Honeywell F150e1034, F150e1026, F150e1000, F150e1018, F150e Owner's Manual

...

whole-house air quality system

F150E

Media Air Cleaner

PRODUCT DATA

FEATURES

F150E

W8600A

AIRWATCH™

APPLICATION

The F150E Media Air Cleaner captures a significant amount of the airborne particles from the air circulated through the unit.

•W8600A AIRWATCH™ filter change indicator.

•High efficiency media filter captures particles as small as 0.3 micron.

•Efficiency ratings based on the American Society of Heating, Refrigerating and Air Conditioning Engineers Standard 52.2-1999.

•Applicable to all gas, oil, and electric forced warm air furnaces and to compressor cooling up to 5 tons.

•Mounts in the return air duct.

•Cabinet can support weight of residential furnace and evaporator coil.

•Requires no electrical connections.

•Mounts in any position.

•Requires no maintenance except periodic media filter replacement.

•Quick and easy media filter replacement.

•Later upgrade to higher performing Honeywell media or electronic air cleaner is easy.

|

Contents |

Application......................................................................... |

1 |

Features ............................................................................ |

1 |

Specifications .................................................................... |

2 |

Ordering Information ......................................................... |

2 |

Planning the Installation .................................................... |

3 |

Installation ........................................................................ |

6 |

Checkout ........................................................................... |

7 |

® U.S. Registered Trademark

© 2004 Honeywell International Inc. 68-0245EF-3

All Rights Reserved

F150E MEDIA AIR CLEANER

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not include normal manufacturing tolerances; therefore, an individual unit may not exactly match the listed specifications. This product is tested and calibrated under closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

Model:

F150E Media Air Cleaner includes cabinet, access door and pleated media filter, and W8600A AirWatch™ Indicator.

Application:

Use with gas, oil, and electric forced warm air furnaces and with compressor cooling. Can be used with heat pumps if filter is changed regularly to prevent excessive pressure drop. Not recommended for applications where pressure drop may be critical.

Pressure Drop:

Initial pressure drop at 492 fpm: 0.23 in. wc. Dust fed to 0.5 in. wc pressure drop: 72 grams.

Efficiency:

Efficiency Ratings: Based on American Society of Heating, Refrigerating and Air-Conditioning Engineers Standard 52.2-1999.

Minimum Efficiency Reporting Valve (MERV): 10 at 492 fpm.

Filter Media:

Pleated for greater media capacity.

Capacity And Pressure Drop:

See Fig 2.

Initial Pressure Drop: 0.23 in. wc at 492 fpm.

Temperature Rating:

-40° to +140°F (-40° to +60°C).

Dimensions:

See Fig. 1.

Mounting:

Mounts in any position in the return air duct, usually next to the furnace blower compartment. Cabinet is sturdy enough to support weight of a residential furnace and evaporator coil.Underwriters Laboratories, Inc.:

Listed to UL 900, Class 2.

Included Accessory:

W8600A AirWatch™ Indicator.

Upgrade Path:

The F150E uses the same cabinet as the F300E Electronic Air Cleaner. Upgrade may require installing the cell key, electronic cells, protective screens and installation and wiring of the power box, depending on model.

Initial Efficiency*: |

|

|

Replacement Media: |

|

|

|

|

For optimum system performance, replace the filter every six |

|

|

|

|

months (before heating season and before cooling |

|

INITIAL EFFICIENCY* : |

|

season). Adjust the schedule to you needs, but replace the |

||

|

|

|

||

|

|

|

filter at least annually. |

|

85.1% |

|

16 x 20 |

FC100A1003 |

|

EFFICIENCY% |

|

|

||

|

|

61.8% |

Filter Size (in.) |

Part Number |

|

|

|

16 x 25 |

FC100A1029 |

|

|

|

24.8% |

|

|

|

|

20 x 25 |

FC100A1037 |

3.0 - 10.0 |

1.0 - 3.0 |

0.3 - 1.0 |

|

|

|

|

% EFFICIENCY |

20 x 20 |

FC100A1011 |

*LMS Technologies Inc. |

Fractional Efficiency Testing FC100, 2004. |

|

||

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1.Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2.Honeywell Customer Care 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0245EF-3 |

2 |

F150E MEDIA AIR CLEANER

|

1 |

1 |

(29) |

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIM. B |

|

DIM. A |

|

|

|

|

|

|

|

|

|

(SEE TABLE) |

|

(SEE TABLE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

3 |

7 |

5 |

|

|

|

|

|

|

|

|

8 |

8 |

|

|

|

|

DIM. C (SEE TABLE) |

|

(22) |

||||

6 4 |

8 |

|

|

|

|

|

|||||

(22) |

|

|

|

|

|

|

|||||

(172) |

(16) |

|

|

|

DIM. D (SEE TABLE) |

|

|

||||

|

|

|

|

|

|

|

|

|

|||

F150E SIZE |

|

DIM. A |

|

DIM. B |

|

DIM. C |

|

DIM. D |

|

|

|

IN. |

MM |

|

IN. |

MM |

IN. |

MM |

IN. |

MM |

IN. |

MM |

|

16 X 25 |

406 X 635 |

14-7/16 |

367 |

16-3/16 |

411 |

23-1/4 |

591 |

25-1/2 |

648 |

|

|

20 X 25 |

508 X 635 |

18-7/16 |

468 |

20-3/16 |

513 |

23-1/4 |

591 |

25-1/2 |

648 |

|

|

16 X 20 |

406 X 508 |

14-7/16 |

367 |

16-3/16 |

411 |

18-1/4 |

457 |

20-1/2 |

521 |

|

|

20 X 20 |

508 X 508 |

18-7/16 |

468 |

20-3/16 |

513 |

18-1/4 |

457 |

20-1/2 |

521 |

M22578 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 1. Installation dimensions in in. (mm) of air cleaner.

FILTER SIZE 20 X 25 16 X 25 20 X 20

16 X 20

0.300

1

WC) |

0.250 |

|

|

(IN. |

0.200 |

DROP |

0.150 |

PRESSURE |

0.100 |

|

0.050

0.000

0 |

500 |

1000 |

1500 |

2000 |

AIRFLOW (CFM)

1WHEN FIRST INSTALLED. PRESSURE DROP INCREASES AS FILTER BECOMES LOADED. REPLACE FILTER WHEN PRESSURE DROP REACHES 0.5 IN. WC. (0.1 kPa).

M14709A

Fig. 2. Capacity, Pressure Drop and Area of

F150E Filter Media.

PLANNING THE INSTALLATION

Location

The media air cleaner should be installed where all the air passing through the system is circulated through it. The best location is in the return air duct next to the blower compartment so the media air cleaner can help to keep the blower motor and evaporator coils clean. Do not mount in the supply air duct.

For most efficient air cleaning, spread airflow evenly across the face of the media. If the duct is a different size than the media air filter cabinet, gradual transitions are required. If the duct turns sharply just before the air filter, turning vanes are required.

Choose a location that is readily accessible for checking and replacing the filter. Allow at least 26 in. (660 mm) clearance in front of the unit for removal of the cartridge.

Install the media air filter where the temperature will not exceed the ratings in the Specifications.

3 |

68-0245EF-3 |

F150E MEDIA AIR CLEANER

Applications With Air Conditioning

Mount the media air cleaner upstream of the evaporator coil in a cooling system. The filter will help to keep the coil clean and reduce maintenance.

Applications With A Humidifier

The media air cleaner is compatible with humidifiers. Avoid applications where water mist will reach the media. If an atomizing humidifier is used, the filter media will require replacement more often because of minerals in the water.

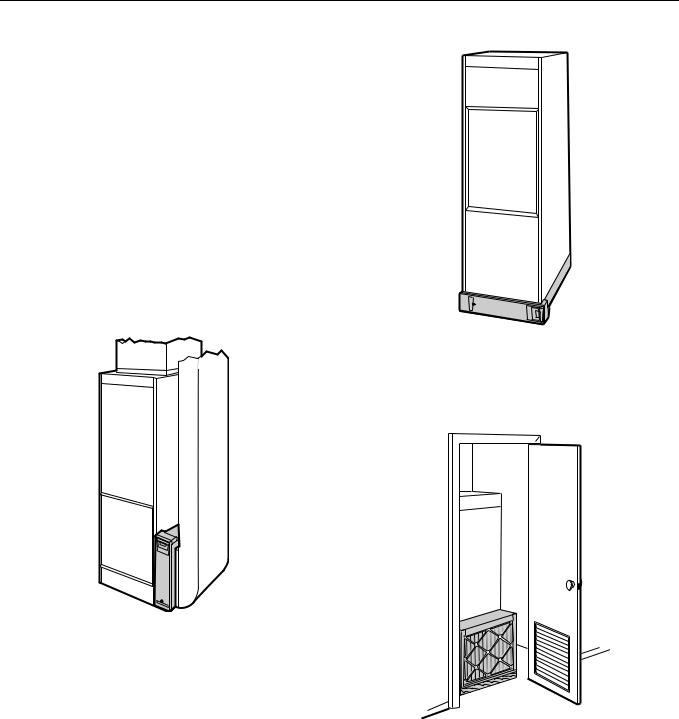

Choose Mounting Position

The media air cleaner can be mounted in any position, but the arrow on the cartridge must point in the same direction as the airflow. See Figs. 3-10 for proper location of the media air cleaner for a variety of furnace installations. Note that the media air cleaner cabinet is sturdy enough to easily support the weight of the furnace and evaporator coil. See Fig. 4.

M940A

Fig. 4. Highboy furnace, with installation beneath furnace. Media air cleaner is mounted horizontally where return enters from below.

M939A

Fig. 3. Highboy furnace, with side installation. Media air filter is mounted vertically where return enters side inlet of furnace.

M941A

Fig. 5. Highboy furnace, with closet installation. Media air cleaner is mounted vertically on furnace between furnace and louvered return air opening in closet door.

68-0245EF-3 |

4 |

F150E MEDIA AIR CLEANER

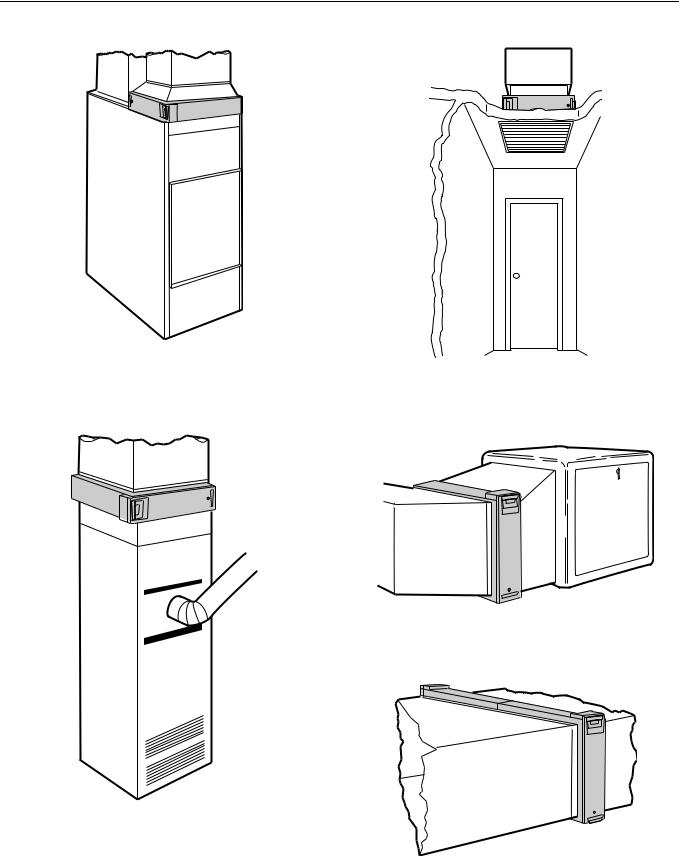

M942A

Fig. 6. Lowboy furnace, with media air cleaner mounted horizontally in return plenum just above furnace and opposite heating plenum.

M943A

Fig. 7. Counterflow furnace, with media air cleaner mounted horizontally in return duct or plenum just above furnace.

M944A

Fig. 8. Central fan installation, with media air cleaner mounted horizontally in central return duct.

M945A

Fig. 9. Horizontal furnace, with media air filter mounted vertically in return duct near furnace.

M946A

Fig. 10. Two or more media air cleaners used in a high capacity system.

5 |

68-0245EF-3 |

Loading...

Loading...