Emerson Fisher 585C Installation Instructions

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

Fisherr 585C Series Piston Actuators

Contents |

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Educational Services . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Actuator with Handwheel . . . . . . . . . . . . . . . . . . . . . |

8 |

Actuator with Spring Return . . . . . . . . . . . . . . . . . . |

10 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Bypass Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Three-Way Valve Applications Note . . . . . . . . . . . . |

11 |

Actuator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Size 25 & 50 Actuator Mounting . . . . . . . . . . . . . . . |

11 |

Size 60-130 Actuator Mounting . . . . . . . . . . . . . . . |

13 |

Stem Connector Assembly (Size 60-130) . . . . |

13 |

585C Handwheels . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

Handwheel Operation (Sizes 25 & 50) . . . . . . . . . . |

14 |

Handwheel Operation (Sizes 60-130) . . . . . . . . . . |

14 |

Maintenance (Sizes 25 & 50) . . . . . . . . . . . . . . . . . . . |

15 |

Replacing Handwheel Housing O-Ring or |

|

Thrust Bearings (Sizes 25 & 50) . . . . . . . . . . . . . |

16 |

Replacing Seals, Changing Action, or |

|

Changing Bias Spring(s) (Sizes 25 & 50) . . . . . . |

17 |

Maintenance (Sizes 60-130) . . . . . . . . . . . . . . . . . . . |

20 |

Side-Mounted Handwheel Maintenance |

|

(Sizes 60-130) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

Disassembly of Handwheel Constructions |

|

(Sizes 60 and 68) . . . . . . . . . . . . . . . . . . . . . |

21 |

Figure 1. Fisher 585C Series Piston Actuator

X0175-1 |

|

Disassembly of Handwheel Constructions |

|

(Sizes 80-130) . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Reassembly (Sizes 60-130) . . . . . . . . . . . . . . . |

22 |

Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Sizes 25 & 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Sizes 60-130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

Introduction

Scope of Manual

This instruction manual provides information on installation, maintenance, and parts ordering for the Fisher 585C piston actuators. Refer to separate instruction manuals for information about other equipment and accessories used with these actuators.

Information for the 585CLS long stroke actuator can be found in the Fisher 585CLS instruction manual (D103793X012).

Do not install, operate, or maintain a 585C Series actuator without being fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important

www.Fisher.com

585C Actuator |

Instruction Manual |

October 2013 |

D102087X012 |

|

|

to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office before proceeding.

Description

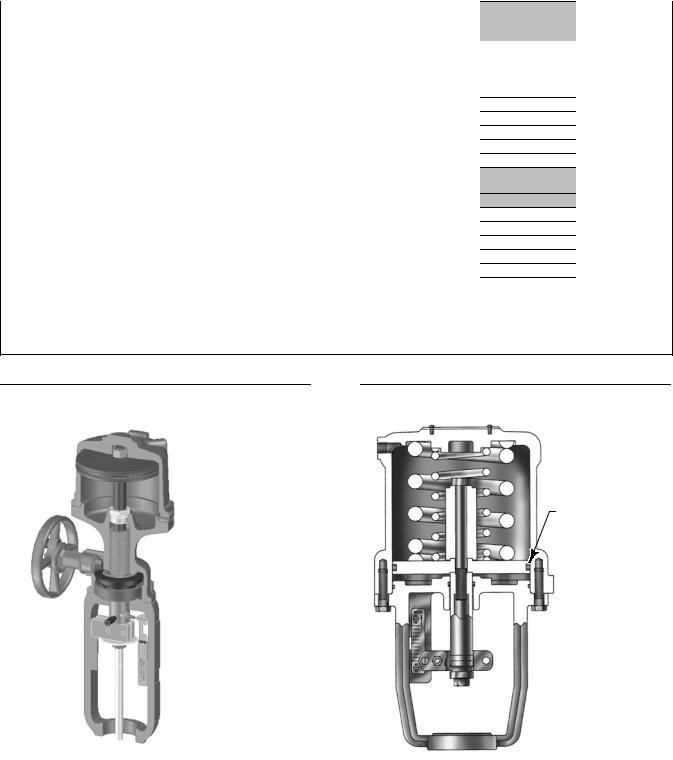

585C pneumatic piston actuators ( figure 1) provide accurate throttling or on-off control of sliding-stem valves. The 585C actuator uses a double-acting cylinder, which requires air pressure for operation.

Size 25 and 50 actuators are available as a springless construction or with a bias spring. Depending on configuration, the bias spring will retract or extend the piston rod upon loss of cylinder air pressure. Size 60 through 130 actuators are available as springless constructions only.

585C actuators are typically supplied with a DVC6200 digital valve controller, or a 3600 P/P or I/P analog positioner. The 585C actuator is available with a top-mounted or side-mounted manual handwheel, depending on actuator size.

Specifications

Specifications for the 585C piston actuators are given in table 1. Some individual actuators come from the factory with specifications stamped on a nameplate attached to the yoke.

Educational Services

For information on available courses for Fisher 585C Series piston actuators, as well as a variety of other products, contact:

Emerson Process Management Educational Services, Registration P.O. Box 190; 301 S. 1st Ave. Marshalltown, IA 50158-2823 Phone: 800-338-8158 or

Phone: 641-754-3771

FAX: 641-754-3431

e-mail: education@emerson.com

2

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

Table 1. 585C Specifications (sizes 25-130)

Operating Pressure(1)

Sizes 25-50

Maximum Allowable: 10.3 bar (150 psig) Minimum Recommended: 1.4 bar (20 psig) Sizes 60-130

Maximum Allowable: See table 8 Minimum Recommended: 2.4 bar (35 psig)

Travel

See table 2

Thrust Capabilities

See tables 4 through 8

Stroking Speeds

Varies with actuator size, actuator spring, travel, and supply pressure. If stroking speed is critical, consult your Emerson Process Management sales office

Piston Area

See table 2

Cylinder Volumetric Displacement

See table 2

Operative Temperature Limits(1)

For All Sizes

With Nitrile O-Rings: -40 to 80_C (-40 to 175_F), standard

With Fluorocarbon O-Rings: -18 to 149_C (0 to 300_F), optional

Yoke Boss and Valve Stem Diameters

See table 3

Pressure Connections

Size 25-60

J 1/4 NPT internal (standard), or J 3/8 NPT internal (optional)

Sizes 68-130

J 1/2 NPT internal (standard)

Instrument Mounting

Universal NAMUR mounting

Construction Materials

Part

Yoke

Piston

Cylinder

Bolting and Fasteners

Springs

(sizes 25 & 50 only)

O-Rings

Actuator Stem

Stem Connection

Travel Indicator Scale

Paint

Cylinder Seal Bushings (sizes 60-130 only)

Stem Connector (sizes 60-130)

Material

Ductile Iron

Aluminum

Aluminum

NCF (non-corroding finish)

Alloy Steel

Nitrile (std), Fluorocarbon

Chrome-plated Steel

Stainless Steel

Stainless Steel

Polyester Powder

Brass

Zinc-plated steel

Approximate Weights (less positioner and handwheel)

Size 25

2-1/8 inch yoke boss, 7 kg (16 pounds) 2-13/16 inch yoke boss, 8 kg (17 pounds) Size 50

2-13/16 inch yoke boss, 20 kg (45 pounds) 3-9/16 inch yoke boss, 22 kg (48 pounds) Size 60: 31 kg (68 pounds)

Size 68: 54 kg (120 pounds) Size 80: 102 kg (225 pounds) Size 100: 113 kg (250 pounds) Size 130: 188 kg (415 pounds)

Options

Sizes 25 and 50

J Top-mounted handwheel, see figures 5, 7, and 8 and table 9

J Cylinder bypass valve J Limit switches J Fisher 4200 position transmitter

Sizes 60-130

J Integral side-mounted handwheel, (figure 9) Sizes 25-130

J FIELDVUEt mounting options

J Fisher 377 trip valve system to fail actuator J up or J down or J lock in last position

J TopWorxt DXP M21GNEB electrical valve stem position switch

J Micro-Switch limit switches

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

3

585C Actuator |

|

|

|

|

|

|

Instruction Manual |

|||

October 2013 |

|

|

|

|

|

|

|

|

D102087X012 |

|

|

|

|

|

|

|

|

|

|

||

Table 2. Fisher 585C Piston Cylinder Clearance Volumes |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PISTON AT TOP OF CYLINDER (SPRINGS BELOW PISTON FOR SIZE 25 AND 50) |

|

|

||||

Actuator |

|

|

Piston Area |

Maximum Actuator Travel |

Upper Clearance Volume |

Volume Below Piston |

||||

Size |

|

cm2 |

|

Inches2 |

cm |

Inches |

cm3 |

Inches3 |

cm3 |

Inches3 |

25 |

|

168 |

|

26 |

2.9 |

1.125 |

104 |

6.3 |

1750 |

107 |

|

|

|

|

|

|

|

|

|

|

|

50 |

|

303 |

|

47 |

5.1 |

2 |

330 |

20 |

5200 |

320 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.1 |

2 |

310 |

19 |

2700 |

163 |

|

|

|

|

|

|

|

|

|

|

|

60 |

|

358 |

|

55.5 |

10 |

4 |

310 |

19 |

4400 |

270 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

8 |

310 |

19 |

8200 |

500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.1 |

2 |

1230 |

75 |

7500 |

460 |

|

|

|

|

|

|

|

|

|

|

|

68 |

|

571 |

|

88.5 |

10.2 |

4 |

1230 |

75 |

7500 |

460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20.3 |

8 |

1230 |

75 |

13300 |

810 |

|

|

|

|

|

|

|

|

|

|

|

80 |

|

571 |

|

88.5 |

10.2 |

4 |

1230 |

75 |

7500 |

460 |

|

|

|

|

|

|

|

|

|||

|

|

20.3 |

8 |

1230 |

75 |

13300 |

810 |

|||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

100 |

|

842 |

|

130.5 |

10.2 |

4 |

1700 |

104 |

10700 |

650 |

|

|

|

|

|

|

|

|

|||

|

|

20.3 |

8 |

1700 |

104 |

19200 |

1170 |

|||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

130 |

|

1430 |

|

221.5 |

10.2 |

4 |

4600 |

280 |

18500 |

1130 |

|

|

|

|

|

|

|

|

|||

|

|

20.3 |

8 |

4600 |

280 |

33000 |

2000 |

|||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PISTON AT BOTTOM OF CYLINDER (SPRINGS ABOVE PISTON FOR SIZE 25 AND 50) |

|

|

||||

Actuator |

|

|

Piston Area |

Maximum Actuator Travel |

Lower Clearance Volume |

Volume Above Piston |

||||

Size |

|

cm2 |

|

Inches2 |

cm |

Inches |

cm3 |

Inches3 |

cm3 |

Inches3 |

25 |

|

168 |

|

26 |

2.9 |

1.125 |

77 |

4.7 |

1790 |

109 |

|

|

|

|

|

|

|

|

|

|

|

50 |

|

303 |

|

47 |

5.1 |

2 |

350 |

22 |

5200 |

320 |

|

|

|

|

|

|

|

|

|

|

|

Table 3. Yoke Boss and Valve Stem Diameters

ACTUATOR SIZE |

|

YOKE BOSS DIAMETER |

|

VALVE STEM DIAMETER |

||

mm |

|

Inches |

mm |

|

Inches |

|

|

|

|

||||

25 |

54 |

|

2-1/8 |

9.5 |

|

3/8 |

71 |

|

2-13/16 |

12.7 |

|

1/2 |

|

|

|

|

||||

|

|

|

|

|

|

|

50 |

71 |

|

2-13/16 |

12.7 |

|

1/2 |

90 |

|

3-9/16 |

19.1 |

|

3/4 |

|

|

|

|

||||

|

|

|

|

|

|

|

60 |

90 |

|

3-9/16 |

19.1 |

|

3/4 |

|

|

|

|

|

|

|

68 |

90 |

|

3-9/16 |

19.1 |

|

3/4 |

|

|

|

|

|

|

|

80 |

127 |

|

5, 5H |

25.4 |

|

1 |

|

31.8 |

|

1-1/4 |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

100 |

127 |

|

5, 5H |

25.4 |

|

1 |

|

31.8 |

|

1-1/4 |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

130 |

127 |

|

5, 5H |

25.4 |

|

1 |

|

31.8 |

|

1-1/4 |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

1. Heavy actuator to bonnet bolting.

4

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

Actuator Thrust Capabilities

Table 4. Fisher 585C Size 25 and 50 Actuator Thrust Capabilities, U.S. Units (spring retracts actuator stem)

|

|

ACTUATOR |

SPRING |

SPRING |

|

NET THRUST FOR 585C WITH ACTUATOR STEM FULLY |

|

|

SPRINGS |

|

|||||||

ACTU- |

SPRING |

THRUST W/ |

THRUST W/ |

|

|

|

EXTENDED AT FULL TRAVEL |

|

|

|

|

|

|||||

ATOR |

RATE, |

STEM |

ACTUATOR |

ACTUATOR |

|

|

|

Operating Pressure, psig |

|

|

|

|

USED, |

|

|||

TRAVEL, |

STEM |

STEM |

|

|

|

|

|

|

|

BY |

|

||||||

SIZE |

lb/in |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

|

125 |

150 |

|

||||

INCHES |

RETRACTED, |

EXTENDED, |

|

COLOR |

|

||||||||||||

|

|

|

POUNDS |

POUNDS |

|

|

|

|

Force, Pounds |

|

|

|

|

|

|

|

|

|

0 |

All |

0 |

0 |

1040 |

1300 |

1560 |

1820 |

2080 |

2340 |

2600 |

2860 |

|

3250 |

3900 |

Springs |

|

|

|

Not Used |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5625 |

200 |

313 |

730 |

990 |

1250 |

1510 |

1760 |

2020 |

2280 |

2540 |

|

2930 |

3580 |

|

|

|

200 |

0.75 |

200 |

350 |

690 |

950 |

1210 |

1470 |

1730 |

1990 |

2250 |

2510 |

|

2900 |

3550 |

Gold |

|

|

0.875 |

200 |

375 |

660 |

920 |

1180 |

1440 |

1700 |

1960 |

2220 |

2480 |

|

2870 |

3520 |

|||

|

|

|

|

|

|||||||||||||

|

|

1.125 |

200 |

425 |

610 |

870 |

1130 |

1390 |

1650 |

1910 |

2170 |

2430 |

|

2820 |

3470 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5625 |

400 |

625 |

410 |

670 |

930 |

1190 |

1450 |

1710 |

1970 |

2230 |

|

2620 |

3270 |

|

|

|

400 |

0.75 |

400 |

700 |

340 |

600 |

860 |

1120 |

1380 |

1640 |

1900 |

2160 |

|

2550 |

3200 |

Light |

|

|

0.875 |

400 |

750 |

290 |

550 |

810 |

1070 |

1330 |

1590 |

1850 |

2110 |

|

2500 |

3150 |

Green |

||

|

|

|

|||||||||||||||

|

|

1.125 |

400 |

850 |

190 |

450 |

710 |

970 |

1230 |

1490 |

1750 |

2010 |

|

2400 |

3050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

0.5625 |

500 |

781 |

260 |

520 |

780 |

1040 |

1300 |

1560 |

1820 |

2080 |

|

2460 |

3110 |

|

|

|

0.75 |

500 |

875 |

160 |

420 |

680 |

940 |

1200 |

1460 |

1720 |

1980 |

|

2370 |

3020 |

|

|

|

|

500 |

|

White |

||||||||||||||

|

0.875 |

500 |

938 |

100 |

360 |

620 |

880 |

1140 |

1400 |

1660 |

1920 |

|

2310 |

2960 |

|||

|

|

|

|

|

|||||||||||||

|

|

1.125 |

500 |

1063 |

X |

240 |

500 |

760 |

1010 |

1270 |

1530 |

1790 |

|

2180 |

2830 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5625 |

700 |

1094 |

X |

200 |

460 |

720 |

980 |

1240 |

1500 |

1760 |

|

2150 |

2800 |

|

|

|

700 |

0.75 |

700 |

1225 |

X |

70 |

330 |

590 |

850 |

1110 |

1370 |

1630 |

|

2020 |

2670 |

Gold & |

|

|

0.875 |

700 |

1313 |

X |

X |

250 |

510 |

760 |

1020 |

1280 |

1540 |

|

1930 |

2580 |

White |

||

|

|

|

|||||||||||||||

|

|

1.125 |

700 |

1488 |

X |

X |

70 |

330 |

590 |

850 |

1110 |

1370 |

|

1760 |

2410 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5625 |

900 |

1406 |

X |

X |

150 |

410 |

670 |

930 |

1190 |

1450 |

|

1840 |

2490 |

Light |

|

|

900 |

0.75 |

900 |

1575 |

X |

X |

X |

240 |

500 |

760 |

1020 |

1280 |

|

1670 |

2320 |

||

|

|

Green |

|||||||||||||||

|

0.875 |

900 |

1688 |

X |

X |

X |

130 |

390 |

650 |

910 |

1170 |

|

1560 |

2210 |

|||

|

|

|

& White |

||||||||||||||

|

|

1.125 |

900 |

1913 |

X |

X |

X |

X |

160 |

420 |

680 |

940 |

|

1330 |

1980 |

||

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

All |

0 |

0 |

1840 |

2300 |

2760 |

3220 |

3680 |

4140 |

4600 |

5060 |

|

5750 |

6900 |

Springs |

|

|

|

Not Used |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.75 |

330 |

578 |

1310 |

1780 |

2250 |

2720 |

3190 |

3660 |

4140 |

4610 |

|

5310 |

6490 |

|

|

|

330 |

0.875 |

330 |

619 |

1270 |

1740 |

2210 |

2680 |

3150 |

3620 |

4090 |

4570 |

|

5270 |

6450 |

Pink |

|

|

1.125 |

330 |

701 |

1180 |

1660 |

2130 |

2600 |

3070 |

3540 |

4010 |

4480 |

|

5190 |

6370 |

|||

|

|

1.5 |

330 |

825 |

1060 |

1530 |

2000 |

2470 |

2950 |

3420 |

3890 |

4360 |

|

5070 |

6250 |

|

|

|

|

2 |

330 |

990 |

900 |

1370 |

1840 |

2310 |

2780 |

3250 |

3720 |

4190 |

|

4900 |

6080 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.75 |

600 |

1050 |

840 |

1310 |

1780 |

2250 |

2720 |

3190 |

3660 |

4130 |

|

4840 |

6020 |

|

|

|

600 |

0.875 |

600 |

1125 |

760 |

1230 |

1700 |

2170 |

2650 |

3120 |

3590 |

4060 |

|

4770 |

5950 |

Light |

|

|

1.125 |

600 |

1275 |

610 |

1080 |

1550 |

2020 |

2500 |

2970 |

3440 |

3910 |

|

4620 |

5800 |

|||

|

|

Blue |

|||||||||||||||

|

|

1.5 |

600 |

1500 |

390 |

860 |

1330 |

1800 |

2270 |

2740 |

3210 |

3680 |

|

4390 |

5570 |

||

|

|

|

|

|

|||||||||||||

|

|

2 |

600 |

1800 |

90 |

560 |

1030 |

1500 |

1970 |

2440 |

2910 |

3380 |

|

4090 |

5270 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

0.75 |

930 |

1628 |

260 |

730 |

1200 |

1670 |

2140 |

2610 |

3090 |

3560 |

|

4260 |

5440 |

|

|

930 |

0.875 |

930 |

1744 |

140 |

610 |

1080 |

1560 |

2030 |

2500 |

2970 |

3440 |

|

4150 |

5330 |

Pink & |

||

|

1.125 |

930 |

1976 |

X |

380 |

850 |

1320 |

1790 |

2270 |

2740 |

3210 |

|

3910 |

5090 |

Light |

||

|

|

1.5 |

930 |

2325 |

X |

30 |

500 |

970 |

1450 |

1920 |

2390 |

2860 |

|

3570 |

4750 |

Blue |

|

|

|

2 |

930 |

2790 |

X |

X |

40 |

510 |

980 |

1450 |

1920 |

2390 |

|

3100 |

4280 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.75 |

1550 |

2710 |

X |

X |

110 |

580 |

1050 |

1520 |

1990 |

2460 |

|

3165 |

4345 |

|

|

|

1550 |

0.875 |

1550 |

2906 |

X |

X |

X |

385 |

855 |

1325 |

1795 |

2265 |

|

2970 |

4150 |

Green |

|

|

1.125 |

1550 |

3294 |

X |

X |

X |

X |

465 |

935 |

1405 |

1875 |

|

2580 |

3760 |

|||

|

|

1.5 |

1550 |

3875 |

X |

X |

X |

X |

X |

355 |

825 |

1295 |

|

2000 |

3180 |

|

|

|

|

2 |

1550 |

4650 |

X |

X |

X |

X |

X |

X |

50 |

520 |

|

1225 |

2405 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.75 |

1880 |

3290 |

X |

X |

X |

X |

470 |

940 |

1410 |

1880 |

|

2585 |

3765 |

|

|

|

1880 |

0.875 |

1880 |

3525 |

X |

X |

X |

X |

235 |

705 |

1175 |

1645 |

|

2350 |

3530 |

Pink & |

|

|

1.125 |

1880 |

3995 |

X |

X |

X |

X |

X |

235 |

705 |

1175 |

|

1880 |

3060 |

|||

|

|

Green |

|||||||||||||||

|

|

1.5 |

1880 |

4700 |

X |

X |

X |

X |

X |

X |

X |

470 |

|

1175 |

2355 |

||

|

|

|

|

|

|||||||||||||

|

|

2 |

1880 |

5640 |

X |

X |

X |

X |

X |

X |

X |

X |

|

235 |

1415 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X–Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

5

585C Actuator |

Instruction Manual |

October 2013 |

D102087X012 |

|

|

Table 5. Fisher 585C Size 25 and 50 Actuator Thrust Capabilities, Metric Units (spring retracts actuator stem)

|

|

ACTU- |

SPRING |

SPRING |

|

|

NET THRUST FOR 585C WITH ACTUATOR STEM FULLY |

|

|

|

|

|||||

ACTU- |

SPRING |

THRUST W/ |

THRUST W/ |

|

|

|

EXTENDED AT FULL TRAVEL |

|

|

|

SPRINGS |

|

||||

ATOR |

ACTUATOR |

ACTUATOR |

|

|

|

|

|

|

|

|

|

|

USED, |

|

||

ATOR |

RATE, |

STEM |

|

|

|

Operating Pressure, bar |

|

|

|

|

||||||

STEM |

STEM |

|

|

|

|

|

|

BY |

|

|||||||

SIZE |

N/mm |

TRAVEL, |

2.8 |

3.4 |

4.1 |

4.8 |

5.5 |

6.2 |

6.9 |

7.6 |

8.6 |

10.3 |

|

|||

RETRACTED, |

EXTENDED, |

COLOR |

|

|||||||||||||

|

|

mm |

N |

N |

|

|

|

|

Force, N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Springs |

|

|

0 |

All |

0 |

0 |

4626 |

5783 |

6939 |

8096 |

9252 |

10,409 |

11,565 |

12,722 |

14,457 |

17,348 |

Not |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Used |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.3 |

890 |

1393 |

3247 |

4404 |

5560 |

6717 |

7829 |

8985 |

10,142 |

11,298 |

13,033 |

15,925 |

|

|

|

35.0 |

19.1 |

890 |

1558 |

3069 |

4226 |

5382 |

6539 |

7695 |

8852 |

10,008 |

11,165 |

12,900 |

15,791 |

Gold |

|

|

22.2 |

890 |

1669 |

2936 |

4092 |

5249 |

6405 |

7562 |

8718 |

9875 |

11,032 |

12,766 |

15,658 |

|||

|

|

|

|

|||||||||||||

|

|

28.6 |

890 |

1891 |

2713 |

3870 |

5026 |

6183 |

7340 |

8496 |

9653 |

10,809 |

12,544 |

15,435 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.3 |

1780 |

2781 |

1824 |

2980 |

4137 |

5293 |

6450 |

7606 |

8763 |

9919 |

11,654 |

14,546 |

|

|

|

70.1 |

19.1 |

1780 |

3115 |

1512 |

2669 |

3825 |

4982 |

6139 |

7295 |

8452 |

9608 |

11,343 |

14,234 |

Light |

|

|

22.2 |

1780 |

3338 |

1290 |

2447 |

3603 |

4760 |

5916 |

7073 |

8229 |

9386 |

11,121 |

14,012 |

Green |

||

|

|

|||||||||||||||

|

|

28.6 |

1780 |

3783 |

845 |

2002 |

3158 |

4315 |

5471 |

6628 |

7784 |

8941 |

10,676 |

13,567 |

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.3 |

2225 |

3475 |

1156 |

2313 |

3470 |

4626 |

5783 |

6939 |

8096 |

9252 |

10,943 |

13,834 |

|

|

|

|

87.6 |

19.1 |

2225 |

3894 |

712 |

1868 |

3025 |

4181 |

5338 |

6494 |

7651 |

8807 |

10,542 |

13,434 |

White |

|

|

22.2 |

2225 |

4174 |

445 |

1601 |

2758 |

3914 |

5071 |

6227 |

7384 |

8541 |

10,275 |

13,167 |

|||

|

|

|

|

|||||||||||||

|

|

28.6 |

2225 |

4730 |

X |

1068 |

2224 |

3381 |

4493 |

5649 |

6806 |

7962 |

9697 |

12,588 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.3 |

3115 |

4868 |

X |

890 |

2046 |

3203 |

4359 |

5516 |

6672 |

7829 |

9564 |

12,455 |

|

|

|

122.6 |

19.1 |

3115 |

5451 |

X |

311 |

1468 |

2624 |

3781 |

4938 |

6094 |

7251 |

8985 |

11,877 |

Gold & |

|

|

22.2 |

3115 |

5843 |

X |

X |

1112 |

2269 |

3381 |

4537 |

5694 |

6850 |

8585 |

11,476 |

White |

||

|

|

|||||||||||||||

|

|

28.6 |

3115 |

6622 |

X |

X |

311 |

1468 |

2624 |

3781 |

4938 |

6094 |

7829 |

10,720 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.3 |

4005 |

6257 |

X |

X |

667 |

1824 |

2980 |

4137 |

5293 |

6450 |

8185 |

11,076 |

Light |

|

|

|

19.1 |

4005 |

7009 |

X |

X |

X |

1068 |

2224 |

3381 |

4537 |

5694 |

7428 |

10,320 |

||

|

157.7 |

Green & |

||||||||||||||

|

22.2 |

4005 |

7512 |

X |

X |

X |

578 |

1735 |

2891 |

4048 |

5204 |

6939 |

9831 |

|||

|

|

White |

||||||||||||||

|

|

28.6 |

4005 |

8513 |

X |

X |

X |

X |

712 |

1868 |

3025 |

4181 |

5916 |

8807 |

||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Springs |

|

|

0 |

All |

0 |

0 |

8180 |

10,200 |

12,300 |

14,300 |

16,400 |

18,400 |

20,500 |

22,500 |

25,600 |

30,700 |

Not |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Used |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19.1 |

1468 |

2571 |

5827 |

7918 |

10,008 |

12,099 |

14,190 |

16,280 |

18,416 |

20,506 |

23,620 |

28,869 |

|

|

|

|

22.2 |

1468 |

2753 |

5649 |

7740 |

9831 |

11,921 |

14,012 |

16,102 |

18,193 |

20,328 |

23,442 |

28,691 |

|

|

|

57.8 |

28.6 |

1468 |

3118 |

5249 |

7384 |

9475 |

11,565 |

13,656 |

15,747 |

17,837 |

19,928 |

23,086 |

28,335 |

Pink |

|

|

|

38.1 |

1468 |

3670 |

4715 |

6806 |

8896 |

10,987 |

13,122 |

15,213 |

17,303 |

19,394 |

22,552 |

27,801 |

|

|

|

|

50.8 |

1468 |

4404 |

4003 |

6094 |

8185 |

10,275 |

12,366 |

14,457 |

16,547 |

18,638 |

21,796 |

27,045 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19.1 |

2669 |

4671 |

3736 |

5827 |

7918 |

10,008 |

12,099 |

14,190 |

16,280 |

18,371 |

21,529 |

26,778 |

|

|

|

|

22.2 |

2669 |

5004 |

3381 |

5471 |

7562 |

9653 |

11,788 |

13,878 |

15,969 |

18,060 |

21,218 |

26,467 |

Light |

|

|

105.1 |

28.6 |

2669 |

5671 |

2713 |

4804 |

6895 |

8985 |

11,121 |

13,211 |

15,302 |

17,392 |

20,551 |

25,800 |

||

|

Blue |

|||||||||||||||

|

|

38.1 |

2669 |

6672 |

1735 |

3825 |

5916 |

8007 |

10,097 |

12,188 |

14,279 |

16,369 |

19,528 |

24,777 |

||

|

|

|

|

|||||||||||||

|

|

50.8 |

2669 |

8007 |

400 |

2491 |

4582 |

6672 |

8763 |

10,854 |

12,944 |

15,035 |

18,193 |

23,442 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

19.1 |

4137 |

7242 |

1157 |

3247 |

5338 |

7428 |

9519 |

11,610 |

13,745 |

15,836 |

18,949 |

24,198 |

|

|

|

22.2 |

4137 |

7758 |

623 |

2713 |

4804 |

6939 |

9030 |

11,121 |

13,211 |

15,302 |

18,460 |

23,709 |

Pink & |

||

|

|

|||||||||||||||

|

162.9 |

28.6 |

4137 |

8790 |

X |

1690 |

3781 |

5872 |

7962 |

10,097 |

12,188 |

14,279 |

17,392 |

22,641 |

Light |

|

|

|

38.1 |

4137 |

10,342 |

X |

133 |

2224 |

4315 |

6450 |

8541 |

10,631 |

12,722 |

15,880 |

21,129 |

Blue |

|

|

|

50.8 |

4137 |

12,410 |

X |

X |

178 |

2269 |

4359 |

6450 |

8541 |

10,631 |

13,789 |

19,038 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19.1 |

6894 |

12054 |

X |

X |

489 |

2580 |

4670 |

6761 |

8852 |

10942 |

14078 |

19,328 |

|

|

|

|

22.2 |

6894 |

12925 |

X |

X |

X |

1712 |

3803 |

5894 |

7984 |

10075 |

13211 |

18,460 |

|

|

|

271.4 |

28.6 |

6894 |

14652 |

X |

X |

X |

X |

2068 |

4159 |

6249 |

8340 |

11476 |

16,725 |

Green |

|

|

|

38.1 |

6894 |

17236 |

X |

X |

X |

X |

X |

1579 |

3670 |

5760 |

8896 |

14,145 |

|

|

|

|

50.8 |

6894 |

20683 |

X |

X |

X |

X |

X |

X |

222 |

2313 |

5449 |

10,698 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19.1 |

8362 |

14634 |

X |

X |

X |

X |

2091 |

4181 |

6272 |

8362 |

11498 |

16,748 |

|

|

|

|

22.2 |

8362 |

15679 |

X |

X |

X |

X |

1045 |

3136 |

5226 |

7317 |

10453 |

15,702 |

Pink & |

|

|

329.2 |

28.6 |

8362 |

17770 |

X |

X |

X |

X |

X |

1045 |

3136 |

5226 |

8362 |

13,612 |

||

|

Green |

|||||||||||||||

|

|

38.1 |

8362 |

20906 |

X |

X |

X |

X |

X |

X |

X |

2091 |

5226 |

10,476 |

||

|

|

|

|

|||||||||||||

|

|

50.8 |

8362 |

25087 |

X |

X |

X |

X |

X |

X |

X |

X |

1045 |

6294 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X–Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect.

6

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

Table 6. Fisher 585CR Size 25 and 50 Actuator Thrust Capabilities, U.S. Units (spring extends actuator stem)

|

|

SPRING |

|

TOTAL THRUST FOR 585CR WITH ACTUATOR STEM FULLY |

|

|

|

||||||||

|

SPRING |

THRUST W/ |

|

|

|

|

|

EXTENDED |

|

|

|

|

|

|

|

ACTUATOR |

RATE, |

ACTUATOR |

|

|

|

Operating Pressure, psig(1) |

|

|

|

SPRINGS USED, BY COLOR |

|

||||

SIZE |

lb/in |

STEM |

40 |

50 |

60 |

70 |

|

80 |

90 |

100 |

110 |

125 |

150 |

|

|

|

EXTENDED, |

|

|

|

|||||||||||

|

|

POUNDS |

|

|

|

|

Force, Pounds |

|

|

|

|

|

|

||

|

0 |

0 |

1040 |

1300 |

1560 |

1820 |

|

2080 |

2340 |

2600 |

2860 |

3250 |

3900 |

Springs Not Used |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 |

200 |

1240 |

1500 |

1760 |

2020 |

|

2280 |

2540 |

2800 |

3060 |

3450 |

X |

Gold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25(2) |

400 |

400 |

1440 |

1700 |

1960 |

2220 |

|

2480 |

2740 |

3000 |

3260 |

3650 |

X |

Light Green |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

500 |

1540 |

1800 |

2060 |

2320 |

|

2580 |

2840 |

3100 |

3360 |

3750 |

X |

White |

||

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

700 |

1740 |

2000 |

2260 |

2520 |

|

2780 |

3040 |

3300 |

3560 |

X |

X |

Gold & White |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

900 |

1940 |

2200 |

2460 |

2720 |

|

2980 |

3240 |

3500 |

3760 |

X |

X |

Light Green & White |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

1840 |

2300 |

2760 |

3220 |

|

3680 |

4140 |

4600 |

5060 |

5750 |

6900 |

Springs Not Used |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

330 |

330 |

2210 |

2680 |

3150 |

3620 |

|

4090 |

4560 |

5030 |

5500 |

6205 |

X |

Pink |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50(3) |

600 |

600 |

2480 |

2950 |

3420 |

3890 |

|

4360 |

4830 |

5300 |

5770 |

6475 |

X |

Light Blue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

930 |

930 |

2810 |

3280 |

3750 |

4220 |

|

4690 |

5160 |

5630 |

6100 |

6805 |

X |

Pink & Light Blue |

||

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1550 |

1550 |

3430 |

3900 |

4370 |

4840 |

|

5310 |

5780 |

6250 |

6720 |

X |

X |

Green |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1880 |

1880 |

3760 |

4230 |

4700 |

5170 |

|

5640 |

6110 |

6580 |

7050 |

X |

X |

Pink & Green |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X–Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect. 1. The maximum design pressure for size 25 and 50 actuator is 150 psig.

2. Maximum thrust is 3900 lbs.

3. Maximum thrust is 6900 lbs.

Table 7. Fisher 585CR Size 25 and 50 Actuator Thrust Capabilities, Metric Units (spring extends actuator stem)

|

|

SPRING |

|

TOTAL THRUST FOR 585CR WITH ACTUATOR STEM FULLY |

|

|

|

||||||||

|

SPRING |

THRUST W/ |

|

|

|

|

EXTENDED |

|

|

|

|

|

|

||

ACTUATOR |

RATE, |

ACTUATOR |

|

|

|

Operating Pressure, bar(1) |

|

|

|

SPRINGS USED, BY |

|

||||

SIZE |

N/mm |

STEM |

2.8 |

3.4 |

4.1 |

4.8 |

5.5 |

6.2 |

6.9 |

7.6 |

8.6 |

10.3 |

COLOR |

|

|

|

EXTENDED, |

|

|

||||||||||||

|

|

N |

|

|

|

|

Force, N |

|

|

|

|

|

|

||

|

0 |

0 |

4626 |

5782 |

6939 |

8095 |

9251 |

10408 |

11565 |

12721 |

14456 |

17347 |

Springs Not Used |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

35.0 |

890 |

5516 |

6672 |

7828 |

8985 |

10141 |

11298 |

12454 |

13610 |

15346 |

X |

Gold |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

25(2) |

70.0 |

1780 |

6405 |

7562 |

8718 |

9874 |

11031 |

12188 |

13344 |

14500 |

16235 |

X |

Light Green |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

87.6 |

2225 |

6850 |

8006 |

9163 |

10319 |

11476 |

12632 |

13789 |

14945 |

16680 |

X |

White |

|||

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

122.6 |

3115 |

7740 |

8896 |

10052 |

11209 |

12365 |

13655 |

14678 |

15835 |

X |

X |

Gold & White |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

157.6 |

4005 |

8629 |

9786 |

10942 |

12099 |

13255 |

14412 |

15568 |

16724 |

X |

X |

Light Green & White |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0 |

0 |

8180 |

10200 |

12300 |

14300 |

16400 |

18400 |

20500 |

22500 |

25600 |

30700 |

Springs Not Used |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

57.8 |

1468 |

9830 |

11921 |

14011 |

16102 |

18192 |

20282 |

22373 |

24464 |

27600 |

X |

Pink |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

50(3) |

105.1 |

2670 |

11031 |

13122 |

15212 |

17303 |

19393 |

21484 |

23574 |

25665 |

28800 |

X |

Light Blue |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

162.8 |

4135 |

12499 |

14589 |

16680 |

18770 |

20861 |

22952 |

25042 |

27133 |

30269 |

X |

Pink & Light Blue |

|||

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

271.4 |

6894 |

15256 |

17347 |

19438 |

21528 |

23619 |

25709 |

27800 |

29891 |

X |

X |

Green |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

329.2 |

8362 |

16724 |

18815 |

20906 |

22996 |

25087 |

27177 |

29268 |

31358 |

X |

X |

Pink & Green |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X–Indicates where the listed supply pressure is not sufficient to overcome the opposing bias spring effect. 1. The maximum design pressure for size 25 and 50 actuator is 10.3 bar.

2. Maximum thrust is 17347 N.

3. Maximum thrust is 31358 N.

7

585C Actuator |

Instruction Manual |

October 2013 |

D102087X012 |

|

|

Table 8. Fisher 585C Thrust (springless construction)

|

PISTON |

|

|

|

|

TOTAL THRUST FOR 585C(1) |

|

|

|

MAXIMUM ALLOWABLE |

|

|||

ACTUATOR |

|

|

|

|

Operating Pressure, bar(3) |

|

|

|

|

|||||

AREA |

|

|

|

|

|

|

|

THRUST |

|

|||||

SIZE |

2.8 |

3.4 |

4.1 |

4.8 |

|

5.5 |

6.2 |

6.9 |

7.6 |

8.6 |

10.3 |

|

||

|

|

|

|

|||||||||||

|

cm2 |

|

|

|

|

|

Force, |

Newtons |

(2) |

|

|

|

Newtons |

|

25 |

168 |

4630 |

5780 |

6940 |

8100 |

|

9260 |

10400 |

11600 |

12700 |

14500 |

17300 |

17300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

303 |

8180 |

10200 |

12300 |

14300 |

|

16400 |

18400 |

20500 |

22500 |

25600 |

30700 |

31400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

358 |

9880 |

12300 |

14800 |

17300 |

|

19800 |

22200 |

24700 |

27200 |

30900 |

36900 |

36900 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

571 |

15700 |

19700 |

23600 |

27600 |

|

31500 |

35400 |

39400 |

43300 |

49200 |

55600 |

55600(4) |

|

80 |

571 |

15700 |

19700 |

23600 |

27600 |

|

31500 |

35400 |

39400 |

43300 |

49200 |

58700 |

58700 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

842 |

23200 |

29000 |

34800 |

40600 |

|

46400 |

52200 |

58000 |

63900 |

72600 |

86700 |

86700 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

130 |

1430 |

39400 |

49300 |

59100 |

69000 |

|

78700 |

88500 |

98800 |

108100 |

X |

X |

111200 |

|

ACTUATOR |

PISTON |

|

|

|

|

|

Operating |

Pressure, |

psig(3) |

|

|

|

MAXIMUM ALLOWABLE |

|

AREA |

40 |

50 |

60 |

70 |

|

80 |

90 |

100 |

110 |

125 |

150 |

THRUST |

|

|

SIZE |

|

|

||||||||||||

|

Inches2 |

|

|

|

|

|

Force, Pounds(2) |

|

|

|

Pounds |

|

||

25 |

26 |

1040 |

1300 |

1560 |

1820 |

|

2080 |

2340 |

2600 |

2860 |

3250 |

3900 |

3900 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

47 |

1840 |

2300 |

2760 |

3220 |

|

3680 |

4140 |

4600 |

5060 |

5750 |

6900 |

7050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

55.5 |

2220 |

2780 |

3330 |

3890 |

|

4440 |

5000 |

5550 |

6110 |

6940 |

8300 |

8300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

88.5 |

3540 |

4430 |

5310 |

6200 |

|

7080 |

7970 |

8850 |

9740 |

11100 |

12500 |

12500(4) |

|

80 |

88.5 |

3540 |

4430 |

5310 |

6200 |

|

7080 |

7970 |

8850 |

9740 |

11100 |

13200 |

13200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

130.5 |

5220 |

6530 |

7830 |

9140 |

|

10440 |

11700 |

13100 |

14400 |

16300 |

19500 |

19500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

130 |

221.5 |

8860 |

11100 |

13300 |

15500 |

|

17700 |

19900 |

22200 |

24300 |

X |

X |

25000 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X–Indicates where the listed supply pressure will exceed the maximum thrust allowable.

1. The maximum design pressure for size 25 through 100 actuators is 10.3 bar (150 psig). The size 68 and 130 actuators are limited to 9.7 and 7.8 bar (140 and 113 psig) respectively. 2. The size 25 and 50 data is for the construction without a bias spring.

3. Minimum operating pressure for sizes 60-130 actuators is 2.4 bar (35 psig).

4. The size 68 actuator with a handwheel is limited to 40000 Newtons (9000 lb) thrust.

Principle of Operation

The 585C piston actuator (figures 2 and 3) uses a piston that moves inside the actuator cylinder. An O-ring (see figure 3) provides a seal between the piston and the cylinder.

From an equilibrium state, the actuator reacts to a force unbalance that is created by increasing supply pressure on one side of the piston, and decreasing it on the other. This moves the piston up or down, and results in a repositioning of the valve plug.

Actuator with Handwheel (figures 2 and 5)

The handwheel version can be used to open or close the valve manually (either during normal operation or in an emergency), to position the valve at any point in the stroke, or to act as a travel stop.

Size 25 and 50 actuators use an integral top-mounted handwheel. See figure 5.

Size 60 to 130 actuators use a side-mounted handwheel, and come with a spring-loaded ball detent which prevents vibration from changing the handwheel setting. Handwheels for most types are either 203 mm (8 inches) in diameter with beveled gears or 432 mm (17 inches) in diameter with worm gears.

8

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

Handwheel Specifications

Table 9. Fisher 585C Handwheel Specifications

|

HANDWHEEL |

HANDWHEEL |

TURNS PER mm |

MAXIMUM RIM |

HANDWHEEL |

HANDWHEEL |

|

ACTUATOR SIZE |

DIAMETER |

FORCE REQUIRED |

OUTPUT FORCE |

WEIGHT |

|||

MOUNTING |

TRAVEL |

||||||

|

|

mm |

|

Newtons |

Newtons |

kg |

|

25 |

Top-Mounted |

356 |

0.5 |

325 |

12,810 |

17 |

|

|

|

|

|

|

|

||

50 |

482 |

0.5 |

445 |

23,790 |

20 |

||

|

|||||||

|

|

|

|

|

|

|

|

60(1) |

|

203 |

0.6 |

276 |

40000 |

28 |

|

60(2) |

|

356 |

0.6 |

160 |

40000 |

30 |

|

68(1) |

Integral |

203 |

0.6 |

276 |

40000 |

30 |

|

68(2) |

356 |

0.6 |

160 |

40000 |

33 |

||

Side-Mounted |

|||||||

80 |

432 |

0.4 |

423 |

50000 |

35 |

||

|

|||||||

|

|

|

|

|

|

|

|

100 |

|

432 |

0.4 |

623 |

75600 |

94 |

|

|

|

|

|

|

|

|

|

130 |

|

432 |

0.4 |

623 |

75600 |

123 |

|

|

|

|

|

|

|

|

|

|

HANDWHEEL |

HANDWHEEL |

TURNS PER INCH |

MAXIMUM RIM |

HANDWHEEL |

HANDWHEEL |

|

ACTUATOR SIZE |

DIAMETER |

FORCE REQUIRED |

OUTPUT FORCE |

WEIGHT |

|||

MOUNTING |

TRAVEL |

||||||

|

Inches |

Pounds |

Pounds |

Pounds |

|||

|

|

|

|||||

25 |

Top-Mounted |

14 |

12 |

73 |

2880 |

37 |

|

|

|

|

|

|

|

||

50 |

19 |

12 |

100 |

5350 |

45 |

||

|

|||||||

|

|

|

|

|

|

|

|

60(1) |

|

8 |

16 |

62 |

9000 |

61 |

|

60(2) |

|

14 |

16 |

36 |

9000 |

66 |

|

68(1) |

Integral |

8 |

16 |

62 |

9000 |

66 |

|

68(2) |

14 |

16 |

36 |

9000 |

71 |

||

Side-Mounted |

|||||||

80 |

17 |

10 |

95 |

11250 |

77 |

||

|

|||||||

|

|

|

|

|

|

|

|

100 |

|

17 |

10 |

140 |

17000 |

208 |

|

|

|

|

|

|

|

|

|

130 |

|

17 |

10 |

140 |

17000 |

272 |

|

|

|

|

|

|

|

|

1.2 and 4 inch maximum travel constructions.

2.8 inch maximum travel construction.

Figure 2. Fisher 585C Piston Actuator with Handwheel

Figure 3. Fisher 585C Piston Actuator with Spring Return

PISTON

O-RING

E0410 |

|

W7447-1 |

|

|

|

9

585C Actuator |

Instruction Manual |

October 2013 |

D102087X012 |

|

|

Actuator with Spring Return (figure 3)

585C size 25 & 50 actuators are available with bias springs in two configurations. The 585C actuator, with the bias spring under the piston, fully retracts the actuator stem upon loss of cylinder pressure. The 585C actuator, with the bias spring on top of the piston, fully extends the actuator stem upon loss of cylinder pressure. No additional parts are required to convert from one actuator type to the other.

For more detailed information on the 3610 positioner and DVC6200 digital valve controllers, refer to the Principle of Operation section in the 3610 and DVC6200 Instruction Manuals.

Installation

WARNING

WARNING

To avoid personal injury or property damage caused by cylinder fracture as a result of piston impact, install the stem connector securely before supplying pressure to the positioner. Use only a regulator-controlled air supply to move the actuator piston so that you can install the stem connector. Do not use the positioner to move the actuator piston before installing the stem connector.

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal injury.

To avoid personal injury or property damage caused by bursting of pressure-retaining parts, be certain the cylinder pressure or other pressure ratings do not exceed the limits listed in table 1. Use pressure-limiting or pressure-relieving devices to prevent cylinder pressure or other pressure ratings from exceeding these limits.

Check with your process or safety engineer for any additional measures that must be taken to protect against process media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance sections in this instruction manual.

When an actuator and valve are shipped together as a control valve assembly, the actuator is normally mounted on the valve. Follow the valve instructions when installing the control valve in the pipeline. If the actuator is shipped separately or if it is necessary to mount the actuator on the valve, perform the Actuator Mounting procedures in this instruction manual corresponding to your actuator size. For information on mounting valve positioners, refer to the 3610 or DVC6200 instruction manuals for details.

If a 585C actuator is being installed without a positioner, the cylinder loading pressures should be supplied through a 4-way solenoid valve or a switching valve. The bottom side of the piston is pressured through the bottom side of the mounting flange on the actuator yoke (key 6, figures 4 and 6) for sizes 25 and 50 or the connection at the lower side of the cylinder (key 1, figure 9 to 12) for sizes 60 to 130. The top side of the piston is pressured through the connection in the cylinder cover (key 1 for figures 4, 6; and 9 to 12).

The supply pressure medium should be clean, dry filtered air. If the supply source is capable of exceeding the maximum actuator operating pressure or positioner supply pressure, appropriate steps must be taken during installation to protect the positioner and all connected equipment against overpressure.

WARNING

WARNING

Dropping the actuator and any attached accessories and/or valve may cause personal injury and/or equipment damage. For all mounting procedures use an adequately sized chain, sling, hoist, or crane to handle the actuator and any attached

10

Instruction Manual |

585C Actuator |

D102087X012 |

October 2013 |

|

|

accessories and/or valve. Use caution during lifting and handling to prevent slippage, swinging, faulty equipment connections, or sudden shock loads.

CAUTION

To avoid damage to actuator parts and difficult operation of actuator handwheels, open the bypass valve before using a handwheel.

If manual operation is required, the actuator should be equipped with a manual handwheel. To manually move the piston rod with the handwheel, first open the bypass needle valve (key 66 for sizes 25 and 50, figure 8; key 92 for sizes 60 to 130, figure 13), place the handwheel pointer in the neutral position, and insert the locking pin in the sleeve assembly (for size 60-130). Then turn the handwheel in the selected direction as indicated on the wheel.

The control valve should be located where it will be accessible for servicing. Room should be left above and below the control valve to permit removal of the actuator and valve plug.

Bypass Assembly

The bypass is furnished as shown in figures 5, 7, 8, and 13 only when a handwheel actuator is specified. The bypass allows the pressure to equalize on either side of the piston, so that the manual actuator can be used to position the valve.

Flow through the bypass tubing is controlled by an angle needle valve (key 66 for figures 5, 7, and 8; and key 92 for figure 13), which is operated manually. This valve should be closed when air pressure is being used to operate the valve.

Three-Way Valve Applications Note

WARNING

WARNING

To avoid loss of control of process fluid and subsequent personal injury or property damage caused by bursting of pressure-retaining parts, be sure the cylinder pressure does not exceed 80 psig in high cycle-rate, fast stroking speed, three-way valve applications.

In three-way valve applications where the actuator fully strokes at a frequency of once per minute or faster, and the stroking speed is rapid (less than 0.5 seconds per stroke), there is a possibility that the stem can fracture at the plug if the actuator cylinder pressure is greater than 80 psig. This can cause loss of control of process fluid and further damage to the actuator. Consideration should be given to the use of high-strength, fatigue-resistant stem materials in these applications.

Actuator Mounting

Size 25 and 50 Actuator Mounting

The following procedure describes how to mount a 585C actuator size 25 and 50 on a push-down-to-close valve so that the piston stem to valve plug stem connection allows full travel and proper shutoff. Key numbers referenced in the following steps are shown in figures 4 through 8.

11

Loading...

Loading...