Furuno FR-2115, FR-2125 User Manual

MARINE RADAR

MODEL FR-2115/2125

C

9 - 5 2 , A s h i h a r a - c h o , N i s h i n o m i y a , J a p a n

T e l e p h o n e : |

0 7 9 8 - 6 5 - 2 1 1 1 |

T e l e f a x : |

0 7 9 8 - 6 5 - 4 2 0 0 |

A l l r i g h t s r e s e r v e d .  Printed in Japan

Printed in Japan

P U B . N o . I M E - 3 4 6 4 0 - M

( T E N I ) |

F R - 2 1 1 5 / 2 1 2 5 |

|

Y o u r L o c a l A g e n t / D e a l e r

Y o u r L o c a l A g e n t / D e a l e r

F I R S T E D I T I O N |

: |

J U L . |

1 9 9 8 |

M |

: |

O C T . |

1 1 , 2 0 0 1 |

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

WARNING

WARNING

Radio Frequency Radiation

Hazard

The radar antenna emits electromagnetic radio frequency (RF) energy which can be harmful, particularly to your eyes. Never look directly into the antenna aperture from a close distance while the radar is in operation or expose yourself to the transmitting antenna at a close distance.

Distances at which RF radiation levels of 100 and 10 W/m2 exist are given in the table below.

Note: If the antenna unit is installed at a close distance in front of the wheel house, your administration may require halt of transmission within a certain sector of antenna revolution. This is possible—Ask your FURUNO representative or dealer to provide this feature.

|

Radiator |

Distance to |

Distance to |

|

Model |

100 W/m2 |

10 W/m2 |

||

type |

||||

|

point |

point |

||

|

|

|||

|

|

|

|

|

|

XN12AF |

|

3.50 m |

|

FR-2115 |

|

0.10 m |

|

|

XN20AF |

3.50 m |

|||

worst case |

||||

|

|

|

||

|

XN24AF |

|

1.40 m |

|

|

|

|

|

|

|

XN12AF |

|

|

|

FR-2125 |

|

1.10 m |

10.0 m |

|

XN20AF |

||||

worst case |

worst case |

|||

|

|

|||

|

XN24AF |

|

|

|

|

|

|

|

WARNING

WARNING

|

Do not open the equipment |

|

|

unless totally familiar with |

|

|

electrical circuits and |

|

|

service manual. |

|

ELECTRICAL |

Only qualified personnel |

|

should work inside the |

||

SHOCK |

||

HAZARD |

equipment. |

|

|

|

|

|

Wear a safety belt and hard |

|

|

hat when working on the |

|

|

antenna unit. |

Serious injury or death can result if someone falls from the radar antenna mast.

Construct a suitable service platform from which to install the antenna unit.

Serious injury or death can result if someone falls from the radar antenna mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can result if the power is left on or is applied while the equipment is being installed.

Do not install the display unit where it may get wet from rain or water splash.

Water in the display unit can result in fire, electrical shock or equipment damage.

i

WARNING

WARNING

Be sure that the power supply is compatible with the voltage rating of the equipment.

Connection of an incorrect power supply can cause fire or equipment damage. The voltage rating of the equipment appears on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a different cable is used.

CAUTION

CAUTION

Ground the equipment to prevent electrical shock and mutual interference.

Observe the following compass safe distances to prevent deviation of a magnetic compass:

|

Standard |

Steering |

|

|

compass |

compass |

|

|

|

|

|

Display |

1.70 m |

0.90 m |

|

Unit |

|||

|

|

||

Scanner Unit |

1.70 m |

1.90 m |

|

(2115) |

|||

|

|

||

|

|

|

|

Scanner Unit |

2.10 m |

1.20 m |

|

(2125) |

|||

|

|

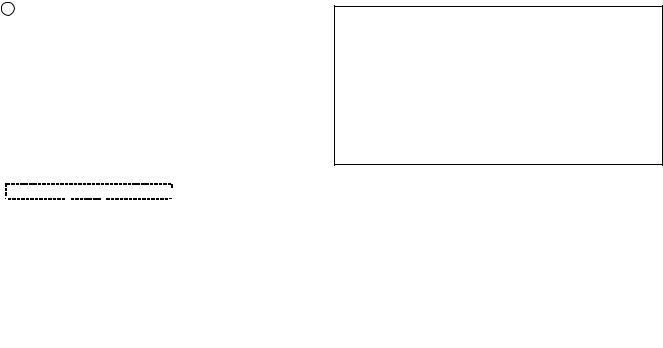

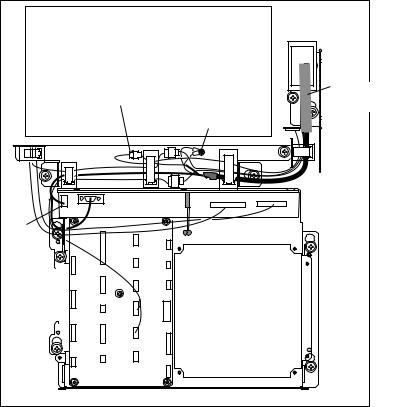

POWER Switch in AC

Powered Display Unit

The display unit designed to run on AC power has a power switch inside its base which cuts off 100/200 VAC power to the display unit. Pull the display unit forward several centimeters to access the switch. TURN THE SWITCH OFF (as well as the main POWER switch) WHENEVER ACCESSING INSIDE THE DISPLAY UNIT.

POWER Switch

J106

J106

J105

J105

J104

J104

J103

J103

J446 |

J466 |

J462 |

J465 |

Display unit, inside view

ii

TABLE OF CONTENTS

EQUIPMENT LISTS ............................................................................ |

iv |

SYSTEM CONFIGURATION ............................................................... |

vi |

MOUNTING

1.1 |

Scanner Unit ............................................................................................................. |

1-1 |

1.2 |

Display Unit ............................................................................................................... |

1-5 |

WIRING

2.1 |

Scanner Unit ............................................................................................................. |

2-1 |

2.2 |

Display Unit ............................................................................................................... |

2-6 |

2.3 |

Changing AC Power Specification for Display Unit ................................................. |

2-12 |

INITIALIZATION AND ADJUSTMENT

3.1 |

Tuning Initialization .................................................................................................... |

3-1 |

3.2 |

Accessing Menus for Initialization and Adjustment ................................................... |

3-1 |

3.3 |

Adjusting Video Signal Level ..................................................................................... |

3-2 |

3.4 |

Heading Alignment .................................................................................................... |

3-2 |

3.5 |

Adjusting Sweep Timing ............................................................................................ |

3-3 |

3.6 |

Suppressing Main Bang ............................................................................................ |

3-3 |

3.7 |

Confirming Magnetron Heater Voltage ...................................................................... |

3-4 |

3.8 |

Initual Setting Menu .................................................................................................. |

3-5 |

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 |

Gyro Converter GC-8 ................................................................................................ |

4-1 |

4.2 |

ARP Board ARP-26 ................................................................................................... |

4-7 |

4.3 |

RP Board RP-26...................................................................................................... |

4-10 |

4.4 |

Performance Monitor PM-30 ................................................................................... |

4-14 |

4.5 |

Alarm Kit .................................................................................................................. |

4-15 |

4.6 |

AC-DC Conversion Kit ............................................................................................ |

4-17 |

PACKING LISTS........................................................................................................ |

A-1 |

OUTLINE DRAWINGS ............................................................................................ |

D-1 |

INTERCONNECTION DIAGRAM ...................................................................... |

S-1 |

SCHEMATIC DIAGRAMS ..................................................................................... |

S-2 |

iii

EQUIPMENT LISTS

Standard Supply

Name |

Type |

Code No. |

Qty |

Remarks |

|

|

|

|

|

|

|

|

XN12AF-RSB0074-062 |

— |

|

FR-2115, 24 rpm, 1200mm, |

|

|

|

CP03-24201 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN12AF-RSB0075-062 |

— |

|

FR-2115, 42 rpm, 1200mm, |

|

|

|

CP03-24201 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN20AF-RSB0074-062 |

— |

|

FR-2115, 24 rpm, 2000mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN20AF-RSB0075-062 |

— |

|

FR-2115, 42 rpm, 2000mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN24AF-RSB0074-062 |

— |

|

FR-2115, 24 rpm, 2400mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN24AF-RSB0075-062 |

— |

|

FR-2115, 42 rpm, 2400mm, |

|

Scanner |

|

CP03-19101 |

|||

|

|

1 |

|||

Unit |

XN12AF-RSB0074-063 |

— |

FR-2125, 24 rpm, 1200mm, |

||

|

|||||

|

|

CP03-24201 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN12AF-RSB0075-063 |

— |

|

FR-2125, 42 rpm, 1200mm, |

|

|

|

CP03-24201 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN20AF-RSB0074-063 |

— |

|

FR-2125, 24 rpm, 2000 mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN20AF-RSB0075-063 |

— |

|

FR-2125, 42 rpm, 2000 mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN24AF-RSB0074-063 |

— |

|

FR-2125, 24 rpm, 2400 mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

XN24AF-RSB0075-063 |

— |

|

FR-2125, 42 rpm, 2400 mm, |

|

|

|

CP03-19101 |

|||

|

|

|

|

||

|

|

|

|

|

|

Display Unit |

RDP-124 |

— |

1 |

|

|

|

|

|

|

|

|

Spare Parts |

SP03-12500 |

000-089-390 |

1 |

DC ship's mains |

|

|

|

|

|||

SP03-12510 |

000-089-391 |

100 VAC ship's mains |

|||

|

|

||||

|

|

|

|

|

iv

Standard Supply

Name |

Type |

Code No. |

Qty |

Remarks |

|

|

|

|

|

|

|

|

|

|

|

CP03-19104 (Scanner unit), |

|

|

CP03-19100 |

000-089-393 |

|

CP03-19103 (Display unit), |

|

|

|

S03-75-15 |

|

||

|

|

|

|

|

|

|

|

|

|

(15 m signal cable) |

|

|

|

|

|

|

|

|

|

|

|

CP03-19104 (Scanner unit), |

|

|

CP03-19110 |

000-089-394 |

|

CP03-19103 (Display unit), |

|

|

|

|

|

S03-75-20 |

S |

|

|

|

|

|

|

|

|

|

|

CP03-19104 (Scanner unit), |

|

|

|

|

|

e |

|

|

CP03-19120 |

000-089-395 |

|

CP03-19103 (Display unit), |

|

|

|

e |

|||

Installation |

|

|

|

S03-75-30 |

|

|

|

1 |

|

||

Materials |

|

|

CP03-19104 (Scanner unit), |

p |

|

|

|

|

|||

|

CP03-19130 |

000-089-396 |

|

CP03-19103 (Display unit), |

a |

|

|

S03-74-15 |

c |

||

|

|

|

|

||

|

|

|

|

(15 m signal cable) |

k |

|

|

|

|

CP03-19104 (Scanner unit), |

i |

|

CP03-19140 |

000-089-397 |

|

CP03-19103 (Display unit), |

n |

|

|

|

|

S03-74-20 |

g |

|

|

|

|

|

|

|

|

|

|

CP03-19104 (Scanner unit), |

l |

|

CP03-19150 |

000-089-398 |

|

CP03-19103 (Display unit), |

|

|

|

i |

|||

|

|

|

|

S03-74-30 |

|

|

|

|

|

s |

|

|

|

|

|

|

|

|

|

|

|

FP03-06201, FP03-06502, |

t |

|

FP03-06510 |

000-089-400 |

|

FP03-06503, |

s |

|

|

|

|

Dust cover CRT (03-144-1338) |

|

|

|

|

|

|

|

Accessories |

|

|

1 |

For console type |

|

|

|

FP03-06201, FP03-06502, |

|

||

|

|

|

|

|

|

|

FP03-06550 |

000-089-476 |

|

FP03-06503, |

|

|

|

|

|

FP03-06504, |

|

|

|

|

|

Dust cover CRT (03-144-1338) |

|

|

|

|

|

|

|

Optional Equipment

Name |

Type |

Code No. |

Remarks |

|

|

|

|

|

|

Gyro Converter |

GC-8 |

008-446-520 |

Separate order |

|

|

|

|

|

|

Interswitch |

RJ-7 |

— |

|

|

|

|

|

|

|

Interswitch |

RJ-8 |

— |

|

|

|

|

|

|

|

Performance Monitor |

PM-30 |

— |

Mandatory for IMO radar |

|

|

|

|

|

|

Transformer Unit |

RU-1758 |

000-030-416 |

For 100/110/220 VAC |

|

|

|

|

|

|

Transformer Unit |

RU-1803 |

000-030-420 |

For 440 VAC |

|

|

|

|

|

|

Rectifier |

RU-3424 |

000-030-497 |

|

|

|

|

|

|

|

Performance Monitor |

OP03-150 |

008-485-490 |

|

|

Installation Kit |

|

|||

|

|

|

||

|

|

|

|

|

ARPA |

ARP-26-2E |

008-485-500 |

|

|

|

|

|

|

|

|

RP-26-T-2E |

008-485-510 |

|

|

Video Plotter |

|

|

|

|

RP-26-Z-2E |

008-485-520 |

For separate type control |

||

|

||||

|

head |

|||

|

|

|

||

|

|

|

|

|

Slave Display |

FMD-8010 |

— |

|

|

|

|

|

|

|

Separate Control Head |

OP03-151 |

008-485-530 |

|

|

Mounting Kit |

|

|||

|

|

|

||

|

|

|

|

|

Power Cable |

CVV-S (8X2C)-15 m |

000-560-634 |

For DC spec. display unit |

|

|

|

|

|

|

Alarm Kit |

OP03-156 |

008-500-650 |

|

|

|

|

|

|

|

AC-DC Conversion Kit |

OP03-161-24 |

008-499-760 |

24 rpm antenna |

|

|

|

|

|

|

AC-DC Conversion Kit |

OP03-161-42 |

008-499-770 |

24 rpm antenna |

|

|

|

|

|

|

Interface Unit |

IF-2300 |

— |

Mandatory for IMO radar |

|

|

|

|

|

v

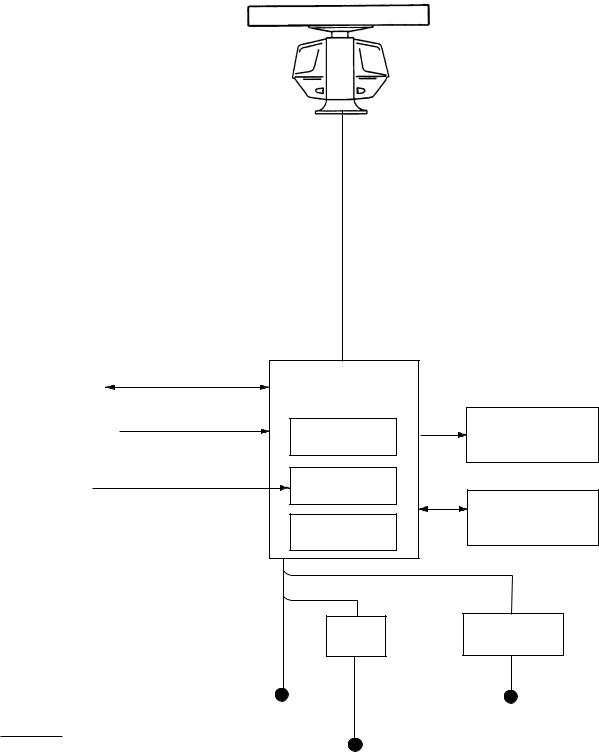

SYSTEM CONFIGURATION

SCANNER UNIT

FR-2115: XN12AF-RSB-0074-062

XN12AF-RSB-0075-062

XN20AF-RSB-0074-062

XN20AF-RSB-0075-062

XN24AF-RSB-0074-062

XN24AF-RSB-0075-062

FR-2125: XN12AF-RSB-0074-063

XN12AF-RSB-0075-063

XN20AF-RSB-0074-063

XN20AF-RSB-0075-063

XN24AF-RSB-0074-063

XN24AF-RSB-0075-063

Navigator |

IEC-61162-1 Serial Data |

DISPLAY UNIT |

|

(Input/Output) |

RDP-124 |

||

|

|||

Speed Log IEC-61162-1 Serial Data |

ARPA |

||

|

(Input) |

ARP-26 |

|

|

|

||

Gyrocompass |

|

Gyro Converter |

|

|

GC-8 |

||

|

|

||

Video Plotter

RP-26

DC spec

Rectifier

RU-3424

Ship’s Mains

Option 24/32 VDC

or

100/110/115/220/230 VAC

1φ, 50/60 Hz

AC spec or DC spec to be selected.

Slave Display

FMD-8010

Performance

Monitor

PM-30

AC spec

Transformer Unit

RU-1803

440 VAC

1φ, 50/60 Hz

vi

MOUNTING

1.1 Scanner Unit

Mounting considerations

•The scanner unit is generally installed either on top of the wheelhouse or on the radar mast, on a suitable platform. Locate the scanner unit where there is a good all-round view.

(a) On bridge |

(b) Common mast |

(c) Radar mast |

Figure 1-1 Mounting methods

•No funnel, mast or derrick should be within the vertical beamwidth of the scanner in the bow direction, especially zero degrees ±5°, to prevent blind sectors and false echoes on the radar picture.

•It is rarely possible to place the scanner unit where a completely clear view in all directions is available. Thus, you should determine the angular width and relative bearing of any shadow sectors for their influence on the radar at the first opportunity after fitting.

•Locate the antenna of a direction finder clear of the scanner unit to prevent interference to the direction finder. A separation of more than two meters is recommended.

•To lessen the chance of picking up electrical interference, avoid where possible routing the signal cable near other onboard electrical equipment. Also avoid running the cable in parallel with power cables.

•A magnetic compass will be affected if placed too close to the scanner unit.

Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass,1.70 m (FR-2115), 2.10 m (FR-2125), Steering compass, 1.90 m (FR-2115), 1.20 m (FR-2125).

•Do not paint the radiator aperture, to ensure proper emission of the radar waves.

•The signal cable run between the scanner and the display is available in lengths of 15 m (standard), 20 m, and 30 m. Whatever length is used it must be unbroken; namely, no splicing allowed.

•The scanner base is made of cast aluminum. To prevent electrolytic corrosion of the scanner base, use the seal washers and corrosion-proof rubber mat and ground the unit with the ground wire (supplied).

•Deposits and fumes from a funnel or other exhaust vent can adversely affect

the aerial performance and hot gases may distort the radiator portion. The scanner unit must not be mounted where the temperature is more than 70°C.

•Leave sufficient space around the unit for maintenance and servicing. See the scanner unit outline drawing for recommended maintenance space.

1-1

Assembling the scanner unit

The scanner unit consists of the scanner radiator and the scanner unit chassis, and they are packed separately. Fasten the scanner radiator to the scanner unit chassis as follows:

1.For the XN20AF, XN24AF, attach two guide pins to the underside of the scanner radiator.

2.Remove the waveguide cap from the radiator bracket. The cap may be discarded.

3.Coat the waveguide flange with anticorrosive sealant as shown in Figure 1-2.

10 mm O-ring

Hole for |

Hole for |

a guide pin |

a guide pin |

5 mm

Anticorrosive sealant

Figure 1-2 Coating the waveguide flange with anticorrosive sealant

4.Coat fixing holes for the scanner radiator with anticorrosive sealant.

5.Grease the O-ring and set it to the O-ring groove of the radiator flange.

6.Set the scanner radiator to the radiator bracket.

7.For the XN20AF, XN24AF, coat hex bolts (M8 x 40, slotted washer head, 8pcs.) with anticorrosive sealant and use them to loosely fasten the scanner radiator to the scanner unit chassis. For the XN12AF, coat hex bolts, flat washers and spring washers with anticorrosive sealant and use them to loosely fasten the scanner radiator to the scanner unit chassis.

8.Remove two guide pins (inserted at step 1), and then tighten fixing bolts.

CAUTION

CAUTION

Be sure to remove the guide pins.

Injury may result if the guide pins loosen and fall.

1-2

Antenna radiator

Guide pin (XN20AF, XN24AF only)

Waveguide

Radiator bracket

|

Hex bolt (M8X40), 8 pcs. |

|

(XN20AF, XN24AF only) |

|

Hex bolt (M8X35), 8 pcs. |

|

Flat washer |

|

Spring washer |

O-ring |

(XN12AF only) |

Figure 1-3 Fastening the radiator to the radiator bracket

Fastening the scanner unit to the mounting platform

The scanner unit may be assembled before hoisting it to the mounting platform. However, do not lift the scanner unit by the radiator. Always hold the unit by its housing. When using a crane or hoist, lift the unit by the hoist rings which should be fastened to the bolt fixing covers of the scanner housing.

CAUTION

CAUTION

DO NOT lift the antenna unit by the radiator; lift it by the hoist rings. (Be sure to remove rings after hoisting the antenna unit.)

Hoist |

NO! |

|

|

ring |

|

|

130cm |

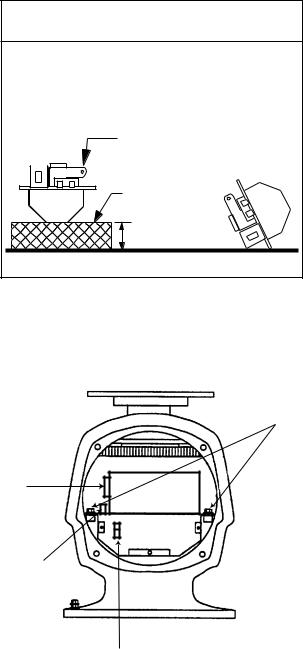

1.Construct a suitable mounting platform referring to the outline drawing at the back of the manual.

2.Drill four mounting holes of 15 mm diameter and one cable entry hole of about 50 mm diameter in the mounting platform.

3.Lay the rubber mat (supplied) on the mounting platform.

1-3

4.Place the scanner unit on the rubber mat orienting the unit so the bow mark on its base is facing the ship’s bow.

Ground terminal

Rubber mat

Bow mark

Figure 1-4 Scanner unit, front view

5.Fasten the scanner unit to the mounting platform with M12x60 hex bolts, nuts, flat washers and seal washers.

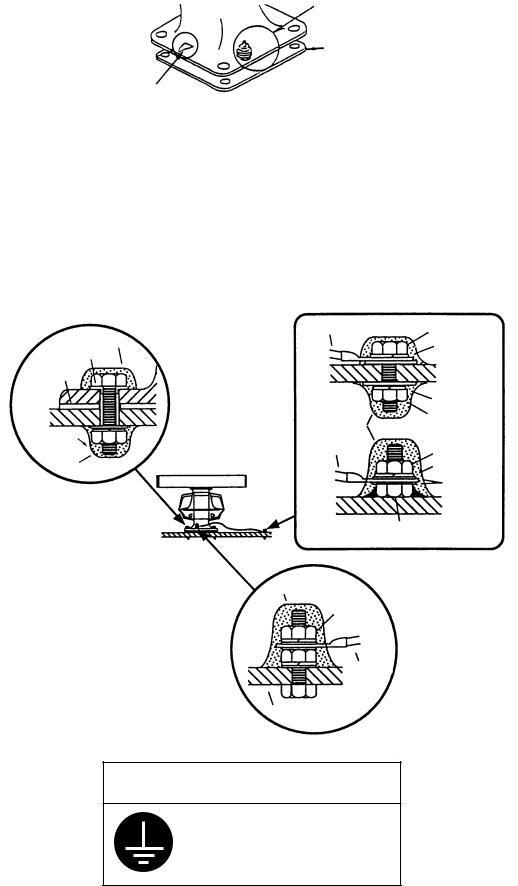

6.Using hex bolt (M6x25), nut (M6) and flat washer (M6) establish the ground system on the mounting platform as shown in Figure 1-5. The location should be within 370 mm of the ground terminal on the scanner unit. Connect the ground wire (RW-4747, 370 mm, supplied) between the grounding point and ground terminal on the scanner unit. Coat the entire ground system with silicone sealant (supplied).

|

|

|

Ground wire |

Hex bolt |

Anticorrosive sealant |

|

Spring washer |

||

Seal washer |

|

|||

|

|

|||

Rubber mat |

|

|

||

|

|

|

|

Spring washer |

|

|

|

Anticorrosive |

Hex nut |

|

|

|

OR |

|

Anticorrosive |

sealant |

|||

sealant |

Ground wire |

Hex nut |

||

|

|

|

||

|

|

|

|

|

|

|

|

|

Spring washer |

|

|

|

|

|

|

|

|

|

Flat washer |

|

|

|

|

Hex bolt welded to |

|

|

|

|

ship's superstructure |

|

|

|

Anticorrosive sealant |

|

|

|

|

Ground |

|

|

|

|

terminal |

|

Ground wire

Antenna base

CAUTION

CAUTION

Ground the equipment to prevent electrical shock and mutual interference.

Figure 1-5 How to mount the scanner unit

1-4

1.2 Display Unit

Before mounting the display unit

If Gyro Converter GC-8 (option) is to be used, install and setup the GYRO CON-

VERTER Board before mounting the display unit, because of the difficulty involved in doing it after the display unit is installed. Instructions for installation and setup are in Chapter 4.

Mounting considerations

When selecting a mounting location, keep in mind the following points:

•Select a location where the display unit can be viewed and operated conveniently and where the screen can be viewed while facing towards the bow.

•Locate the unit out of direct sunlight and way from heat sources because of heat that can build up inside the cabinet.

•Locate the equipment away from places subject to water splash and rain.

•The display unit is very heavy. Be sure the mounting location is strong enough to support the weight of the unit under the continued vibration which is normally experienced on the ship. If necessary reinforce the mounting location.

•Determine the mounting location considering the length of the signal cable between the scanner unit and the display unit. (The signal cable comes in lengths of 15, 20 or 30 meters; maximum 100 meters).

•Leave sufficient space on the sides and rear of the unit to facilitate maintenance. Also, leave a foot or so of “service loop” in cables behind the unit so it can be pulled forward for servicing or easy removal of connectors.

•A magnetic compass will be affected if placed too close to the display unit. Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 1.70 m, Steering compass, 0.90 m.

Mounting procedure

Tabletop mounting

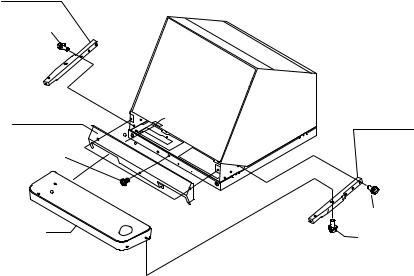

Two people are necessary to complete this procedure.

1.Make four holes of 12 mm diameter in the mounting location referring to the outline drawing at end of this manual.

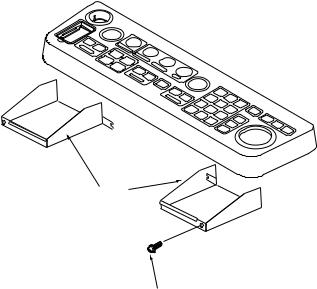

2.Unfasten the screws fixing the right and left arm covers on the control head.

Left and right arm covers

M4X10

3. Unfasten bolts (four total) hid- |

|

den by the arm covers. |

Figure 1-6 Control head |

|

1-5

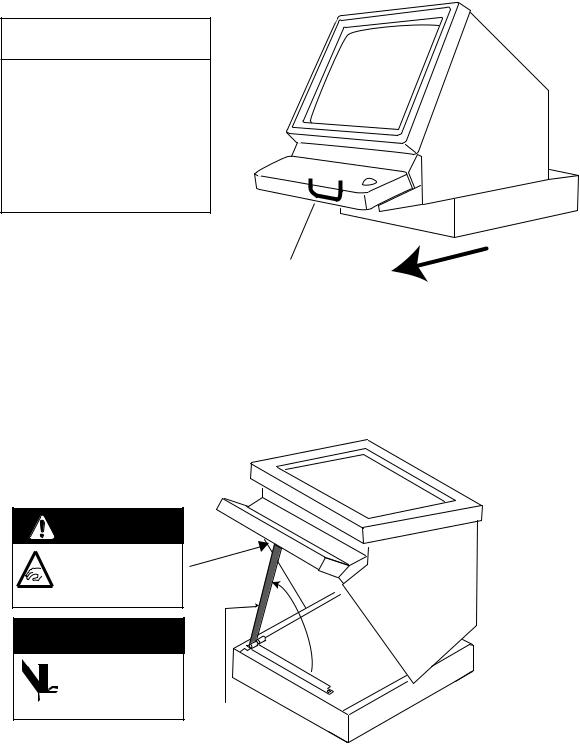

4.While one person is holding the mounting base at the sides, pull the handle on the underside of the control head to draw the display unit toward you until you hear a click.

CAUTION

CAUTION

Use two people to complete this step.

The display unit may fall to the deck when it is pulled forward, since the mounting base is not yet fastened to the mounting location.

Handle |

Pull forward |

|

Figure 1-7 Display unit

5.This step requires two people to complete. While raising the monitor until the CRT is horizontal, fix the stay as follows:

a)Raise the stay as shown below.

Two warning labels on the underside of monitor

HORIZONTAL

WARNING

Possibility of injury. Hold handle when mounting display unit.

WARNING

WARNING

Display unit may fall.

Lock stay before

Lock stay before

servicing.

Stay

Figure 1-8 Display unit, inside view

1-6

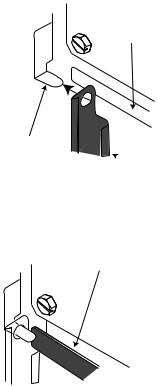

b) While pushing the stopper, set the catch on the display unit in the hole at the front edge of the stay.

Stopper

Catch

Stay

Stay

Figure 1-9 Setting catch to hole in stay

c) Release hand from stopper.

Release stopper; fix stay.

Figure 1-10 Stay fixed

6.Fasten the display unit to the mounting location at front fixing holes (2 points) with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

7.Retract the stay and lower the monitor.

8.The rear left fixing hole is hidden under the PTU board cover. Remove the cover as follows:

(1)Unfasten five M3x8 screws at the top of the PTU cover and two M4x8 screws at the front of the cover to slide the cover toward you.

1-7

(2)Remove the cover by grasping the knob on the top of the cover.

Fixing hole (rear)

*Screw (M3x8, 5 pcs.)

Slide forward

Knob |

* |

*

* |

* |

Screw (M4x8, 2 pcs.) |

Fixing hole (front) |

Figure 1-11 How to dismount the PTU cover

9.Fasten the display unit to the mounting location at rear fixing holes (2 points) with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied)

10.Close the PTU board cover.

11.Push the monitor forward until you hear a click. 12.Refasten the bolts removed at step 3.

13.Fix the left and right arm covers.

Console type mounting

1.Make six holes of 15 mm diameter and a cable entrance hole through the deck referring to the outline drawing at end of this manual.

2.Open the front cover.

3.Fix the equipment by using M12 bolts, nuts and washers.

4.Hoist the console to the deck by using the eye bolts attached to the console.

Remove the eye bolts and set the cosmetic caps (w/washers) to the eye bolt holes.

1-8

Separating the control head

The control head connects to the display unit with a connection cable, thus it can be located where desired, using the separate control head kit (option). Follow the procedure on the next page to separate the control head from the display unit.

Separate type control head kit (Type: OP03-151, No.: 008-485-530)

Name |

Type |

Qty |

Code No. |

Remarks |

|

|

|

|

|

Cable Assy. |

UL246SB20P/1P |

1 |

000-140-812 |

10 m, 03S9422 |

|

|

|

|

|

Nonslip Rubber Feet |

SJ-5003 |

4 |

000-801-787 |

w/double-sided tape |

|

|

|

|

|

Monitor Front Cover |

03-144-1361 |

1 |

100-263-340 |

|

|

|

|

|

|

KB Fixing Plate |

03-144-1691 |

1 |

100-263-940 |

|

|

|

|

|

|

Handle Plate |

03-144-1632 |

1 |

100-268-040 |

|

|

|

|

|

|

Dust Cover KB |

03-144-1693 |

1 |

100-271-760 |

|

|

|

|

|

|

Screw |

M4x10 |

3 |

000-881-446 |

|

|

|

|

|

|

Label |

86-003-1011 |

1 |

100-236-230 |

|

|

|

|

|

|

Nonslip Rubber |

03-144-1694 |

1 |

100-271-760 |

|

|

|

|

|

|

Display unit modification procedure

1.Raise the monitor unit referring to procedure for tabletop mounting on page 1-

7.

2.Unplug two connectors from the control head cable (P412 from MOTHER Board and J583 and unfasten two earth wires.

PTU COVER |

|

J583 |

Control Head |

Cable |

|

Earth Wire |

|

J418 |

|

MB 03P9251 |

|

P412 |

|

INT |

|

03P9252 |

|

Figure 1-12 Display unit, inside view

1-9

3.Lower the monitor.

4.Unfasten the M4 screw fixing the ground terminal of the connection cable.

5.Push the monitor forward until you hear a click.

6.Unscrew four screws fixing the top cover of the display unit.

7.Remove three clamps fixing the connection cable in the monitor unit.

8.Unfasten four screws fixing the right and left brackets on the control head.

9.Unfasten four screws fixing the right and left covers of the display unit.

10.Unfasten six screws fixing the right and left KB arms.

11.Unfasten three screws fixing the panel cover.

KB arm (L) 03-144-1341

M5x25 SUS 3 pcs.

Panel cover |

KB arm (R) |

|

03-144-1345 |

||

03-144-1342 |

||

|

||

M4x10, 3 pcs. |

|

M5x25 SUS 3 pcs.

Control head |

M5x25 SUS 4 pcs. |

|

Figure 1-13 Detaching the control head

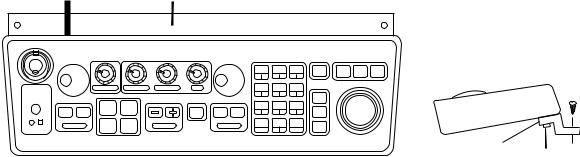

Control head modification procedure

1.Unfasten eight screws (M4X8) on the underside of the control head. Unplug connectors P314, P312 and P317 from the control head. Separate the KB bottom plate from the control head.

2.Unfasten the screw (M4) fixing the ground terminal and two screws (M4X8) fixing the clamp. Remove the connection cable assy.

3.Unfasten two screws (M6X12) from the inside of the bottom plate of the control head to dismount the handle.

1-10

4.Replace the cable assy. with cable assy. UL2464SB2-0P/1P (10 m, supplied) as below and reassemble the control head.

5.Attach warning label to the bottom plate.

P312 FX Connector

KB |

BOTTOM |

|

|

PLATE |

|

Upset Screw

M6X12 (2 pcs.)

KB Clamp

Handle

Attach warning label

J314 |

J317 |

(underside) |

|

|

|||

J312 |

|

|

|

|

(underside) |

||

|

|

||

|

(underside) |

||

Earth Wire

P314 XH3P

Replace with |

Spacer Pan-head Screw M4X8 (2 pcs.) |

cable assy. in |

Be careful not to pinch cable between |

kit. |

KB clamp and spacer. |

Screw

M4X8 (8 pcs.)

Lay cable in slot.

Figure 1-14 Control head

Connection of display unit to control head

1.Attach the handle to the handle plate, using the screws for the handle and bottom cover of the control head.

2.Attach the handle plate to location where the KB arms were fastened.

3.Pull the monitor toward you until you hear click.

4.Lead in the cable assy. (option) from the rear entrance of the display unit. See Chapter 2.

5.Raise the monitor and fix the stay.

6.Inside the display unit, fasten ground wire of the cable assembly with an M4 screw on the chassis.

1-11

7.Plug in two connectors of connection cable (P412, J583: See illustration on the previous page.)

8.Lower the monitor.

9.Attach the monitor front cover (option) to the place the panel cover have been, using the screw for the panel cover.

10.Attach rubber to feet to the bottom of the keyboard if the keyboard is not going to be permanently fixed. To fix the keyboard to a desired location, fasten the KB fixing plate to the keyboard and desired location with two upset screws (M5X25, formerly used to fasten KB arms) and two tapping screws (φ6.5, local supply) as below.

KB Fixing Plate

CONTROL HEAD |

φ6.5 |

|

SIDE VIEW |

||

Tapping |

||

|

||

|

Screw |

|

KB Fixing |

M5X25 |

|

Plate |

||

CONTROL HEAD TOP VIEW |

Upset |

|

|

Screw |

Figure 1-15 How to attach KB fixing plate

11.Set dust cover KB (supplied) on the control head.

Attachment of hood

1.Set two spacers (supplied) to the lower two of the four M5 holes in the CRT panel.

2.Screw two screws (supplied) into the holes in the hood.

3.Set the bottom of the hood to the screws at the bottom of the CRT panel, and then fasten the two screws at the top of the hood to the CRT panel.

1-12

WIRING

2.1 Scanner Unit

CAUTION

CAUTION

The magnetron in the transceiver module will demagnetize if it contacts ferrous material. When dismounting the transceiver module, lay it on its side or on top of non-ferrous material as shown below.

Transceiver module |

(magnetron inside) |

Non-ferrous |

block |

Height more than 5 cm

1.Open the scanner unit cover.

2.Disconnect plugs P611, P801 and P821.

3.Unfasten the transceiver module (two bolts). Remove the transceiver module.

Fixing bolts

J611

J801

J821

Figure 2-1 Scanner unit, front view

2-1

4.Unfasten the four fixing bolts on the cable gland at the base of the scanner unit. Remove clamping ring, rubber gasket and washers.

From left: Clamping ring, washer, rubber gasket and washer

Signal cable

Figure 2-2 Scanner unit, front view, cover removed

5.Pass the signal cable through the cable entry hole in the scanner unit mounting platform. Trim the cable so about 80 cm of it protrudes past the cable gland.

6.Slide the clamping ring, washer, rubber gasket and washer onto the cable in that order.

7.Fabricate the signal cable as shown on page 2-4 (signal cable S03-74), or page 2-5 (signal cable S03-75).

8.Referring to Figure 2-3, pass the outer and inner shields between the signal cable and the clamping ring. Fasten the cable gland.

Clamping

ring

Washers

Rubber gasket

Figure 2-3 Passing cable shields between cable and clamping ring

9.Connect the signal cable to the terminal board RTB801 by referring to the interconnection diagram. Leave “slack” in the coaxial wire to prevent breakage.

10.Bind cores of cables with cable ties.

11.Mount the transceiver module. Connect plugs P611, P801 and P821. Fasten the shield to the ground terminal on the transceiver module.

2-2

12.If the scanner is mounted 2° or more left of ship’s bow, adjust the position of S901 so it becomes “on” (contact between #1 and #2 on pcb MP-3795). To access S901, open the bow side cover; S901 is above the drive gear.

S901

RTB801

Bow mark

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 12 13 14 |

15 16 17 18 19 |

20 21 22 23 24 25 26 27 28 |

||||||||

Figure 2-4 Scanner unit, front view

13.Confirm that all screws are tightened and all wiring is properly made. Coat waterproofing gasket, bolts and tapping holes of scanner unit with silicone grease. Check that the waterproofing gasket is seated as shown in Figure 2-5.

Close the scanner unit cover.

Coat gasket with silicone grease.

DO NOT use silicone sealant.

CORRECT

WRONG

Figure 2-5 Correct seating of waterproofing gasket

2-3

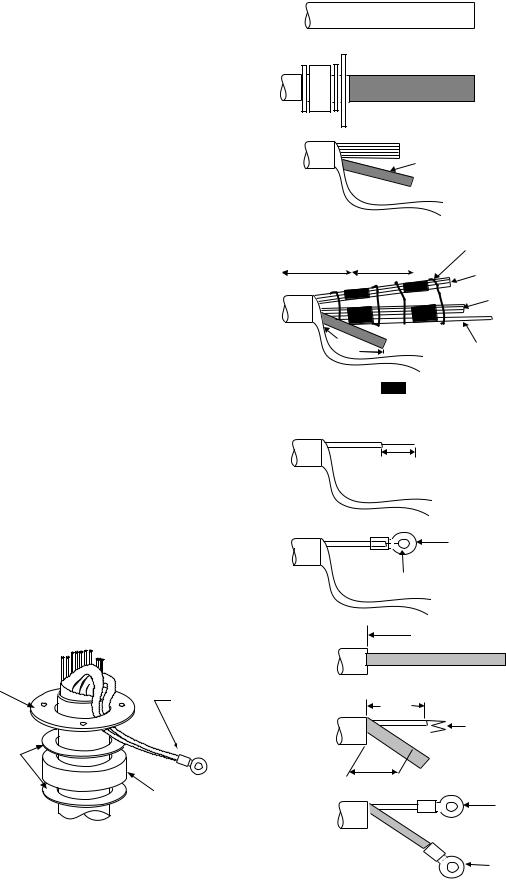

Fabricating signal cable S03-75

1.Remove the vinyl sheath by 450 mm.

2.Slide the clamping ring, washer, rubber gasket and washer onto the signal cable in that order.

3.Unravel the outer shield to expose the cores in the outer layer. Then, unravel the inner shield to expose the cores in the inner layer.

Label all inner cores to aid in identification.

4.Attach EMI cores to all inner cores and all outer cores, and tie them with cable ties, etc..

Note:There are two types of the EMI core, thick and thin.

5.Trim each core (except coaxial wire) considering its location on the terminal board.

6.Trim the inner and outer shields leaving 500

mmeach. Twist shields together and attach crimp-on lug FV5.5-4 (blue, ø4).

7.Remove insulation of each core by about 6

mm.Fix crimp-on lug FV1.25-M3 (red, ø3) to each core.

8.Fabricate the coaxial cable. Make the length

10 mm longer than the shield to prevent wire strain. Attach crimp-on lug FVD1.25-3 (red, ø3) to coaxial cable.

Clamping

ring |

Crimp-on lug |

|

(FV5.5-5, Blue, φ4) |

Washers

Rubber gasket

Figure 2-7 How to ground signal cable S03-75

VINYL SHEATH  450 mm

450 mm

Inner shield

under |

Cable tie |

|

70-130mm |

||

100mm |

||

Outer cores |

||

|

||

|

Inner cores |

500mm |

Coax cable |

= EMI cores

Outer cores : RFC-13 (thick) Inner cores : RFC-10 (thin)

6 mm

Red (φ3)

Crimp-on lug (FV1.25-M3)

75 mm

2C-2V

50 mm

6 mm

6 mm

Fold four times

45 mm |

Cut here |

|

Red (φ3) (FVD1.25-3)

Red (φ3) (FVD1.25-3)

Figure 2-6 How to fabricate signal cable S03-75

2-4

Loading...

Loading...