Emerson Fisher Baumann 24000SB Data Sheet

24000SB Valve |

Product Bulletin |

52.1:24SB |

|

D103334X012 |

March 2013 |

|

|

Baumannt 24000SB Barstock

Control Valve

This rugged Baumann control valve is recommended for low-flow, high-pressure, industrial control applications. S31600 / S31603 stainless steel barstock valve body and bonnet is suitable for process pressures up to 413 barg (6000 psig). The 24000SB is the ideal solution for applications that exceed the operating range of our other 24000 series valves. Various end connections ranging from threaded (standard), buttweld, and flanged add versatility to this high-pressure product line. Special high nickel alloy constructions are available and round out the basic S31600/S31603 stainless steel offering.

Features

Compact and light-weight design reduces installed piping costs.

Dual plug and stem guiding provides increased stability during plug travel.

Multiple trim capacity reductions available to meet

changing process requirements with Cv ratings as low as 0.00013.

Optional extended bonnet for applications ranging from -195 to 537_C (-320 to 1000_F).

Epoxy powder-coated actuator with stainless steel fasteners for corrosion resistance.

Multi-spring, field-reversible actuator with reduced deadband, permits direct operation from remote signal devices.

Actuator and yoke can be removed from the valve assembly while maintaining packing integrity.

Optional ENVIRO-SEAL™ packing system to meet critical emission control requirements.

W9756

24000SB Control Valve with Baumann 32 Actuator and FIELDVUE DVC2000 Digital Valve Controller

W9757

W9758

Baumann 24000SB Control Valve with

Flanges and Extension Bonnet

Fisherr FIELDVUE™ digital valve controller available for remote calibration and diagnostics in facilities utilizing the PlantWeb™ architecture.

www.Fisher.com

|

Product Bulletin |

24000SB Valve |

|

|

52.1:24SB |

|

|

|

March 2013 |

D103334X012 |

|

|

|

|

|

|

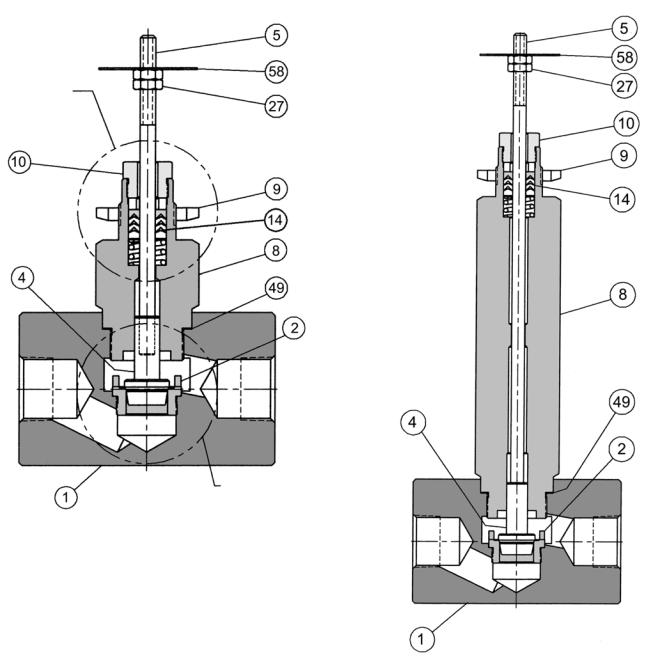

Figure 1. Valve Body Subassembly with Standard |

Figure 2. Valve Body with Extension Bonnet |

|

|

PTFE Spring-Loaded V-Ring Packing |

|

|

|

|

|

|

SEE PACKING

OPTIONS ON

PAGE 4

SEE LOW FLOW

TRIM DETAIL

INFIGURES3AND4

E1263

E1264

2

24000SB Valve |

Product Bulletin |

52.1:24SB |

|

D103334X012 |

March 2013 |

|

|

Table 1. Materials of Construction

Key |

Description |

|

Material |

|

||

No. |

S31603 Stainless Steel |

N10276 Nickel Alloy(1) |

N08020 Nickel Alloy(1) |

N04400 Nickel Alloy(1) |

||

|

||||||

1(1) |

Valve Body |

ASME SA479 S31600/ |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

S31603 Dual Certified |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

2(1) |

Seat Ring (standard) (For low flow |

ASTM A276 S31600/ |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

trim, refer to tables 2 & 3) |

S31603 Dual Certified |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

ASME SA479 S21800 |

|

|

|

|

|

Plug (Metal Seat) Cv ≤2.5 |

(standard) / ASTM A582 |

|

|

|

|

|

S41600 |

|

|

|

||

|

|

|

|

|

||

|

|

Condition T (optional) |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

|

|

|

||||

|

|

ASTM A276 S31600/ |

||||

|

|

|

|

|

||

4(1) |

Plug (Metal Seat) Cv ≥4.0 |

S31603(standard) / |

|

|

|

|

ASTM A582 S41600 |

|

|

|

|||

|

|

|

|

|

||

|

|

Condition T (optional) |

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A276 S31600/ |

|

|

|

|

|

Plug (Soft Seat) |

S31603 with PTFE |

ASME SB574 |

ASTM B473 |

ASME SB164 N04400/ |

|

|

(Polytetrafluoroethylene) |

N10276/PTFE |

N08020/PTFE |

PTFE |

||

|

|

|||||

|

|

insert |

|

|

|

|

|

|

|

|

|

|

|

5(1) |

Stem |

ASTM A276 S31600 |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

8(1) |

Bonnet |

ASME SA479 S31600/ |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

S31603 Dual Certified |

||||||

|

|

|

|

|

||

9 |

Drive Nut (Yoke) |

|

S30400 |

|

||

|

|

|

|

|

|

|

10(1) |

Packing Follower |

ASTM A276 S31600/ |

ASME SB574 N10276 |

ASTM B473 N08020 |

ASME SB164 N04400 |

|

S31603 Dual Certified |

||||||

|

|

|

|

|

||

14(1) |

V-Ring Packing (standard) |

|

Refer to page 4 |

|

||

|

|

|

|

|

||

Packing (optional) |

|

Refer to page 4 |

|

|||

|

|

|

||||

|

|

|

|

|

||

27 |

Lock Nut |

|

Stainless Steel (18-8 Stainless Steel) |

|

||

|

|

|

|

|

||

49 |

Body Gasket |

|

Graphite Grade GHR with S31600 Insert |

|

||

|

|

|

|

|

||

58 |

Travel Indicator |

|

ASME SA240 S30400 |

|

||

|

|

|

|

|

|

|

1. For optional valve and trim materials, consult your Emerson Process Management sales office for price and delivery. N08020 and N04400 nickel alloy materials have pressure-temperature ratings less than 206 barg (3000 psig) or 413 barg (6000 psig) respectively.

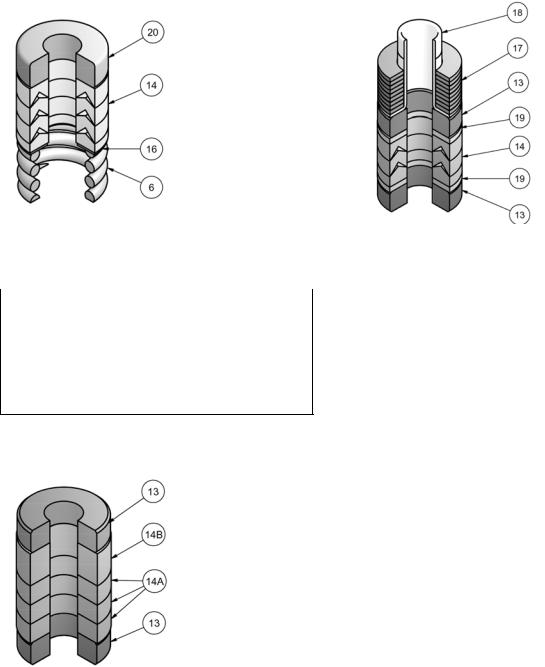

Figure 3. Optional 151 Low Flow Trim Assembly

E1246

Table 2. 151 Low Flow Trim

Key Number |

Description |

Material |

|

|

2(1) |

Seat Ring |

ASTM A276 S31600/ S31603 |

||

4(1) |

Plug |

ASME SA479 S21800 |

||

|

|

Seat Sub-Assembly |

||

|

|

|

||

|

Cage |

ASTM A276 S31600/ S31603 |

||

|

|

|

||

51(1) |

Seat |

PTFE |

||

|

|

|

||

Collar |

ASTM A276 S31600/ S31603 |

|||

|

||||

|

|

|

||

|

Washer |

ASTM A276 S31600 Cond B |

||

|

|

|

||

|

Insert |

ASTM A276 S31600/ S31603 |

||

|

|

|

|

|

1. For optional trim materials, consult your Emerson Process Management sales office for price and delivery.

Figure 4. Optional 177 Low Flow Trim Assembly

E1247

Table 3. 177 Low Flow Trim

Key Number |

|

Description |

Material |

|

|

2(1) |

|

|

Seat Ring |

ASTM A276 S31600/ S31603 |

|

|

|

|

Seat Sub-Assembly |

||

|

|

|

|

|

|

|

|

23 |

Gland |

ASTM A276 S31600/ S31603 |

|

|

|

|

|

|

|

2a(1) |

|

24 |

Retainer Nut |

ASTM A276 S31600/ S31603 |

|

|

|

25 |

Insert |

Reinforced PTFE |

|

|

|

|

|

|

|

|

|

26 |

Housing |

ASTM A276 S31600/ S31603 |

|

|

|

|

|

|

|

4(1) |

|

|

Plug |

ASME SA479 S21800 |

|

1. For optional trim materials, consult your Emerson Process Management sales office for price and delivery.

3

|

Product Bulletin |

24000SB Valve |

|

|

52.1:24SB |

|

|

|

March 2013 |

D103334X012 |

|

|

|

|

|

|

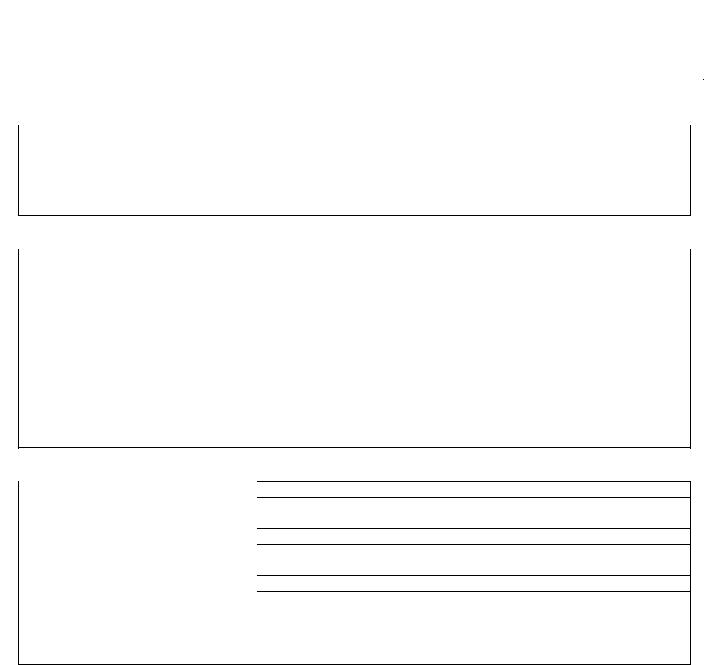

Figure 5. Standard Spring-Loaded PTFE V-Ring |

Figure 7. ENVIRO-SEAL Packing Kit (Optional) |

|

|

Packing Kit |

|

|

|

|

|

|

E1240

E1248

Table 4. Standard Spring-Loaded PTFE V-Ring

Packing Kit

Key Number |

Description |

Material |

|

|

6(1) |

Spring |

ASTM A313 S30200 |

||

14 |

Packing Set |

PTFE (Polytetrafluoroethylene) / |

||

PTFE, 25% carbon filled |

||||

|

|

|||

|

|

|

||

16 |

Washer |

ASME SA240 S31600 |

||

|

|

|

||

20 |

Spacer |

J-2000 |

||

(filled-Polytetrafluoroethylene) |

||||

|

|

|||

|

|

|

|

|

1. N10276 nickel alloy valve body construction is furnished with N10276 nickel alloy spring.

Figure 6. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

E1241

Table 5. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

Key Number |

Description |

Material |

13 |

Bushings |

Carbon-Graphite |

|

|

|

14A |

Packing Rings |

Graphite |

|

|

|

14B |

Packing Ring |

Graphite |

|

|

|

Table 6. ENVIRO-SEAL Packing Kit (Optional)

Key Number |

Description |

Material |

|

13 |

Bushings |

Carbon-Graphite |

|

|

|

|

|

14 |

Packing Rings |

PTFE (Polytetrafluoroethylene) / |

|

PTFE, 25% carbon filled |

|||

|

|

||

|

|

|

|

17 |

Belleville |

N06600 Nickel Alloy (ASTM B637 |

|

Spring |

N07718, 40 HRC max) |

||

|

|||

|

|

|

|

18 |

Bushing |

PEEK (polyetheretherketone) |

|

|

|

|

|

19 |

Washers |

Modified PTFE |

|

|

|

|

Special ENVIRO-SEAL

Packing Note

The ENVIRO-SEAL PTFE packing system is suitable for 100 ppm environmental applications on services up to 51.7 barg (750 psig) and process temperatures ranging from -46 to 232_C (-50 to 450_F).

For non-environmental applications, this packing system offers excellent performance at the same temperature range up to the maximum valve working pressure.

Temperature limits apply to packing arrangements only. Complete valve assembly temperature limits may differ, refer to appropriate pressure/temperature ratings.

(Reference Fisher Packing Selection Guidelines for Sliding-Stem Valves, Bulletin 59.1:062, D101986X012).

4

24000SB Valve |

Product Bulletin |

52.1:24SB |

|

D103334X012 |

March 2013 |

|

|

Table 7. Technical Specifications

NOMINAL PIPE SIZE |

|

DN 15, 20, and 25 (NPS 1/2, 3/4, and 1) |

|

END CONNECTIONS |

|

Standard |

Threaded (NPT) |

|

Available(1) |

Buttweld, Flanged (CL150 to CL2500) |

|

|

|

||

PRESSURE RATING |

|

See Pressure-Temperature Ratings, tables 12, 13, 14, 15, 16, and 17 |

|

CHARACTERISTIC |

|

Equal Percentage or Linear |

|

|

|

|

|

1. Consult your Emerson Process Management sales office for other available connections.

Table 8. Temperature Ratings for Packing and Seat Material(1)

|

PTFE Soft Seat |

151 Trim |

-29 to 177_C (-20 to 350_F) |

||

|

|

|

|

||

SEATING MATERIAL |

577 & 677 Trim |

-73 to 232_C (-100 to 450_F) |

|||

|

|||||

Reinforced PTFE |

177 Trim |

-73 to 232_C (-100 to 450_F) |

|||

|

|||||

|

Metal Seat |

102, 548, 588, 648, 688 Trim |

-195 to 537_C (-320 to 1000_F) |

||

|

BONNET STYLE |

PACKING |

TEMPERATURE LIMIT |

|

|

|

|

Spring Loaded PTFE Packing |

-73 to 232_C (-100 to 450_F) |

||

|

|

|

|

||

PACKING AND BONNET |

Standard Bonnet(2) |

ENVIRO-SEAL |

-45 to 232_C (-50 to 450_F) |

||

|

Graphite |

-73 to 232_C (-100 to 450_F) |

|||

COMBINATIONS |

|

||||

|

Spring Loaded PTFE Packing |

-195 to 232_C (-320 to 450_F) |

|||

|

|

||||

|

|

|

|

||

|

Extension Bonnet |

ENVIRO-SEAL |

-45 to 232_C (-50 to 450_F) |

||

|

|

Graphite |

-195 to 537_C (-320 to 1000_F) |

||

|

|

|

|

|

|

1. Temperature limits apply to seating or packing arrangements only. Complete valve assembly temperature limits may differ, refer to appropriate pressure/temperature ratings. For more information on packing selection, reference Fisher Packing Selection Guidelines for Sliding-Stem Valves, Bulletin 59.1:062, D101986X012.

2. PTFE packing may be used in cryogenic service but becomes stiff.

Table 9. Actuator Specifications

TYPE |

32, 54, 70 Multi-Spring Diaphragm (Single Acting) |

|

DIAPHRAGM AREA |

210, 350, 450 cm2 / 32, 54, 70 in2 |

|

AIR FAILURE |

32 and 54 Fails Open or Closed (Field Reversible) / 70 Fails Closed ONLY |

|

TRAVEL(1) |

12.7 or 19.1 mm / 0.50 or 0.75 inches |

|

AMBIENT TEMPERATURE RANGE |

-29_C to 71_C / -20_F to 160_F |

|

MAXIMUM AIR PRESSURE |

2.4 barg / 35 psig |

|

DIAPHRAGM MATERIAL(2) |

NBR (Nitrile) / TPES (Polyester Thermoplastic) |

|

SPRING CASES |

Steel, Powder Epoxy-Coated with Stainless Steel Fasteners |

|

YOKE |

S30400 SST (for Baumann 32 and 54 SST actuator option only) |

|

Ductile Iron, Powder Epoxy-Coated |

||

|

||

|

|

1.Dual travel stops are available on Baumann 32 and 54 actuators. These are not field reversible.

2.Optional reinforced VMQ (Silicone) diaphragm with FKM (Fluorocarbon) O-ring actuator stem seal for high temperature conditions (-29_C to 121_C / -20_F to 250_F) is available with Baumann 32 and 54 actuators ONLY.

5

Loading...

Loading...