Furuno FR-2135S User Manual

Back

9-52 Ashihara-cho,

Nishinomiya, Japan

Telephone : 0798-65-2111

Telefax : 0798-65-4200

All rights reserved. |

Printed in Japan |

PUB.No. IME-34690-L

( TENI ) FR-2135S

Your Local Agent/Dealer

FIRST EDITION : OCT. 1998

L : JUL. 10,2003

*00080839301*

*00080839301*

* 0 0 0 8 0 8 3 9 3 0 1 *

*IME34690L00*

*IME34690L00*

* I M E 3 4 6 9 0 L 0 0 *

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

WARNING

WARNING

Radio Frequency Radiation

Hazard

The radar scanner emits electromagnetic radio frequency (RF) energy which can be harmful, particularly to your eyes. Never look directly into the scanner aperture from a close distance while the radar is in operation or expose yourself to the transmitting scanner at a close distance.

Distances at which RF radiation levels of 100 and 10 W/m2 exist are given in the table below.

Note: If the scanner unit is installed at a close distance in front of the wheelhouse, your administration may require halt of transmission within a certain sector of scanner revolution. This is possible—Ask your FURUNO representative or dealer to provide this feature.

|

Radiator |

Distance to |

Distance to |

|

Model |

100 W/m2 |

10 W/m2 |

||

type |

||||

|

point |

point |

||

|

|

|||

|

|

|

|

|

FR-2135S |

SN30AF |

— |

0.7m |

|

|

|

|

||

SN36AF |

— |

0.5m |

||

|

||||

|

|

|

|

WARNING

WARNING

|

Do not open the equipment |

|

|

unless totally familiar with |

|

|

electrical circuits and |

|

|

service manual. |

|

ELECTRICAL |

Only qualified personnel |

|

should work inside the |

||

SHOCK |

||

HAZARD |

equipment. |

|

|

|

|

|

Wear a safety belt and hard |

|

|

hat when working on the |

|

|

scanner unit. |

Serious injury or death can result if someone falls from the radar scanner mast.

Construct a suitable service platform from which to install the scanner unit.

Serious injury or death can result if someone falls from the radar scanner mast.

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can result if the power is left on or is applied while the equipment is being installed.

Do not install the display unit where it may get wet from rain or water splash.

Water in the display unit can result in fire, electrical shock or equipment damage.

i

WARNING

WARNING

Be sure that the power supply is compatible with the voltage rating of the equipment.

Connection of an incorrect power supply can cause fire or equipment damage. The voltage rating of the equipment appears on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a different cable is used.

CAUTION

CAUTION

Ground the equipment to prevent electrical shock and mutual interference.

Observe the following compass safe distances to prevent deviation of a magnetic compass:

|

Standard |

Steering |

|

|

compass |

compass |

|

|

|

|

|

Display |

1.70 m |

0.90 m |

|

Unit |

|||

|

|

||

|

|

|

|

Scanner |

5.00 m |

2.80 m |

|

Unit |

|||

|

|

||

|

|

|

|

Power |

|

|

|

supply |

0.50 m |

0.30 m |

|

unit |

|||

|

|

||

PSU-004 |

|

|

|

|

|

|

ii

TABLE OF CONTENTS

EQUIPMENT LISTS ............................................................................ |

iv |

SYSTEM CONFIGURATION ............................................................... |

vi |

MOUNTING

1.1 |

Scanner Unit ............................................................................................................. |

1-1 |

1.2 |

Display Unit ............................................................................................................... |

1-7 |

1.3 |

Power Supply Unit ................................................................................................... |

1-15 |

WIRING

2.1 |

Display Unit ............................................................................................................... |

2-1 |

2.2 |

Scanner Unit ............................................................................................................. |

2-6 |

2.3 |

Changing AC Power Specification of Display Unit ................................................... |

2-11 |

2.4 |

Power Supply Unit ................................................................................................... |

2-12 |

INITIALIZATION AND ADJUSTMENT

3.1 |

Tuning Initialization.................................................................................................... |

3-1 |

3.2 Accessing Menus for Initialization and Adjustment ................................................... |

3-1 |

|

3.3 |

Adjusting Video Signal Level ..................................................................................... |

3-1 |

3.5 |

Adjusting Sweep Timing ............................................................................................ |

3-3 |

3.6 |

Suppressing Main Bang ............................................................................................ |

3-3 |

3.7 |

Confirming Magnetron Heater Voltage ...................................................................... |

3-4 |

3.8 |

Initial Setting Menus .................................................................................................. |

3-5 |

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 |

Gyro Converter GC-8 ................................................................................................ |

4-1 |

4.2 |

ARP Board ARP-26 ................................................................................................... |

4-7 |

4.3 |

RP Board RP-26 ...................................................................................................... |

4-10 |

4.4 |

Performance Monitor PM-50 ................................................................................... |

4-14 |

4.5 |

Alarm Kit .................................................................................................................. |

4-15 |

PACKING LISTS ........................................................................................................ |

A-1 |

OUTLINE DRAWINGS ............................................................................................ |

D-1 |

INTERCONNECTION DIAGRAM ...................................................................... |

S-1 |

SCHEMATIC DIAGRAMS ..................................................................................... |

S-2 |

iii

EQUIPMENT LISTS

Standard Supply

Name |

Type |

Code No. |

Qty |

|

Remarks |

|

|

|

|

|

|

|

|

|

|

|

SN30AF |

- |

1 |

Radiator |

|

|

|

|

|

|

|

|

|||

|

SN36AF |

- |

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

RSB-0026 |

- |

1 |

Antenna chassis, with or without deicer |

|||

Scanner Unit |

|

|

|||||

RSB-0031 |

- |

||||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

RSB-0088 |

- |

|

|

|

|

|

|

|

|

|

|

|

||

|

RSB-0089 |

- |

|

Antenna chassis for HSC |

|

||

|

|

|

|

|

|

|

|

|

RSB-0090 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Display Unit |

RDP-124 |

- |

1 |

|

|

|

|

|

|

|

|

|

|

||

|

PSU-004-70-23-S |

- |

|

3φ , 220/230 VAC |

|

||

|

|

|

|

|

|

||

Power Supply |

PSU-004-80-10-S |

- |

1 |

3φ , 380/440 VAC |

|

||

Unit |

|

|

|

|

|

||

PSU-004-70-23-HK |

- |

|

3φ , 220/230 VAC |

|

|||

|

|

|

|||||

|

|

|

|

|

|

||

|

PSU-004-80-23-HK |

- |

|

3φ , 380/440 VAC |

|

||

|

|

|

|

|

|

||

Spare Parts |

SP03-13100 |

000-087-698 |

1 |

SP03-12506 (Display Unit), |

|

||

SP03-10320 (Power Supply Unit) |

|

||||||

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

CP03-14603, CP03-19105, |

|

||

|

CP03-20000 |

000-087-699 |

|

CP03-13907 Signal cable |

|

||

|

|

|

|

S03-74-15 (15 m) |

S |

||

|

|

|

|

|

|

||

|

|

|

|

CP03-14603, CP03-19105, |

E |

||

|

CP03-20010 |

000-087-700 |

|

CP03-13907 |

Signal cable |

E |

|

Installation |

|

|

1 |

S03-74-20 (20 m) |

P |

||

Materials |

|

|

CP03-14603, CP03-19105, |

||||

|

|

|

|||||

|

CP03-20020 |

000-087-701 |

|

CP03-13907 |

Signal cable |

A |

|

|

|

C |

|||||

|

|

|

|

S03-74-30 (30 m) |

|||

|

|

|

|

K |

|||

|

|

|

|

|

|

||

|

|

|

|

CP03-14603, CP03-19105, |

|||

|

|

|

|

I |

|||

|

CP03-20030 |

000-087-702 |

|

CP03-13907 |

Signal cable |

||

|

|

N |

|||||

|

|

|

|

S03-74-60 (60 m) |

|||

|

|

|

|

G |

|||

|

|

|

|

|

|

||

|

|

|

|

FP03-06201, FP03-06502, |

L |

||

|

FP03-06610 |

000-087-704 |

|

FP03-06503, FP03-02710 |

|||

|

|

|

|

Dust cover |

|

I |

|

|

|

|

|

|

|

S |

|

Accessories |

|

|

1 |

For console type: |

|||

|

|

T |

|||||

|

|

FP03-06201, FP03-06504, |

|||||

|

|

|

|

S |

|||

|

FP03-06630 |

000-087-714 |

|

FP03-06502, FP03-06503, |

|||

|

|

|

|||||

|

|

|

|

FP03-02710 |

|

|

|

|

|

|

|

Dust cover |

|

|

|

|

|

|

|

|

|

|

|

iv

Optional Equipment

Name |

Type |

Code No. |

Qty |

Remarks |

|

|

|

|

|

|

|

Remote Display |

FMD-8010 |

– |

1 |

|

|

|

|

|

|

|

|

Gyro Converter |

GC-8-2 |

008-446-520 |

1 set |

Separate order |

|

|

|

|

|

|

|

Interswitch |

RJ-7 |

– |

1 |

|

|

|

|

|

|

|

|

Interswitch |

RJ-8 |

– |

1 |

|

|

|

|

|

|

|

|

Performance Monitor |

PM-50 |

– |

1 |

Mandatory for IMO radar |

|

|

|

|

|

|

|

|

RU-5693 |

000-030-456 |

1 |

110 V → 220 V, 3φ |

|

|

for scanner unit |

||||

|

|

|

|

||

|

|

|

|

|

|

|

RU-1803 |

000-030-497 |

1 |

440 V → 100 V, 1φ |

|

|

for display unit |

||||

|

|

|

|

||

Transformer |

|

|

|

|

|

RU-6522 |

000-030-410 |

1 |

220 V → 200 V, 3φ |

||

Unit |

|||||

for scanner unit |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

RU-3305 |

000-030-448 |

1 |

For deicer |

|

|

|

|

|

|

|

|

RU-5466-1 |

000-030-453 |

1 |

440 V → 200 V, 3φ |

|

|

for scanner unit |

||||

|

|

|

|

||

|

|

|

|

|

|

PM Installation Kit |

OP03-150 |

008-485-490 |

1 set |

|

|

|

|

|

|

|

|

ARPA |

ARP-26 |

008-485-500 |

1 set |

|

|

|

|

|

|

|

|

|

RP-26-T |

008-485-510 |

|

Tabletop, console type |

|

Video Plotter |

|

|

1 set |

|

|

RP-26-Z |

008-485-520 |

For separate control |

|||

|

|

||||

|

|

head |

|||

|

|

|

|

||

|

|

|

|

|

|

Separate Control Head |

OP03-151 |

008-485-530 |

1 |

|

|

Mounting Kit |

|

||||

|

|

|

|

||

|

|

|

|

|

|

Alarm Kit |

OP03-156 |

008-500-650 |

1 |

|

|

|

|

|

|

|

|

Interface Unit |

IF-2300 |

– |

1 |

Mandatory for IMO radar |

|

|

|

|

|

|

v

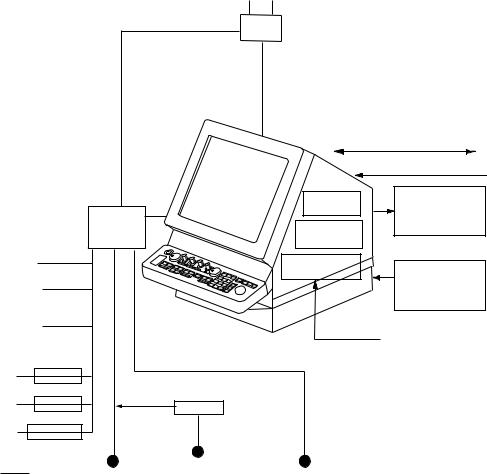

SYSTEM CONFIGURATION

SCANNER UNIT |

|

SN30AF/SN36AF |

POWER SUPPLY

UNIT PSU-004

220 VAC, 3φ , 60 Hz

200 VAC, 3φ , 50 Hz

440 VAC, 3φ , 60 Hz

380 VAC, 3φ , 50 Hz

For HSC

220 VAC, 3φ , 50 Hz

220 VAC, 3φ , 60 Hz

440 VAC, 3φ , 60 Hz

110 VAC, 3φ , |

|

RU-5693 |

60 Hz |

|

|

220 VAC, 3φ , |

|

RU-6522 |

50 Hz |

|

|

440 VAC, 3φ , |

RU-5466-1 |

|

50 Hz |

|

|

OPTION

RSB-0026/0031

RSB-0088/0089/0090 (For HSC)

|

|

|

IEC 61162-1 (Input/Output) Navigator |

|

|

|

|

|

IEC 61162-1 (Input) |

|

|

DISPLAY UNIT |

Speed Log |

|

|

|

|

||

|

|

RDP-124 |

ARPA Board |

Slave Display |

|

|

ARP-26 |

||

|

|

|

FMD-8010 |

|

|

|

|

Video Plotter |

|

|

|

|

|

|

For |

|

|

RP-26 |

|

|

|

Gyro Converter |

Performance |

|

|

|

|

||

UNITSCANNER |

DISPLAYFor |

For DE-ICER |

GC-8 |

|

|

Monitor |

|||

|

|

|

|

|

|

|

|

|

PM-50 |

|

|

|

|

Gyrocompass |

|

UNIT |

|

|

|

|

|

RU-1803 |

|

|

|

|

440 VAC |

|

|

|

|

1φ , 50/60 Hz |

|

|

|

SHIP’S MAINS |

|

|

|

|

100/110/115/ |

100 VAC |

|

|

|

220/230 VAC |

1φ , 50/60 Hz |

|

|

1φ , 50/60 Hz

vi

MOUNTING

1.1 Scanner Unit

Mounting considerations

•The scanner unit is generally installed either on top of the wheelhouse or on the radar mast, on a suitable platform. Locate the scanner unit where there is a good all-round view.

•No funnel, mast or derrick should be within the vertical beamwidth of the scanner in the bow direction, especially zero degrees ±5°, to prevent blind sectors and false echoes on the radar picture.

•It is rarely possible to place the scanner unit where a completely clear view in all directions is available. Thus, you should determine the angular width and relative bearing of any shadow sectors for their influence on the radar at the first opportunity after fitting.

•Locate the antenna of a direction finder clear of the scanner unit to prevent interference to the direction finder. A separation of more than two meters is recommended.

•To lessen the chance of picking up electrical interference, avoid where possible routing the signal cable near other onboard electrical equipment. Also avoid running the cable in parallel with power cables.

•A magnetic compass will be affected if placed too close to the scanner unit. Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 5.0 m, Steering compass, 2.80 m.

•Do not paint the radiator aperture, to ensure proper emission of the radar waves.

•The signal cable run between the scanner and the display is available in lengths of 15 m (standard), 20 m, 30 m and 60 m. Whatever length is used it must be unbroken; namely, no splicing allowed.

•Deposits and fumes from a funnel or other exhaust vent can adversely affect

the aerial performance and hot gases may distort the radiator portion. The scanner unit must not be mounted where the temperature is more than 70°C.

•The scanner base is made of cast aluminum. To prevent electrolytic corrosion of the scanner base, use the seal washers and corrosion-proof rubber mat and ground the unit with the ground wire (supplied).

•Leave sufficient space around the unit for maintenance and servicing. See the scanner unit outline drawing for recommended maintenance space.

1-1

Installation precaution for S-band scanner unit

If an S-band scanner unit is mounted near the end of a platform to provide sufficient rotation clearance for the radiator, the scanner unit, because of its weight, swings up and down by ship’s vibration and rolling, exerting excessive levels of stress at the base of the radiator, which can damage the radiator. To prevent this, relocate the scanner unit, or if relocation is not possible, reinforce the platform.

Pole for DF, etc.

Remarkable vibration (pitching)

Mounting position

EXAMPLE

Pole for DF

Mount the scanner unit Directly on the mast or on the platform, as near as possible to the center of the mast.

Figure 1-1 Mounting of S-band scanner unit

1-2

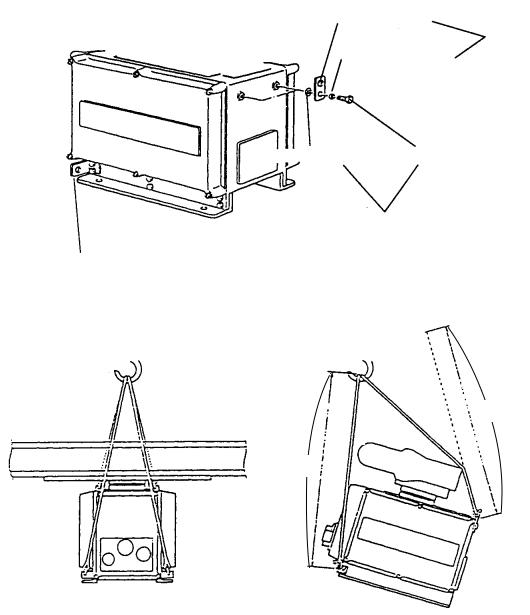

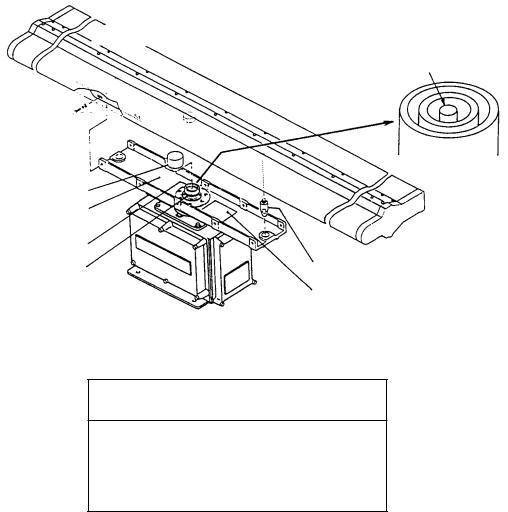

How to lift scanner unit

1.Fix the scanner radiator to the scanner unit chassis.

2.Attach the lifting fixtures and collars as shown in Figure 1-2 and 1-3.

.

3. Position the radiator as shown in Figure 1-3 and arrange the ropes A=. 2m

.

and B=. 1.8m.

Lifting fixture

|

Supplied as installation |

Collar for fixing |

materials. Remove after |

installation. |

Spring washer |

(M12) |

Hex bolt (M12X20) |

Remove lifting fixture, coat threads of hex bolts with silicone grease, and then insert bolts in scanner body.

Lifting hook (2 pcs.)

Figure 1-2 Attachment of lifting fixtures and collar

.

B=1. .8m

. * A=2. .0m

*

* Protect radiator with cardboard or cloth at locations marked with asterisk.

Figure 1-3 Attachment of ropes

1-3

Scanner unit assembling

The scanner radiator and the scanner housing are shipped in separate packages.

Assemble them as below. The scanner unit may be assembled before hoisting it to the mounting platform. However, do not lift the scanner unit by the radiator.

Scanner unit assembling procedure

1.Screw the guide pins (2 pcs.) in the radiator.

2.Remove the protective cap from the choke guide.

3.Grease O-ring and set it to groove of the choke guide.

4.Place the radiator on the radiator bracket. (Radiator direction is shown by the logo on the bracket. If reversely oriented the radiator cannot be set to the bracket.)

5.Loosely fix the radiator to the radiator bracket with hex bolts (M10 x 25), spring washers and flat washers.

6.Remove the guides pins and tighten hexagon bolts.

Scanner radiator

Spring washer, flat washer, 10 pcs. each, M1025

Protective cap

Radiator bracket

Choke guide

O-ring

(JIS B2401- 1A-G60, 2 pcs.)

Do not remove the teflon tube from the center conductor.

Guide pin (2 pcs.)

Instruction label for scanner aperature direction

Figure 1-4 Assembling the radiator

CAUTION

CAUTION

Be sure to remove the guide pins.

Injury may result if the guide pins loosen and fall.

1-4

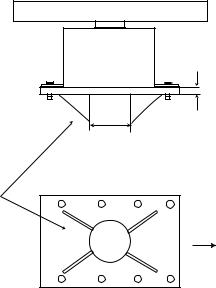

Fastening the scanner unit to the mounting platform

See the figure on the next page for scanner unit mounting.

1.Referring to the scanner outline drawing, drill four bolt holes (15 mm dia.) in the radar mast platform or the deck.

•The diameter of the mast for fixing the scanner unit platform must be over 15 mm.

•The thickness of the scanner unit platform must be over 15 mm.

•The reinforcement ribs must be installed diagonally as shown below.

Over 15 mm

Use two nuts.

250 mm diameter or more,

6 mm thick or more

Install the reinforcement ribs diagonally.

Ship’s bow

BOTTOM VIEW

Figure 1-5 Installation of reinforcement ribs

2.Place the corrosion-proof rubber mat (supplied) on the mounting platform.

3.Hoist the scanner unit as shown on page 1-3 and place it on the rubber mat. Orient the cable gland toward the ship’s stern (or port, starboard). Remove the lifting fixtures and collars.

4.Fix the scanner base to the mounting platform with four M12x70 hex bolts, nuts, washers and seal washers (supplied).

5.Arrange the grounding terminal at the nearest grounding spot with the M6x25 hex bolt, nut and washers (supplied). Then, fix a ground wire (RW-4747, 340 mm long) to the terminal.

6.Connect the other end of the ground wire to the ground terminal of the scanner unit.

7.Coat grounding terminal and fixing bolts on the scanner unit with silicone sealant (supplied).

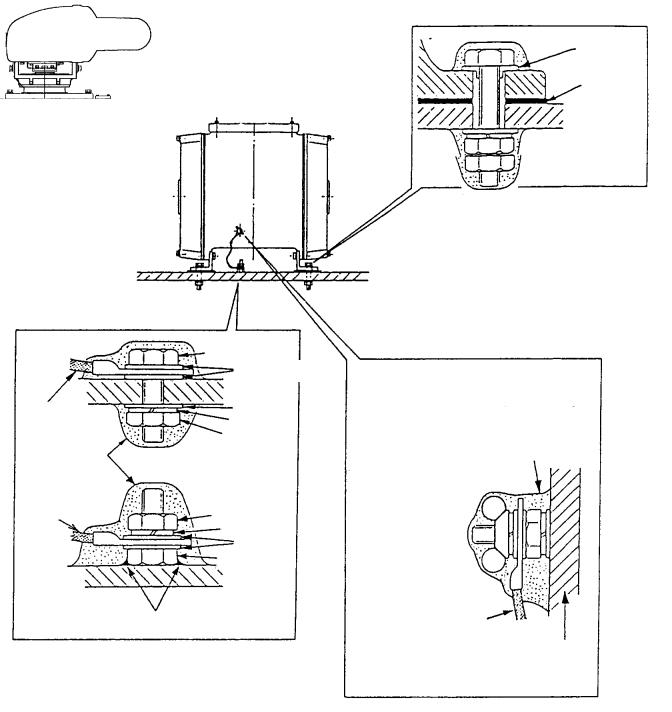

1-5

Seal washer

Corrosionproof rubber mat

Use two nuts.

Set corrosion-proof rubber mat, bolt scanner unit to mounting location, and coat exposed hardware with silicone sealant.

Hex bolt

Flat washer

Ground wire |

|

Flat washer |

|

|

Spring washer |

||

|

|

||

|

|

|

|

Coat with |

Hex nut |

||

|

|

|

|

silicone |

OR |

||

sealant. |

|

|

|

Ground wire |

Hex nut |

||

|

|||

|

|

Spring washer |

|

|

|

Flat washer |

|

|

|

|

|

|

Hex bolt |

|

|

Welding

Arrange ground terminal as close as possible to scanner unit.

Coat with silicone sealant after fastening ground wire.

Ground wire

Scanner body

Ground terminal provided on scanner base.

Figure 1-6 Mounting of scanner unit

1-6

1.2 Display Unit

Before mounting the display unit

If Gyro Converter GC-8 (option) is to be used, install and setup the GYRO CON-

VERTER Board before mounting the display unit, because of the difficulty involved in doing it after the display unit is installed. Instructions for installation and setup are in Chapter 4.

Mounting considerations

When selecting a mounting location, keep in mind the following points:

•Select a location where the display unit can be viewed and operated conveniently and where the screen can be viewed while facing towards the bow.

•Locate the unit out of direct sunlight and away from heat sources because of heat that can build up inside the cabinet.

•Locate the equipment away from places subject to water splash and rain.

•The display unit is very heavy. Be sure the mounting location is strong enough to support the weight of the unit under the continued vibration which is normally experienced on the ship. If necessary reinforce the mounting location.

•Determine the mounting location considering the length of the signal cable between the scanner unit and the display unit and the power cable between the display unit and Power Supply Unit PSU-004.

•Leave sufficient space on the sides and rear of the unit to facilitate maintenance. Also, leave a foot or so of “service loop” in cables behind the unit so it can be pulled forward for servicing or easy removal of connectors.

•A magnetic compass will be affected if placed too close to the display unit. Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 1.70 m, Steering compass, 0.90 m.

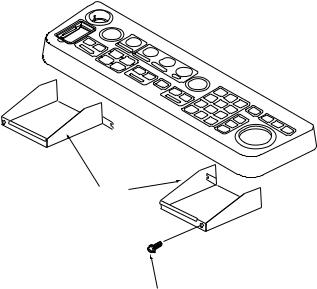

Mounting procedure

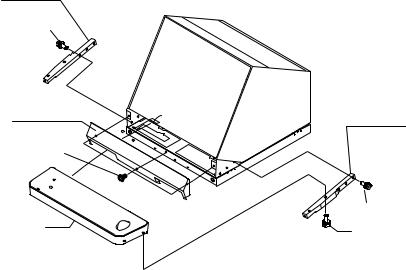

Tabletop mounting

This procedure requires two people to complete.

1.Make four holes of 12 mm diameter referring to the outline drawing at end of this manual.

2.Unfasten the screws fixing the right and left brackets on the control head

3.Unfasten bolts (four total) in the brackets.

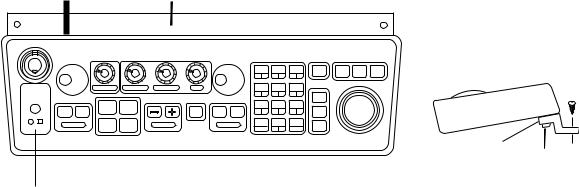

Left, right arm cover

M4x10

Figure 1-7 Control head

1-7

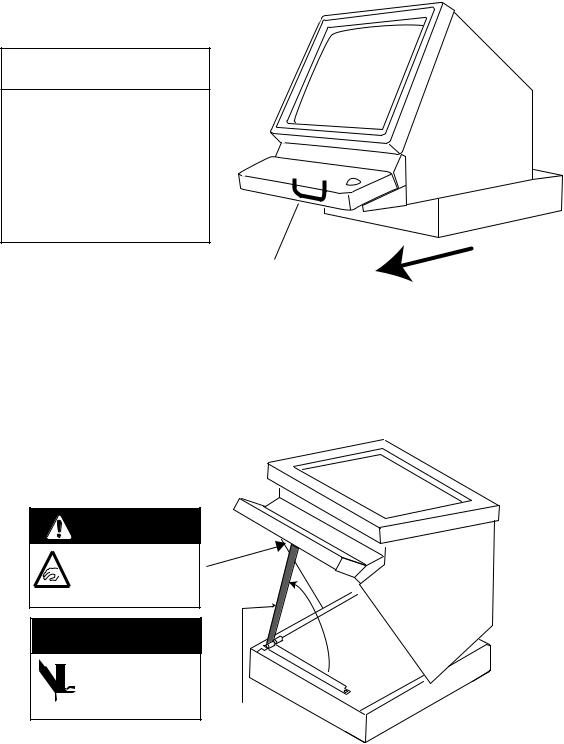

4.While one person is holding the mounting base at the sides, pull the handle on the underside of the control head to draw the display unit toward you until you hear a click.

CAUTION

CAUTION

Use two people to complete this step.

The display unit may fall to the deck when it is pulled forward, since the mounting base is not yet fastened to the mounting location.

Handle |

Pull forward |

|

|

Figure 1-8 Display unit |

|

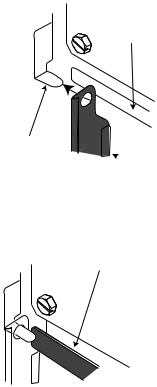

5.This step requires two people to complete. While raising the monitor until the CRT is horizontal, fix the stay as follows:

a)Raise the stay as shown below.

Two warning labels on the underside of monitor

HORIZONTAL

WARNING

Possibility of injury. Hold handle when mounting display unit.

WARNING

WARNING

Display unit may fall.

Lock stay before

Lock stay before

servicing.

Stay

Figure 1-9 Display unit, inside view

b) While pushing the stopper, set the catch on the display unit in the hole at the front edge of the stay.

1-8

Stopper

Catch

Stay

Stay

Figure 1-10 Setting catch to hole in stay c) Release hand from stopper.

Release stopper; fix stay.

Figure 1-11 Stay fixed

6.Fasten the display unit to the mounting location at front fixing holes (2 points) with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

You cannot fasten the display unit at the rear fixing holes while the monitor is raised.

7.Retract the stay and lower the monitor.

8.Fasten the display unit to the mounting locations at rear fixing holes (2 points) with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

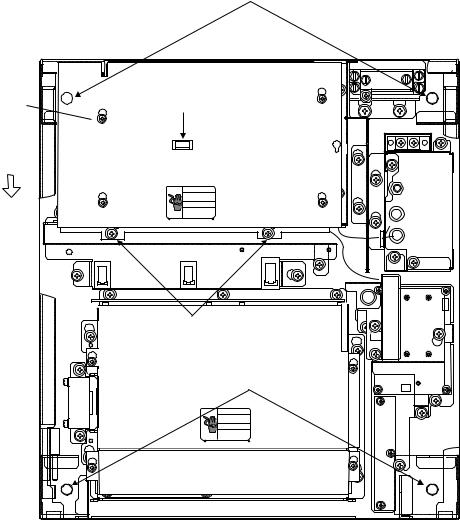

The rear left hole is hid under the PTU cover. Remove the cover as follows:

(1)Unfasten five M3x8 screws at the top of the PTU cover and two M4x8 screws at the front of the cover to slide the cover toward the front side.

(2)Remove the cover by grasping the knob on the top of the cover.

1-9

*M3x8, 5 pcs.

Slide forward.

Fixing hole (rear)

Knob |

* |

*

* |

* |

M4x8, 2 pcs. |

Fixing hole (front) |

Figure 1-12 How to remove the PTU cover

9. Push the monitor forward until you hear a click.

10.Fix the brackets with the M10 bolts removed at step 2.

Console type mounting

1.Make six holes of 15 mm diameter and a cable entrance hole through the deck referring to the outline drawing at end of this manual.

2.Open the front cover.

3.Fix the equipment with M12 bolts, nuts and washers.

4.Hoist the console to the deck by using the eye bolts attached to the console. Remove the eye bolts and set the cosmetic caps to the eye bolt holes.

Separating the control head

The control head connects to the display unit with a connection cable, thus it can be located where desired, using the separate control head kit (option). Follow the procedure on the next page to separate the control head from the display unit.

1-10

Separate type control head kit (Type: OP03-151, No.: 008-485-530)

Name |

Type |

Qty |

Code no. |

Remarks |

|

|

|

|

|

Cable Assy. |

UL246SB20P/1P |

1 |

000-140-812 |

10 m, 03S9422 |

|

|

|

|

|

Rubber Feet |

SJ-5003 |

4 |

000-801-787 |

w/tape |

|

|

|

|

|

Monitor Front Cover |

03-255-1361 |

1 |

100-263-340 |

|

|

|

|

|

|

KB Fixing Plate |

03-144-1691 |

1 |

100-263-940 |

|

|

|

|

|

|

Handle Plate |

03-144-1632 |

1 |

100-268-041 |

|

|

|

|

|

|

Dust cover KB |

03-144-1693 |

1 |

100-271-760 |

|

|

|

|

|

|

Screw |

M4x10 |

3 |

000-881-446 |

|

|

|

|

|

|

Label |

86-003-1011 |

1 |

100-236-230 |

|

|

|

|

|

|

Nonship Rubber |

03-144-1694 |

1 |

100-271-760 |

|

|

|

|

|

|

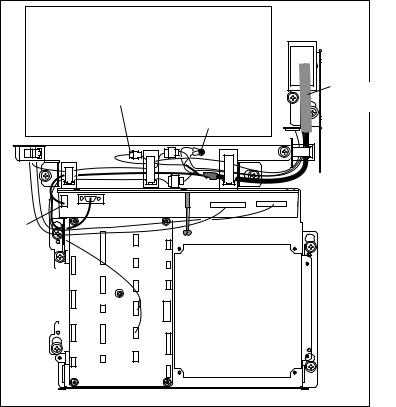

Display unit modification procedure

1.Raise the monitor unit referring to procedure for tabletop mounting on page 1- 8.

2.Unplug two connectors from the control head cable (P412 from MOTHER Board and J583 and unfasten two earth wires.

PTU COVER |

|

J583 |

Control Head |

Cable |

|

Earth Wire |

|

J418 |

|

MB 03P9251 |

|

P412 |

|

INT |

|

03P9252 |

|

Figure 1-13 Display unit, inside view

3. Lower the monitor.

1-11

4.Unfasten the M4 screw fixing the ground terminal of the connection cable.

5.Push the monitor forward until you hear a click.

6.Unscrew four screws fixing the top cover of the display unit.

7.Remove three clamps fixing the connection cable in the monitor unit.

8.Unfasten four screws fixing the right and left brackets on the control head.

9.Unfasten four screws fixing the right and left covers of the display unit.

10.Unfasten six screws fixing the right and left KB arms.

11. Unfasten three screws fixing the panel cover.

KB arm (L) 03-144-1341

M5X25 SUS 3 pcs.

Panel cover |

KB arm (R) |

|

03-144-1345 |

||

03-144-1342 |

||

|

||

M4X10, 3 pcs. |

|

M5X25 SUS 3 pcs.

Control head |

M5X25 SUS 4 pcs. |

|

Figure 1-14 Detaching the control head

1-12

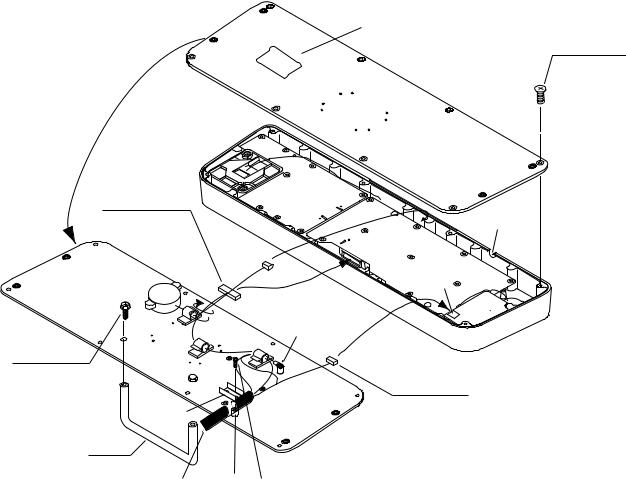

Control head modification procedure

1.Unfasten eight screws (M4X8) on the underside of the control head. Unplug connectors P314, P312 and P317 from the control head. Separate the KB bottom plate from the control head.

2.Unfasten the screw (M4) fixing the ground terminal and two screws (M4X8) fixing the clamp. Remove the connection cable assy.

3.Unfasten two screws (M6X12) from the inside of the bottom plate of the control head to dismount the handle.

4.Replace the cable assy. with cable assy. UL2464SB2-0P/1P (10 m, supplied) as below and reassemble the control head.

5.Paste warning label to the bottom plate.

P312 FX Connector

KB |

BOTTOM |

|

|

PLATE |

|

Upset Screw

M6X12 (2 pcs.)

KB Clamp

Handle

Warning label

J314 |

J317 |

(underside) |

|

|

|||

J312 |

|

|

|

|

(underside) |

||

|

|

||

|

(underside) |

||

Earth Wire

P314 XH3P

Replace with |

Spacer Pan-head Screw M4X8 (2 pcs.) |

cable assy. in |

Be careful not to pinch cable between |

kit. |

KB clamp and spacer. |

Screw

M4X8 (8 pcs.)

Lay cable in slot.

Figure 1-15 Control head

Connection of display unit to control head

1-13

Connection of display unit to control head

1.Attach the handle to the handle plate, using the screws for the handle and bottom cover of the control head.

2.Attach the handle plate to location where the KB arms were fastened.

3.Pull the monitor toward you until you hear click.

4.Lead in the cable assy. (option) from the rear entrance of the display unit. See

Chapter 2.

5.Raise the monitor and fix the stay.

6.Inside the display unit, fasten ground wire of the cable assembly with an M4 screw on the chassis.

7.Plug in two connectors of connection cable (P412, J583: See illustration on the previous page.)

8.Lower the monitor.

9.Attach the monitor front cover (option) to the place the panel cover have been, using the screw for the panel cover.

10.Attach rubber to feet to the bottom of the keyboard if the keyboard is not going to be permanently fixed. To fix the keyboard to a desired location, fasten the KB fixing plate to the keyboard and desired location with two upset screws (M5X25, formerly used to fasten KB arms) and two tapping screws (φ 6.5, local supply) as below.

KB Fixing Plate

CONTROL HEAD |

φ 6.5 |

|

SIDE VIEW |

||

Tapping |

||

|

||

|

Screw |

|

KB Fixing |

M5X25 |

|

Plate |

||

CONTROL HEAD TOP VIEW |

Upset |

|

|

Screw |

Tuning compartment (Performance Monitor SW inside)

Figure 1-16 How to attach KB fixing plate

11.Set dust cover KB (supplied) on the control head.

Attachment of hood

1.Set two spacers (supplied) to the lower two of the four M5 holes in the CRT panel.

2.Screw two screws (supplied) into the holes in the hood.

3.Set the bottom of the hood to the screws at the bottom of the CRT panel, and then fasten the two screws at the top of the hood to the CRT panel.

1-14

1.3 Power Supply Unit

The Power Supply Unit PSU-004 does not contain usual operating controls. Therefore, it can be installed in any recessed place either in vertical or horizontal position. (For the console mount display unit, the PSU-004 can be installed inside the console.) However, select a dry and well-ventilated location and observe the compass safe distances below to prevent deviation of a magnetic compass: Standard compass, 0.50 m, Steering compass, 0.30 m. Fasten the unit to chosen location with four M6 screws.

1-15

This page is intentionally left blank.

WIRING

2.1 Display Unit

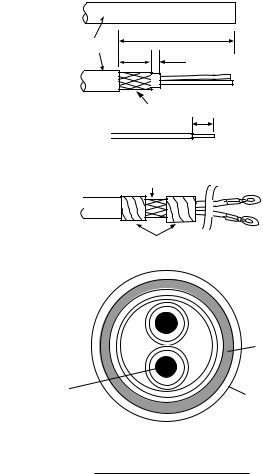

Fabricating the power cable DPYCY-3.5 (JIS cable)

1.Remove the vinyl sheath by 80 mm.

2.Cut off jute tape wrapped around the armor.

3.Unravel the armor to expose the cores by about 35 mm.

4.Remove insulation of cores by about 10 mm. Fix crimp-on lugs to the cores and armor.

5.Cover the armor with vinyl tape, leaving the portion which will lie inside the cable clamp untaped.

(a) |

DPYCY-3.5 |

|

Vinyl sheath |

About 80 mm |

|

40 mm 5 mm |

||

|

||

(b) |

|

|

|

Armor 10 mm |

(c)

Lay this part in cable clamp.

(d)

Taping

|

|

Armor |

|

Core |

2 |

Vinyl |

|

S = 3.5 mm |

|||

|

sheath |

||

= 2.4 mm |

|

||

DPYCY-3.5 sectional view

Figure 2-1 Fabrication of power cable DPYCY-3.5 (JIS cable)

2-1

Loading...

Loading...