Emerson Fisher D4 Instruction Manual

Instruction Manual |

D4 Valve |

D103042X012 |

November 2013 |

|

|

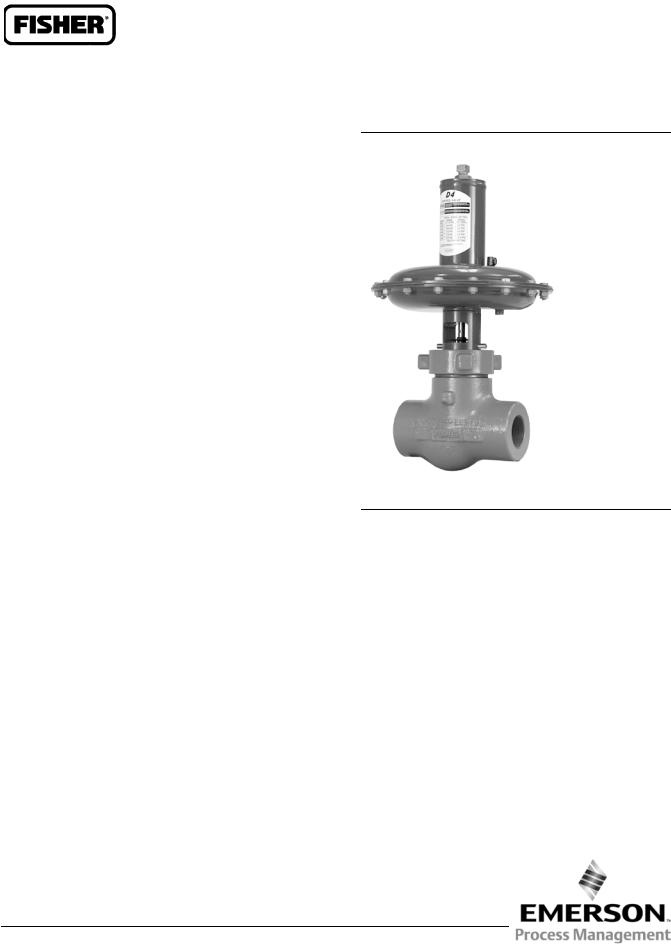

Fisherr D4 Control Valve Assembly

Contents |

Figure 1. Fisher D4 Control Valve |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Educational Services . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Spring Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Valve Plug and Seat Ring . . . . . . . . . . . . . . . . . . . . . . |

6 |

Valve Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

W8531

Introduction

Scope of Manual

This instruction manual provides installation, maintenance, and parts information for the Fisher D4 control valve.

Do not install, operate, or maintain a D4 control valve without being fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office before proceeding.

Description

The D4 control valve is a compact, rugged valve designed primarily for high-pressure throttling applications. This valve is ideal for use on pressure and flow control applications within the oil and gas production industry. The D4 valve also makes an excellent dump valve for high-pressure separators and scrubbers.

The D4 control valve meets the metallurgical requirements of NACE MR0175/ISO 15156 without environmental limits for temperatures below 135_C (275_F). If the temperature is above 135_C (275_F), the N07718 Belleville washers will impose some limits, as shown in table 3.

www.Fisher.com

D4 Valve |

Instruction Manual |

November 2013 |

D103042X012 |

|

|

Table 1. Specifications

Available Configurations

Spring-to-Close

Spring-to-Open

Valve Body Sizes and End Connection Styles(1)

See table 2

Maximum Inlet Pressures and Temperatures(1)

If the valve nameplate shows an ASME pressure-temperature class, maximum inlet pressure and temperature is consistent with the applicable class per ASME B16.34. If the nameplate does not show an ASME class, it will show a maximum cold working pressure at 38_C (100_F) (for example, 293 bar [4250 psi])

Maximum Pressure Drops(1)

See tables 4, 5, 6, and 7

Input Signal to Actuator

See tables 4, 5, 6, and 7

Actuator Maximum Casing Pressure(1)

3.4 bar (50 psig)

Shutoff Classification per ANSI/FCI 70-2 and IEC 60534-4

Class IV

Material Temperature Capabilities(1)

Actuator Assembly: -40 to 93 C (-40 to 200 F)

Valve Body Assembly:

Standard Bonnet O-Ring: -40 to 135 C (-40 to 275 F) Optional Fluorocarbon Bonnet O-Ring: -23 to 204 C (-10 to 400 F)

Flow Characteristic

Equal percentage

Flow Direction

Flow up only

Port Diameters

See table 2

Valve Plug Travel

19 mm (0.75 inch)

Valve Plug Style

Micro-Form valve plug

Actuator Diaphragm Effective Area

452 cm2 (69 inches2)

Actuator Pressure Connection Size

1/4 NPT internal

1. The pressure or temperature limits in the referenced tables and any applicable ASME code limitations should not be exceeded.

Specifications

Table 1 lists specifications for the D4 control valve. Some of the specifications for a given control valve as it originally comes from the factory are stamped on a nameplate located on the actuator spring barrel.

Educational Services

For information on available courses for Fisher D4 valves, as well as a variety of other products, contact:

Emerson Process Management Educational Services, Registration P.O. Box 190; 301 S. 1st Ave. Marshalltown, IA 50158-2823 Phone: 800-338-8158 or

Phone: 641-754-3771 FAX: 641-754-3431

e-mail: education@emerson.com

2

Instruction Manual |

|

|

|

|

|

|

|

|

|

|

|

|

D4 Valve |

||||

D103042X012 |

|

|

|

|

|

|

|

|

|

|

|

|

|

November 2013 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Table 2. Valve Sizes and Connection Styles |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

VALVE |

|

|

PORT |

SCREWED |

|

|

RAISED FACE (RF) FLANGED |

|

|

RING TYPE JOINT |

|||||||

|

|

|

|

|

|

|

(RTJ) FLANGED |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

SIZE, |

|

|

DIAMETER, |

|

|

|

|

|

|

|

|

|

|

||||

|

|

4250 psi |

CL150 |

CL300 |

CL600 |

|

CL900 and |

|

CL600 |

|

CL900 and |

||||||

NPS |

|

|

(INCHES) |

|

|

|

|||||||||||

|

|

|

CL1500 |

|

|

CL1500 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1 |

|

|

0.25, 0.375, |

|

X |

X |

X |

|

X |

|

X |

|

X |

|

|

X |

|

|

|

0.5, 0.75 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

0.25, 0.375, 0.5 |

X |

X |

X |

|

X |

|

X |

|

X |

|

|

X |

|||

|

|

0.75, 1, 1.25 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

X = Available construction. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Table 3. D4 Environmental Limits for NACE MR0175/ISO 15156 with Sour Trim |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

MAXIMUM TEMPERATURE |

|

|

MAXIMUM H2S PARTIAL PRESSURE |

|

|

COMPATIBLE WITH |

||||||||

|

_C |

|

|

_F |

|

|

MPa |

|

|

|

psia |

|

ELEMENTAL SULFUR? |

||||

|

232 |

|

|

450 |

|

|

0.2 |

|

|

|

30 |

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

204 |

|

|

400 |

|

|

1.4 |

|

|

|

200 |

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

199 |

|

|

390 |

|

|

2.3 |

|

|

|

330 |

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

191 |

|

|

375 |

|

|

2.5 |

|

|

|

360 |

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

149 |

|

|

300 |

|

|

2.8 |

|

|

|

400 |

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

135 |

|

|

275 |

|

|

|

No Limit |

|

|

|

|

|

Yes |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 4. Maximum Shutoff Pressure Drops(1) for Fisher D4 Control Valves (Spring-to-Close) When Used with Typical Control Instrumentation(2)

INPUT SIGNAL TO |

0 to 1.2 Bar |

0 to 1.4 Bar |

0 to 2.0 Bar |

0 to 2.3 Bar |

0 to 2.4 Bar |

0 to 3.4 Bar |

|

||||||||||

ACTUATOR |

(0 to 18 Psig) |

(0 to 20 Psig) |

(0 to 30 Psig) |

(0 to 33 Psig) |

(0 to 35 Psig) |

(0 to 50 Psig) |

|

||||||||||

|

SPRING |

|

Light Rate |

|

|

|

|

|

|

Heavy Rate |

|

|

|

|

|||

INITIAL SPRING |

0.77 Bar |

0.77 Bar |

0.85 Bar |

1.05 Bar |

1.18 Bar |

1.18 Bar |

|

||||||||||

SETTING |

(11.2 Psig) |

(11.2 Psig) |

(12.4 Psig) |

(15.3 Psig) |

(17.1 Psig) |

(17.1 Psig) |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PORT DIAMETER |

|

|

|

|

|

Maximum Pressure Drop |

|

|

|

|

|

|

|||||

mm |

|

Inches |

Bar |

Psi |

Bar |

Psi |

Bar |

|

Psi |

Bar |

|

Psi |

Bar |

Psi |

Bar |

Psi |

|

6.4 |

|

0.25 |

293(3) |

4250(3) |

293(3) |

4250(3) |

293 |

|

4250 |

293 |

|

4250 |

293 |

4250 |

293 |

4250 |

|

9.5 |

|

0.375 |

293(3) |

4250(3) |

293(3) |

4250(3) |

293 |

|

4250 |

293 |

|

4250 |

293 |

4250 |

293 |

4250 |

|

12.7 |

|

0.5 |

191 |

2765 |

191 |

2765 |

219 |

|

3180 |

288 |

|

4180 |

293 |

4250 |

293 |

4250 |

|

19.1 |

|

0.75 |

80 |

1160 |

80 |

1160 |

92 |

|

1340 |

123 |

|

1785 |

143 |

2080 |

143 |

2080 |

|

25.4 |

|

1 |

42 |

610 |

42 |

610 |

49 |

|

715 |

67 |

|

965 |

78 |

1130 |

78 |

1130 |

|

31.8 |

|

1.25 |

25 |

365 |

25 |

365 |

30 |

|

430 |

41 |

|

590 |

48 |

700 |

48 |

700 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.The pressure or temperature limits in the referenced tables and any applicable ASME code limitations should not be exceeded.

2.For example, use the column marked 0-1.4 bar (0-20 psig) for a 0.21-1.0 bar (3-15 psig) pneumatic controller with 1.4 bar (20 psig) supply pressure.

3.For applications with downstream pressure in excess of 196 bar (2845 psig), use 196 bar (2845 psig) for Maximum Shutoff Pressure.

Table 5. Maximum Shutoff Pressure Drops(1) for Fisher D4 Control Valves (Spring-to-Close) When Used with Instrumentation with Restricted Output Range(2)

INPUT SIGNAL TO |

0.4 to 2.0 Bar |

|

|

|

0.14 to 2.3 Bar |

|

||||

ACTUATOR |

(6 to 30 Psig) |

|

|

|

(2 to 33 Psig) |

|

||||

|

SPRING |

Heavy Rate |

|

|

|

Heavy Rate |

|

|||

INITIAL SPRING |

0.97 Bar |

|

|

|

1.17 Bar |

|

||||

SETTING |

(14.0 Psig) |

|

|

|

(17.0 Psig) |

|

||||

PORT DIAMETER |

|

|

Maximum Pressure Drop |

|

|

|

|

|||

mm |

|

Inches |

Bar |

|

Psi |

|

Bar |

|

Psi |

|

6.4 |

|

0.25 |

293(3) |

|

4250(3) |

|

293 |

|

4250 |

|

9.5 |

|

0.375 |

210(3) |

|

3045(3) |

|

293 |

|

4250 |

|

12.7 |

|

0.5 |

113 |

|

1635 |

|

282 |

|

4095 |

|

19.1 |

|

0.75 |

45 |

|

655 |

|

120 |

|

1750 |

|

25.4 |

|

1 |

23 |

|

330 |

|

65 |

|

945 |

|

31.8 |

|

1.25 |

13 |

|

185 |

|

39 |

|

580 |

|

|

|

|

|

|

|

|

|

|

|

|

1.The pressure or temperature limits in the referenced tables and any applicable ASME code limitations should not be exceeded.

2.For example, an Electro-Pneumatic Transducer calibrated for 0.4-2.0 bar (6-30 psig) output pressure.

3.For applications with downstream pressure in excess of 118 bar (1715 psig), use 118 bar (1715 psig) for Maximum Shutoff Pressure.

3

D4 Valve |

|

|

|

|

|

|

|

|

|

|

|

|

Instruction Manual |

|

||||

November 2013 |

|

|

|

|

|

|

|

|

|

|

|

|

|

D103042X012 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Table 6. Maximum Shutoff Pressure Drops(1) for Fisher D4 Control Valves (Spring-to-Open) |

|

|

|

|

||||||||||||||

When Used with Typical Control Instrumentation(2) |

|

|

|

|

|

|

|

|

|

|

|

|||||||

INPUT SIGNAL TO |

0 to 1.2 Bar |

0 to 1.4 Bar |

|

0 to 2.0 Bar |

0 to 2.3 Bar |

0 to 2.4 Bar |

0 to 3.4 Bar |

|

||||||||||

ACTUATOR |

(0 to 18 Psig) |

(0 to 20 Psig) |

|

(0 to 30 Psig) |

(0 to 33 Psig) |

(0 to 35 Psig) |

(0 to 50 Psig) |

|

||||||||||

|

SPRING |

|

Light Rate |

|

|

|

|

|

|

|

Heavy Rate |

|

|

|

|

|||

INITIAL SPRING |

0.23 Bar |

0.23 Bar |

|

0.28 Bar |

0.28 Bar |

0.28 Bar |

0.28 Bar |

|

||||||||||

SETTING |

(3.4 Psig) |

(3.4 Psig) |

|

(4.0 Psig) |

(4.0 Psig) |

(4.0 Psig) |

(4.0 Psig) |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PORT DIAMETER |

|

|

|

|

|

|

Maximum Pressure Drop |

|

|

|

|

|

|

|||||

mm |

|

Inches |

Bar |

Psi |

Bar |

Psi |

|

Bar |

|

Psi |

Bar |

|

Psi |

Bar |

Psi |

Bar |

Psi |

|

6.4 |

|

0.25 |

293(3) |

4250(3) |

293(3) |

4250(3) |

|

293 |

|

4250 |

293 |

|

4250 |

293 |

4250 |

293 |

4250 |

|

9.5 |

|

0.375 |

293(3) |

4250(3) |

293(3) |

4250(3) |

|

293 |

|

4250 |

293 |

|

4250 |

293 |

4250 |

293 |

4250 |

|

12.7 |

|

0.5 |

187 |

2715 |

233 |

3380 |

|

293 |

|

4250 |

293 |

|

4250 |

293 |

4250 |

293 |

4250 |

|

19.1 |

|

0.75 |

78 |

1135 |

99 |

1430 |

|

147 |

|

2130 |

178 |

|

2575 |

198 |

2875 |

293 |

4250 |

|

25.4 |

|

1 |

41 |

600 |

53 |

765 |

|

80 |

|

1160 |

97 |

|

1410 |

109 |

1575 |

195 |

2830 |

|

31.8 |

|

1.25 |

24 |

355 |

32 |

465 |

|

49 |

|

715 |

60 |

|

875 |

68 |

985 |

123 |

1785 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.The pressure or temperature limits in the referenced tables and any applicable ASME code limitations should not be exceeded.

2.For example, use the column marked 0-1.4 bar (0-20 psig) for a 0.21-1.0 bar (3-15 psig) pneumatic controller with 1.4 bar (20 psig) supply pressure.

3.For applications with downstream pressure in excess of 190 bar (2760 psig), use 190 bar (2760 psig) for Maximum Shutoff Pressure.

Table 7. Maximum Shutoff Pressure Drops(1) for Fisher D4 Control Valves (Spring-to-Open) When Used with Instrumentation with Restricted Output Range(2)

INPUT SIGNAL TO |

0.4 to 2.0 Bar |

|

|

|

0.14 to 2.3 Bar |

|

||||

ACTUATOR |

(6 to 30 Psig) |

|

|

|

(2 to 33 Psig) |

|

||||

|

SPRING |

Heavy Rate |

|

|

|

Heavy Rate |

|

|||

INITIAL SPRING |

0.69 Bar |

|

|

|

0.42 Bar |

|

||||

SETTING |

(10.0 Psig) |

|

|

|

(6.1 Psig) |

|

||||

PORT DIAMETER |

|

|

Maximum Pressure Drop |

|

|

|

|

|||

mm |

|

Inches |

Bar |

|

Psi |

|

Bar |

|

Psi |

|

6.4 |

|

0.25 |

293(3) |

|

4250(3) |

|

293 |

|

4250 |

|

9.5 |

|

0.375 |

293(3) |

|

4250(3) |

|

293 |

|

4250 |

|

12.7 |

|

0.5 |

196 |

|

2845 |

|

293 |

|

4250 |

|

19.1 |

|

0.75 |

82 |

|

1195 |

|

156 |

|

2265 |

|

25.4 |

|

1 |

43 |

|

630 |

|

85 |

|

1235 |

|

31.8 |

|

1.25 |

26 |

|

380 |

|

52 |

|

765 |

|

|

|

|

|

|

|

|

|

|

|

|

1.The pressure or temperature limits in the referenced tables and any applicable ASME code limitations should not be exceeded.

2.For example, an Electro-Pneumatic Transducer calibrated for 0.4-2.0 bar (6-30 psig) output pressure.

3.For applications with downstream pressure in excess of 202 bar (2925 psig), use 202 bar (2925 psig) for Maximum Shutoff Pressure.

Installation

WARNING

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal injury.

To avoid personal injury or property damage caused by bursting of pressure-retaining parts or by uncontrolled process fluid, be certain the service conditions do not exceed the limits shown on the valve nameplate and in tables 1, 4, 5, 6, and 7. Use pressure-relieving devices required by government or accepted industry codes and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this instruction manual.

4

Instruction Manual |

D4 Valve |

D103042X012 |

November 2013 |

|

|

WARNING

WARNING

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature, pressure drop, and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve materials with process media rests solely with the purchaser and end-user. Since some body/trim material combinations are limited in their pressure drop and temperature ranges, do not apply any other conditions to the valve without first contacting your Emerson Process Management sales office.

WARNING

WARNING

Avoid personal injury or property damage caused by possible actuator failure. The use of a rigidly-mounted support on the actuator casing may cause additional stress on the actuator leading to premature wear and/or failure of the actuator components.

CAUTION

To avoid product damage, inspect the valve before installation for any damage or any foreign material that may have collected in the valve body. Also remove any pipe scale, welding slag, or other foreign material from the pipeline.

1.Before installing the control valve assembly, inspect it for any damage and for any foreign material that may have collected in the valve body.

2.Remove any pipe scale, welding slag, and other foreign material from the pipeline.

3.The control valve can be installed in any position, but normally the actuator is vertical above the valve. Install the valve so the flow direction arrow on the side of the valve indicates the direction of the process flow.

4.Install the valve following local and national piping codes when they apply to the application. For screwed connections, treat the external pipe threads with a good grade pipe compound. For flanged valves, use suitable gaskets between valve and pipeline flanges.

5.If continuous operation is required during maintenance and inspection, install a conventional three-valve bypass around the valve.

6.Connect loading pressure for the Spring-to-Open configuration to the 1/4-18 NPT connection in the upper casing assembly (key 23) as shown in figure 5. The Spring-to-Close configuration loading pressure connection is in the lower casing assembly (key 39) as shown in figure 4.

Spring Adjustment

The spring has a fixed pressure span over which loading pressure will stroke the valve. Adjustment of the spring compression shifts the span so that more or less loading pressure is required to start travel. Since the span does not change, there will be a corresponding increase or decrease in the pressure requirements at the end of the valve stroke.

In order to maximize shutoff pressure drop values, the actuator spring must be accurately adjusted for each Input Signal Pressure Range. If the actuator has been disassembled or pressure conditions have changed, the spring may require adjustment. Refer to tables 2 and 4 to determine the Initial Spring Set values based on the Input Signal range that is available to the actuator. These values include packing friction.

5

D4 Valve |

Instruction Manual |

November 2013 |

D103042X012 |

|

|

Spring-to-Close

Refer to figure 4.

1.Loosen the adjusting screw nut (key 44).

2.Turn the adjusting screw (key 31) clockwise to compress the spring or counterclockwise to decrease spring compression.

3.After adjustment, tighten the adjusting screw nut (key 44).

Spring-to-Open

Refer to figure 5.

1.Unscrew the spring case assembly (key 27).

2.Turn the adjusting stem nut (key 44) clockwise to compress the spring or counterclockwise to decrease spring compression.

3.After adjustment, replace the spring case assembly (key 27).

Maintenance

Refer to figure 4.

Valve parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of inspection and maintenance depends on the severity of the service conditions.

WARNING

WARNING

Avoid personal injury from sudden release of process pressure or bursting of parts. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

DAlways wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal injury.

DDisconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the actuator cannot suddenly open or close the valve.

DUse bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

DThe valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings.

DCheck with your process or safety engineer for any additional measures that must be taken to protect against process media.

Valve Plug and Seat Ring

The D4 control valve is designed to allow easy access to the valve plug and seat ring without disturbing the packing. Refer to other sections of this instruction manual if additional maintenance is required.

6

Instruction Manual |

D4 Valve |

D103042X012 |

November 2013 |

|

|

Disassembly

1.Remove the loading pressure tubing and any accessories that may hamper disassembly.

2.Break the hammer nut (key 6) loose with a hammer. Continue turning the hammer nut by using a hammer or a large adjustable wrench, tightened around one ear of the hammer nut. If the bonnet is stuck on the valve, continue to unscrew the hammer nut. The hammer nut will contact the spring pins (key 7) and will force the bonnet out of the valve. Carefully lift the actuator, bonnet, and valve plug assembly from the valve body.

WARNING

WARNING

The spring pins must always be in place during valve operation. They provide a safeguard against injury when the unit is being disassembled.

3.Use a socket wrench to loosen the seat ring (key 3).

4.Remove the seat ring (key 3) and seat ring gasket (key 9) from the valve body.

5.Inspect parts for wear or damage that would prevent proper operation of the valve body. Carefully clean the seat ring gasket surfaces and seat ring threads.

WARNING

WARNING

Be careful to avoid damaging the seating surface on the valve plug or seat ring as damage in these areas will allow excessive leakage at shutoff. Avoid damaging the highly polished valve stem surface. A damaged valve stem could cut the packing and allow process fluid to leak to the atmosphere.

Table 8. Torque for Seat Ring (Key 3)

VALVE SIZE |

|

RECOMMENDED TORQUE |

|

NPS |

NSm |

|

LbfSft |

1 |

407 |

|

300 |

|

|

|

|

2 |

698 |

|

515 |

|

|

|

|

6.For spring-to-close only: To remove the valve plug (key 2), drive out the groove pin (key 4) and unscrew the valve plug from the stem (key 47). If the groove pin (key 4) is not exposed, verify that downward movement of the stem is not restricted by instrument linkages attached to the stem (key 47).

If the valve plug cannot be easily unscrewed from the stem, use a punch to keep the stem from turning as the plug is removed.

7.For spring-to-open only: To remove the valve plug (key 2), first remove the spring case assembly (key 27). Remove the adjustment screw nut (key 44), the upper spring seat (key 29), and the spring (key 30). Push the adjustment stem (key 31) fully downward until the diaphragm plate (key 40) contacts the cap screws (key 38), exposing the groove pin (key 4) in the plug. If the groove pin (key 4) is not exposed, verify that downward movement of the stem is not restricted by instrument linkages attached to the stem (key 47). Drive out the groove pin (key 4) and unscrew the valve plug from the stem (key 47).

If the valve plug cannot be easily unscrewed from the stem, use a punch to keep the stem from turning as the plug is removed.

Assembly

1. Make sure the bonnet O-ring (key 8) is on the bonnet and lubricated with lithium grease (key 49).

7

D4 Valve |

Instruction Manual |

November 2013 |

D103042X012 |

|

|

2.Install the plug (key 2) on the stem (key 47) and insert a new groove pin (key 4).

3.Thoroughly clean the seat ring and bonnet threads in the valve body (key 1). Also clean the valve body seat ring gasket surfaces.

4.Apply anti-seize lubricant (key 54) to the threads of the seat ring (key 3), and its mating threads in the valve body.

5.Apply anti-seize lubricant (key 54) to the seat ring gasket (key 9) and install into the valve body.

6.Screw the seat ring into the valve body. Use a socket wrench to tighten the seat ring to the torque values shown in table 8. Remove all excess lubricant after tightening.

7.Lubricate (key 54) the threads on the valve body and hammer nut and the contact surfaces of the bonnet and hammer nut flange. Install the bonnet and actuator assembly with pinned valve plug onto the valve body. Tighten the hammer nut using an adjustable wrench until the nut stops turning. A few hammer blows will be required to ensure that the assembly is tight.

8.See the actuator assembly and spring adjustment sections of this manual.

Valve Packing

Note

These instructions apply to valves manufactured with serial numbers equal to and greater than 18679262. See Appendix A for information on packing constructions with serial numbers less than 18679262.

If your D4 valve assembly has a packing retainer lock ring (see figure 6), proceed to Appendix A.

WARNING

WARNING

Observe the warning at the start of the Maintenance section.

The valve stem packing can only be accessed from within the valve body. If packing maintenance is required, first disassemble per steps 1, 2, and 6 or 7 in the Valve Plug and Seat Ring Disassembly section of this document.

Disassembly

1.Unscrew the packing retainer (key 10) from the bonnet (key 5).

2.Remove the five Belleville springs (key 11), packing spacer (key 14), packing (key 13), and two anti-extrusion rings (key 12) from the bonnet, using a formed wire hook.

3.Clean and inspect the packing box wall to ensure that the packing surfaces are not damaged. If the surface condition is damaged, and cannot be improved by light sanding, replace the bonnet by contacting your Emerson Process Management sales office.

4.Inspect the valve stem for scratches or wear, and valve plug for wear or damage. Replace if necessary.

8

Loading...

Loading...