Emerson EZH, EZHSO Instruction Manual

Instruction Manual

NTAEZH0811

November 2008 - Rev. 06

Types EZH and EZHSO

Types EZH and EZHSO Pressure Reducing Regulators

Contents |

|

Introduction ........................................................................ |

2 |

Characteristics ................................................................... |

3 |

Labelling ............................................................................ |

5 |

Dimensions and Weights ................................................... |

6 |

Description ......................................................................... |

8 |

Principle of Operation......................................................... |

8 |

Monitoring Systems............................................................ |

11 |

Installation ......................................................................... |

13 |

Startup and Adjustment ..................................................... |

15 |

Shutdown ........................................................................... |

16 |

Maintenance ...................................................................... |

17 |

Troubleshooting ................................................................. |

24 |

Spare Parts ........................................................................ |

25 |

Parts List ............................................................................ |

26 |

!WARNING

Failure to follow these instructions or to properly install and maintain this equipment could result in an explosion and/or fire causing property damage and personal injury or death.

Fisher® regulators must be installed, operated, and maintained in accordance with federal, state, and local codes, rules and regulations, and Emerson Process Management Regulator Technologies, Inc. (Regulator Technologies) instructions.

If the regulator vents gas or a leak develops in the system, service to the unit may be required. Failure to correct trouble could result in a hazardous condition.

Call a gas service person to service the unit. Only a qualified person must install or service the regulator.

R94

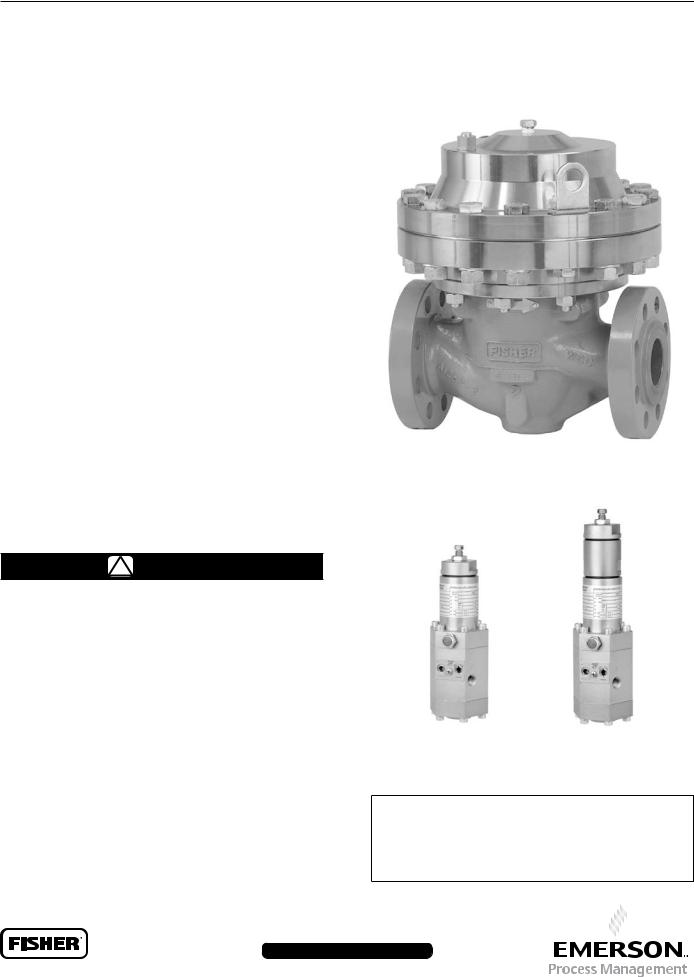

Figure 1. Type EZH Pressure Reducing Regulator

TYPE PRX-120 |

TYPE PRX-120/AP |

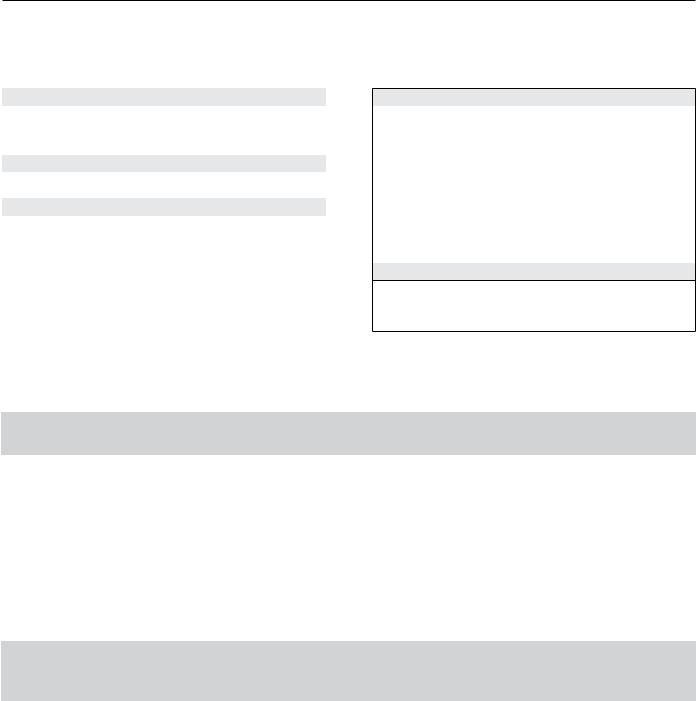

Figure 2. PRX Series Pressure Reducing Pilots

Types EZH, EZHSO, EZH OS2, and EZHSO OS2 regulators are in conformity with the

Pressure Equipment Directive

PED 97/23/EC and are classified in Category IV.

Europe, Middle East, and Africa Document Only

www.fisherregulators.com

Types EZH and EZHSO

INTRODUCTION

Scope of Manual

This manual provides installation, startup, maintenance, and parts ordering information for the Types EZH and EZHSO pressure-reducing regulators and Type PRX pilot with Type SA/2 pilot supply filter regulator.

Information on other equipment used with this regulator is found in separate manuals.

Product Description

Types EZH and EZHSO regulators are accurate pilotoperated pressure balanced, soft-seated regulators. They are designed for use in high pressure natural gas transmission/city gate stations, large capacity distribution systems, and power plant feeds. They provide smooth, reliable operation, tight shutoff, and long life.

Type EZHSO "Spring-to-Open" version could be used when other overpressure protection options are foreseen, for example in a monitor configuration. In this case, in event of failure, the main regulator will stay completely open, allowing the monitor to take control. The monitor could be "Spring-to-Close" to ensure a double protection to downstream pipe.

Available Configurations:

•Types EZH and EZHSO ("E Body")

Single regulator without slam shut

•Types EZH and EZHSO ("X Body")

Single regulator in a X Body

In case of modification made on a pressure equipment like cap replacement by a slam shut it's mandatory to comply to the local codes, rules and regulations. Contact us imperatively.

•Types EZH OS2 and EZHSO OS2 ("X Body")

Single regulator with integrated slam shut

Pilot Description

Type PRX Pilot

The Types EZH and EZHSO pressure-reducing regulators can be equipped with a PRX Series pilot mounted on the main valve for pressure reducing or wide-open monitoring applications. The PRX Series pressure reducing pilots have the ability to handle a wide range of setpoints from 1 to 80 bar:

•Type PRX/120:

Outlet pressure range of 1 to 40 bar. The Type PRX/120 can be used as the pilot on single stage pressure reducing regulators, as the monitor pilot, or as the working pilot in wide-open monitor systems.

•Type PRX/120-AP:

Outlet pressure range of 30 to 80 bar. The Type PRX/120-AP can be used as the pilot on single stage pressure reducing regulators, as the monitor pilot, or as the working pilot in wide-open monitor systems.

•Type PRX/125:

Identical to the Type PRX/120, except the restriction screw is removed. The Type PRX/125 can only be used as the monitor override pilot on working monitor applications.

•Type PRX/125-AP:

Identical to the Type PRX/120-AP, except the restriction screw is removed. The Type PRX/125-AP can only

be used as the monitor override pilot on working monitor applications.

•Type SA/2 Pilot Supply Filter Regulator:

The Type SA/2 pilot supply filter regulator provides a constant pressure supply to the PRX Series pilot of 3 bar over the set pressure. The Type SA/2 has an integral

5-micron filter. For easy maintenance a block valve can be installed to separate the regulator from the pilot.

Regulator Options

•Silencer (Figure 22)

The Type EZH silencer (Whisper III) is integrated in the regulator and is composed of a drilled cage.

The Whisper III silencer is available for DN 25, 50, 80, and 100 and allows a noise attenuation up to 8dB.

•Flow Coefficient Reduction (Figure 16)

The flow reduction is realised by replacement of the regulator standard seat by a reduction seat ( key 2).

•Type RPE Electrical Pilot Heater (Figure 25)

The Type RPE is used for reheating the gas supplying pressure reducing regulator pilots. The Type RPE avoids the inconveniences caused by freezing which can occur during high pressure drops.

Actuator

The actuator is an integral pressure type. All pressure parts are designed to resist up to 100 bar. The diaphragm is strong and can resist to a differential of 100 bar.

Europe, Middle East, and Africa Document Only

2

Types EZH and EZHSO

CHARACTERISTICS

Table 1. General Characteristics for Types EZH and EZHSO Regulator

OPERATING PRESSURE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A352LCC Body, Actuator, Valve, |

|

|

PS |

100 bar max |

|

|

Pilot Body, Slam shut |

|

|

|

||

|

|

|

|

|

|

|

|

Associated BMS(1), according to size |

|

PSD |

10 to 100 bar |

|

|

|

Type |

|

|

IS |

Integral strength(4) |

|

OPERATING TEMPERATURE(2) |

|

|

TS |

-20 / 60°C Class 2 |

|

|

Sizes available |

|

|

DN |

25, 50, 80, and 100 |

|

|

Noise level reduction |

|

|

Up to 8 dB |

|

|

|

REGULATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

European EN Standard |

|

|

|

EN 334 |

|

|

Inlet Pressure |

|

|

Pu |

2 to 100 bar |

|

|

Outlet Pressure |

|

|

Pd |

1 to 80 bar |

|

|

Minimum Differential |

|

|

DP min |

1 bar (Type EZH) |

|

|

|

|

3.8 bar (Type EZHSO) |

|

|||

|

|

|

|

|

|

|

Maximum Differential |

|

|

DP max |

99 bar (Type EZH) |

|

|

|

|

96.2 bar (Type EZHSO) |

|

|||

|

|

|

|

|

|

|

Accuracy (optimal) |

|

|

AC |

See Table 2 |

|

|

Lock-Up Pressure Class |

|

|

SG |

Up to 5%(3) |

|

|

Lock-Up Pressure Zone Class |

|

|

SZ |

Up to 5%(3) |

|

|

(1) |

BMS - Safety Manometric Box |

(3) |

Contact us with your operating conditions |

|||

(2) |

Standard version |

(4) |

Depending on BMS configuration for Type EZH OS2 |

|||

SLAM SHUT

European EN Standard |

|

|

|

EN 14382 |

|

Operation Class |

|

|

|

A or B (see Figure 3) |

|

Maximum Operating Differential |

DP max |

|

100 bar |

||

Response Time |

|

ta |

|

<1 s |

|

|

|

Diaphragm, |

|

|

Up to ±2.5% |

Accuracy |

|

Bellows |

AG |

|

|

|

|

|

|||

|

|

Piston |

|

|

Up to ±5% |

Set Pressure Range |

|

Wdu-Wdo |

|

0.010 / 100 bar |

|

Flow Coefficient |

|

Qf |

|

13 |

|

Internal Automatic Bypass |

Cg |

|

25 |

||

Rearming |

|

Manual after rectification of fault |

|

||

Position Indicator |

|

On mechanism box |

|

||

|

|

|

Fluid |

|

|

Groups 1 and 2 according to PED 97/23/EC, Gas 1st and 2nd family according to EN 437, or other gases (compressed air, nitrogen).

The gas must be non corrosive, clean

(filtration on inlet side necessary) and dry.

Table 2. Outlet Pressure Ranges, Accuracy Class, and Pilot Spring Information

TYPE |

OUTLET PRESSURE |

AC (ACCURACY CLASS) |

PILOT CONTROL SPRING INFORMATION |

||

|

|

|

|||

ADJUSTMENT RANGES (bar) |

TYPE EZH |

TYPE EZHSO |

Spring Colour |

||

|

|||||

|

|

||||

|

|

|

|

|

|

|

1.0 to 1.8 |

2.5% |

2.5% |

Yellow |

|

|

1.8 to 3.0 |

2.5% |

2.5% |

Green |

|

|

3.0 to 5.5 |

2.5% |

2.5% |

Blue |

|

PRX/120 and |

5.5 to 8.5 |

2.5% |

2.5% |

Black |

|

PRX/125 |

8.5 to 14.5 |

1% |

2.5% |

Silver |

|

|

14.5 to 23.0 |

1% |

2.5% |

Gold |

|

|

23.0 to 30.0 |

1% |

2.5% |

Aluminium |

|

|

30.0 to 40.0 |

1% |

2.5% |

Red |

|

|

|

|

|

|

|

PRX/120-AP and |

30.0 to 80.0 |

1% |

2.5% |

Clear |

|

PRX/125-AP |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

R95 |

|

|

|

Table 3a. 2:1 Line Flow Coefficients, Regulator, and Slam-Shut Travel |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TYPES EZH (DN 25 - 100) AND EZHSO (DN 25 - 100) |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REDUCTION |

|

|

WITH SLAM SHUT (X BODY) |

|

|

WITHOUT SLAM SHUT (E BODY) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DN 25 |

|

DN 50 |

DN 80 |

DN 100 |

DN 25 |

|

DN 50 |

DN 80 |

|

DN 100 |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

284 |

|

1078 |

2247 |

3567 |

280 |

|

1088 |

2266 |

|

3696 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Qf |

1 |

210 |

|

908 |

1684 |

2969 |

218 |

|

829 |

1698 |

|

2902 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

126 |

|

671 |

1058 |

1763 |

128 |

|

607 |

1066 |

|

1784 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

79 |

|

385 |

685 |

1062 |

81 |

|

370 |

690 |

|

1072 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

550 |

|

2092 |

4359 |

6920 |

544 |

|

2110 |

4396 |

|

7170 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Cg |

1 |

408 |

|

1762 |

3266 |

5760 |

423 |

|

1609 |

3294 |

|

5630 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

245 |

|

1301 |

2052 |

3420 |

249 |

|

1177 |

2069 |

|

3460 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

154 |

|

746 |

1328 |

2060 |

157 |

|

718 |

1339 |

|

2080 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

31.3 |

|

38.3 |

30.8 |

32.5 |

35.5 |

|

33.5 |

30.8 |

|

31.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

C1 |

1 |

34.3 |

|

35.3 |

33.9 |

35.3 |

38.7 |

|

31.9 |

33.9 |

|

34.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

33.6 |

|

38.8 |

37.8 |

37.3 |

39.7 |

|

35.6 |

37.8 |

|

36.3 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

32.1 |

|

40.8 |

33.6 |

37.1 |

39.1 |

|

38.2 |

33.6 |

|

37.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Regulator travel (mm) |

9 |

|

17 |

25 |

30 |

9 |

|

17 |

25 |

|

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slam-shut travel (mm) |

|

15 |

30 |

50 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

R96

Europe, Middle East, and Africa Document Only

3

Types EZH and EZHSO

Table 3b. 2:1 Line Flow Coefficients, Regulator with Integrated Whisper III Silencer

TYPES EZH (DN 25 - 100) WITH WHISPER III AND EZHSO (DN 25 - 100) WITH WHISPER III

|

REDUCTION |

|

SLAM SHUT INTEGRATED (X BODY) |

|

|

WITHOUT SLAM SHUT (E BODY) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DN 25 |

|

DN 50 |

DN 80 |

|

DN 100 |

DN 25 |

|

DN 50 |

DN 80 |

|

DN 100 |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

223 |

|

781 |

1693 |

|

2742 |

255 |

|

793 |

1708 |

|

2789 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Qf |

1 |

215 |

|

764 |

1418 |

|

2479 |

209 |

|

716 |

1172 |

|

2438 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

140 |

|

603 |

975 |

|

1644 |

127 |

|

566 |

984 |

|

1711 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

87 |

|

370 |

685 |

|

1041 |

81 |

|

358 |

690 |

|

1057 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

433 |

|

1516 |

3285 |

|

5320 |

495 |

|

1539 |

3313 |

|

5410 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cg |

1 |

417 |

|

1482 |

2751 |

|

4810 |

406 |

|

1389 |

2774 |

|

4730 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

273 |

|

1169 |

1892 |

|

3190 |

247 |

|

1099 |

1908 |

|

3320 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

168 |

|

718 |

1328 |

|

2020 |

158 |

|

695 |

1339 |

|

2050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

35.5 |

|

37 |

30.8 |

|

31.7 |

33.8 |

|

33.5 |

30.8 |

|

30.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C1 |

1 |

35.4 |

|

37.5 |

33.6 |

|

34.1 |

39.4 |

|

34.1 |

33.6 |

|

32.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

32.3 |

|

39.5 |

37.1 |

|

36.4 |

39.9 |

|

35.7 |

37.1 |

|

35.7 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

32.9 |

|

39.4 |

38.3 |

|

37.6 |

39.9 |

|

37.7 |

38.3 |

|

37.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 4. Failure Mode Analysis

PART NAME |

FAILURE |

CAUSE OF |

EFFECT |

REGULATOR TYPE |

REGULATOR REACTION MODE |

||

(WORST CASE) |

FAILURE |

||||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Decrease of feeding |

EZHSO |

Open |

--- |

|

|

Filter blocked/ |

Debris or aromatics |

pressure gives |

||||

Filter |

|

|

|

||||

clogged |

present in the gas |

decrease of |

EZH |

--- |

Close |

||

|

|||||||

|

|

|

motorization pressure |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Debris or aromatics |

Increase |

EZHSO |

Open |

--- |

|

Pilot Disk |

Pilot cannot be closed |

motorization |

|

|

|

||

present in the gas |

EZH |

Open |

--- |

||||

|

|

pressure |

|||||

|

|

|

|||||

|

|

|

|

|

|

|

|

Pilot Lower |

|

Debris or aromatics |

Decrease |

EZHSO |

Open |

--- |

|

Pilot cannot control |

motorization |

|

|

|

|||

Diaphragm |

present in the gas |

EZH |

--- |

Close |

|||

|

pressure |

||||||

|

|

|

|||||

|

|

|

|

|

|

|

|

Pilot Upper |

Pilot cannot feed |

Debris or aromatics |

Decrease |

EZHSO |

Open |

--- |

|

motorization |

|

|

|

||||

Diaphragm |

the regulator |

present in the gas |

EZH |

--- |

Close |

||

pressure |

|||||||

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Not proper |

|

Balancing of |

EZHSO |

Open |

--- |

|

|

|

pressures and charge |

|||||

Regulator |

performance of |

Debris or aromatics |

|

|

|

||

or discharge of |

|

|

|

||||

Diaphragm |

the motorization |

present in the gas |

|

|

|

||

the motorization |

|

|

|

||||

|

pressure chamber |

|

EZH |

--- |

Close |

||

|

|

pressure chamber |

|||||

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Type SA/2 loading |

EZHSO |

--- |

Close |

|

|

|

|

upper casing of |

||||

|

|

|

|

|

|

||

Pilot |

Frozen Pilot, |

Moisture in the gas, |

regulator, Pilot |

|

|

|

|

Type SA/2 working |

high pressure drop |

not supplying |

|

|

|

||

|

|

|

|

||||

|

|

|

loading pressure |

EZH |

--- |

Close |

|

|

|

|

to lower casing |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

R96B

Europe, Middle East, and Africa Document Only

4

Types EZH and EZHSO

Connections

Inlet/Outlet : CL150 RF - CL300 RF - CL600 RF

PN 16B - PN 25B - PN 40B

Other configurations available

(contact factory)

Pilot feed: |

1/4’’ NPT female |

Pilot Reject: |

1/4’’ NPT female |

Pilot impulse: |

1/4’’ NPT female |

Slam-shut impulse: |

1/4’’ NPT female |

BM* vent: |

1/4’’ NPT female |

Impulse tube diameter: |

Interior Ø 8/10 mm |

Contact switch: |

See NTAOS2 |

* BM - Mechanism Box |

|

Material

Body: |

Steel |

Connecting parts and bottom: |

Steel |

Actuator: |

Steel |

Regulator/Slam-shut orifice: |

Stainless steel |

Regulator valve plug: |

Stainless steel |

Slam-shut valve plug: |

Stainless steel |

Regulator plug disc/ |

|

Slam-shut O-rings: |

Nitrile (NBR) or |

|

Fluorocarbon (FKM) |

LABELLING

|

|

|

|

|

|

|

|

BMS Setting |

|

Security Class |

||||

|

|

|

|

|

|

|

|

|

|

|

A |

|

B |

|

|

|

|

|

|

|

|

|

Max only |

|

BMS 027/017 |

BMS 162 |

|||

|

|

|

|

|

|

|

|

|

BMS 236/315 |

BMS 071 |

||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

Min only |

|

All |

|

|

|

|

OS2 |

- |

|

|

|

|

|

|

Max-Min |

|

types of BMS |

|

|

|

|

|

|

|

Standard |

|

EN 14382 |

|

- |

|

|

|

|

|

|

|

EZH |

EZHSO |

|

|

|

|

Failure mode |

FC |

FO |

||||||

DN 25 |

50 80 100 |

|

CL150 RF |

CL300 RF |

CL600 RF |

PN16B |

PN25B |

PN40B |

Other configurations available (contact factory)

REGULATEUR/REGULATOR |

|

norme |

EN 334 |

mode défaillance |

DN |

|

|

PN |

|

|

FISHER |

||||

|

standard |

failure mode |

|

|

|

|

|||||||||

SECURITE/SLAM SHUT |

|

norme |

|

classe sécurité |

Pumax |

|

|

bar |

|

FRANCEL |

|

|

|||

|

standard |

|

slam shut class |

|

|

|

|

|

|||||||

|

1 (Gaz Naturel)Cat IV PS |

|

|

|

2 |

|

|

28320 Gallardon-France |

|

|

|||||

GROUPE |

|

bar |

PT |

bar |

Temp TS |

-20/+60°C |

Class |

Type |

Cg |

0062 |

|||||

série |

Date Fab/Test |

DD MM YEAR |

|

matériau |

A352LCC+A350LF2 |

|

|

|

|

|

|||||

N°serial |

Mfg/Test date |

|

shell |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Reduction |

0 |

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

Cg |

|

See Table 3 |

|

||

|

|

|

|

|

|

|

|

|

|

IS |

Depending on BMS |

|

|

||

|

|

|

|

|

|

|

|

|

|

DS |

configuration |

|

|

||

|

|

CLASS |

|

PN |

|

||

|

150 |

|

300 |

600 |

16B |

25B |

40B |

Pumax |

18.9 |

|

50 |

100 |

16 |

25 |

40 |

PT |

32 |

|

79 |

158 |

26 |

40 |

63 |

PS |

18.9 |

|

50 |

100 |

16 |

25 |

40 |

Figure 3. Types EZH OS2 and EZHSO OS2 Label (X Body)

Europe, Middle East, and Africa Document Only

Failure mode FC FO

DN 25 50 80 100

REGULATEUR/

REGULATOR

DN |

PN |

mode défaillance failure mode

N° sérieserial

CL150 RF |

CL300 RF |

CL600 RF |

PN16B |

PN25B |

PN40B |

Other configurations available (contact factory)

EZH EZHSO

|

|

norme |

|

|

|

|

|

|

Reduction |

|

0 |

1 |

|

2 |

3 |

|

|

|

|

|

EN 334 |

|

|

Cg |

|

|

See table 3 |

|

|||||

|

|

standard |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Type |

IS |

|

|

Cg |

|

|

|

|

Date |

DD MM YEAR |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Date Fab/Test |

|

|

|

|

|

|

|

|

||||||||

Mfg/Test date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

PS |

|

|

|

|

bar |

PT |

|

bar |

Pumax |

bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLASS |

|

PN |

|

|

|

|

Temp TS |

|

|

|

|

Class 2 |

|

|

|

150 |

300 |

600 |

16B |

25B |

40B |

|||

|

|

|

-20/+60°C |

|

|

|

|||||||||||||

|

|

matériau |

|

|

|

|

|

|

|

|

|

|

Pumax |

18.9 |

50 |

100 |

16 |

25 |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

shell |

|

|

|

A352LCC+A350LF2 |

|

0062 |

PT |

32 |

79 |

158 |

26 |

40 |

63 |

||||

(Gaz Naturel) |

|

|

|

FISHER |

|

|

|

||||||||||||

GROUPE |

1 Cat |

IV |

|

|

|

FRANCEL |

|

|

PS |

18.9 |

50 |

100 |

16 |

25 |

40 |

||||

|

|

|

|

|

28320 Gallardon-France |

|

|

|

|

|

|

|

|

|

|||||

R97

Figure 4. Types EZH and EZHSO Label (E Body)

5

Types EZH and EZHSO

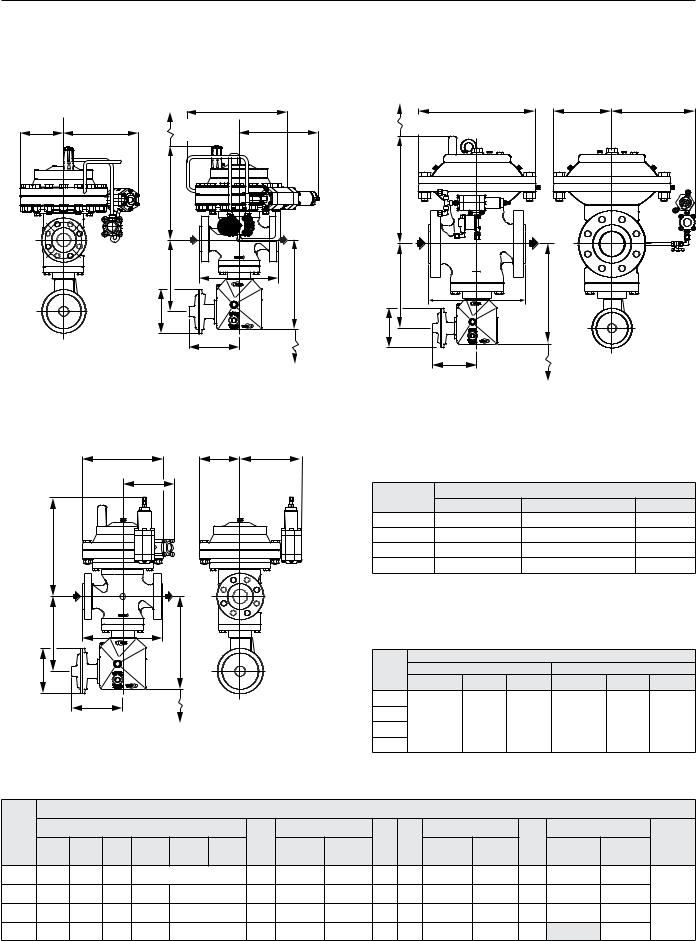

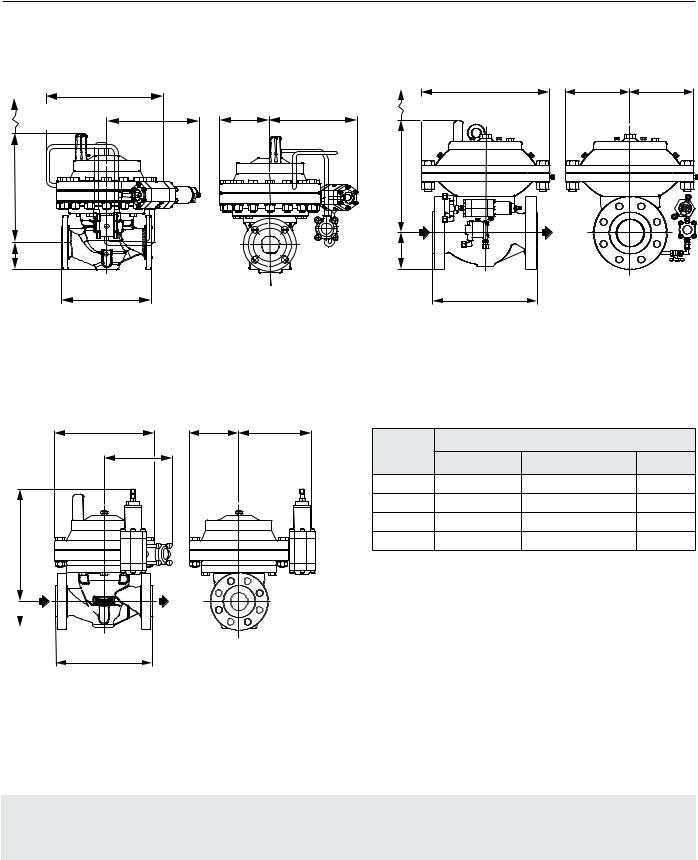

DIMENSIONS AND WEIGHTS |

|

|

|

|

|

|||

|

|

DN 25, 50, and 80 |

|

|

|

DN 100 |

|

|

|

|

|

|

E |

|

E |

I |

H |

|

|

|

Indicator cover |

J |

K |

Indicator cover |

|

|

I |

H |

K |

removal clearance |

|

|

|||

removal clearance |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

C |

|

|

|

B |

A |

|

D |

B |

D |

|

A |

|

G |

|

|

|

G |

|

F |

25 mm |

|

|

|

Mechanism box |

|

25 mm |

|

removal clearance |

F |

|

|

Mechanism box |

||

|

|

|

|

|

|

|

removal clearance |

|

|

|

R112a |

Figure 5. Dimensions — Types EZH OS2 and EZHSO OS2

(Horizontal Position)

DN 25, 50, 80, and 100

E |

I |

H |

Table 5. Approximate Regulator Weights |

|

|

|

J |

|

Types EZH OS2 and EZHSO OS2 |

|

|

|

|

|

|

|

|

|

|

DN |

|

WEIGHTS (kg) |

|

|

|

CL150/PN 16B |

CL300/PN 25B/PN 40B |

CL600 |

|

|

|

|

|||

|

|

25 |

49 |

50 |

51 |

C |

|

50 |

81 |

83 |

85 |

|

80 |

168 |

175 |

177 |

|

|

|

||||

|

|

100 |

237 |

250 |

265 |

|

|

For Type EZHSO OS2 version add 1 kg |

|

R113a |

|

|

B |

|

|

A |

|

|

|

|

Table 6a. Dimensions — Types EZH OS2 and EZHSO OS2 |

||||||||

|

|

|

|

|

D |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OVERALL DIMENSIONS (mm) |

|

||||

|

G |

|

|

|

|

|

|

|

DN |

|

|

F |

|

|

|

G |

|

|

|

|

|

|

|

|

|

|

|

Diaphragm |

Piston |

Bellows |

Diaphragm |

Piston |

Bellows |

||

|

|

F |

|

|

25 mm |

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

Mechanism box |

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

removal clearance |

|

|

|

|

181 |

204 |

|

223 |

162 |

71 |

74 |

|

Figure 6. Dimensions — Types EZH OS2 and EZHSO OS2 |

|

80 |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

100 |

|

|

|

|

|

|

|

|

||||||||

|

|

|

(Vertical Position) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Table 6b. Dimensions — Types EZH OS2 and EZHSO OS2 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

MAXIMUM OVERALL DIMENSIONS (mm) |

|

|

|

|

|

|

||||

DN |

|

|

|

A |

|

|

C |

|

|

|

H |

|

|

J |

|

|

|

|

|

|

|

|

B |

|

|

D |

E |

|

|

|

I |

|

|

K |

|

|

CL150 CL300 CL600 PN 16B PN 25B PN 40B |

Type PRX |

Type PRX |

Type PRX Type PRX |

Type PRX |

Type PRX |

|||||||||||

|

|

|

|

|

|

||||||||||||

|

|

Horizontal |

Vertical |

|

|

Horizontal Vertical |

|

Horizontal |

Vertical |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

25 |

184 |

197 |

210 |

|

193.5 |

250 |

290 |

310 |

315 |

320 |

260 |

250 |

|

113 |

280 |

190 |

38 |

50 |

254 |

267 |

286 |

254 |

267 |

265 |

320 |

320 |

330 |

380 |

310 |

310 |

|

144 |

270 |

190 |

|

|

|

||||||||||||||||

80 |

298 |

317 |

337 |

310 |

317 |

301 |

400 |

400 |

366 |

500 |

390 |

390 |

|

200 |

270 |

270 |

51 |

100 |

352 |

368 |

394 |

350 |

368 |

345 |

442 |

427 |

410 |

580 |

394 |

394 |

|

240 |

|

140 |

|

|

|

|

|||||||||||||||

R114a

Europe, Middle East, and Africa Document Only

6

Types EZH and EZHSO

DN 25, 50, and 80 |

DN 100(1) |

|

|

E |

|

|

|

E |

I |

H |

|

Indicator cover |

|

|

|

K |

Indicator cover |

|

|

|

J |

I |

H |

removal clearance |

|

|

||

K |

|

|

|

|||||

removal clearance |

|

|

|

|

|

|

|

|

C |

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

A |

|

R115a |

Figure 7. Dimensions — Types EZH and EZHSO

(Horizontal Position)

|

DN 25, 50, 80, and 100 |

|

Table 7. Approximate Regulator Weights |

|

|

|

|

|

Types EZH and EZHSO(1) |

|

|

E |

I |

H |

|

|

|

|

|

DN |

|

WEIGHTS (kg) |

|

|

J |

CL150/PN 16B |

CL300/PN 25B/PN 40B |

CL600 |

|

|

|

|

|||

|

|

25 |

38 |

39 |

40 |

|

|

50 |

71 |

74 |

75 |

|

|

80 |

145 |

151 |

153 |

C |

|

100 |

211 |

224 |

239 |

|

(1) For Type EZHSO version add 1 kg |

|

|

||

|

|

|

R116a |

||

B

A

Figure 8. Dimensions — Types EZH and EZHSO

(Vertical Position)

Table 8. Dimensions — Types EZH and EZHSO

|

|

|

|

|

|

|

MAXIMUM OVERALL DIMENSIONS (mm) |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DN |

|

|

|

A |

|

|

|

C |

|

|

H |

|

|

J |

|

|

|||

|

|

|

|

|

|

B |

|

|

|

E |

|

|

|

I |

|

|

|

K |

|

|

CL150 |

CL300 |

CL600 |

PN 16B |

PN 25B |

PN 40B |

Type PRX |

|

Type PRX |

Type PRX |

|

Type PRX |

Type PRX |

|

Type PRX |

||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

Horizontal |

|

Vertical |

|

Horizontal |

|

Vertical |

|

Horizontal |

|

Vertical |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

25 |

184 |

197 |

210 |

|

193.5 |

|

62 |

290 |

|

310 |

320 |

260 |

|

250 |

113 |

280 |

|

190 |

38 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

254 |

267 |

286 |

254 |

267 |

83 |

320 |

|

320 |

380 |

310 |

|

310 |

144 |

270 |

|

190 |

||

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

298 |

317 |

337 |

310 |

317 |

105 |

400 |

|

400 |

500 |

390 |

|

390 |

200 |

270 |

|

270 |

51 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

352 |

368 |

394 |

350 |

368 |

137 |

442 |

|

427 |

580 |

394 |

|

394 |

240 |

|

|

140 |

||

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R117a

Europe, Middle East, and Africa Document Only

7

Types EZH and EZHSO

|

TYPE |

FILTER |

SA/2 |

|

V |

R |

M |

UPPER

DIAPHRAGM

TYPE |

|

PRX/120 |

PILOT DISK |

|

S |

B

L

A

LOWER REGULATOR DIAPHRAGM DIAPHRAGM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TYPE EZH |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Inlet pressure (Pu) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motorization pressure (Pm) |

TYPE PRX: |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Pilot feeding pressure (Pup) |

S - BLEED PORT |

TYPE SA/2 |

|

|

|

|

|

|

|

|

|||||

|

Outlet pressure (Pd) |

B - SUPPLY PORT |

V - SENSING |

|

|

|

|

|

|

|

|

|||||

|

L - MOTORIZATION PORT |

R - PILOT |

|

|

|

|

|

|

|

R98 |

||||||

|

Atmospheric pressure (Pb) |

|

|

|

|

|

|

|

||||||||

|

A - SENSING PORT |

M - INLET |

|

|

|

|

|

|

|

|

||||||

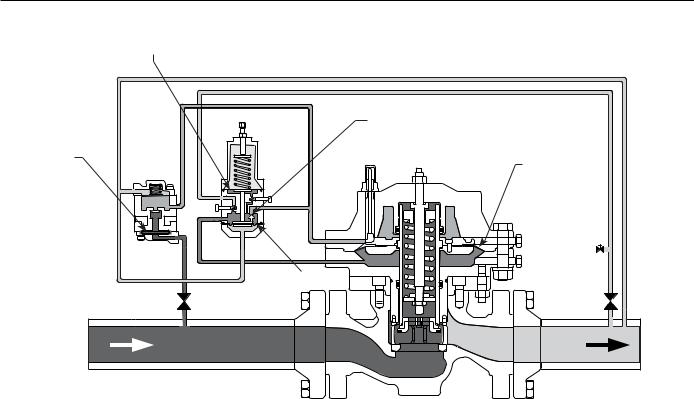

Figure 9. Type EZH DN 25/50/80 (Spring-to-Close Version) Operational Schematic

DESCRIPTION

The Types EZH and EZHSO regulators consist of:

•Version without Integral Slam-Shut Valve:

-An "E Body" or an "X Body plus a cap"

-A compensation valve, an interchangeable orifice

-An actuator with position indicator

-A pilot system adapted to the required pressure setpoint

•Version with Integral Slam-Shut Valve:

-Same parts and sub-assemblies as in the version without slam shut

-An "X Body"

-A valve with tight shut-off O-ring

-An automatic slam-shut bypass

-A release relay Type OS2 (see instruction manual NTAOS2) consisting of:

·A mechanism box (BM)

·A safety manometric box (BMS) connected to the outlet side of the regulator

PRINCIPLE OF OPERATION

Type EZH — Spring-to-Close Version

Type EZH Single-Pilot Regulator

(Figures 9 and 10)

The pilot-operated Type EZH uses inlet pressure as the operating medium, which is reduced through pilot operation to load the actuator diaphragm. Outlet pressure (Pd) opposes the motorization pressure (Pm) in the actuator and also opposes the pilot control spring.

When the outlet pressure (Pd) drops below the setting of the pilot control spring, pilot control spring force on the pilot diaphragm thus opens the pilot valve plug, providing additional motorization pressure (Pm) to the actuator diaphragm. This diaphragm motorization pressure opens the main valve plug, supplying the required flow to the downstream system.

Any excess motorization pressure on the actuator diaphragm escapes downstream through the bleed restriction in

the pilot.

Europe, Middle East, and Africa Document Only

8

Types EZH and EZHSO

V

R

R

S

M |

B |

|

L |

|

A |

R2

RP |

IP |

IS |

|

Inlet pressure (Pu) |

|

|

|

Motorization pressure (Pm) |

TYPE PRX: |

|

|

|

||

|

|

||

|

Pilot feeding pressure (Pup) |

S - BLEED PORT |

TYPE SA/2 |

|

Outlet pressure (Pd) |

B - SUPPLY PORT |

V - SENSING |

|

L - MOTORIZATION PORT |

R - PILOT |

|

|

Atmospheric pressure (Pb) |

||

|

A - SENSING PORT |

M - INLET |

Figure 10. Type EZH-OS2 DN 100 (Spring-to-Close Version) Operational Schematic

When the gas demand in the downstream system has been satisfied, the outlet pressure (Pd) increases. The increased pressure is transmitted through the downstream control line and acts on the pilot diaphragm. This pressure exceeds the pilot spring setting and moves the Type PRX diaphragm, closing the Type PRX orifice and interrupting the motorization pressure supply to main valve actuator.

The excess of motorization pressure (Pm) acting on both the main diaphragm and Type PRX pilot bleeds to the downstream system through a bleed restriction in the pilot.

For Type EZH DN 100 a check valve (Figure 26) is installed between outlet pressure and motorization pressure impulse lines; this valve will protect the diaphragm assembly from wrong procedures during startup, avoiding a too high pressure differential between outlet and motorization pressure.

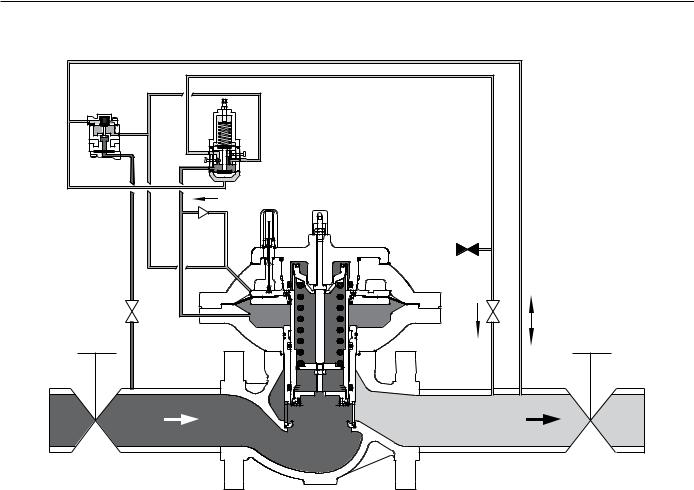

Type EZHSO — Spring-to-Open Version

Type EZHSO Single-Pilot Regulator

(Figures 11 and 12)

CAUTION

CAUTION

The pilot-operated Type EZHSO (Spring-to- Open version) will fail in open position in case of main valve diaphragm failure or lack of pressure supply to the pilot (see Table 4 for Failure Mode Analysis).

Europe, Middle East, and Africa Document Only

9

Types EZH and EZHSO

UPPER DIAPHRAGM

TYPE |

PILOT DISK |

PRX/120 |

|

FILTER |

|

TYPE |

|

|

|

|

V |

SA/2 |

|

|

R |

M

REGULATOR

DIAPHRAGM

S |

B

|

L |

|

|

A |

R3 |

|

|

|

|

LOWER DIAPHRAGM |

|

R2 |

|

R4 |

TYPE EZHSO

|

Inlet pressure (Pu) |

|

|

|

Motorization pressure (Pm) |

TYPE PRX: |

|

|

|

||

|

|

||

|

Pilot feeding pressure (Pup) |

S - BLEED PORT |

TYPE SA/2 |

|

Outlet pressure (Pd) |

B - SUPPLY PORT |

V - SENSING |

|

L - MOTORIZATION PORT |

R - PILOT |

|

|

Atmospheric pressure (Pb) |

||

|

A - SENSING PORT |

M - INLET |

Figure 11. Type EZHSO DN 25/50/80 (Spring-to-Open Version) Operational Schematic

Type EZHSO uses inlet pressure as the operating medium, which is reduced through pilot operation to load the actuator diaphragm (lower chamber). The upper case of

Type EZHSO actuator is filled with pressure coming from pre-regulator Type SA/2, which reduces inlet pressure (Pu) to the constant value of outlet pressure plus approximately 3 bar. This pressure opposes the main spring force

that tends to open the regulator. Outlet or downstream pressure (Pd) opposes the pilot control spring. When outlet pressure drops below the setting of the pilot control spring, pilot control spring force on the pilot diaphragm opens the pilot valve plug, providing additional motorization pressure (Pm) to the actuator diaphragm.

This diaphragm motorization pressure opens the main valve plug, supplying the required flow to the downstream system.

Any excess motorization pressure on the actuator diaphragm escapes downstream through the bleed restriction in the pilot.

When outlet pressure increases over the setting of the pilot spring, the pilot valve plug will be closed reducing motorization pressure to the actuator diaphragm; the pressure in the upper case will force the regulator to close.

For Type EZHSO DN 100 a check valve (Figure 26) is installed between outlet pressure and loading pressure

impulse lines; this valve will protect the diaphragm assembly from wrong procedures during startup, avoiding a too high pressure differential between outlet and motorization pressure.

EZH and EZHSO Series Adjustment

The adjustment of the regulator is performed by means of the pilot adjusting screw, which causes variation of the compression of the control spring.

Adjustment is performed while the regulator is in operation with the aid of a pressure gauge to monitor downstream pressure.

The shut-off valve downstream of the regulator must not be completely closed, it is necessary that a small quantity of gas flows downstream to allow the outlet side to vent when it is necessary to lower the pressure.

Loosen the Type PRX pilot locknut and turn the adjusting screw slowly clockwise to increase outlet pressure and counterclockwise to decrease outlet pressure. Use a pressure gauge to monitor the outlet pressure until the desired pressure is reached. No adjustment is needed to the Type SA/2 stabilizer filter.

Europe, Middle East, and Africa Document Only

10

Types EZH and EZHSO

V |

|

|

R |

|

|

|

S |

|

M |

B |

|

|

L |

|

|

A |

|

|

R3 |

|

|

|

R4 |

R2 |

|

|

|

RP |

IP |

|

Inlet pressure (Pu) |

|

|

|

Motorization pressure (Pm) |

TYPE PRX: |

|

|

|

||

|

|

||

|

Pilot feeding pressure (Pup) |

S - BLEED PORT |

TYPE SA/2 |

|

Outlet pressure (Pd) |

B - SUPPLY PORT |

V - SENSING |

|

L - MOTORIZATION PORT |

R - PILOT |

|

|

Atmospheric pressure (Pb) |

||

|

A - SENSING PORT |

M - INLET |

Figure 12. Type EZHSO DN 100 (Spring-to-Open Version) Operational Schematic

MONITORING SYSTEMS

Monitoring regulation is overpressure protection by containment, therefore, there is no relief valve to vent to the atmosphere. When the working regulator fails to control the pressure, a monitor regulator installed in series, which has been sensing the downstream and control pressure, goes into operation to maintain the downstream pressure at a slightly higher level than normal pressure. During an overpressure situation, the monitoring system keeps the customer on line.

Also testing is relatively easy and safe. To perform a periodic test on a monitoring regulator, increase the outlet set pressure of the working regulator and watch the outlet pressure to determine if the monitoring regulator takes over at the appropriate outlet pressure.

Wide-Open Monitoring Systems

In normal operation of a wide-open configuration, the working regulator controls the system’s outlet pressure. With a higher outlet pressure setting, the monitor regulator senses a pressure lower than its setpoint and tries to increase outlet pressure by going wide open. If the working regulator fails, the monitoring regulator assumes control and holds the outlet pressure at its outlet pressure setting.

Figure 13 shows an upstream wide-open monitor TypeEZH

(Spring-to-Close) and a downstream active regulator

Type EZHSO (Spring-to-Open). With this configuration, in case of regulator main diaphragm failure, it will fail in open position letting the monitor work properly; in case of monitor main diaphragm failure, it will fail in close

position guaranteeing a protection against overpressure to downstream system.

Europe, Middle East, and Africa Document Only

11

Loading...

Loading...