Emerson Fisher CV500, Fisher V500, Fisher 8510, Fisher 8560, Fisher Vee-Ball V150 Instruction Manual

...

Instruction Manual |

KALREZ System - Rotary-Shaft Valves |

D102137X012 |

May 2011 |

|

|

KALREZr Packing System

for Fisherr Rotary Shaft Valves

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Removing the Actuator . . . . . . . . . . . . . . . . . . . . . . . |

2 |

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Installing a KALREZ Packing System . . . . . . . . . . . . . |

4 |

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Tightening Procedures . . . . . . . . . . . . . . . . . . . |

5 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for KALREZ valve stem packing (KVSP) systems. These systems are available for Fisher rotary valves with 12.7 through 38.1 mm (1/2 through 1 1/2 inch) shaft diameters. The system can be used with many rotary valves, as shown in table 1. Refer to appropriate valve and actuator instruction manuals for necessary information relating to the disassembly and assembly of the valve and actuator.

Do not install, operate, or maintain a KALREZ packing system without being fully trained and qualified in valve, actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office before proceeding.

Description

See table 1 for valve designs and shaft diameters where KALREZ packing systems can be applied.

Emerson Process Management offers KALREZ packing systems that you can easily install into your existing valves or that you can purchase with new valves. The KVSP 500 Series uses Vespelr CR 6100 backup rings and KALREZ seal rings.

The external live loading provides a constant load over the life of the packing material, which reduces the need for packing box adjustment and maintenance.

Installation

Use these instructions to install KALREZ packing in valves that have standard packing, or when inspecting or replacing KALREZ packing.

Table 2 lists part numbers for KALREZ packing sets only. When retrofitting valves to KALREZ packing, contact your Emerson Process Management sales office for information on additional parts needed.

www.Fisher.com

KALREZ System - Rotary-Shaft Valves |

Instruction Manual |

|

May 2011 |

D102137X012 |

|

|

|

|

Table 1. Specifications |

|

|

|

|

|

Applicable Valve Designs |

(1/2, 5/8, 3/4, 7/8, 1, 1 1/4 and 1 1/2 inches). See |

|

A41, 8510, 8510B (single arrangements only), 8550, |

table 2 |

|

|

||

and 8560 valves; V100, V150, V200, V300 and V500 |

|

|

Vee Ballt valves; and CV500 Cam Vee Ball valves. |

Pressures and Temperatures(1) |

|

See table 2 |

||

|

||

Applicable Shaft Diameters |

Maximum Application Temperature |

|

260_C (500_F) |

||

|

||

Vee Ball and Eccentric Disc Valves: J 12.7, J 15.9, |

Maximum Application Pressure |

|

J 19.1, J 22.2, J 25.4, J 31.8, and J 38.1 mm |

Pressure is limited to the maximum valve rating |

|

|

|

1. The pressure/temperature limits in this manual, in the valve literature, and any applicable code or standard limitation should not be exceeded.

Removing the Actuator

WARNING

WARNING

Avoid personal injury from sudden release of process pressure or uncontrolled movement of parts. Before performing any installation operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when loosening the packing box pipe plug.

D Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

You must remove the actuator from the valve when you install KALREZ packing systems. To allow proper readjustment of the Vee Ball, eccentric disc, or valve disc position, it is recommended that you remove the valve from the pipeline. Refer to appropriate valve and actuator instruction manuals.

WARNING

WARNING

Avoid personal injury or equipment damage from uncontrolled movement of parts. If a spring return actuator is used, be sure the actuator spring is resting on its travel stop. If something is obstructing shaft rotation, it is possible that disconnecting the shaft connector will allow the spring to force the actuator to the end of its rotation. Refer to the appropriate valve and actuator instruction manuals to remove the actuator.

2

Instruction Manual |

KALREZ System - Rotary-Shaft Valves |

D102137X012 |

May 2011 |

|

|

|

|

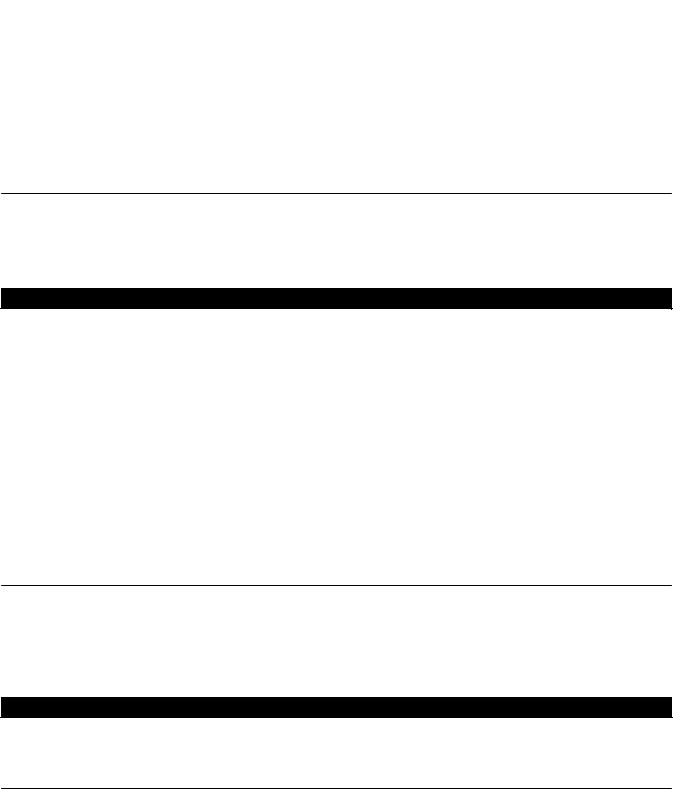

Figure 1. KALREZ Packing Arrangements |

|

|

STANDARD |

OUTBOARD END |

|

|

|

PACKING BOX |

|

||

|

PACKING BOX |

|

||

V100 |

- 12.7, 19.1, 25.4, 31.8 |

|

||

(1/2, 3/4, 7/8, 1, 1 1/4 ) SHAFT |

8510 - 12.7, 15.9, 19.1, 25.4, |

|

||

V150 |

- 12.7, 19.1, 25.4 |

31.8 (1/2, 5/8, 3/4, 1, 1 1/4) OPTIONAL DEEP |

||

SHAFT |

PACKING BOX |

|||

(1/2, 3/4, 1 SHAFT |

||||

|

||||

V200 |

& V300 - 12.7, 15.9, 19.1, 25.4 |

|

V100 - 12.7, 19.1, 25.4 (1/2,3/4, 7/8, 1) SHAFT |

|

|

|

|||

(1/2, 5/8, 3/4, 1) SHAFT |

|

|

||

V500 |

- 12.7, 15.9, 25.4, 31.8 |

|

|

|

(1/2, 5/8, 1, 1 1/4) SHAFT |

|

|

||

8510, 8550, 8560, & A41 - 12.7, 15.9, 19.1, 25.4,31.8 (1/2, 5/8, 3/4, 1, 1 1/4) SHAFT

STANDARD |

|

|

|

PACKING BOX |

OUTBOARD END |

|

|

|

|

|

|

V100, V500, 8510, 8550, 8560 & |

PACKING BOX |

STANDARD |

OPTIONAL DEEP |

A41 - 38.1 (1 1/2) SHAFT |

8510 - 38.1 (1 1/2) SHAFT |

||

|

|

PACKING BOX |

PACKING BOX |

|

|

V150 - 31.8, 38.1 (1 1/4, 1 1/2) SHAFT |

|

|

|

V200 - 31.8 (1 1/4) SHAFT |

V100 - 31.8 (1 1/4) SHAFT |

|

|

V150 - 31.8, 38.1 (1 1/4, 1 1/2) SHAFT |

|

|

|

OPTIONAL DEEP |

|

|

|

PACKING BOX |

|

8510 |

|

V100 - 38.1 (1 1/2) SHAFT |

|

|

|

mm(INCHES) |

|

OUTBOARD END |

|

|

|

|

|

|

|

44B7499-A |

|

|

|

|

|

|

|

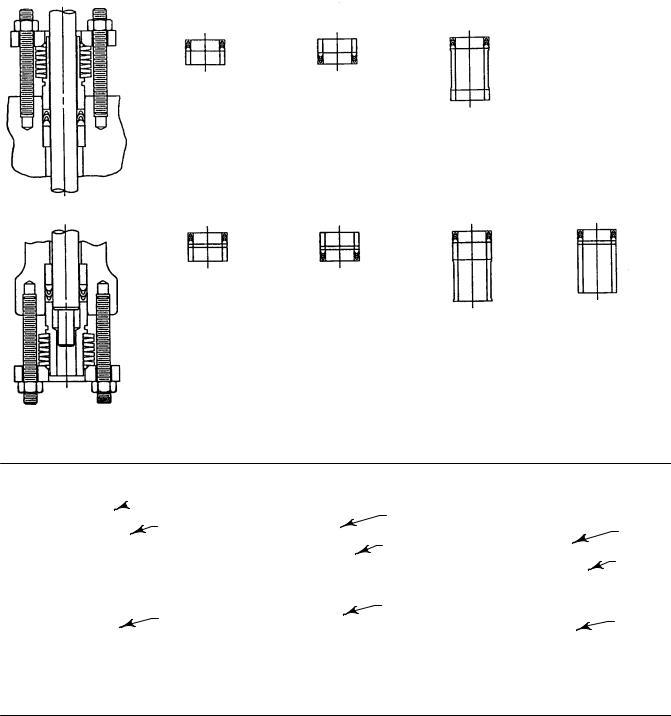

Figure 2. Belleville Spring Stacking Order

O-RING

O-RING

O-RING

BELLEVILLE |

|

O-RING |

SPRINGS (9) |

|

|

BELLEVILLE |

|

|

|

|

|

|

SPRINGS (7) |

BELLEVILLE |

|

|

|

|

|

SPRINGS (5) |

|

PACKING |

|

PACKING |

FOLLOWER |

PACKING |

FOLLOWER |

|

|

|

FOLLOWER |

|

|

|

12B8319-A

SIZE 12.7 & 15.9 mm (1/2 & 5/8 inch) SHAFT

B2409-1

12B8320-A |

12B8321-A |

SIZE 19.1, 22.2 & 25.4 mm |

SIZE 31.8 & 38.1 mm |

(3/4, 7/8, & 1 inch) SHAFT |

(1 1/4 & 1 1/2 inch) SHAFT |

3

Loading...

Loading...