Nissan Pathfinder 2001 User Manual

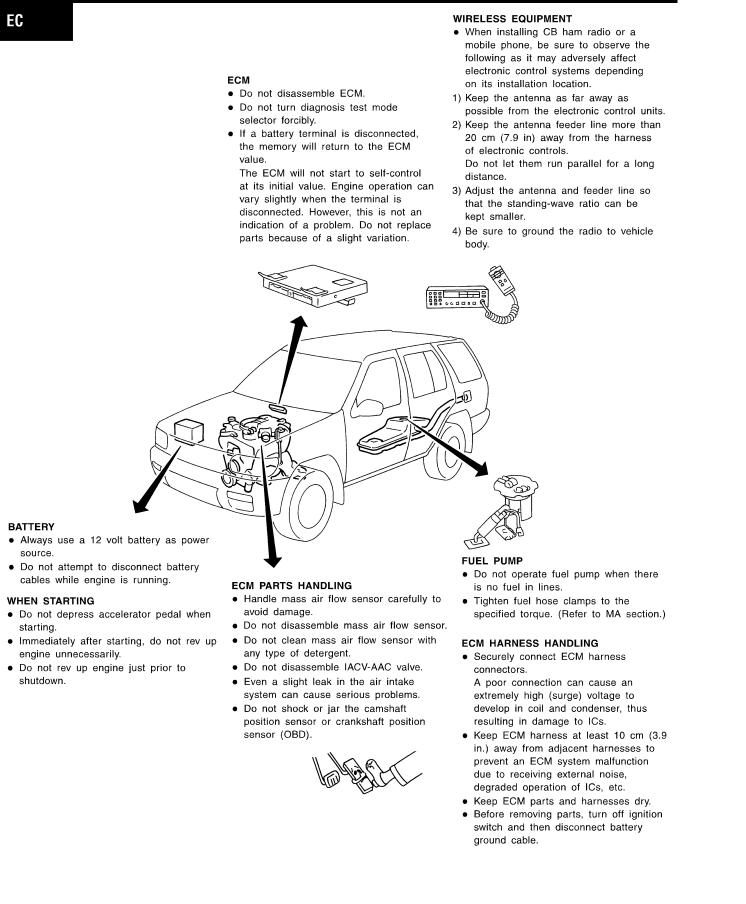

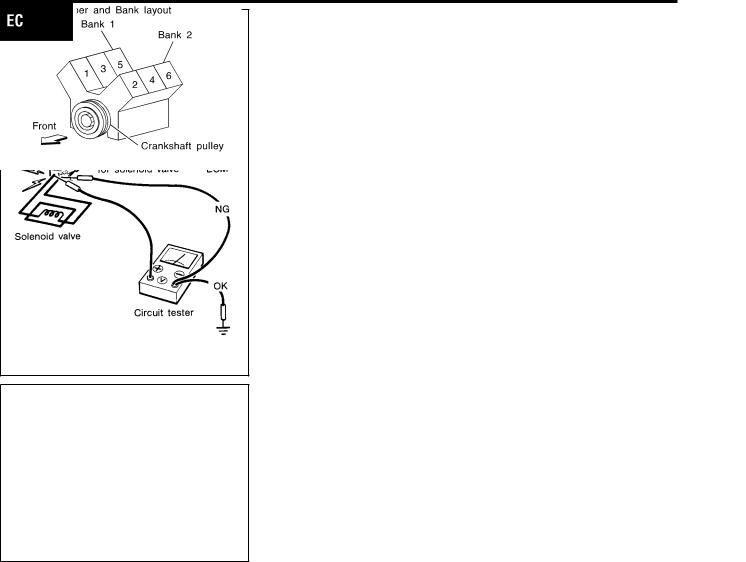

ENGINE CONTROL SYSTEM

SECTION EC

GI

MA

EM

LC

MODIFICATION NOTICE:

IThe SMART C/U - PREVIOUS is applicable for the 2WD models up to serial number 567231 and for the 4WD models up to serial number 584967.

IThe SMART C/U - NEW is applicable for the 2WD models from serial number 567231 and for the 4WD FE models from serial number 584967.

CL

CONTENTS

MT

TROUBLE DIAGNOSIS - INDEX .................................... |

8 |

Alphabetical & P No. Index for DTC ........................... |

8 |

PRECAUTIONS ............................................................. |

14 |

Supplemental Restraint System (SRS) ″AIR |

|

BAG″ and ″SEAT BELT PRE-TENSIONER″............. |

14 |

Precautions for On Board Diagnostic (OBD) |

|

System of Engine and A/T......................................... |

14 |

Engine Fuel & Emission Control System .................. |

15 |

Precautions ................................................................ |

16 |

Wiring Diagrams and Trouble Diagnosis................... |

17 |

PREPARATION ............................................................. |

18 |

Special Service Tools ................................................ |

18 |

Commercial Service Tools ......................................... |

18 |

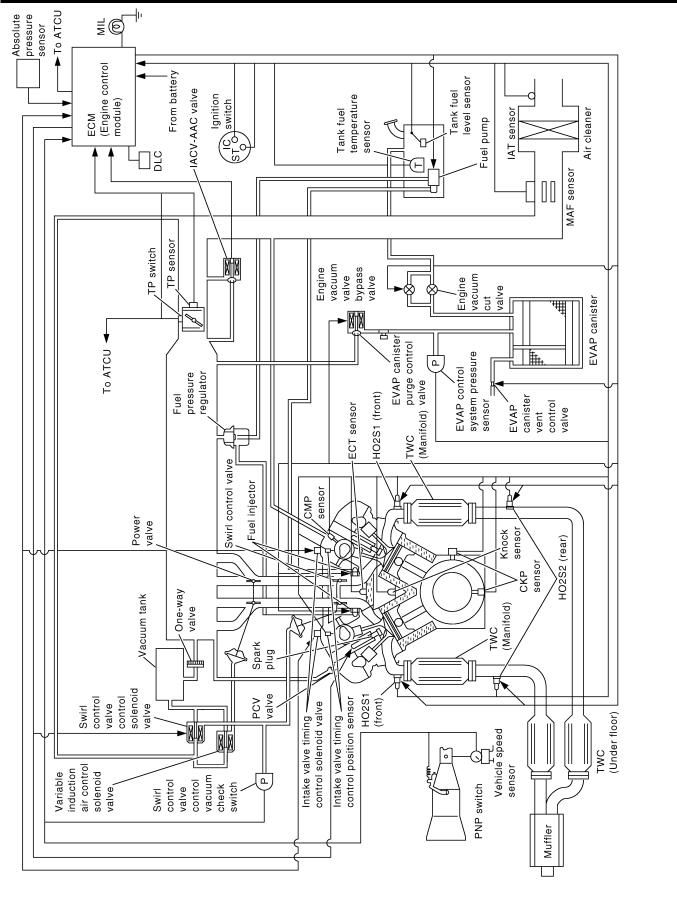

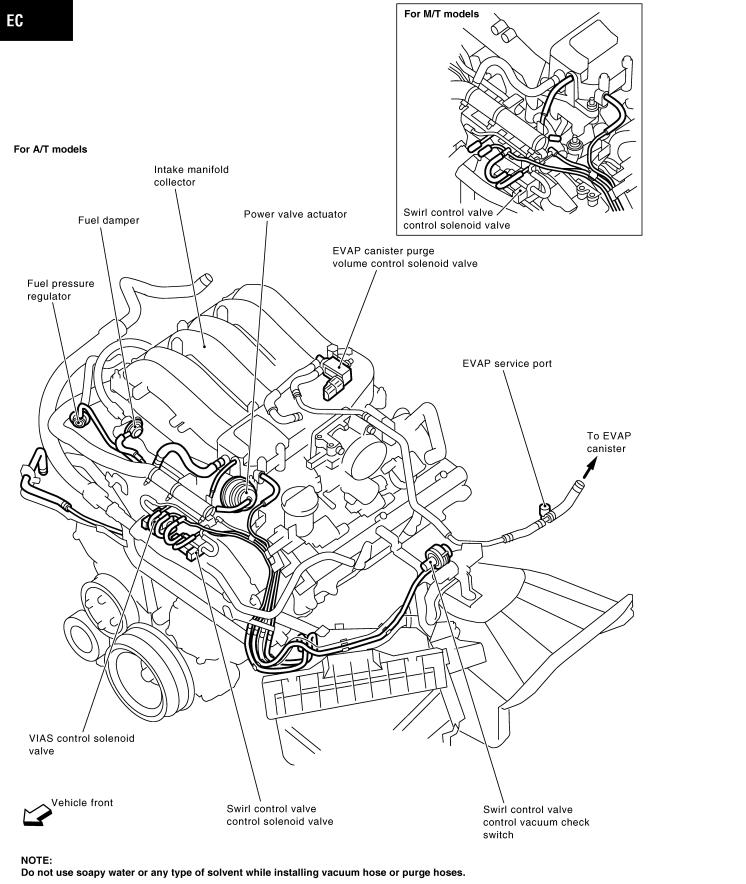

ENGINE AND EMISSION CONTROL OVERALL |

|

SYSTEM......................................................................... |

20 |

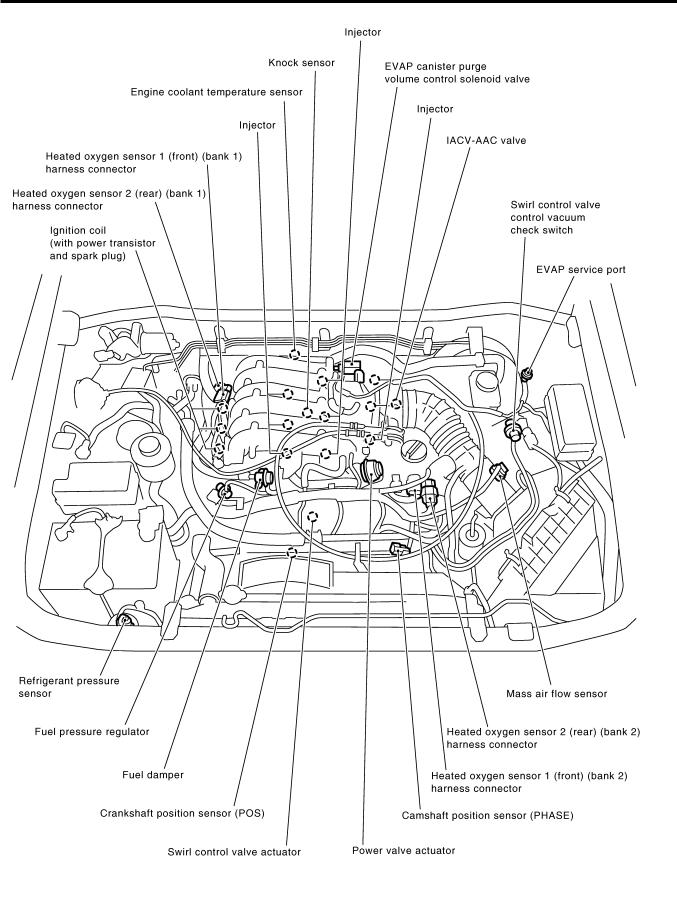

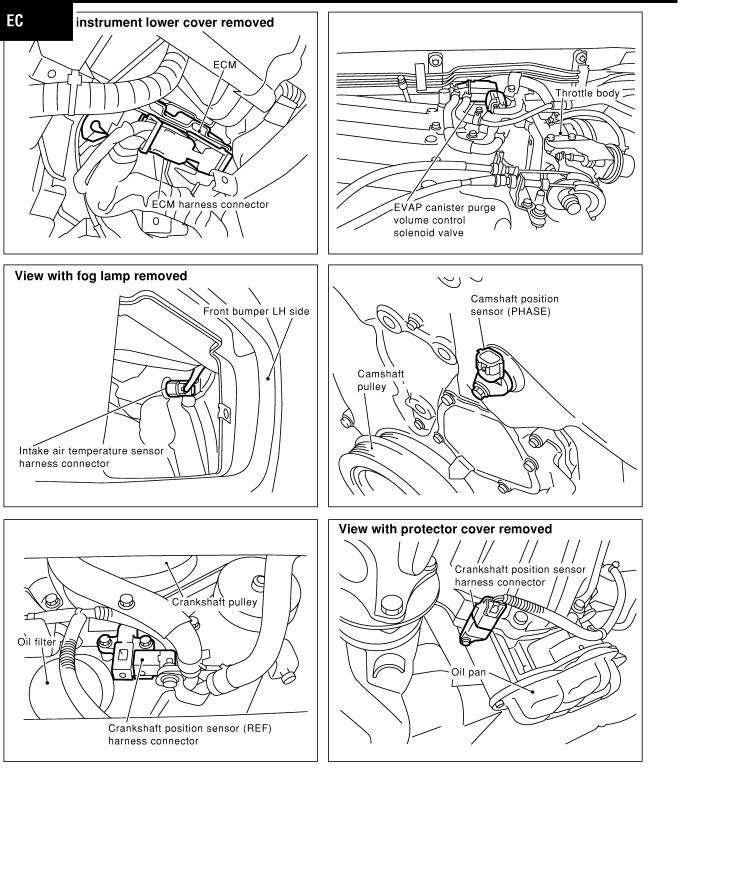

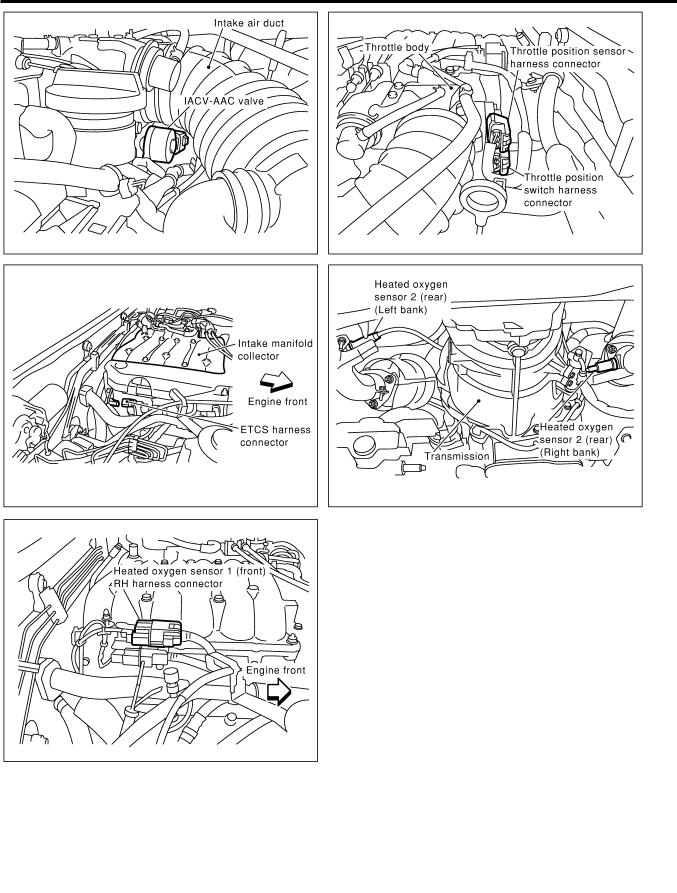

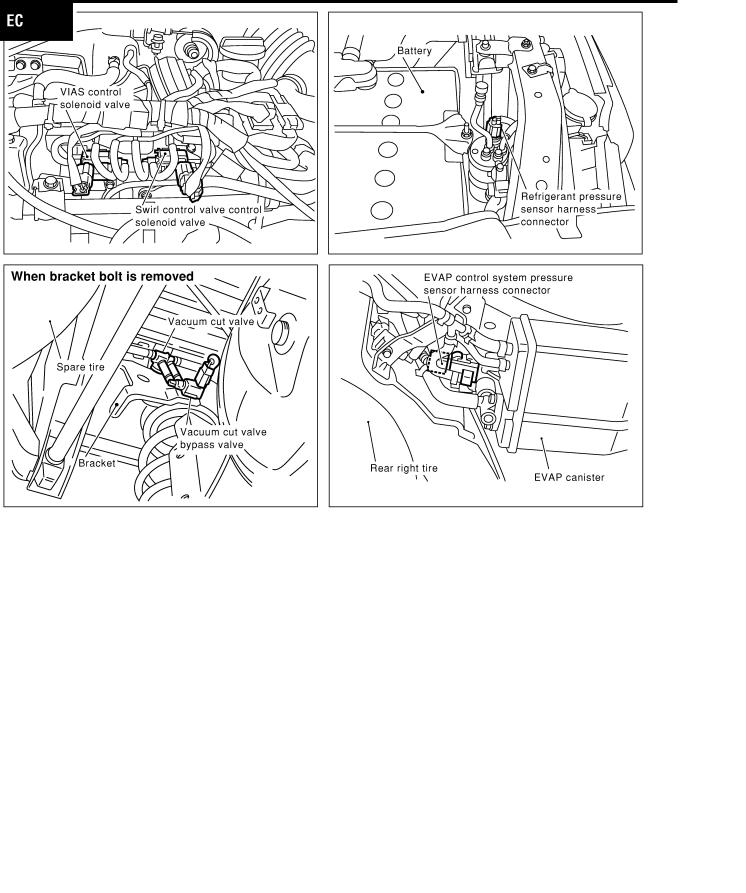

Engine Control Component Parts Location............... |

20 |

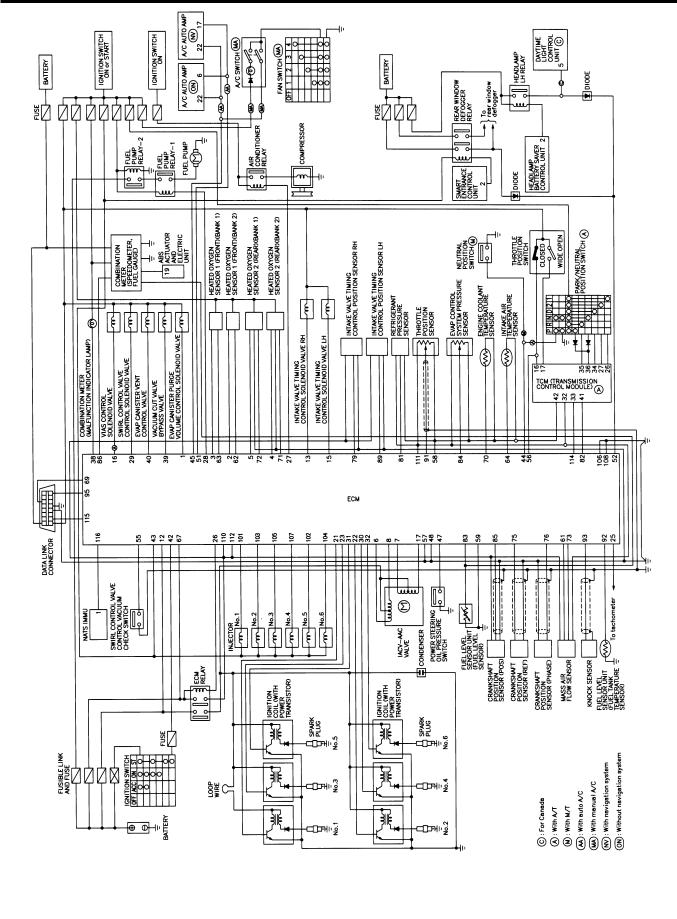

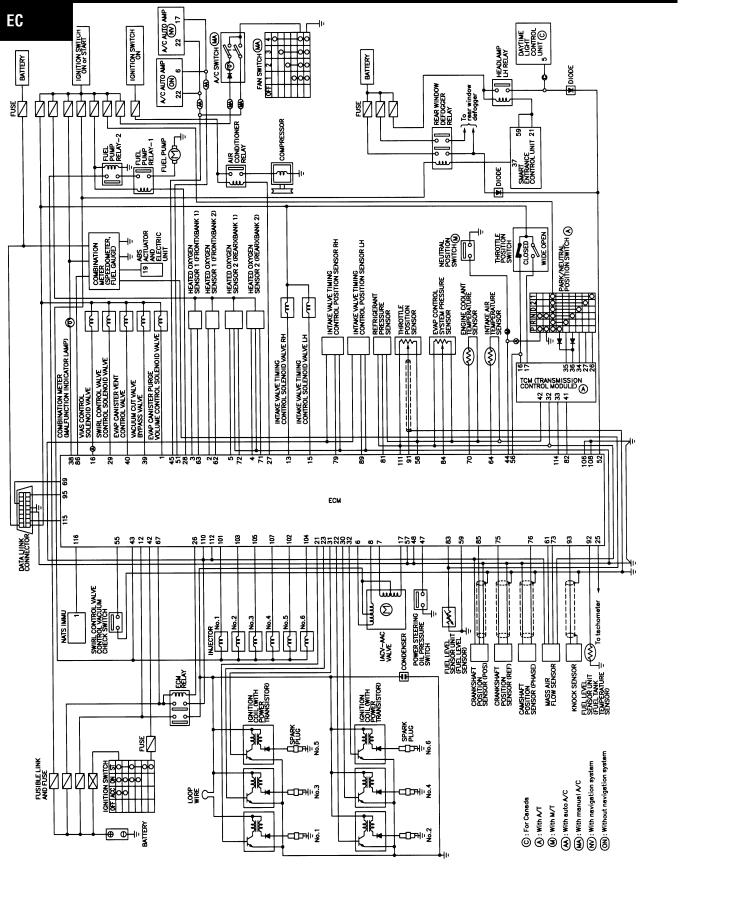

Circuit Diagram .......................................................... |

24 |

System Diagram ........................................................ |

26 |

Vacuum Hose Drawing .............................................. |

27 |

System Chart ............................................................. |

28 |

ENGINE AND EMISSION BASIC CONTROL |

|

SYSTEM DESCRIPTION ............................................... |

29 |

Multiport Fuel Injection (MFI) System ....................... |

29 |

Electronic Ignition (EI) System .................................. |

31 |

Air Conditioning Cut Control...................................... |

32 |

Fuel Cut Control (at no load & high engine |

|

speed) ........................................................................ |

33 |

Evaporative Emission System ................................... |

33 |

Positive Crankcase Ventilation .................................. |

39 |

BASIC SERVICE PROCEDURE ................................... |

40 |

Fuel Pressure Release .............................................. |

40 |

Fuel Pressure Check ................................................. |

40 |

Fuel Pressure Regulator Check ................................ |

41 |

Injector ....................................................................... |

42 |

How to Check Idle Speed and Ignition Timing.......... |

43 |

Idle Speed/Ignition Timing/Idle Mixture Ratio |

|

AT |

Adjustment ................................................................. |

44 |

|

Idle Air Volume Learning ........................................... |

59 |

|

ON BOARD DIAGNOSTIC SYSTEM |

|

TF |

DESCRIPTION ............................................................... |

61 |

|

Introduction ................................................................ |

61 |

|

Two Trip Detection Logic ........................................... |

61 |

PD |

Emission-related Diagnostic Information ................... |

62 |

|

Malfunction Indicator Lamp (MIL).............................. |

76 |

AX |

OBD System Operation Chart ................................... |

77 |

|

CONSULT-II ............................................................... |

83 |

|

Generic Scan Tool (GST) .......................................... |

97 |

SU |

TROUBLE DIAGNOSIS - INTRODUCTION.................. |

99 |

|

Introduction ................................................................ |

99 |

|

Work Flow................................................................ |

101 |

BR |

TROUBLE DIAGNOSIS - BASIC INSPECTION ......... |

103 |

|

Basic Inspection....................................................... |

103 |

ST |

TROUBLE DIAGNOSIS - GENERAL |

|

|

DESCRIPTION ............................................................. |

116 |

|

DTC Inspection Priority Chart.................................. |

116 |

RS |

Fail-safe Chart ......................................................... |

117 |

|

Symptom Matrix Chart............................................. |

118 |

|

CONSULT-II Reference Value in Data Monitor |

|

BT |

Mode ........................................................................ |

122 |

|

Major Sensor Reference Graph in Data Monitor |

|

|

Mode ........................................................................ |

124 |

HA |

ECM Terminals and Reference Value ..................... |

127 |

|

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .. |

136 |

SC |

Description ............................................................... |

136 |

|

Testing Condition ..................................................... |

136 |

|

Inspection Procedure............................................... |

136 |

EL |

Diagnostic Procedure .............................................. |

137 |

|

TROUBLE DIAGNOSIS FOR INTERMITTENT |

|

|

INCIDENT..................................................................... |

140 |

IDX |

Description ............................................................... |

140 |

|

Diagnostic Procedure .............................................. |

140 |

|

CONTENTS (Cont'd)

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ |

141 |

ECM Terminals and Reference Value ..................... |

141 |

Main Power Supply and Ground Circuit.................. |

142 |

DTC P0100 MASS AIR FLOW SENSOR (MAFS)...... |

150 |

Component Description ........................................... |

150 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

150 |

ECM Terminals and Reference Value ..................... |

150 |

On Board Diagnosis Logic....................................... |

151 |

Possible Cause........................................................ |

151 |

DTC Confirmation Procedure .................................. |

151 |

Overall Function Check ........................................... |

153 |

Wiring Diagram ........................................................ |

154 |

Diagnostic Procedure .............................................. |

155 |

DTC P0105 ABSOLUTE PRESSURE SENSOR ........ |

158 |

Component Description ........................................... |

158 |

On Board Diagnosis Logic....................................... |

158 |

DTC Confirmation Procedure .................................. |

158 |

Diagnostic Procedure .............................................. |

159 |

DTC P0110 INTAKE AIR TEMPERATURE |

|

SENSOR ...................................................................... |

160 |

Component Description ........................................... |

160 |

On Board Diagnosis Logic....................................... |

160 |

Possible Cause........................................................ |

160 |

DTC Confirmation Procedure .................................. |

160 |

Wiring Diagram ........................................................ |

162 |

Diagnostic Procedure .............................................. |

163 |

DTC P0115 ENGINE COOLANT TEMPERATURE |

|

SENSOR (ECTS) (CIRCUIT) ....................................... |

165 |

Component Description ........................................... |

165 |

On Board Diagnosis Logic....................................... |

165 |

Possible Cause........................................................ |

166 |

DTC Confirmation Procedure .................................. |

166 |

Wiring Diagram ........................................................ |

167 |

Diagnostic Procedure .............................................. |

168 |

DTC P0120 THROTTLE POSITION SENSOR ........... |

170 |

Description ............................................................... |

170 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

170 |

ECM Terminals and Reference Value ..................... |

171 |

On Board Diagnosis Logic....................................... |

171 |

Possible Cause........................................................ |

171 |

DTC Confirmation Procedure .................................. |

172 |

Wiring Diagram ........................................................ |

176 |

Diagnostic Procedure .............................................. |

177 |

DTC P0125 ENGINE COOLANT TEMPERATURE |

|

SENSOR (ECTS) ......................................................... |

182 |

Description ............................................................... |

182 |

On Board Diagnosis Logic....................................... |

182 |

Possible Cause........................................................ |

183 |

DTC Confirmation Procedure .................................. |

183 |

Wiring Diagram ........................................................ |

184 |

Diagnostic Procedure .............................................. |

185 |

DTC P0130, P0150 HEATED OXYGEN SENSOR 1 |

|

(FRONT) (BANK 1)/(BANK 2) (CIRCUIT) .................. |

187 |

Component Description ........................................... |

187 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

187 |

ECM Terminals and Reference Value ..................... |

187 |

On Board Diagnosis Logic....................................... |

188 |

Possible Cause........................................................ |

188 |

DTC Confirmation Procedure .................................. |

189 |

Overall Function Check ........................................... |

189 |

Wiring Diagram ........................................................ |

191 |

Diagnostic Procedure .............................................. |

193 |

DTC P0131, P0151 HEATED OXYGEN SENSOR 1 |

|

(FRONT) (BANK 1)/(BANK 2) (LEAN SHIFT |

|

MONITORING) ............................................................. |

197 |

Component Description ........................................... |

197 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

197 |

ECM Terminals and Reference Value ..................... |

197 |

On Board Diagnosis Logic....................................... |

198 |

Possible Cause........................................................ |

198 |

DTC Confirmation Procedure .................................. |

198 |

Overall Function Check ........................................... |

199 |

Diagnostic Procedure .............................................. |

200 |

DTC P0132, P0152 HEATED OXYGEN SENSOR 1 |

|

(FRONT) (BANK 1)/(BANK 2) (RICH SHIFT |

|

MONITORING) ............................................................. |

205 |

Component Description ........................................... |

205 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

205 |

ECM Terminals and Reference Value ..................... |

205 |

On Board Diagnosis Logic....................................... |

206 |

Possible Cause........................................................ |

206 |

DTC Confirmation Procedure .................................. |

206 |

Overall Function Check ........................................... |

207 |

Diagnostic Procedure .............................................. |

208 |

DTC P0133, P0153 HEATED OXYGEN SENSOR 1 |

|

(FRONT) (BANK 1)/(BANK 2) (RESPONSE |

|

MONITORING) ............................................................. |

213 |

Component Description ........................................... |

213 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

213 |

ECM Terminals and Reference Value ..................... |

213 |

On Board Diagnosis Logic....................................... |

214 |

Possible Cause........................................................ |

214 |

DTC Confirmation Procedure .................................. |

215 |

Overall Function Check ........................................... |

216 |

Wiring Diagram ........................................................ |

217 |

Diagnostic Procedure .............................................. |

219 |

DTC P0134, P0154 HEATED OXYGEN SENSOR 1 |

|

(FRONT) (BANK 1)/(BANK 2) (HIGH VOLTAGE)...... |

226 |

EC-2

CONTENTS (Cont'd) |

GI |

Component Description ........................................... |

226 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

226 |

ECM Terminals and Reference Value ..................... |

226 |

On Board Diagnosis Logic....................................... |

227 |

Possible Cause........................................................ |

227 |

DTC Confirmation Procedure .................................. |

227 |

Wiring Diagram ........................................................ |

229 |

Diagnostic Procedure .............................................. |

231 |

DTC P0135, P0155 HEATED OXYGEN SENSOR 1 |

|

HEATER (FRONT) (BANK 1)/(BANK 2)..................... |

235 |

Description ............................................................... |

235 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

235 |

ECM Terminals and Reference Value ..................... |

235 |

On Board Diagnosis Logic....................................... |

236 |

Possible Cause........................................................ |

236 |

DTC Confirmation Procedure .................................. |

236 |

Wiring Diagram ........................................................ |

237 |

Diagnostic Procedure .............................................. |

239 |

DTC P0137, P0157 HEATED OXYGEN SENSOR 2 |

|

(REAR) (BANK 1)/(BANK 2) (MIN. VOLTAGE |

|

MONITORING) ............................................................. |

242 |

Component Description ........................................... |

242 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

242 |

ECM Terminals and Reference Value ..................... |

242 |

On Board Diagnosis Logic....................................... |

242 |

Possible Cause........................................................ |

243 |

DTC Confirmation Procedure .................................. |

243 |

Overall Function Check ........................................... |

243 |

Wiring Diagram ........................................................ |

245 |

Diagnostic Procedure .............................................. |

247 |

DTC P0138, P0158 HEATED OXYGEN SENSOR 2 |

|

(REAR) (BANK 1)/(BANK 2) (MAX. VOLTAGE |

|

MONITORING) ............................................................. |

252 |

Component Description ........................................... |

252 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

252 |

ECM Terminals and Reference Value ..................... |

252 |

On Board Diagnosis Logic....................................... |

252 |

Possible Cause........................................................ |

253 |

DTC Confirmation Procedure .................................. |

253 |

Overall Function Check ........................................... |

253 |

Wiring Diagram ........................................................ |

255 |

Diagnostic Procedure .............................................. |

257 |

DTC P0139, P0159 HEATED OXYGEN SENSOR 2 |

|

(REAR) (BANK 1)/(BANK 2) (RESPONSE |

|

MONITORING) ............................................................. |

262 |

Component Description ........................................... |

262 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

262 |

ECM Terminals and Reference Value ..................... |

262 |

MA |

On Board Diagnosis Logic....................................... |

262 |

|

Possible Cause........................................................ |

263 |

|

DTC Confirmation Procedure .................................. |

263 |

EM |

Overall Function Check ........................................... |

263 |

|

Wiring Diagram ........................................................ |

265 |

|

Diagnostic Procedure .............................................. |

267 |

LC |

DTC P0140, P0160 HEATED OXYGEN SENSOR 2 |

|

|

(REAR) (BANK 1)/(BANK 2) (HIGH VOLTAGE)........ |

272 |

|

Component Description ........................................... |

272 |

|

CONSULT-II Reference Value in Data Monitor |

|

|

Mode ........................................................................ |

272 |

FE |

ECM Terminals and Reference Value ..................... |

272 |

|

On Board Diagnosis Logic....................................... |

272 |

|

Possible Cause........................................................ |

273 |

CL |

DTC Confirmation Procedure .................................. |

273 |

|

Overall Function Check ........................................... |

273 |

|

Wiring Diagram ........................................................ |

275 |

MT |

Diagnostic Procedure .............................................. |

277 |

|

DTC P0141, P0161 HEATED OXYGEN SENSOR 2 |

|

AT |

HEATER (REAR) (BANK 1)/(BANK 2)....................... |

281 |

|

Description ............................................................... |

281 |

|

CONSULT-II Reference Value in Data Monitor |

|

TF |

Mode ........................................................................ |

281 |

|

ECM Terminals and Reference Value ..................... |

281 |

|

On Board Diagnosis Logic....................................... |

282 |

PD |

Possible Cause........................................................ |

282 |

|

DTC Confirmation Procedure .................................. |

282 |

AX |

Wiring Diagram ........................................................ |

284 |

|

Diagnostic Procedure .............................................. |

286 |

|

DTC P0171 (RIGHT, -B1), P0174 (LEFT, -B2) |

|

SU |

FUEL INJECTION SYSTEM FUNCTION (LEAN)....... |

289 |

|

On Board Diagnosis Logic....................................... |

289 |

|

Possible Cause........................................................ |

289 |

BR |

DTC Confirmation Procedure .................................. |

289 |

|

Wiring Diagram ........................................................ |

291 |

|

Diagnostic Procedure .............................................. |

293 |

ST |

DTC P0172 (RIGHT, -B1), P0175 (LEFT, -B2) |

|

|

FUEL INJECTION SYSTEM FUNCTION (RICH)........ |

297 |

RS |

On Board Diagnosis Logic....................................... |

297 |

|

Possible Cause........................................................ |

297 |

|

DTC Confirmation Procedure .................................. |

297 |

BT |

Wiring Diagram ........................................................ |

299 |

|

Diagnostic Procedure .............................................. |

301 |

|

DTC P0180 FUEL TANK TEMPERATURE |

304 |

HA |

SENSOR ...................................................................... |

|

|

Component Description ........................................... |

304 |

SC |

On Board Diagnosis Logic....................................... |

304 |

|

Possible Cause........................................................ |

304 |

|

DTC Confirmation Procedure .................................. |

305 |

EL |

Wiring Diagram ........................................................ |

306 |

|

Diagnostic Procedure .............................................. |

307 |

|

IDX

EC-3

CONTENTS (Cont'd)

DTC P0217 COOLANT OVERTEMPERATURE |

|

ENRICHMENT PROTECTION..................................... |

309 |

On Board Diagnosis Logic....................................... |

309 |

Possible Cause........................................................ |

309 |

Overall Function Check ........................................... |

309 |

Diagnostic Procedure .............................................. |

311 |

Main 12 Causes of Overheating.............................. |

314 |

DTC P0300 - P0306 NO. 6 - 1 CYLINDER |

|

MISFIRE, MULTIPLE CYLINDER MISFIRE ............... |

315 |

On Board Diagnosis Logic....................................... |

315 |

Possible Cause........................................................ |

315 |

DTC Confirmation Procedure .................................. |

316 |

Diagnostic Procedure .............................................. |

316 |

DTC P0325 KNOCK SENSOR (KS) ........................... |

323 |

Component Description ........................................... |

323 |

ECM Terminals and Reference Value ..................... |

323 |

On Board Diagnosis Logic....................................... |

323 |

Possible Cause........................................................ |

323 |

DTC Confirmation Procedure .................................. |

323 |

Wiring Diagram ........................................................ |

325 |

Diagnostic Procedure .............................................. |

326 |

DTC P0335 CRANKSHAFT POSITION SENSOR |

|

(CKPS) (POS) .............................................................. |

329 |

Component Description ........................................... |

329 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

329 |

ECM Terminals and Reference Value ..................... |

330 |

On Board Diagnosis Logic....................................... |

330 |

Possible Cause........................................................ |

330 |

DTC Confirmation Procedure .................................. |

331 |

Wiring Diagram ........................................................ |

332 |

Diagnostic Procedure .............................................. |

333 |

DTC P0340 CAMSHAFT POSITION SENSOR |

|

(CMPS) (PHASE)......................................................... |

337 |

Component Description ........................................... |

337 |

ECM Terminals and Reference Value ..................... |

337 |

On Board Diagnosis Logic....................................... |

337 |

Possible Cause........................................................ |

338 |

DTC Confirmation Procedure .................................. |

338 |

Wiring Diagram ........................................................ |

339 |

Diagnostic Procedure .............................................. |

340 |

DTC P0420 (RIGHT BANK, -B1), P0430 (LEFT |

|

BANK, -B2) THREE WAY CATALYST FUNCTION ... |

342 |

On Board Diagnosis Logic....................................... |

342 |

Possible Cause........................................................ |

342 |

DTC Confirmation Procedure .................................. |

343 |

Overall Function Check ........................................... |

343 |

Diagnostic Procedure .............................................. |

344 |

DTC P0440 EVAP CONTROL SYSTEM (SMALL |

|

LEAK) (NEGATIVE PRESSURE)................................ |

347 |

On Board Diagnosis Logic....................................... |

347 |

Possible Cause........................................................ |

347 |

DTC Confirmation Procedure .................................. |

349 |

Diagnostic Procedure .............................................. |

350 |

DTC P0443 EVAP CANISTER PURGE VOLUME |

|

CONTROL SOLENOID VALVE (CIRCUIT)................. |

362 |

Description ............................................................... |

362 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

362 |

ECM Terminals and Reference Value ..................... |

363 |

On Board Diagnosis Logic....................................... |

363 |

Possible Cause........................................................ |

363 |

DTC Confirmation Procedure .................................. |

364 |

Wiring Diagram ........................................................ |

365 |

Diagnostic Procedure .............................................. |

366 |

DTC P0446 EVAPORATIVE EMISSION (EVAP) |

|

CANISTER VENT CONTROL VALVE (CIRCUIT) ...... |

369 |

Component Description ........................................... |

369 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

369 |

ECM Terminals and Reference Value ..................... |

369 |

On Board Diagnosis Logic....................................... |

369 |

Possible Cause........................................................ |

370 |

DTC Confirmation Procedure .................................. |

370 |

Wiring Diagram ........................................................ |

371 |

Diagnostic Procedure .............................................. |

372 |

DTC P0450 EVAPORATIVE EMISSION (EVAP) |

|

CONTROL SYSTEM PRESSURE SENSOR .............. |

376 |

Component Description ........................................... |

376 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

376 |

ECM Terminals and Reference Value ..................... |

376 |

On Board Diagnosis Logic....................................... |

377 |

Possible Cause........................................................ |

377 |

DTC Confirmation Procedure .................................. |

377 |

Wiring Diagram ........................................................ |

379 |

Diagnostic Procedure .............................................. |

380 |

DTC P0455 EVAP CONTROL SYSTEM (GROSS |

|

LEAK)........................................................................... |

389 |

On Board Diagnosis Logic....................................... |

389 |

Possible Cause........................................................ |

389 |

DTC Confirmation Procedure .................................. |

391 |

Diagnostic Procedure .............................................. |

392 |

DTC P0460 FUEL LEVEL SENSOR FUNCTION |

|

(SLOSH)....................................................................... |

402 |

Component Description ........................................... |

402 |

On Board Diagnostic Logic...................................... |

402 |

Possible Cause........................................................ |

402 |

DTC Confirmation Procedure .................................. |

402 |

Wiring Diagram ........................................................ |

403 |

Diagnostic Procedure .............................................. |

404 |

DTC P0461 FUEL LEVEL SENSOR FUNCTION ....... |

406 |

Component Description ........................................... |

406 |

On Board Diagnostic Logic...................................... |

406 |

EC-4

CONTENTS (Cont'd) |

GI |

Possible Cause........................................................ |

406 |

Overall Function Check ........................................... |

406 |

DTC P0464 FUEL LEVEL SENSOR CIRCUIT ........... |

408 |

Component Description ........................................... |

408 |

On Board Diagnostic Logic...................................... |

408 |

Possible Cause........................................................ |

408 |

DTC Confirmation Procedure .................................. |

408 |

Wiring Diagram ........................................................ |

409 |

Diagnostic Procedure .............................................. |

410 |

DTC P0500 VEHICLE SPEED SENSOR (VSS) ......... |

412 |

Component Description ........................................... |

412 |

ECM Terminals and Reference Value ..................... |

412 |

On Board Diagnosis Logic....................................... |

412 |

Possible Cause........................................................ |

413 |

DTC Confirmation Procedure .................................. |

413 |

Overall Function Check ........................................... |

414 |

Wiring Diagram ........................................................ |

415 |

Diagnostic Procedure .............................................. |

416 |

DTC P0505 IDLE AIR CONTROL VALVE (IACV) - |

|

AUXILIARY AIR CONTROL (AAC) VALVE ............... |

417 |

Description ............................................................... |

417 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

418 |

ECM Terminals and Reference Value ..................... |

418 |

On Board Diagnosis Logic....................................... |

418 |

Possible Cause........................................................ |

418 |

DTC Confirmation Procedure .................................. |

418 |

Wiring Diagram ........................................................ |

420 |

Diagnostic Procedure .............................................. |

421 |

DTC P0510 CLOSED THROTTLE POSITION |

|

SWITCH ....................................................................... |

426 |

Component Description ........................................... |

426 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

426 |

ECM Terminals and Reference Value ..................... |

426 |

On Board Diagnosis Logic....................................... |

426 |

Possible Cause........................................................ |

426 |

DTC Confirmation Procedure .................................. |

427 |

Overall Function Check ........................................... |

427 |

Wiring Diagram ........................................................ |

429 |

Diagnostic Procedure .............................................. |

430 |

DTC P0600 A/T COMMUNICATION LINE.................. |

434 |

System Description.................................................. |

434 |

ECM Terminals and Reference Value ..................... |

434 |

On Board Diagnosis Logic....................................... |

434 |

Possible Cause........................................................ |

434 |

DTC Confirmation Procedure .................................. |

434 |

Wiring Diagram ........................................................ |

436 |

Diagnostic Procedure .............................................. |

437 |

DTC P0605 ECM ......................................................... |

438 |

Component Description ........................................... |

438 |

On Board Diagnosis Logic....................................... |

438 |

Possible Cause........................................................ |

438 |

MA |

DTC Confirmation Procedure .................................. |

438 |

|

Diagnostic Procedure .............................................. |

439 |

|

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2) |

|

EM |

INTAKE VALVE TIMING CONTROL .......................... |

440 |

|

Description ............................................................... |

440 |

|

CONSULT-II Reference Value in Data Monitor |

|

LC |

Mode ........................................................................ |

440 |

|

ECM Terminals and Reference Value ..................... |

441 |

|

On Board Diagnosis Logic....................................... |

442 |

|

Possible Cause........................................................ |

442 |

|

DTC Confirmation Procedure .................................. |

443 |

FE |

DTC P1111 (RIGHT, -B1), P1136 (LEFT, -B2) |

|

|

INTAKE VALVE TIMING CONTROL SOLENOID |

|

|

VALVE (CIRCUIT)........................................................ |

445 |

CL |

Component Description ........................................... |

445 |

|

CONSULT-II Reference Value in Data Monitor |

|

|

Mode ........................................................................ |

445 |

MT |

ECM Terminals and Reference Value ..................... |

445 |

|

On Board Diagnosis Logic....................................... |

446 |

AT |

Possible Cause........................................................ |

446 |

|

DTC Confirmation Procedure .................................. |

446 |

|

Wiring Diagram ........................................................ |

447 |

TF |

Diagnostic Procedure .............................................. |

449 |

|

DTC P1130 SWIRL CONTROL VALVE CONTROL |

|

|

SOLENOID VALVE...................................................... |

452 |

PD |

Description ............................................................... |

452 |

|

CONSULT-II Reference Value in Data Monitor |

|

AX |

Mode ........................................................................ |

453 |

|

ECM Terminals and Reference Value ..................... |

453 |

|

On Board Diagnosis Logic....................................... |

453 |

SU |

Possible Cause........................................................ |

454 |

|

DTC Confirmation Procedure .................................. |

454 |

|

Wiring Diagram ........................................................ |

456 |

BR |

Diagnostic Procedure .............................................. |

457 |

|

DTC P1140 (RIGHT, -B1), P1145 (LEFT, -B2) |

|

|

INTAKE VALVE TIMING CONTROL POSITION |

|

ST |

SENSOR (CIRCUIT) .................................................... |

475 |

|

Component Description ........................................... |

475 |

RS |

CONSULT-II Reference Value in Data Monitor |

|

|

Mode ........................................................................ |

475 |

|

ECM Terminals and Reference Value ..................... |

476 |

BT |

On Board Diagnosis Logic....................................... |

476 |

|

Possible Cause........................................................ |

477 |

|

DTC Confirmation Procedure .................................. |

477 |

HA |

Wiring Diagram ........................................................ |

478 |

|

Diagnostic Procedure .............................................. |

480 |

SC |

DTC P1148 (RIGHT BANK, -B1), P1168 (LEFT |

|

|

BANK, -B2) CLOSED LOOP CONTROL ................... |

484 |

|

On Board Diagnosis Logic....................................... |

484 |

EL |

Possible Cause........................................................ |

484 |

|

DTC Confirmation Procedure .................................. |

484 |

|

IDX

EC-5

CONTENTS (Cont'd)

Overall Function Check ........................................... |

485 |

Diagnostic Procedure .............................................. |

485 |

DTC P1165 SWIRL CONTROL VALVE CONTROL |

|

VACUUM CHECK SWITCH......................................... |

486 |

Component Description ........................................... |

486 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

486 |

ECM Terminals and Reference Value ..................... |

486 |

On Board Diagnosis Logic....................................... |

487 |

Possible Cause........................................................ |

487 |

DTC Confirmation Procedure .................................. |

487 |

Wiring Diagram ........................................................ |

488 |

Diagnostic Procedure .............................................. |

489 |

DTC P1320 IGNITION SIGNAL................................... |

492 |

Component Description ........................................... |

492 |

ECM Terminals and Reference Value ..................... |

492 |

On Board Diagnosis Logic....................................... |

492 |

Possible Cause........................................................ |

493 |

DTC Confirmation Procedure .................................. |

493 |

Wiring Diagram ........................................................ |

494 |

Diagnostic Procedure .............................................. |

497 |

DTC P1335 CRANKSHAFT POSITION SENSOR |

|

(CKPS) (REF) .............................................................. |

503 |

Component Description ........................................... |

503 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

503 |

ECM Terminals and Reference Value ..................... |

503 |

On Board Diagnosis Logic....................................... |

504 |

Possible Cause........................................................ |

504 |

DTC Confirmation Procedure .................................. |

504 |

Wiring Diagram ........................................................ |

506 |

Diagnostic Procedure .............................................. |

507 |

DTC P1336 CRANKSHAFT POSITION SENSOR |

|

(CKPS) (POS) (COG) .................................................. |

510 |

Component Description ........................................... |

510 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

510 |

ECM Terminals and Reference Value ..................... |

511 |

On Board Diagnosis Logic....................................... |

511 |

Possible Cause........................................................ |

511 |

DTC Confirmation Procedure .................................. |

512 |

Wiring Diagram ........................................................ |

513 |

Diagnostic Procedure .............................................. |

514 |

DTC P1441 EVAP CONTROL SYSTEM (VERY |

|

SMALL LEAK) ............................................................. |

519 |

On Board Diagnosis Logic....................................... |

519 |

Possible Cause........................................................ |

519 |

DTC Confirmation Procedure .................................. |

520 |

Diagnostic Procedure .............................................. |

522 |

DTC P1444 EVAP CANISTER PURGE VOLUME |

|

CONTROL SOLENOID VALVE................................... |

534 |

Description ............................................................... |

534 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

534 |

ECM Terminals and Reference Value ..................... |

535 |

On Board Diagnosis Logic....................................... |

535 |

Possible Cause........................................................ |

535 |

DTC Confirmation Procedure .................................. |

536 |

Wiring Diagram ........................................................ |

537 |

Diagnostic Procedure .............................................. |

538 |

DTC P1446 EVAPORATIVE EMISSION (EVAP) |

|

CANISTER VENT CONTROL VALVE (CLOSE)......... |

546 |

Component Description ........................................... |

546 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

546 |

ECM Terminals and Reference Value ..................... |

546 |

On Board Diagnosis Logic....................................... |

546 |

Possible Cause........................................................ |

547 |

DTC Confirmation Procedure .................................. |

547 |

Wiring Diagram ........................................................ |

548 |

Diagnostic Procedure .............................................. |

549 |

DTC P1447 EVAPORATIVE EMISSION (EVAP) |

|

CONTROL SYSTEM PURGE FLOW |

|

MONITORING .............................................................. |

554 |

System Description.................................................. |

554 |

On Board Diagnosis Logic....................................... |

554 |

Possible Cause........................................................ |

554 |

DTC Confirmation Procedure .................................. |

555 |

Overall Function Check ........................................... |

556 |

Diagnostic Procedure .............................................. |

557 |

DTC P1448 EVAPORATIVE EMISSION (EVAP) |

|

CANISTER VENT CONTROL VALVE (OPEN)........... |

565 |

Component Description ........................................... |

565 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

565 |

ECM Terminals and Reference Value ..................... |

565 |

On Board Diagnosis Logic....................................... |

565 |

Possible Cause........................................................ |

566 |

DTC Confirmation Procedure .................................. |

566 |

Overall Function Check ........................................... |

567 |

Wiring Diagram ........................................................ |

568 |

Diagnostic Procedure .............................................. |

569 |

DTC P1464 FUEL LEVEL SENSOR CIRCUIT |

|

(GROUND SIGNAL) .................................................... |

574 |

Component Description ........................................... |

574 |

On Board Diagnostic Logic...................................... |

574 |

Possible Cause........................................................ |

574 |

DTC Confirmation Procedure .................................. |

574 |

Wiring Diagram ........................................................ |

575 |

Diagnostic Procedure .............................................. |

576 |

DTC P1490 VACUUM CUT VALVE BYPASS |

|

VALVE (CIRCUIT)........................................................ |

577 |

Description ............................................................... |

577 |

EC-6

CONTENTS (Cont'd)

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

577 |

ECM Terminals and Reference Value ..................... |

577 |

On Board Diagnosis Logic....................................... |

578 |

Possible Cause........................................................ |

578 |

DTC Confirmation Procedure .................................. |

578 |

Wiring Diagram ........................................................ |

579 |

Diagnostic Procedure .............................................. |

580 |

DTC P1491 VACUUM CUT VALVE BYPASS |

|

VALVE.......................................................................... |

583 |

Description ............................................................... |

583 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

583 |

ECM Terminals and Reference Value ..................... |

583 |

On Board Diagnosis Logic....................................... |

584 |

Possible Cause........................................................ |

584 |

DTC Confirmation Procedure .................................. |

584 |

Overall Function Check ........................................... |

585 |

Wiring Diagram ........................................................ |

586 |

Diagnostic Procedure .............................................. |

587 |

DTC P1605 A/T DIAGNOSIS COMMUNICATION |

|

LINE ............................................................................. |

595 |

Component Description ........................................... |

595 |

On Board Diagnosis Logic....................................... |

595 |

Possible Cause........................................................ |

595 |

DTC Confirmation Procedure .................................. |

595 |

DTC P1706 PARK/NEUTRAL POSITION (PNP) |

|

SWITCH ....................................................................... |

596 |

Component Description ........................................... |

596 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

596 |

ECM Terminals and Reference Value ..................... |

596 |

On Board Diagnosis Logic....................................... |

596 |

Possible Cause........................................................ |

596 |

DTC Confirmation Procedure .................................. |

597 |

Overall Function Check ........................................... |

598 |

Wiring Diagram ........................................................ |

599 |

Diagnostic Procedure .............................................. |

600 |

VARIABLE INDUCTION AIR CONTROL SYSTEM |

|

(VIAS)........................................................................... |

603 |

Description ............................................................... |

603 |

ECM Terminals and Reference Value ..................... |

604 |

Wiring Diagram ........................................................ |

605 |

Diagnostic Procedure .............................................. |

606 |

INJECTOR ................................................................... |

609 |

Component Description ........................................... |

609 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

609 |

ECM Terminals and Reference Value ..................... |

609 |

Wiring Diagram ........................................................ |

610 |

Diagnostic Procedure .............................................. |

611 |

START SIGNAL........................................................... |

614 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

614 |

ECM Terminals and Reference Value ..................... |

614 |

Wiring Diagram ........................................................ |

615 |

Diagnostic Procedure .............................................. |

616 |

FUEL PUMP................................................................. |

618 |

System Description.................................................. |

618 |

Component Description ........................................... |

618 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

618 |

ECM Terminals and Reference Value ..................... |

619 |

Wiring Diagram ........................................................ |

620 |

Diagnostic Procedure .............................................. |

621 |

POWER STEERING OIL PRESSURE SWITCH......... |

627 |

Component Description ........................................... |

627 |

CONSULT-II Reference Value in Data Monitor |

|

Mode ........................................................................ |

627 |

ECM Terminals and Reference Value ..................... |

627 |

Wiring Diagram ........................................................ |

628 |

Diagnostic Procedure .............................................. |

629 |

REFRIGERANT PRESSURE SENSOR ...................... |

632 |

Description ............................................................... |

632 |

ECM Terminals and Reference Value ..................... |

632 |

Wiring Diagram ........................................................ |

633 |

Diagnostic Procedure .............................................. |

634 |

ELECTRICAL LOAD SIGNAL..................................... |

636 |

ECM Terminals and Reference Value ..................... |

636 |

Wiring Diagram ........................................................ |

637 |

Diagnostic Procedure .............................................. |

639 |

MIL & DATA LINK CONNECTORS ............................ |

642 |

Wiring Diagram ........................................................ |

642 |

SERVICE DATA AND SPECIFICATIONS (SDS) ....... |

643 |

Fuel Pressure Regulator.......................................... |

643 |

Idle Speed and Ignition Timing................................ |

643 |

Mass Air Flow Sensor.............................................. |

643 |

Engine Coolant Temperature Sensor ...................... |

643 |

Heated Oxygen Sensor 1 Heater (front) ................. |

643 |

Fuel Pump ............................................................... |

643 |

IACV-AAC Valve ...................................................... |

643 |

Injector ..................................................................... |

643 |

Resistor.................................................................... |

643 |

Throttle Position Sensor .......................................... |

644 |

Calculated Load Value............................................. |

644 |

Intake Air Temperature Sensor................................ |

644 |

Heated Oxygen Sensor 2 Heater (rear) .................. |

644 |

Crankshaft Position Sensor (REF) .......................... |

644 |

Fuel Tank Temperature Sensor ............................... |

644 |

Camshaft Position Sensor (PHASE) ....................... |

644 |

GI

MA

EM

LC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EC-7

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC

Alphabetical & P No. Index for DTC

NAEC0001

ALPHABETICAL INDEX FOR DTC

NAEC0001S01

Items |

DTC*1 |

Reference page |

|

(CONSULT-II screen terms) |

|||

|

|

||

|

|

|

|

Unable to access ECM |

Ð |

EC-117 |

|

|

|

|

|

ABSL PRES SEN/CIRC |

P0105 |

EC-158 |

|

|

|

|

|

AIR TEMP SEN/CIRC |

P0110 |

EC-160 |

|

|

|

|

|

A/T 1ST GR FNCTN |

P0731 |

AT-120 |

|

|

|

|

|

A/T 2ND GR FNCTN |

P0732 |

AT-126 |

|

|

|

|

|

A/T 3RD GR FNCTN |

P0733 |

AT-132 |

|

|

|

|

|

A/T 4TH GR FNCTN |

P0734 |

AT-138 |

|

|

|

|

|

A/T COMM LINE |

P0600*2 |

EC-434 |

|

|

|

|

|

A/T DIAG COMM LINE |

P1605 |

EC-595 |

|

|

|

|

|

A/T TCC S/V FNCTN |

P0744 |

AT-153 |

|

|

|

|

|

ATF TEMP SEN/CIRC |

P0710 |

AT-105 |

|

|

|

|

|

CAM PS/CIRC (PHS) |

P0340 |

EC-337 |

|

|

|

|

|

CLOSED LOOP-B1 |

P1148 |

EC-484 |

|

|

|

|

|

CLOSED LOOP-B2 |

P1168 |

EC-484 |

|

|

|

|

|

CLOSED TP SW/CIRC |

P0510 |

EC-426 |

|

|

|

|

|

COOLANT T SEN/CIRC*3 |

P0115 |

EC-165 |

|

|

|

|

|

*COOLANT T SEN/CIRC |

P0125 |

EC-182 |

|

|

|

|

|

CPS/CIRC (POS) COG |

P1336 |

EC-510 |

|

|

|

|

|

CPS/CIRCUIT (POS) |

P0335 |

EC-329 |

|

|

|

|

|

CPS/CIRCUIT (REF) |

P1335 |

EC-503 |

|

|

|

|

|

CYL 1 MISFIRE |

P0301 |

EC-315 |

|

|

|

|

|

CYL 2 MISFIRE |

P0302 |

EC-315 |

|

|

|

|

|

CYL 3 MISFIRE |

P0303 |

EC-315 |

|

|

|

|

|

CYL 4 MISFIRE |

P0304 |

EC-315 |

|

|

|

|

|

CYL 5 MISFIRE |

P0305 |

EC-315 |

|

|

|

|

|

CYL 6 MISFIRE |

P0306 |

EC-315 |

|

|

|

|

|

ECM |

P0605 |

EC-438 |

|

|

|

|

|

ENGINE SPEED SIG |

P0725 |

AT-116 |

|

|

|

|

|

ENG OVER TEMP |

P0217 |

EC-309 |

|

|

|

|

|

ENG OVER TEMP |

P1217 |

LC-25 |

|

|

|

|

|

EVAP GROSS LEAK |

P0455 |

EC-389 |

|

|

|

|

|

EVAP PURG FLOW/MON |

P1447 |

EC-554 |

|

|

|

|

|

EVAP SYS PRES SEN |

P0450 |

EC-376 |

|

|

|

|

|

EVAP SMALL LEAK |

P0440 |

EC-347 |

|

|

|

|

|

EVAP VERY SMALL LEAK |

P1441 |

EC-519 |

|

|

|

|

EC-8

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

Items |

DTC*1 |

Reference page |

|

(CONSULT-II screen terms) |

|||

|

|

||

|

|

|

|

FUEL LEVL SEN/CIRC |

P0464 |

EC-408 |

|

|

|

|

|

FUEL LEVL SEN/CIRC |

P1464 |

EC-574 |

|

|

|

|

|

FUEL LEVEL SENSOR |

P0461 |

EC-406 |

|

|

|

|

|

FUEL LV SE (SLOSH) |

P0460 |

EC-402 |

|

|

|

|

|

FUEL SYS-LEAN/BK1 |

P0171 |

EC-289 |

|

|

|

|

|

FUEL SYS-LEAN/BK2 |

P0174 |

EC-289 |

|

|

|

|

|

FUEL SYS-RICH/BK1 |

P0172 |

EC-297 |

|

|

|

|

|

FUEL SYS-RICH/BK2 |

P0175 |

EC-297 |

|

|

|

|

|

FUEL TEMP SEN/CIRC |

P0180 |

EC-304 |

|

|

|

|

|

HO2S1 HTR (B1) |

P0135 |

EC-235 |

|

|

|

|

|

HO2S1 HTR (B2) |

P0155 |

EC-235 |

|

|

|

|

|

HO2S1 (B1) |

P0130 |

EC-187 |

|

|

|

|

|

HO2S1 (B1) |

P0131 |

EC-197 |

|

|

|

|

|

HO2S1 (B1) |

P0132 |

EC-205 |

|

|

|

|

|

HO2S1 (B1) |

P0133 |

EC-213 |

|

|

|

|

|

HO2S1 (B1) |

P0134 |

EC-226 |

|

|

|

|

|

HO2S1 (B2) |

P0150 |

EC-187 |

|

|

|

|

|

HO2S1 (B2) |

P0151 |

EC-197 |

|

|

|

|

|

HO2S1 (B2) |

P0152 |

EC-205 |

|

|

|

|

|

HO2S1 (B2) |

P0153 |

EC-213 |

|

|

|

|

|

HO2S1 (B2) |

P0154 |

EC-226 |

|

|

|

|

|

HO2S2 (B1) |

P0137 |

EC-242 |

|

|

|

|

|

HO2S2 (B1) |

P0138 |

EC-252 |

|

|

|

|

|

HO2S2 (B1) |

P0139 |

EC-262 |

|

|

|

|

|

HO2S2 (B1) |

P0140 |

EC-272 |

|

|

|

|

|

HO2S2 (B2) |

P0157 |

EC-242 |

|

|

|

|

|

HO2S2 (B2) |

P0158 |

EC-252 |

|

|

|

|

|

HO2S2 (B2) |

P0159 |

EC-262 |

|

|

|

|

|

HO2S2 (B2) |

P0160 |

EC-272 |

|

|

|

|

|

HO2S2 HTR (B1) |

P0141 |

EC-281 |

|

|

|

|

|

HO2S2 HTR (B2) |

P0161 |

EC-281 |

|

|

|

|

|

IACV/AAC VLV/CIRC |

P0505 |

EC-417 |

|

|

|

|

|

IGN SIGNAL-PRIMARY |

P1320 |

EC-492 |

|

|

|

|

|

INTK TIM S/CIRC-B1 |

P1140 |

EC-475 |

|

|

|

|

|

INTK TIM S/CIRC-B2 |

P1145 |

EC-475 |

|

|

|

|

|

INT/V TIM CONT-B1 |

P1110 |

EC-440 |

|

|

|

|

|

INT/V TIM CONT-B2 |

P1135 |

EC-440 |

|

|

|

|

GI

MA

EM

LC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EC-9

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

Items |

DTC*1 |

Reference page |

|

(CONSULT-II screen terms) |

|||

|

|

||

|

|

|

|

INT/V TIM V/CIR-B1 |

P1111 |

EC-445 |

|

|

|

|

|

INT/V TIM V/CIR-B2 |

P1136 |

EC-445 |

|

|

|

|

|

KNOCK SEN/CIRC-B1 |

P0325*2 |

EC-323 |

|

|

|

|

|

L/PRES SOL/CIRC |

P0745 |

AT-162 |

|

|

|

|

|

MAF SEN/CIRCUIT*3 |

P0100 |

EC-150 |

|

|

|

|

|

MULTI CYL MISFIRE |

P0300 |

EC-315 |

|

|

|

|

|

NATS MALFUNCTION |

P1610 - P1615*2 |

EL-328 |

|

|

|

|

|

NO DTC IS DETECTED. |

|

|

|

FURTHER TESTING |

P0000 |

Ð |

|

MAY BE REQUIRED. |

|

|

|

|

|

|

|

O/R CLTCH SOL/CIRC |

P1760 |

AT-185 |

|

|

|

|

|

P-N POS SW/CIRCUIT |

P1706 |

EC-596 |

|

|

|

|

|

PNP SW/CIRC |

P0705 |

AT-99 |

|

|

|

|

|

PURG VOLUME CONT/V |

P0443 |

EC-362 |

|

|

|

|

|

PURG VOLUME CONT/V |

P1444 |

EC-534 |

|

|

|

|

|

SFT SOL A/CIRC*3 |

P0750 |

AT-168 |

|

|

|

|

|

SFT SOL B/CIRC*3 |

P0755 |

AT-172 |

|

|

|

|

|

SWIRL CONT SOL/V |

P1130 |

EC-452 |

|

|

|

|

|

SWL CON VC SW/CIRC |

P1165 |

EC-486 |

|

|

|

|

|

TCC SOLENOID/CIRC |

P0740 |

AT-148 |

|

|

|

|

|

TP SEN/CIRC A/T*3 |

P1705 |

AT-176 |

|

|

|

|

|

TRTL POS SEN/CIRC*3 |

P0120 |

EC-170 |

|

|

|

|

|

TW CATALYST SYS-B1 |

P0420 |

EC-342 |

|

|

|

|

|

TW CATALYST SYS-B2 |

P0430 |

EC-342 |

|

|

|

|

|

VC CUT/V BYPASS/V |

P1491 |

EC-583 |

|

|

|

|

|

VC/V BYPASS/V |

P1490 |

EC-577 |

|

|

|

|

|

VEH SPEED SEN/CIRC*4 |

P0500 |

EC-412 |

|

|

|

|

|

VEH SPD SEN/CIR A/T*4 |

P0720 |

AT-111 |

|

|

|

|

|

VENT CONTROL VALVE |

P0446 |

EC-369 |

|

|

|

|

|

VENT CONTROL VALVE |

P1446 |

EC-546 |

|

|

|

|

|

VENT CONTROL VALVE |

P1448 |

EC-565 |

|

|

|

|

*1: 1st trip DTC No. is the same as DTC No. *2: This DTC is displayed with CONSULT-II only.

*3: When the fail-safe operation occurs, the MIL illuminates.

*4: The MIL illuminates when both the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the same time.

NOTE:

IRegarding R50 models, ª-B1º and ªBK1º indicate right bank and ª-B2º and ªBK2º indicate left bank.

IBank 1 (-B1 or BK1) includes No. 1 cylinder.

EC-10

|

TROUBLE DIAGNOSIS Ð INDEX |

||

|

|

Alphabetical & P No. Index for DTC (Cont'd) |

|

|

|

|

|

P NO. INDEX FOR DTC |

|

|

=NAEC0001S02 |

|

|

|

|

|

|

|

|

DTC*1 |

Items |

|

Reference page |

(CONSULT-II screen terms) |

|

||

|

|

|

|

|

|

|

|

Ð |

Unable to access ECM |

|

EC-117 |

|

|

|

|

|

NO DTC IS DETECTED. |

|

|

P0000 |

FURTHER TESTING |

|

Ð |

|

MAY BE REQUIRED. |

|

|

|

|

|

|

P0100 |

MAF SEN/CIRCUIT*3 |

|

EC-150 |

|

|

|

|

P0105 |

ABSL PRES SEN/CIRC |

|

EC-158 |

|

|

|

|

P0110 |

AIR TEMP SEN/CIRC |

|

EC-160 |

|

|

|

|

P0115 |

COOLANT T SEN/CIRC*3 |

|

EC-165 |

|

|

|

|

P0120 |

THRTL POS SEN/CIRC*3 |

|

EC-170 |

|

|

|

|

P0125 |

*COOLANT T SEN/CIRC |

|

EC-182 |

|

|

|

|

P0130 |

HO2S1 (B1) |

|

EC-187 |

|

|

|

|

P0131 |

HO2S1 (B1) |

|

EC-197 |

|

|

|

|

P0132 |

HO2S1 (B1) |

|

EC-205 |

|

|

|

|

P0133 |

HO2S1 (B1) |

|

EC-213 |

|

|

|

|

P0134 |

HO2S1 (B1) |

|

EC-226 |

|

|

|

|

P0135 |

HO2S1 HTR (B1) |

|

EC-235 |

|

|

|

|

P0137 |

HO2S2 (B1) |

|

EC-242 |

|

|

|

|

P0138 |

HO2S2 (B1) |

|

EC-252 |

|

|

|

|

P0139 |

HO2S2 (B1) |

|

EC-262 |

|

|

|

|

P0140 |

HO2S2 (B1) |

|

EC-272 |

|

|

|

|

P0141 |

HO2S2 HTR (B1) |

|

EC-281 |

|

|

|

|

P0150 |

HO2S1 (B2) |

|

EC-187 |

|

|

|

|

P0151 |

HO2S1 (B2) |

|

EC-197 |

|

|

|

|

P0152 |

HO2S1 (B2) |

|

EC-205 |

|

|

|

|

P0153 |

HO2S1 (B2) |

|

EC-213 |

|

|

|

|

P0154 |

HO2S1 (B2) |

|

EC-226 |

|

|

|

|

P0155 |

HO2S1 HTR (B2) |

|

EC-235 |

|

|

|

|

P0157 |

HO2S2 (B2) |

|

EC-242 |

|

|

|

|

P0158 |

HO2S2 (B2) |

|

EC-252 |

|

|

|

|

P0159 |

HO2S2 (B2) |

|

EC-262 |

|

|

|

|

P0160 |

HO2S2 (B2) |

|

EC-272 |

|

|

|

|

P0161 |

HO2S2 HTR (B2) |

|

EC-281 |

|

|

|

|

P0171 |

FUEL SYS-LEAN/BK1 |

|

EC-289 |

|

|

|

|

P0172 |

FUEL SYS-RICH/BK1 |

|

EC-297 |

|

|

|

|

P0174 |

FUEL SYS-LEAN/BK2 |

|

EC-289 |

|

|

|

|

P0175 |

FUEL SYS-RICH/BK2 |

|

EC-297 |

|

|

|

|

P0180 |

FUEL TEMP SEN/CIRC |

|

EC-304 |

|

|

|

|

GI

MA

EM

LC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EC-11

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

DTC*1 |

Items |

Reference page |

|

(CONSULT-II screen terms) |

|||

|

|

||

|

|

|

|

P0217 |

ENG OVER TEMP |

EC-309 |

|

|

|

|

|

P0300 |

MULTI CYL MISFIRE |

EC-315 |

|

|

|

|

|

P0301 |

CYL 1 MISFIRE |

EC-315 |

|

|

|

|

|

P0302 |

CYL 2 MISFIRE |

EC-315 |

|

|

|

|

|

P0303 |

CYL 3 MISFIRE |

EC-315 |

|

|

|

|

|

P0304 |

CYL 4 MISFIRE |

EC-315 |

|

|

|

|

|

P0305 |

CYL 5 MISFIRE |

EC-315 |

|

|

|

|

|

P0306 |

CYL 6 MISFIRE |

EC-315 |

|

|

|

|

|

P0325*2 |

KNOCK SEN/CIRC-B1 |

EC-323 |

|

|

|

|

|

P0335 |

CPS/CIRCUIT (POS) |

EC-329 |

|

|

|

|

|

P0340 |

CAM PS/CIRC (PHS) |

EC-337 |

|

|

|

|

|

P0420 |

TW CATALYST SYS-B1 |

EC-342 |

|

|

|

|

|

P0430 |

TW CATALYST SYS-B2 |

EC-342 |

|

|

|

|

|

P0440 |

EVAP SMALL LEAK |

EC-347 |

|

|

|

|

|

P0443 |

PURG VOLUME CONT/V |

EC-362 |

|

|

|

|

|

P0446 |

VENT CONTROL VALVE |

EC-369 |

|

|

|

|

|

P0450 |

EVAP SYS PRES SEN |

EC-376 |

|

|

|

|

|

P0455 |

EVAP GROSS LEAK |

EC-389 |

|

|

|

|

|

P0460 |

FUEL LV SE (SLOSH) |

EC-402 |

|

|

|

|

|

P0461 |

FUEL LEVEL SENSOR |

EC-406 |

|

|

|

|

|

P0464 |

FUEL LEVL SEN/CIRC |

EC-408 |

|

|

|

|

|

P0500 |

VEH SPEED SEN/CIRC*4 |

EC-412 |

|

|

|

|

|

P0505 |

IACV/AAC VLV/CIRC |

EC-417 |

|

|

|

|

|

P0510 |

CLOSED TP SW/CIRC |

EC-426 |

|

|

|

|

|

P0600*2 |

A/T COMM LINE |

EC-434 |

|

|

|

|

|

P0605 |

ECM |

EC-438 |

|

|

|

|

|

P0705 |

PNP SW/CIRC |

AT-99 |

|

|

|

|

|

P0710 |

ATF TEMP SEN/CIRC |

AT-105 |

|

|

|

|

|

P0720 |

VEH SPD SEN/CIR A/T*4 |

AT-111 |

|

|

|

|

|

P0725 |

ENGINE SPEED SIG |

AT-116 |

|

|

|

|

|

P0731 |

A/T 1ST GR FNCTN |

AT-120 |

|

|

|

|

|

P0732 |

A/T 2ND GR FNCTN |

AT-126 |

|

|

|

|

|

P0733 |

A/T 3RD GR FNCTN |

AT-132 |

|

|

|

|

|

P0734 |

A/T 4TH GR FNCTN |

AT-138 |

|

|

|

|

|

P0740 |

TCC SOLENOID/CIRC |

AT-148 |

|

|

|

|

|

P0744 |

A/T TCC S/V FNCTN |

AT-153 |

|

|

|

|

|

P0745 |

L/PRESS SOL/CIRC |

AT-162 |

|

|

|

|

EC-12

TROUBLE DIAGNOSIS Ð INDEX

|

|

Alphabetical & P No. Index for DTC (Cont'd) |

|

|

|

|

|

DTC*1 |

Items |

|

Reference page |

(CONSULT-II screen terms) |

|

||

|

|

|

|

|

|

|

|

P0750 |

SFT SOL A/CIRC*3 |

|

AT-168 |

|

|

|

|

P0755 |

SFT SOL B/CIRC*3 |

|

AT-172 |

|

|

|

|

P1110 |

INT/V TIM CONT-B1 |

|

EC-440 |

|

|

|

|

P1111 |

INT/V TIM V/CIR-B1 |

|

EC-445 |

|