Nissan Primera User Manual

B ENGINE

SECTION

FUEL SYSTEM

CONTENTS

A

FL

C

D

E

PREPARATION .......................................................... |

2 |

Commercial Service Tool ........................................ |

2 |

FUEL SYSTEM .......................................................... |

3 |

Checking Fuel Lines ................................................ |

3 |

General Precautions ............................................... |

3 |

FUEL FILTER (YD22DDTI) ........................................ |

4 |

Removal and Installation ......................................... |

4 |

REMOVAL ............................................................ |

4 |

INSTALLATION .................................................... |

4 |

INSPECTION AFTER INSTALLATION ................ |

4 |

Air Bleeding ............................................................. |

5 |

Draining Water ........................................................ |

5 |

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND |

|

FUEL PUMP ASSEMBLY (EXCEPT YD22DDTI) ...... |

6 |

Removal and Installation ......................................... |

6 |

REMOVAL ............................................................ |

6 |

INSPECTION AFTER REMOVAL ........................ |

8 |

INSTALLATION .................................................... |

8 |

INSPECTION AFTER INSTALLATION ................ |

8 |

FUEL LEVEL SENSOR UNIT (YD22DDTI) ............. |

10 |

F |

|

Removal and Installation ....................................... |

10 |

|

|

REMOVAL .......................................................... |

10 |

|

|

INSTALLATION .................................................. |

11 |

G |

|

INSPECTION AFTER INSTALLATION |

12 |

||

|

|||

FUEL TANK ............................................................. |

13 |

|

|

Removal and Installation (YD22DDTi) ................... |

13 |

H |

|

REMOVAL |

13 |

||

|

|||

INSTALLATION .................................................. |

14 |

|

|

INSPECTION AFTER INSTALLATION ............... |

15 |

I |

|

Removal and Installation (Except YD22DDTi) ....... |

15 |

||

REMOVAL .......................................................... |

15 |

|

|

INSTALLATION .................................................. |

17 |

|

|

Inspection After Installation ................................... |

17 |

J |

|

SERVICE DATA AND SPECIFICATIONS (SDS) ..... |

18 |

|

|

Standard and Limit ................................................. |

18 |

|

|

Tightening Torque .................................................. |

18 |

|

K

L

M

FL-1

PREPARATION

PREPARATION

Commercial Service Tool

PFP:00002

EBS00GVM

Tool number |

|

Tool name |

Description |

|

|

Fuel tank lock ring wrench |

Removing and installing fuel tank lock ring |

ZZA0122D

FL-2

|

FUEL SYSTEM |

|

|

|

|

FUEL SYSTEM |

PFP:17503 |

|

Checking Fuel Lines |

|

A |

EBS00GRB |

||

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration. FL If necessary, repair or replace faulty parts.

C

D

SMA803A

General Precautions |

EBS00GRC |

WARNING:

when replacing fuel line parts, be sure to observe the following.

●Put a “ CAUTION: FLAMMABLE” sign in workshop.

●Be sure to work in a well-ventilated area and furnish workshop with a CO2 fire extinguisher.

●Do not smoke while servicing fuel system, keep open flames and spark away from work area.

CAUTION:

● Before removing fuel line parts, carry out the following procedures.

– a) Put drained fuel in an explosion-proof container and put the lid on securely, keep the container in safe area.

– b) Release fuel pressure from fuel line. Refer to EC-58, "FUEL PRESSURE RELEASE" (QG engine models WITH EURO-OBD), EC-591, "FUEL PRESSURE RELEASE" (QG engine models WITHOUT EURO-OBD), EC-1001, "FUEL PRESSURE RELEASE" (QR engine models WITH EURO-OBD), EC1443, "FUEL PRESSURE RELEASE" (QR engine models WITHOUT EURO-OBD).

– c) Disconnect battery ground cable.

●Always replace O-ring and clamps with new ones.

●Do not tighten hose clamps excessively to avoid damaging hoses.

●Do not kink or twist tubes when they are being installed.

●Do not tighten hose clamps excessively to avoid damaging hoses. Tighten high-pressure rubber hose clamp so that clamp

end is 3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber hose clamps.

Ensure that screw does not contact adjacent parts.

●After installing tubes, run engine and check for fuel leaks at connections.

●Use only a Genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the MI may come on.

●For servicing “Evaporative Emission System” parts, refer to

EC-554, "EVAPORATIVE EMISSION SYSTEM" (QG engine |

MMA104A |

|

models WITH EURO-OBD), EC-952, "EVAPORATIVE EMIS-

SION SYSTEM" (QG engine models WITHOUT EURO-OBD), EC-1408, "EVAPORATIVE EMISSION SYSTEM" (QR engine models WITH EURO-OBD), EC-1723, "EVAPORATIVE EMISSION SYSTEM" (QR engine models WITHOUT EURO-OBD).

E

F

G

H

I

J

K

L

M

FL-3

FUEL FILTER (YD22DDTI)

FUEL FILTER (YD22DDTI)

Removal and Installation

REMOVAL

PFP:16400

EBS00GX5

SBIA0134E

1.Remove air duct and upper air cleaner case.

2.Remove fuel filter protector.

3.Disconnect fuel hoses from fuel filter bracket.

CAUTION:

Plug the pipe to prevent fuel from draining.

4.Remove fuel filter with bracket.

CAUTION:

Do not splash fuel during removal. If fuel is splashed, immediately wipe it off.

PBIC0739E

5.Using band-type filter wrench (commercial service tool), remove fuel filter.

6.Turn fuel filter upside down to drain fuel.

7.Remove drain plug from fuel filter.

SBIA0136E

INSTALLATION

Install in reverse order of removal, paying attention to following.

●Replace O-ring on drain plug with new one.

●Screw the fuel filter by hand until O-ring contacts sealing surface of bracket. Then tighten it by turning approximately 2/3 turn.

●After installation, bleed air from fuel path. Refer to FL-5, "Air Bleeding" .

INSPECTION AFTER INSTALLATION

Run engine and check for fuel leakage at connections.

FL-4

FUEL FILTER (YD22DDTI)

Air Bleeding

After fuel filter is replaced and after fuel system components are removed/installed, bleed air from fuel path as follows.

1.Move priming pump up and down to bleed air from fuel path.

2.When air is bled, pumping of priming pump becomes heavy stop operation at that time.

3.Crank the engine until it starts. Do not crank the engine for more than 30 seconds.

4.If the engine does not starts, stop cranking and repeat step 1 above.

5.If the engine does not operate smoothly after it has started, race it two or three times.

EBS00GX7

PBIC0740E

6.If air cannot be bled easily (pumping of priming pump does not become heavy), disconnect feed-side of

hose between fuel filter and electronically controlled fuel injection pump. After that, operate priming pump and confirm that fuel comes out.

CAUTION:

Prepare a tray to collect fuel. Prevent fuel from adhering to rubber parts, especially the engine mount insulator.

A

FL

C

D

E

F

Draining Water |

EBS00GX8 |

||

1. |

Prepare a tray at the drain hose open end. |

|

G |

|

|

||

2. |

Loosen drain cock turning counter clockwise in view from bot- |

|

|

|

tom, and operate priming pump to drain water from fuel filter. |

|

H |

CAUTION: |

|

||

|

|

||

●Coolant in filter is drained with fuel. Prepare larger capacity tray than fuel filter volume.

● |

Drained coolant is mixed with fuel. Prevent fuel from adher- |

|

I |

|

|

|

|||

|

ing to rubber parts such as engine mount insulator. |

|

|

|

3. |

After draining, close drain plug by hand. |

|

J |

|

CAUTION: |

|

|||

SBIA0138E |

||||

If drain plug is tightened excessively, it may be damaged and |

|

|

|

|

|

|

|

||

fuel will leak. Do not use tools to tighten drain plug. |

|

K |

||

4. |

Bleed air in fuel piping and check for fuel leakage. Refer to FL-5, "Air Bleeding" . |

|

||

|

|

|||

5. |

Start engine. |

|

|

|

L

M

FL-5

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY (EX-

CEPT YD22DDTI)

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

(EXCEPT YD22DDTI) |

PFP:17042 |

Removal and Installation |

EBS00GRD |

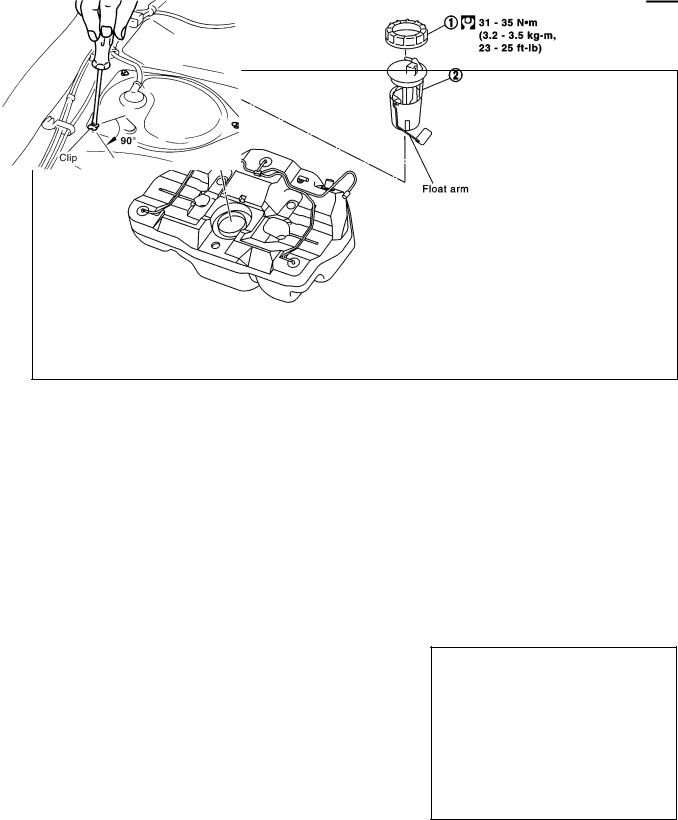

PBIC0765E

1 Lock ring |

2 |

Fuel level sensor unit, fuel filter and |

3 Seal packing |

|

fuel pump assembly |

||||

|

|

|

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3, "General Precautions" .

1.Release fuel pressure from fuel line.

Refer to EC-58, "FUEL PRESSURE RELEASE" (QG engine models WITH EURO-OBD), EC-591, "FUEL PRESSURE RELEASE" (QG engine models WITHOUT EURO-OBD), EC-1001, "FUEL PRESSURE RELEASE" (QR engine models WITH EURO-OBD), EC-1443, "FUEL PRESSURE RELEASE" (QR engine models WITHOUT EURO-OBD).

2.Open fuel filler lid.

3.Open the filler cap and release the pressure inside the fuel tank.

4.Remove rear seat cushion.

5.Remove inspection hole cover, harness connector and fuel feed hose.

JFE613A

FL-6

Loading...

Loading...