Nissan XTrail T30 2005 User Manual

I BODY

SECTION SE

SEAT

A

B

C

D

CONTENTS

E

PRECAUTIONS ......................................................... |

|

2 |

Precautions for Supplemental Restraint System |

|

|

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- |

|

|

SIONER” ................................................................. |

|

2 |

Service Notice ......................................................... |

|

2 |

Precautions ............................................................. |

|

2 |

PREPARATION .......................................................... |

|

3 |

Special Service Tools .............................................. |

|

3 |

Commercial Service Tools ....................................... |

|

3 |

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... |

4 |

|

Work Flow ............................................................... |

|

4 |

CUSTOMER INTERVIEW .................................... |

|

4 |

DUPLICATE THE NOISE AND TEST DRIVE ...... |

|

5 |

CHECK RELATED SERVICE BULLETINS .......... |

|

5 |

LOCATE THE NOISE AND IDENTIFY THE |

|

|

ROOT CAUSE ..................................................... |

|

5 |

REPAIR THE CAUSE .......................................... |

|

5 |

CONFIRM THE REPAIR ...................................... |

|

6 |

Generic Squeak and Rattle Troubleshooting .......... |

|

6 |

INSTRUMENT PANEL ......................................... |

|

6 |

CENTER CONSOLE ............................................ |

|

6 |

DOORS ................................................................ |

|

6 |

TRUNK ................................................................. |

|

7 |

SUNROOF/HEADLINING .................................... |

|

7 |

SEATS .................................................................. |

|

7 |

UNDERHOOD ...................................................... |

|

7 |

Diagnostic Worksheet ............................................. |

|

8 |

POWER SEAT ......................................................... |

|

10 |

Wiring Diagram — SEAT — ................................ |

... 10 |

|

HEATED SEAT ......................................................... |

12 |

F |

|

Schematic .............................................................. |

12 |

|

|

Wiring Diagram — HSEAT — .............................. |

... 13 |

|

|

FRONT SEAT ........................................................... |

17 |

G |

|

Component Parts Drawing |

17 |

||

|

|||

MANUAL SEAT .................................................. |

17 |

|

|

POWER SEAT .................................................... |

18 |

H |

|

Removal and Installation |

19 |

||

|

|||

REMOVAL .......................................................... |

19 |

|

|

..................................................INSTALLATION |

19 |

SE |

|

Disassembly and Assembly of Seatback ............... |

19 |

||

MANUAL SEAT .................................................. |

19 |

|

|

|

|||

POWER SEAT .................................................... |

21 |

|

|

Disassembly and Assembly of Seat Cushion ........ |

22 |

J |

|

MANUAL SEAT .................................................. |

22 |

|

|

POWER SEAT .................................................... |

23 |

|

|

REAR SEAT ............................................................. |

24 |

K |

|

Component Parts Drawing |

24 |

||

|

|||

STANDARD SEAT .............................................. |

24 |

|

|

SEAT WITH ARMREST ...................................... |

25 |

L |

|

Removal and Installation |

26 |

||

|

|||

SEAT CUSHION ................................................. |

26 |

|

|

SEATBACK ......................................................... |

26 |

|

|

REAR SEAT STRIKER (SIDE) ........................... |

27 |

M |

|

REAR SEAT CENTER BRACKET ...................... |

27 |

|

|

REAR SEAT STRIKER (FLOOR) ....................... |

27 |

|

|

Disassembly and Assembly ................................... |

27 |

|

|

REAR SEATBACK LOCK KNOB ........................ |

27 |

|

|

ARMREST .......................................................... |

27 |

|

Revision: 2005 March |

SE-1 |

2005 X-Trail |

|

PRECAUTIONS |

|

|

PRECAUTIONS |

PFP:00001 |

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER” AIS005SX

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

●To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

●Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see the SRS section.

●Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

Service Notice |

AIS005SY |

●When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent scratches.

●Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or damage them.

●Apply sealing compound where necessary when installing parts.

●When applying sealing compound, be careful that the sealing compound does not protrude from parts.

●When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust prevention measures.

Precautions |

AIS005SZ |

●When removing or disassembling any part, be careful not to damage or deform it. Protect parts, which may get in the way with cloth.

●When removing parts with a screwdriver or other tool, protect parts by wrapping tools with vinyl or tape.

●Keep removed parts protected with cloth.

●If a clip is deformed or damaged, replace it.

●If an unreusable part is removed, replace it with a new one.

●Tighten bolts and nuts firmly to the specified torque.

●After re-assembly has been completed, make sure each part functions correctly.

●Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth. Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely. Then wipe the area with a soft dry cloth.

●Do not use any organic solvent, such as thinner or benzine.

Revision: 2005 March |

SE-2 |

2005 X-Trail |

|

PREPARATION |

|

|

|

|

PREPARATION |

PFP:00002 |

|

Special Service Tools |

|

A |

AIS0065W |

||

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number |

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

||

(Kent-Moore No.) |

|

|

Description |

|

|

|

|

|

Tool name |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

(J-39570) |

|

|

|

|

|

|

||

|

|

Locating the noise |

|

|

|

D |

||

Chassis ear |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

SIIA0993E |

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

F |

(J-43980) |

|

|

|

|

|

|

||

NISSAN Squeak and Rattle |

|

|

Repairing the cause of the noise |

|

|

|

|

|

Kit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

SIIA0994E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Commercial Service Tools |

|

|

|

AIS005T0 |

||||

|

|

|

|

|

|

|

|

H |

|

Tool name |

|

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SE |

|

Engine ear |

|

|

Location the noise |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

J |

|

|

SIIA0995E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

M |

Revision: 2005 March |

SE-3 |

2005 X-Trail |

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

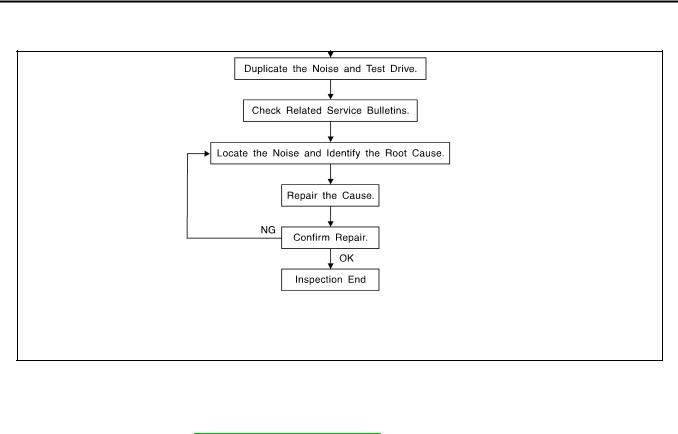

Work Flow

PFP:00000

AIS0061D

SBT842

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diagnostic Worksheet during the interview to document the facts and conditions when the noise occurs and any customer's comments; refer toSE-8, "Diagnostic Worksheet" . This information is necessary to duplicate the conditions that exist when the noise occurs.

●The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist when the noise occurs (or does not occur).

●If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is concerned about. This can be accomplished by test driving the vehicle with the customer.

●After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics are provided so the customer, service adviser and technician are all speaking the same language when defining the noise.

●Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

●Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch dependent on materials/often brought on by activity.

●Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing clip or fastener/incorrect clearance.

●Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

●Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver action or road conditions.

●Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

●Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

●Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

●Weather conditions, especially humidity and temperature, may have a great effect on noise level.

Revision: 2005 March |

SE-4 |

2005 X-Trail |

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to duplicate the noise with the vehicle stopped by doing one or all of the following:

1)Close a door.

2)Tap or push/pull around the area where the noise appears to be coming from.

3)Rev the engine.

4)Use a floor jack to recreate vehicle “twist”.

5)At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

●Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

●If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

A

B

C

D

E

F

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1.Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2.Narrow down the noise to a more specific area and identify the cause of the noise by:

●removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken or lost during the repair, resulting in the creation of new noise.

●tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only temporarily.

● feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the noise.

● placing a piece of paper between components that you suspect are causing the noise.

● looking for loose components and contact marks.

Refer to SE-6, "Generic Squeak and Rattle Troubleshooting" .

G

H

SE

J

K

REPAIR THE CAUSE

●If the cause is a loose component, tighten the component securely.

●If the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick] |

|

|

Insulates connectors, harness, etc. |

|

|

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × |

3.35 in)/76884- |

|

71L02: 15 × 25 mm (0.59 × 0.98 in) |

|

|

INSULATOR (Foam blocks) |

|

|

Insulates components from contact. Can be used to fill space behind a panel. |

|

|

73982-9E000: 45 mm (1.77 in) thick, 50 × |

50 mm (1.97 × 1.97 in)/73982- |

|

50Y00: 10 mm (0.39 in) thick, 50 × 50 mm (1.97 × 1.97 in) |

|

|

Revision: 2005 March |

SE-5 |

2005 X-Trail |

L

M

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in) FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications. 68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll The following materials, not found in the kit, can also be used to repair squeaks and rattles. UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications. SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months. SILICONE SPRAY

Use when grease cannot be applied. DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting |

AIS0061E |

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1.The cluster lid A and instrument panel

2.Acrylic lens and combination meter housing

3.Instrument panel to front pillar garnish

4.Instrument panel to windshield

5.Instrument panel mounting pins

6.Wiring harnesses behind the combination meter

7.A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by pressing on the components while driving to stop the noise. Most of these incidents can be repaired by applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring harness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1.Shifter assembly cover to finisher

2.A/C control unit and cluster lid C

3.Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1.Finisher and inner panel making a slapping noise

2.Inside handle escutcheon to door finisher

3.Wiring harnesses tapping

4.Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: 2005 March |

SE-6 |

2005 X-Trail |

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner. |

A |

In addition look for: |

|

1.Trunk lid dumpers out of adjustment

2. |

Trunk lid striker out of adjustment |

B |

|

||

3. |

The trunk lid torsion bars knocking together |

|

4. |

A loose license plate or bracket |

|

C

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) causing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1.Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2.Sunvisor shaft shaking in the holder

3.Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

D

E

F

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when |

G |

|||

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the |

|

|||

noise. |

|

|||

Cause of seat noise include: |

H |

|||

1. |

Headrest rods and holder |

|||

|

||||

2. |

A squeak between the seat pad cushion and frame |

|

|

|

3. |

The rear seatback lock and bracket |

SE |

||

|

|

|

||

These noises can be isolated by moving or pressing on the suspected components while duplicating the conditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

J

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1.Any component mounted to the engine wall

2.Components that pass through the engine wall

3.Engine wall mounts and connectors

4.Loose radiator mounting pins

5.Hood bumpers out of adjustment

6.Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or insulating the component causing the noise.

K

L

M

Revision: 2005 March |

SE-7 |

2005 X-Trail |

SQUEAK AND RATTLE TROUBLE DIAGNOSES

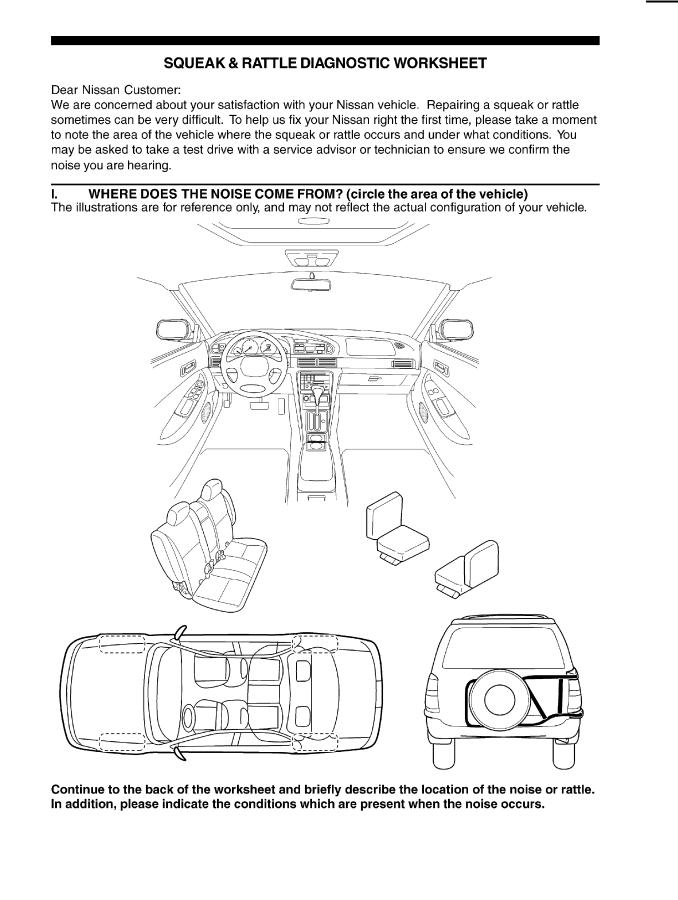

Diagnostic Worksheet |

AIS0061F |

PIIB0723E

Revision: 2005 March |

SE-8 |

2005 X-Trail |

SQUEAK AND RATTLE TROUBLE DIAGNOSES

A

B

C

D

E

F

G

H

SE

J

K

L

M

SBT844

Revision: 2005 March |

SE-9 |

2005 X-Trail |

Loading...

Loading...