Siemens SC6002XL, SC6802XL Service Manual

s

SC 6002XL Patient Monitor

Field Service Manual

EM Guidelines, 1997-04-02

E331.E551U.719.01.01.02

Replaces/Ersetzt:

ASK-T941-04-7600

ADVISORY

Siemens is liable for the safety of its equipment only if maintenance, repair, and modifications are performed by authorized personnel, and if components affecting the equipment's safety are replaced with Siemens spare parts.

Any modification or repair not done by Siemens personnel must be documented. Such documentation must:

•be signed and dated

•contain the name of the company performing the work

•describe the changes made

•describe any equipment performance changes.

It is the responsibility of the user to contact Siemens to determine warranty status and/or liabilities if other than an authorized Siemens Service Representative repairs or makes modifications to medical devices.

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

1.1 |

Service Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

1.2 |

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

1.3 |

Technical Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

2 |

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

2.1 |

Monitored Patient Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

2.2 |

SC 6002XL Monitor Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

2.3 |

TFT-LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

2.4 |

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

2.5 |

Monitor/Software Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

3 |

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

|

3.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

3.2 |

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

4 |

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

4.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

Table 1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

4.2 |

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

Table 1-2 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

4.3 |

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

|

Table 1-3 Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

4.4 |

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

|

Table 1-4 Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

4.5 |

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

Table 1-5 Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

5 |

Monitor Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

5.1 |

Main Screen Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

5.2 |

Menu Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

5.3 |

Alarm Limits Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

5.4 |

Alarm Silence Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

5.5 |

All Alarms Off Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

5.6 |

NBP Start/Stop Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

5.7 |

Zoom Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

5.8 |

Record Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

i |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

Chapter 2: Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

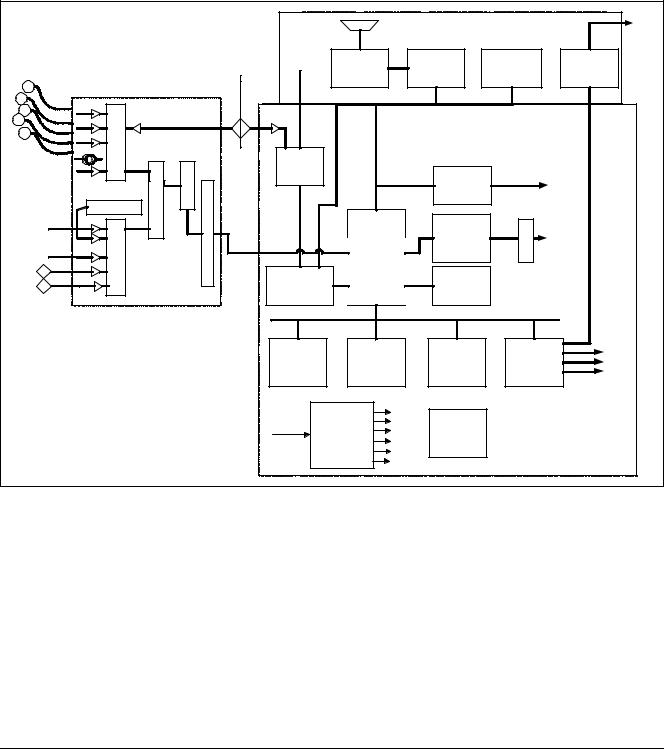

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2-1 SC6002XL Patient Monitor Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Parameter Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Main PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 LCD Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Network Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Front Panel Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Pod Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Battery Control and ON/OFF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 BOOT Process, Flash Memory, and DRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 68HC11 Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

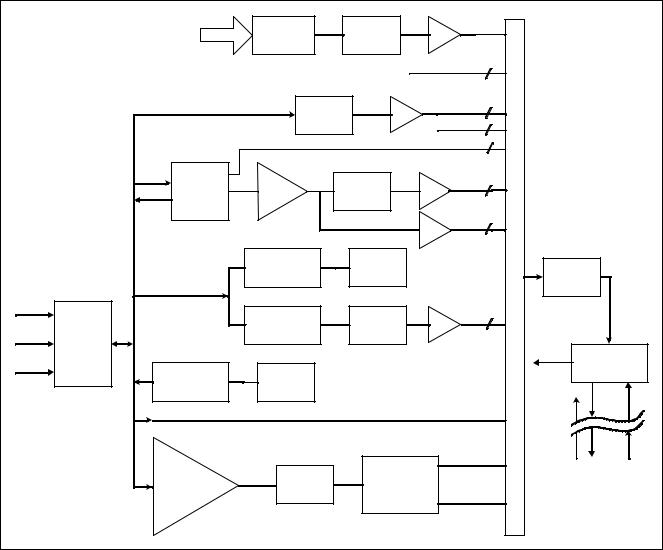

4 Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 NIBP Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-2 Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Physiological Parameter Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

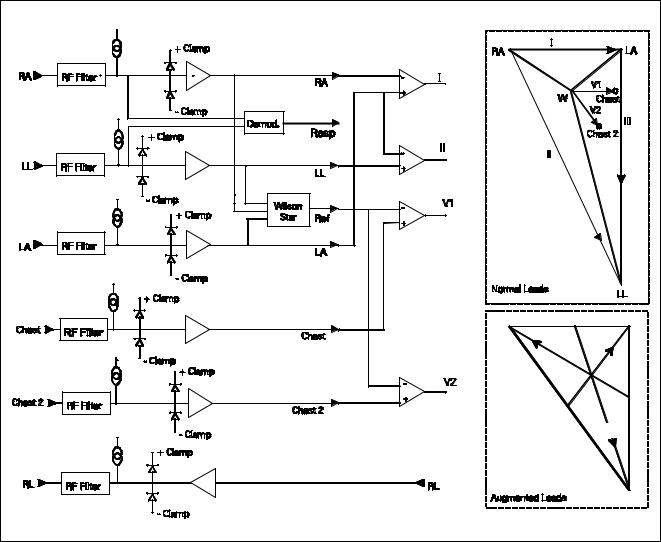

5.1 ECG/Resp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 2-1 Parameter Sampling Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.1 ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 2-3 Lead-Forming Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.2 Lead Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.3 Lead-Off Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.4 Low-Pass Filtering and Common Mode Enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Respiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

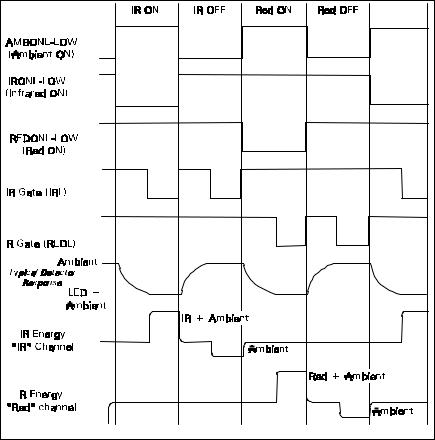

Figure 2-4 SpO2 Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 SpO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.1 SpO2 Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-5 Sensor LED Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.2 Input Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.3 Brightness Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.4 Ambient Light Rejection Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

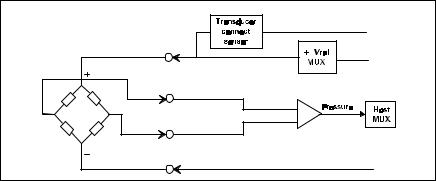

Figure 2-6 IBP Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

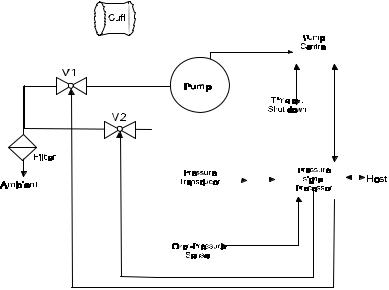

5.5 Non-Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.5.1 NBP Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2-7 NBP Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

ii |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

5.5.2 NBP System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 5.5.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 5.5.4 NBP Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 5.5.5 Valve Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 5.5.6 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 5.5.7 Power Supply Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 5.5.8 Safety Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 5.5.9 Pressure Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

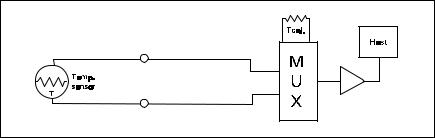

Figure 2-8 Temperature Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 5.6 Temperature Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 5.6.1 Reference Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 5.6.2 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Figure 2-9 etCO2 Sensing Process Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 6 etCO2 Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Figure 2-10 Power System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 6.1 Power Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 6.1.1 Main Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 6.1.2 AC Power Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3: Subassembly Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|||

1 |

Introduction |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

2 |

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

||

3 |

Service Policy and Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

||

4 |

Non-Invasive Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

||

|

4.1 |

Replacing Rotary Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

4.2 |

Replacing Foot Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

5 |

Accessing Replaceable Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

||

|

Figure 3-1 |

Right Side Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

5.1 |

Removing Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

|

5.1.1 |

Removing Right-Hand Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

Figure 3-2 |

Removing Left Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

|

|

5.1.2 |

Removing Left Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

|

5.1.3 |

Reinstalling Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Figure 3-3 |

Bezel Retaining Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

5.2 |

Front Bezel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

Figure 3-4 |

Front Bezel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

5.3 |

Replacing Optical Encoder Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

Figure 3-5 |

Optical Encoder Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

|

|

||

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

iii |

||

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

|

Field Service Manual |

|

SC 6002XL Patient Monitor |

|

|

|

|

|

|

5.4 |

Front Bezel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 30 |

||

|

Figure 3-6 |

TFT-LCD Display Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 30 |

|

5.5 |

Removing/Installing TFT-LCD Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 30 |

||

|

|

5.5.1 |

Removing TFT-LCD Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 30 |

|

|

5.5.2 |

Installing TFT-LCD Display Subassembly . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 31 |

|

Figure 3-7 |

Speaker Subasssembly Connector . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 31 |

|

5.6 |

Speaker Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 31 |

||

|

Figure 3-8 |

TFT-LCD Display Subassembly (Back View). . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 32 |

|

5.7 |

Front Panel PC Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 32 |

||

5.8 |

Inverter Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 32 |

||

|

Figure 3-9 |

Backlight Retaining Tabs Location . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 33 |

|

5.9 |

TFT-LCD Display Backlight Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 33 |

||

|

5.10PodPort PC Board Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 33 |

||

|

|

5.10.1 Removing PodPort PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 33 |

|

|

Figure 3-10 Removing PodPort PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 34 |

||

|

|

5.10.2 Installing PodPort PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 34 |

|

|

Figure 3-11 Removing Intermediate Subassembly . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 35 |

||

|

5.11Replacing Intermediate Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 35 |

||

|

|

5.11.1 |

Removing Intermediate Subssembly . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 35 |

|

|

5.11.2 |

Installing Intermediate Subssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 35 |

|

5.12Replacing Main Processor Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 36 |

||

|

|

5.12.1 Removing Main Processor Subassembly . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 36 |

|

|

Figure 3-12 Securing Screw Access Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 36 |

||

|

Figure 3-13 Accessing Main Processor Subassembly . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 36 |

||

|

Figure 3-14 Connector Locations on Main Processor Subassembly . . . . . . . . . |

. . . . . . . . . . . . . . . . 37 |

||

|

|

5.12.2 Installing Main Processor Subassembly . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 37 |

|

|

5.13Monitor Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 38 |

||

|

|

5.13.1 |

Removing Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 38 |

|

Figure 3-15 Removing Handle retaining Plate . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 39 |

||

|

|

5.13.2 |

Installing Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 39 |

|

Figure 3-16 Location of NBP Subassembly in Rear Housing . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 40 |

||

|

5.14Replacing NBP Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 40 |

||

|

|

5.14.1 |

Removing NBP Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 40 |

|

|

5.14.2 |

Installing NBP Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 40 |

|

5.15Replacing NBP Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 41 |

||

|

Figure 3-17 NBP Air Intake Filter Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 41 |

||

|

|

5.15.1 Replacing Air Intake Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 41 |

|

|

Figure 3-18 NBP Manifold Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 42 |

||

|

|

|

||

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

iv |

||

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

5.15.2 Replacing Manifold Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 5.16Replacing Battery Connector Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Figure 3-19 Battery Connector Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Figure 3-20 Battery Connector Subassembly Access Inside Rear Housing . . . . . . . . . . . . . . . . . . . . 43 5.17Correcting Hardware Revision Number Stored in Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 5.17.1 Windows 3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 5.17.2 Windows 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 5.17.3 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Figure 3-21 Support Menu (Item numbers may differ in different versions of installed software.) . . 45

Chapter 4: Functional Verification and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1 Functional Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 1.1 Power Circuits and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 1.2 Optical Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 1.3 TFT-LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 1.4 Fixed Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 1.5 ECG/RESP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 1.6 Asystole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 1.7 SpO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 1.8 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1.8.1 Functional Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 1.8.2 Temperature Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Table 4-1 Resistance Value vs. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 1.9 etCO2 (if installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Figure 4-1 Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.10Non-Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 1.10.1 System Setup and Pneumatics Leakage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 1.10.2 Functional and Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 Figure 4-2 IBP Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 1.11Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 2 Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Table 4-2 Leakage Current Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Figure 4-3 Block Diagram: Earth Leakage Current (AC/DC Power Adapter) . . . . . . . . . . . . . . . . . . . 56 Figure 4-4 Block Diagram: Earth Leakage Current (CPS/Docking Station) . . . . . . . . . . . . . . . . . . . . 56 Figure 4-5 Block Diagram: Earth Leakage Current (Infinity Docking Station) . . . . . . . . . . . . . . . . . . 56

3 Calibrating NBP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 Table 4-3 NBP Calibration Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

v |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

3.2 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Figure 4-6 Calibration Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 3.3 Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Figure 4-7 NBP Characterization Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 3.3.1 Characterization Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 3.3.2 Windows 3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 3.3.3 Windows 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 3.3.4 Complete Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Figure 4-8 Support Menu (Item numbers may differ between versions of installed software.) . . . . 61

Chapter 5: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

||

1.1 |

Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

|

|

1.1.1 |

No Response When POWER ON/OFF Key Pressed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

|

Table 5-1 Power-On Problems |

63 |

|

|

1.1.2 |

Power On/Off Piezo Tone Fails to Sound. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

Table 5-2 Power-off Alarm Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

|

1.1.3 |

Power-Up Sequence Fails to Complete Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

Table 5-3 Power-up Process Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

1.2 |

Optical Encoder Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 |

||

|

Table 5-4 Rotary Knob Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

1.3 |

TFT-LCD Display Malfunction.Fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

|

Table 5-5 LCD Display Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

65 |

|

1.4 |

Fixed Key Fails to Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

|

Table 5-6 Fixed Key Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

1.5 |

Visual or Audible Alarm Reporting Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

|

Table 5-7 Alarm Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

1.6 |

NBP Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

|

|

Table 5-8 NBP Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

|

1.7 |

etCO2 Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 |

||

|

Table 5-9 etCO2 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

|

1.8 |

No Printout from Recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 |

||

|

Table 5-10Recorder Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

|

1.9 |

Isolating Cable Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

1.10Patient-Related Data Not Retained or Monitor Fails to Compute Trends . . . . . . . . . . . . . . . . . . . . . |

69 |

||

Appendix A: Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Table A-1 SC 6000XL - Replaceable Parts and Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

|

Figure A-1 SC 6002XL Exploded View |

73 |

|

|

|

|

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

vi |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

Figure A-2 NBP Subassembly (shown with filters exposed) . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 73 |

Appendix B: Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 75 |

Figure B-1 IBP Connector (see Table B-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 75 |

Figure B-2 MultiMed Pod Connector (see Table B-2) . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 75 |

Table B-1 IBP Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 75 |

Table B-2 MultiMed Pod Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 75 |

Figure B-3 Docking Station Connector (see Table B-3) . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 76 |

Figure B-4 SHP ACC CBL ALARM UNTERM 5M (see Table B-4) . . . . . . . . . . |

. . . . . . . . . . . . . . . . 76 |

Table B-3 Docking Station Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 76 |

Table B-4 Remote Alarm Cable Color Code . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 76 |

Figure B-5 Interface Plate Connector (see Table B-5) . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 77 |

Figure B-6 SHP ACC CBL Y RECORDER/ALARM (see Table B-6) . . . . . . . . . . |

. . . . . . . . . . . . . . . . 77 |

Table B-5 Interface Plate Connectors Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 77 |

Table B-6 Remote Alarm Cable Color Code . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 77 |

Figure B-7 Basic/Device CPS Connectors - Infinity Network (see Table B-7) . . |

. . . . . . . . . . . . . . . . 78 |

Table B-7 InfinityNet CPS Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 78 |

Figure B-8 Infinity Docking Station Connectors(Refer to Table B-8.) . . . . . . . . |

. . . . . . . . . . . . . . . . 79 |

Table B-8 Infinity Docking Station Connectors . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 79 |

Figure B-9 PodPort Connector (see Table B-9) . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 80 |

Table B-9 PodPort Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . 80 |

Appendix C: Error and Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 1.1 Startup Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 1.2 Diagnostic Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 Table C-1 Support Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 1.3 Severity Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

1.4 Reset Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 2 Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Table C-2 Startup Diagnostic Log Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Table C-3 Exception Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Table C-4 Hardware-related Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Table C-5 Intertask Mail Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 Table C-6 Miscellaneous Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 Table C-7 Alternative Memory Manager to PSOS OSL Messages . . . . . . . . . . . . . . . . . . . . . . . . . 86 Table C-8 NP Subsystem Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Table C-9 Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 Table C-10INTER Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 Table C-11Print Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

vii |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

Table C-12MAIN Processor Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table C-13ACT Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table C-14Audio Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table C-15Database Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table C-16Front End Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table C-17Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table C-18Monitoring Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table C-19SpO2 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table C-20HCOM Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table C-21LCOM Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table C-22NET Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table C-23etCO2 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix D: Functional Verification Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

105 |

Appendix E: Supplemental Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

Software Installation Instructions - Software Version VE0 . . . . . . . . . . . . . |

109 |

Service Setup Instructions - Software Version VE0 . . . . . . . . . . . . . . . . . . . |

110 |

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

viii |

6k2XLSMftcvr.cd-rom.fm/06-00/kaupp

Chapter 1: Introduction

1 Introduction

1.1 Service Strategy

1.2 Replaceable Parts

1.3Technical Manual Conventions

In keeping with the service strategy for the SC6002XL, this service manual provides the necessary information required to service an SC 6002XL patient monitor in the field. The SC 6002XL is both a stationary and a portable monitor designed to monitor patient vital signs (refer to user’s guide for monitoring options). For stationary operation near a bedside, the monitor is connected to an AC/DC power adapter or placed on a specially designed docking station attached to a shelf, wall, or rolling stand that securely locks it into place. While on the docking station, the monitor is powered by a CPS or an IDS power supply. When the monitor is detached from a CPS or IDS, it is powered by a lead acid battery or by an optional Lithium ion battery. The monitor is reattached to the AC/DC Power Adapter or placed back on a CPS or IDS to recharge the battery.

The monitor has been designed for high reliability, with an estimated MTBF of 50,000 hours (5.7 yrs.) of continuous operation.

Therefore, the service strategy is based on few failures in the field, a clear definition of failure analysis by field service personnel, and a quick repair turnaround. The field repair philosophy is based on the distributed and approved spare parts list. Refer to Appendix A: Replaceable Parts.

This manual is intended to serve as a source of technical information, for qualified field service personnel to use in servicing SC6002XL patient monitor in accordance with the Siemens Service Strategy. Field service is expected to be successful “First-Time Every Time.”

SC 6002XL monitors have several replaceable subassemblies, each of which also has replaceable subassemblies and/or components.

•Front Bezel Subassembly

•Front Panel PC Board

•TFT-LCD Display Subassembly,

•Main Processor Subassembly,

•NBP Subassembly, and

•Rear Housing Subassembly with integrated serial number chip.

Individual “consumable” replaceable parts include the battery, fluorescent backlight, and NBP filters. A complete listing of spare parts is included in Appendix A: Replaceable Parts of this manual. Replacement of components other than those listed in Appendix A should be performed only at Siemens service depots in Danvers, MA, U.S.A. or in Solna, Sweden, where specialized repair and testing equipment can assure product reliability.

The following conventions are employed in this manual:

A NOTE calls attention to items of special interest or provides additional related information about a specific topic:

Note: Attempting to repair any PC board to the component level may void any warranty, either express or implied.

A Caution indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate property damage. It may also alert against unsafe practices.

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

1 |

6k2XLSMC1.cd-rom.fm/06-00/kaupp

SC 6002XL Patient Monitor |

Field Service Manual |

|

|

Caution |

3 |

|

Printed circuit boards in these monitors contain components that are easily damaged by static electricity. Open monitors only in a static-protected environment. Observe proper procedures to prevent damage to the equipment resulting from static discharge.

A Warning indicates a potentially hazardous situation which, if not avoided, may result in death or serious injury.

2 Product Overview

Warning

Do not operate this product in the presence of flammable gasses or liquids. If this device is operated where flammable anesthetics, skin cleansers, or disinfectants are used, the possibility of an explosion cannot be excluded. This product must be operated only in strict conformance with local fire prevention regulations.

SC 6002XL Patient Monitors are light-weight, battery-equipped, hand-held or semi-permanently mounted devices for general purpose monitoring of a preconfigured set of physiological parameters. When not connected to a hospital’s main ac power, they use a battery with approximately 1¼ hours (3 hrs. for Li option battery) of operating time. A power adapter, CPS/ docking station combination, or IDS, which also charges the battery, can be used to operate the monitor from the hospital’s main ac power circuit.

2.1Monitored Patient Parameters

The SC6002XL monitors the following physiological parameters:

• ECG (three-lead, five-lead, or six-lead pod)

•Respiration

•Pulse Oximetry (SpO2 and PR)

•Temperature

•NBP

•IBP1, IBP2 (locked option)

•etCO2 via PodComm Port (locked option)

•Arrythmia

•OCRG (locked option)

•Dual Lead S-T Segment Analysis (locked option, ≥ VF0 SW required)

2.2SC 6002XL Monitor All functions are controlled by a 16-position rotary knob and nine front

Controls |

panel fixed keys - Alarm Silence, Record, Alarm Limits, NBP Start/Stop, All |

|

Alarms Off, Zoom, Main Screen, Menu, and ON/OFF. Turning the rotary |

|

knob locates different menu items, and pressing the knob in selects the |

|

item. Depending on the item selected, pressing the knob in may either |

|

bring up another menu or initiate an action. See Section 5. For detailed |

|

operating instructions, consult the SC 6002XL Patient Monitor User Guide |

|

applicable to the installed software. |

2.3 TFT-LCD Display

The SC 6002XL monitor has a 6.5 inch (16.5cm), 3-channel color TFT-LCD display. Waveforms display in Erase Bar mode at 25 ±20% mm/s (except for respiration and etCO2 waveforms which display at 6.25 ±20% mm/s). All displays for a given parameter (label, unit of measure, and waveform) are in the same color. If a waveform is not displayed for a parameter, its label is gray.

2 |

Siemens Medical Systems, EM-PCS, Danvers |

ASK-T941-04-7600 |

6k2XLSMC1.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

|

|

2.4 |

Alarms |

Alarm limits can be set either on a user-definable setup table, or |

|

|

automatically based on current parameter values. Three alarm grades, |

|

|

each with a distinct alarm tone, announce alarm situations of varying |

|

|

severity: |

|

|

• life-threatening (asystole or ventricular fibrillation - red) |

|

|

• serious (parameter limit alarms - yellow) |

|

|

• advisory (technical alarms - white) |

|

|

The message field background and parameter field of the parameter in |

|

|

alarm are displayed in the color associated with the alarm grade as given |

|

|

above. |

2.5 |

Monitor/Software |

Each monitor has a unique ID chip installed in its rear housing for diagnostic |

|

Tracking |

and tracking purposes, and un/locking optional software features. |

3Preventative Maintenance

3.1 |

General |

SC 6002XL monitors require replacement of the lead-acid battery (12 months), |

||

|

|

NBP air intake filter (24 months) and fluorescent bulb (45K - 50K hours). |

|

|

|

|

Siemens recommends that a full functional verification be performed |

|

|

|

|

annually. See Chapter 4: Functional Verification and Calibration. Also, some |

||

|

|

national jurisdictions require that a temperature calibration (see Section |

|

|

|

|

1.8.2 in Chapter 4) and an NBP calibration be performed at least every two |

||

|

|

years. Refer to Section 3, Calibrating NBP System in Chapter 4 for the NBP |

||

|

|

calibration procedure. |

|

|

|

|

|

Note: Replace the internal manifold filter on the NBP subassembly |

|

|

|

|

only if the NBP subassembly should fail characterization. |

|

3.2 |

Battery |

To obtain maximum life from a new lead-acid battery, install the battery |

|

|

|

|

into the monitor and run the monitor on battery power for a period of 15 |

|

|

|

|

minutes. After the 15 minute period, either plug in the monitor’s power |

|

|

|

|

adapter or lock the monitor onto a powered docking station and charge the |

||

|

|

battery, or remove the battery from the monitor and connect the battery to |

||

|

|

an external charger. (This initial sequence is not needed for Li batteries.) |

|

|

|

|

When in storage or not in use for an extended period of time, lead-acid |

|

|

|

|

batteries self-discharge and develop a “float-charge” as a characteristic of |

|

|

|

|

the self-discharge process. The “float charge” must be drained off before |

|

|

|

|

the battery can be properly charged. If a new battery is immediately placed |

||

|

|

on a charger, the “float charge” provides an incorrect indication of the |

|

|

|

|

battery’s charge condition, and the charger may not fully charge the battery. |

||

|

|

Between discharges, the lead-acid battery must be recharged as soon as |

||

|

|

possible. Once charged, it can be stored for ª 4 months without recharging. |

||

|

|

Siemens recommends that the battery charge be maintained at >80% to |

||

|

|

maximize the battery’s capacity and cycle life. Starting at a 100% charge |

||

|

|

level, at room temperature the battery will self-discharge below the |

|

|

|

|

acceptable minimum in about 6 months on a shelf and in about 2 months |

||

|

|

in an unpowered spare monitor. |

|

|

|

|

|

|

|

|

|

|

Warning |

|

|

|

|

Dispose of used batteries in accordance with local regulations |

|

|

|

|

governing disposal of hazardous materials. |

|

|

|

|

|

|

|

|

|

|

|

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

3 |

||

6k2XLSMC1.cd-rom.fm/06-00/kaupp

SC 6002XL Patient Monitor |

Field Service Manual |

|

|

4 Technical Data

Technical Data included in this Section is as of publication date of this Manual. Changes are reported in User Guide applicable to installed SW.

4.1 General

Table 1-1 General Specifications

Parameter |

Specification |

|

|

Power Requirements |

100-250 VAC through AC power adapter |

|

|

Mains Frequency |

50/60 Hz |

|

|

AC Power Consumption |

60 VA AC |

|

|

Battery Type |

Lead-acid: PANASONIC LC-T121R8PU or equivalent |

|

Lithium-ion: Siemens Li+ Battery Pack |

|

|

DC Input |

11 - 14 V; 32 W continuous, 49 W peak |

|

|

Battery Operating Time (means |

Lead-acid: 75 mins |

running with NBP measurement |

Lithium-ion: 180 mins |

every 15 min @ 25°C temperature, |

|

no etCO2 running |

|

Battery Recharging Time |

Lead-acid: 5 ½ hours, typical |

|

Lithium-ion: 8 hours, typical |

|

|

Battery Charge/Discharge/Charge: |

Lithium-ion only (operating as defined above): 2 hours, charging for 2 |

|

hours, operating 2 hours |

|

|

Patient Leakage Current |

< 10 µA @ 110 V and 60 Hz (per UL 544) |

|

< 10 µA @ 220 V and 50 Hz (per IEC 601-1) |

|

|

Chassis Leakage Current with |

< 100 µA @ 110 V and 60 Hz (per UL 544) |

battery eliminator |

< 500 µA @ 220 V and 50 Hz (per IEC 601-1) |

|

|

4.2 Environmental

Table 1-2 Environmental Specifications

|

Parameter |

|

Environmental Specification |

|

|

|

|

|

|

|

|

|

Cooling Method |

|

Convection and cooling chimney (no fan) |

|

|

|

|

|

|

|

|

|

Temperature: |

|

|

|

|

|

Operating |

|

0°C to +40°C (without recorder) |

|

|

|

Storage |

|

-20°C to +50°C |

|

|

|

|

|

|

|

|

|

Relative Humidity: |

|

|

|

|

|

Operating |

|

>30% and <95%, non-condensing |

|

|

|

Storage |

|

>10% and <95% non-condensing |

|

|

|

|

|

|

|

|

|

Altitude: |

|

|

|

|

|

Operating |

|

-381 to +3048 m (-1250 to 10,000 ft.) |

|

|

|

|

|

525 to 795 mmHg (70.0 to 106 kPa) |

|

|

|

Storage |

|

-381 to 5486 m (-1250 to 18,000 ft.) |

|

|

|

|

|

375 to 795 mmHg (50.0 to 106 kPa) |

|

|

|

|

|

|

|

|

|

Water Resistance |

|

Drip-Proof |

|

|

|

|

|

|

|

|

|

Dimensions (H x W x D): |

|

196 x 223 x 134 mm (7.7 x 8.8 x 5.3 in) (w/ rotary knob) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Siemens Medical Systems, EM-PCS, Danvers |

ASK-T941-04-7600 |

|

||

6k2XLSMC1.cd-rom.fm/06-00/kaupp

|

|

Field Service Manual |

|

SC 6002XL Patient Monitor |

|

||

|

|

|

|

|

|

||

|

|

Table 1-2 Environmental Specifications (Continued) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Parameter |

|

Environmental Specification |

|

|

|

|

|

|

|

|

|

|

|

|

Weight: |

|

|

|

|

|

|

|

|

SC 6002XL (w/o etCO2) |

|

3.42 kg (7.54 lb) w/ lead-acid battery |

|

|

|

|

|

|

|

3.22 kg (7.10 lb) w/ lithium-ion battery |

|

|

|

|

|

|

|

2.87 kg (6.32 lb)) w/o battery |

|

|

|

|

|

Battery |

|

Lead-acid: 0.55 kg (1.22 lb) |

|

|

|

|

|

|

|

Lithium-ion: 0.35 kg (0.78 lb) |

|

|

|

|

|

|

|

|

|

|

|

|

Finish: |

|

Front: white |

|

|

|

|

|

|

according to Siemens |

|

Rear and Handle: anthracite gray |

|

|

|

|

|

Corporate Design Guidelines |

|

Material: ABS Polycarbonate Blend (injection molded plastic) |

|

|

|

|

|

|

|

|

|

|

4.3 |

Display |

|

|

|

|

||

|

|

Table 1-3 Display Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameter |

|

Specification |

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

Color Thin Film Transistor - Liquid Crystal Display (TFT-LCD) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Size |

|

170 mm (6.7 in) diagonal |

|

|

|

|

|

|

|

|

|

|

|

|

|

Resolution |

|

640 x 480 pixels |

|

|

|

|

|

|

|

|

|

|

|

|

|

Active Viewing Area |

|

132.5 x 99.4 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pixel pitch |

|

0.207 mm x 0.207 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

Sweep Speeds |

|

fixed 25 mm/s ±20% for ECG, SpO2, and IBP curves |

|

|

|

|

|

|

|

|

fixed 6.25 mm/s ±20% for Rsp and etCO2 curves |

|

|

|

|

Display Mode |

|

Erase bar (updates waveforms from left to right) |

|

|

|

|

|

|

|

|

|

|

|

4.4 |

Outputs |

|

|

|

|

||

|

|

Table 1-4 Output Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameter |

|

Specification |

|

|

|

|

|

|

|

|

|

|

|

|

QRS Synchronization: |

|

|

|

|

|

|

|

|

Timing: |

|

For heart rates from 30 to 250 [1/min], with QRS widths from 40 to 120 |

|

|

|

|

|

|

|

msec and QRS amplitudes from 0.5 to 5 mV, a sync pulse is delayed no |

|

|

|

|

|

|

|

more than 35 msec from peak of R-wave for each valid QRS complex. |

|

|

|

|

|

Output Pulse: |

|

+12 V, 100 ms duration |

|

|

|

|

|

|

|

|

|

|

|

|

Alarm Output |

|

12 V Open collector output for external alarm indicator |

|

|

|

|

|

|

|

|

|

|

|

|

|

Recorder |

|

UART interface w/ recorder through interface plate or docking station |

|

|

|

|

|

|

|

|

connector |

|

|

|

|

|

|

|

|

|

|

|

|

Debug Port |

|

UART interface w/ a PC to retrieve diagnostic information through |

|

|

|

|

|

|

|

|

interface plate or docking station connector |

|

|

|

|

|

|

|

|

|

|

|

|

External VGA |

|

Video signals sent to external VGA display for remote viewing of |

|

|

|

|

|

|

|

|

SC6002XL screen. -- not available when Infinity Serial Hub interface plate |

|

|

|

|

|

|

|

in use. |

|

|

|

|

|

|

|

|

|

|

|

|

Export Protocol |

|

UART interface w/ external devices using proprietary export protocol. -- |

|

|

|

|

|

|

|

|

not available when Infinity Serial Hub interface plate in use. |

|

|

|

|

|

|

|

|

|

|

|

|

Network |

|

Serial connection to Infinity Network through Infinity Serial Hub interface |

|

|

|

|

|

|

|

|

plate or docking station connector. |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

5 |

|

||||

6k2XLSMC1.cd-rom.fm/06-00/kaupp

SC 6002XL Patient Monitor Field Service Manual

4.5 Connectors

Table 1-5 Connector Specifications

Parameter |

Specification |

|

|

DC Input |

Siemens 2-pin power connector |

|

|

Docking Station |

Siemens 28-pin connector to provide Alarm Output, Recorder, Debug |

|

Port, Network, External VGA and Power |

|

|

Memory Card |

PCMCIA slot |

|

|

QRS Sync |

Phone jack connector |

|

|

MultiMed Pod |

16-pin shielded female input connector |

|

|

IBP |

7-pin shielded female input connector |

|

|

NBP Hose |

One-hand coupling system |

|

|

etCO2 |

7-pin shielded female PodComm connector |

Note: For patient parameter specifications, refer to User Guide applicable to installed software version.

5 Monitor Controls

5.1Main Screen Key

5.2Menu Key

The rotary knob in the lower right corner of the front panel is a pointing and selecting device. Turn the knob to select a screen area or menu item or to change a default value, and press the knob in to confirm your selection and to set a default value. Press Main Screen key to return to the MAIN screen.

Note: Instructions in this chapter are intended to provide only a cursory overview of basic monitor controls for accessing and performing service-related functions. Refer to the User Guide for the installed software version for complete operating information.

Pressing the Main Screen key exits the current menu or screen and displays the home screen.

--provides access to the Main menu. In general, functions of direct concern to the CSE or Biomed are accessed via Monitor Setup → Biomed on the Main menu. Password-protected service-related functions are to be performed by only authorized technical personnel. Use Biomed password (375) to access the following:

•Save Setups - Confirm or Cancel

•Locked Options - four locks into which monitor-specific 2-digit codes must be entered to enable locked options

•Diagnostic Logs

•Units

-Temperature - °C or °F

-Pressure - mmHg or kPa

•Service - requires Service password. (The password is given on the Service Setup Instructions for the installed software version.)

-Update Software

-Line Frquency - set the frequency equal to the ac mains line according to local conditions (50 or 60 Hz).

Note: An incorrect setting of line frequency can cause artifact or excessive waveform noise on the ECG waveform.

-Language - selection appropriate for clinical site

6 |

Siemens Medical Systems, EM-PCS, Danvers |

ASK-T941-04-7600 |

6k2XLSMC1.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

5.3Alarm Limits Key

5.4Alarm Silence Key

5.5All Alarms Off Key

5.6NBP Start/Stop Key

5.7Zoom Key

5.8Record Key

-Test Pulse - Confirm or Cancel, one-shot test pulses for ECG (1mV spike) and Temp (–5°C and +50°C, respectively). An

additional test is performed for IBP, Resp Pulse, and SpO2. Test indication is reported in the trend table.)

•Exit

--calls up a setup table for alarms.

1)Turn rotary knob to select desired parameter field and limits, and press knob in to activate your selection.

2)The number representing the limit value turns black on a blue background, indicating that you can change it. Turn knob to change value.

3)When desired setting is displayed, press knob in to set value.

4)Press MAIN Screen key to return to MAIN screen.

--silences an active alarm tone for 1 minute ±5 seconds, and turns active blinking parameter areas into active steady parameter areas

--suspends alarms for a fixed 3-minute ±5 second period.

--starts and stops non-invasive blood pressure measurement.

--used for fast access to all parameters or NBP parameter box bottom channel screen setups, choice made from a user menu.

With an R50™ recorder connected, press the Record fixed key to start a manual, timed recording.

Note: If a recorder is not connected, pressing the Record fixed key writes 15 seconds of waveform and vital signs information to internal memory. SC 6002XL monitors can store up to five recordings, which are automatically printed as soon as the recorder is connected.

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

7 |

6k2XLSMC1.cd-rom.fm/06-00/kaupp

Field Service Manual |

SC 6002XL Patient Monitor |

|

|

This page intentionally left blank.

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

8 |

6k2XLSMC1.cd-rom.fm/06-00/kaupp

Chapter 2: Functional Description

1 Overview

SC 6002XL monitors are configured patient monitors running on one processor, an MPC821 Power PC processor, which attends to all monitoring functions, controls all graphics functions, generates video and timing signals for the LCD screen, and interfaces with the PCMCIA. It also performs several peripheral control functions, such as NIBP control, audio volume control, and timing generation for the front end. See Figure 2-1.

|

|

|

|

Front Panel |

|

To |

|

|

|

|

|

|

|

etCO2 |

|

Double |

CUFF |

Audio |

Keyboard |

LCD |

PodCom |

||

Xducer |

|||||||

|

(640 x 480) |

Option |

|||||

Meas. |

Safety |

|

|

|

|||

|

|

|

|

|

|||

ECG |

|

|

|

|

|

|

|

|

M |

NIBP |

|

|

|

|

|

|

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

NIBP |

|

|

|

|

|

Resp |

|

|

A |

|

|

|

|

|

|

|

|

|

|

Driver |

|

|

|

|

|

||

|

|

|

S |

|

|

|

Video |

|

|

|

|

|

A |

I |

|

|

|

|

RGB |

||

|

|

I |

|

|

|

DAC |

|

|||

|

|

D |

s |

|

|

|

|

|

||

|

LED Drive |

C |

|

|

|

|

|

|

||

|

C |

o |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

LCD |

|

|

|

|

||

|

|

|

|

l |

|

|

Network |

X |

|

|

SpO 2 |

|

|

|

|

Control |

|

|

|||

|

|

|

a |

|

|

F |

|

|||

M |

|

|

|

|

(HDLC/ |

Network |

||||

|

|

|

t |

|

CP |

|

CEPT) |

M |

|

|

Temp |

U |

|

|

i |

|

|

R |

|

||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||

IBP1 |

X |

|

|

o |

|

|

|

|

|

|

|

|

|

n |

µController |

Processor |

|

PCMCIA |

|

|

|

IBP2 |

|

|

|

|

|

|

||||

|

Front End |

|

(68HC11) |

(MPC821) |

|

Card |

|

|

||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

8 |

32 |

|

16 |

|

|

|

|

|

|

|

SRAM |

DRAM |

|

Flash |

Quad |

Record |

|

|

|

|

|

Memory |

Memory |

|

Memory |

Debug |

|

|

|

|

|

|

|

UART |

||||

|

|

|

|

|

(512KB) |

(4MB) |

|

(2MB) |

Export |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

+12 |

|

|

|

|

|

|

|

|

11 - 15v |

POWER |

+3.3V |

BATTERY |

|

|

|

|

|

|

|

+5V |

CHARGER |

|

|

||

|

|

|

|

|

|

CONVERSION |

|

|

||

|

|

|

|

|

|

+18 |

(Li or Pb) |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

+42 |

|

|

|

|

|

|

|

|

|

|

-5V |

|

|

Main Board |

Figure 2-1 SC6002XL Patient Monitor Block Diagram

2 Parameter Inputs

The data acquisition front end acquires and digitizes signals derived from a three-, five-, or six-electrode ECG patient lead set, a Nellcor® SpO2 transducer, an Impedance respiration measurement system, a thermistorbased Temperature transducer, and two strain-gauge IBP transducers (IBP2 = locked option). The NIBP main transducer signal is digitized together with the rest of the front end parameters. See Section 4 and Section 5 for more detailed information.

3 Main PC Board

The Main MPC821 Power PC processor not only attends to monitoring functions, but also controls all graphics functions, generates the video and timing signals for the LCD screen, interfaces with the PCMCIA, and controls the network link. In addition, it performs a host of peripheral control functions, such as NIBP control, audio volume control, and timing generation for the front end.

ASK-T941-04-7600 |

Siemens Medical Systems, EM-PCS Danvers |

9 |

6k2XLSMC2.cd-rom.fm/06-00/kaupp

SC 6002XL Patient Monitor |

Field Service Manual |

|

|

3.1LCD Control

3.2Network Interface

3.3Front Panel Circuitry

3.4Pod Interface

3.5Battery Control and ON/OFF Control

A set of buffer/drivers are used to drive the 6.5” screen. In parallel, a triple video DAC generates analog RGB signals for an external monitor (typically a CRT).

The SC 6002XL monitor interfaces with the physical interface device (e.g., CPS, IDS or IHUB) automatically when connection to the device has been detected. Connections to INFINITY network services are established and maintained by software components resident on both the SC 6002XL and the physical interface device.

The front panel circuit processes the audio information, drives the fluorescent tubes on the LCD, implements a secondary alarm in case the unit resets or turns off, and routes the video and timing signals to the screen. It also routes the UART signal coming from the Pod interface to the main board Quad UART.

The Pod Interface generates an isolated voltage to power the pod and also converts the Pod Comm protocol from the pod into a UART stream that can be interpreted by the microprocessor.