Emerson Fisher 655, Fisher 655R Installation Instructions

Instruction Manual

D100305X012

Fisherr 655 and 655R Actuators

for Self‐Operated Control

655 and 655R Actuators

December 2010

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 2.................................

Specifications 2...............................

Installation 2...................................

Actuator Mounting 3...........................

Loading Connections 7.........................

Startup 7......................................

Startup for Pressure‐Reducing Service 7...........

Startup for Pressure‐Relief Service 7..............

Adjustment for Pressure‐Reducing or

Pressure‐Relief Service 8.....................

Shutdown 8...................................

Maintenance 8.................................

Actuator 9...................................

Top‐Mounted Handwheel 12....................

Parts Ordering 14...............................

Parts List 14...................................

Figure 1. Fisher 655‐ED Pressure‐Reducing Valve

W0466‐1

Introduction

Scope of Manual

This instruction manual provides installation, adjustment, maintenance, and parts ordering for the Fisher 655 and

655R actuators and the top‐mounted handwheel. Refer to separate instruction manuals for information about valves

and accessories used with these actuators.

Do not install, operate, or maintain 655 or 655R actuators without being fully trained and qualified in valve, actuator,

and accessory installation, operation and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

655 and 655R Actuators

December 2010

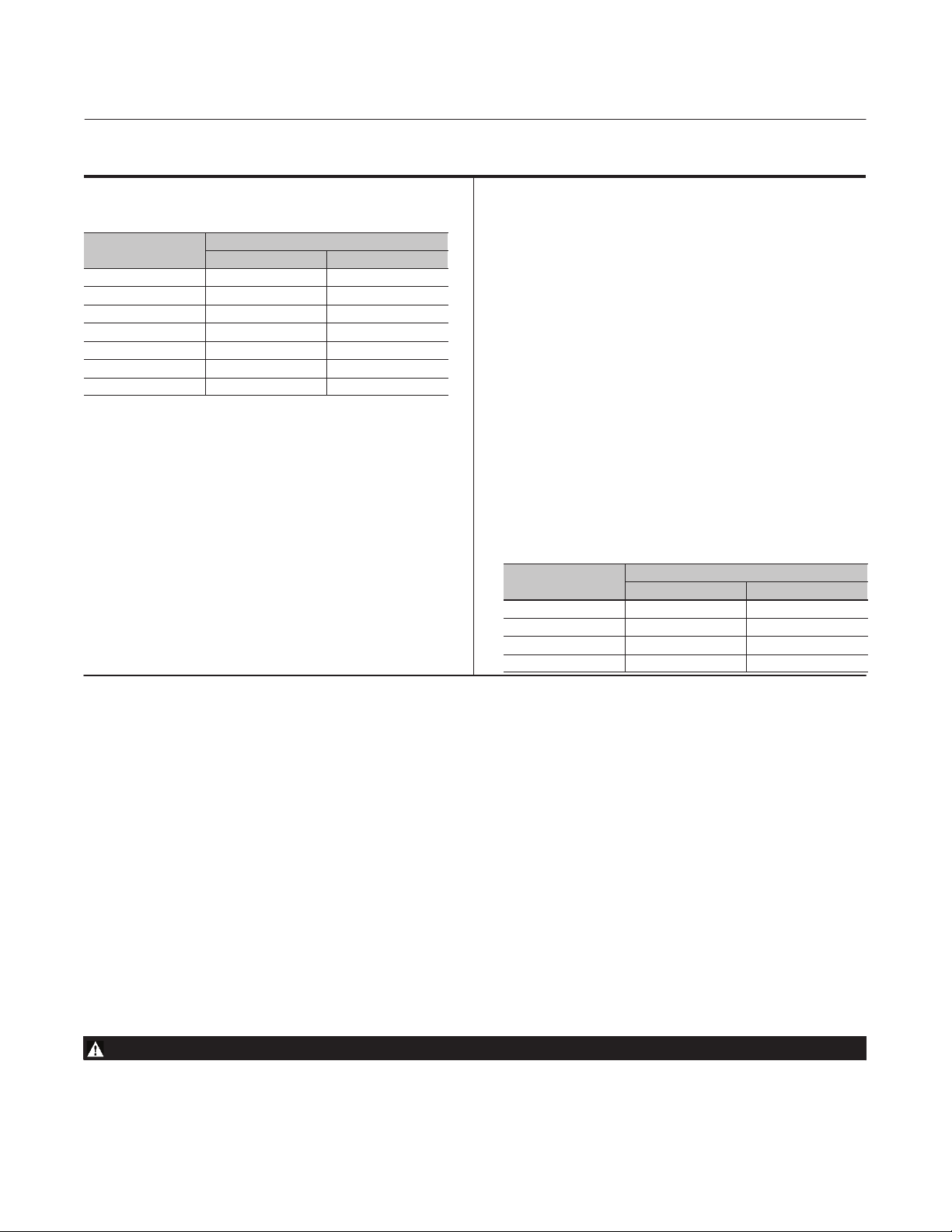

Table 1. Specifications

Instruction Manual

D100305X012

Actuator Sizes and Maximum Casing Pressures

ACTUATOR

SIZE

3A, 4A 17.2 250

3B, 4B 12.1 175

32, 42 6.9 100

33, 43 4.5 65

34, 44 3.1 45

35, 45 2.1 30

36, 46 1.0 15

MAXIMUM CASING PRESSURE

Bar Psig

Actuator Pressure Setting Ranges

See table 2

Actuator Yoke Boss and Valve Stem Connection

Diameters

Sizes 3A through 36: 54 mm (2‐1/8 inch) yoke boss

with 9.5 mm (3/8 inch) stem connection

Sizes 4A through 46: 71 mm (2‐13/16 inch) yoke boss

with 12.7 mm (1/2 inch) stem connection

Maximum Travel

Sizes 3A and 4A: 11 mm (0.4375 inch) plus

3 mm (0.125 inch) for seating

All Other Sizes: 19 mm (0.75 inch) plus 3 mm (0.125

inch) for seating

Effective Diaphragm Area

See table 3

Spring Rate

See key 6 in the parts list section

Temperature Capabilities

-29 to 82_C (-20 to 180_F) with standard diaphragm

material. For the fluid and temperature capabilities of

nonstandard diaphragm materials, consult your

Emerson Process Management sales office

Casing Pressure Connections

1/2 NPT internal

Approximate Weights

ACTUATOR

SIZE

3A, 3B, 32, 33 20 45

34, 35, 36 23 50

4A, 4B, 42, 43 29 65

44, 45, 46 34 75

APPROXIMATE WEIGHT

Kg Lb

Description

655 and 655R actuators (figure 1) are pressure‐actuated, spring‐and‐diaphragm actuators used in conjunction with

various valves to provide control for a wide variety of pressure regulation applications. 655 actuators are used for

pressure‐reducing service when mounted on push‐down‐to‐close valves such as the Fisher ED and ET valves. 655R

actuators are used for pressure‐relief service when mounted on push‐down‐to‐open valves such as the Fisher EDR and

ETR valves. Both types are self‐operated and direct‐acting; that is, increasing pressure in the diaphragm casing forces

the actuator stem downward, and decreasing the pressure allows the actuator spring to lift the actuator stem upward.

Specifications

Specifications for the 655 and 655R actuators are shown in table 1. Information for a specific actuator is also found on

the nameplate of that actuator.

Installation

WARNING

To avoid personal injury or property damage caused by bursting of pressure‐retaining parts, be certain the service

conditions do not exceed the casing pressure limits listed in table 1. Use pressure‐limiting or pressure‐relieving devices to

prevent service conditions from exceeding these limits.

2

Instruction Manual

D100305X012

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

655 and 655R Actuators

December 2010

655 and 655R actuators are normally shipped mounted on a valve. Refer to the appropriate valve instruction manual

when installing the valve in the pipeline. If the actuator is shipped separately or if it is necessary to mount the actuator

on the valve, perform the procedures described in the Actuator Mounting portion of this section.

CAUTION

To avoid premature wear of the diaphragm due to debris in the pressure line to the diaphragm, install a strainer in the

pipeline ahead of the regulator or relief valve.

Before installing the actuator, inspect it for any damage. Also, keep any adjacent piping clean and free of pipe scale or

other debris that could possibly disrupt service. It is recommended that a strainer be installed in the pipeline ahead of

the regulator or relief valve to protect it while in service. And a conventional three‐valve bypass (see figure 2) should

be placed around the regulator or relief valve to permit continuous operation when it is being installed or repaired.

Actuator Mounting

The actuator may be installed either above or below the pipeline.

CAUTION

In steam service applications, avoid premature wear of the diaphragm, due to high temperature steam, by installing the

valve with the actuator positioned below the pipeline.

If the regulator or relief valve is to be used for steam service, the valve should be installed with the actuator positioned

below the pipeline, and the control line should be sloped down toward the diaphragm casing. This is to ensure that

any forming condensate will maintain a water seal to protect the diaphragm.

The following procedure describes how to mount the actuator on either a push‐down‐to‐close or a

push‐down‐to‐open valve so that the actuator stem and valve stem thread engagement will allow full travel and

proper shutoff. Refer to figure 3 for actuator mounting components. Key numbers refer to figure 4 unless otherwise

stated.

1. Turn the adjusting screw (key 10) into the yoke (key 7) to force the diaphragm (key 2) and diaphragm plate (key 4)

against the upper diaphragm casing (key 1).

2. Perform the following steps as appropriate for either push‐down‐to‐close or push‐down‐to‐open valve action.

CAUTION

In the following procedures, do not rotate the valve plug while it is seated since this may cause damage to the seating

surfaces and thereby allow excessive leakage. Also, during travel adjustment, use tools carefully to avoid damaging the

valve plug stem. A damaged stem could cut the packing and allow leakage.

3

655 and 655R Actuators

December 2010

Instruction Manual

D100305X012

For Push‐Down‐To‐Close Valves:

a. Place the actuator part way over the valve stem. Then, place the yoke locknut over the valve stem, and slide the

travel indicator disk (key 11, if used) on top of the hex nuts (key 12).

b. Set the actuator onto the valve body. The length of the valve stem will prevent the actuator yoke (key 7) from

sitting on the bonnet properly. Measure the distance from the bottom of the actuator yoke to the mating

shoulder on the bonnet, and then add the valve plug travel to this measurement.

c. Raise the actuator so the valve plug can be lifted off the seat ring.

Note

Either turn the actuator, or tighten the hex nuts together, and use a wrench on the hex nuts to turn the valve plug and stem

assembly.

Thread the valve stem into the actuator stem the distance measured in the previous step.

d. Lower the actuator onto the valve body bonnet, and tighten the yoke locknut.

e. Connect the pressure control lines as described in the Loading Connection portion of this section.

f. Stroke the actuator, and measure the stem movement to check travel. If the movement is more than full travel,

turn the valve stem out of the actuator stem the amount of over‐travel. If movement is less than full travel, turn

the valve stem into the actuator stem the amount of under‐travel.

For Push‐Down‐To‐Open Valves:

a. Place the actuator, yoke locknut, and travel indicator disk (key 11, if used) over the valve stem. Support the

actuator above the valve body so the actuator stem and valve stem do not contact when the valve plug is seated.

b. Connect the pressure control lines as described in the Loading Connection portion of this section.

c. Move the valve plug, by hand, from the seated to the open position, and make sure that valve stem movement

corresponds to the desired travel.

d. Stroke the actuator until the diaphragm plate (key 4) contacts the down travel stop (see

figure 3).

e. With the valve plug positioned as described in step c above, lower the actuator until the actuator stem contacts

the valve stem, and measure the distance from the bottom of the actuator yoke to the mating shoulder on the

bonnet.

f. Thread the valve stem into the actuator stem until the thread engagement is equal to the distance measured in

the previous step. Tighten the hex nuts (key 12) together, and use a wrench to turn the valve plug and stem

assembly.

g. Lower the actuator onto the valve body bonnet, and tighten the yoke locknut.

h. Stroke the actuator, and measure the stem movement to check travel. If the movement is more than full travel,

turn the valve stem into the actuator stem the amount of over‐travel. If the movement is less than full travel,

turn the valve stem out of the actuator stem the amount of under‐travel.

4

Instruction Manual

D100305X012

655 and 655R Actuators

December 2010

Table 2. Actuator Pressure‐Setting Ranges

ACTUA‐

TOR

SIZE

3A, 4A

3B, 4B

32, 42

33, 43

1. Effects of packing box friction, unbalance, and weight of valve plug not considered in calculations.

SPRING PART

NUMBER

1E792427082 5.4 78 12.0 174 4.5 65 10.1 146

1F714327092 3.0 44 9.3 135 3.0 43 8.2 119 1E795427082 0.8 11 1.6 23 0.6 9.0 1.3 19

1F176927092 2.2 32 6.6 96 2.6 37 5.9 85

1F176827092 1.8 26 5.4 78 2.3 34 5.2 75 1F714327092 0.3 5.0 1.1 16 0.3 5.0 0.9 13

1F176727032 1.3 19 4.1 59 1.4 20 3.9 57 1F176927092 0.3 3.8 0.8 11 0.3 4.0 0.7 10

1E793327082 3.4 50 7.4 107 3.0 43 4.4 64 1F176827092 0.2 2.8 0.6 8.5 0.1 2.0 0.6 8.5

3B

1E795427082 2.9 42 6.3 92 2.4 35 4.4 64

1E793327082 3.4 50 7.4 107 3.0 43 6.1 89 1E795427082 0.5 7.0 1.0 15 0.4 5.5 0.8 11

4B

1E795427082 2.9 42 6.3 92 2.4 35 5.3 77

1E792427082 2.4 35 5.4 78 2.0 29 4.4 64 1E795427082 0.5 7.0 1.0 15 0.4 5.5 0.9 13

1F714327092 1.4 20 4.1 60 1.3 19 3.7 53

1F176927092 1.0 14 3.0 43 1.2 17 2.6 38 1F714327092 0.2 3.3 0.7 10 0.2 3.2 0.6 9.0

1E793327082 2.2 32 4.5 65 1.8 26 2.6 38 1F176927092 0.2 2.4 0.5 7.2 0.2 2.8 0.4 6.3

32

1E795427082 1.8 26 3.8 55 1.5 22 2.6 38 1F176827092 0.1 2.0 0.4 5.9 0.2 2.5 0.4 5.5

1E793327082 2.2 32 4.5 65 1.8 26 3.7 53 1F176727032 0.1 1.5 0.3 4.4 0.1 1.5 0.3 4.2

42

1E795427082 1.8 26 3.8 55 1.5 22 3.1 45 1F714427112 0.07 1.0 0.2 2.9 0.09 1.3 0.2 2.8

1E792427082 1.5 22 3.2 47 1.2 18 2.6 38

1F714327092 0.8 12 2.5 36 0.8 12 2.1 31 1E795427082 0.3 4.9 0.8 11 0.3 4.2 0.5 7.7

1E793327082 1.3 19 2.8 40 1.1 16 1.7 24

33

1E795427082 1.1 16 2.3 34 0.9 13 1.7 24 1E795427082 0.3 4.9 0.8 11 0.3 4.2 0.6 9.0

1E793327082 1.3 19 2.8 40 1.1 16 2.3 33

43

1E795427082 1.1 16 2.3 34 0.9 13 1.9 28 1F714327092 0.2 2.3 0.5 7.1 0.2 2.3 0.4 6.3

1E792427082 1.0 14 2.0 29 0.8 11 1.7 24 1F176927092 0.1 1.7 0.4 5.1 0.1 2.0 0.3 4.5

1F714327092 0.5 7.0 1.5 22 0.5 7.0 1.4 20 1F176827092 0.09 1.3 0.3 4.2 0.1 1.8 0.3 4.0

1F176927092 0.4 5.2 1.1 16 0.3 5.0 1.1 16 1F176727032 0.07 1.0 0.2 3.1 0.08 1.1 0.2 3.0

1E793327082 0.9 13 1.9 28 0.8 11 1.1 16 1F714427112 0.05 0.7 0.1 2.1 0.06 0.9 0.1 2.0

34

1E795427082 0.8 11 1.6 23 0.6 9.0 1.1 16 1F713027112 0.02 0.34 0.08 1.1 0.05 0.7 0.07 1.0

PRESSURE

REDUCTION

Minimum Maximum Minimum Maximum Minimum Maximum Minimum Maximum

Bar Psig Bar Psig Bar Psig Bar Psig Bar Psig Bar Psig Bar Psig Bar Psig

(1)

PRESSURE

RELIEF

ACTUA‐

TOR

SIZE

44

34, 44

35

45

35, 45

36

46

36, 46

PRESSURE

SPRING PART

NUMBER

1E793327082 0.9 13 1.9 28 0.8 11 1.6 23

1E792427082 0.6 9.0 1.4 20 0.5 7.0 1.1 16

1E793327082 0.6 8.3 1.2 18 0.5 7.0 0.8 11

1E793327082 0.6 8.3 1.2 18 0.5 7.0 1.0 15

1E792427082 0.4 5.8 0.9 13 0.3 5.0 0.8 11

1E793327082 0.4 5.8 0.9 13 0.3 5.0 0.5 7.7

1E793327082 0.4 5.8 0.9 13 0.3 5.0 0.8 11

1E792427082 0.3 4.1 0.6 9.2 0.2 3.5 0.5 7.7

REDUCTION

PRESSURE

RELIEF

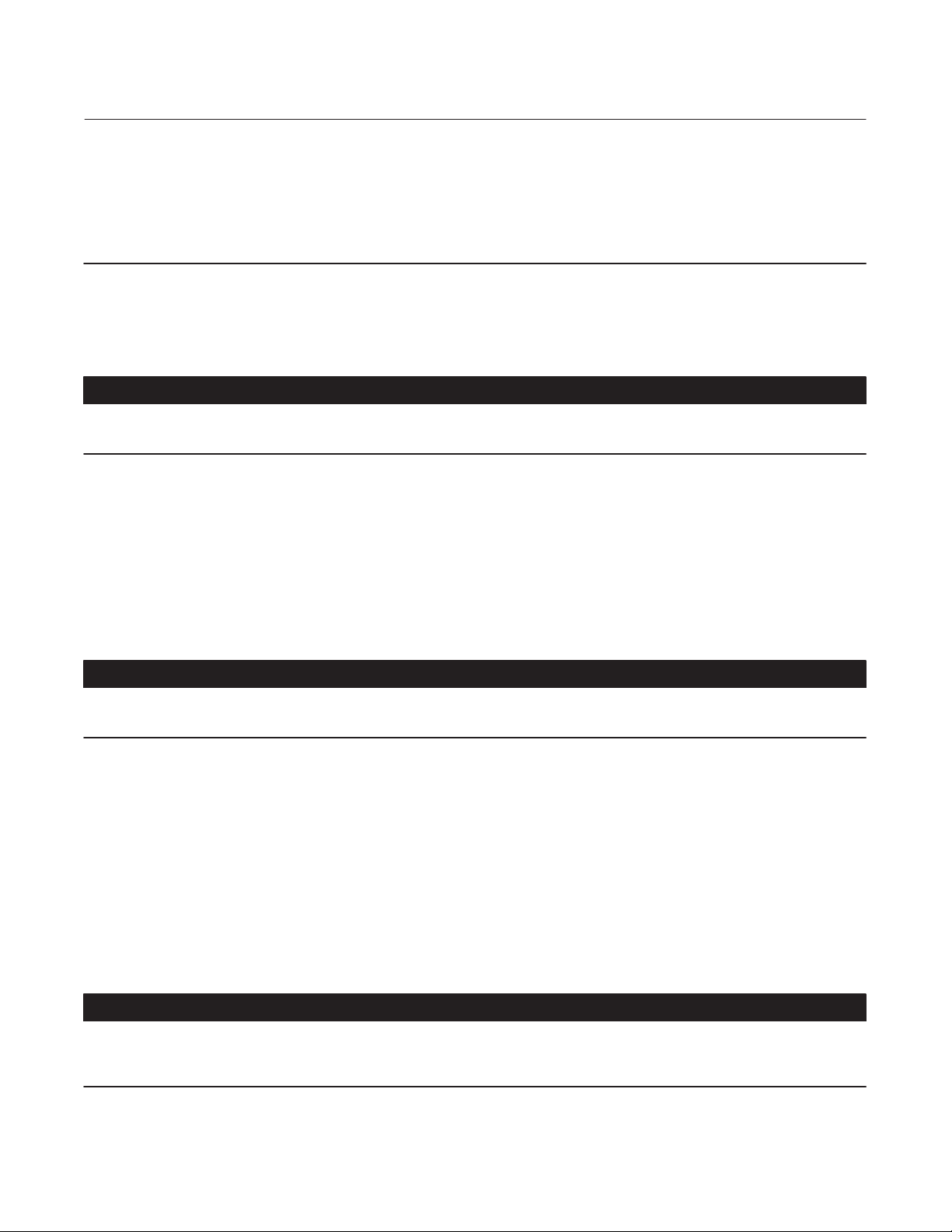

Figure 2. Typical Installation Schematics

LARGE PORT

NEEDLE VALVE

655 ACTUATOR

13A6502‐A

13A6503‐A

A1628‐1

STRAINER

PRESSURE‐REDUCING INSTALLATION PRESSURE‐RELIEF INSTALLATION

DIRECT‐ACTING BALANCED

PLUG VALVE BODY

1/2 NPT

CONTROL LINE

BYPASS LINE

1/2 NPT CONTROL LINE

LARGE PORT NEEDLE VALVE

STRAINER

655R ACTUATOR

BYPASS LINE

REVERSE‐ACTING BALANCED

PLUG VALVE BODY

5

Loading...

Loading...