Emerson Fisher V250 Data Sheet

Product Bulletin

51.3:V250 November 2007

V250 Valve

Design V250 Rotary Control Valve

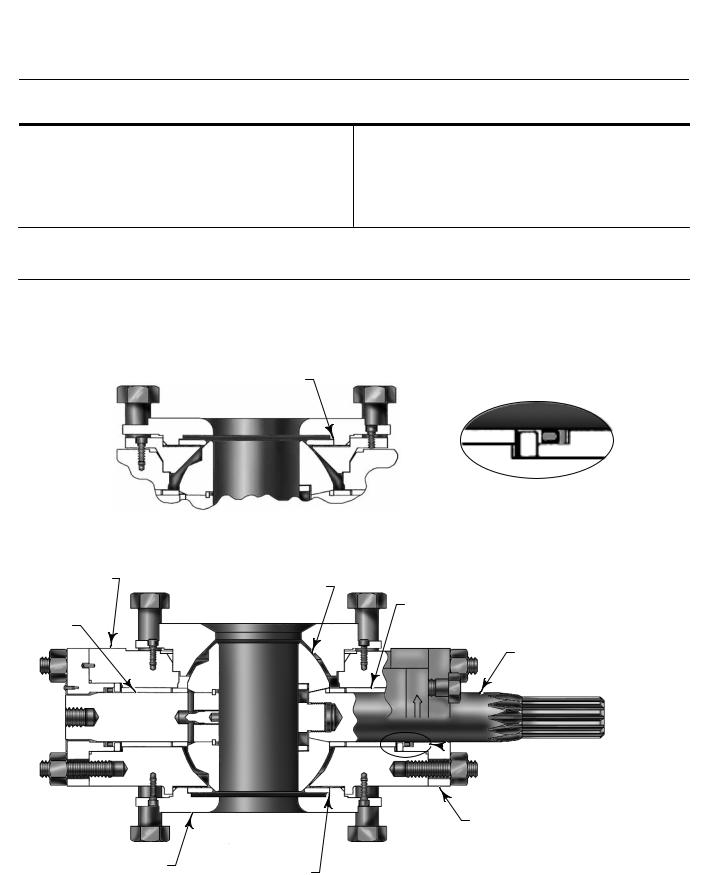

The Design V250 Hi-Ball rotary control valve (figure 1) is designed for heavy-duty throttling and on-off applications. Depending on size, this valve installs between two CL600 or CL900 pipeline flanges. The Design V250 valve is available with a single ball seal, flow ring, or dual-seal construction. Single-seal constructions are used in tight shutoff applications; the flow ring construction can satisfy higher temperature requirements. The dual-seal construction, with a seal in the inlet and outlet openings, is used in bidirectional flow-shutoff applications. The Design V250 Hi-Ball valve is typically used for throttling and controlled flow applications in gas transmission lines, gas distribution, or liquid pipelines.

Note

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use and maintenance of any product. Responsibility for the selection, use, and maintenance of any product remains with the purchaser and end-user.

Features

DHigh Pressure Drop Capabilities—Depending on the construction, a Design V250 valve is capable

of a maximum static pressure differential of 103 bar (1500 psi) at 82°C (180°F) for CL600, and 155 bar (2250 psi) for CL900 constructions at 38°C (100°F) for LCC steel and CF8M (316 stainless steel).

DEfficient Operation—Tapered-polygon

ball-to-shaft connection (see figure 5) and clamped splined actuator connection (see figure 6) remove lost motion or deadband from the drive train for throttling control applications.

D Excellent Flow Control—Reduced ball port design provides a modified equal percentage flow characteristic and an excellent response characteristic.

W4177 / IL

Figure 1. Design V250 Valve with Type 1061 Actuator

DTight Shutoff—Shutoff with the Design V250 ball seal is 0.0001 percent of maximum capacity.

DGreater Capacities—Design V250 ball valve construction offers greater capacities than conventional globe valves for both compressible and incompressible fluids.

DSour Service Capability—Materials are available for applications handling sour service. These materials comply with the requirements of NACE MR0175-2002.

DLong Service Life—Pressure-balanced drive shaft design with PTFE-lined bearings and pressure-assisted shaft sealing arrangement provides for a long life of reliable service.

DMinimum Maintenance—Two-piece ball and shaft assembly allows for complete trim overhaul; parts replacement is kept to a minimum.

DExcellent Environmental Capabilities—The optional live loaded packing system is designed with very smooth shaft surfaces and live loading to provide excellent sealing.

D100053X012

www.Fisher.com

V250 Valve

Product Bulletin

51.3:V250

November 2007

Specifications

Available Configuration

Flangeless ball valve assembly with J single ball seal, J flow ring, or J dual ball seal

Valve Body Sizes and End Connection Styles

NPS 4 through 12 flangeless valves retained by line flange bolts and designed to fit between CL600 or CL900 J raised-face or J ring-type joint flanges (ASME B16.5)

NPS 16 through 24 flangeless valves retained by line flange bolts and designed to fit between CL600 J raised-face or J ring-type joint flanges (ASME B16.5)

Maximum Inlet Pressure(1)

NPS 4 through 12 consistent with CL600 or CL900 (ASME B16.34)

NPS 16 through 24 consistent with CL600 (ASME B16.34)

Maximum Allowable Shutoff Pressure Drop(1,2)

Single-Seal and Dual-Seal Construction: See figure 3.

Flow Ring Construction: Limited by the pressure-temperature rating of the valve body

Shutoff Classification

Single-Seal and Dual-Seal Constructions:

0.0001% of maximum valve capacity (less than 1% of Class IV, ANSI/FCI 70-2 and IEC 60534-4)

Flow Ring Construction: 1% of maximum valve capacity

Construction Materials

See table 1

Seal Material Temperature Capability(1)

Single-Seal and Dual-Seal Construction:

J –46 to 82°C (–50 to 180°F) for LCC steel and CF8M [316 stainless steel (SST)] valve bodies

Flow Ring with Nitrile O-Rings: J –46 to 93°C (–50 to 200°F) for LCC steel and CF8M valve bodies

Flow Ring with Fluorocarbon O-Rings: J –46 to 204°C (–50 to 400°F) for LCC steel and CF8M valve bodies

Flow Characteristic

Modified equal percentage

Flow Direction

Single Seal Construction: Forward-flow only (see figure 4)

Flow Ring Construction: Forwardor reverse-flow (see figure 4)

Dual Seal Construction: Required to provide shutoff for bi-directional flow

Flow Coefficients

See the section titled Coefficients in this bulletin, or see Catalog 12

Noise Levels

See Catalog 12 for sound pressure level prediction

Maximum Ball Rotation

90 degrees

Actuator Mounting

J Right-hand or J left-hand mounted as viewed from the valve inlet for forward-flow

Shaft and Bore Diameters

See figure 8

(continued)

2

Product Bulletin

51.3:V250 November 2007

V250 Valve

Specifications (continued)

Approximate Weights |

seal configuration for bi-directional shutoff (this |

|

See table 2 |

configuration incorporates a tapped and plugged |

|

Options |

connection which can be used in a double block |

|

and bleed system to test seal integrity), J Live |

||

J Line flange bolts, J Sour service trim(3), |

||

Loaded PTFE Packing |

JBuried service actuator adaptation, and J Dual

1.The pressure or temperature limits in this bulletin and any applicable standard or code limitations should not be exceeded.

2.The maximum allowable shutoff pressure drops are further limited for the following constructions. The NPS 12 with S20910 drive shaft is limited to 128 bar (1862 psi) from –46 to 59°C (–50 to 139°F) and to 103 bar (1490 psi) at 93°C (200°F). The NPS 16 with 17-4PH steel, with 2-1/2 inch splined driveshaft is limited to 1000 psi (69 bar), and with the S20910, 2-1/2 inch splined drive shaft is limited to 55 bar (795 psi) at all service temperatures. The NPS 24 with S20910 drive shaft is limited to 92 bar (1336 psi) at all service temperatures.

3.See table 1 for sour service trim materials.

OUTLET

BALL

SEAL

W7169-1 / IL

W7170-1 / IL

VIEW A

SEAL DETAIL

OUTLET SIDE OF VALVE BODY FOR

OPTIONAL DUAL SEAL CONSTRUCTION

VALVE

BODY

BALL

FOLLOWER

SHAFT

|

VALVE |

|

INLET |

SEAL PROTECTOR |

INLET |

RING OR FLOW RING |

BALL |

W7169-1 / IL |

SEAL |

|

MAIN SHAFT

BEARING

DRIVE SHAFT

SEE VIEW A

SEE VIEW A

SEAL

CARRIER

Figure 2. Sectional View of Design V250 Valve

3

Loading...

Loading...