Emerson Fisher DLC3010 HART Instruction Manual

Instruction Manual |

DLC3010 Digital Level Controller |

D102748X012 |

October 2014 |

|

|

Fisherr FIELDVUE™ DLC3010 Digital Level

Controller

This manual applies to:

Device Type |

3010 |

Device Revision |

1 |

Hardware Revision |

1 |

Firmware Revision |

8 |

DD Revision |

3 |

Contents

Section 1 Introduction and Specifications . 3

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conventions Used in this Manual . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Educational Services . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2 Installation . . . . . . . . . . . . . . . . . |

13 |

Configuration: On the Bench or in the Loop . . . . . . |

13 |

Protecting the Coupling and Flexures . . . . . . . . . . . |

13 |

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

Hazardous Area Classifications and Special |

|

Instructions for “Safe Use” and Installations |

|

in Hazardous Locations . . . . . . . . . . . . . . . . . . . . |

15 |

Mounting the 249 Sensor . . . . . . . . . . . . . . . . . . . . |

15 |

Digital Level Controller Orientation . . . . . . . . . . . . |

16 |

Mounting the Digital Level Controller |

|

on a 249 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

Mounting the Digital Level Controller for High |

|

Temperature Applications . . . . . . . . . . . . . . . . . |

18 |

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Shielded Wire . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Power/Current Loop Connections . . . . . . . . . . . . . |

23 |

RTD Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Two Wire RTD Connections . . . . . . . . . . . . . . . |

23 |

Three Wire RTD Connections . . . . . . . . . . . . . |

23 |

Communication Connections . . . . . . . . . . . . . . . . . |

23 |

Test Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Multichannel Installations . . . . . . . . . . . . . . . . . . . . |

24 |

Alarm Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Changing Jumper Position . . . . . . . . . . . . . . . . . . . . 25 Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation in Conjunction with a Rosemount Ã333 HART Tri Loopt HART to Analog

Signal Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Multidrop Communication . . . . . . . . . . . . . . . . . . . . 93

Section 3 Overview . . . . . . . . . . . . . . . . . . . 29 Section 4 Setup and Calibration . . . . . . . . 33

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Configuration Advice . . . . . . . . . . . . . . . . . . . . . . . . . 34 Preliminary Considerations . . . . . . . . . . . . . . . . . . . . 34 Write Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Level Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Manual Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Process Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Device Information . . . . . . . . . . . . . . . . . . . . . . . . . 46 Instrument Display . . . . . . . . . . . . . . . . . . . . . . . . . . 47 Alert Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Primary Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

www.Fisher.com

DLC3010 Digital Level Controller |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Burst Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Introduction: Calibration of Smart Instruments . . |

54 |

Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Guided Calibration . . . . . . . . . . . . . . . . . . . . . . |

54 |

Full Calibration . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

ÃMin/Max Calibration . . . . . . . . . . . . . . . . . . . |

55 |

ÃTwo Point Calibration . . . . . . . . . . . . . . . . . . |

55 |

ÃWeight Calibration . . . . . . . . . . . . . . . . . . . . |

56 |

Theoretical Calibration . . . . . . . . . . . . . . . . . . . |

56 |

Partial Calibration . . . . . . . . . . . . . . . . . . . . . . . |

57 |

ÃCapture Zero . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

ÃTrim Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

ÃTrim Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

Secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

Temperature Calibration . . . . . . . . . . . . . . . . . |

58 |

ÃTrim Instrument Temperature . . . . . . . . . . |

59 |

ÃTrim Process Temperature . . . . . . . . . . . . . . |

59 |

Manual Entry of Process Temperature . . . . . . |

59 |

Analog Output CalibratIon . . . . . . . . . . . . . . . . |

59 |

ÃScaled D/A Trim . . . . . . . . . . . . . . . . . . . . . . |

59 |

Calibration Examples . . . . . . . . . . . . . . . . . . . . . . . . |

60 |

Calibration with Standard displacer and |

|

Torque Tube . . . . . . . . . . . . . . . . . . . . . . . . . |

60 |

Calibration with Overweight Displacer . . . . . . |

61 |

Density Applications - with Standard Displacer |

|

and Torque Tube . . . . . . . . . . . . . . . . . . . . . |

63 |

Calibration at Process Conditions (Hot Cut Over) |

|

when input cannot be varied . . . . . . . . . . . |

63 |

Entering Theoretical Torque Tube Rates . . . . |

64 |

Excessive Mechanical Gain . . . . . . . . . . . . . . . . |

65 |

Determining the SG of an Unknown Fluid . . . |

65 |

Accuracy Considerations . . . . . . . . . . . . . . . . . . . . . |

65 |

Effect of Proportional Band . . . . . . . . . . . . . . . |

65 |

Density Variations in Interface Applications . . |

65 |

Extreme Temperatures . . . . . . . . . . . . . . . . . . . |

66 |

Temperature Compensation . . . . . . . . . . . . . . |

66 |

Section 5 Service Tools . . . . . . . . . . . . . . . |

67 |

Active Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

70 |

Section 6 Maintenance and |

|

Troubleshooting . . . . . . . . . . . . . . . . . . . . |

71 |

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

Hardware Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

Test Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

Removing the Digital Level |

|

Controller from the Sensor . . . . . . . . . . . . . . . . . . . . |

74 |

Removing the DLC3010 Digital Level Controller |

|

from a 249 Sensor . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

Standard Temperature Applications . . . . . . . . |

75 |

High Temperature Applications . . . . . . . . . . . |

76 |

LCD Meter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . |

76 |

Removing the LCD Meter Assembly . . . . . . . . . . . . |

77 |

Replacing the LCD Meter Assembly . . . . . . . . . . . . |

77 |

Electronics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

Removing the Electronics Module . . . . . . . . . . . . . |

78 |

Replacing the Electronics Module . . . . . . . . . . . . . |

78 |

Terminal Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

79 |

Removing the Terminal Box . . . . . . . . . . . . . . . . . . |

79 |

Replacing the Terminal Box . . . . . . . . . . . . . . . . . . . |

79 |

Removing and Replacing the Inner Guide |

|

and Access Handle Assembly . . . . . . . . . . . . . . . . . . |

80 |

Lever Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

Removing the Lever Assembly . . . . . . . . . . . . . . . . |

81 |

Replacing the Lever Assembly . . . . . . . . . . . . . . . . |

82 |

Packing for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

Section 7 Parts . . . . . . . . . . . . . . . . . . . . . . |

85 |

Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Mounting Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

DLC3010 Digital Level Controllers . . . . . . . . . . . . . 86

Transducer Assembly . . . . . . . . . . . . . . . . . . . . . . . . 87

Terminal Box Assembly . . . . . . . . . . . . . . . . . . . . . . 88

Terminal Box Cover Assembly . . . . . . . . . . . . . . . . . 88

Mounting Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

249 Sensors with Heat Insulator . . . . . . . . . . . 89

Appendix A Principle of Operation . . . . . . |

93 |

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

Digital Level Controller Operation . . . . . . . . . . . . . . |

94 |

Appendix B Field Communicator

ÃMenu Tree . . . . . . . . . . . . . . . . . . . . . . . . 99

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

2

Instruction Manual |

Introduction and Specifications |

D102748X012 |

October 2014 |

|

|

Section 1 Introduction and Specifications

Scope of Manual

This instruction manual includes specifications, installation, operating, and maintenance information for FIELDVUE DLC3010 digital level controllers.

This instruction manual supports the 475 or 375 Field Communicator with device description revision 3, used with DLC3010 instruments with firmware revision 8. You can obtain information about the process, instrument, or sensor using the Field Communicator. Contact your Emerson Process Management sales office to obtain the appropriate software

Note

AMS Suite: Intelligent Device Manager can also be used to calibrate and configure the DLC3010, and to obtain information about the process, instrument, or sensor.

Do not install, operate, or maintain a DLC3010 digital level controller without being fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to carefully read, understand, and follow all of the contents of this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office.

Conventions Used in this Manual

This manual describes using the Field Communicator to calibrate and configure the digital level controller.

Procedures that require the use of the Field Communicator have the text path and the sequence of numeric keys required to display the desired Field Communicator menu.

For example, to access the Full Calibration menu:

Field Communicator |

Configure > Calibration > Primary > Full Calibration (2-5-1-1) |

|

|

Menu selections are shown in italics, e.g., Calibrate. An overview of the Field Communicator menu structure is shown in Appendix B.

Description

DLC3010 Digital Level Controllers

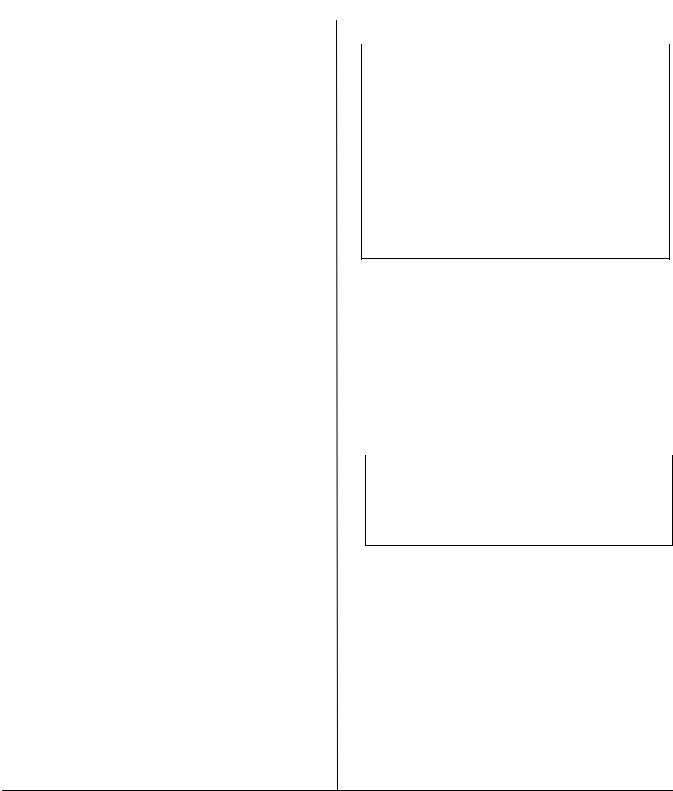

DLC3010 digital level controllers (figure 1 1) are used with level sensors to measure liquid level, the level of interface between two liquids, or liquid specific gravity (density). Changes in level or specific gravity exert a buoyant force on a

3

Introduction and Specifications |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

displacer, which rotates the torque tube shaft. This rotary motion is applied to the digital level controller, transformed to an electrical signal and digitized. The digital signal is compensated and processed per user configuration requirements, and converted back to a 4 20 mA analog electrical signal. The resulting current output signal is sent to an indicating or final control element.

Figure 1 1. FIELDVUE DLC3010 Digital Level Controller

W7977-1

DLC3010 digital level controllers are communicating, microprocessor based level, interface, or density sensing instruments. In addition to the normal function of providing a 4 20 milliampere current signal, DLC3010 digital level controllers, using the HARTR communications protocol, give easy access to information critical to process operation. You can gain information from the process, the instrument, or the sensor using a Field Communicator with device descriptions (DDs) compatible with DLC3010 digital level controllers. The Field Communicator may be connected at the digital level controller or at a field junction box.

Using the Field Communicator, you can perform several operations with the DLC3010 digital level controller. You can interrogate, configure, calibrate, or test the digital level controller. Using the HART protocol, information from the field can be integrated into control systems or be received on a single loop basis.

DLC3010 digital level controllers are designed to directly replace standard pneumatic and electro pneumatic level transmitters. DLC3010 digital level controllers mount on a wide variety of caged and cageless 249 level sensors. They mount on other manufacturers' displacer type level sensors through the use of mounting adaptors.

249 Caged Sensors (see table 1 6)

D 249, 249B, 249BF, 249C, 249K, and 249L sensors side mount on the vessel with the displacer mounted inside a cage outside the vessel. (The 249BF caged sensor is available only in Europe, Middle East, and Africa.)

249 Cageless Sensors (see table 1 7)

D 249BP, 249CP, and 249P sensors top mount on the vessel with the displacer hanging down into the vessel.

D 249VS sensor side mounts on the vessel with the displacer hanging out into the vessel.

D 249W wafer style sensor mounts on top of a vessel or on a customer supplied cage.

Specifications

Specifications for the DLC3010 digital level controller are shown in table 1 1. Specifications for the 249 sensor are shown in table 1 3. Specifications for the Field Communicator can be found in the Product Manual for the Field Communicator.

4

Instruction Manual |

Introduction and Specifications |

D102748X012 |

October 2014 |

|

|

Related Documents

Other documents containing information related to the DLC3010 digital level controller and 249 sensors include:

D Bulletin 11.2:DLC3010 - FIELDVUE DLC3010 Digital Level Controller (D102727X012)

D FIELDVUE DLC3010 Digital Level Controller Quick Start Guide (D103214X012)

D Using FIELDVUE Instruments with the Smart HART Loop Interface and Monitor (HIM) (D103263X012)

D Audio Monitor for HART Communications (D103265X012)

D Fisher 249 Caged Displacer Sensors Instruction Manual (D200099X012)

D Fisher 249 Cageless Displacer Sensors Instruction Manual (D200100X012)

D Fisher 249VS Cageless Displacer Sensor Instruction Manual (D103288X012)

D Fisher 249W Cageless Wafer Style Level Sensor Instruction Manual (D102803X012)

D Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters (D103066X012)

D Bolt Torque Information (D103220X012)

D Technical Monograph 7: The Dynamics of Level and Pressure Control

D Technical Monograph 18: Level Trol Density Transmitter

D Technical Monograph 26: Guidelines for Selection of Liquid Level Control Equipment

These documents are available from your Emerson Process Management sales office. Also visit our website at www.Fisher.com.

Educational Services

For information on available courses for the DLC3010 digital level controller, as well as a variety of other products, contact:

Emerson Process Management Educational Services, Registration

Phone: +1-641-754-3771 or +1-800-338-8158 e mail: education@emerson.com http://www.emersonprocess.com/education

5

Introduction and Specifications |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

Table 1 1. DLC3010 Digital Level Controller Specifications |

|

|

|

Available Configurations

DLC3010 Digital Level Controller:

Mounts on caged and cageless 249 sensors. See tables 1 6 and 1 7 and sensor description.

Function: Transmitter

Communications Protocol: HART

Input Signal

Level, Interface, or Density: Rotary motion of torque tube shaft proportional to changes in liquid level, interface level, or density that change the buoyancy of a displacer.

Process Temperature: Interface for 2 or 3 wire 100 ohm platinum RTD for sensing process temperature, or optional user entered target temperature to permit compensating for changes in specific gravity

Output Signal

Analog: 4 20 milliamperes DC (JÉdirect action—increasing level, interface, or density increases output; or JÉreverse action—increasing level, interface, or density decreases output)

High saturation: 20.5 mA

Low saturation: 3.8 mA

High alarm: 22.5 mA

Low Alarm: 3.7 mA

Only one of the above high/low alarm definitions is available in a given configuration. NAMUR NE 43 compliant when high alarm level is selected.

Digital: HART 1200 Baud FSK (frequency shift keyed)

HART impedance requirements must be met to enable communication. Total shunt impedance across the master device connections (excluding the master and transmitter impedance) must be between 230 and 1100 ohms. The transmitter HART receive impedance is defined as:

Rx: 42K ohms and Cx: 14 nF

Note that in point to point configuration, analog and digital signalling are available. The instrument may be queried digitally for information, or placed in Burst mode to regularly transmit unsolicited process information digitally. In multi drop mode, the output current is fixed at 4 mA, and only digital communication is available.

Performance

|

DLC3010 |

w/ NPS 3 |

|

|

Performance |

249W, Using |

w/ All Other |

||

Digital Level |

||||

Criteria |

a 14 inch |

249 Sensors |

||

Controller(1) |

||||

|

Displacer |

|

||

|

|

|

||

Independent |

$0.25% of |

$0.8% of |

$0.5% of |

|

Linearity |

output span |

output span |

output span |

|

|

|

|

|

|

Hysteresis |

<0.2% of |

- - - |

- - - |

|

output span |

||||

|

|

|

||

|

|

|

|

|

Repeatability |

$0.1% of full |

$0.5% of |

$0.3% of |

|

scale output |

output span |

output span |

||

|

||||

|

|

|

|

|

Dead Band |

<0.05% of |

- - - |

- - - |

|

input span |

||||

|

|

|

||

|

|

|

|

|

Hysteresis plus |

- - - |

<1.0% of |

<1.0% of |

|

Deadband |

output span |

output span |

||

|

||||

|

|

|

|

NOTE: At full design span, reference conditions. 1. To lever assembly rotation inputs.

At effective proportional band (PB)<100%, linearity, dead band, and repeatability are derated by the factor (100%/PB)

Operating Influences

Power Supply Effect: Output changes <±0.2% of full scale when supply varies between min. and max voltage specifications.

Transient Voltage Protection: The loop terminals are protected by a transient voltage suppressor. The specifications are as follows:

Pulse Waveform |

Max VCL |

Max IPP |

|

Rise Time |

Decay to |

(Clamping |

(Pulse Peak |

(ms) |

50% (ms) |

Voltage) (V) |

@ Current) (A) |

10 |

1000 |

93.6 |

16 |

|

|

|

|

8 |

20 |

121 |

83 |

|

|

|

|

Note: μs = microsecond

Ambient Temperature: The combined temperature effect on zero and span without the 249 sensor is less than 0.03% of full scale per degree Kelvin over the operating range -40 to 80_C (-40 to 176_F)

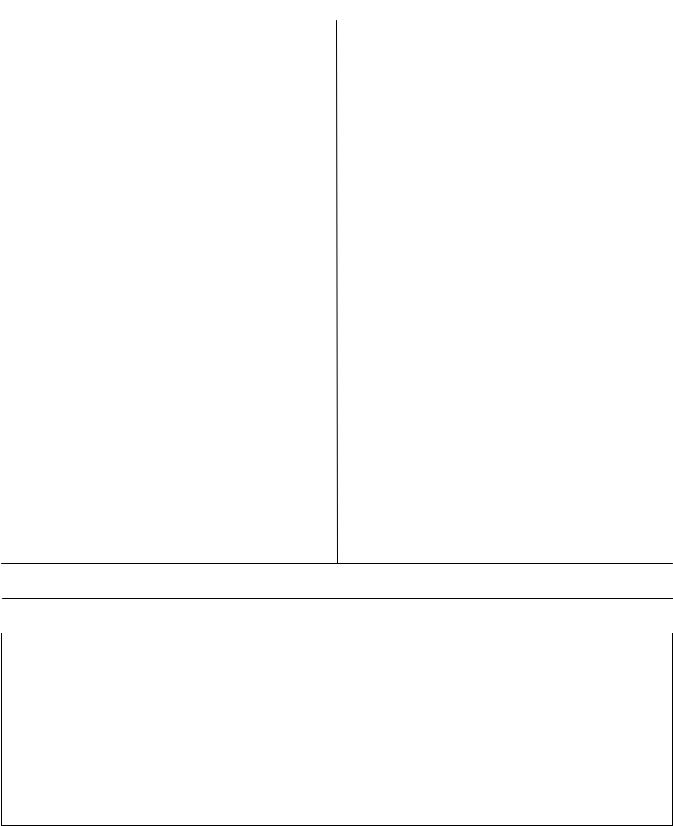

Process Temperature: The torque rate is affected by the process temperature (see figure 1 2). The process density may also be affected by the process temperature.

Process Density: The sensitivity to error in knowledge of process density is proportional to the differential density of the calibration. If the differential specific gravity is 0.2, an error of 0.02 specific gravity units in knowledge of a process fluid density represents 10% of span.

-continued-

6

Instruction Manual |

Introduction and Specifications |

D102748X012 |

October 2014 |

|

|

Table 1 1. DLC3010 Digital Level Controller Specifications (continued) |

|

Electromagnetic Compatibility

Meets EN 61326 1 and EN 61326 2 3 ÃImmunity—Industrial locations per Table 2 of ÃÃEN 61326 1 and Table AA.2 of EN 61326 2 3. ÃÃPerformance is shown in table 1 2 below. ÃEmissions—Class A

ÃÃISM equipment rating: Group 1, Class A

Supply Requirements (See figure 2 10)

12 to 30 volts DC; instrument has reverse polarity protection.

A minimum compliance voltage of 17.75 is required to guarantee HART communication.

Compensation

Transducer compensation: for ambient temperature. Density parameter compensation: for process temperature (requires user supplied tables).

Manual compensation: for torque tube rate at target process temperature is possible.

Digital Monitors

Linked to jumper selected Hi (factory default) or Lo analog alarm signal:

Torque tube position transducer: Drive monitor and signal reasonableness monitor

User configurable alarms: Hi Hi and Lo Lo Limit process alarms

HART readable only:

RTD signal reasonableness monitor: When RTD installed

Processor free time monitor.

Writes remaining in Non Volatile Memory monitor. User configurable alarms: Hi and Lo limit process alarms, Hi and Lo limit process temperature alarms, and Hi and Lo limit electronics temperature alarms

Diagnostics

Output loop current diagnostic. LCD meter diagnostic.

Spot specific gravity measurement in level mode: used to update specific gravity parameter to improve process measurement

Digital signal tracing capability: by review of “troubleshooting variables”, and

Basic trending capability for PV, TV and SV.

LCD Meter Indications

LCD meter indicates analog output on a percent scale bar graph. The meter also can be configured to display:

Process variable in engineering units only. Percent range only.

Percent range alternating with process variable or Process variable, alternating with process temperature (and degrees of pilot shaft rotation).

Electrical Classification

Hazardous Area:

CSA— Intrinsically Safe, Explosion proof, Division 2, Dust Ignition proof

FM— Intrinsically Safe, Explosion proof, Non incendive, Dust Ignition proof

ATEX— Intrinsically Safe, Type n, Flameproof IECEx— Intrinsically Safe, Type n, Flameproof

Electrical Housing:

CSA— Type 4X |

ATEX— IP66 |

FM— NEMA 4X |

IECEx— IP66 |

Other Classifications/Certifications

FSETAN—Russian - Federal Service of Technological, Ecological and Nuclear Inspectorate

GOST R—Russian GOST R

INMETRO— National Institute of Metrology, Standardization, and Industrial Quality (Brazil)

NEPSI— National Supervision and Inspection Centre for Explosion Protection and Safety of Instrumentation (China)

PESO CCOE— Petroleum and Explosives Safety Organisation - Chief Controller of Explosives (India)

TIIS— Technology Institution of Industrial Safety (Japan)

Contact your Emerson Process Management sales office for classification/certification specific information

Minimum Differential Specific Gravity

With a nominal 4.4 degrees torque tube shaft rotation for a 0 to 100 percent change in liquid level (specific gravity=1), the digital level controller can be adjusted to provide full output for an input range of 5% of nominal input span. This equates to a minimum differential specific gravity of 0.05 with standard volume displacers.

-continued-

7

Introduction and Specifications |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

Table 1 1. DLC3010 Digital Level Controller Specifications (continued) |

|

|

|

Minimum Differential Specific Gravity (continued)

See 249 sensor specifications for standard displacer volumes and standard wall torque tubes. Standard volume for 249C and 249CP sensors is 980 cm3 (60 in3), most others have standard volume of 1640 cm3 (100 in3).

Operating at 5% proportional band will degrade accuracy by a factor of 20. Using a thin wall torque tube, or doubling the displacer volume will each roughly double the effective proportional band. When proportional band of the system drops below 50%, changing displacer or torque tube should be considered if high accuracy is a requirement.

Mounting Positions

Digital level controllers can be mounted right or left of displacer, as shown in figure 2 5.

Instrument orientation is normally with the coupling access door at the bottom, to provide proper drainage of lever chamber and terminal compartment, and to limit gravitational effect on the lever assembly. If alternate drainage is provided by user, and a small performance loss is acceptable, the instrument could be mounted in 90 degree rotational increments around the pilot shaft axis. The LCD meter may be rotated in 90 degree increments to accommodate this.

Construction Materials

Case and Cover: Low copper aluminum alloy Internal: Plated steel, aluminum, and stainless steel;

encapsulated printed wiring boards; Neodymium Iron Boron Magnets

Electrical Connections

Two 1/2 14 NPT internal conduit connections; one on bottom and one on back of terminal box. M20 adapters available.

Options

JHeat insulator. See description under Ordering Information. J Mountings for Masoneilant, Yamatake, and Foxborot Eckhardt displacers available. J Level Signature Series Test (Performance Validation Report) available (EMA only) for instruments factory mounted on 249 sensor.

JFactory Calibration: available for instruments factory mounted on 249 sensor, when application, process temperature and density(s) are supplied.

JDevice is compatible with user specified remote indicator.

Operating Limits

Process Temperature: See table 1 4 and figure 2 7.

Ambient Temperature and Humidity: See below

Conditions |

Normal |

Transport and |

Nominal |

|

Limits(1,2) |

Storage Limits |

Reference |

||

|

||||

Ambient |

-40 to 80_C |

-40 to 85_C |

25_C |

|

Temperature |

(-40 to 176_F) |

(-40 to 185_F) |

(77_F) |

|

|

|

|

|

|

Ambient |

0 to 95%, |

0 to 95%, |

|

|

Relative |

40% |

|||

(non condensing) |

(non condensing) |

|||

Humidity |

|

|||

|

|

|

||

|

|

|

|

Weight

Less than 2.7 Kg (6 lbs)

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1.LCD meter may not be readable below -20_C (-4_F)

2.Contact your Emerson Process Management sales office or application engineer if temperatures exceeding these limits are required.

Table 1 2. EMC Summary Results—Immunity

Port |

Phenomenon |

Basic Standard |

Test Level |

Performance |

|

Criteria(1)(2) |

|

||||

|

|

|

|

|

|

|

Electrostatic discharge (ESD) |

IEC 61000 4 2 |

4 kV contact |

A |

|

|

8 kV air |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80% |

|

|

Enclosure |

Radiated EM field |

IEC 61000 4 3 |

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80% |

A |

|

|

|

|

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80% |

|

|

|

|

|

|

|

|

|

Rated power frequency |

IEC 61000 4 8 |

60 A/m at 50 Hz |

A |

|

|

magnetic field |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Burst |

IEC 61000 4 4 |

1 kV |

A |

|

|

|

|

|

|

|

I/O signal/control |

Surge |

IEC 61000 4 5 |

1 kV (line to ground only, each) |

B |

|

|

|

|

|

|

|

|

Conducted RF |

IEC 61000 4 6 |

150 kHz to 80 MHz at 3 Vrms |

A |

|

|

|

|

|

|

|

Note: RTD wiring must be shorter than 3 meters (9.8 feet)

1. A = No degradation during testing. B = Temporary degradation during testing, but is self recovering. Specification limit = +/- 1% of span.

2. HART communication was considered as “not relevant to the process” and is used primarily for configuration, calibration, and diagnostic purposes.

8

Instruction Manual |

Introduction and Specifications |

D102748X012 |

October 2014 |

|

|

Figure 1 2. Theoretical Reversible Temperature Effect on Common Torque Tube Materials

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

Gnorm

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.98 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

0.96 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.94 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.92 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N05500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N06600 |

0.90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N10276 |

0.88 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.86 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.84 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S31600 |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

340 |

360 |

380 |

400 |

420 |

||

TEMPERATURE (_C)

TORQUE RATE REDUCTION

(NORMALIZED MODULUS OF RIGIDITY)

1.00

0.98

1

0.96

Gnorm

0.94 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.92 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N05500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N06600 |

0.90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N10276 |

0.88 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.86 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.84 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S31600 |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

650 |

700 |

750 |

800 |

TEMPERATURE (_F)

NOTE:

1  DUE TO THE PERMANENT DRIFT THAT OCCURS NEAR AND ABOVE 260_C (500_F), N05500 IS NOT RECOMMENDED FOR TEMPERATURES ABOVE 232_C (450_F).

DUE TO THE PERMANENT DRIFT THAT OCCURS NEAR AND ABOVE 260_C (500_F), N05500 IS NOT RECOMMENDED FOR TEMPERATURES ABOVE 232_C (450_F).

9

Introduction and Specifications |

Instruction Manual |

|

October 2014 |

D102748X012 |

|

|

|

|

Table 1 3. 249 Sensor Specifications |

|

|

Input Signal |

equalizing connection styles are numbered and are |

|

Liquid Level or Liquid to Liquid Interface Level:From 0 |

shown in figure 1 3. |

|

|

||

to 100 percent of displacer length |

Mounting Positions |

|

Liquid Density: From 0 to 100 percent of |

||

|

||

displacement force change obtained with given |

Most level sensors with cage displacers have a |

|

displacer volume—standard volumes are JÉ980 cm3 |

rotatable head. The head may be rotated through |

|

(60 inches3) for 249C and 249CP sensors or JÉ1640 |

360 degrees to any of eight different positions, as |

|

cm3 (100 inches3) for most other sensors; other |

shown in figure 2 5. |

|

volumes available depending upon sensor |

|

|

construction |

Construction Materials |

|

Sensor Displacer Lengths |

See tables 1 5, 1 6, and 1 7 |

|

|

||

See tables 1 6 and 1 7 footnotes |

Operative Ambient Temperature |

|

Sensor Working Pressures |

See table 1 4 |

|

For ambient temperature ranges, guidelines, and use |

||

|

||

Consistent with applicable ANSI |

of optional heat insulator, see figure 2 7. |

|

pressure/temperature ratings for the specific sensor |

|

|

constructions shown in tables 1 6 and 1 7 |

Options |

|

Caged Sensor Connection Styles |

J Heat insulator, see description under Ordering |

|

Information J Gauge glass for pressures to 29 bar at |

||

|

||

Cages can be furnished in a variety of end connection |

232_C (420 psig at 450_F), and J Reflex gauges for |

|

styles to facilitate mounting on vessels; the |

high temperature and pressure applications |

|

|

|

Table 1 4. Allowable Process Temperatures for Common 249 Sensor Pressure Boundary Materials

MATERIAL |

PROCESS TEMPERATURE |

||

Min. |

Max. |

||

|

|||

Cast Iron |

-29_C (-20_F) |

232_C (450_F) |

|

|

|

|

|

Steel |

-29_C (-20_F) |

427_C (800_F) |

|

|

|

|

|

Stainless Steel |

-198_C (-325_F) |

427_C (800_F) |

|

|

|

|

|

N04400 |

-198_C (-325_F) |

427_C (800_F) |

|

|

|

|

|

Graphite |

|

|

|

Laminate/SST |

-198_C (-325_F) |

427_C (800_F) |

|

Gaskets |

|

|

|

|

|

|

|

N04400/PTFE |

-73_C (-100_F) |

204_C (400_F) |

|

Gaskets |

|||

|

|

||

|

|

|

|

Table 1 5. Displacer and Torque Tube Materials

Part |

Standard Material |

Other Materials |

|

|

|

316 Stainless Steel, |

|

Displacer |

304 Stainless Steel |

N10276, N04400, |

|

Plastic, and Special |

|||

|

|

||

|

|

Alloys |

|

|

|

|

|

Displacer Stem |

|

N10276, N04400, |

|

Driver Bearing, |

316 Stainless Steel |

other Austenitic |

|

Displacer Rod |

Stainless Steels, and |

||

|

|||

and Driver |

|

Special Alloys |

|

|

|

|

|

Torque Tube |

N05500(1) |

316 Stainless Steel, |

|

N06600, N10276 |

|||

|

|

||

|

|

|

1. N05500 is not recommended for spring applications above 232_C (450_F). Contact your Emerson Process Management sales office or application engineer if temperatures exceeding this limit are required.

10

Instruction Manual |

|

|

|

|

Introduction and Specifications |

||||||||

D102748X012 |

|

|

|

|

|

|

|

|

|

|

|

October 2014 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1 6. Caged Displacer Sensors(1) |

|

|

|

|

|

|

|||||||

TORQUE TUBE |

|

|

|

|

|

STANDARD CAGE, HEAD, |

|

EQUALIZING CONNECTION |

|

|

PRESSURE RATING(2) |

||

|

SENSOR |

|

AND TORQUE TUBE ARM |

|

|

|

|

|

|||||

ORIENTATION |

|

|

|

Style |

|

Size (NPS) |

|||||||

|

|

|

|

|

MATERIAL |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

249(3) |

|

|

|

Cast iron |

|

Screwed |

|

1 1/2 or 2 |

CL125 or CL250 |

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Flanged |

|

2 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screwed or optional socket weld |

|

1 1/2 or 2 |

CL600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 1/2 |

CL150, CL300, or |

|

|

|

249B, 249BF(4) |

|

Steel |

|

Raised face or optional ring type joint |

|

CL600 |

|||||

|

|

|

|

|

|

|

|||||||

Torque tube |

|

|

|

|

|

|

|

|

flanged |

|

2 |

|

CL150, CL300, or |

arm rotatable |

|

|

|

|

|

|

|

|

|

|

|

CL600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

with respect to |

|

|

|

|

|

|

|

|

Screwed |

|

1 1/2 or 2 |

CL600 |

|

equalizing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 1/2 |

CL150, CL300, or |

||

connections |

|

|

|

|

|

|

|

|

|

|

|||

|

249C(3) |

|

316 stainless steel |

|

|

|

CL600 |

||||||

|

|

|

Raised face flanged |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

2 |

|

CL150, CL300, or |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

CL600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

249K |

|

Steel |

|

Raised face or optional ring type joint |

|

1 1/2 or 2 |

CL900 or CL1500 |

||||

|

|

|

|

flanged |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

249L |

|

Steel |

|

Ring type joint flanged |

|

2(5) |

CL2500 |

||||

1. Standard displacer lengths for all styles (except 249) are 14, 32, 48, 60, 72, 84, 96, 108 and 120 inches. The 249 uses a displacer with a length of either 14 or 32 inches. |

|||||||||||||

2. EN flange connections available in EMA (Europe, Middle East and Africa). |

|

|

|

|

|

|

|||||||

3. Not available in EMA. |

|

|

|

|

|

|

|

|

|

|

|

|

|

4. The 249BF available in EMA only. Also available in EN size DN 40 with PN 10 to PN 100 flanges and size DN 50 with PN 10 to PN 63 flanges. |

|

|

|

||||||||||

5. Top connection is NPS 1 ring type joint flanged for connection styles F1 and F2. |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1 7. Cageless Displacer Sensors(1) |

|

|

|

|

|

|

|||||||

|

|

|

|

|

Standard Head(2), Wafer |

|

|

|

|

|

|

|

|

Mounting |

Sensor |

|

|

Body(6) and Torque Tube |

|

|

Flange Connection (Size) |

|

Pressure Rating(3) |

||||

|

|

|

|

|

|

Arm Material |

|

|

|

|

|

|

|

|

|

249BP(4) |

|

Steel |

|

NPS 4 raised face or optional ring type joint |

|

CL150, CL300, or CL600 |

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

NPS 6 or 8 raised face |

|

CL150 or CL300 |

|||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

Mounts on |

249CP |

|

316 Stainless Steel |

|

NPS 3 raised face |

|

CL150, CL300, or CL600 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

CL900 or 1CL500 |

|||

top of vessel |

|

|

|

|

|

|

NPS 4 raised face or optional ring type joint |

|

|||||

|

|

|

|

|

|

|

(EN PN 10 to DIN PN 250) |

||||||

|

|

249P(5) |

|

Steel or stainless steel |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

NPS 6 or 8 raised face |

|

CL150, CL300, CL600, CL900, |

|||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

CL1500, or CL2500 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WCC (steel) LCC (steel), or |

|

|

|

|

|

CL125, CL150, CL250, CL300, |

||

Mounts on |

|

|

|

|

For NPS 4 raised face or flat face |

|

CL600, CL900, or CL1500 |

||||||

249VS |

|

CF8M (316 stainless steel) |

|

|

|||||||||

side of vessel |

|

|

|

|

|

|

(EN PN 10 to DIN PN 160) |

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

WCC, LCC, or CF8M |

|

For NPS 4 buttweld end, XXZ |

|

CL2500 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounts on top of |

|

|

|

WCC or CF8M |

|

For NPS 3 raised face |

|

CL150, CL300, or CL600 |

|||||

vessel or on |

|

|

|

|

|

||||||||

249W |

|

|

|

|

|

|

|

|

|

|

|||

customer |

|

LCC or CF8M |

|

For NPS 4 raised face |

|

CL150, CL300, or CL600 |

|||||||

|

|

|

|

|

|||||||||

supplied cage |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

1. Standard displacer lengths are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches. |

|

|

|

|

|

|

|||||||

2. Not used with side mounted sensors. |

|

|

|

|

|

|

|

|

|

||||

3. EN flange connections available in EMA (Europe, Middle East and Africa). |

|

|

|

|

|

|

|||||||

4. Not available in EMA. |

|

|

|

|

|

|

|

|

|

|

|

|

|

5. 249P available in EMA only. |

|

|

|

|

|

|

|

|

|

||||

6. Wafer Body only applicable to the 249W. |

|

|

|

|

|

|

|

|

|

||||

11

Introduction and Specifications |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

|

|

Figure 1 3. Style Number of Equalizing Connections |

|

STYLE 1 |

AND LOWER SIDE CONNECTIONS, |

|

TOP AND BOTTOM CONNECTIONS, |

||

SCREWED (S 3) OR FLANGED (F 3) |

||

SCREWED (S 1) OR FLANGED (F 1) |

||

|

STYLE 2

TOP AND LOWER SIDE CONNECTIONS,

SCREWED (S 2) OR FLANGED (F 2)

28B5536 1

B1820 2

STYLE 4

UPPER SIDE AND BOTTOM CONNECTIONS, SCREWED (S 4) OR FLANGED (F 4)

12

Instruction Manual |

Installation |

D102748X012 |

October 2014 |

|

|

Section 2 Installation

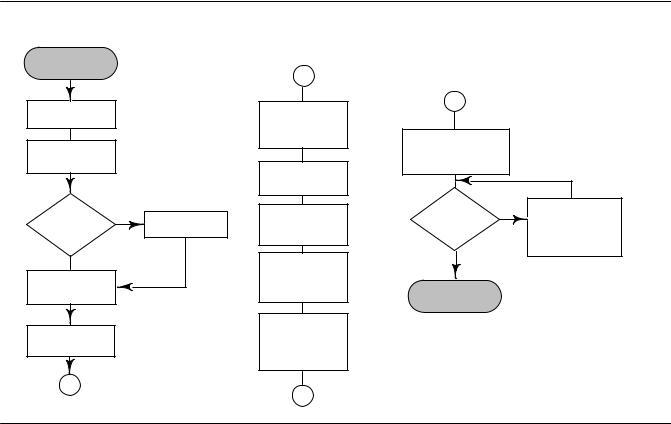

This section contains digital level controller installation information including an installation flowchart (figure 2 1), mounting and electrical installation information, and a discussion of failure mode jumpers.

Configuration: On the Bench or in the Loop

Configure the digital level controller before or after installation. It may be useful to configure the instrument on the bench before installation to ensure proper operation, and to familiarize yourself with its functionality.

Protecting the Coupling and Flexures

CAUTION

Damage to flexures and other parts can cause measurement errors. Observe the following steps before moving the sensor and controller.

Lever Lock

The lever lock is built in to the coupling access handle. When the handle is open, it positions the lever in the neutral travel position for coupling. In some cases, this function is used to protect the lever assembly from violent motion during shipment.

A DLC3010 controller will have one of the following mechanical configurations when received:

1.A fully assembled and coupled caged displacer system shipped with the displacer or driver rod blocked within the operating range by mechanical means. In this case, the access handle (figure 2 4) will be in the unlocked position. Remove the displacer blocking hardware before calibration. (See the appropriate sensor instruction manual). The coupling should be intact.

CAUTION

When shipping an instrument mounted on a sensor, if the lever assembly is coupled to the linkage, and the linkage is constrained by the displacer blocks, use of the lever lock may result in damage to bellows joints or flexure.

2.If the displacer cannot be blocked because of cage configuration or other concerns, the transmitter is uncoupled from the torque tube by loosening the coupling nut, and the access handle will be in the locked position. Before placing such a configuration into service, perform the Coupling procedure found on page 38.

3.For a cageless system where the displacer is not connected to the torque tube during shipping, the torque tube itself stabilizes the coupled lever position by resting against a physical stop in the sensor. The access handle will be in the unlocked position. Mount the sensor and hang the displacer. The coupling should be intact.

13

Installation |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

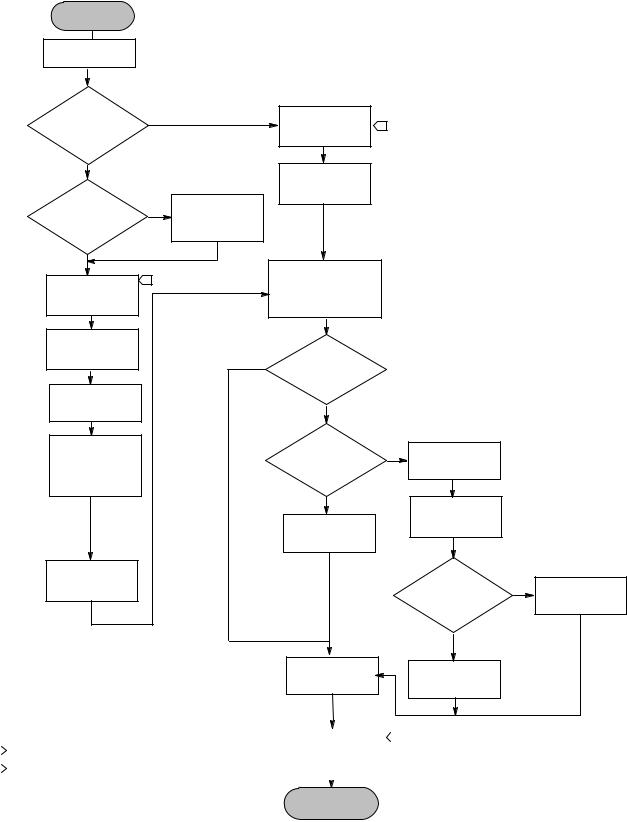

Figure 2 1. Installation Flowchart

START HERE

Check Alarm

Jumper Position

Factory mounted |

Yes |

|

Wire |

|

|

|

|

|

|

Digital Level |

1 |

|

|

|

|

on 249 sensor? |

|

|

|

|

|

||

|

|

Controller |

|

|

|

||

|

|

|

|

|

|

|

|

No |

|

|

Power |

|

|

|

|

|

|

|

Digital Level |

|

|

|

|

High |

|

|

Controller |

|

|

|

|

Yes |

Install heat |

|

|

|

|

|

|

temperature |

|

|

|

|

|

||

|

insulator |

|

|

|

|

|

|

application? |

|

|

|

|

|

|

|

|

assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

Enter Tag, Messages, |

|

|

|

|

Mount and Wire 1 |

|

Date, and check or set |

|

|

|

|

|

Digital level |

|

|

target application data |

|

|

|

|

|

|

|

|

|

|

|

|

Controller |

|

|

|

|

|

|

|

Power |

|

|

|

|

|

|

|

Digital level |

|

|

|

|

|

|

|

Controller |

|

Yes |

Density |

|

|

|

|

|

|

|

Measurement? |

|

|

|

|

Set Level Offset |

|

|

|

|

|

|

|

to Zero |

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

Use Setup Wizard |

|

|

Using |

Yes |

Set |

|

|

to enter sensor |

|

|

Temperature |

|

|

||

|

|

|

Temperature |

|

|

||

data and |

|

|

Correction? |

|

|

|

|

|

|

|

Units |

|

|

||

calibration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

condition |

|

|

|

|

|

|

|

|

|

|

No |

|

Setup specific |

|

|

|

|

|

|

|

|

|

|

|

|

|

Set |

|

gravity tables |

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Gravity |

|

|

|

|

Calibrate |

|

|

|

|

|

|

|

sensor |

|

|

|

|

|

Yes |

Setup and |

|

|

|

|

|

Using RTD? |

|

|

|

|

|

|

|

|

Calibrate RTD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No |

|

|

Set

Range Values

Enter Process

Temperature

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: |

Disable Writes |

|

2 |

|

||

|

|

|

|||||

|

|

|

|

|

|

||

|

1 IF USING RTD FOR TEMPERATURE CORRECTION, |

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

ALSO WIRE RTD TO DIGITAL LEVEL CONTROLLER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 DISABLING WRITES IS EFFECTIVE ONLY IF THE DLC3010 REMAINS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWERED UP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DONE |

||||

|

|

|

|

|

|

|

|

14

Instruction Manual |

Installation |

D102748X012 |

October 2014 |

|

|

4.If the controller was shipped alone, the access handle will be in the locked position. All Mounting, Coupling and Calibration procedures must be performed.

The access handle includes a retaining set screw, as shown in figures 2 4 and 2 6. The screw is driven in to contact the spring plate in the handle assembly before shipping. It secures the handle in the desired position during shipping and operation. To set the access handle in the open or closed position, this set screw must be backed out so that its top is flush with the handle surface.

Mounting

WARNING

WARNING

To avoid personal injury, always wear protective gloves, clothing, and eyewear when performing any installation operations.

Personal injury or property damage due to sudden release of pressure, contact with hazardous fluid, fire, or explosion can be caused by puncturing, heating, or repairing a displacer that is retaining process pressure or fluid. This danger may not be readily apparent when disassembling the sensor or removing the displacer. Before disassembling the sensor or removing the displacer, observe the appropriate warnings provided in the sensor instruction manual.

Check with your process or safety engineer for any additional measures that must be taken to protect against process media.

Hazardous Area Classifications and Special Instructions for “Safe Use” and Installations in Hazardous Locations

Refer to the DLC3010 Quick Start Guide (D103214X012) that ships with the instrument for Hazardous Area Classifications and Special Instructions for “Safe Use” and Installations in Hazardous Locations. If a copy of this quick start guide is needed contact your Emerson Process Management sales office or visit our website at www.Fisher.com.

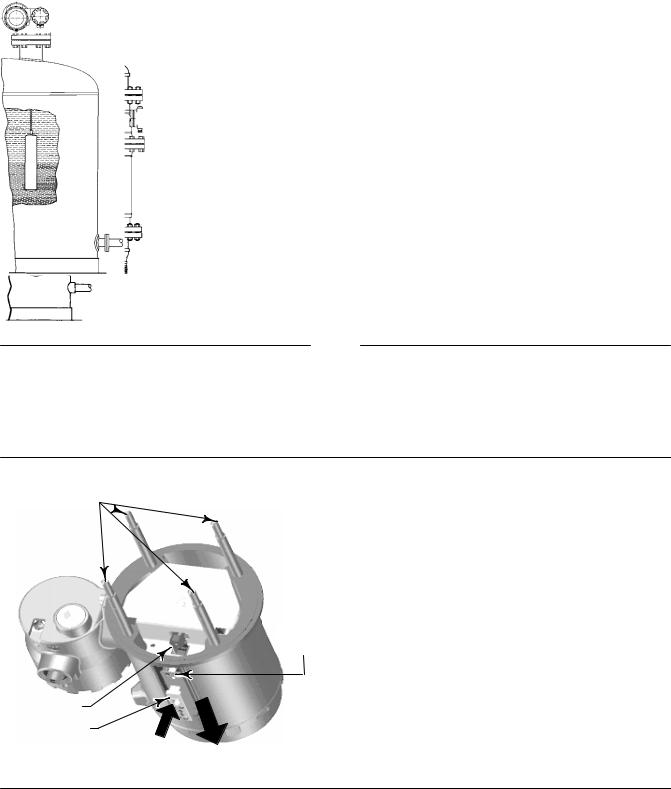

Mounting the 249 Sensor

The 249 sensor is mounted using one of two methods, depending on the specific type of sensor. If the sensor has a caged displacer, it typically mounts on the side of the vessel as shown in figure 2 2. If the sensor has a cageless displacer, the sensor mounts on the side or top of the vessel as shown in figure 2 3.

The DLC3010 digital level controller is typically shipped attached to the sensor. If ordered separately, it may be convenient to mount the digital level controller to the sensor and perform the initial setup and calibration before installing the sensor on the vessel.

Note

Caged sensors have a rod and block installed on each end of the displacer to protect the displacer in shipping. Remove these parts before installing the sensor to allow the displacer to function properly.

15

Installation |

|

Instruction Manual |

October 2014 |

|

D102748X012 |

|

|

|

|

|

|

Figure 2 2. Typical Caged Sensor Mounting |

|

Figure 2 3. Typical Cageless Sensor Mounting |

A3788 1

A3789 1

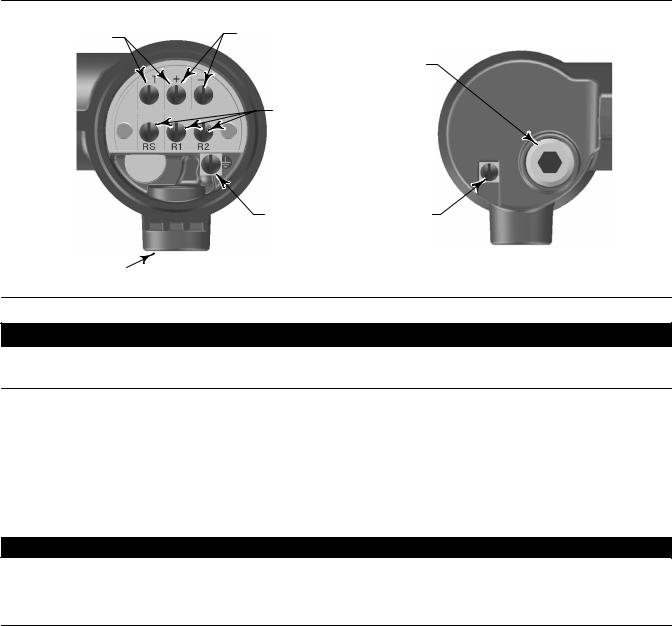

Digital Level Controller Orientation

Mount the digital level controller with the torque tube shaft clamp access hole (see figure 2 4) pointing downward to allow accumulated moisture drainage.

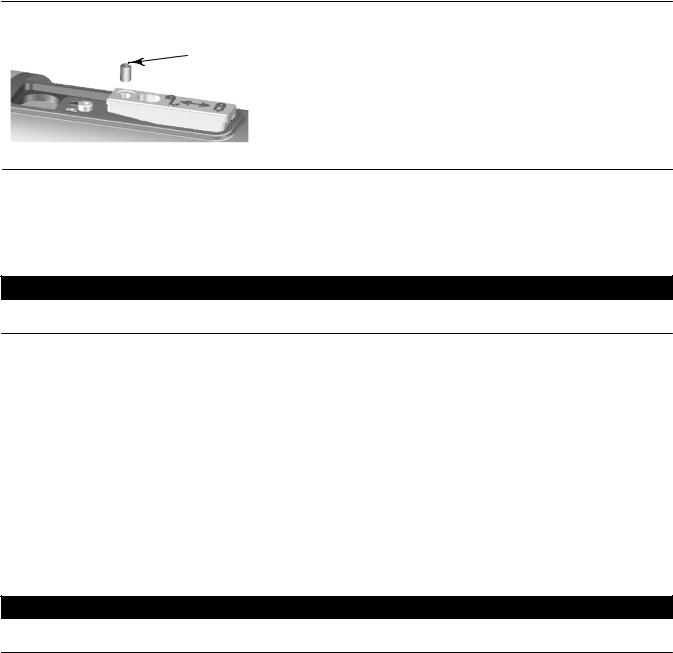

Figure 2 4. Sensor Connection Compartment (Adapter Ring Removed for Clarity)

MOUNTING

STUDS

SHAFT CLAMP

SET SCREW

PRESS HERE TO

MOVE ACCESS

HANDLE

ACCESS

HOLE

SLIDE ACCESS HANDLE TOWARD FRONT OF UNIT TO EXPOSE ACCESS HOLE

16

Instruction Manual |

Installation |

D102748X012 |

October 2014 |

|

|

Note

If alternate drainage is provided by the user, and a small performance loss is acceptable, the instrument could be mounted in 90 degree rotational increments around the pilot shaft axis. The LCD meter may be rotated in 90 degree increments to accommodate this.

The digital level controller and torque tube arm are attached to the sensor either to the left or right of the displacer, as shown in figure 2 5. This can be changed in the field on the 249 sensors (refer to the appropriate sensor instruction manual). Changing the mounting also changes the effective action, because the torque tube rotation for increasing level, (looking at the protruding shaft), is clockwise when the unit is mounted to the right of the displacer and counter clockwise when the unit is mounted to the left of the displacer.

All caged 249 sensors have a rotatable head. That is, the digital level controller can be positioned at any of eight alternate positions around the cage as indicated by the position numbers 1 through 8 in figure 2 5. To rotate the head, remove the head flange bolts and nuts and position the head as desired.

Figure 2 5. Typical Mounting Positions for the FIELDVUE DLC3010 Digital Level Controller on Fisher 249 Sensor

SENSOR |

LEFT OF DISPLACER |

RIGHT OF DISPLACER |

|

|

1 |

|

1 |

1 |

CAGED |

|

|

CAGELESS |

|

|

1 NOT AVAILABLE FOR SIZE NPS 2 CL300 AND CL600 249C SENSOR. |

|

|

19B2787 Rev. D |

|

|

19B6600 Rev. C |

|

|

B1407 2 |

|

|

|

|

17 |

Installation |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

Mounting the Digital Level Controller on a 249 Sensor

Refer to figure 2 4 unless otherwise indicated.

1.If the set screw in the access handle (figure 2 6) is driven against the spring plate, back it out until the head is flush with the outer surface of the handle, using a 2 mm hex key. Slide the access handle to the locked position to expose the access hole. Press on the back of the handle as shown in figure 2 4 then slide the handle toward the front of the unit. Be sure the locking handle drops into the detent.

Figure 2 6. Close up of Set Screw

SET SCREW

2.Using a 10 mm deep well socket inserted through the access hole, loosen the shaft clamp (figure 2 4). This clamp will be re tightened in the Coupling portion of the Initial Setup section.

3.Remove the hex nuts from the mounting studs. Do not remove the adapter ring.

CAUTION

Measurement errors can occur if the torque tube assembly is bent or misaligned during installation.

4.Position the digital level controller so the access hole is on the bottom of the instrument.

5.Carefully slide the mounting studs into the sensor mounting holes until the digital level controller is snug against the sensor.

6.Reinstall the hex nuts on the mounting studs and tighten the hex nuts to 10 NSm (88.5 lbfSin).

Mounting the Digital Level Controller for High Temperature Applications

Refer to figure 2 8 for parts identification except where otherwise indicated.

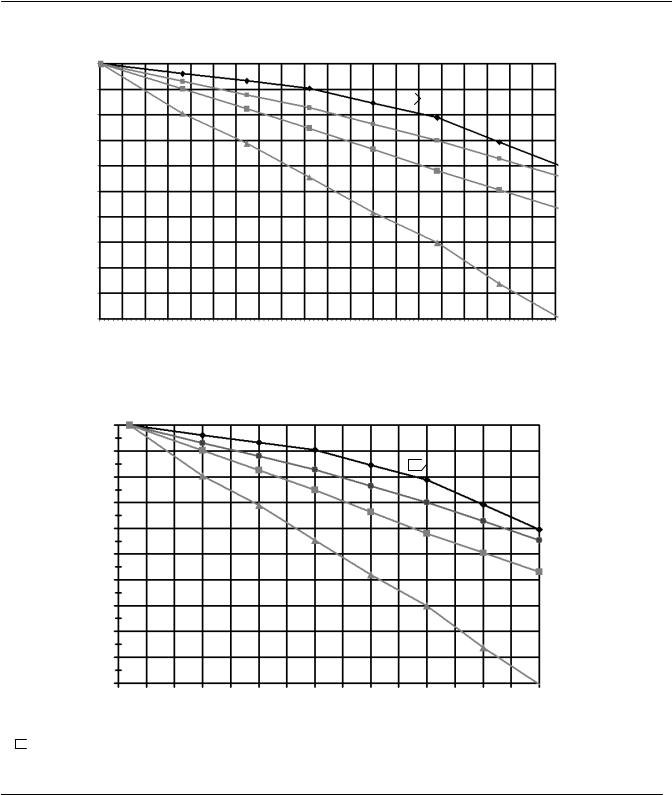

The digital level controller requires an insulator assembly when temperatures exceed the limits shown in figure 2 7. A torque tube shaft extension is required for a 249 sensor when using an insulator assembly.

CAUTION

Measurement errors can occur if the torque tube assembly is bent or misaligned during installation.

18

Instruction Manual |

Installation |

D102748X012 |

October 2014 |

|

|

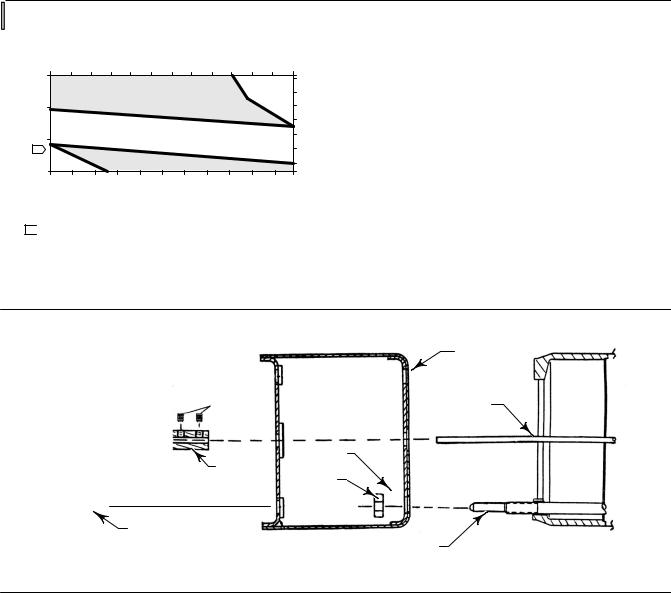

Figure 2 7. Guidelines for Use of Optional Heat Insulator Assembly

|

|

|

|

AMBIENT TEMPERATURE (_C) |

|

|

|

PROCESS TEMPERATURE ( C) |

||||||

PROCESS TEMPERATURE ( F) |

-40 |

-30 |

-20 |

-10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80425 |

|

800 |

|

|

|

|

|

|

|

|

|

|

|

400 |

||

|

|

|

|

|

|

|

|

|

|

|

TOO |

|||

|

|

|

|

HEAT INSULATOR |

|

|

300 |

|||||||

|

|

|

|

|

|

HOT |

||||||||

|

|

|

|

REQUIRED |

|

|

|

|

||||||

400 |

|

|

|

|

|

|

|

200 |

||||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

100 |

||

0 |

|

|

NO HEAT INSULATOR NECESSARY |

|

0 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

1 |

TOO |

|

HEAT INSULATOR |

|

|

|

|

|

|

-100 |

||||

|

|

|

|

|

|

|

|

-200 |

||||||

-325 |

COLD |

|

REQUIRED |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

160 176 |

|||||||

-40 |

-20 |

0 |

20 |

40 |

60 |

|

80 |

100 |

120 |

140 |

||||

AMBIENT TEMPERATURE (_F)

STANDARD TRANSMITTER

NOTES:

1  FOR PROCESS TEMPERATURES BELOW -29_C (-20_F) AND ABOVE 204_C (400_F) SENSOR MATERIALS MUST BE APPROPRIATE FOR THE PROCESS; SEE TABLE 1 4.

FOR PROCESS TEMPERATURES BELOW -29_C (-20_F) AND ABOVE 204_C (400_F) SENSOR MATERIALS MUST BE APPROPRIATE FOR THE PROCESS; SEE TABLE 1 4.

2. IF AMBIENT DEW POINT IS ABOVE PROCESS TEMPERATURE, ICE FORMATION MIGHT CAUSE INSTRUMENT MALFUNCTION AND REDUCE INSULATOR EFFECTIVENESS.

39A4070 B

A5494 1

Figure 2 8. Digital Level Controller Mounting on Sensor in High Temperature Applications

MN28800 20A7423 C B2707

|

INSULATOR |

|

(KEY 57) |

|

SHAFT |

SET SCREWS |

EXTENSION |

(KEY 60) |

(KEY 58) |

|

WASHER |

SHAFT |

(KEY 78) |

|

|

COUPLING |

HEX NUTS |

(KEY 59) |

(KEY 34) |

CAP SCREWS |

|

(KEY 63) |

MOUNTING STUDS |

|

|

|

(KEY 33) |

SENSOR |

DIGITAL LEVEL CONTROLLER |

1.For mounting a digital level controller on a 249 sensor, secure the shaft extension to the sensor torque tube shaft via the shaft coupling and set screws, with the coupling centered as shown in figure 2 8.

2.Slide the access handle to the locked position to expose the access hole. Press on the back of the handle as shown in figure 2 4 then slide the handle toward the front of the unit. Be sure the locking handle drops into the detent.

3.Remove the hex nuts from the mounting studs.

4.Position the insulator on the digital level controller, sliding the insulator straight over the mounting studs.

5.Install 4 washers (key 78) over the studs. Install the four hex nuts and tighten.

6.Carefully slide the digital level controller with the attached insulator over the shaft coupling so that the access hole is on the bottom of the digital level controller.

7.Secure the digital level controller and insulator to the torque tube arm with four cap screws.

8.Tighten the cap screws to 10 NSm (88.5 lbfSin).

19

Installation |

Instruction Manual |

October 2014 |

D102748X012 |

|

|

Electrical Connections

WARNING

WARNING

Select wiring and/or cable glands that are rated for the environment of use (such as hazardous area, ingress protection and temperature). Failure to use properly rated wiring and/or cable glands can result in personal injury or property damage from fire or explosion.

Wiring connections must be in accordance with local, regional, and national codes for any given hazardous area approval. Failure to follow the local, regional, and national codes could result in personal injury or property damage from fire or explosion.

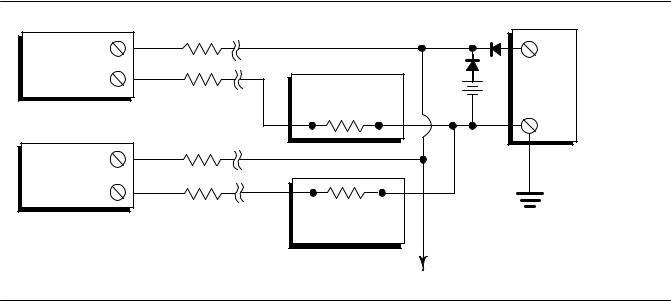

Proper electrical installation is necessary to prevent errors due to electrical noise. A resistance between 230 and 1100 ohms must be present in the loop for communication with a Field Communicator. Refer to figure 2 9 for current loop connections.

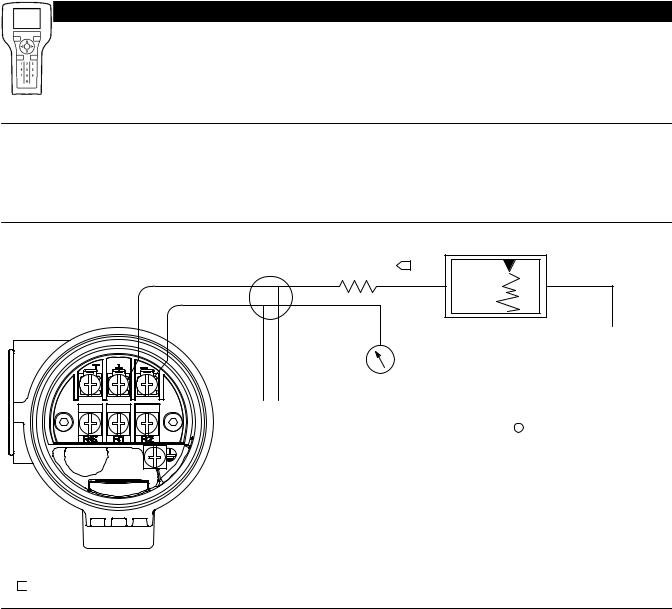

Figure 2 9. Connecting a Field Communicator to the Digital Level Controller Loop

230 W 3 RL 3 1100 W |

1 |

+ |

|

− |

|

|

|

+ |

+ |

Reference meter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

for calibration |

|

|

|

|

POWER |

||||||||

|

or monitoring |

|

|

|

|

SUPPLY |

|||||||

|

operation. May |

|

|

|

|

|

|

|

|

|

|

|

|

|

be a voltmeter |

|

|

|

|

|

|

|

|

|

|

− |

|

|

|

|

|

|

|

|

|

|

|

|

|||

− |

across 250 ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

resistor or a |

|

|

|

|

|

|

|

|

|

|

|

|

|

current meter. + |

|

|

|

− |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Field Communicator may be connected at any

termination point in the signal loop. Signal loop must have between 250 and 1100 ohms load for communication.

Signal loop may be grounded at any point or left ungrounded.

NOTE:

1 THIS REPRESENTS THE TOTAL SERIES LOOP RESISTANCE.

THIS REPRESENTS THE TOTAL SERIES LOOP RESISTANCE.

E0363

Power Supply

To communicate with the digital level controller, you need a 17.75 volt DC minimum power supply. The power supplied to the transmitter terminals is determined by the available supply voltage minus the product of the total loop resistance and the loop current. The available supply voltage should not drop below the lift off voltage. (The lift off voltage is the minimum “available supply voltage” required for a given total loop resistance). Refer to figure 2 10 to

20

Instruction Manual |

Installation |

D102748X012 |

October 2014 |

|

|

determine the required lift off voltage. If you know your total loop resistance you can determine the lift off voltage. If you know the available supply voltage, you can determine the maximum allowable loop resistance.

Figure 2 10. Power Supply Requirements and Load Resistance

Maximum Load = 43.5 X (Available Supply Voltage - 12.0)

783 |

|

|

|

|

|

Load (Ohms) |

|

|

|

Operating |

|

|

|

|

|

|

|

250 |

|

|

|

Region |

|

|

|

|

|

|

|

0 |

|

|

|

|

|

10 |

12 |

15 |

20 |

25 |

30 |

LIFT OFF SUPPLY VOLTAGE (VDC)

If the power supply voltage drops below the lift off voltage while the transmitter is being configured, the transmitter may output incorrect information.

The DC power supply should provide power with less than 2% ripple. The total resistance load is the sum of the resistance of the signal leads and the load resistance of any controller, indicator, or related pieces of equipment in the loop. Note that the resistance of intrinsic safety barriers, if used, must be included.

Field Wiring

Note

For intrinsically safe applications, refer to the instructions supplied by the barrier manufacturer.

WARNING

WARNING