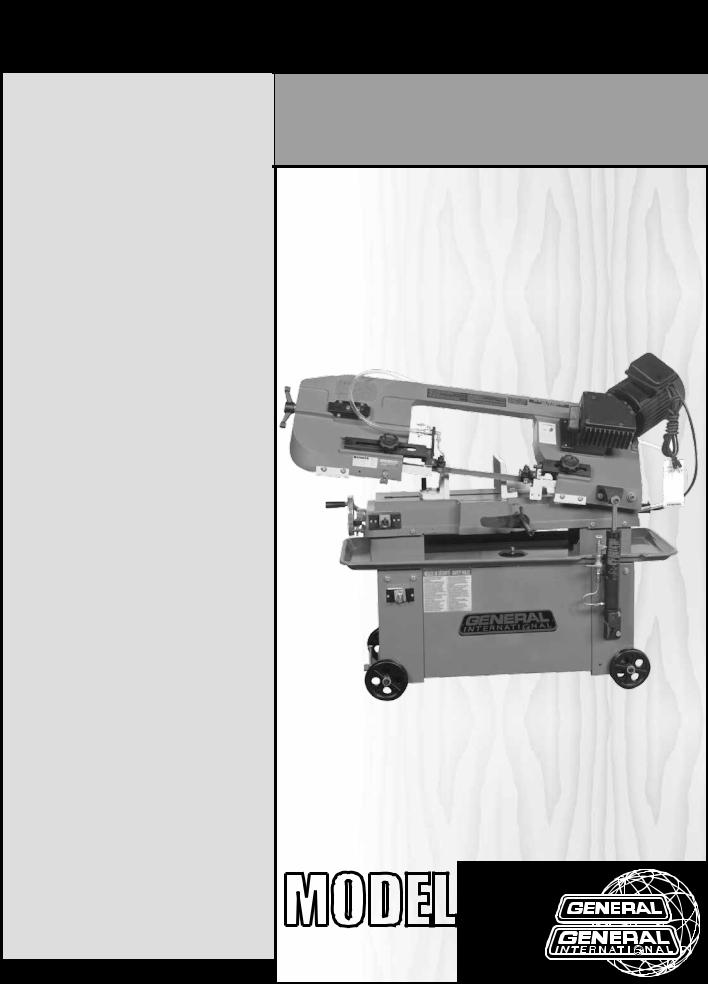

General 90-700 User Manual

SETUP & OPERATION MANUAL

FEATURES

Steel stand and heavy-duty cast-iron frame with built-in oil recovery tray.

Versatile metal cutting bandsaw with vertical raising head, horizontal cut and a removable work table.

Stand mounted on 4 durable wheels.

Heavy-duty “acme” type screw vise for quick and easy handwheel adjustment 45º to 90º mitering.

Coolant system with built-in tank and pump. Adjustable hydraulic down feed control.

3 speed quick change gearbox. Automatic shut-off.

SPECIFICATIONS

•Cutting capacity at 90º (Rectangular) 7” x 12” (179 x 305 mm)

•Cutting capacity at 90º (Round) 7” (179 mm)

•Cutting capacity at 45º (Rectangular) 4” x 7” (102 x 178 mm)

•Cutting capacity at 45º (Round) 4” (102 mm)

•Blade size

3/4” x 0.035” x 93” (19 x 0.9 x 2360 mm)

•Blade speeds 85, 145, 180 fpm

•Base dimensions

51” x 20” (1295 x 508 mm)

•Overall dimensions (l x w x h)

491/4”x 27 1/8”x 40 3/4”(1250 x 690 x 1035 mm)

•Motor (pre-wired 120 V)

1HP, 120/240 V, 1 Ph, 9/4.5 A

•Weight

330lbs (150 kg)

Version #3_Revision #1 - May 2015 (S/NO 9000010515)

© Copyright General International

7” X 12” METAL CUTTING BANDSAW

MODEL

#90-700

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3 Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General® International model 90-700 7” x 12” Metal Cutting Bandsaw. This bandsaw has been carefully tested and inspected before shipment and if properly used and maintained, will provide you with years of reliable service. For your safety, as well as to ensure optimum performance and trouble-free operation, and to get the most from your investment, please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features of this bandsaw as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal metalworking instruction, nor to offer the user instruction in the craft of metalworking. If you are not sure about the safety of performing a certain operation or procedure, do not proceed until you can confirm, from knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

DISCLAIMER: The information and specifications in this manual pertain to the unit as it was supplied from the factory at the time of printing. Because we are committed to making constant improvements, General® International reserves the right to make changes to components, parts or features of this unit as deemed necessary, without prior notice and without obligation to install any such changes on previously delivered units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit with which it

was supplied.However,special orders and“after factory” modifications may render some or all information in this manual inapplicable to your machine. Further, as several generations of this model of Metal Cutting Bandsaw and several versions of this manual may be in circulation, if you own an earlier or later version of this unit, this manual may not depict your unit exactly. If you have any doubts or questions contact your retailer or our support line with the model and serial number of your unit for clarification.

GENERAL® INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products are carefully inspected during all stages of production and each unit is thoroughly inspected upon completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace any part or component which upon examination, proves to be defective in either workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime Warranty does not cover any product used for professional or commercial production purposes nor for industrial or educational applications. Such cases are covered by our Standard 2-year Limited Warranty only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial and educational applications are warranted for a period of 2 years (24 months) from the date of purchase. General® International agrees to repair or replace any part or component which upon examination, proves to be defective in either workmanship or material to the original purchaser during this 2-year warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty, all defective parts, components or machinery must be returned freight or postage prepaid to General® International, or to a nearby distributor, repair center or other location designated by General® International. For further details call our service department at 1-888-949-1161 or your local distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of purchase and a“letter of claim”must be included (a warranty claim form can also be used and can be obtained, upon request, from General® International or an authorized distributor) clearly stating the model and serial number of the unit (if applicable) and including an explanation of the complaint or presumed defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by General® International to have been directly or indirectly caused by or resulting from; improper use, or lack of or improper maintenance, misuse or abuse, negligence, accidents, damage in handling or transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

TABLE OF CONTENTS

Rules for safe operation..................................................................................................... |

5 |

Electrical requirements....................................................................................................... |

6 |

Identification of main parts and components................................................................... |

7 |

Unpacking.......................................................................................................................... |

8 |

Basic functions................................................................................................................... |

8 |

Placement within the shop................................................................................................. |

9 |

Assembly instructions.................................................................................................. |

9 - 10 |

Installing the wheels............................................................................................................................................ |

9 |

Installing the workpiece stop........................................................................................................................... |

10 |

Installing the table for vertical cutting............................................................................................................ |

10 |

Install the coolant/recovery tray filter............................................................................................................. |

10 |

Basic adjustments and controls................................................................................ |

11 - 17 |

Connecting to a power source....................................................................................................................... |

11 |

Main On/Off switch........................................................................................................................................... |

11 |

Replacing a blade..................................................................................................................................... |

11 - 12 |

Adjusting blade tension.................................................................................................................................... |

13 |

Adjusting blade tracking........................................................................................................................... |

13 - 14 |

Squaring the blade to the work table............................................................................................................ |

14 |

Squaring the vise to the blade/Using the vise........................................................................................ |

14 - 15 |

Adjusting the blade guides.............................................................................................................................. |

15 |

Adjusting the thrust bearings........................................................................................................................... |

16 |

Adjusting the blade guards............................................................................................................................. |

16 |

Changing speeds.............................................................................................................................................. |

16 |

Cutting feed rate............................................................................................................................................... |

17 |

Using the coolant pump................................................................................................................................... |

17 |

Immobilizing the machine............................................................................................................................... |

17 |

Operating Instructions...................................................................................................... |

18 |

Checklist before starting................................................................................................................................... |

18 |

Operation step-by-step..................................................................................................................................... |

18 |

Maintenance.................................................................................................................... |

19 |

Cleaning............................................................................................................................................................. |

19 |

Lubrication......................................................................................................................................................... |

19 |

Trouble shooting........................................................................................................ |

20 - 21 |

Parts list & diagrams................................................................................................. |

22 - 29 |

Contact information......................................................................................................... |

30 |

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and holds itself harmless for any injury that may result from the improper use of it’s equipment.

1.Do not operate the bandsaw when tired, distracted or under the effects of drugs, alcohol or any medIcation that impairs reflexes or alertness.

2.The work area should be well lit, clean and free of debris.

3.Keep children and visitors at a safe distance when the bandsaw is in operation; do not permit them to operate the bandsaw.

4.Childproof and tamper proof your shop and all machinery with locks, master electrical switches and switch keys, to prevent unauthorized or unsupervised use.

5.STAY ALERT! Give your work your undivided attention. Even a momentary distraction can lead to serious injury.

6.Fine particulate dust is a carcinogen that can be hazardous to health. Work in a well-ventilated area. Wear face, eye, ear, respiratory and body protection devices.

7.Do not wear loose clothing, gloves, bracelets, necklaces or other jewelry while the bandsaw is in operation.

8.Be sure that adjusting wrenches, tools, drinks and other clutter are removed from the machine and/or the table surface before operating.

9.Keep hands well away from the blade and all moving parts. Use a brush, not hands, to clear away chips and dust.

10.Adjust and position the blade guides before starting to cut.

11.Adjust blade tension and tracking before starting to cut.

12.Blade teeth must point down toward the table.

13.Be sure that the blade has gained full operating speed before starting to cut.

14.Always use a clean, properly sharpened blade. Dirty or dull blades are unsafe and can lead to accidents.

15.Use suitable workpiece support if the workpiece does not have a flat surface.

16.Make sure the workpiece is securely held in place in the vise.

17.Do not work on long stock without adequate support on the out feed end of the table.

18.Do not push or force stock into the blade. The bandsaw will perform better and more safely when working at the rate for which it was designed.

19.Avoid working from awkward or off balance positions. Do not overreach and keep both feet on floor.

20.Keep guards in place and in working order. If a guard must be removed for maintenance or cleaning be sure it is properly re-attached before using the saw again.

21.Never leave the machine unattended while it is run-- ning or with the power on.

22.Use of parts and accessories NOT recommended by General® International may result in equipment malfunction or risk of injury.

23.Never stand on machinery. Serious injury could result if the tool is tipped over or if the cutting tool is unintentionally contacted.

24.Always disconnect the saw from the power source before servicing or changing accessories such as blades, or before performing any maintenance or cleaning, or if the machine will be left unattended.

25.Make sure that the switch is in the “OFF” position before plugging in the power cord.

26.Make sure the machine is properly grounded. If equipped with a 3-prong plug it should be used with a three-pole receptacle. Never remove the third prong.

27.Donotusethisbandsawforotherthanitsintendeduse. If used for other purposes, General® International disclaims any real or implied warranty and holds it self harmless for any injury, which may result from that use.

5

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH GREATER VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE MACHINE. IF IN DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

A

B C

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit, grounding reduces the risk of electric shock. The motor of this machine is wired for 120 V single phase operation and is equipped with a 3-conductor cord and a 3-prong grounding plug A to fit a grounded type receptacle B. Do not remove the 3rd prong (grounding pin) to make it fit into an old 2-hole wall socket or extension cord. If an adaptor plug is used C, it must be attached to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some areas. Check your local codes. If you have any doubts or if the supplied plug does not correspond to your electrical outlet, consult a qualified electrician before proceeding.

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of handling the amperage draw from your machine, as well as any other machines that could be operating on the same circuit. If you are unsure, consult a qualified electrician. If the circuit breaker trips or the fuse blows regularly, your machine may be operating on a circuit that is close to its amperage draw capacity. However, if an unusual amperage draw does not exist and a power failure still occurs, contact a qualified technician or our service department.

CONVERTING THE MOTOR TO 240V

Note: When converting motor voltage on a machine that is equipped with a magnetic switch, the switch contactor must also be changed out for one made for the appropriate voltage, as well as the thermal relay/circuit breaker and “power in” indicator light (if applicable). Failure to make these necessary modifications to the switch will lead to malfunction and permanent switch failure.

Should you need to convert your machine’s motor from 120 V to 240 V power, contact a qualified electrician. Unless you are a qualified electrician, we do not recommend attempting this conversion on your own. If you choose to do so, you may risk serious personal injury, damage to the motor and voiding the warranty of your machine. We suggest you ask your local General International distributor to recommend qualified electricians in your area (or perhaps one of their own technicians) who can make this conversion properly and safely.

EXTENSION CORDS

If you find it necessary to use an extension cord with your machine, use only 3-wire extension cords that have 3-prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a damaged extension cord or plug immediately.Make sure the cord rating is suitable for the amperage listed on the motor I.D. plate. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The accompanying chart shows the correct size extension cord to be used based on cord length and motor I.D. plate amp rating. If in doubt, use the next heavier gauge. The smaller the number, the heavier the gauge.

TABLE - MINIMUM GAUGE FOR CORD

EXTENSION CORD LENGTH

AMPERES |

50 feet |

100 feet |

200 feet |

300 feet |

< 5 |

18 |

16 |

16 |

14 |

|

|

|

|

|

6 to 10 |

18 |

16 |

14 |

12 |

|

|

|

|

|

10 to 12 |

16 |

16 |

14 |

12 |

|

|

|

|

|

12 to 16 |

14 |

12 |

*NR |

*NR |

|

|

|

|

|

*NR = Not Recommended

6

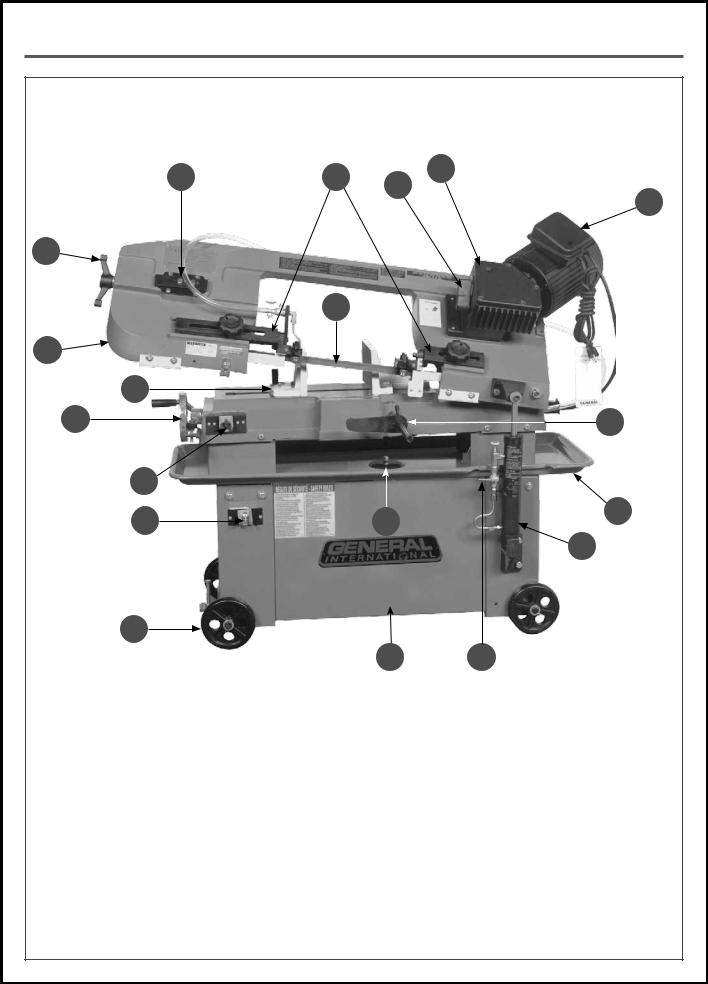

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

|

R |

O |

S |

I |

|

|

|

J |

|

|

|

|

|

|

A |

|

|

|

|

|

|

H |

|

|

B |

|

|

|

|

|

C |

|

|

|

|

D |

|

|

K |

|

E |

|

|

|

|

F |

P |

|

L |

|

|

|

||

|

|

|

|

N |

|

G |

|

|

|

|

|

M |

Q |

|

A. BLADE TENSIONING HANDLE |

K. WORKPIECE STOP |

|||

B. |

BLADE ARM |

L. |

COOLANT RECOVERY TRAY |

|

C. |

VISE |

M. STAND |

|

|

D. |

VISE ADJUSTMENT HANDWHEEL |

N. FEED RATE CONTROL CYLINDER |

||

E. |

MAIN ON/OFF SWITCH |

O. BLADE GUARDS/BLADE GUIDES |

||

F. |

COOLANT PUMP SWITCH |

P. |

RECOVERY TRAY FILTER |

|

G. |

WHEELS (4) |

Q. |

HYDRAULIC DOWNFEED CONTROL VALVE |

|

H. |

BLADE |

R. |

BLADE TENSION INDICATOR |

|

I. |

GEAR BOX |

S. |

SPEED CHANGE LEVER |

|

J. |

MOTOR |

|

|

|

7

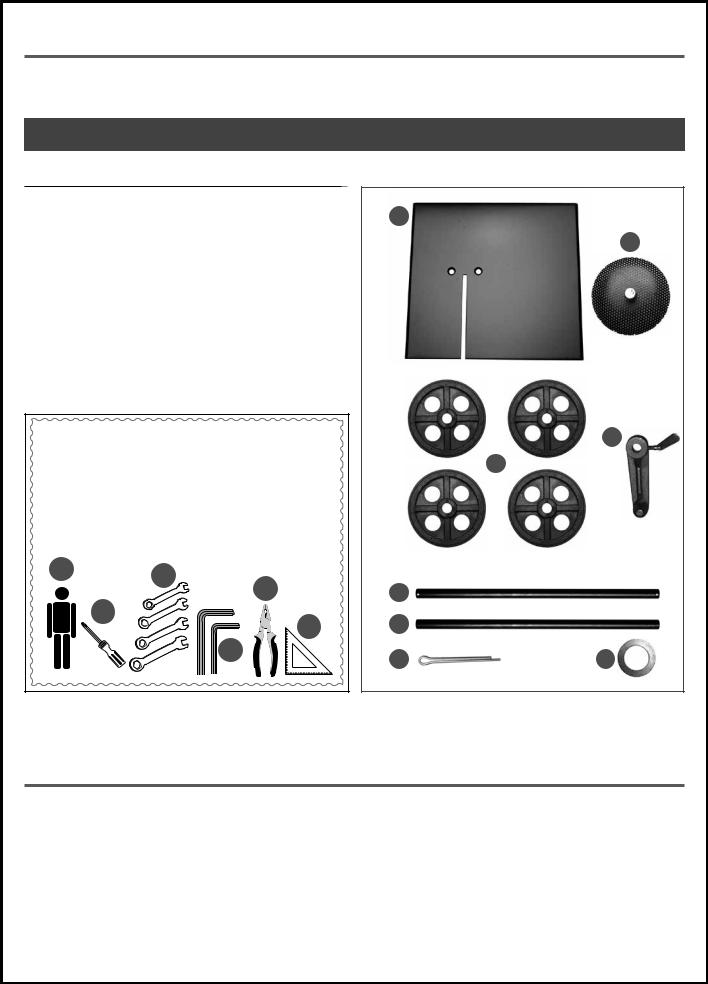

UNPACKING

Carefully unpack and remove the unit and its components from its shipping container and check for missing or damaged items as per the list of contents below.

NOTE: PLEASE REPORT ANY DAMAGED OR MISSING ITEMS TO YOUR GENERAL® INTERNATIONAL DISTRIBUTOR IMMEDIATELY.

LIST |

OF CONTENTS |

QTY |

A. |

VERTICAL CUTTING TABLE |

....................................................... 1 |

B. |

COOLANT FILTER...................................................................... |

1 |

C. |

WHEEL....................................................................................... |

4 |

D. |

WORKPIECE STOP..................................................................... |

1 |

E. |

WHEEL AXLE.............................................................................. |

2 |

F. |

STOP SHAFT............................................................................... |

1 |

G. |

COTTER PIN .............................................................................. |

4 |

H. |

FLAT WHEEL WASHER................................................................ |

4 |

ADDITIONAL REQUIREMENTS FOR SET UP

A.EXTRA PERSON FOR HELP WITH LIFTING

B.PHILLIPS SCREWDRIVER

C.10, 12,14 & 20 MM WRENCHES

D.4 & 6 MM ALLEN KEYS

E.PLIERS

F.SQUARE

A C

E

B

F

A

B

D

C

E |

|

F |

|

G |

H |

BASIC FUNCTIONS

This 7” x 12” horizontal metal cutting band saw is designed for both vertical and horizontal cutting in metalworking and machine shops for cutting various types of bar stock, channel stock, piping, and thin-walled tubing.

With three blade speeds to accommodate a wide range of cutting needs, the unit features an automatic hydraulically controlled down feed with auto shutoff at the end of the cutting cycle.

The coolant system with built-in pump is designed to supply a continuous flow of liquid coolant to the cutting area to prevent overheating of both the blade and the workpiece, providing cleaner cuts and prolonging blade life.

8

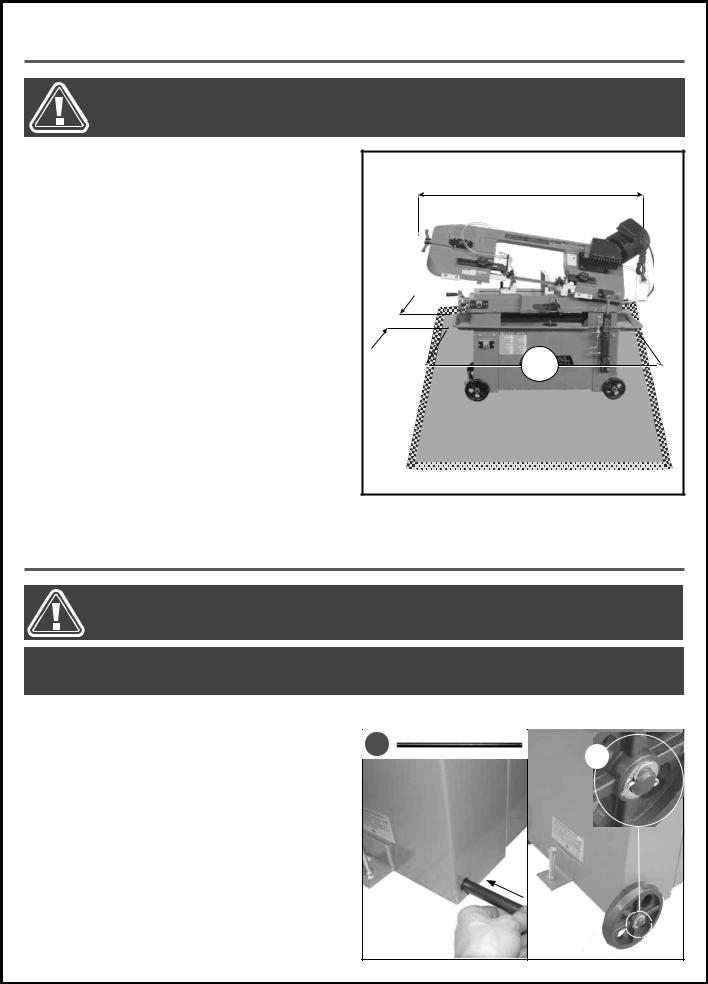

PLACEMENT WITHIN THE SHOP / SAFETY ZONE

THIS METAL CUTTING BANDSAW MODEL 90-700 IS HEAVY. DO NOT OVER-EXERT. A HOIST OR FORKLIFT WITH STRAPS SHOULD BE USED TO LIFT THIS MACHINE. TO LIMIT THE RISK OF SERIOUS INJURY OR DAMAGE TO THE MACHINE, ANY EQUIPMENT USED TO LIFT THIS MACHINE SHOULD HAVE A RATED CAPACITY IN EXCESS OF 330 LBS (150 KG).

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated only on a solid, flat and stable floor that is able to support the weight of the machine (330 lbs - 150 kg) and the operator. Using the dimensions shown as a guideline, plan for placement within your shop that will allow the operator to work unencumbered and unobstructed by foot traffic (either passing shop visitors or other shop workers) or other tools or machinery.

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple operators, it is advisable to establish a safety zone around shop machinery. A clearly defined “no-go” zone on the floor around each machine can help avoid accidents that could cause injury to either the operator or the shop visitor.

It is advisable to take a few moments to either paint (using non-slip paint) or using tape, define on the floor the limits or perimeter of each machines safety zone. Take steps to ensure that all operators and shop visitors are aware that these areas are off limits whenever a machine is running for everyone but the individual operating the unit.

20" |

16" |

40" |

ASSEMBLY INSTRUCTIONS

BEFORE ASSEMBLING, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER CORD IS UNPLUGGED. DO NOT PLUG IN OR TURN ON THE MACHINE UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

TIP: TO INSTALL THE WHEELS, YOU WILL NEED TO LIFT THE MACHINE. DUE TO THE WEIGHT OF THE MACHINE, ADEQUATE LIFTING EQUIPMENT SUCH AS A JACK, HOIST, OR FORKLIFT WITH STRAPS IS REQUIRED. ANY EQUIPMENT USED TO LIFT THE MACHINE MUST HAVE A MINIMUM WEIGHT CAPACITY OF 330 LBS (150 KG).

INSTALLING THE WHEELS |

|

|

1. At one end of the machine, install an axle A as |

A |

|

shown. |

|

B |

|

|

|

Note: The ends of the axle should protrude beyond the sides of the machine.

2.Lift the machine and install the wheels on the ends of the axle.

3.Slide a flat washer onto the axle against each wheel and then insert a cotter pin through the holes on each end of axle as shown B.

4. Fold down the prongs of the cotter pin as shown. 5. Repeat the steps with the other axle and wheels.

9

Loading...

Loading...