Bosch B942, B942W Installation Manual

1 | Overview

The B942/B942W is an SDI2 compatible device. The keypad has user adjustable options such as volume and screen brightness, and has a display that shows color graphics. The B942 keypad connects to the SDI2 bus on the control panel. You can connect more than one keypad to the control panel by wiring them in parallel.

You can program, diagnose, and troubleshoot the system from the keypad as well as remotely through Remote Programming Software (RPS). The keypad provides four inputs and one output.

1 |

2 |

3 |

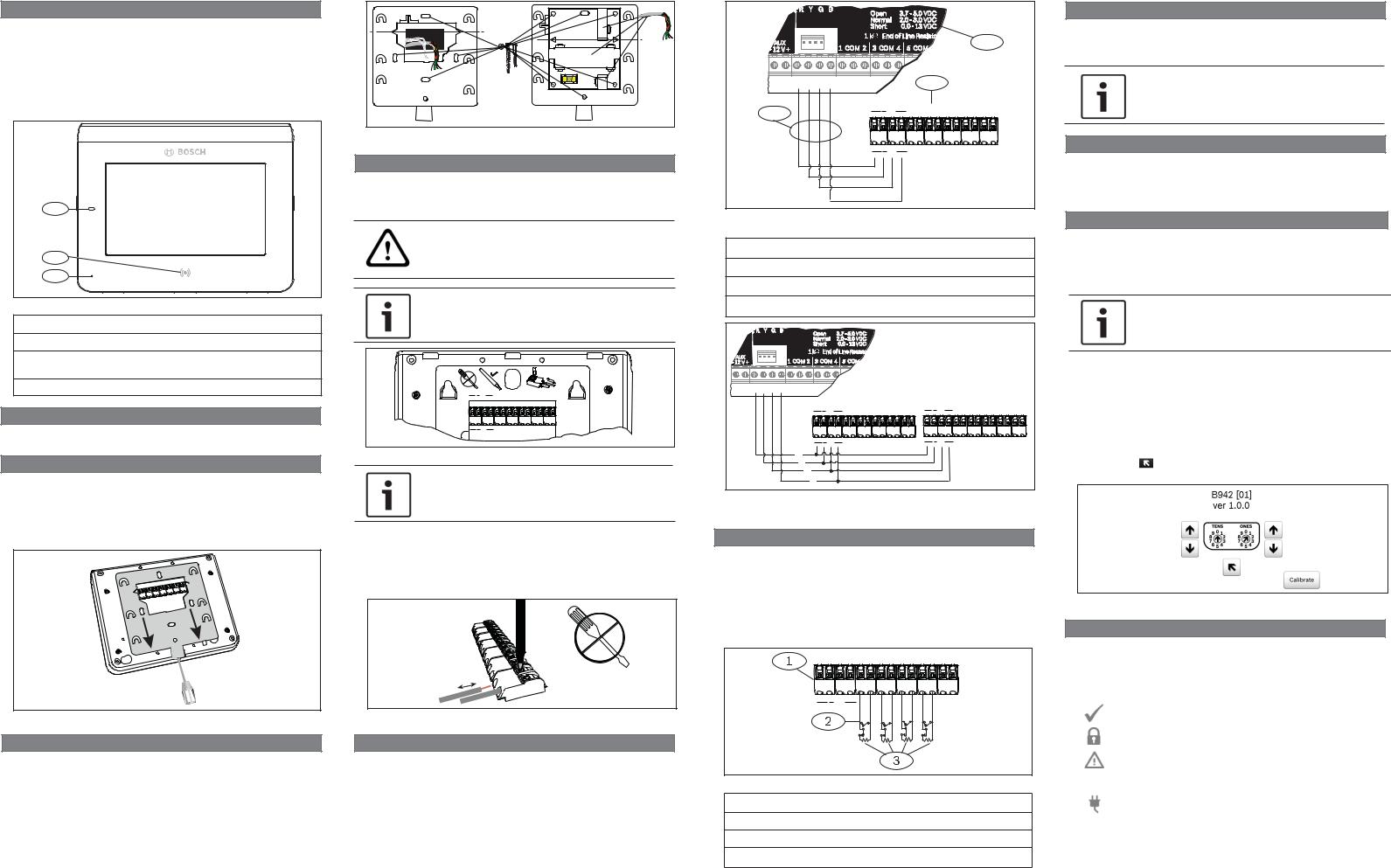

Figure 1.1: Touch screen keypad

Callout ― Description

1 ― Power indicator LED (shows even when screen dims)

2 ― Integrated proximity reader (for use with RF ID tokens and access cards)

3 ― Presence sensor

2 | Install the mounting plate

To install the keypad mounting plate, first remove the plate from the back of the keypad.

2.1 | Remove the mounting plate

Removing the mounting plate from the keypad:

1.Insert a slotted screwdriver under the retention clip to release the clip. Do not pry upwards or twist. Refer to Figure 2.1.

2.With your other hand, slide the mounting plate towards the bottom of the keypad to unhook the mounting plate from the keypad. Refer to Figure 2.1.

Figure 2.1: Removing the keypad from base

2.2 | Mount the mounting plate

Choose the flush mounting plate (Figure 2.2 left side) for flush mounting, or the surface mounting plate (Figure 2.3 right side) for surface mounting.

Mounting the plate on the wall:

1.The surface plate includes a bubble level. Use the plate as a template to mark the desired mounting surface with mounting locations. Refer to Figure 2.2 for mounting hole locations.

2.Pull the wiring through the desired wire opening.

3.Use the appropriate mounting hardware (supplied) to attach the mounting plate to the mounting surface.

GAUGE |

STRIP |

Figure 2.2: Mounting the plate

3 | Wire the keypad

Prior to placing the keypad on the mounting plate, wire the keypad to the control panel, and to any inputs and any output, as desired. The terminal block for wiring is clearly marked.

CAUTION!

Remove all power (AC and battery) before making any connections. Failure to do so might result in personal injury and/or equipment damage.

NOTICE!

Do not use a screwdriver on the terminals. Use a ballpoint pen instead to avoid permanent damage to the terminals.

R Y |

G B |

1 COM 2 COM 3 COM 4 COM NO |

C |

PWR A |

B COM |

||

R Y |

G B |

1 COM 2 COM 3 COM 4 COM NO |

C |

PWR A |

B COM |

Figure 3.1: Keypad back (with mounting plate removed)

NOTICE!

Use the strip gauge on the mounting plate to strip the wires to 7 mm. Only one (1) wire per terminal.

Place the keypad on a smooth surface when wiring.

To insert wires into the terminals, use a ballpoint pen to press the button on the terminal release, and with the other hand, push the wire into the terminal. (Refer to Figure 3.2.) When you remove the pen, the terminal release locks in the wire. To remove wires, press the terminal release, push the wire gently, and then pull the wire out.

Figure 3.2: Inserting wire into the terminals

3.1 | Wire to the control panel

When you wire the keypad to a control panel, use the control panel terminals labeled R, Y, G, B (PWR, A, B, COM). Connect them to the keypad terminals labeled R, Y, G, B (PWR, A, B, COM).

Refer to Figure 3.3.

You can connect keypads to the SDI2 data bus by parallel wire run from the control panel to each keypad, wire from keypad to keypad, or a combination of the two techniques. Refer to Figure 3.4.

R |

Y |

G |

B |

Open |

3.7 - 5.0 VDC |

|

|

|

|

|

|

||

|

|

|

|

Normal |

2.0 - 3.0 VDC |

|

|

|

|

|

Short |

0.0 - 13 VDC |

|

AUX |

|

|

1 k End of Line Resistors |

1 |

||

|

|

1 COM 2 |

3 COM 4 5 COM 6 |

|||

- 12 V + |

|

|

|

|||

COM AUX |

R |

Y |

G |

B |

1 |

COM |

2 |

3 |

COM |

|

3 |

|

|

|

PWR A |

B COM |

|

|

|

|

|

|

|

|

|||

2 |

R Y G B |

|

|

|

R |

Y |

G |

B |

|

|

|||

|

|

|

|

|

|

|

1 COM 2 COM 3 COM 4 COM NO |

C |

|||||

|

|

|

|

|

|

|

PWR A |

B COM |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

Y |

G |

B |

1 COM 2 COM 3 COM 4 COM NO |

C |

|

|

|

|

|

|

|

|

PWR A |

B COM |

||||

Figure 3.3: Wiring the keypad to the SDI2 bus connection (B5512 shown)

Callout ― Description

1 ― Control panel

2 ― Terminal wiring

3 ― Keypad’s wiring terminal block

R |

Y |

G |

B |

Open |

3.7 - 5.0 VDC |

|

|

|

|

||

|

|

|

|

Normal |

2.0 - 3.0 VDC |

|

|

|

|

Short |

0.0 - 13 VDC |

AUX |

|

|

1 k End of Line Resistors |

||

|

|

1 COM 2 |

3 COM 4 5 COM 6 |

||

- 12 V + |

|

|

|||

COM AUX R Y |

G B 1 COM 2 3 COM |

PWR A |

B COM |

R Y G B |

|

|

|

R |

Y |

G B |

1 COM 2 COM 3 COM 4 COM NO C |

PWR A |

B COM |

||

R |

Y |

G B |

1 COM 2 COM 3 COM 4 COM NO C |

PWR A |

B COM |

||

R |

|

|

|

Y |

|

|

|

G |

|

|

|

B |

|

|

|

R Y |

G B |

1 COM 2 COM 3 COM 4 COM NO |

C |

PWR A |

B COM |

||

R Y |

G B |

1 COM 2 COM 3 COM 4 COM NO |

C |

PWR A |

B COM |

Figure 3.4: Installing multiple keypads using the SDI2 terminals (B5512 shown)

3.2 | Wire the inputs

Wire resistance on each sensor input must be less than

100 Ω with the detection devices connected. The terminal block supports 18 to 22 AWG (1.02 to 0.65 mm) wires.

The keypad detects open, short, normal, and ground fault circuit conditions on its sensor loops and transmits the conditions to the control panel. Each sensor loop is assigned a point number and transmits to the control panel individually. Run wires away from the premises telephone and AC wiring.

R Y |

G B |

1 COM 2 COM 3 COM 4 COM NO |

C |

PWR A |

B COM |

Figure 3.5: Installing sensor loop wiring

Callout ― Description

1 ― Keypad terminal strip

2 ― Keypad sensor loops

3 ― 1 kΩ EOL resistor (ICP-1K22AWG-10)

3.3 | Wire the output

The keypad provides one NO (normally open) output. (It includes NO and C (COMMON) terminals.) When the output is in an active (energized) state, the NO has continuity with the C terminal.

NOTICE!

Do not exceed relay contact ratings of 1.0 A, 24 VDC, resistive load.

3.4 | Mount the keypad

After wiring the keypad, mount the keypad onto the mounting plate by seating the mounting hook openings over the mounting hooks and then sliding the keypad down.

4 | Set the address

Use the steps below to set the address for the keypad. If multiple SDI2 keypads reside on the same system, each SDI2 keypad must have a unique address. For single-digit addresses 1 through 9, set the tens switch to 0.

Figure 4.1 shows the address switch setting for address 1.

NOTICE!

Only use your finger or a stylus intended for touch screens to operate the keypad.

Setting the keypad address:

1.When you apply power to the keypad, the start up screen shows. You can also show the startup screen by pressing and holding the Time/ Date in the ribbon bar for 5 seconds, or by pressing and holding anywhere on the Call for Service screen. Press screen hold the countdown icon for 5 seconds. The keypad addressing page shows.

2.To set the address, use the up and down arrows on the right of the switches image to change the ones digit, and the arrows on the left to change the tens digit.

3.Press the (Escape) icon to save the setting and return to the power up screen.

Figure 4.1: Keypad addressing page

5 | Status indicators

You can diagnose and troubleshoot the system using the keypad’s status indicators. Refer to Table 5.1.

Status |

Function |

indicator |

|

|

Ready to turn on (arm) |

|

|

|

Turned on (armed) |

|

|

|

System trouble |

|

|

GAS |

Gas alarm |

|

|

|

AC power present |

|

|

Table 5.1: Keypad status indicators

Loading...

Loading...