Nissan XTrail T30 2005 User Manual

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

A

B

SECTION AT

CONTENTS

INDEX FOR DTC ........................................................ 5

Alphabetical Index .................................................... 5

DTC No. Index ......................................................... 6

PRECAUTIONS .......................................................... 7

Precautions for Supplementa l Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 7

Precautions for On Board Diagnostic (OBD) System

of A/T and Engine .................................................... 7

Precautions .............................................................. 7

Service Notice or Precautions .................................. 9

Wiring Diagrams and Trouble Diagnosis ................ 10

PREPARATION ..................................... .....................11

Special Service Tools ..............................................11

Commercial Service Tools ...................................... 15

A/T FLUID ................................................................. 17

Checking A/T Fluid ................................................. 17

Changing A/T Fluid ..................... ....... ...... ....... ....... 18

A/T Fluid Cooler Cleaning ...................................... 18

A/T CONTROL SYSTEM .......................................... 21

Cross-Sectional View ............................................. 21

Shift Mechanism ..................................................... 22

TCM Function ........... ...... ....... ...... ....... ...... ....... ....... 31

CAN Communication .............................................. 32

Input/Output Signal of TCM .................................... 32

Line Pressure Control ........... ...... ....... ...... ....... ....... 33

Shift Control ........................................................... 34

Lock-Up Control ..................................................... 35

Engine Brake Control (Overrun Clutch Control) ..... 36

Control Valve ............ ...... ....... ...... ........................... 38

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 39

Introduction ............................................................ 39

OBD-II Function for A/T System ............................. 39

One or Two Trip Detection Logic of OBD-II ............ 39

OBD-II Diagnostic Trouble Code (DTC) ................. 39

Malfunction Indicator Lamp (MIL) ........................... 42

TROUBLE DIAGNOSIS ............................................ 43

DTC Inspection Priority Chart ................................ 43

Fail-Safe ................................ ................................. 43

How to Perform Trouble Diagnoses for Quick and

AUTOMATIC TRANSAXLE

Accurate Repair ......................................................45

A/T Electrical Parts Location ..................................50

Circuit Diagram .......................................................51

Inspections before Trouble Diagnosis ....................52

Road Test ...............................................................57

Check before Engine Is Started ..............................57

Check at Idle ...........................................................58

Cruise Test — Part 1 .............................................. 60

Cruise Test — Part 2 .............................................. 63

Cruise Test — Part 3 .............................................. 64

Vehicle Speed When Shifting Gears ......................66

Vehicle Speed When Performing and Releasing

Lock-Up ..................................................................66

Symptom Chart .......................................................67

TCM Terminals and Reference Value .....................77

CONSULT-II Function (A/T) ................... ...... ....... ....80

Diagnostic Procedure Without CONSULT-II ........... 91

DTC U1000 CAN COMMUNICATION LINE .............. 95

Description ................... ...... ....... ...... ........................ 95

On Board Diagnosis Logic ......................................95

Possible Cause .......................................................95

DTC Confirmation Procedure ................................. 95

Wiring Diagram — AT — CAN ................................96

Diagnostic Procedure .............................................97

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ....................................................................98

Description ................... ...... ....... ...... ........................ 98

CONSULT-II Reference Value ............... ...... ....... ....98

On Board Diagnosis Logic ......................................98

Possible Cause .......................................................98

DTC Confirmation Procedure ................................. 98

Wiring Diagram — AT — PNP/SW .........................99

Diagnostic Procedure ...........................................101

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................104

Description ................... ...... ....... ...... ......................104

CONSULT-II Reference Value ............... ...... ....... ..104

On Board Diagnosis Logic ....................................104

Possible Cause .....................................................104

DTC Confirmation Procedure ...............................104

AT

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-1

Wiring Diagram — AT — FTS ...............................105

Diagnostic Procedure ...........................................106

Component Inspection ..........................................108

DTC P0720 VEHI CLE SPEED SENSOR ·A/T (REV -

OLUTION SENSOR) ...............................................109

Description ................ .......................... ..................109

CONSULT-II Reference Value ..............................109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................... ....... .....109

Wiring Diagram — AT — VSSA/T ..........................111

Diagnostic Procedure ...........................................112

DTC P0725 ENGINE SPEED SIGNAL ...................115

Description ................ .......................... ..................115

CONSULT-II Reference Value ..............................115

On Board Diagnosis Logic ....................................115

Possible Cause .....................................................115

DTC Confirmation Procedure ................... ....... .....115

Wiring Diagram — AT — ENGSS .........................117

Diagnostic Procedure ...........................................118

DTC P0731 A/T 1ST GEAR FUNCTION .................120

Description ................ .......................... ..................120

On Board Diagnosis Logic ....................................120

Possible Cause .....................................................120

DTC Confirmation Procedure ................... ....... .....120

Wiring Diagram — AT — 1STSIG .........................122

Diagnostic Procedure ...........................................123

DTC P0732 A/T 2ND GEAR FUNCTION ................125

Description ................ .......................... ..................125

On Board Diagnosis Logic ....................................125

Possible Cause .....................................................125

DTC Confirmation Procedure ................... ....... .....125

Wiring Diagram — AT — 2NDSIG ........................127

Diagnostic Procedure ...........................................128

DTC P0733 A/T 3RD GEAR FUNCTION ................130

Description ................ .......................... ..................130

On Board Diagnosis Logic ....................................130

Possible Cause .....................................................130

DTC Confirmation Procedure ................... ....... .....130

Wiring Diagram — AT — 3RDSIG ........................132

Diagnostic Procedure ...........................................133

DTC P0734 A/T 4TH GEAR FUNCTION ................135

Description ................ .......................... ..................135

CONSULT-II Reference Value ..............................135

On Board Diagnosis Logic ....................................135

Possible Cause .....................................................135

DTC Confirmation Procedure ................... ....... .....135

Wiring Diagram — AT — 4THSIG ........................137

Diagnostic Procedure ...........................................138

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE ............................... ...... ....... .....142

Description ................ .......................... ..................142

CONSULT-II Reference Value ..............................142

On Board Diagnosis Logic ....................................142

Possible Cause .....................................................142

DTC Confirmation Procedure ................... ....... .....142

Wiring Diagram — AT — TCV ..............................143

Diagnostic Procedure ...........................................144

Component Inspection ..........................................146

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) .147

Description ............................................................147

CONSULT-II Reference Value ...............................147

On Board Diagnosis Logic ....................................147

Possible Cause .....................................................147

DTC Confirmation Procedure ................................148

Wiring Diagram — AT — TCCSIG ........................149

Diagnostic Procedure ............................................150

DTC P0745 LINE PRESSURE SOLENOID VALVE .155

Description ............................................................155

CONSULT-II Reference Value ...............................155

On Board Diagnosis Logic ....................................155

Possible Cause .....................................................155

DTC Confirmation Procedure ................................155

Wiring Diagram — AT — LPSV ............................157

Diagnostic Procedure ............................................158

Component Inspection ..........................................161

DTC P0750 SHIFT SOLENOID VALVE A ...............162

Description ............................................................162

CONSULT-II Reference Value ...............................162

On Board Diagnosis Logic ....................................162

Possible Cause .....................................................162

DTC Confirmation Procedure ................................162

Wiring Diagram — AT — SSV/A ...........................163

Diagnostic Procedure ............................................164

Component Inspection ..........................................166

DTC P0755 SHIFT SOLENOID VALVE B ...............167

Description ............................................................167

CONSULT-II Reference Value ...............................167

On Board Diagnosis Logic ....................................167

Possible Cause .....................................................167

DTC Confirmation Procedure ................................167

Wiring Diagram — AT — SSV/B ...........................168

Diagnostic Procedure ............................................169

Component Inspection ..........................................171

DTC P1705 ACCELERAT OR P EDAL POSITION

(APP) SENSOR .......................................................172

Description ............................................................172

CONSULT-II Reference Value ...............................172

On Board Diagnosis Logic ....................................172

Possible Cause .....................................................172

DTC Confirmation Procedure ................................172

Wiring Diagram — AT — TPS ...............................174

Diagnostic Procedure ............................................175

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE ................................................ ............. ....... ..177

Description ............................................................177

CONSULT-II Reference Value ...............................177

On Board Diagnosis Logic ....................................177

Possible Cause .....................................................177

DTC Confirmation Procedure ................................177

Wiring Diagram — AT — OVRCSV ......................178

Diagnostic Procedure ............................................179

Component Inspection ..........................................181

DTC VEHICLE SPEED SENSOR MTR ...................182

Description ............................................................182

CONSULT-II Reference Value ...............................182

On Board Diagnosis Logic ....................................182

Possible Cause .....................................................182

Revision: 2005 March 2005 X-Trail

AT-2

DTC Confirmation Procedure ............................... 182

Wiring Diagram — AT — VSSMTR ...................... 184

Diagnostic Procedure ........................................... 185

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE) . 187

Description ........................................................... 187

CONSULT-II Reference Value .............................. 187

On Board Diagnosis Logic ................................... 187

Possible Cause .................................................... 187

DTC Confirmation Procedure ............................... 187

Wiring Diagram — AT — BA/FTS ........................ 189

Diagnostic Procedure ........................................... 190

Component Inspection ......................................... 193

MAIN POWER SUPPLY AND GROUND CIRCUIT . 194

Description ........................................................... 194

On Board Diagnosis Logic ................................... 194

Possible Cause .................................................... 194

DTC Confirmation Procedure ............................... 194

Wiring Diagram — AT — MAIN ............................ 195

Diagnostic Procedure ........................................... 196

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ..................................................................... 198

Description ........................................................... 198

On Board Diagnosis Logic ................................... 198

Possible Cause .................................................... 198

DTC Confirmation Procedure ............................... 198

Diagnostic Procedure ........................................... 199

DTC CONTROL UNIT(EEPROM) ........................... 200

Description ........................................................... 200

On Board Diagnosis Logic ................................... 200

Possible Cause .................................................... 200

DTC Confirmation Procedure ............................... 200

Diagnostic Procedure ........................................... 201

TROUBLE DIAGNOSES FOR SYMPTOMS .......... 202

Wiring Diagram — AT — NONDTC ...................... 202

O/D OFF Indicator Lamp Does Not Come On ..... 205

Engine Cannot Be Started in “P” and “N” Position . 207

In “P” Position, Vehicle Moves Forward or Backward

When Pushed ....................................................... 208

In “N” Position, Vehicle Moves ............................. 209

Large Shock. “N” → “R” Position ...........................211

Vehicle Does Not Creep Backward in “R” Position . 212

Vehicle Does Not Creep Forward in “D”, “2” or “1”

Position ................................................................ 215

Vehicle Cannot Be Started From D

A/T Does Not Shift: D

D

4 → D2 ............................................................... 220

A/T Does Not Shift: D

A/T Does Not Shift: D

1 → D2 or Does Not Kickdown:

2 → D3 ............................... 223

3 → D4 ............................... 226

1 ..................... 217

A/T Does Not Perform Lock-Up ........................... 228

A/T Does Not Hold Lock-Up Condition ................. 229

Lock-Up Is Not Released ..................................... 231

Engine Speed Does Not Return to Idle (Light Braking D

4 → D3 ) ....................................................... 232

A/T Does Not Shift: D

4 → D3 , When Overdrive Con-

trol Switch “ON” → “OFF” ..................................... 234

A/T Does Not Shift: D

3 → 22 , When Selector Lev er

“D” → “2” Position ................................................ 235

A/T Does Not Shift: 2

2 → 11 , When Selector Lev er

“2” → “1” on Position ............................................237

Vehicle Does Not Decelerate by Engine Brake ....240

TCM Self-Diagnosis Does Not Activate ................244

SHIFT CONTROL SYSTEM ....................................251

Control Device Removal and Installation ..............251

Adjustment of A/T Position ...................................252

Checking of A/T Position ......................................253

A/T SHIFT LOCK SYSTEM ....................................254

Description ................... ...... ....... ...... ......................254

Shift Lock System Electrical Parts Location .........254

Wiring Diagram — AT — SHIFT ...........................255

Diagnostic Procedure ...........................................256

KEY INTERLOCK CABLE ......................................258

Components .........................................................258

Removal ...............................................................258

Installation ............................................................259

ON-VEHICLE SERVICE ..........................................260

Control Valve Assembly and Accumulators ..........260

Park/Neutral Position (PNP) Switch .....................263

Differential Side Oil Seal Replacement ................265

Revolution Sensor Replacement ..........................267

AIR BREATHER HOSE ..........................................268

Removal and Installation ......................................268

TRANSAXLE ASSEMBLY ......................................269

Removal and Installation ......................................269

OVERHAUL ............................................................272

Components .........................................................272

Oil Channel ...........................................................278

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................279

DISASSEMBLY .......................................................280

Disassembly .........................................................280

REPAIR FOR COMPONENT PARTS .....................296

Manual Shaft ........................................................296

Oil Pump ...............................................................299

Control Valve Assembly ........................................304

Control Valve Upper Body ....................................313

Control Valve Lower Body ....................................317

Reverse Clutch .....................................................320

High Clutch ..... ...... ....... ....................................... ..325

Forward and Overrun Clutches ............................331

Low & Reverse Brake ...........................................338

Rear Internal Gear, Forward Clutch Hub and Over-

run Clutch Hub .......................... ...... ....... ...... ....... ..342

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................346

Band Servo Piston Assembly ...............................352

Final Drive ............................................................358

ASSEMBLY ............. ................................................362

Assembly (1) .........................................................362

Adjustment (1) ......................................................363

Assembly (2) .........................................................368

Adjustment (2) ......................................................375

Assembly (3) .........................................................378

SERVICE DATA AND SPECIFICATIONS (SDS) ....385

General Specifications . ...... ....... ...... ......................385

Vehicle Speed When Shifting Gears ....................385

Vehicle Speed When Performing and Releasing

Look-Up ....................... .........................................385

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-3

Stall Revolution .....................................................385

Line Pressure .......................................................385

Control Valves .......................................................386

Accumulator .............. ................................ ............386

Clutch and Brakes ................................................387

Final Drive ............................................................389

Planetary Carrier and Oil Pump ............................390

Input Shaft ............................................................390

Reduction Pinion Gear .........................................391

Band Servo ...........................................................391

Output Shaft ..........................................................392

Bearing Retainer ............................. ....... ...... ....... ..392

Total End Play .......................................................392

Reverse Clutch End Play ......................................392

Removal and Installation .......................................393

Shift Solenoid Valves ............................................393

Solenoid Valves ....................................................393

A/T Fluid Temperature Sensor ..............................393

Revolution Sensor .................................................393

Dropping Resistor .................................................393

Revision: 2005 March 2005 X-Trail

AT-4

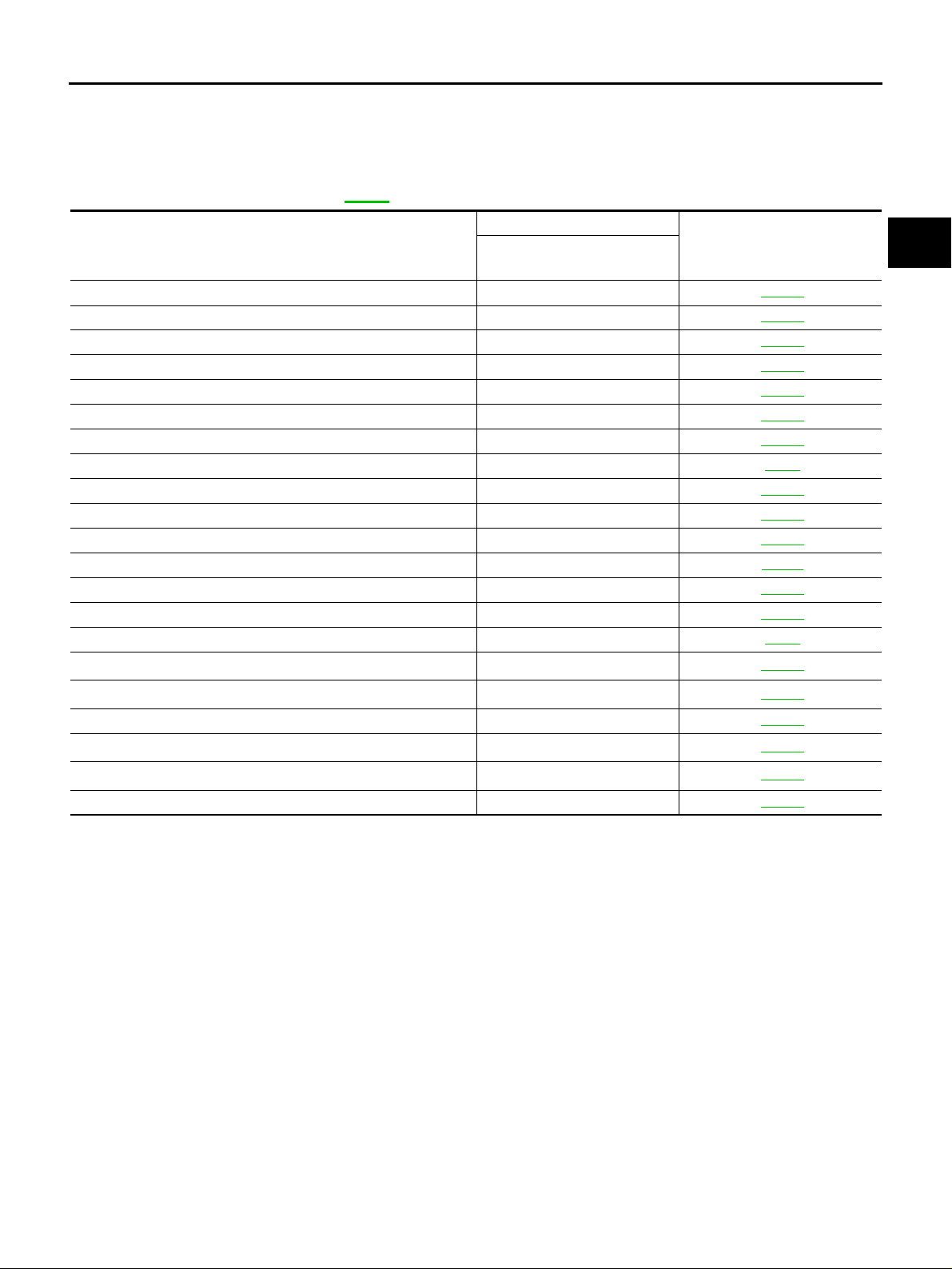

INDEX FOR DTC

INDEX FOR DTC PFP:00024

Alphabetical Index ACS008HT

NOTE:

If DTC “U1000” is displayed wi th other DTC, first perform the trouble diagnos is for “DTC U1000 CAN

COMMUNICATION LINE”. Refer to AT-95

Items

(CONSULT-II screen terms)

A/T 1ST GR FNCTN P0731 AT-120

A/T 2ND GR FNCTN P0732 AT-125

A/T 3RD GR FNCTN P0733 AT-130

A/T 4TH GR FNCTN P0734 AT-135

A/T TCC S/V FNCTN P0744 AT-147

ATF TEMP SEN/CIRC P0710 AT-104

BATT/FLUID TEMP SEN — AT-187

CAN COMM CIRCUIT U1000 AT-95

CONTROL UNIT (RAM) — AT-198

CONTROL UNIT (ROM) — AT-198

CONT UNIT(EEP ROM) — AT-200

ENGINE SPEED SIG P0725 AT-115

LINE PRESSURE S/V P0745 AT-155

OVERRUN CLUTCH S/V P1760 AT-177

PNP SW/CIRC P0705 AT-98

SHIFT SOLENOID/V A*

SHIFT SOLENOID/V B*

T/C CLUTCH SOL/V P0740 AT-142

THROTTLE POSI SEN*

VHCL SPEED SEN·A/T*

VHCL SPEED SEN·MTR — AT-182

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution senso r signal” and the “Vehicle speed sensor signal ” meet the fail-safe co ndition at

the same time.

2

2

2

3

.

DTC

CONSULT-II

*1

GST

P0750 AT-162

P0755 AT-167

P1705 AT-172

P0720 AT-109

Reference page

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-5

INDEX FOR DTC

DTC No. Index ACS008HU

NOTE:

If DTC “U1000” is displayed with other DTC, first perform the trouble diagnosis for “DTC U1000 CAN

COMMUNICATION LINE”. Refer to AT-95

DTC

CONSULT-II

*1

GST

P0705 PNP SW/CIRC AT-98

P0710 ATF TEMP SEN/CIRC AT-104

P0720

P0725 ENGINE SPEED SIG AT-115

P0731 A/T 1ST GR FNCTN AT-120

P0732 A/T 2ND GR FNCTN AT-125

P0733 A/T 3RD GR FNCTN AT-130

P0734 A/T 4TH GR FNCTN AT-135

P0740 T/C CLUTCH SOL/V AT-142

P0744 A/T TCC S/V FNCTN AT-147

P0745 LINE PRESSURE S/V AT-155

P0750

P0755

P1705

P1760 OVERRUN CLUTCH S/V AT-177

U1000 CAN COMM CIRCUIT AT-95

— BATT/FLUID TEMP SEN AT-187

— CONTROL UNIT (RAM) AT-198

— CONTROL UNIT (ROM) AT-198

— CONT UNIT(EEP ROM) AT-200

— VHCL SPEED SEN·MTR AT-182

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, th e MIL ill um in ate s.

*3: The MIL illuminates when bot h the “Revolution sens or signal” and the “Vehicle speed sensor si gnal” meet the fail-safe condi tion at

the same time.

VHCL SPEED SEN·A/T*

SHIFT SOLENOID/V A*

SHIFT SOLENOID/V B*

THROTTLE POSI SEN*

.

Items

(CONSULT-II screen terms)

3

2

2

2

Reference page

AT-109

AT-162

AT-167

AT-172

Revision: 2005 March 2005 X-Trail

AT-6

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “ AIR BAG” and “SEAT BELT PRE-TENSIONER”

ACS007QJ

A

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PRE-TENSIO NER”, used along

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of col lision. Information necessary to service the system safely is in cluded in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid ren dering the SRS ino perative, w hich could inc rease the ris k of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n o f the s ys t em . F or re mo va l of Spiral Cable and Ai r

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for On Board Diagnostic (OBD) System of A/T and Engine ACS007QK

The ECM has an on boa rd diagnos tic system. It wil l light up the m alfunction indicator la mp (MIL) to warn th e

driver of a malfunction causing emission deterioration.

CAUTION:

● Be sure to turn the ignition switch OFF a nd disconnect battery negative cable from battery nega-

tive terminal before any repair or inspectio n w ork . The open/s hort c irc uit of re la ted s witches, sensors, solenoid valves, etc. will cause the MIL to light up.

● Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water,

grease, dirt, bent terminals, etc.)

● Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

● Be sure to connect the rubber tub es prope rly after work . A misco nnected or dis conne cted rub ber

tube may cause the MIL to light u p due to a ma lfunction o f the EGR system or fuel inj ection system, etc.

● Be sure to eras e the u nnecess ary mal function i nformatio n (repairs compl eted) from the TC M and

ECM before returning the vehicle to the custom er.

Precautions ACS007QN

B

AT

D

E

F

G

H

I

J

K

L

● Before connecting or dis connecting the TCM harness con-

nector, turn ignition switch OFF and disconnect battery

negative cable from battery negative term inal. Failu re to do

so may damage the TCM. Because battery voltage is

applied to TCM even if ignition switch is turned off.

SEF289H

Revision: 2005 March 2005 X-Trail

AT-7

M

PRECAUTIONS

● When connecting or discon necting pin connectors into or

from TCM, take care not to damage pin term inals (bend or

break).

Make sure that th ere are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

● Before replacing TCM, perform TCM input/output signal

inspection and make s ure whether TCM fu nctions properly

or not. Refer to AT-77, "

Value" .

TCM Terminals and Reference

AAT470A

MEF040DA

● After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

The DTC should not be disp layed in th e “DTC Co nfirmati on

Procedure” if the repair is completed.

● Before proceeding with disassembly, thoroughly clean th e out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

● Disassembly should be done in a clean work area.

● Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

SEF217U

of the transaxle.

● Place disassembled parts in order for easier and pro per assembly.

● All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

● Gaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

● It is very important to perform functional tests whenever they are indicated.

● The valve bo dy co ntains precision p a rts and requires extre me ca re w h en p ar t s ar e r em ov ed and s er v ic ed .

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from be coming scattered or lost .

● Properly installed valves, sle ev e s, plugs, etc. will slide along bore s in valve body under their own we ig ht.

● Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

● Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

● Clean or replace ATF cooler if excessive forei gn mate rial is fo und in oi l pan or clog ging strain er. Refer to

AT-9, "

● After over haul, refill the transaxle with new ATF.

● When the A/T drain plug is remove d, only some of t he fluid is drai ned. O ld A/T flu id wil l remain i n torque

ATF COOLER SERVICE" .

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”, AT-17, "

A/T FLUID" .

Revision: 2005 March 2005 X-Trail

AT-8

PRECAUTIONS

Service Notice or Precautions ACS007QO

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and cl ean the A/T oil c ooler mounted in the radiator or replace the radi ator. Flush cooler lines us ing

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning procedure. For radiator replacement, refer to CO-11, "

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

● External leaks in the hub weld area.

● Converter hub is scored or damaged.

● Converter pilot is broken, damaged or fits poorly into crankshaft.

● Steel particles are found after flushing the cooler and cooler lines.

● Pump is damaged or steel particle s are foun d in the con ve rte r.

● Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

● Converter is contaminated with engine coolant containing antifreeze.

● Internal malfunction of stator roller clutch.

● Heavy clutch debris due to overheating (blue converter).

● Steel particles or clutch lining m a teri al found in fluid filter o r on magnet indicat es th at l in ing m aterial came

from converter when no internal parts in unit are worn or damaged.

The torque converter should not be replaced if:

● The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

● The threads in one or more of the converter bolt holes are damaged.

● Transaxle malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch

plate lining material in unit and inside the fluid filter.

● Vehicle has been exposed to high mileage (only). The exception may be where the torque converter

clutch damp er plate lining has seen excess wear by vehicles ope rated in heavy and/ or constant traffic,

such as taxi, delivery or police use.

RADIATOR" , CO-14, "RADIAT OR (ALUMINUM TYPE)" .

A

B

AT

D

E

F

G

H

I

J

OBD-II SELF-DIAGNOSIS

● A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the

table on AT-8 2 , "

nostic result.

● The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM mem-

ories.

Always perform the procedure “HOW TO ERASE DTC” on AT-40, "

plete the repair and avoid unnecessary blinking of the MIL.

● The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

– PNP switch

– A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD-II, refer to AT-39, "

● Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness con nec tor.

For description and how to dis c onnect, refer to PG-44, "

SELF-DIAGNOSTIC RESULT MODE" for the indicator used to display each self-diag-

HOW TO ERASE DTC" to com-

ON BOARD DIAGNOSTIC (OBD) SYSTEM" .

HARNESS CONNECTOR" .

K

L

M

Revision: 2005 March 2005 X-Trail

AT-9

PRECAUTIONS

Wiring Diagrams and Trouble Diagnosis ACS007QP

When reading wiring diag ram s, refer to the foll owin g:

● GI-14, "How to Read Wiring Diagrams"

● PG-2, "POWER SUPPLY ROUTING"

When performing troubl e dia gn os is, refer to the following:

● GI-10, "How to Follow Trouble Diagnoses"

● GI-26, "How to Perform Efficient Diagnosis for an Electrical Incident"

Revision: 2005 March 2005 X-Trail

AT-10

PREPARATION

PREPARATION PFP:00100

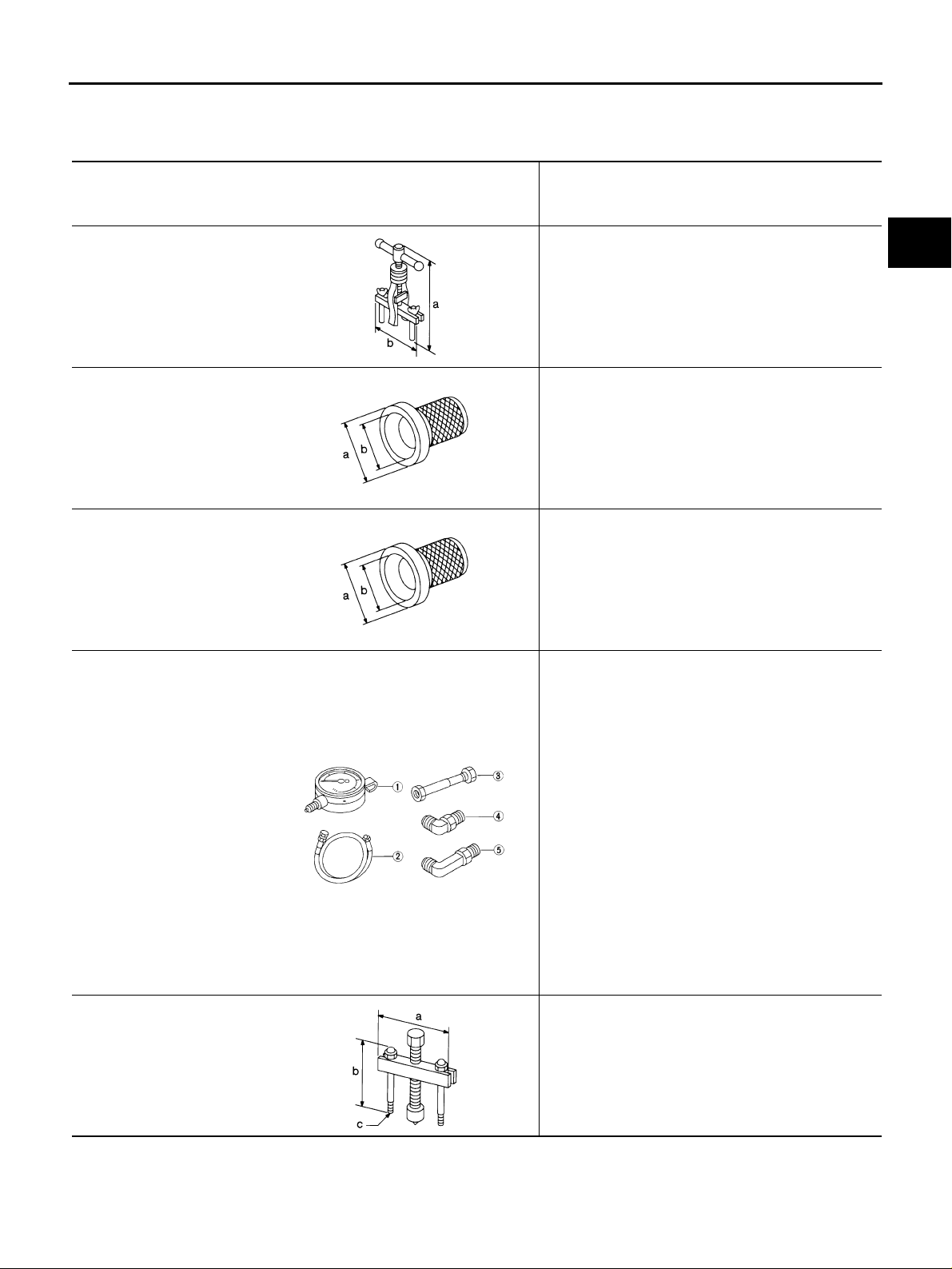

Special Service Tools ACS007QQ

The actual shapes of Kent-Moore tools may differ from those of spec ial ser vi ce tool s illust rat ed here.

Tool number

(Kent-Moore No.)

Tool name

Description

A

B

KV381054S0

(J-34286)

Puller

ST33400001

(J-26082)

Drift

KV40100621

(J-25273)

Drift

ST2505S001

(J-34301)

Oil pressure gauge set

1. ST25051001

(J-34301)

Oil pressure gauge

2.ST25052000

(J-34301)

Hose

3.ST25053000

(J-25695-3)

Joint pipe

4.ST25054000

(J-25695-4)

Adapter

5.ST25055000

(J-25695-5)

Adapter

ST27180001

(J-25726-A)

Puller

NT414

NT086

NT086

NT097

● Removing dif ferential sid e bearing outer race

● Removing idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

● Installing differential side oil seal

● Installing oil pump housing oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Instal l ing differential side oil seal (With AWD models)

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Measuring line pressure

Removing idler gear

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 x 1.25P

AT

D

E

F

G

H

I

J

K

L

M

NT424

Revision: 2005 March 2005 X-Trail

AT-11

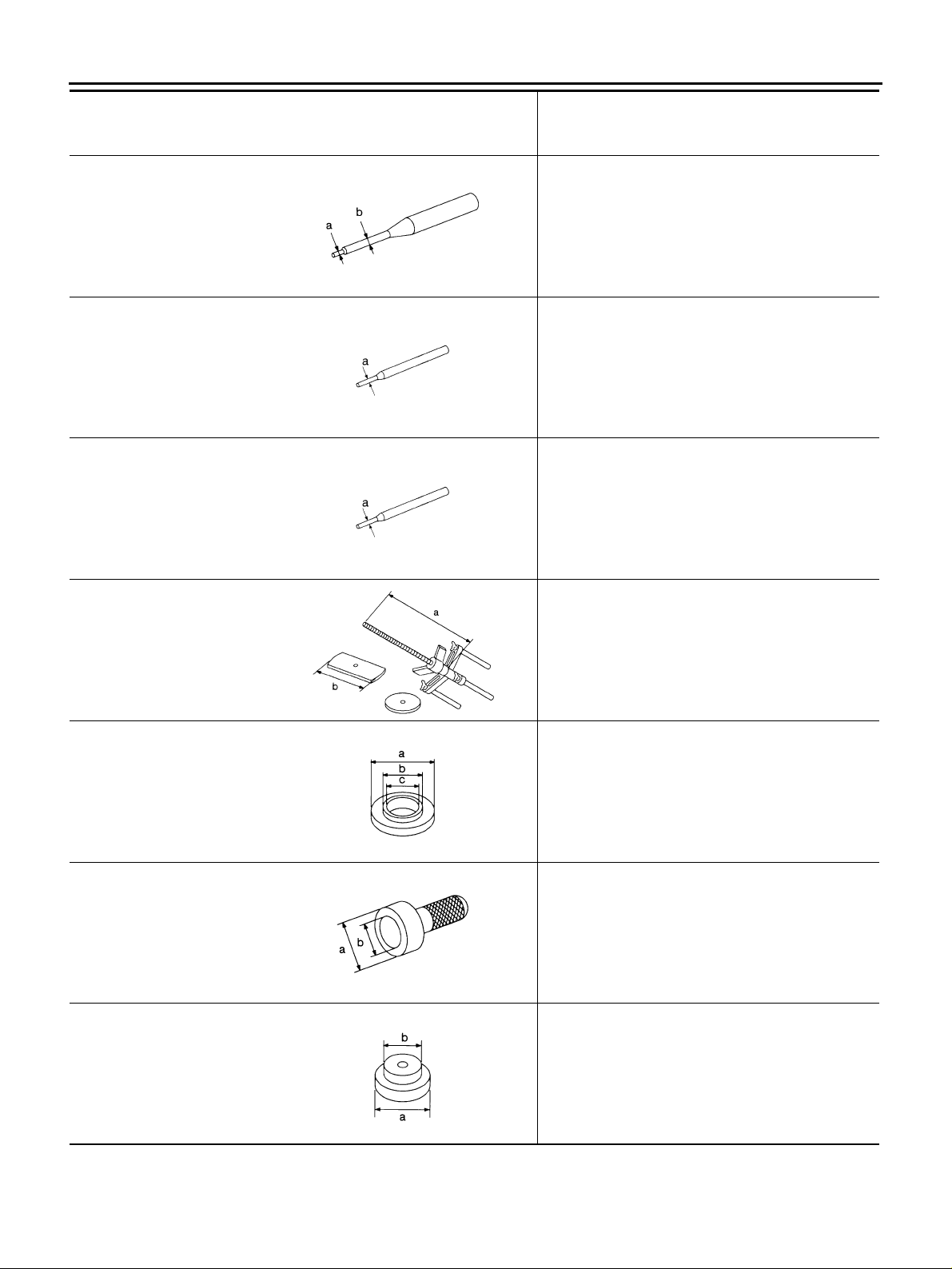

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Description

ST23540000

(J-25689-A)

Pin punch

ST25710000

(J-25689-A)

Pin punch

KV32101000

(J-25689-A)

Pin punch

KV31102400

(J-34285)

Clutch spring compressor

Removing and installing parking rod plate and

manual plate retaining pins

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

NT442

Aligning groove of manual shaft and hole of

transaxle case

a: 2 mm (0.08 in) dia.

NT410

● Installing manual shaft retaining pin

● Removing and i nstalling pinion m at e shaf t lock pin

a: 4 mm (0.16 in) dia.

NT410

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

KV40100630

(J-26092)

Drift

ST30720000

(J-25405)

Bearing installer

ST35321000

(—)

Drift

NT423

● Installing reduction pinion gear bearing inner race

● Installing idler gear bearing inner race

a: 67.5 mm (2.657 in) dia.

b: 44 mm (1.73 in) dia.

c: 38.5 mm (1.516 in) dia.

NT107

Installing idler gear bearing outer race

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

NT115

Installing output shaft bearing

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

NT073

Revision: 2005 March 2005 X-Trail

AT-12

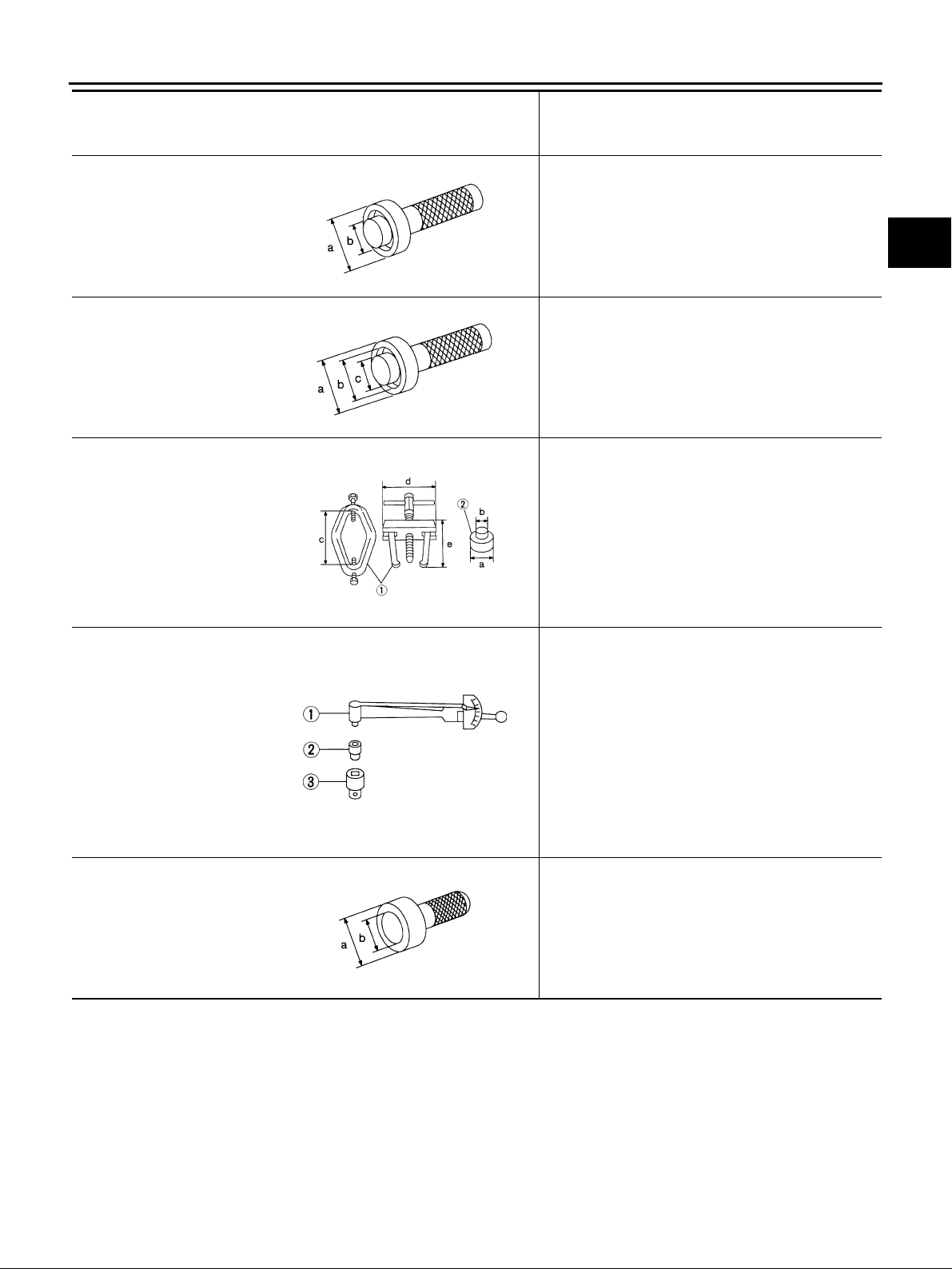

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

ST33230000

(J-25805-01)

Drift

ST33220000

(—)

Drift

ST3306S001

(J-22888-D)

Differential side bearing

puller set

1.ST33051001

(J-22888-D)

Puller

2.ST33061000

(J-8107-2)

Adapter

ST3127S000

(J-25765-A)

Preload gauge

1.GG91030000

(J-25765-A)

Torque wrench

2.HT62940000

(—)

Socket adapter

3.HT62900000

(—)

Socket adapter

ST35271000

(J-26091)

Drift

NT084

NT085

AMT153

NT124

Description

Installing differential side bearing inner race

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

Selecting differential side bearing adjusting shim

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.

Removing differentia l side bearing inne r race

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 in)

● Checking fina l drive assembly turning torque

● Checking reduct i on pi nion gear tur ning t orque

Installing idler gear

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.

A

B

AT

D

E

F

G

H

I

J

K

L

M

NT115

Revision: 2005 March 2005 X-Trail

AT-13

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Description

KV38107700

(J-39713)

Preload adapter

KV38105210

(J-39883)

Preload adapter

Selecting differential side beari ng adjus ti ng shim

NT087

● Selecting differential si de bearing adjust ing shim

● Checking fluid drive assembly turning torque

NT075

Revision: 2005 March 2005 X-Trail

AT-14

PREPARATION

Commercial Service Tools ACS007QR

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Puller Removing idler gear bearing inner race

NT077

Puller Removing reduction pinion gear bearing inner

race

a: 60 mm (2.36 in) dia.

b: 35 mm (1.38 in) dia.

A

B

AT

D

E

F

G

NT411

Drift Installing radial needle bearing on bearing

retainer

a: 36 mm (1.42 in) dia.

NT083

Drift Installing manual shaft oil seal

a: 22 mm (0.87 in) dia.

NT083

Drift Removing radial needle bearing from bearing

retainer

a: 33.5 mm (1.319 in) dia.

NT083

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-15

PREPARATION

Tool name Description

Drift Installing differential side bearing outer race

(RH side)

a: 75 mm (2.95 in) dia.

NT083

Drift Installing differential side bearing outer race

(LH side)

a: 100 mm (3.94 in) dia.

NT083

Revision: 2005 March 2005 X-Trail

AT-16

A/T FLUID

A/T FLUID PFP:KLE40

Checking A/T Fluid ACS007QS

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid temperatures of 30 to 50°C (86 to 122°F) using “COLD” range on A/

T fluid level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave sel ector lever in “P” position.

c. Check A/T fluid level with engine idling.

SMA827CA

d. Remove A /T f lui d level gauge and note reading. If l ev el is a t lo w

side of either range, and A/T fluid to the A/T fluid charging pipe.

CAUTION:

When wiping away the A/T fluid level gauge, always use

lint-free paper, not a cloth one.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly fix the A/T fluid level gau ge to the A/T fluid chargin g

pipe using a stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A /T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle f or approximately 5 minutes in urban areas.

5. Recheck A/T fluid level at A/T fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

● When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

● Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using a stopper attached.

6. Check A/T fluid condition.

● If A/T fluid is very dark or sm ells burned, ch ecking operation

of A/T. Flush cooling system after repair of A/T.

● If A/T fluid contai ns frictional ma terial (clutches, bands, etc. ),

replace radiato r and flush cooler line using cl eaning solvent

and compressed air after repair of A/T. Refer to CO-11,

"RADIATOR" , CO-14, "RADIATOR (ALUMINUM TYPE)" .

7. Install th e remov ed A/ T flui d lev el ga uge in the A /T flu id ch argin g

pipe.

CAUTION:

Firmly fix the A/T fluid level gau ge to the A/T fluid chargin g

pipe using a stopper attached.

SMA051D

SAT638A

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-17

A/T FLUID

Changing A/T Fluid ACS007QT

1. Warm up A/T fluid.

2. S top engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

CAUTION:

Do not reuse drain plug gasket.

Fluid grade:

NISSAN Automatic Transmission Fluid (ATF),

TM

DEXRON

Refer to MA-11, "

LUBRICANTS" .

Fluid capacity (With torque converter):

Approx. 8.5 (9 US qt, 7-1/2 lmp qt)

Drain plug

4. Run engine at idle speed for 5 minutes .

5. Check A/T fluid level and condition. Refer to AT- 17, "

steps 2 through 5.

III/MERCONTM , or equivalent ATF.

RECOMMENDED FLUIDS AND

:34 N·m (3.5 kg-m, 25 ft-lb)

SMA027D

Checking A/T Fl uid" . If A/T fluid is still dirty, repeat

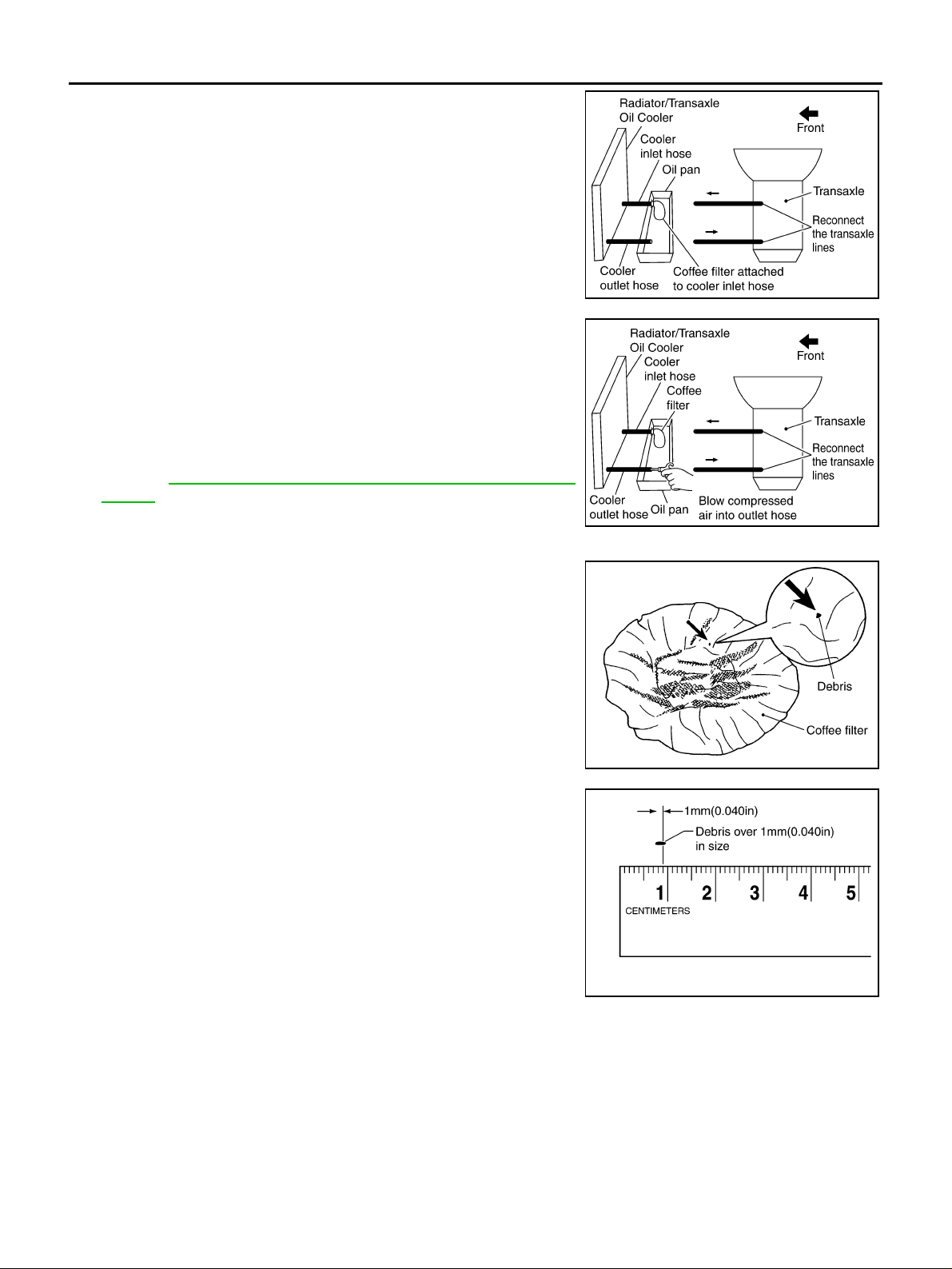

A/T Fluid Cooler Cleaning ACS008HQ

Whenever an a utomatic transaxle is repaired , overhauled, or replaced, the A/T fluid cooler mounted i n the

radiator must be inspected and cleaned.

Metal debris and f ric tion mate rial, i f pr ese nt, c an be com e trap ped in the A /T flu id cool er. This debris c an c ontaminate the newly servi ced A/T or, in severe cases, can blo ck or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

1. Position an oil pan under the automatic transaxle's inlet and outlet cooler hose s.

2. Identify the inlet and outlet fluid cooler hoses.

3. Disconne ct the flui d co oler i nlet a nd ou tle t rubb er h oses from t he

steel cooler tubes or bypass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any A/T fl uid that remains in the cooler ho ses to drain int o

the oil pan.

SCIA5628E

Revision: 2005 March 2005 X-Trail

AT-18

A/T FLUID

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 99 9MP-AM00 6) into the coole r outlet hose.

CAUTION:

● Wear safety glasses and rubber gloves when spraying

the Transmission Cooler Cleaner .

● Spray cooler cleaner only with ad equ ate venti lation.

● Avoid contact with eyes and skin.

● Do not breat h vapors or spray mis t.

6. Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose .

8. Wrap a shop rag around th e air gun tip and of the cooler outle t

hose.

A

B

AT

SCIA5629E

D

E

F

G

SCIA5630E

9. Blow compressed air regulated to 5 - 9 kg/cm

2

(70 - 130 psi) through the cooler outlet ho se for 10 sec-

onds to force out any remaining fluid.

10. Repeat steps 5 through 9 t hree additional times.

11. Position an oil pan under the banjo bolts that connect the fluid cooler steel lines to the transaxle.

12. Remove the banjo bolts.

13. Flush each steel li ne from the cooler side back tow ard the transaxle by spraying Transmiss ion Cooler

Cleaner in a continuous stream for 5 seconds.

2

14. Blow compressed air regulated to 5 - 9 kg/cm

(70 - 130 psi) through each steel line from the c oo ler s id e

back toward the transaxle for 10 seconds to force out any remaining fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ens ure all debris is removed from the banjo bolts and fittings.

17. Perform AT-19, "

A/T FLUID COOLER DIAGNOSIS PROCEDURE" .

A/T FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exterior may lead to inaccurate debris identification.

1. Position an oil pan under the automat ic transaxle's inlet and outlet cooler hoses.

2. Clean the ext erior and tip of the cooler inlet hose.

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 99 9MP-AM00 6) into the coole r outlet hose.

CAUTION:

● Wear safety glasses and rubber gloves when spraying

the Transmission Cooler Cleaner .

● Spray cooler cleaner only with ad equ ate venti lation.

● Avoid contact with eyes and skin.

● Do not breat h vapors or spray mis t.

4. Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

SCIA5629E

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-19

A/T FLUID

5. Tie a common white, basket-type coffee filter to the end of the

cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet ho se.

7. Wrap a shop rag around the ai r gun tip and end of co oler outlet

hose.

8. Blow compressed air regulated to 5 - 9 kg/cm

through the cooler outlet hose to force any remaining A/T fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform AT-20, "

A/T FLUID COOLER INSPECTION PROCE-

DURE" .

2

(70 - 130 psi)

SCIA5631E

SCIA5632E

A/T FLUID COOLER INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T f luid co oler/radi ator can be re-u sed an d

the procedu re is ended.

b. If one or more pieces of debris are found that are over 1mm

(0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter, the fluid cooler is not serviceable . The radiator/

fluid cooler must be replaced and the inspection procedure is

ended.

SCIA2967E

SCIA5659E

A/T FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oil is cleaned from all components.

Revision: 2005 March 2005 X-Trail

AT-20

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM PFP:31036

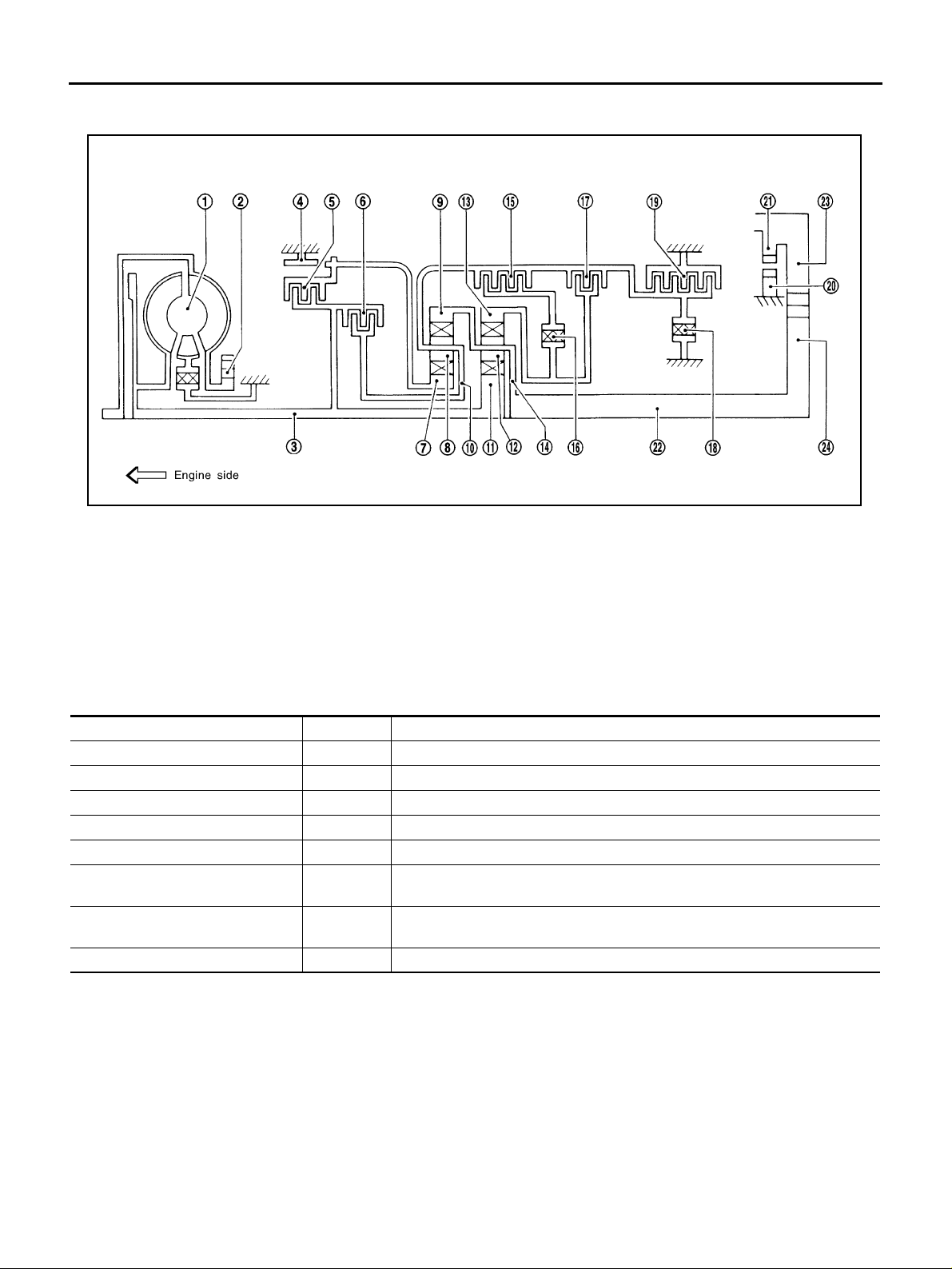

Cross-Sectional View ACS007JH

A

B

AT

D

E

F

G

1. Band servo piston assembly 2. Reverse clutch drum 3. Converter hous ing

4. Oil pump 5. Brake band 6. Reverse clutch

7. High clutch 8. Front planetary gear 9. Low one-way clutch

10. Rear planetary gear 11. Forward clutch 12. Overrun clutch

13. Low & reverse brake 14. Output gear 15. Idler gear

16. Forward one-way clutch 17. Reduc tion pi nion gear 18. Final gear

19. Differential case 20. Input shaft 21. Torque converter

22. Side cover 23. Transaxle case

H

I

J

K

L

M

SCIA4112E

Revision: 2005 March 2005 X-Trail

AT-21

A/T CONTROL SYSTEM

Shift Mechanism ACS007JI

CONSTRUCTION

SAT998I

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Fr ont pi nion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idler gear 24. Output gear

FUNCTION OF CLUTCH AND BRAKE

Clutch and brake components Abbr. Function

5 Reverse clutch R/ C To transmit input power to front sun gear 7 .

6 High clutch H/C To transmit input power to front planetary carrier 10 .

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16 .

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13 .

4 Brake band B/B To lock front sun gear 7 .

16 Forward one-way clutch F/O.C

18 Low one-way clutch L/O.C

19 Low & reverse brake L & R/B To lock front planetary carrier 10 .

When forward clutch 15 is engaged, to stop rear internal gear 13 from rotating

in opposite direction against engine revol uti on.

To stop front planetary carrier 10 from rotating in opposite direction against

engine revolution.

Revision: 2005 March 2005 X-Trail

AT-22

CLUTCH AND BAND CHART

Shift posi-

tion

P

R

N

2nd *1A B

D*4

3rd *1A *2C C B

4th C *3C C

2

2nd B

3rd *2C C B

R/C

5

1st *1D B B

1st BB

H/C

6

F/C

15

A/T CONTROL SYSTEM

O/C

17

2nd

apply

Band servo

3rd

release

4th

apply

F/O.C16L/O.C18L&R/B19Lock-

up

*1

Remarks

PARK

POSITION

REVERSE

POSITION

NEUTRAL

POSITION

Automatic

shift

1 ⇔ 2 ⇔ 3

⇔ 4

Automatic

shift

1 ⇔ 2 ⇐ 3

A

B

AT

D

E

F

G

1st BB

1

2nd B

3rd *2C C B

● *1: Operates when overdrive control switch is set in “OFF” posi tion.

● *2: Oil pressure is applied to both 2nd “apply ” side and 3rd “rele ase” side of band s ervo piston. Howe ver, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

● *3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

● *4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position .

● : Operates.

● A: Operates when throttle opening is less than 3/16, activating engine brake.

● B: Operates during “progressive” acceleration.

● C: Operates but does not affect power transmission.

● D: Operates when throttle opening is less than 3/16, but doe s not a ffect engine brake.

Locks (held

stationary)

in 1st speed

1 ⇐ 2 ⇐ 3

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-23

A/T CONTROL SYSTEM

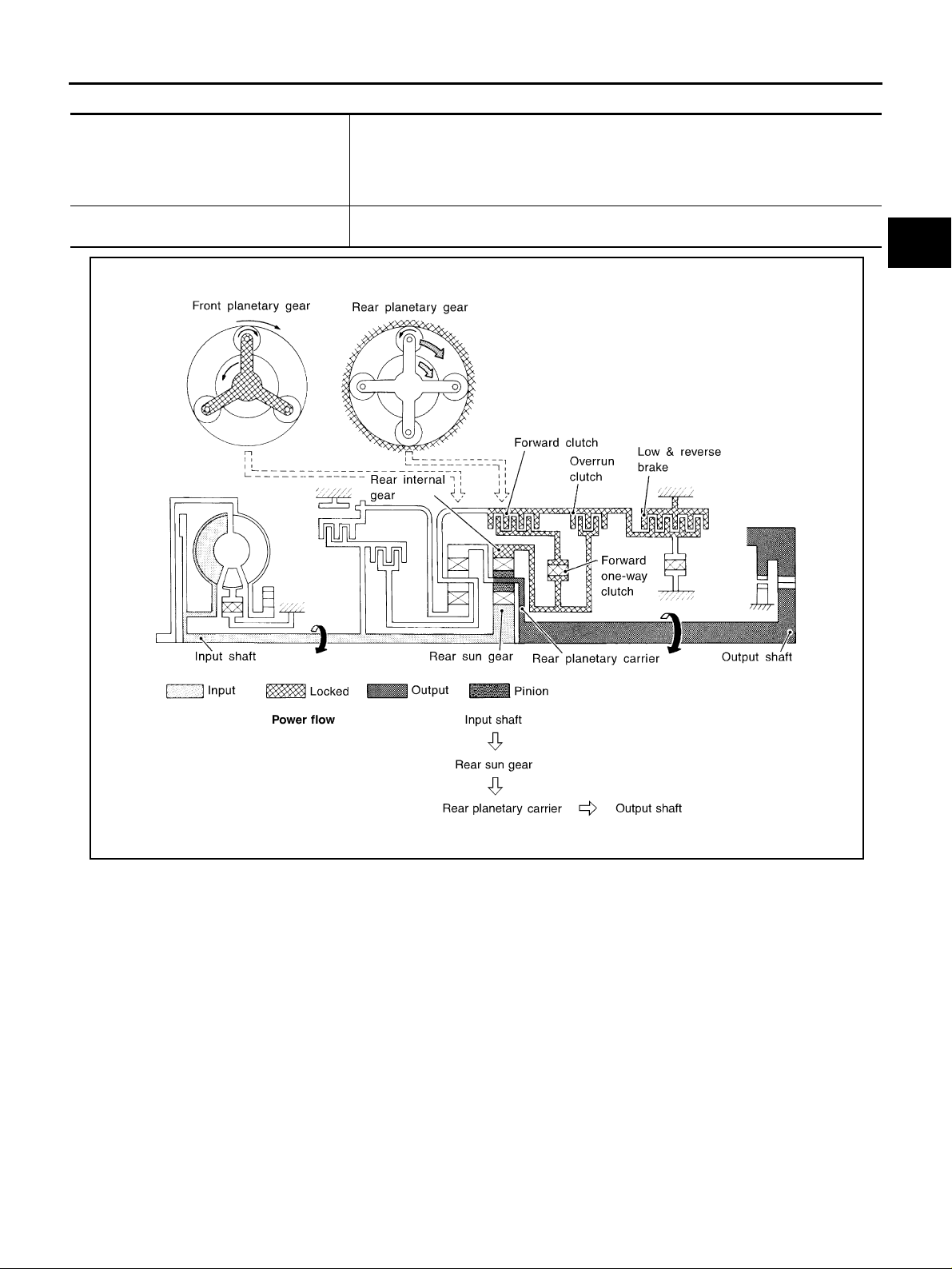

POWER TRANSMISSION

“N” and “P” Positions

● “N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

● “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power trai n is locked.

SAT991I

Revision: 2005 March 2005 X-Trail

AT-24

A/T CONTROL SYSTEM

“11 ” Position

● Forward clutch

● Forward one-way clutch

● Overrun clutch

● Low & rever se bra ke

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

As overrun clutch engages, rear internal gear is locked by the operation of low and

reverse brake.

This is different from that of D1 and 21 .

ating.

A

B

AT

D

E

F

G

SCIA1816E

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-25

“D1 ” and “21 ” Posi t i ons

● Forward one-way clutch

● Forward clutch

● Low one-way clutch

Overrun clutch

engagement conditions

(Engine brake)

A/T CONTROL SYSTEM

Rear internal gear is locked to rotate counterclockwi se bec ause of the functioning of

these three clutches.

D

1 : Overdrive control switch “OFF” and throttle opening i s less tha n 3/16

1 : Always engaged

2

At D

1 and 21 positions, engine brake is not act ivat ed due t o free tu rning of low on e-

way clutch.

SAT377J

Revision: 2005 March 2005 X-Trail

AT-26

“D2 ”, “22 ” and “12 ” Positions

● Forward clutch

● Forward one-way

clutch

● Brake band

Overrun clutch

engagement conditions

Rear sun gear drives rear planetary carrier and combined f ron t interna l gea r. Front internal gear now

rotates around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward oneway clutch, this rotation of rear internal gear increases t he spee d of r ear plan etary carrie r com pared wi th

that of the 1st speed.

2 : Overdrive control switch “OFF” and throttle opening is less tha n 3/1 6

D

2

2 and 12 : Always engaged

A/T CONTROL SYSTEM

A

B

AT

D

E

F

G

SAT378J

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-27

“D3 ”, “23 ” and “13 ” Positio n s

● High clutch

● Forward clutch

● Forward one-way

clutch

Overrun clutch

engagement conditions

Input power is transmitted to front planetary carrier throu gh hi gh clut ch. And front pla netary carri er is connected to rear internal gear by operation of forwar d cl ut ch and f orward one-way clutch.

This rear internal gear rotation and another input (the rear sun gear) accompany rear planetary carrier to

turn at the same speed.

3 : Overdrive control switch “OFF” and throttle opening is less than 3/16

D

3 and 13 : Always engaged

2

A/T CONTROL SYSTEM

SCIA7229E

Revision: 2005 March 2005 X-Trail

AT-28

“D4 ” (OD) Position

● High clutch

● Brake band

● Forward clutch (Does not affect power

transmission)

Engine brake

A/T CONTROL SYSTEM

Input power is transmitted to front carrier through high clutch.

This front carrier turns around the sun gear which is fixe d by bra ke band and makes

front inte rn al gear (output) turn fa s t e r.

At D

4 position, there is no one-way clutch in the power trans axl e line and engi ne

brake can be obtained when decelerating.

A

B

AT

D

E

F

G

SAT380J

H

I

J

K

L

M

Revision: 2005 March 2005 X-Trail

AT-29

“R” Positi on

● Reverse clutch

● Low & reverse brake

Engine brake

A/T CONTROL SYSTEM

Front planetary carrier is stationary because of the operation of low and reverse brake.

Input power is transmitted to front sun gear through re ver se cl ut ch, which drives front

internal gear in the opposite direction.

As there is no one-way clutch in the power transaxle line, engi ne bra ke can be

obtained when decelerating.

SAT381J

Revision: 2005 March 2005 X-Trail

AT-30

Loading...

Loading...