Emerson Fisher Baumann 24003 Data Sheet

24003 Valve |

Product Bulletin |

52.1:243WY |

|

D103329X012 |

November 2012 |

|

|

Baumann™ 24003 3-Way Bronze or Stainless Steel Control Valve

The Baumann 24003 3-way control valve is ideally suited for control of flow and temperature where mixing or diverting service is required. This 3-way valve uses a rugged cast bronze or CF8M stainless steel body with S31600 austenitic stainless steel trim for extended service life.

Features

Compact and light weight design reduces installed piping costs.

Optional ENVIRO-SEALt packing system to meet critical emission control requirements; suitable for use in light duty chemical service (not for use in corrosive service). This option is available in the stainless steel version only.

High quality S31600 austenitic stainless steel trim materials.

Dual plug and stem guiding provides increased stability during plug travel.

Multiple trim capacity reductions available to meet changing process requirements.

Epoxy powder-coated actuator with stainless steel fasteners for corrosion resistance.

Multi-spring, field-reversible actuator with reduced deadband, permits direct operation from remote signal devices.

Actuator and yoke can be removed from the valve assembly while maintaining packing integrity.

W9764

Stainless Steel 3-Way Valve with Baumann 32 Actuator

W9765

Fisherr FIELDVUEt digital valve controllers available |

Bronze 3-Way Valve with Baumann 54 Actuator and |

for remote calibration and diagnostics in facilities |

FIELDVUE DVC2000 Digital Valve Controller |

|

|

utilizing the PlantWebt architecture. |

|

www.Fisher.com

|

Product Bulletin |

|

|

24003 Valve |

|

|

|

52.1:243WY |

|

|

|

||

|

November 2012 |

|

|

D103329X012 |

|

|

|

|

|

|

|

|

|

|

Table 1. Flow Direction(1) |

|

|

|

||

|

Service |

|

Inlet |

Outlet |

|

|

|

Diverting |

|

C |

U and L |

|

|

|

|

|

|

|

|

|

|

Mixing |

|

U and L |

C |

|

|

|

|

|

|

|

|

|

|

1. C = Common port, U = Upper port, L = Lower port |

|

|

|

||

|

|

|

|

|

|

|

|

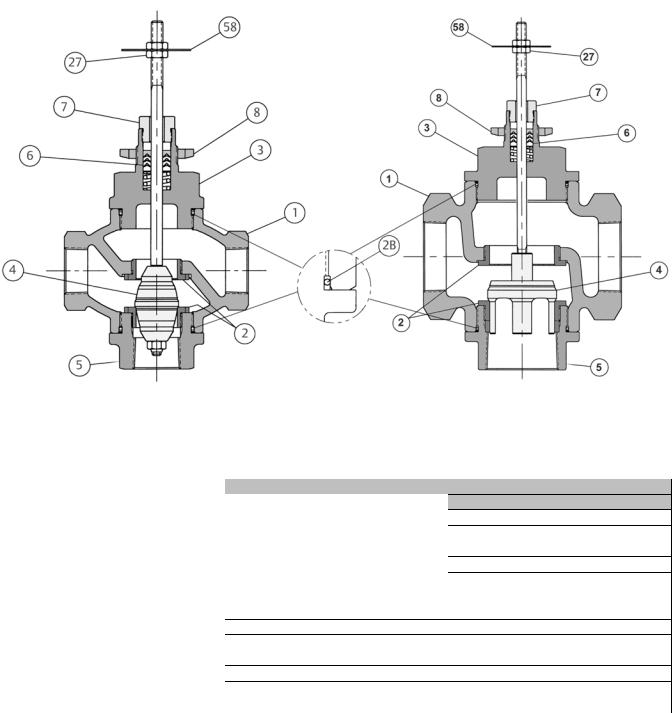

Figure 1. Baumann 24000F Valve Body with Standard Bonnet and NPS 1 Integral Seat |

|

||||

|

|

|||||

O-RING USED IN

STAINLESS STEEL VALVE

ASSEMBLY ONLY

E1281 |

NPS 1/2 and 1 |

NPS 1-1/2 and 2 |

Table 2. Materials of Construction

KEY |

DESCRIPTION |

|

|

MATERIAL |

||

NO. |

|

Bronze |

|

Stainless Steel |

||

|

|

|

|

|||

1 |

Valve Body |

|

Bronze ASTM B62 |

|

ASTM A351 CF8M |

|

|

|

|

|

|

|

|

2 |

Seat Rings |

|

ASTM A276 S31600 Condition A |

|

ASTM A276 S31600 Condition A |

|

|

|

|

|

|

|

|

2B |

O-Ring |

|

N/A |

|

TFE/P (tetrafluoroethylene/propylene) |

|

|

|

|

|

|

|

|

3 |

Bonnet |

|

Bronze ASTM B62 |

|

ASTM A351 CF8M |

|

|

|

|

|

|

|

|

4 |

Plug & Stem Assembly |

ASTM A276 S31600 Condition A |

|

ASTM A276 S31600 Condition A |

||

|

|

|

|

|

|

|

5 |

Bottom Port |

|

Bronze ASTM B62 |

|

ASTM A351 CF8M |

|

|

|

|

Standard |

PTFE (Polytetrafluoroethylene) / PTFE, 25% carbon filled |

||

6 |

Packing |

|

|

Molded Graphite Ribbon (Flexible Graphite) |

||

|

Optional |

|||||

|

|

|

ENVIRO-SEAL (Stainless Steel ONLY) |

|||

|

|

|

|

|||

|

|

|

|

|

||

7 |

Packing Follower |

|

ASTM A276 S31600 Condition A Stainless Steel |

|||

|

|

|

|

|||

8 |

Drive Nut (Yoke) |

|

ASTM A194 S30400 Gr. 8 |

|||

|

|

|

|

|||

27 |

Locknuts |

|

Stainless Steel (18-8 SST) |

|||

|

|

|

|

|

||

58 |

Travel Indicator |

|

|

ASTM A240 S30400 |

||

|

|

|

|

|

|

|

2

|

24003 Valve |

Product Bulletin |

|

|

52.1:243WY |

|

|

|

D103329X012 |

November 2012 |

|

|

|

|

|

|

Figure 2. Standard Spring-Loaded PTFE V-Ring |

Figure 4. ENVIRO-SEAL Packing Kit (Optional for |

|

|

Packing Kit |

Stainless Steel Only) |

|

|

|

|

|

E1240

Table 3. Standard Spring-Loaded PTFE V-Ring

Packing Kit

Key Number |

Description |

Material |

|

6 |

Spring |

ASTM A313 S30200 |

|

|

|

|

|

14 |

Packing Set |

PTFE (Polytetrafluoroethylene) / |

|

PTFE, 25% carbon filled |

|||

|

|

||

|

|

|

|

16 |

Washer |

ASTM A240 S31600 |

|

|

|

|

|

20 |

Spacer |

J-2000 |

|

(filled-Polytetrafluoroethylene) |

|||

|

|

||

|

|

|

E1248

Table 5. ENVIRO-SEAL Packing Kit (Optional for Stainless Steel Only)

Key Number |

Description |

Material |

|

13 |

Bushing |

Carbon-Graphite |

|

|

|

|

|

14 |

Packing Set |

PTFE (Polytetrafluoroethylene) / |

|

PTFE, 25% carbon filled |

|||

|

|

||

|

|

|

|

17 |

Belleville |

N06600 Nickel Alloy (ASTM B637 |

|

Spring |

N07718, 40 HRC max) |

||

|

|||

|

|

|

|

18 |

Bushing |

PEEK (polyetheretherketone) |

|

|

|

|

|

19 |

Washer |

Modified PTFE |

|

|

|

|

Figure 3. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

E1241

Table 4. Molded Graphite (Flexible Graphite)

Packing Kit (Optional)

Key Number |

Description |

Material |

13 |

Bushings |

Carbon-Graphite |

|

|

|

14A |

Packing Rings |

Graphite |

|

|

|

14B |

Packing Ring |

Graphite |

|

|

|

Special ENVIRO-SEAL Packing Note

The ENVIRO-SEAL PTFE packing system is suitable for 100 ppm environmental applications on services up to 51.7 barg (750 psig) and process temperatures ranging from -46 to 232_C (-50 to 450_F).

For non-environmental applications, this packing system offers excellent performance at the same temperature range up to the maximum valve working pressure.

Temperature limits apply to packing arrangements only. Complete valve assembly temperature limits may differ, refer to appropriate pressure/temperature ratings.

(Reference Fisher Packing Selection Guidelines for Sliding-Stem Valves, Bulletin 59.1:062, D101986X012).

3

Loading...

Loading...