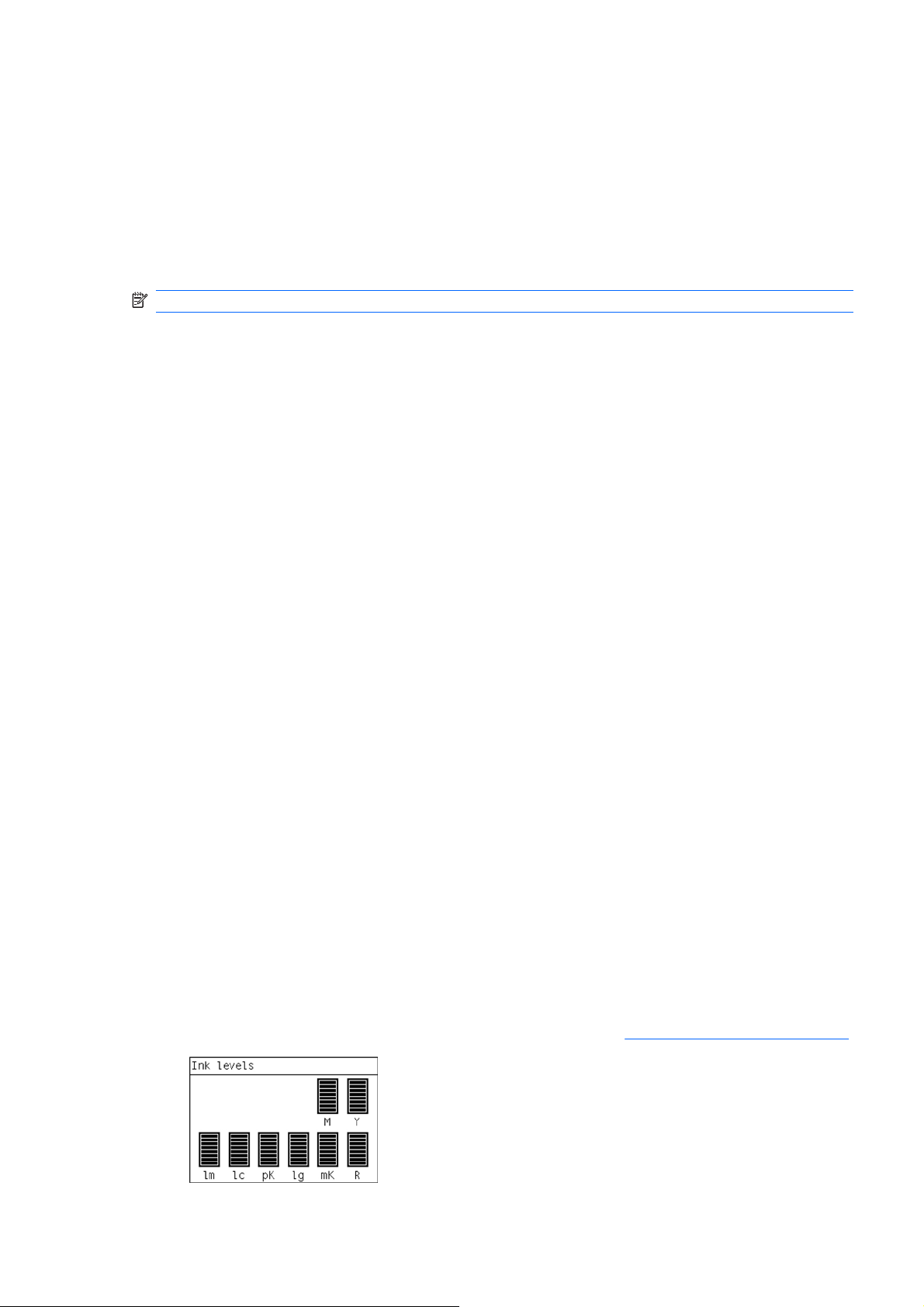

Ink Cartridge Levels

The front panel displays Ink Levels shown as level bars. These bars represent how much ink is remaining

in the Ink Cartridges: as ink is used up the bars get shorter in length.

There are two methods for checking the ink levels of your Ink Cartridges.

“View Ink Levels” Direct Access Key

●

Pressing the “View ink levels” direct access key on the Front Panel will immediately show you the

ink levels. For more information about direct access keys, refer

Using the Front Panel on page 3.

ENWW Ink Cartridge Levels, Information, and Replacement 11

“View Ink Levels” from the ink menu

●

Choosing the View ink levels options from the Ink menu will immediately show you the ink levels:

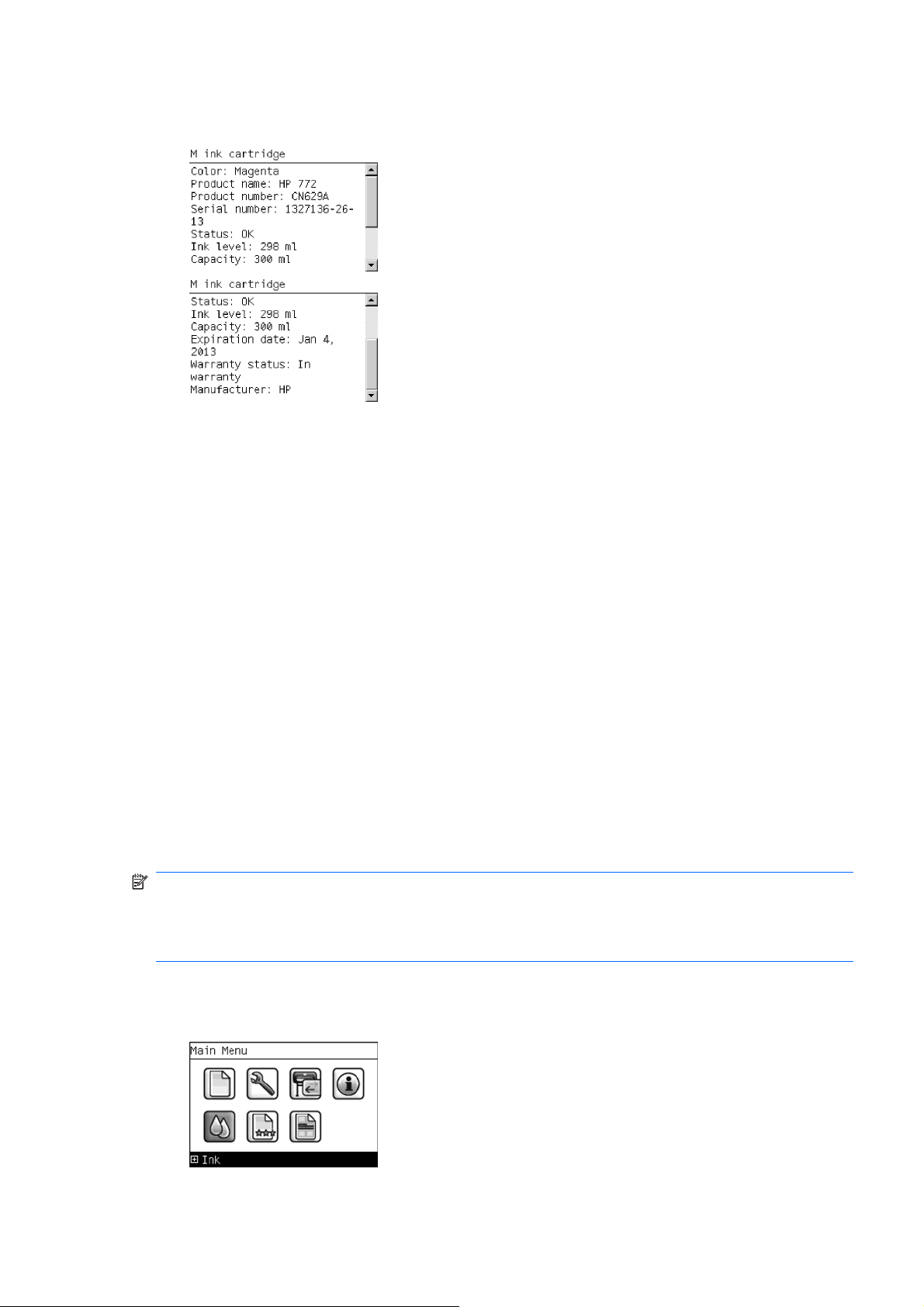

Obtaining Ink Cartridge Information

1. Scroll to the Ink Menu icon and press OK

2. In the Ink Menu submenu, scroll to Ink cartridge information and press OK

3. In the Ink cartridge information submenu, scroll to the Ink Cartridge that you want information

on and press OK.

12 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

4. The front panel displays information on the selected Ink Cartridge. Use the Arrow keys to scroll

through the information.

The information supplied is:

●

The make of the Ink Cartridge.

●

The product number of the Ink Cartrid ge .

●

The serial number of the Ink Cartridge.

●

The current status of the Ink Cartridge.

●

The current ink level of the ink cartridge in milliliters.

●

Original capacity of the ink cartridge in milliliters.

●

The manufacturer of the Ink Cartridge (hp is recommended).

●

The current warranty status of the Ink Cartridge.

Changing an Ink Cartridge

There are two occasions when you need to remove an ink cartridge:

●

The ink cartridge is very low and you want to replace it with a full cartridge for unattended printin g

(you can use up the remaining ink in the first cartridge at a more convenient time).

●

The ink cartridge is empty or faulty, and you must replace it to continue printing.

NOTE: Do not try to remove an ink cartridge w hile printing. Remove an ink cartridge only if you are

ready to insert another one.

Make sure the printer wheels are locked (the brake lever is pressed down) to prevent the printer from

moving.

Change an ink cartridge using the following procedure:

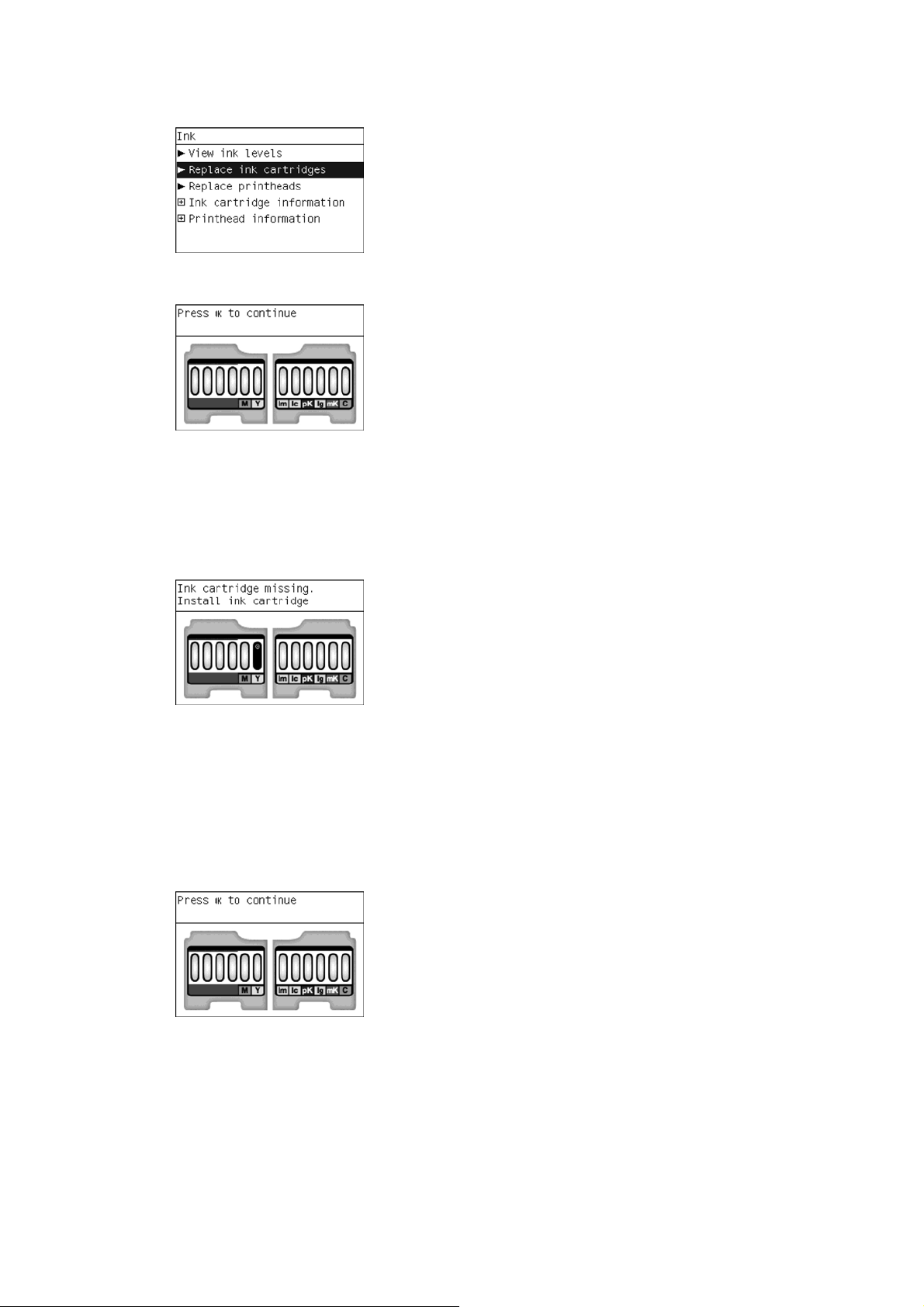

1. Scroll to the Ink Menu icon and press OK.

ENWW Ink Cartridge Levels, Information, and Replacement 13

2. In the Ink Menu submenu, scroll to Replace ink cartridges and press OK.

3. The front panel displays the status of the Ink Cartridges.

4. Press OK to continue.

5. Open the relevant Ink Cartridge cover fo r th e Ink Cartridge you want to replace.

6. Pull the required Ink Cartridge straight up to remove it from the printer.

7. The front panel indicates the missing Ink Cartridge.

8. Before removing the cartridge from its wrapping, shake it vigorously.

9. Unwrap the new ink cartridge, find the label identifying the ink color. Check that the letter or letters

marking the empty slot, matches the letter or letters on the cartridge label.

10. Insert the ink cartridge into its slot.

11. Push the cartridge into the slot until it snaps into position. You should hear a beep and see

confirmation that the cartridge has been inserted.

12. When all cartridges have been inserted, close the cover.

14 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

Printhead Information, Replacement and Alignment

Obtaining Printhead Information

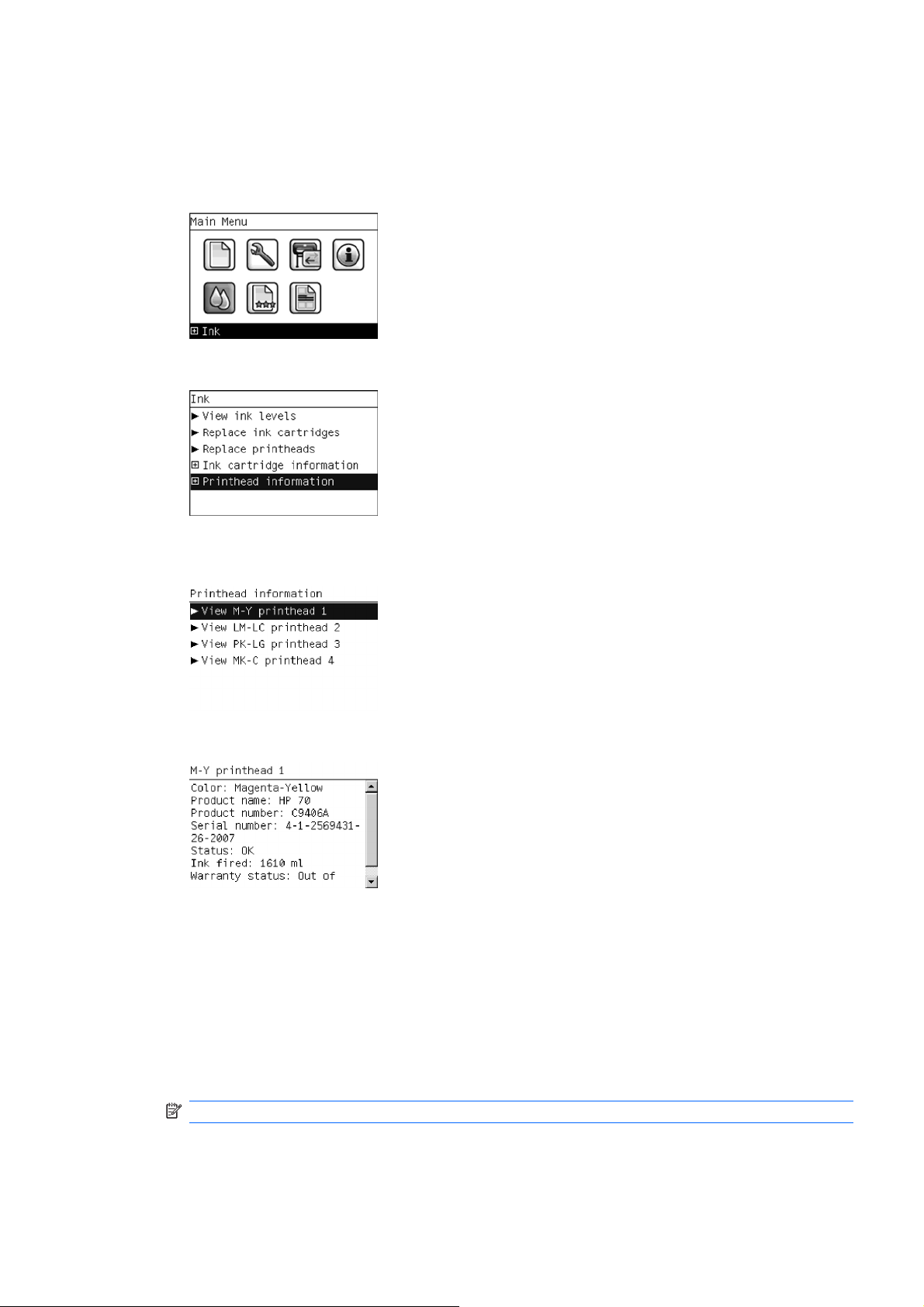

1. Scroll to the Ink Menu icon and press OK.

2. In the Ink Menu submenu, scroll to Printhead information and press OK.

3. In the Printhead Information submenu, scroll to the Printhead that you want information on and

press OK.

4. The front panel displays information on the selected Printhead.

The information supplied is:

●

The make of the printhead.

●

The product number of the Printhea d.

●

The serial number of the Printhead.

●

The current status of the printhead.

●

How much ink has been fired (consumed) by the printhead.

NOTE: It is possible for a printhead to consume more than one Ink Cartridge.

●

The current warranty status of the Printhead.

ENWW Printhead Information, Replacement and Alignment 15

Changing a Printhead

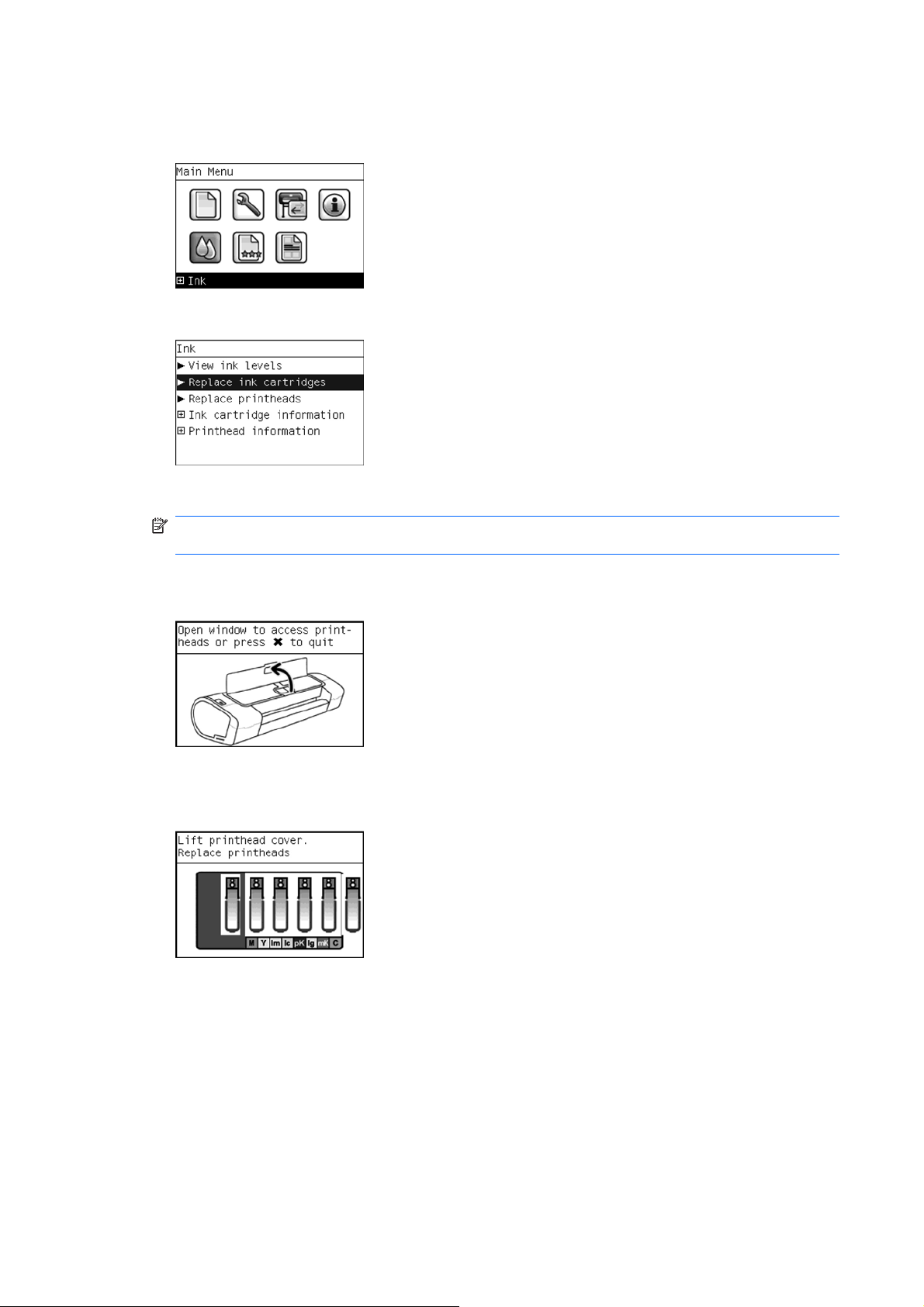

1. Scroll to the Ink Menu icon and press OK.

2. In the Ink Menu submenu, scroll to Replace printheads and pressOK .

3. The printer moves the Carriage to the correct position to replace Printheads.

NOTE: If the carriage is left in the removal position for more than three minutes without inserting

or removing any printheads, it will try to move back to its normal position at the right-hand end.

4. When the carriage has stopped moving, the front panel display will prompt you to open the wi ndow

and lift the carriage cover.

5. Open the window.

6. Lift the Carriage cover to access the printhea d s.

7. Lift the blue handle and pull the Printhead straight up out of the Carriage.

16 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

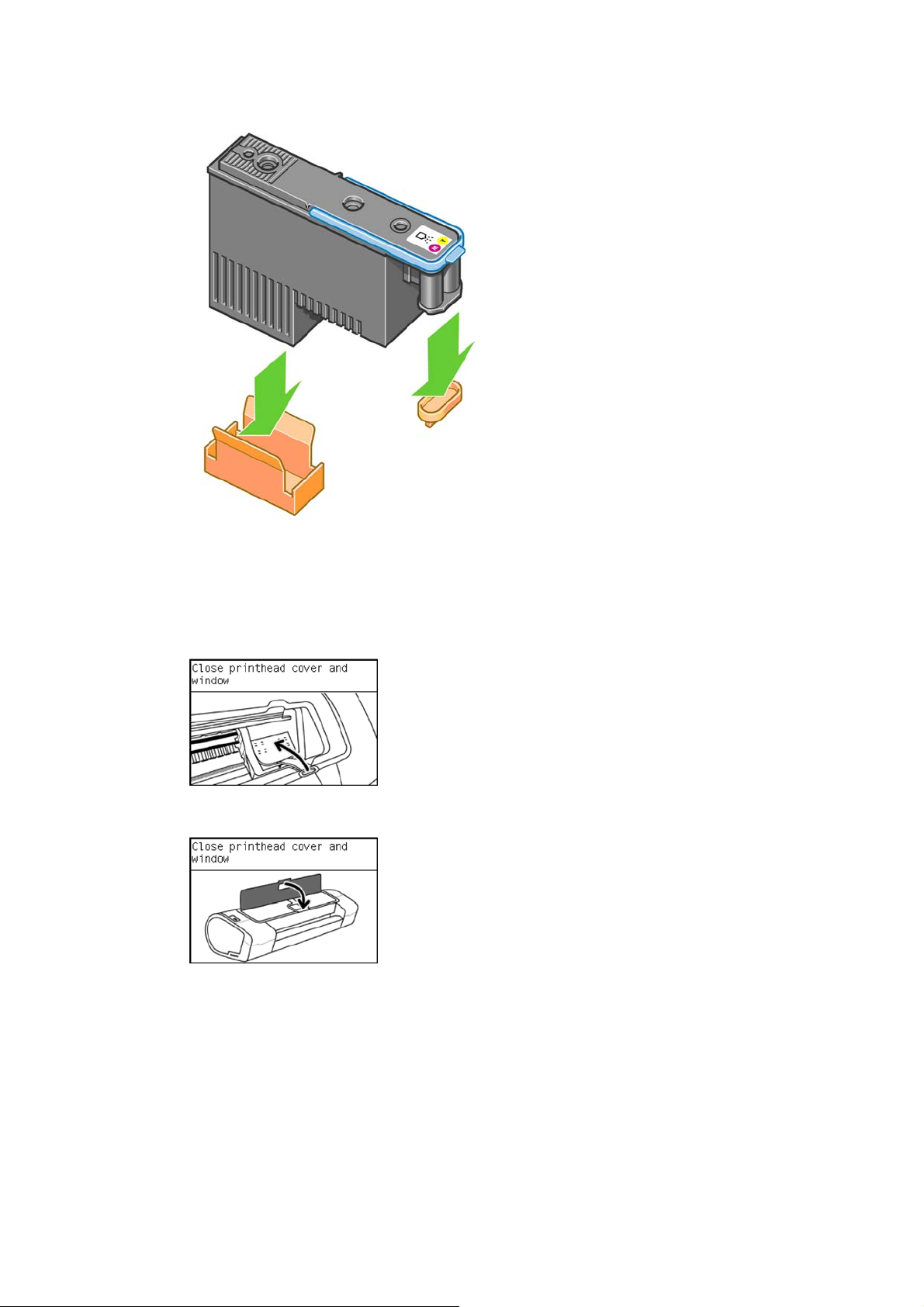

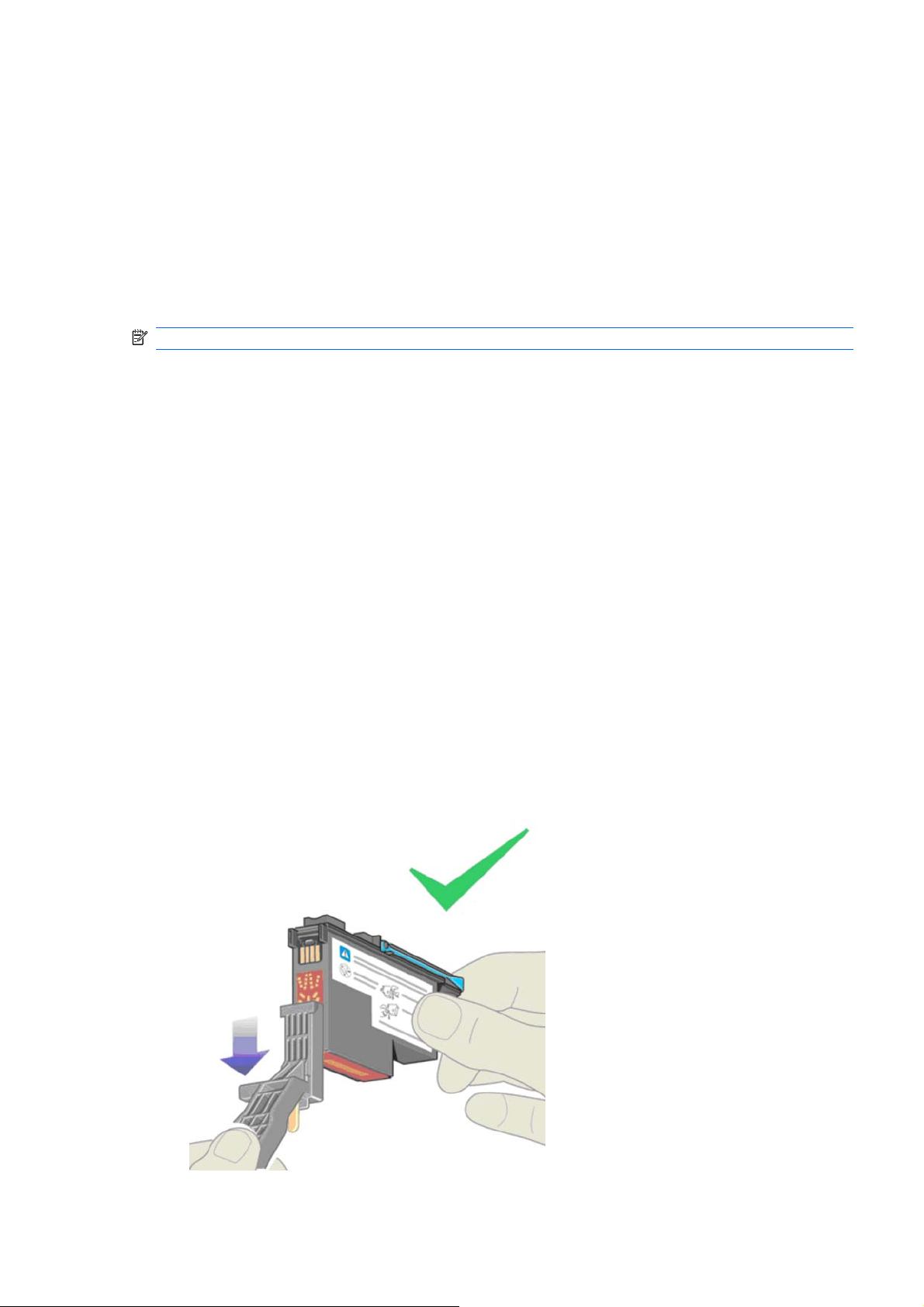

8. To insert a new printhead first remove the or an ge p ro te c tive ca ps.

9. The printhead is designed to prevent you from accidentally inserting it into the wrong slot. Check

that the colored label on the printhead matches the colored label of the carriage slot into which th e

printhead is to be inserted. Insert the printhead slowly and vertically, straight down. It may be

damaged if you insert it too fast, or at an angle, or if you rotate it as you insert it.

10. Insert all other printheads that need to be installed, and close the carriage cover.

11. Close the Window.

12. When all the printheads have been inserted correctly and accepted by the printer, the printer will

beep. If the printer does not beep when you insert the printhead an d the Replace message appears

on the front panel display, the printhead may need to be reinserted.

The front panel display confirms that all printheads are correctly inserted. The printer will start

checking and preparing the printheads. The front panel display confirms that all printheads are

correctly inserted. The printer will start checking and preparing the printheads. The default routine

process, when all printheads are changed, takes 25 minutes. If the printer finds problems in

preparing the printheads, it will take longer, up to 55 minutes. For a single printhead insertion, the

times vary between 15 and 35 minutes. After all printheads are checked and prepared, for the

printhead realignment.

ENWW Printhead Information, Replacement and Alignment 17

Aligning Printheads

Precise alignment between printheads is essential for accurate colors, smooth color transitions, and

sharp edges in graphical elements. Your printer has an automatic printhead alignment process which

runs whenever a printhead has been accessed or replaced.

In cases where the paper has jammed, you have used a custom paper, or are experiencing problems

with color accuracy you may need to align the printheads. If the paper has jammed, it is re commende d

that you reinsert the printheads and initiate the realignment procedure with the Image Quality

Maintenance menu.

NOTE: Do not use transparent and semi-transparent paper to align the printheads. Photo paper is

recommended for the best quality.

Reinsert Printheads Procedure

1. If the realignment process is running and the wrong paper is loaded, press the cancel key on the

front panel. Do not print if the realignment process has been canceled. You can restart the

alignment with the Image Quality Maintenance menu procedure.

2. Load the paper you wish to use. You can use a roll or cut sheet.

3. Remove and reinsert all the printheads, see Remove a printhead and Insert a printhead. This will

start the printhead alignment procedure.

4. Ensure the transparent window closed, as a strong light source near the printer during printhead

realignment can affect alignment.

5. The process will take about six minutes. Wait until the front panel display shows the process

complete before using the printer.

Image Quality Maintenance Procedure

1. Load the paper you wish to use. You can use a rol l or cut sheet, however, it must be at le ast a 16

inches roll, or an A2 portrait sheet (420mm x 594mm). Do not use transparent and semi-transparent

paper to align the printheads. Photo paper is recommended for the best results; plain, bond and

thin coated papers provide acceptable but marginal results.

2. Press the Menu key to return to the main menu and select the Image Quality Maintenance menu

icon.

3. Select Alig n printheads. The printer will check to see if it has en ough paper to run the realignment.

18 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

4. If the loaded paper is satisfactory, the printer will run the realignment and print a realignment

pattern. Ensure the transparent window is closed, as a strong light source near the printer during

printhead realignment can affect alignment.

Figure 1-1 Z5200 Plot:

5. The process will take about eight minutes. Wait until the front panel display shows the process

complete before using the printer.

Scanning errors during alignment

If the alignment process fails, a Scanning problems message appears on the front panel. This means

that the alignment has not completed successfully. Ther efore the printer is not aligned and the alignment

should be repeated before printing with good image quality. The problem may be due to:

●

The paper used was not valid, repeat the alignment with valid paper.

●

Printhead health problems, clean printheads.

●

The alignment was done with the transparent window open, repeat th e alignment with the window

closed.

If the problem persists after using valid paper, cleaning the printheads, a nd keeping the window closed,

there may be a Failure in the scanning system needing reparation or the printheads, although clean,

may not work and need to be replaced.

ENWW Printhead Information, Replacement and Alignment 19

Ink Cartridge and Printhead Status Messages

Ink Cartridge Status Messages

OK The Ink Cartridge is operating correctly and no action is

required.

Missing There is no Ink Cartridge present, or it is not properly

connected to the printer

Low The Low message is an early warning sign and it is advisable

that new supplies should be obtained of that particular color.

The amount of ink remaining in the Ink Cartridge depends on

it’s capacity, but there is approximately 14% of ink available for

the user.

Very Low When theVery Low message is displayed, overnight printing

should not be attempted. Changing the Ink Cartridge is

strongly recommended to prevent the printer from stopping

halfway through a print. There is approximately 8% of ink

available for the user.

Empty The printer will stop and will not be able to continue printing

until a new Ink Cartridge has been installed. If this occurs

halfway through printing an image, you should check the

quality of this image, as stopping mid-plot can affect the print.

It would be recommended to reprint the image once a new Ink

Cartridge has been installed.

Reseat You are recommended to remove the Ink Cartridge and then

reinsert it.

Replace You are recommended to replace the Ink Cartridge with a new

Ink Cartridge.

Altered There is something unexpected about the Ink Cartridge's

status.

Expired The Ink Cartridge has passed the expiration date.

Printhead status messages

OK The Printhead is operating correctly and no action is required.

Missing There is no Printhead present, or it is not properly connected

to the printer.

Test printhead

separately

You are recommended to test the printheads individually to find

the failing printhead. Remove all the printheads and insert

them alone one by one, Closing the latch and the carriage

cover after every insertion. The front panel display will indicate

the failing one showing the reseat or replace message.

Reseat You are recommended to start the printhead removal process

from the front panel, but instead of removing the printhead,

simply press the OK key on the front panel.

Replace You are recommended to remove the printhead and then

reinsert it; if that fails, clean the electrical connections; if that

fails, replace the printhead with a new printhead.

Replacement

incomplete

A printhead replacement process has not completed

successfully, relaunch the replacement process and let it finish

completely (it is not needed to change the printheads).

Remove The printhead is not a suitable type for use in printing (for

instance, a setup printhead).

20 Chapter 1 Ink Supplies Troubleshooting & Print Quality ENWW

Solving Ink Supplies Problems

Most of the problems that you could encounter when working with the ink supplies are solved with

guidance from the front panel. A full list of front panel messages are supplied in the User’s Guide.

You Cannot Insert the Ink Cartridge Into the Printer

1. Ensure that you have the correct hp Ink Cartridge.

2. Ensure that the Ink Cartridge is the correct color for that slot.

3. Ensure that the Ink Cartridge is the correct orientation, with the color coded label at the top.

NOTE: Never clean inside the Ink Cartridge slo ts as this can cause damage to the Printer.

You Cannot Insert the Printhead Into the Printer

1. Ensure that you have the correct hp Printhead.

2. Ensure that the printhead is the correct color for that slot.

3. Ensure that the printhead is in the correct orientation.

4. Ensure that the protective cap is removed from the Printhead.

The front panel says to reset or replace a printhead

1. From the front panel, turn the power off then ON.

2. Check the front panel display message, if it shows the ready message, the printer is ready to print.

If the problem remains continue with the next step.

3. Remove the printhead.

4. Clean the electrical connections on the backside of the printhead with a lint free cloth. You can

carefully use a mild rubbing alcohol if moisture is needed to remove residue. Do not use water.

You can use the Flex Contacts Cleaning Tool.

This is a delicate process and may damage the printh ead. Do not touch the n ozzles on the bottom

side of the printhead, especially not with any alcohol.

ENWW Solving Ink Supplies Problems 21

Loading...

Loading...