PEUGEOT E1A Workshop Manual

Réf: 755815

WORKSHOP

MANUAL

DIAGNOSTIC

SALES DIVISION

NETWORK TECHNICAL INFORMATION

CONTENTS

Page: 2

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

CHARACTERISTICS ............................................................................................................................... 4

Machine markings: ................................................................................................................................. 4

Characteristics:........................................................................................................................................ 4

Frame:..................................................................................................................................................... 4

Capacities:............................................................................................................................................... 4

Dimensions:............................................................................................................................................. 4

Weight:.................................................................................................................................................... 4

Tyres:....................................................................................................................................................... 4

Engine markings:.................................................................................................................................... 4

SERVICE AND COMMISSIONING INSTRUCTIONS.......................................................................... 5

Check:...................................................................................................................................................... 5

Change:................................................................................................................................................... 5

Check and change:.................................................................................................................................. 5

Test machine:.......................................................................................................................................... 5

Battery commissioning and maintenance procedure............................................................................... 6

Commissioning:....................................................................................................................................... 6

Charging after prolonged immobilisation ............................................................................................... 7

Procedure:............................................................................................................................................... 7

Checks before handing over to the customer:.......................................................................................... 8

SPECIAL IMPORTANT POINTS............................................................................................................ 9

TIGHTENING TORQUES AND SPECIAL TOOLS............................................................................. 10

Tightening torques: ............................................................................................................................... 10

Frame:................................................................................................................................................... 10

Engine:.................................................................................................................................................. 10

Standard:............................................................................................................................................... 10

Special tools:.......................................................................................................................................... 10

TEP USER INSTRUCTIONS.................................................................................................................. 11

Presentation: ......................................................................................................................................... 11

Functioning:.......................................................................................................................................... 11

Apparatus functions:.............................................................................................................................. 11

Instructions for use: .............................................................................................................................. 11

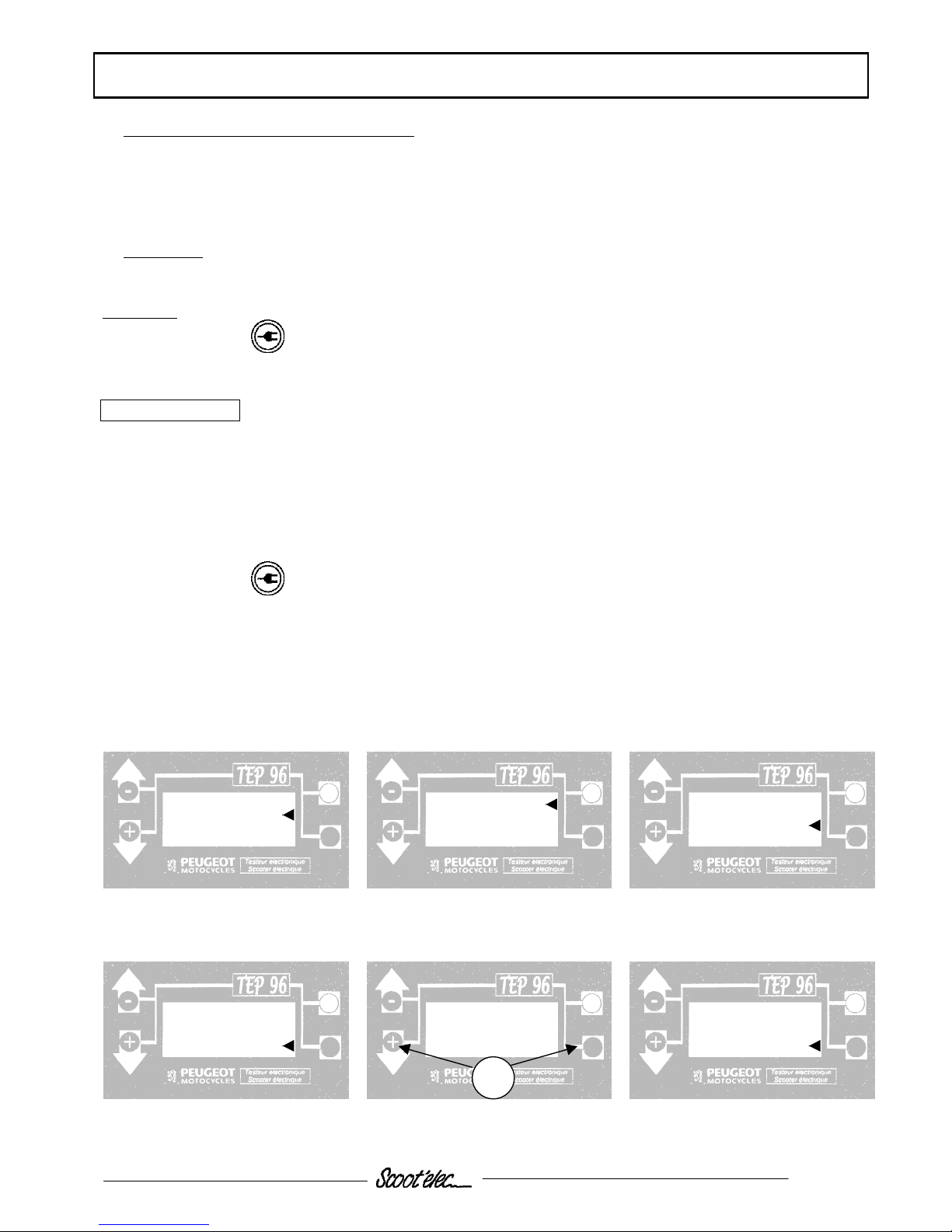

Example of checking the charge with the TEP 96: ............................................................................... 12

In case of a fault on your TEP96:......................................................................................................... 12

Precautions:........................................................................................................................................... 12

TEP96 Version 2.0 logic diagram (the TEP96 screen order) :.............................................................. 13

Faults logic diagram: ............................................................................................................................ 14

Permanent defects:.............................................................................................................................. 14

Intermittent defects:............................................................................................................................ 14

Intermittent or permanent faults:......................................................................................................... 14

Actuators logic diagram:....................................................................................................................... 15

States logic diagram:............................................................................................................................. 16

Variables logic diagram: ....................................................................................................................... 17

6Volt BATTERY CELL DISCHARGE BENCH INSTRUCTIONS FOR USE.................................... 18

Characteristics:...................................................................................................................................... 18

Presentation: ......................................................................................................................................... 18

Protection:............................................................................................................................................. 18

Instructions for use: .............................................................................................................................. 18

Battery cell discharge:........................................................................................................................... 18

Precautions:........................................................................................................................................... 18

TROUBLESHOOTING LOGIC DIAGRAM......................................................................................... 19

CONTENTS

Page: 3

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

Incident: the machine does not charge 100%:....................................................................................... 19

Incident: the machine does not charge:................................................................................................. 20

Incident: problems during the maintenance charge:............................................................................ 21

Incident: when the ignition is turned on, the machine does not start:.................................................. 23

Incident: impossible to enter immobiliser code: .................................................................................... 24

Incident: no drive from motor:.............................................................................................................. 25

Incident: motor traction fault: (motor does not run, lacks performance)............................................ 26

Incident: loss of range: ......................................................................................................................... 27

Range test:............................................................................................................................................. 28

ECU AND MOTOR DIAGNOSTIC........................................................................................................ 29

Incidents:............................................................................................................................................... 29

Causes: .................................................................................................................................................. 29

Troubleshooting:................................................................................................................................... 29

1/Fault diagnosis:................................................................................................................................ 29

2/To determine the faulty component:................................................................................................. 30

3/Checking the motor: ........................................................................................................................ 31

CHANGING THE ELECTRONIC CONTROL UNIT .......................................................................... 32

Important point: .................................................................................................................................... 32

Method for TEP 96 version 1.5. before July 1998:................................................................................ 32

Method for TEP 96 version 2.0. after July 1998:................................................................................... 32

BATTERY REPLACEMENT PROCEDURE (3 cells)........................................................................... 34

Important point: .................................................................................................................................... 34

Method for TEP 96 version 1.5. before July 1998:................................................................................ 34

Method for TEP 96 version 2.0. after July 1998:................................................................................... 34

CHARACTERISTICS

Page: 4

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

CHARACTERISTICS

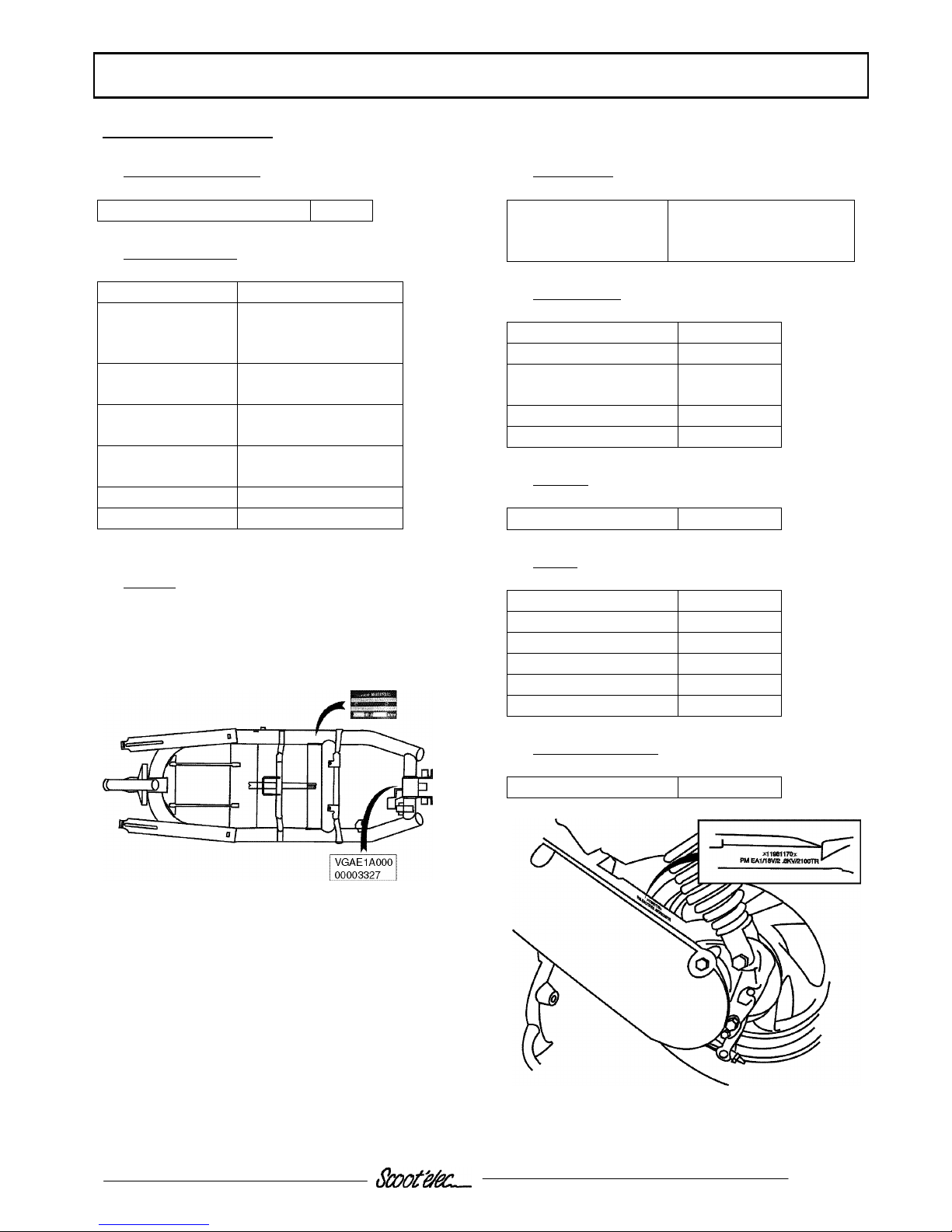

Machine markings:

Model code E1A

Characteristics:

Engine

Characteristics Direct current and

separate excitation

Energy recovery on

motor braking

Marque Leroy Somer or

Schabmüller

Max. power

output

2.8 kW

Engine speed 2100 rpm

Torque speed 2000 rpm

Frame:

1 Manufacturer’s plate

2 VIN number

Capacities:

Relay module 0.12 litres

Esso Gear oil (EZL 848)

P/N 753054

Dimensions:

Length 1755 mm

Width 695 mm

Height without rear

view mirror

1100 mm

Ground clearance 160 mm

Wheelbase 1300 mm

Weight:

Weight 115 kg

Tyres:

Front wheel 2.5"x10"

Front tyre 100/80x10

Front tyre pressure 2.5 bar

Rear wheel 2.5"x10"

Rear tyre 110/80x10

Rear tyre pressure 2.5 bar

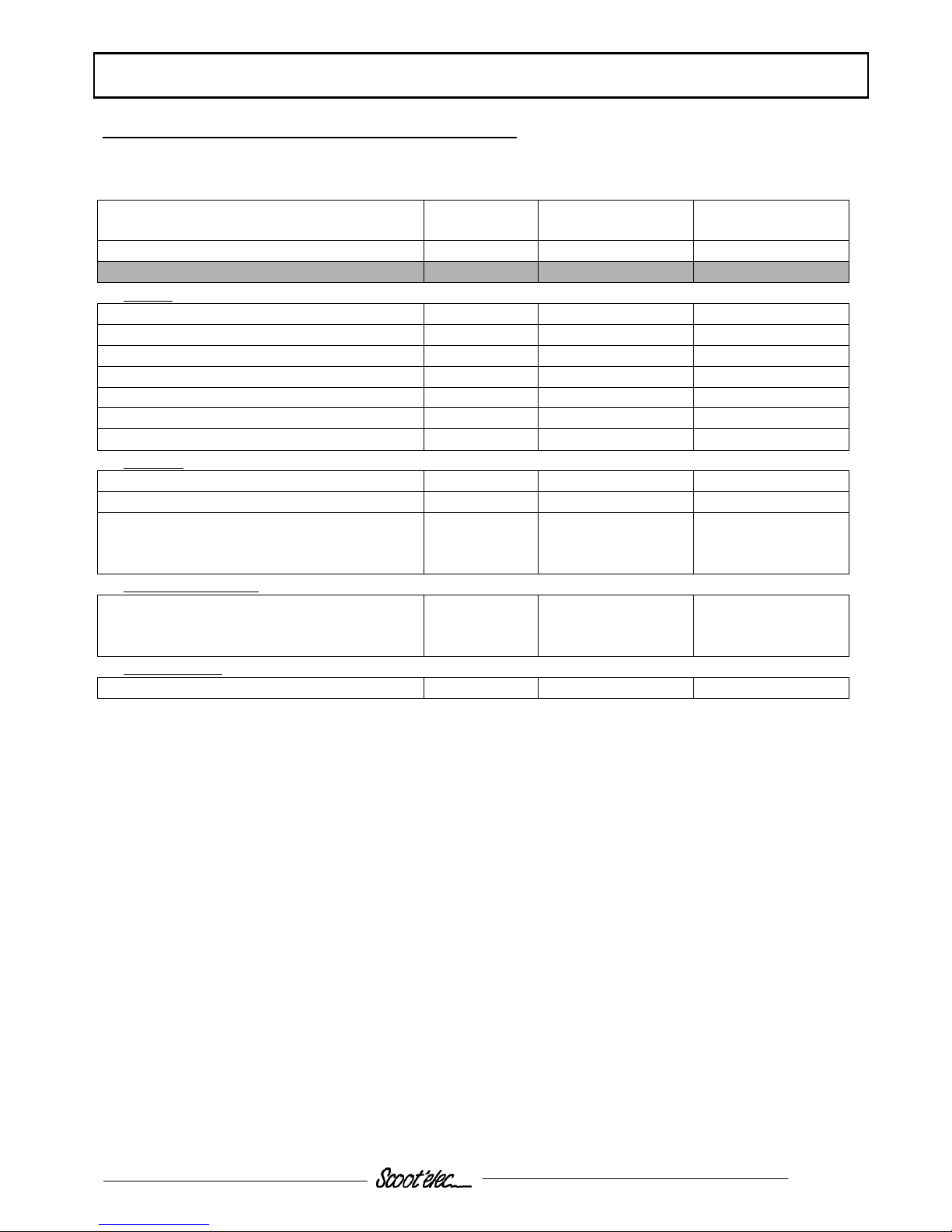

Engine markings:

Engine type EA1

SERVICE AND COMMISSIONING PLAN

Page: 5

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

SERVICE AND COMMISSIONING INSTRUCTIONS

Heavy duty servicing is aimed at machines used under “harsh” conditions: door-to-door calls, intensive

urban use (courrier service)

Servicing operations 500 Kms

or 3 months

Every 5000 Kms

or months

Every 10000 Kms

Heavy duty service 500 Kms Every 2500 Kms Every 5000 Kms

Check:

Diagnostic readout X X X

Throttle control X X X

Functioning of electrical equipment X X X

Front and rear brake control X X X

Tyre pressures X

Tyre condition, pressure and wear X X

Tightness of nuts and bolts X X X

Change:

Front and rear brake lining X

Grease cam spindle X X

Drive belt 10000 km for

heavy duty

service

Check and change:

Motor brushes #

(depending on engine manufacturer)

10000 km for

heavy duty

service

X

Test machine:

On road X X X

# if necessary

SERVICE AND COMMISSIONING PLAN

Page: 6

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

Battery commissioning and maintenance procedure

Remark: the maintenance procedure is identical to the commissioning procedure

Important:

It is essential to use distilled water supplied by PEUGEOT MOTOCYCLES under P/N: 973582

The use of distilled water from another sources will destroy the battery.

It is forbidden to pour in distilled water before the end of charging.

Commissioning:

Ensure you have 3 litres of PEUGEOT distilled water, P/N: 973582.

• Connect the charge cable to the 230 V – 10/16 A mains.

• The charge lamp comes on with a beep, the battery lamp flashes

• Press key “V” on the keypad there is a beep and hold until there is a second beep.

• Release the « V » key, a series of 3 beeps indicates the operation is to commence, the charge lamp

flashes.

• If it does not flash, repeat the operations more quickly.

The commissioning procedure has started and will take 10 to 15 minutes.

At the end of charging, the lamps stay on indicating that water may be added to the battery.

Note:

From this point on, you may leave the machine connected to the mains for a period of 72 hours. Beyond this

time, you will have to repeat the procedure from the start.

• Disconnect the charging cable, the lamps stay on. You now have a maximum of 30 minutes to

add water to the battery.

• Open the maintenance cover with a Torx screwdriver and slowly pour in the distilled water (P/N:

973582) until the water runs out of the overflow under the scooter.

• Close and tighten the maintenance cover, the lamps go off indicating the end of

commissioning.

• Wait for a minimum of 15 seconds before turning on the ignition.

SERVICE AND COMMISSIONING PLAN

Page: 7

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

Charging after prolonged immobilisation

After not being used for a few months, the battery voltage may drop below 8 volts and it is impossible to put

the machine on charge.

In this case, the battery needs to be “woken up” by one or more connections / disconnections to and from the

mains socket.

Procedure:

1. Connect the charging connector to the mains.

Important:

• The charge lamp does not come on on the instrument panel.

• No beep on the multifunction keypad.

• The fan does not run.

This is normal.

Do not turn on the scooter lights.

Do not connect the TEP96.

2. Leave the connector connected 5 minutes to the mains

3. Disconnect the connector from the mains and reconnect it immediately

Repeat operations 2 and 3 until:

• The charge lamp comes on on the instrument panel.

• The multifunction key pad sounds a beep.

• The charger fan starts.

After 5 minutes charging (for ECU, electronic control unit, Software version 4.2.4, production prior to July

97)

Connect the TEP96 to the machine

The DISCHARGE value must be between 0 and 110 Ah

If the number of discharged Ah is over 110, use the TEP96 to carry out a “Exchange battery” procedure

Press the two buttons (A) for 3

seconds

OTHER FUNCTIONS

♦ Reading variables

♦ Memory battery

♦ Check in disjunct.

♦

All variables

♦ Large Amperemeter

♦ Large voltmeter

♦ Large speedometer

*VARIABLE (PAGE 2)*

Charge =0.0Ah

Discharge = 65.2Ah

Overcharg = 0.0Ah

OTHER FUNCTIONS

♦ Ιdentity UCE

♦ Ιdentity TEP

♦ SPECIAL FUNCTIONS

TO OPENING SPECIALS

FUNCTIONS

REQUEST AGREEMENT

PEUGEOT MOTOCYCLES

SPECIAL FUNCTIONS

♦ Exchange UCE

♦ Exchange battery

A

SERVICE AND COMMISSIONING PLAN

Page: 8

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

Checks before handing over to the customer:

Check the wheel nuts are tight

Front wheel: 6 m.daN

Rear wheel 10 m.daN

Check all nuts and bolts are tight

Check brake adjustment and efficiency

Check the tyre pressures cold

Front wheel: 2.5 bar

Rear wheel 2.5 bar

Check operation of the lights, flashers, road and pedestrian horn, and brake light

Check operation of the various instrument panel lamps

Check the power reserve

Carry out a road test

SPECIAL IMPORTANT POINTS

Page: 9

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

SPECIAL IMPORTANT POINTS

The scoot'elec is fitted with a coded immobiliser. This system prevents the machine from being started if the

user has not entered the secret code number. See manual.

Charging of the 3 Cadmium-Nickel batteries is by means of the on-board charger fitted with a 220V 10/16A

power connector with earth.

A partial charge may be carried out, and each charge of 10 minutes enables approximately 5 km to be

covered in ECO mode.

If the battery temperature is high, charging will only commence after the time it takes to cool down which is

controlled automatically by the charger and the ECU (which means that the charging time will be prolonged

by the same time).

The lamp will flash until the charge is triggered automatically. See manual.

TIGHTENING TORQUES AND SPECIAL TOOLS

Page: 10

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

TIGHTENING TORQUES AND SPECIAL TOOLS

Tightening torques:

Lower body fairing 0.2m.daN

Footboard 0.4 m.daN

Speedo casing 0.1 m.daN

Saddle cover 0.6 m.daN

Front panel 0.1 m.daN

Rear panel 0.1 m.daN

Side fairings 0.1 m.daN

Rear mudguard * 0.8/0.1 m.daN

Mud flap * 0.6/0.8m.daN

Saddle locking plate 1.2 m.daN

Frame:

Front wheel spindle nut 6 m.daN

Rear wheel spindle nut 10 m.daN

arm to chassis mounting 4.6 m.daN

Shock absorber upper mount 4.3 m.daN

Shock absorber lower mount 2.5 m.daN

Steering locknut 7 m.daN

Engine:

Arm to engine mount 2.3 m.daN

Battery terminal nut 1.2 m.daN

Strap and 200 A fuse 1.2 m.daN

Engine to casing 1 m.daN

Drive pulley 4 m.daN

Driven pulley 4 m.daN

Standard:

Nut and bolt 5 mm diameter 0.5 m.daN

Nut and bolt 6mm diameter 1 m.daN

Nut and bolt 8mm diameter 2.2 m.daN

Nut and bolt 10mm diameter 3.5 m.daN

Nut and bolt 12mm diameter 5.5 m.daN

Special tools:

Description Item no..

Steering column spanner 754086

Discharge bench 753012

TEP 96 753011

Optional charger 5409

* depending on size of bolt

PEUGEOT ELECTRONIC TESTER (TEP 96) USER INSTRUCTIONS

Page: 11

Reproductions or translations, even parrtial, are forbidden without the written consent of Peugeot Motocycles

TEP USER INSTRUCTIONS

VERSION 1.5 AND 2.0

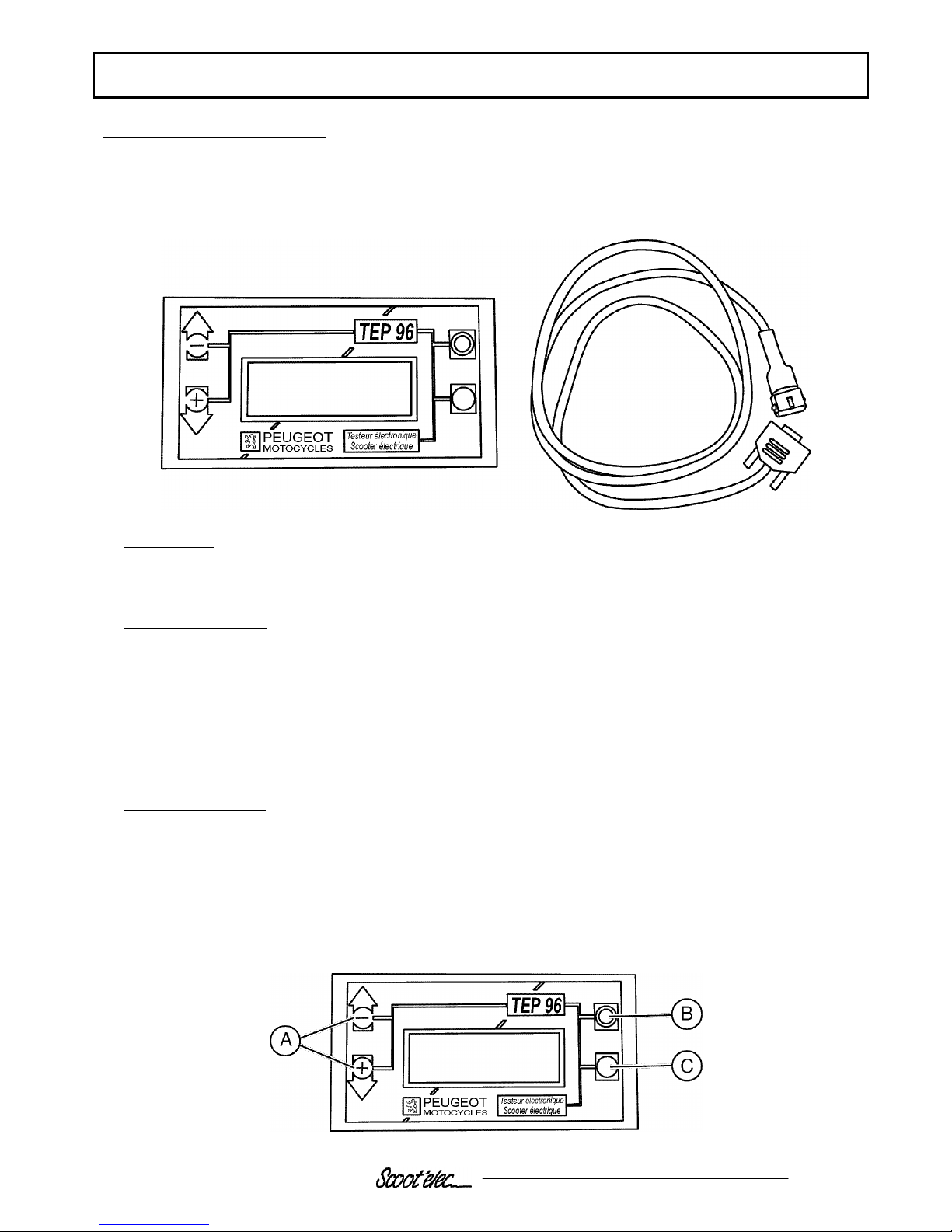

Presentation:

Unit with a display window, and connecting cable

Functioning:

Powered by the machine over the cable, the TEP 96 contains no batteries.

It dialogs with the ECU (Electronic Control Unit).

Apparatus functions:

Reads off the system functioning parameters

Reads off the fault codes recorded by the system

Checks the opening status of the maintenance hatch

Tests the functions (charger, keypad, ignition switch)

Runs the maintenance procedures to:

Change one or more of the traction battery cells

Change the ECU

Instructions for use:

Connect the cable to the TEP 96 unit

Connect the other end of the cable to the diagnostic plug under the machine saddle

Read off the indications in the window

Buttons (A) are used to scroll through the menu or to change from one page to another

Button (B) is used to return to the menu or answer no

Button (C) is used to confirm or answer yes

Loading...

Loading...