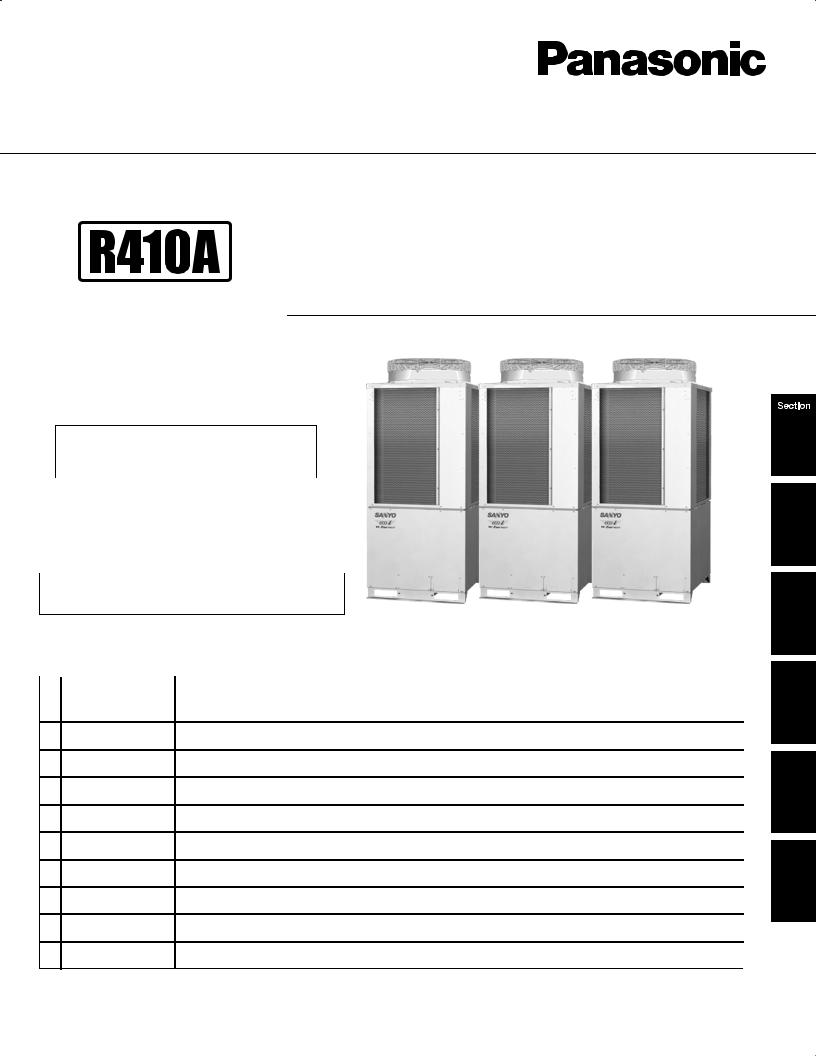

Panasonic U-96MF1U9, U-72MF1U9E, U-96MF1U9E, U-72MF1U9 Service Manual

TEST RUN SERVICE MANUAL

U-72MF1U9

U-72MF1U9E*

U-96MF1U9

U-96MF1U9E*

TENTATIVE

Model No.

Outdoor Units

3WAY VRF SYSTEM

1

2

Class |

72 |

96 |

|

|

|

|

|

|

|

Model Name |

U-72MF1U9 |

U-96MF1U9 |

3 |

|

U-72MF1U9E* |

U-96MF1U9E* |

|||

|

||||

Refrigerant R410A is used in the outdoor units. |

||||

* Salt-Air Damage Resistant Specifications.

Indoor Units

|

Class |

7 |

9 |

12 |

15 |

18 |

19 |

24 |

36 |

48 |

54 |

|

|

|

|

|

|

|

|

|

|

|

|

U1 |

4-Way Cassette |

|

|

S-12MU1U6 |

|

S-18MU1U6 |

|

S-24MU1U6 |

S-36MU1U6 |

|

|

Y1 |

4-Way Cassette 60×60 |

|

|

S-12MY1U6 |

|

S-18MY1U6 |

|

|

|

|

|

D1 |

1-Way Cassette |

S-07MD1U6 |

S-09MD1U6 |

S-12MD1U6 |

|

|

|

|

|

|

|

F1 |

Low Silhouette Ducted |

S-07MF1U6 |

S-09MF1U6 |

S-12MF1U6 |

S-15MF1U6 |

S-18MF1U6 |

|

S-24MF1U6 |

S-36MF1U6 |

S-48MF1U6 |

S-54MF1U6 |

M1 |

Slim Low Static Ducted |

S-07MM1U6 |

S-09MM1U6 |

S-12MM1U6 |

S-15MM1U6 |

S-18MM1U6 |

|

|

|

|

|

E1 |

High Static Pressure |

|

|

|

|

|

|

|

S-36ME1U6 |

S-48ME1U6 |

|

Ducted |

|

|

|

|

|

|

|

|

|||

T1 |

Ceiling |

|

|

S-12MT1U6 |

|

S-18MT1U6 |

|

S-24MT1U6 |

|

|

|

K1 |

Wall Mounted |

S-07MK1U6 |

S-09MK1U6 |

S-12MK1U6 |

|

S-18MK1U6 |

S-19MS1U6** |

S-24MK1U6 |

|

|

|

P1 |

Floor Standing |

S-07MP1U6 |

S-09MP1U6 |

S-12MP1U6 |

S-15MP1U6 |

S-18MP1U6 |

|

S-24MP1U6 |

|

|

|

R1 |

Concealed Floor |

S-07MR1U6 |

S-09MR1U6 |

S-12MR1U6 |

S-15MR1U6 |

S-18MR1U6 |

|

S-24MR1U6 |

|

|

|

|

Standing |

|

|

|

|

|

|

|

|

|

|

** Necessary to install the External Electronic Expansion Valve Kit (Optional:CZ-P56SVK1U).

85464849302000 |

REFERENCE NO. SM830202-00 |

4

5

6

7

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

•Carefully read this instruction booklet before beginning.

•Follow each installation or repair step exactly as shown.

•Observe all local, state, and national electrical codes.

•Pay close attention to all warning and caution notices given in this manual.

This symbol refers to a hazard or

WARNING unsafe practice which can result in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result CAUTION in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation sites and maintenance conditions. If you require help for a special problem, contact our sales/service outlet or your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for improper installation or maintenance service, including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING When Wiring

When Installing…

…In a Room

Properly insulate any tubing run inside a room to prevent “sweating” that can cause dripping and water damage to walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a solid, level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

•Ventilate the room well, in the event that is refrigerant gas leaks during the installation. Be careful not to allow contact of the refrigerant gas with a flame as this will cause the generation of poisonous gas.

•Keep all tubing runs as short as possible.

•Use the flare method for connecting tubing.

•Apply refrigerant lubricant to the matching surfaces of the flare and union tubes before connecting them, then tighten the nut with a torque wrench for a leak-free connection.

•Check carefully for leaks before starting the test run.

When Servicing

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

•Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

•Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

•Ground the unit following local electrical codes.

•Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner can cut your fingers.

•Turn the power OFF at the main power box (mains) before opening the unit to check or repair electrical parts and wiring.

•Keep your fingers and clothing away from any moving parts.

•Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have been left inside the unit being serviced.

CAUTION

•Ventilate any enclosed areas when installing or testing the refrigeration system. Escaped refrigerant gas, on contact with fire or heat, can produce dangerously toxic gas.

•Confirm after installation that no refrigerant gas is leaking. If the gas comes in contact with a burning stove, gas water heater, electric room heater or other heat source, it can cause the generation of poisonous gas.

i

Check of Density Limit

The room in which the air conditioner is to be installed requires a design that in the event of refrigerant gas leaking out, its density will not exceed a set limit.

The refrigerant (R410A), which is used in the airconditioner, is safe, without the toxicity or combustibility of ammonia, and is not restricted by laws imposed to protect the ozone layer. However, since it contains more than air, it poses the risk of suffocation if its density should rise excessively. Suffocation from leakage of refrigerant is almost non-existent. With the recent increase in the number of high density buildings, however, the installation of multi air conditioner systems is on the increase because of the need fo reffective use off loor space, individual control, energy conservation by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is able to replenish a large amount of refrigerant compared to conventional individual air conditioners. If a single unit of the multi air conditioner system is to be installed in a small room, select a suitable model and installation procedure so that if the refrigerant accidentally leaks out, its density does not reach the limit (and in the event of an emergency, measures can be made before injury can occur).

ASHRAE and the International Mechanical Code of the ICC as well as CSA provide guidance and define safeguards related to the use of refrigerants, all of which define a Refrigerant Concentration Level (RCL) of 25 pounds

per 1,000 cubic feet for R410A refrigerant.

For additional guidance and precautions related to refrigerant safety, please refer to the following documents:

International Mechanical Code 2009 (IMC-2009) (or more recently revised)

ASHRAE 15

ASHRAE 34

ii

Contents

Section 1: TEST RUN.............................................................................................................. |

1-1 |

|

1. |

Test Run........................................................................................................... |

1-2 |

2. |

Setting of Unit Control PCB ............................................................................. |

1-4 |

3. |

Auto Address Setting ....................................................................................... |

1-6 |

4. |

Remote Controller Test Run Settings............................................................. |

1-12 |

5. |

Caution for Pump Down................................................................................. |

1-13 |

6. |

Meaning of Alarm Messages ......................................................................... |

1-14 |

Section 2: REMOTE CONTROL FUNCTIONS |

........................................................................2-1 |

|

1. |

Main Operating Functions................................................................................ |

2-2 |

2. |

Wireless Remote Controller............................................................................. |

2-4 |

3. |

Timer Remote Controller................................................................................ |

2-15 |

Section 3: TROUBLE DIAGNOSIS ......................................................................................... |

3-1 |

|

1. |

Contents of Remote Controller Switch Alarm Display...................................... |

3-2 |

2. |

Outdoor Unit Control PCB LED Display........................................................... |

3-4 |

3. |

W-3WAY VRF Alarm Codes............................................................................. |

3-5 |

4. |

Blinking (Inspection) Display on the Remote Controller ............................ |

3-26 |

Section 4: PCB AND FUNCTIONS ......................................................................................... |

4-1 |

|

1. |

Outdoor Unit Control PCB................................................................................ |

4-2 |

2. |

Indoor Unit Control PCB .................................................................................. |

4-7 |

Section 5: SELF-DIAGNOSIS FUNCTION TABLE ................................................................. |

5-1 |

|

1. |

Self-Diagnosis Function Table.......................................................................... |

5-2 |

Section 6: SERVICE CHECKER ............................................................................................. |

6-1 |

|

1. |

Outdoor Unit Maintenance Remote Controller................................................. |

6-2 |

iii

Contents TENTATIVE

1. TEST RUN

Test Run

1. Test Run............................................................................................................................... |

1-2 |

1-1. Preparing for Test Run................................................................................................... |

1-2 |

1-2. Test Run Procedure....................................................................................................... |

1-3 |

2. Setting of Unit Control PCB............................................................................................... |

1-4 |

2-1. Main Outdoor Unit PCB Setting..................................................................................... |

1-4 |

3. Auto Address Setting ......................................................................................................... |

1-6 |

3-1. Auto Address Setting..................................................................................................... |

1-6 |

4. Remote Controller Test Run Settings ............................................................................. |

1-12 |

5. Caution for Pump Down................................................................................................... |

1-13 |

6. Meaning of Alarm Messages ........................................................................................... |

1-14 |

1

2

3

4

5

6

7

1 - 1

1

2

3

4

5

6

7

Test Run

1. Test Run

1-1. Preparing for Test Run

zBefore attempting to start the air conditioner, check the following.

(1)All loose matter is removed from the cabinet, especially steel fi lings, bits of wire, and clips.

(2)The control wiring is correctly connected and all electrical connections are tight.

(3)The protective spacers for the compressor used for transportation have been removed. If not, remove them now.

(4)The transportation pads for the indoor fan have been removed. If not, remove them now.

(5)The power has been connected to the unit for at least 5 hours before starting the compressor. The bottom of the compressor should be warm to the touch and the crankcase heater around the feet of the compressor should be hot to the touch.

(6)Both the gas and liquid tube service valves are open. If not, open them now.

(7)Request that the customer be present for the trial run. Explain the contents of the instruction manual, then have the customer actually operate the system.

(8)Be sure to give the instruction manual and warranty certifi cate to the customer.

(9)When replacing the control PCB, be sure to make all the same settings on the new PCB as were in use before replacement.

The existing EEP ROM is not changed, and is connected to the new control PCB.

ON

(Power must be turned ON at least 5 hours before attempting test run)

(Power must be turned ON at least 5 hours before attempting test run)

Power mains switch

Balance tube

Liquid tube

Discharge tube

Suction tube

1 - 2

Test Run

1. Test Run

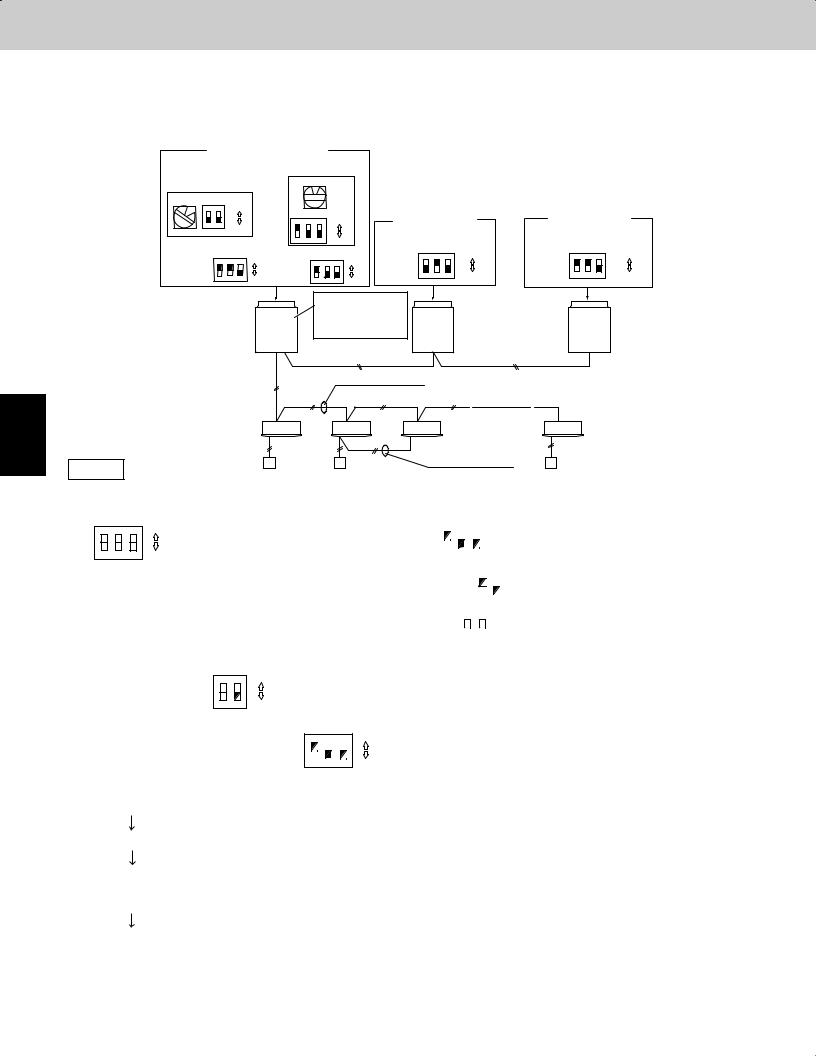

1-2. Test Run Procedure

Items to Check Before the Test Run

Recheck the items to check before the test run.

<Outdoor unit control PCB> Unit No. setting switch (S007)

<Outdoor unit control PCB> Unit No. setting switch (S006)

<Outdoor unit control PCB> Unit No. setting switch (S004 and S005)

(Check the link wiring.)

<Outdoor unit control PCB> Unit No. setting switch (S002 and S003)

NO

Have the outdoor sub units been connected?

YES

*1

Set the unit address.

Set the No. of outdoor units.

Set the No. of indoor units.

Are the inter-unit control wires |

NO |

connected to more than 1 refrigerant |

|

system? |

|

YES |

|

Set the system address. |

|

1.Turn the remote power switch on at least 5 hours before the test, in order to energize the crankcase heater.

2.After performing the leak inspection, applying vacuum, and performing refrigerant charge for the tubing which is connected onsite, fully open the outdoor unit service valve. However if only one outdoor unit is installed, a balance tube is not used. Therefore, leave the valve fully closed.

3.When replacing the control PCB, be sure that the settings on the new PCB match those on the old PCB.

4.Use caution when making the settings. If there are duplicated system addresses, or if the settings for the Nos. of the indoor units are not consistent, an alarm will occur and the system will not start.

5.These settings are not made on the indoor unit PCB.

CASE 1

|

When multiple outdoor main units exist, disconnect the terminals |

Note: It is not necessary to remove |

|

*1 |

The unit with the unit |

||||||||||||

|

extended from the shorted plugs (CN003) at all outdoor main unit |

|

|

the socket that is used to short- |

|||||||||||||

|

|

|

|

|

No. set to 1 is the |

||||||||||||

|

|

PCBs except for 1. |

|

|

|

|

|

|

circuit the terminal plugs from |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

main unit. All other |

||||||

|

|

Alternatively, move the sockets to the OPEN side. |

|

|

the outdoor sub unit PCBs. |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

units are sub units. |

|||||||||

|

|

|

|

|

|

YES |

CASE 2 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

Is it possible to turn ON the power only |

|

|

|

|

|

||||||||||

|

|

for the 1 refrigerant system where the |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

test run will be performed? |

|

|

|

|

|

|

|

|

|

|

|

Turn ON the indoor and |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

NO |

|

|

|

|

|

|

|

|

|

|

|

outdoor unit power for that |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

refrigerant system only. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Will automatic address setting be |

|

|

|

Make necessary corrections. |

|

|

|

|

|

||||||

|

|

|

|

|

Short-circuit the automatic address pin (CN100) |

||||||||||||

|

NO |

performed in Heating mode? |

|

|

|

|

|

|

|

|

|

|

on the outdoor main unit PCB for 1 second or |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

longer, then release it. |

||

|

CASE 3B |

|

YES |

CASE 3A |

|

|

Turn OFF the indoor and |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

outdoor unit power. |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Is it OK to start the compressors? |

Is it OK to start the compressors? |

|

|

|

|

|

|

|

|

|

LED 1 and 2 blink alternately |

||||||

|

|

|

Check the alarm contents. |

|

|

|

(about 2 or 3 minutes). |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn ON the indoor and |

Turn ON the indoor and |

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|||

outdoor unit power. |

outdoor unit power. |

|

|

|

|

|

|

|

|

|

Are LED 1 and 2 on the |

||||||

*2 |

|

*2 |

|

|

|

Make necessary |

|

|

|

|

|

|

|

outdoor unit PCB OFF? |

|||

Short-circuit the mode change pin |

|

|

|

corrections |

|

|

Refer to "Table of Self- |

|

|

||||||||

Short-circuit the automatic address |

|

|

|

|

|

|

|

||||||||||

(CN101) on the outdoor main unit PCB. |

pin (CN100) on the outdoor main |

|

|

|

|

Diagnostic Functions and |

|

|

|

|

|

||||||

|

|

|

|

Description of Alarm Displays." |

|

|

YES |

||||||||||

At the same time, short-circuit the |

unit PCB for 1 second or longer, |

|

|

|

|

|

|

|

|||||||||

|

Turn OFF the indoor |

|

|

|

|||||||||||||

automatic address pin (CN100) for 1 |

then release it. |

|

|

|

|

|

|

|

|||||||||

|

|

and outdoor unit |

|

|

|

|

|

||||||||||

second or longer, then release it. |

|

|

|

|

|

|

|

|

|

||||||||

*3 |

|

*3 |

|

|

|

|

Start indoor and outdoor unit |

Start indoor and outdoor unit |

Check the alarm |

||||

cooling operation. |

|

heating operation. |

||||

|

contents. |

|||||

LED 1 and 2 blink alternately. |

LED 1 and 2 blink alternately. |

|||||

|

|

|||||

|

|

|

NO |

|

|

|

|

|

|

|

|||

|

|

|

|

|

||

|

Are LED 1 and 2 on the |

|

|

|||

|

outdoor unit PCB OFF? |

|

|

|

||

YES

Check that test run preparation is OK.

(Do not allow the short-circuited pins to remain short-circuited.)

Set the wired remote controller for test run.

Refer to the remote |

|

|

NO |

Check and make corrections according to |

|

|

|||

controller test-run |

Does system operate? |

|||

settings. |

|

"Table of Self-Diagnostic Functions." |

||

|

|

|

||

|

|

|

|

|

|

|

YES |

|

|

|

|

|

||

|

Return remote control to normal mode |

|

||

|

End test run. |

|

||

*2 A minimum of 5 hours must have passed after the power was turned ON to the outdoor unit.

*3 All indoor units operate in all refrigerant systems where the power is ON.

1

2

3

4

5

6

7

1 - 3

Test Run

2. Setting of Unit Control PCB

2-1. Main Outdoor Unit PCB Setting

1

2

3

4

5

6

S007 S006 S005 S004 S002 S003

7

CN003

CN101

CN100

1 - 4

Test Run

2. Setting of Unit Control PCB

z Examples of the No. of indoor units settings (S005, S004)

No. of indoor units |

Indoor unit setting (S005) |

Indoor unit setting (S004) |

|||

(3P DIP switch, blue) |

(Rotary switch, red) |

||||

|

10 20 30 |

|

|

||

1 unit (factory setting) |

ON |

|

|

ON |

1 |

All OFF |

|

3 |

|

Set to 1 |

|

|

1 |

2 |

OFF |

|

|

|

ON |

|

|

ON |

1 |

11 units |

|

|

|

||

1 ON |

2 |

3 |

|

Set to 1 |

|

|

1 |

OFF |

|

||

21 units |

ON |

|

|

ON |

1 |

2 ON |

2 |

3 |

|

Set to 1 |

|

|

1 |

OFF |

|

||

31 units |

ON |

|

|

ON |

1 |

3 ON |

2 |

3 |

|

Set to 1 |

|

|

1 |

OFF |

|

||

|

ON |

|

|

ON |

0 |

40 units |

1 & 3 ON |

|

|

|

|

2 |

3 |

|

Set to 0 |

||

|

1 |

OFF |

|

||

z Examples of refrigerant circuit (R.C.) address settings (required when link wiring is used) (S003, S002)

System address No. |

System address (S003) |

System address (S002) |

||||

(2P DIP switch, blue) |

||||||

(Rotary switch, black) |

||||||

|

10 20 |

|

||||

|

ON |

|

|

|||

System 1 (factory setting) |

ON |

|

1 |

Set to 1 |

||

Both OFF |

|

|

|

|||

|

1 |

2 |

OFF |

|

|

|

|

ON |

|

ON |

1 |

|

|

System 11 |

1 ON |

|

|

Set to 1 |

||

2 |

|

|

||||

|

1 |

OFF |

|

|

||

System 21 |

ON |

|

ON |

1 |

Set to 1 |

|

2 ON |

2 |

OFF |

|

|||

|

1 |

|

|

|||

System 30 |

ON |

|

ON |

0 |

Set to 0 |

|

1 & 2 ON |

|

|

||||

2 |

|

|

||||

|

1 |

OFF |

|

|

||

z Examples of the No. of outdoor units settings (S006)

No. of outdoor units |

Outdoor unit setting (S006) |

||||

(3P DIP switch, blue) |

|||||

|

|||||

1 unit (factory setting) |

ON |

|

|

ON |

|

1 ON |

|

|

|

||

|

1 |

2 |

3 |

OFF |

|

|

ON |

|

|

ON |

|

2 units |

2 ON |

|

|

|

|

|

1 |

2 |

3 |

OFF |

|

|

ON |

|

|

ON |

|

3 units |

1 & 2 ON |

|

|

|

|

|

1 |

2 |

3 |

OFF |

|

z Address setting of main outdoor unit (S007)

Unit No. setting |

Address setting of outdoor unit (S007) |

||||

(3P DIP switch, blue) |

|||||

|

|||||

Unit No. 1 (main unit) |

ON |

|

|

ON |

|

|

|

|

|

||

(factory setting) |

1 |

2 |

3 |

OFF |

|

|

|||||

z Address setting of sub outdoor unit |

|

|

|

||

Unit No. setting |

Address setting of outdoor unit (S007) |

||||

(3P DIP switch, blue) |

|||||

|

|||||

Unit No. 2 (sub unit) |

ON |

|

|

ON |

|

2 ON |

|

|

|

||

(factory setting) |

|

|

|

||

1 |

2 |

3 |

OFF |

||

Unit No. 3 (sub unit) |

ON |

|

|

ON |

|

1 & 2 ON |

|

|

|

||

|

1 |

2 |

3 |

OFF |

|

The sub unit control PCB contains the same switches as the main unit control PCB for No. of indoor units, No. of outdoor units, and system address. However it is not necessary to set these switches.

1

2

3

4

5

6

7

1 - 5

1

2

3

4

5

6

7

Test Run

3. Auto Address Setting

3-1. Auto Address Setting

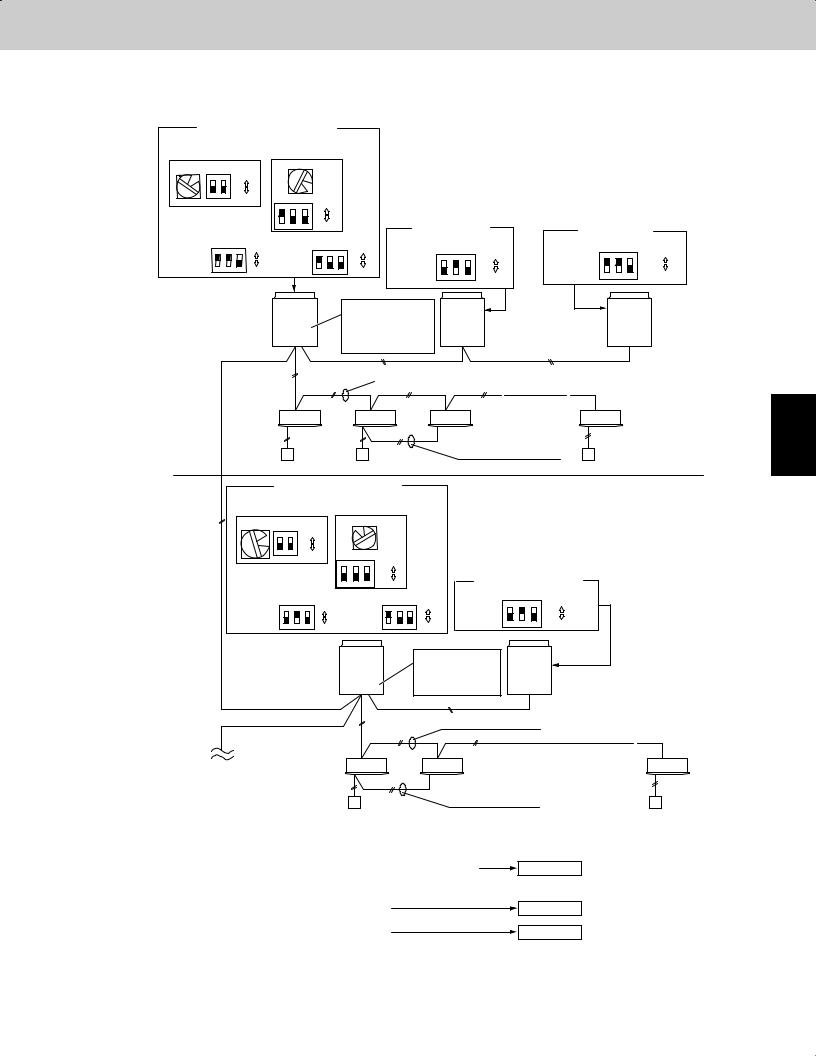

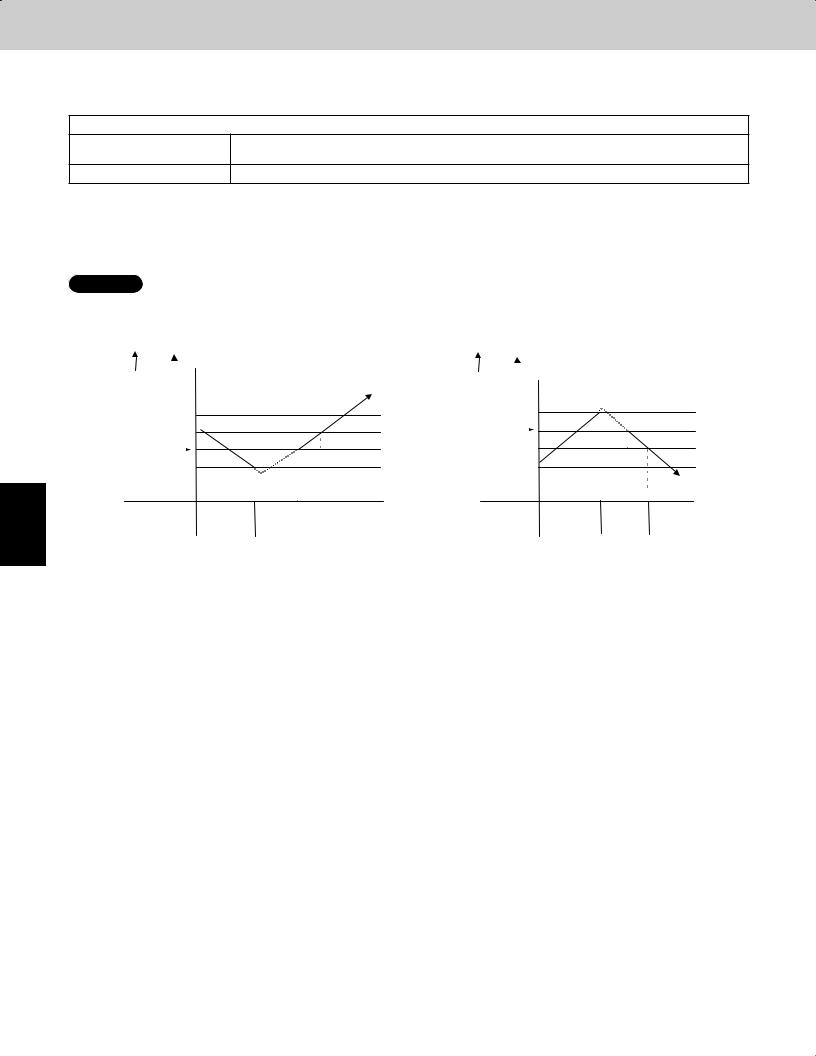

Basic wiring diagram: Example (1)

•If link wiring is not used (The inter-unit control wires are not connected to multiple refrigerant systems.)

Indoor unit addresses can be set without operating the compressors.

No. 1 (main outdoor unit)

|

settings No. of indoor units |

|

System address |

(10 units setting) |

|

(S004) |

||

(system 1 setting) |

||

0 |

(S002) |

(S003) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

ON |

|

|

ON |

|

(S005) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

No. 2 (sub unit) |

No. 3 (sub unit) |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

1 |

2 |

|

OFF |

|

ON |

|

|

|

ON |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

No. of |

|

|

|

|

|

1 |

2 |

3 |

|

OFF |

Unit |

|

|

|

|

|

Unit |

|

(S007) |

|

|

|

(S006) |

|

|

|

(S007) |

|

|

(S007) |

|

|

|

ON |

|||||||||

outdoor |

|

ON |

Unit number |

|

number |

|

ON |

|

|

ON |

number |

ON |

|||||||||

|

ON |

|

|

ON |

|

|

ON |

|

|

|

|

|

|

||||||||

units (3 units |

|

|

|

setting |

|

|

|

setting |

|

|

|

|

|

setting |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

OFF |

1 |

2 3 |

OFF |

|||||

setting) |

|

1 |

2 |

3 |

OFF |

(Unit No. 1) |

|

1 |

2 |

3 |

OFF |

(Unit No. 2) |

(Unit No. 3) |

||||||||

|

|

Leave the socket that |

|

|

|

|

Unit |

is used to short-circuit |

Unit |

|

Unit |

Outdoor Unit |

the terminal plug. |

|

|||

No. 1 |

(CN003) |

No. 2 |

|

No. 3 |

|

|

(Main) |

Outdoor main/sub |

(Sub) |

Outdoor main/sub |

(Sub) |

|

|

|

|

||

|

|

control wiring |

|

control wiring |

|

Inter-unit control wiring

|

Indoor Unit 1-1 |

1-2 |

1-3 |

1-10 |

|

|

|

|

Remote controller |

Case 1 |

Remote controller |

|

|

cross-over wiring |

|

|

|

|

(1) Automatic Address Setting from the Outdoor Unit

1.To set the number of outdoor units, on the outdoor main unit control PCB set the No. of outdoor units DIP switch (S006) to

ON |

|

ON |

|

ON |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

(3 units), and set the unit No. DIP switch (S007) to |

|

|

|

|

|

|

|

|

|

(unit No. 1 - main outdoor unit). |

|||

|

1 2 3 OFF |

|

|

1 |

|

2 |

|

|

3 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

||||

2. On the No. 2 (sub) unit control PCB, set the unit No. switch (S007) to |

|

|

|

|

|

|

|

|

|

(unit No. 2). |

||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

||||

On the No. 3 (sub) unit control PCB, set the unit No. switch (S007) to |

|

|

|

|

|

|

|

|

|

(unit No. 3). |

||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

|

||

3.On the outdoor main unit control PCB, check that the system address rotary switch (S002) is set to “1” and that the DIP

ON ON

switch (S003) is set to |

|

|

|

“0.” (These are the settings at the time of factory shipment.) |

|

|

|

1 2 OFF

4.To set the number of indoor units that are connected to the outdoor unit to 10, on the outdoor main unit control PCB set the

ON ON

No. of indoor units DIP switch (S005) to |

|

|

|

|

|

“1.” and set the rotary switch (S004) to “0.” |

|

|

|

|

|

1 2 3 OFF

5.Turn ON the power to the indoor and outdoor units.

6.On the outdoor main unit control PCB, short-circuit the automatic address pin (CN100) for 1 second or longer, then release it.

(Communication for automatic address setting begins.)

*To cancel, again short-circuit the automatic address pin (CN100) for 1 second or longer, then release it. The LED that indicates that automatic address setting is in progress turns OFF and the process is stopped.

Be sure to perform automatic address setting again.

(Automatic address setting is completed when LEDs 1 and 2 on the outdoor main unit control PCB turn OFF.)

7.Operation from the remote controllers is now possible.

*To perform automatic address setting from the remote controller, perform steps 1 to 5, then use the remote controller and

complete automatic address setting.

z Refer to “Automatic Address Setting from the Remote Controller.”

1 - 6

Test Run

3. Auto Address Setting

Basic wiring diagram: Example (2)

|

• If link wiring is used |

* When multiple outdoor main units exist, remove the socket that is |

|

No. 1 (main outdoor unit) settings |

used to short-circuit the terminal plug (CN003) from all outdoor |

||

main unit PCBs except for one unit. |

|||

|

No. of indoor units |

||

System address |

Alternatively, move the sockets to the “OPEN” side. |

||

(system 1 setting) |

(13 units setting) |

|

|

(S002) |

(S003) |

|

(S004) |

|

|

ON |

|

|

|||

1 |

ON |

|

|

|

|

|

1 |

2 |

OFF |

(S005) |

ON |

|

|

|

|||

|

|

|

|

ON |

|

|

|

|

|

1 |

2 |

3 |

OFF |

|

|

No. 2 (sub unit) |

|

||

|

|

|

|

|

|

|

|

|

|

||||

No. of |

|

(S006) |

Unit |

|

|

(S007) |

|

Unit |

|

|

|

||

|

|

|

|

|

|

(S007) |

|

||||||

outdoor units ON |

|

ON number |

|

ON |

|

ON |

|

ON |

|||||

|

|

|

number |

|

|

||||||||

(3 units |

|

|

|

setting |

|

|

|

|

ON |

||||

setting) |

|

2 |

3 |

|

|

|

|

setting |

|

|

|

||

1 |

OFF (unit No. 1) |

1 2 |

3 |

OFF |

|

|

OFF |

||||||

|

|

|

|

|

|

|

|

|

|

(unit No. 2) |

1 |

2 3 |

|

No. 3 (sub unit)

Unit |

(S007) |

ON |

|

number |

|||

ON |

|||

setting |

|

|

|

(unit No. 3) |

1 2 3 |

OFF |

Outdoor unit |

Unit |

Leave the socket that |

Unit |

|

Unit |

|

is used to short-circuit |

|

|||||

No. 1 |

No. 2 |

|

No. 3 |

|||

system 1 |

|

|||||

the terminal plug. |

|

|||||

(Main) |

(Sub) |

Outdoor main/sub |

(Sub) |

|||

|

||||||

|

(CN003) |

|||||

|

|

|

control wiring |

|

||

|

|

|

|

|

Inter-unit control wiring

|

Indoor unit |

|

1-1 |

1-2 |

1-3 |

1-13 |

|

|

Remote |

|

|

|

Remote controller |

||

|

|

|

|

communication |

wiring |

||

|

controller |

|

|

|

|||

|

|

|

|

|

|

||

No. 2 |

|

|

No. 1 (main unit) settings |

|

|

||

Refrigerant |

System address |

No. of indoor units |

|

||||

circuit |

(system 2 setting) |

(9 units setting) |

|

||||

|

(S002) |

(S003) |

|

(S004) |

|

|

|

|

ON |

|

|

|

|||

|

|

ON |

|

9 |

|

|

|

|

2 |

|

|

|

|

|

|

|

|

1 |

2 |

OFF |

(S005) |

|

|

|

|

|

|

ON |

|

||

|

|

|

|

|

ON |

|

|

|

|

|

|

|

1 |

2 3 |

OFF |

|

|

No. 2 (sub unit) settings |

|||

|

|

|

|

|

|

|

Unit |

|

|

|

|||

No. of |

|

(S006) |

|

Unit |

|

(S007) |

|

|

(S007) |

ON |

|||

outdoor |

|

|

|

ON |

number |

ON |

number |

ON |

|||||

ON |

|

ON |

|

|

|||||||||

units (2 units |

|

|

|

|

setting |

|

|

|

setting |

|

|

|

|

setting) |

1 |

2 |

3 |

OFF (unit No. 1) |

1 2 |

3 |

OFF |

(unit No. 2) |

1 |

2 3 |

OFF |

||

Outdoor unit |

Unit |

No. 1 |

|

system 2 |

(Main) |

Indoor unit 2-1

To other system

link wiring

Remote controller

Move the socket to |

Unit |

the “OPEN”side |

No. 2 |

(CN003). |

(Sub) |

|

Outdoor main/sub control wiring |

Inter-unit control wiring

2-2 2-9

Remote controller cross-over wiring

Make settings as appropriate for the cases listed below. (Refer to the instructions on the following pages.)

· Indoor and outdoor unit power can be turned ON for each system separately. |

Case 2 |

· Indoor and outdoor unit power cannot be turned ON for each system separately. |

|

Automatic address setting in Heating mode |

Case 3A |

Automatic address setting in Cooling mode |

Case 3B |

1

2

3

4

5

6

7

1 - 7

1

2

3

4

5

6

7

Test Run

3. Auto Address Setting

Case 2 Automatic Address Setting (no compressor operation)

zIndoor and outdoor unit power can be turned ON for each system separately. Indoor unit addresses can be set without operating the compressors.

Automatic Address Setting from Outdoor Unit

|

|

|

|

|

ON |

|

|

|

|

|

|

||

1. On the No. 1 |

(main) unit control PCB, set the unit No. switch (S007) to |

|

|

|

|

|

|

|

|

(unit No. 1). |

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

1 |

|

2 |

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

||||

On the No. 2 |

(sub) unit control PCB, set the unit No. switch (S007) to |

|

|

|

|

|

|

|

|

|

|

(unit No. 2). |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

On the No. 3 |

(sub) unit control PCB, set the unit No. switch (S007) to |

ON |

|

|

|

|

|

(unit No. 3). |

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

2.To set the number of outdoor units on the outdoor main unit control PCB, set the No. of outdoor units DIP switch (S006) to

ON ON

(3 units).

1 2 3 OFF

3.On the outdoor main unit control PCB, check that the system address rotary switch (S002) is set to “1” and that the DIP

|

ON |

ON |

switch (S003) is set to “0” |

|

. (These are the settings at the time of factory shipment.) |

1 2 OFF

4.To set the number of indoor units that are connected to the outdoor unit to 13, on the outdoor main unit control PCB set the

ON ON

No. of indoor units DIP switch (S005) to “1” |

|

|

|

|

|

, and set the rotary switch (S004) to “3.” |

|

|

|

|

|

1 2 3 OFF

5.Turn on power to all indoor and outdoor units in the system.

6.Short-circuit the automatic address pin at the outdoor main unit (CN100) for 1 second or longer, then release it.

(Communication for automatic address setting begins.)

*To cancel, again short-circuit the automatic address pin (CN100) for 1 second or longer, then release it. The LED that indicates automatic address setting is in progress turns OFF and the process is stopped. Be sure to perform automatic address setting again.

(Automatic address setting is completed when LEDs 1 and 2 on the outdoor main unit control PCB turn OFF.)

7.Next turn the power ON only for the indoor and outdoor units of the next (different) system. Repeat steps 1 - 5 in the same way to complete automatic address settings for all systems.

8.Operation from the remote controllers is now possible.

*To perform automatic address setting from the remote controller, perform steps 1 - 5, then use the remote controller and complete automatic address setting.

z Refer to “Automatic Address Setting from Remote Controller.”

1 - 8

Test Run

3. Auto Address Setting

Case 3A Automatic Address Setting in Heating Mode

zIndoor and outdoor unit power cannot be turned ON for each system separately.

In the following, automatic setting of indoor unit addresses is not possible if the compressors are not operating. Therefore perform this process only after completing all refrigerant tubing work.

Automatic Address Setting from Outdoor Unit

1.Perform steps 1 - 4 in the same way as for Case 2 .

5.Turn the indoor and outdoor unit power ON at all systems.

6.To perform automatic address setting in Heating mode , on the outdoor main unit control PCB in the refrigerant system where you wish to set the addresses, short-circuit the automatic address pin (CN100) for 1 second or longer, then release it. (Be sure to perform this process for one system at a time. Automatic address settings cannot be performed for more than one system at the same time.)

(Communication for automatic address setting begins, the compressors turn ON, and automatic address setting in Heating mode begins.)

(All indoor units operate.)

*To cancel, again short-circuit the automatic address pin (CN100) for 1 second or longer, then release it. The

LED that indicates automatic address setting is in progress turns OFF and the process is stopped. Be sure to perform automatic address setting again.

(Automatic address setting is completed when the compressors stop and LED 1 and 2 on the main unit control PCB turn OFF.)

7.At the outdoor main unit in the next (different) system, short-circuit the automatic address pin (CN100) for 1 second or

longer, then release it.

(Repeat the same steps to complete automatic address setting for all units.)

8.Operation from the remote controllers is now possible.

*To perform automatic address setting from the remote controller, perform steps 1 - 5, then use the remote controller and to complete automatic address setting.

z Refer to “Automatic Address Setting from Remote Controller.”

1

2

3

4

5

6

7

1 - 9

Test Run

3. Auto Address Setting

|

|

Case 3B |

Automatic Address Setting in Cooling Mode |

|||||

|

|

|

|

|||||

|

|

z Indoor and outdoor unit power cannot be turned ON for each system separately. In the following, automatic setting of indoor |

||||||

|

|

|

unit addresses is not possible if the compressors are not operating. Therefore perform this process only after completing all |

|||||

|

|

|

refrigerant tubing work. |

|||||

|

|

|

Automatic address setting can be performed during Cooling operation. |

|||||

|

|

Automatic Address Setting from Outdoor Unit |

||||||

|

|

|

|

|

|

|

|

|

|

1. |

Perform steps 1 - 4 in the same way as for |

Case 2 |

. |

|

|||

|

|

5. Turn the indoor and outdoor unit power ON at all systems. |

||||||

|

|

|

|

|

|

|

||

|

6. |

To perform automatic address setting in |

Cooling mode |

, on the outdoor main unit control PCB in the refrigerant system |

||||

|

|

|

where you wish to set the addresses, short-circuit the mode change 2P pin (CN101). At the same time, short-circuit the |

|||||

|

|

|

automatic address pin (CN100) for 1 second or longer, then release it. (Be sure to perform this process for one system at a |

|||||

|

|

|

time. Automatic address settings cannot be performed for more than one system at the same time.) |

|||||

|

|

|

(Communication for automatic address setting begins, the compressors turn ON, and automatic address setting in Cooling |

|||||

|

|

|

mode begins.) |

|||||

|

|

|

(All indoor units operate.) |

|||||

1 |

|

|

|

* To cancel, again short-circuit the automatic address pin (CN100) for 1 second or longer, then release it. The |

||||

|

|

|

LED that indicates automatic address setting is in progress turns OFF and the process is stopped. Be sure to |

|||||

|

|

|

perform automatic address setting again. |

|||||

|

|

|

|

|||||

|

|

|

(Automatic address setting is completed when the compressors stop and LED 1 and 2 on the outdoor main unit control PCB |

|||||

|

|

|

turn OFF.) |

|||||

2 |

|

|

||||||

|

7. At the outdoor main unit in the next (different) system, short-circuit the automatic address pin (CN100) for 1 second or |

|||||||

|

|

|||||||

|

|

|

longer, then release it. |

|||||

|

|

|

(Repeat the same steps to complete automatic address setting for all units.) |

|||||

|

|

|

||||||

3 |

|

8. Operation from the remote controllers is now possible. |

||||||

|

|

* Automatic address setting in Cooling mode cannot be done from the remote controller. |

||||||

4

5

6

7

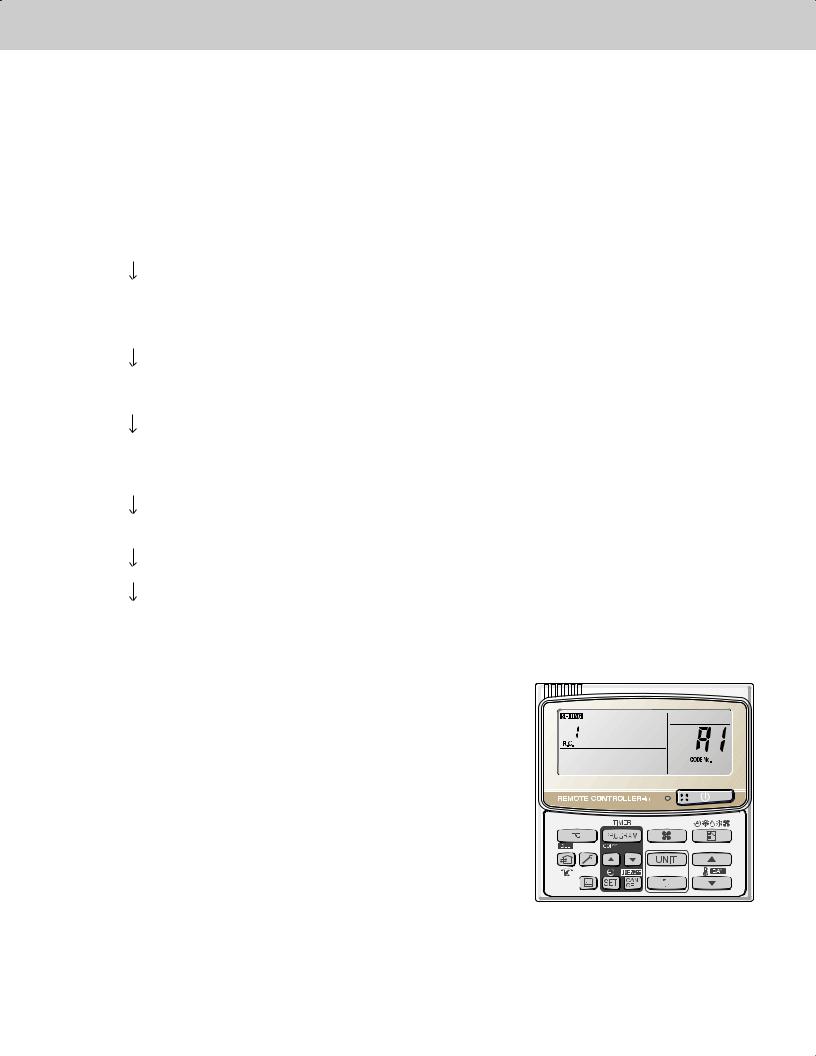

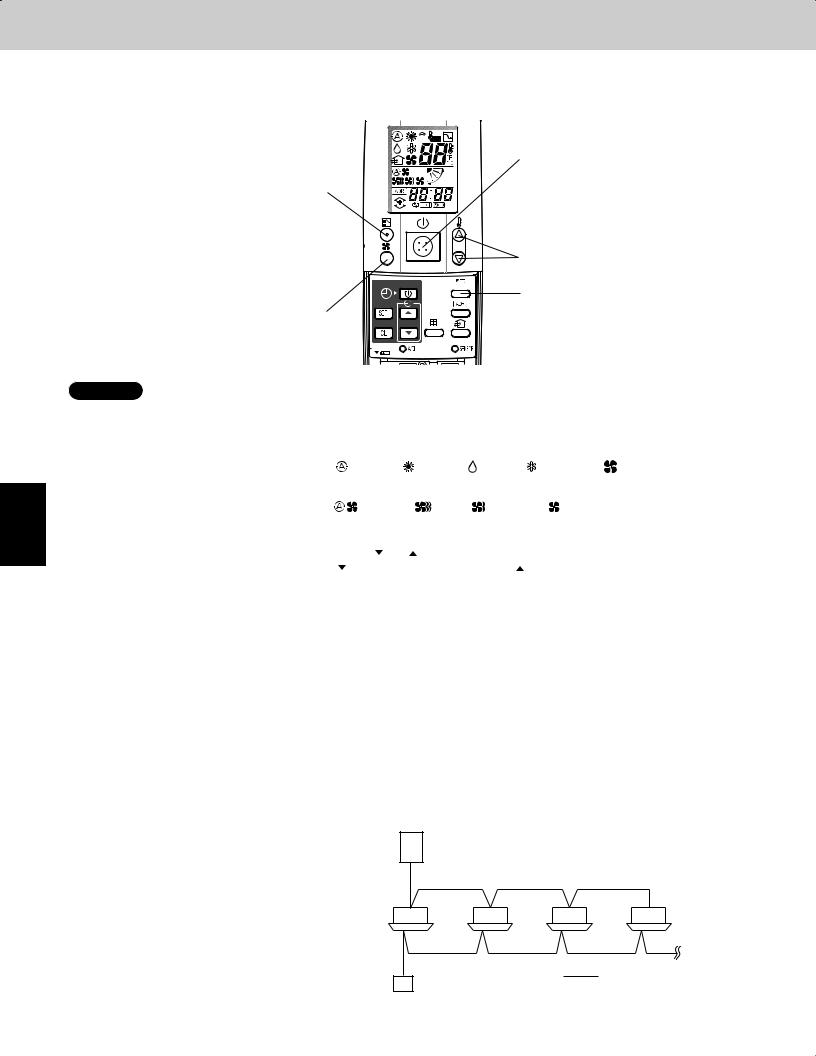

Automatic Address Setting* from the Remote Controller

Selecting each refrigerant system individually for automatic address setting

---Automatic address setting for each system: Item code “A1.”

1. Press the remote controller timer time  button and

button and  button at the same time.

button at the same time.

(Press and hold for 4 seconds or longer.)

2. Next, press either the temperature setting  or

or  button. (Check that the item code is “A1.”)

button. (Check that the item code is “A1.”)

3. Use either the  or

or  button to set the system No. to perform automatic address setting.

button to set the system No. to perform automatic address setting.

4. Then press the  button.

button.

(Automatic address setting for one refrigerant system begins.)

(When automatic address setting for one system is completed, the system returns to normal stopped status.) <Approximately 4 - 5 minutes is required.>

(During automatic address setting, “NOW SETTING” is displayed on the remote controller. This message disappears when automatic address setting is completed.)

5.Repeat the same steps to perform automatic address setting for each successive system.

1 - 10

Test Run

3. Auto Address Setting

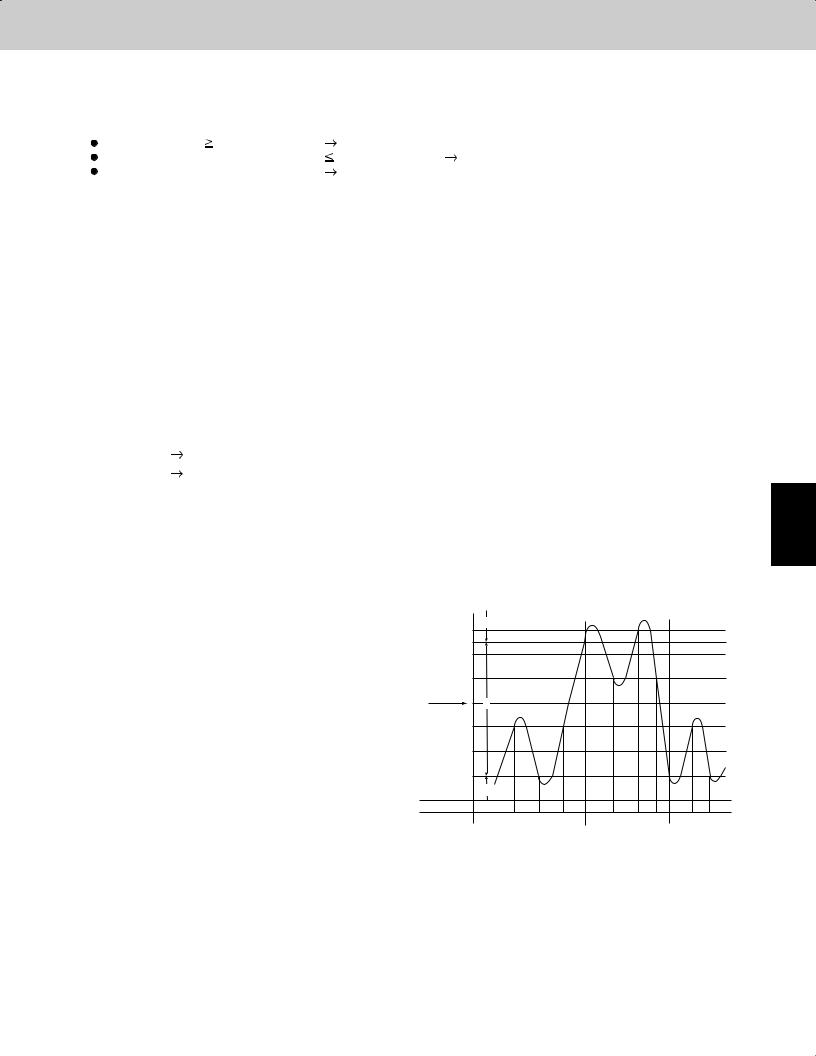

Display during automatic address setting

z On outdoor main unit PCB

LED 2 1

*Do not short-circuit the automatic address setting pin (CN100) again while automatic address setting is in progress. Doing so will cancel the setting operation and will cause LED 1 and 2 to turn OFF.

Blink alternately

*When automatic address setting has been successfully completed, both LED 1 and 2 turn OFF.

*LED 1 is D72. LED 2 is D75.

*If automatic address setting is not completed successfully, refer to the table below and correct the problem. Then perform automatic address setting again.

z Display of LED 1 and 2 on the outdoor unit control PCB

( : ON

: ON  : Blinking

: Blinking  :OFF)

:OFF)

LED1 |

LED2 |

Display meaning |

After the power is turned ON (and automatic address setting is not in progress), no communication with the indoor units in that system is possible.

After the power is turned ON (and automatic address setting is not in progress), 1 or more indoor units are confi rmed in that system; however, the number of indoor units does not match the number that was set.

Automatic address setting is in progress.

Alternating

Automatic address setting completed.

|

At time of automatic address setting, the number of indoor units did not match the number that was set. |

Simultaneous |

“ ”(when indoor units are operating) indication appears on the display. |

Refer to “Table of Self-Diagnostic Functions and Description of Alarm Displays.”

Refer to “Table of Self-Diagnostic Functions and Description of Alarm Displays.”

Alternating

NOTE

“ ” indicates that the solenoid is fused or that there is a CT detection current failure (current is detected when the compressor is OFF).

” indicates that the solenoid is fused or that there is a CT detection current failure (current is detected when the compressor is OFF).

z Remote controller display

is blinking

is blinking

1

2

3

4

5

6

7

1 - 11

3.Auto Address Setting

4.Remote Controller Test Run Settings

Test Run

Request concerning recording the indoor/outdoor unit combination Nos.

After automatic address setting has been completed, be sure to record them for future reference.

List the outdoor main unit system address and the addresses of the indoor units in that system in an easily visible location (next to the nameplate), using a permanent marking pen or similar means that cannot be abraded easily.

Example: (Outdoor) 1 - (Indoor) 1-1, 1-2, 1-3… (Outdoor) 2 - (Indoor) 2-1, 2-2, 2-3…

These numbers are necessary for later maintenance. Please be sure to indicate them.

Checking the indoor unit addresses

Use the remote controller to check the indoor unit address.

<If 1 indoor unit is connected to 1 remote controller>

1.Press and hold the  button and

button and  button for 4 seconds or longer (simple settings mode).

button for 4 seconds or longer (simple settings mode).

2.The address is displayed for the indoor unit that is connected to the remote controller.

(Only the address of the indoor unit that is connected to the remote controller can be checked.)

3.Press the  button again to return to normal remote controller mode.

button again to return to normal remote controller mode.

<If multiple indoor units are connected to 1 remote controller (group control)>

1.Press and hold the  button and

button and  button for 4 seconds or longer (simple settings mode).

button for 4 seconds or longer (simple settings mode).

2.“ALL” is displayed on the remote controller.

3.Next, press the  button.

button.

4.The address is displayed for 1 of the indoor units which is connected to the remote controller. Check that the fan of that indoor unit starts and that air is discharged.

15. Press the  button again and check the address of each indoor unit in sequence.

button again and check the address of each indoor unit in sequence.

6.Press the  button again to return to normal remote controller mode.

button again to return to normal remote controller mode.

2

3

Number changes to indicate which indoor unit is currently selected.

4

5

4. Remote Controller Test Run Settings

1.Press the remote controller  button for 4 seconds or longer. Then press the

button for 4 seconds or longer. Then press the  button.

button.

“TEST RUN” appears on the LCD display while the test run is in progress.

The temperature cannot be adjusted when in Test Run mode.

(This mode places a heavy load on the machines. Therefore use it only when performing the test run.) 2. The test run can be performed using the HEAT, COOL, or FAN operation modes.

NOTE

The outdoor units will not operate for approximately 3 minutes after the power is turned ON and after operation is stopped.

3.If correct operation is not possible, a code is displayed on the remote controller LCD display. (Refer to “Table of Self-Diagnostic Functions” and correct the problem.)

6 |

4. |

After the test run is completed, press the |

button again. Check that “TEST RUN” disappears from the LCD display. (To |

|

prevent continuous test runs, this remote controller includes a timer function that cancels the test run after 60 minutes.) |

||

*If the test run is performed using the wired remote controller, operation is possible even if the cassette-type ceiling panel has not been installed. (“P09” display does not occur.)

7

1 - 12

Test Run

5. Caution for Pump Down

5. Caution for Pump Down

Pump down means refrigerant gas in the system is returned to the outdoor unit. Pump down is used when the unit is to be moved, or before servicing the refrigerant circuit.

This outdoor unit cannot collect more than the rated refrigerant amount as

This outdoor unit cannot collect more than the rated refrigerant amount as

CAUTION shown by the nameplate on the back.  If the amount of refrigerant is more than that recommended, do not conduct pump down. In this case use another refrigerant collecting system.

If the amount of refrigerant is more than that recommended, do not conduct pump down. In this case use another refrigerant collecting system.

1

2

3

4

5

6

7

1 - 13

1

2

3

4

5

6

7

Test Run

6. Meaning of Alarm Messages

6. Meaning of Alarm Messages

Table of Self-Diagnostics Functions and Description of Alarm Displays

Alarm messages are indicated by the blinking of LED 1 and 2 (D72, D75) on the outdoor unit PCB. They are also displayed on the wired remote controller.

z Viewing the LED 1 and 2 (D72 and D75) alarm displays

LED1 |

LED2 |

Alarm contents |

|

|

|

|

|

Alarm Display |

Alternating |

LED 1 blinks M times, then LED 2 blinks N times. The cycle then repeats. |

|

|

|

M = 2: P alarm 3: H alarm 4: E alarm 5: F alarm 6: L alarm |

|

|

N = Alarm No. |

|

|

Example: LED 1 blinks 2 times, then LED 2 blinks 17 times. The cycle then repeats. |

|

|

Alarm is "P17". |

( : Blinling) Connect the outdoor maintenance remote controller to the RC socket on the outdoor main unit control PCB (3P, blue),and check the Alarm Messages on the remote controller display.

: Blinling) Connect the outdoor maintenance remote controller to the RC socket on the outdoor main unit control PCB (3P, blue),and check the Alarm Messages on the remote controller display.

Possible cause of malfunction |

Alarm |

|

Message |

||

|

Serial |

Remote controller is |

Error in receiving serial communication signal. |

<E01> |

|

communication |

detecting error signal from |

(Auto address is not completed.) |

||

|

||||

errors |

indoor unit. |

|

|

|

Error in transmitting serial communication signal. |

<E02> |

|||

Mis-setting |

|

|||

|

|

|

||

Indoor unit is detecting error signal from remote controller and system controller. |

<<E03>> |

|||

|

||||

|

|

|

|

|

|

Indoor unit is detecting error |

Group wiring failure of indoor units in the refrigerant system |

|

|

|

(occurring when remote controller is operated immediately after |

E04 |

||

|

signal from outdoor unit. |

|||

|

automatic address setting) |

|

||

|

|

|

||

|

|

|

|

|

|

Outdoor unit is detecting error |

Error in receiving serial communication signal. |

|

|

|

signal from indoor unit. |

There is an indoor unit which does not send signals when the |

E06 |

|

|

|

power is ON. |

|

|

|

|

|

|

|

|

Improper setting |

Indoor unit address setting is duplicated. |

<<E08>> |

|

|

|

|

||

|

Duplicated remote controller "main" setting. |

<<E09>> |

||

|

|

|||

|

|

|

|

|

|

|

Starting auto. address setting is prohibited. |

E12 |

|

|

|

AP pin / CN102 is shorted while the auto. address setting started. |

||

|

|

|

||

|

|

|

|

|

|

Indoor unit communication |

Error of main indoor unit in receiving serial communication signal |

E18 |

|

|

error of group control wiring. |

from sub indoor units. |

||

|

|

|||

|

|

|

|

|

|

During auto. address setting, |

Number of connected indoor units is less than the number set. |

E15 |

|

|

number of connected units |

|

|

|

|

Number of connected indoor units is more than the number set. |

E16 |

||

|

does not correspond to |

|||

|

|

|

||

|

No indoor unit is connected. |

E20 |

||

|

number set. |

|||

|

|

|

||

|

|

Main outdoor unit is detecting error signal from sub outdoor unit. |

E24 |

|

|

|

|

|

|

|

|

Duplicated outdoor unit address setting. |

E25 |

|

|

|

|

|

|

|

|

Mismatch in "No. of outdoor units" setting. |

E26 |

|

|

|

|

|

|

|

|

Error of sub outdoor unit in receiving signal from main outdoor unit. |

E29 |

|

|

|

|

|

|

|

Improper setting |

Connected indoor unit is not a multi unit. |

<<L02>> |

|

|

|

|

|

|

|

|

Duplication of main indoor unit address setting in group control. |

<L03> |

|

|

|

|

|

|

|

|

Group control wiring is connected to individual control indoor unit. |

L07 |

|

|

|

|

|

|

|

|

Indoor unit address is not set. |

L08 |

|

|

|

|

|

|

|

|

Capacity code of indoor unit is not set. |

<<L09>> |

|

|

|

|

|

|

|

|

Duplication of outdoor system address setting. |

L04 |

|

|

|

|

|

|

|

|

Capacity code of outdoor unit is not set. |

L10 |

|

|

|

|

|

|

|

|

Mismatch of outdoor unit type. |

L17 |

|

|

|

|

|

|

Thermistor |

Indoor unit |

Indoor coil temp. sensor (E1) |

<<F01>> |

|

fault |

|

|

|

|

|

Indoor coil temp. sensor (E3) |

<<F03>> |

||

|

|

|||

|

|

|

|

|

|

|

Indoor suction air (room) temp. sensor (TA) |

<<F10>> |

|

|

|

|

|

|

|

|

Indoor discharge air temp. sensor (BL) |

<<F11>> |

|

|

|

|

|

|

Continued

1 - 14

6. Meaning of Alarm Messages |

Test Run |

|||

|

||||

|

|

|

|

|

Possible cause of malfunction |

|

Alarm |

||

|

Message |

|||

|

|

|

||

Activation of |

Protective device in indoor unit |

Thermal protector in indoor unit fan motor is activated. |

<<P01>> |

|

protective |

is activated. |

|

|

|

Improper wiring connections of ceiling panel. |

<<P09>> |

|||

device |

|

|||

|

|

|

||

|

|

Float switch is activated. |

<<P10>> |

|

|

|

|

|

|

|

|

Operation of protective function of fan inverter. |

P12 |

|

|

|

|

|

|

|

|

O2 sensor (detects low oxygen level) activated. |

P14 |

|

|

|

Incorrect discharge temperature. (Comp. No. 1 (INV)) |

P03 |

|

|

|

|

|

|

|

|

High pressure switch is activated. |

P04 |

|

|

|

|

|

|

|

|

Negtive (defective) phase. |

P05 |

|

|

|

|

|

|

|

|

Compressor running failure resulting from missing phase in the |

P16 |

|

|

|

compressor wiring, etc. (Start failure not caused by IPM or no gas.) |

||

|

|

|

||

|

|

Incorrect discharge temperature. (Comp. No. 2 (constant speed)) |

P17 |

|

|

|

|

|

|

|

|

Outdoor unit fan motor is unusual. |

P22 |

|

|

|

|

|

|

|

|

Overcurrent at time of compressor runs more than 80Hz (DCCT |

|

|

|

|

secondary current or ACCT primary current is detected at a time other |

P26 |

|

|

|

than when IPM has tripped.) |

|

|

|

|

IPM trip (IPM current or temperature) |

H31 |

|

|

|

|

|

|

|

|

Inverter for compressor is unusual. (DC compressor does not operate.) |

P29 |

|

Thermistor fault |

Indoor thermistor is either open |

Indoor coil temp. sensor (E1) |

<<F01>> |

|

|

or damaged. |

|

|

|

|

Indoor coil temp. sensor (E3) |

<<F03>> |

||

|

|

|||

|

|

|

|

|

|

|

Indoor suction air (room) temp. sensor (TA) |

<<F10>> |

|

|

|

|

|

|

|

|

Indoor discharge air temp. sensor (BL) |

<<F11>> |

|

|

|

|

|

|

|

Outdoor thermistor is either |

Comp. No. 1 (INV) discharge gas temp. sensor (DISCH1) |

F04 |

|

|

open or damaged. |

|

|

|

|

Comp. No. 2 (constant speed) discharge gas temp. sensor (DISCH2) |

F05 |

||

|

|

|||

|

|

|

|

|

|

|

Outdoor No. 1 coil gas temp. sensor (EXG1) |

F06 |

|

|

|

Outdoor No. 1 coil liquid temp. sensor (EXL1) |

F07 |

|

|

|

|

|

|

|

|

Outdoor air temp. sensor (AIR TEMP) |

F08 |

|

|

|

|

|

|

|

|

Compressor suction temp. sensor (SCT) |

F12 |

|

|

|

|

|

|

|

|

High pressure sensor. |

F16 |

|

|

|

|

|

|

|

|

Low-pressure sensor failure |

F17 |

|

|

|

|

|

|

|

|

Outdoor No. 2 coil gas temp. sensor (EXG2) |

F23 |

|

|

|

|

|

|

|

|

Outdoor No. 2 coil liquid temp. sensor (EXL2) |

F24 |

|

|

|

|

|

|

EEPROM on indoor unit PCB failure |

|

F29 |

||

|

|

|

|

|

Protective |

Protective device for |

EEPROM on the main or sub outdoor unit PCB has failed. |

F31 |

|

device for |

compressor No.1 (INV) is |

|

|

|

Current is not detected when comp. No. 1 (INV) is ON. |

H03 |

|||

compressor is |

activated. |

|||

activated |

|

|

|

|

Protective device for |

Overload current is detected. |

H11 |

||

|

||||

|

compressor No.2 (constant |

|

|

|

|

Lock current is detected. |

H12 |

||

|

speed) is activated |

|||

|

|

|

||

|

|

Current is not detected when comp. No.2 (constant speed) is ON. |

H13 |

|

|

|

|

|

|

|

|

Discharge gas temperture of comp. No.2 (constant speed) is not |

H15 |

|

|

|

detected. |

||

|

|

|

||

|

|

Low pressure trouble |

H06 |

|

|

|

|

|

|

|

Low oil level alarm. |

|

H07 |

|

|

|

|

|

|

|

Oil sensor fault. |

Comp. No.1 (INV) oil sensor |

H08 |

|

|

(Disconnection, etc.) |

|

|

|

|

Comp. No.2 (constant speed) oil sensor |

H27 |

||

|

|

|||

|

|

|

|

|

Continued

1

2

3

4

5

6

7

1 - 15

6. Meaning of Alarm Messages |

Test Run |

||||

|

|

||||

|

|

|

|

|

|

|

Alarm messages displayed on system controller |

|

|

||

|

|

|

|

|

|

|

Serial |

Error in transmitting serial |

Indoor or main outdoor unit is not oparating correctly. |

|

|

|

communication |

communication signal |

Mis-wiring of control wiring between indoor unit, main outdoor unit and |

C05 |

|

|

errors |

|

system controller. |

|

|

|

Mis-setting |

|

|

|

|

|

Error in receiving serial |

Indoor or main outdoor unit is not operating correctly. |

|

|

|

|

|

|

|

||

|

|

communication signal |

Mis-wiring of control wiring between indoor unit, main outdoor unit and |

C06 |

|

|

|

|

system controller. |

|

|

|

|

|

|

|

|

|

|

|

CN1 is not connected properly. |

|

|

|

|

|

|

|

|

|

Activation of |

Protective device of sub indoor |

When using wireless remote controller or system controller, in order to |

|

|

|

protective |

unit in group control is activated |

check the alarm message in detail, connect wired remote controller to |

P30 |

|

|

device |

|

indoor unit temporarily. |

|

|

|

|

|

|

|

|

NOTE

1.Alarm messages in << >> do not affect other indoor unit operations.

2.Alarm messages in < > sometimes affect other indoor unit operations depending on the fault.

1

2

3

4

5

6

7

1 - 16

Contents |

|

TENTATIVE |

|

Remote Control Functions |

|

|

|

||

2. REMOTE CONTROL FUNCTIONS |

|

|||

1. Main Operating Functions ................................................................................................. |

|

|

2-2 |

|

1-1. Room Temperature Control ........................................................................................... |

2-2 |

|||

1-2. Automatic Control for Heating and Cooling ................................................................... |

2-3 |

|||

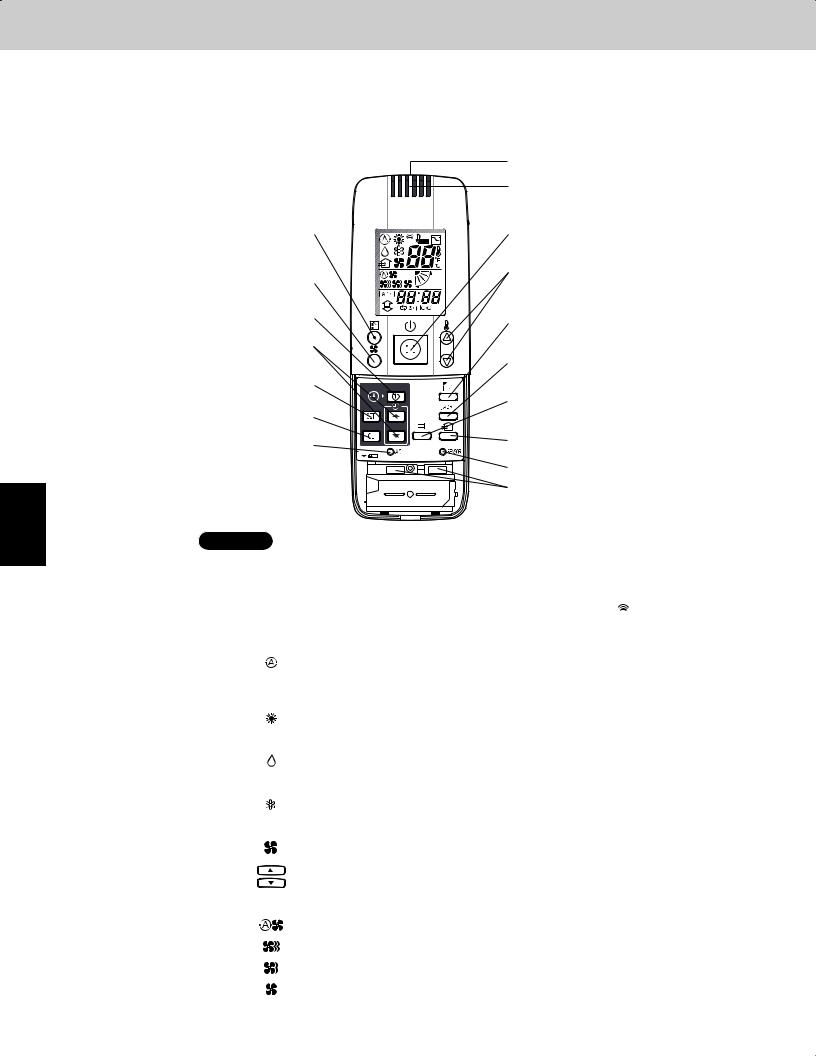

2. Wireless Remote Controller |

.............................................................................................. |

|

2-4 |

|

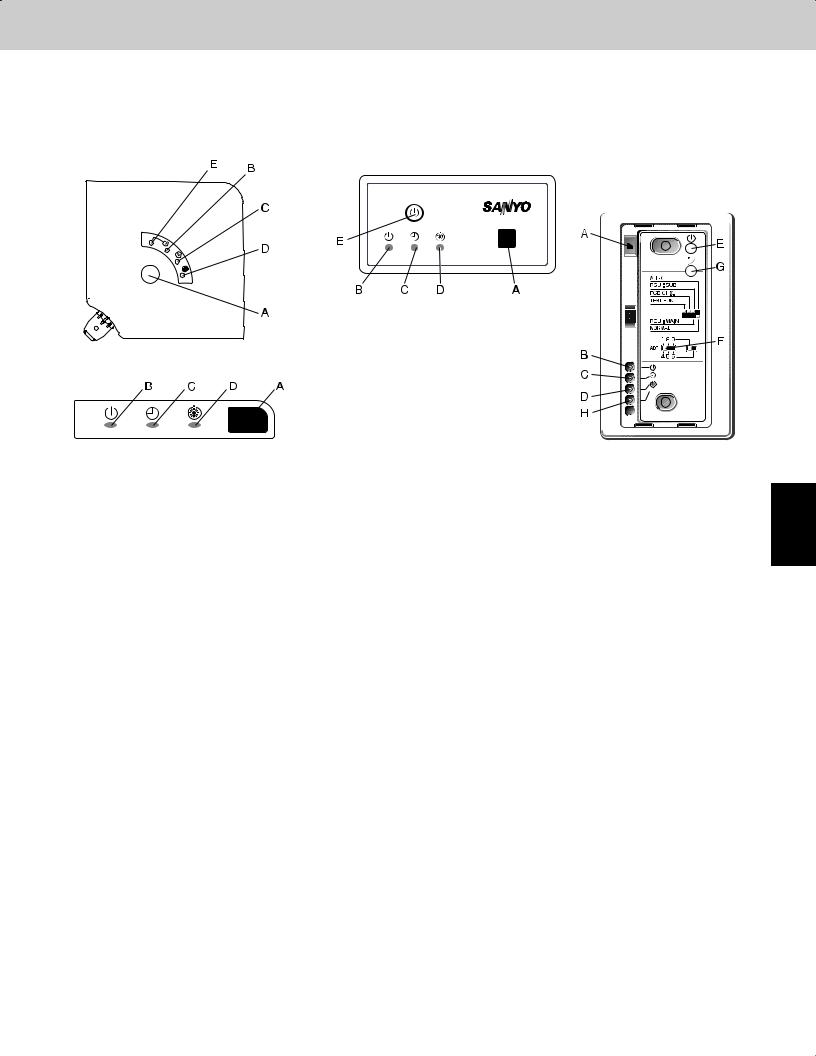

2-1. How to Use the Wireless Remote Controller ................................................................. |

2-4 |

|||

2-2. Receiver ........................................................................................................................ |

|

|

2-7 |

|

2-3. Operation....................................................................................................................... |

|

|

2-8 |

|

2-4. Using the Wireless Remote Control Unit....................................................................... |

2-9 |

|||

2-5. Address Settings ......................................................................................................... |

|

|

2-10 |

|

2-6. Emergency Operation ................................................................................................. |

|

|

2-12 |

|

2-7. Trouble Diagnosis ........................................................................................................ |

|

|

2-14 |

|