Nissan Primera User Manual

B ENGINE

SECTION

ENGINE MECHANICAL

CONTENTS

A

EM

C

D

E

QG |

|

PRECAUTIONS ......................................................... |

6 |

Precautions for Drain Coolant ................................. |

6 |

Precautions for Disconnecting Fuel Piping ............. |

6 |

Precautions for Removal and Disassembly ............ |

6 |

Precautions for Inspection, Repair and Replace- |

|

ment ........................................................................ |

6 |

Precautions for Assembly and Installation .............. |

6 |

Parts Requiring Angular Tightening ........................ |

6 |

Precautions for Liquid Gasket ................................. |

7 |

REMOVAL OF LIQUID GASKET SEALING ......... |

7 |

LIQUID GASKET APPLICATION PROCEDURE..... |

7 |

PREPARATION .......................................................... |

8 |

Special Service Tools .............................................. |

8 |

Commercial Service Tools ..................................... |

10 |

NOISE, VIBRATION, AND HARSHNESS (NVH) |

|

TROUBLESHOOTING ............................................. |

12 |

NVH Troubleshooting —Engine Noise ................ ... |

12 |

Use the Chart Below to Help You Find the Cause |

|

of the Symptom. .................................................... |

13 |

DRIVE BELTS .......................................................... |

14 |

Checking Drive Belts ............................................. |

14 |

Tension Adjustment ............................................... |

15 |

POWER STEERING PUMP AND WATER PUMP |

|

BELT .................................................................. |

15 |

ALTERNATOR AND AIR CONDITIONER COM- |

|

PRESSOR BELT ................................................ |

15 |

Removal and Installation ....................................... |

16 |

REMOVAL .......................................................... |

16 |

INSTALLATION .................................................. |

16 |

AIR CLEANER AND AIR DUCT .............................. |

17 |

Removal and Installation ....................................... |

17 |

REMOVAL .......................................................... |

17 |

INSTALLATION .................................................. |

17 |

Changing Air Cleaner Element .............................. |

18 |

INTAKE MANIFOLD ................................................ |

19 |

Removal and Installation ....................................... |

19 |

REMOVAL .......................................................... |

19 |

INSPECTION AFTER REMOVAL ...................... |

20 |

INSTALLATION .................................................. |

20 |

Disassembly and Assembly ................................... |

21 |

INTAKE MANIFOLD COLLECTOR .................... |

21 |

THROTTLE POSITION SENSOR ...................... |

22 |

EXHAUST MANIFOLD AND CATALYTIC CON- |

|

VERTER ................................................................... |

23 |

Removal and Installation ....................................... |

23 |

REMOVAL .......................................................... |

24 |

INSPECTION AFTER REMOVAL ...................... |

25 |

INSTALLATION .................................................. |

25 |

Disassembly and Assembly ................................... |

26 |

QG16DE ENGINE MODELS .............................. |

26 |

QG18DE ENGINE MODELS .............................. |

26 |

OIL PAN AND OIL STRAINER ................................ |

27 |

Removal and Installation ....................................... |

27 |

REMOVAL .......................................................... |

27 |

INSTALLATION .................................................. |

28 |

INSPECTION AFTER INSTALLATION ............... |

28 |

IGNITION COIL ........................................................ |

29 |

Removal and Installation ....................................... |

29 |

REMOVAL .......................................................... |

29 |

INSTALLATION .................................................. |

29 |

SPARK PLUG (CONVENTIONAL) .......................... |

30 |

Removal and Installation ....................................... |

30 |

REMOVAL .......................................................... |

30 |

INSPECTION AFTER REMOVAL ...................... |

30 |

INSTALLATION .................................................. |

30 |

FUEL INJECTOR AND FUEL TUBE ....................... |

31 |

Removal and Installation ....................................... |

31 |

REMOVAL .......................................................... |

31 |

INSTALLATION .................................................. |

32 |

INSPECTION AFTER INSTALLATION ............... |

33 |

ROCKER COVER .................................................... |

34 |

Removal and Installation ....................................... |

34 |

REMOVAL .......................................................... |

34 |

INSTALLATION .................................................. |

35 |

CAMSHAFT ............................................................. |

36 |

Removal and Installation ....................................... |

36 |

REMOVAL .......................................................... |

36 |

INSTALLATION .................................................. |

39 |

F

G

H

I

J

K

L

M

EM-1

INSPECTION AFTER REMOVAL ....................... |

42 |

Valve Clearance ..................................................... |

44 |

INSPECTION ...................................................... |

44 |

ADJUSTMENT ................................................... |

46 |

TIMING CHAIN ......................................................... |

49 |

Removal and Installation ....................................... |

49 |

REMOVAL .......................................................... |

50 |

INSPECTION AFTER REMOVAL ....................... |

53 |

INSTALLATION ................................................... |

53 |

INSPECTION AFTER INSTALLATION .............. |

55 |

CYLINDER HEAD .................................................... |

57 |

On-Vehicle Service ................................................ |

57 |

CHECKING COMPRESSION PRESSURE ........ |

57 |

Removal and Installation ....................................... |

58 |

REMOVAL .......................................................... |

58 |

INSTALLATION ................................................... |

59 |

Disassembly and Assembly ................................... |

60 |

DISASSEMBLY .................................................. |

60 |

ASSEMBLY ........................................................ |

61 |

Inspection After Disassembly ................................ |

62 |

CYLINDER HEAD DISTORTION ....................... |

62 |

VALVE DIMENSIONS ......................................... |

62 |

VALVE GUIDE CLEARANCE ............................. |

62 |

VALVE GUIDE REPLACEMENT ........................ |

62 |

VALVE SEAT CONTACT .................................... |

64 |

VALVE SEAT REPLACEMENT .......................... |

64 |

VALVE SPRING SQUARENESS ........................ |

65 |

VALVE SPRING DIMENSIONS AND VALVE |

|

SPRING PRESSURE LOAD .............................. |

65 |

ENGINE ASSEMBLY ............................................... |

66 |

Removal and Installation ....................................... |

66 |

REMOVAL .......................................................... |

67 |

INSTALLATION ................................................... |

68 |

INSPECTION AFTER INSTALLATION ............... |

68 |

CYLINDER BLOCK .................................................. |

70 |

Disassembly and Assembly ................................... |

70 |

DISASSEMBLY .................................................. |

71 |

ASSEMBLY ........................................................ |

75 |

How to Select Piston and Bearing ......................... |

80 |

DESCRIPTION ................................................... |

80 |

HOW TO SELECT PISTON ................................ |

80 |

HOW TO SELECT CONNECTING ROD BEAR- |

|

ING ..................................................................... |

82 |

HOW TO SELECT MAIN BEARING ................... |

83 |

Inspection After Disassembly ................................ |

84 |

CRANKSHAFT SIDE CLEARANCE ................... |

84 |

CONNECTING ROD SIDE CLEARANCE .......... |

85 |

PISTON AND PISTON PIN CLEARANCE ......... |

85 |

PISTON RING SIDE CLEARANCE .................... |

86 |

PISTON RING END GAP ................................... |

86 |

CONNECTING ROD BEND AND TORSION ...... |

87 |

CONNECTING ROD BEARING (BIG END) ....... |

87 |

CONNECTING ROD BUSHING OIL CLEAR- |

|

ANCE (SMALL END) .......................................... |

88 |

CYLINDER BLOCK DISTORTION ..................... |

89 |

INNER DIAMETER OF MAIN BEARING HOUS- |

|

ING ...................................................................... |

89 |

PISTON TO CYLINDER BORE CLEARANCE ...89 |

|

OUTER DIAMETER OF CRANKSHAFT JOUR- |

|

NAL ..................................................................... |

90 |

OUTER DIAMETER OF CRANKSHAFT PIN .....90 |

|

OUT-OF-ROUND AND TAPER OF CRANK- |

|

SHAFT ................................................................ |

91 |

CRANKSHAFT RUNOUT ................................... |

91 |

OIL CLEARANCE OF CONNECTING ROD |

|

BEARING ............................................................ |

91 |

OIL CLEARANCE OF MAIN BEARING .............. |

92 |

CRUSH HEIGHT OF MAIN BEARING ............... |

92 |

FLYWHEEL RUNOUT ........................................ |

92 |

SERVICE DATA AND SPECIFICATIONS (SDS) .....93 |

|

Standard and Limit ................................................. |

93 |

GENERAL SPECIFICATIONS ............................ |

93 |

INTAKE MANIFOLD AND EXHAUST MANI- |

|

FOLD .................................................................. |

93 |

DRIVE BELTS ..................................................... |

94 |

SPARK PLUG ..................................................... |

94 |

CYLINDER HEAD ............................................... |

94 |

VALVE ................................................................. |

94 |

CAMSHAFT AND CAMSHAFT BEARING .......... |

98 |

CYLINDER BLOCK ............................................. |

99 |

PISTON, PISTON RING AND PISTON PIN .....100 |

|

CONNECTING ROD ......................................... |

101 |

CRANKSHAFT .................................................. |

101 |

MAIN BEARING ................................................ |

101 |

CONNECTING ROD BEARING ........................ |

102 |

MISCELLANEOUS COMPONENTS ................. |

102 |

Tightening Torque ................................................ |

102 |

QR |

|

PRECAUTIONS ...................................................... |

104 |

Precautions for Drain Coolant .............................. |

104 |

Precautions for Disconnecting Fuel Piping .......... |

104 |

Precautions for Removal and Disassembly ......... |

104 |

Precautions for Inspection, Repair and Replace- |

|

ment ..................................................................... |

104 |

Precautions for Assembly and Installation ........... |

104 |

Parts Requiring Angular Tightening ..................... |

104 |

Precautions for Liquid Gasket .............................. |

105 |

REMOVAL OF LIQUID GASKET SEALING .....105 |

|

LIQUID GASKET APPLICATION PROCEDURE.105 |

|

PREPARATION ...................................................... |

106 |

Special Service Tools ........................................... |

106 |

Commercial Service Tools ................................... |

107 |

NOISE, VIBRATION, AND HARSHNESS (NVH) |

|

TROUBLESHOOTING ........................................... |

110 |

NVH Troubleshooting —Engine Noise ................. . |

110 |

Use the Chart Below to Help You Find the Cause |

|

of the Symptom. ................................................... |

111 |

DRIVE BELTS ......................................................... |

112 |

Checking Drive Belts ............................................ |

112 |

Tension Adjustment .............................................. |

112 |

Removal and Installation ...................................... |

112 |

REMOVAL ......................................................... |

112 |

EM-2

INSTALLATION ................................................. |

112 |

Removal and Installation of Auxiliary Drive Belt |

|

Autotensioner ..................................................... |

113 |

REMOVAL ......................................................... |

113 |

INSTALLATION ................................................. |

113 |

AIR CLEANER AND AIR DUCT ............................. |

114 |

Removal and Installation ...................................... |

114 |

REMOVAL ......................................................... |

114 |

INSTALLATION ................................................. |

115 |

CHANGING AIR CLEANER ELEMENT ............ |

115 |

INTAKE MANIFOLD ............................................... |

116 |

Removal and Installation ...................................... |

116 |

REMOVAL ......................................................... |

116 |

INSTALLATION ................................................. |

118 |

INSPECTION AFTER INSTALLATION ............. |

119 |

EXHAUST MANIFOLD AND THREE WAY CATA- |

|

LYST ...................................................................... |

121 |

Removal and Installation ..................................... |

121 |

REMOVAL ........................................................ |

121 |

INSPECTION AFTER REMOVAL .................... |

122 |

INSTALLATION ................................................ |

122 |

OIL PAN AND OIL STRAINER .............................. |

123 |

Removal and Installation ..................................... |

123 |

REMOVAL ........................................................ |

123 |

INSPECTION AFTER REMOVAL .................... |

124 |

INSTALLATION ................................................ |

124 |

INSPECTION AFTER INSTALLATION ............ |

125 |

IGNITION COIL ...................................................... |

126 |

Removal and Installation ..................................... |

126 |

REMOVAL ........................................................ |

126 |

INSTALLATION ................................................ |

126 |

SPARK PLUG (CONVENTIONAL) ........................ |

127 |

Removal and Installation ..................................... |

127 |

REMOVAL ........................................................ |

127 |

INSPECTION AFTER REMOVAL .................... |

127 |

INSTALLATION ................................................ |

127 |

FUEL INJECTOR AND FUEL TUBE ..................... |

128 |

Removal and Installation ..................................... |

128 |

REMOVAL ........................................................ |

128 |

INSTALLATION ................................................ |

129 |

INSPECTION AFTER INSTALLATION ............ |

130 |

ROCKER COVER .................................................. |

131 |

Removal and Installation ..................................... |

131 |

REMOVAL ........................................................ |

131 |

INSTALLATION ................................................ |

131 |

CAMSHAFT ........................................................... |

133 |

Removal and Installation ..................................... |

133 |

REMOVAL ........................................................ |

133 |

INSTALLATION ................................................ |

135 |

INSPECTION AFTER REMOVAL .................... |

138 |

Valve Clearance .................................................. |

140 |

INSPECTION ................................................... |

140 |

ADJUSTMENT ................................................. |

141 |

TIMING CHAIN ...................................................... |

143 |

Removal and Installation ..................................... |

143 |

REMOVAL ........................................................ |

144 |

INSPECTION AFTER REMOVAL .................... |

147 |

INSTALLATION ................................................ |

148 |

CYLINDER HEAD .................................................. |

152 |

|

|

On-Vehicle Service .............................................. |

152 |

A |

|

CHECKING COMPRESSION PRESSURE ...... |

152 |

|

|

Removal and Installation ..................................... |

153 |

|

|

|

|||

REMOVAL ........................................................ |

153 |

EM |

|

INSPECTION AFTER REMOVAL |

154 |

||

|

|||

................................................INSTALLATION |

154 |

|

|

Disassembly and Assembly ................................. |

155 |

C |

|

DISASSEMBLY |

155 |

||

|

|||

ASSEMBLY ...................................................... |

156 |

|

|

Inspection After Disassembly .............................. |

156 |

|

|

CYLINDER HEAD DISTORTION ..................... |

156 |

D |

|

VALVE DIMENSIONS ....................................... |

157 |

|

|

VALVE GUIDE CLEARANCE ........................... |

157 |

|

|

VALVE GUIDE REPLACEMENT ...................... |

157 |

E |

|

VALVE SEAT CONTACT |

158 |

||

|

|||

VALVE SEAT REPLACEMENT ........................ |

158 |

|

|

VALVE SPRING SQUARENESS ...................... |

160 |

F |

|

VALVE SPRING DIMENSIONS AND VALVE |

|

||

|

|

||

SPRING PRESSURE LOAD ............................ |

160 |

|

|

ENGINE ASSEMBLY ............................................. |

161 |

|

|

Removal and Installation ..................................... |

161 |

G |

|

REMOVAL ........................................................ |

162 |

|

|

INSTALLATION ................................................ |

163 |

|

|

INSPECTION AFTER INSTALLATION ............. |

164 |

H |

|

CYLINDER BLOCK ............................................... |

165 |

|

|

Disassembly and Assembly ................................. |

165 |

|

|

DISASSEMBLY ................................................ |

166 |

I |

|

ASSEMBLY |

170 |

||

|

|||

How to Select Piston and Bearing ....................... |

174 |

|

|

DESCRIPTION ................................................. |

174 |

J |

|

HOW TO SELECT PISTON ............................. |

175 |

||

HOW TO SELECT CONNECTING ROD BEAR- |

|

||

ING ................................................................... |

176 |

|

|

HOW TO SELECT MAIN BEARING ................. |

178 |

K |

|

Inspection After Disassembly .............................. |

181 |

|

|

CRANKSHAFT SIDE CLEARANCE ................. |

181 |

|

|

CONNECTING ROD SIDE CLEARANCE ........ |

182 |

L |

|

PISTON AND PISTON PIN CLEARANCE |

182 |

||

|

|||

PISTON RING SIDE CLEARANCE .................. |

183 |

|

|

PISTON RING END GAP ................................. |

183 |

M |

|

CONNECTING ROD BEND AND TORSION ... 184 |

|||

|

|||

CONNECTING ROD BEARING (BIG END) ..... |

184 |

|

|

CONNECTING ROD BUSHING OIL CLEAR- |

|

|

|

ANCE (SMALL END) ........................................ |

184 |

|

|

CYLINDER BLOCK DISTORTION ................... |

185 |

|

|

INNER DIAMETER OF MAIN BEARING HOUS- |

|

||

ING ................................................................... |

186 |

|

|

PISTON TO CYLINDER BORE CLEARANCE . 186 |

|

||

OUTER DIAMETER OF CRANKSHAFT JOUR- |

|

|

|

NAL .................................................................. |

187 |

|

|

OUTER DIAMETER OF CRANKSHAFT PIN ... |

187 |

|

|

OUT-OF-ROUND AND TAPER OF CRANK- |

|

|

|

SHAFT .............................................................. |

187 |

|

|

CRANKSHAFT RUNOUT ................................. |

188 |

|

|

OIL CLEARANCE OF CONNECTING ROD |

|

|

|

EM-3

BEARING ......................................................... |

188 |

OIL CLEARANCE OF MAIN BEARING ............ |

188 |

CRUSH HEIGHT OF MAIN BEARING ............. |

189 |

OUTER DIAMETER OF LOWER CYLINDER |

|

BLOCK MOUNTING BOLT ............................... |

189 |

OUTER DIAMETER OF CONNECTING ROD |

|

BOLT ................................................................ |

189 |

MOVEMENT AMOUNT OF FLYWHEEL (M/T |

|

MODELS) ......................................................... |

190 |

SERVICE DATA AND SPECIFICATIONS (SDS) ... |

191 |

Standard and Limit ............................................... |

191 |

GENERAL SPECIFICATIONS .......................... |

191 |

INTAKE MANIFOLD AND EXHAUST MANI- |

|

FOLD ................................................................ |

191 |

DRIVE BELTS .................................................. |

191 |

SPARK PLUG ................................................... |

191 |

CYLINDER HEAD ............................................ |

192 |

VALVE ............................................................... |

192 |

CAMSHAFT AND CAMSHAFT BEARING ....... |

195 |

CYLINDER BLOCK .......................................... |

195 |

PISTON, PISTON RING AND PISTON PIN ..... |

196 |

CONNECTING ROD ........................................ |

197 |

CRANKSHAFT ................................................. |

198 |

MAIN BEARING ............................................... |

199 |

CONNECTING ROD BEARING ....................... |

200 |

Tightening Torque ................................................ |

201 |

YD |

|

PRECAUTIONS ...................................................... |

203 |

Precautions for Drain Coolant ............................. |

203 |

Precautions for Disconnecting Fuel Piping .......... |

203 |

Precautions for Removal and Disassembly ......... |

203 |

Precautions for Inspection, Repair and Replace- |

|

ment ..................................................................... |

203 |

Precautions for Assembly and Installation ........... |

203 |

Parts Requiring Angular Tightening ..................... |

203 |

Precautions for Liquid Gasket ............................. |

204 |

REMOVAL OF LIQUID GASKET SEALING ..... |

204 |

LIQUID GASKET APPLICATION PROCEDURE. 204 |

|

PREPARATION ...................................................... |

205 |

Special Service Tools .......................................... |

205 |

Commercial Service Tools ................................... |

207 |

NOISE, VIBRATION, AND HARSHNESS (NVH) |

|

TROUBLESHOOTING ........................................... |

209 |

NVH Troubleshooting —Engine Noise ................ . |

209 |

Use the Chart Below to Help You Find the Cause |

|

of the Symptom. .................................................. 210 |

|

DRIVE BELTS ........................................................ |

211 |

Checking Drive Belts ........................................... |

211 |

Tension Adjustment ............................................. |

211 |

AIR CONDITIONER COMPRESSOR BELT ..... |

212 |

ALTERNATOR AND WATER PUMP BELT ....... |

212 |

Removal and Installation ..................................... |

212 |

REMOVAL ........................................................ |

212 |

INSTALLATION ................................................. |

212 |

AIR CLEANER AND AIR DUCT ............................ |

213 |

Removal and Installation ...................................... |

213 |

REMOVAL ......................................................... |

213 |

INSTALLATION ................................................. |

213 |

CHANGING AIR CLEANER ELEMENT ............ |

213 |

CHARGE AIR COOLER ......................................... |

215 |

Removal and Installation ...................................... |

215 |

REMOVAL ......................................................... |

215 |

INSPECTION AFTER REMOVAL ..................... |

215 |

INSTALLATION ................................................. |

215 |

INTAKE MANIFOLD ............................................... |

216 |

Removal and Installation ...................................... |

216 |

REMOVAL ......................................................... |

216 |

INSPECTION AFTER REMOVAL ..................... |

217 |

INSTALLATION ................................................. |

217 |

INSPECTION AFTER INSTALLATION ............. |

218 |

CATALYST .............................................................. |

219 |

Removal and Installation ...................................... |

219 |

REMOVAL ......................................................... |

219 |

INSTALLATION ................................................. |

219 |

EXHAUST MANIFOLD AND TURBOCHARGER .. |

220 |

Removal and Installation ...................................... |

220 |

REMOVAL ......................................................... |

220 |

INSTALLATION ................................................. |

221 |

INSPECTION AFTER INSTALLATION ............. |

221 |

Disassembly and Assembly ................................. |

222 |

REMOVAL ......................................................... |

222 |

INSPECTION AFTER REMOVAL ..................... |

222 |

Turbocharger ........................................................ |

223 |

ROTOR SHAFT CLEARANCE ......................... |

223 |

ROTOR SHAFT END PLAY .............................. |

223 |

TURBINE WHEEL ............................................ |

224 |

COMPRESSOR WHEEL .................................. |

224 |

VARIABLE NOZZLE TURBOCHARGER CON- |

|

TROL ACTUATOR ............................................ |

224 |

TROUBLE DIAGNOSIS OF TURBOCHARGER.224 |

|

OIL PAN AND OIL STRAINER ............................... |

226 |

Removal and Installation ...................................... |

226 |

REMOVAL ......................................................... |

226 |

INSPECTION AFTER REMOVAL ..................... |

228 |

INSTALLATION ................................................. |

228 |

INSPECTION AFTER INSTALLATION ............. |

230 |

GLOW PLUG .......................................................... |

231 |

Removal and Installation ...................................... |

231 |

REMOVAL ......................................................... |

231 |

INSTALLATION ................................................. |

231 |

VACUUM PUMP ..................................................... |

232 |

Removal and Installation ...................................... |

232 |

INSPECTION BEFORE REMOVAL .................. |

232 |

REMOVAL ......................................................... |

232 |

INSTALLATION ................................................. |

233 |

INSPECTION AFTER INSTALLATION ............. |

233 |

Disassembly and Assembly ................................. |

234 |

DISASSEMBLY ................................................. |

234 |

ASSEMBLY ....................................................... |

234 |

EM-4

INJECTION TUBE AND FUEL INJECTOR ........... |

236 |

Removal and Installation ..................................... |

236 |

REMOVAL ........................................................ |

236 |

INSTALLATION ................................................ |

237 |

INSPECTION AFTER INSTALLATION ............ |

238 |

FUEL SUPPLY PUMP ........................................... |

239 |

Removal and Installation ..................................... |

239 |

REMOVAL ........................................................ |

239 |

INSPECTION AFTER REMOVAL .................... |

244 |

INSTALLATION ................................................ |

244 |

ROCKER COVER .................................................. |

248 |

Removal and Installation ..................................... |

248 |

REMOVAL ........................................................ |

248 |

INSTALLATION ................................................ |

249 |

INSPECTION AFTER INSTALLATION ............ |

249 |

CAMSHAFT ........................................................... |

250 |

Removal and Installation ..................................... |

250 |

REMOVAL ........................................................ |

250 |

INSPECTION AFTER REMOVAL .................... |

251 |

INSTALLATION ................................................ |

254 |

Valve Clearance .................................................. |

255 |

INSPECTION ................................................... |

255 |

ADJUSTMENTS ............................................... |

256 |

SECONDARY TIMING CHAIN .............................. |

259 |

Removal and Installation ..................................... |

259 |

REMOVAL ........................................................ |

259 |

INSPECTION AFTER REMOVAL .................... |

261 |

INSTALLATION ................................................ |

262 |

PRIMARY TIMING CHAIN ..................................... |

264 |

Removal and Installation ..................................... |

264 |

REMOVAL ........................................................ |

266 |

INSPECTION AFTER REMOVAL .................... |

268 |

INSTALLATION ................................................ |

269 |

CYLINDER HEAD .................................................. |

274 |

On-Vehicle Service .............................................. |

274 |

CHECKING COMPRESSION PRESSURE ..... 274 |

|

Removal and Installation ..................................... |

275 |

REMOVAL ........................................................ |

275 |

INSPECTION AFTER REMOVAL .................... |

276 |

INSTALLATION ................................................ |

276 |

Disassembly and Assembly ................................ |

279 |

DISASSEMBLY ................................................ |

279 |

ASSEMBLY ...................................................... |

280 |

INSPECTION AFTER DISASSEMBLY ............ |

280 |

ENGINE ASSEMBLY ............................................. |

285 |

Removal and Installation ..................................... |

285 |

REMOVAL ........................................................ |

285 |

INSTALLATION ................................................ |

287 |

INSPECTION AFTER INSTALLATION ............ |

287 |

CYLINDER BLOCK ............................................... |

288 |

Disassembly and Assembly ................................ |

288 |

DISASSEMBLY ................................................ |

289 |

ASSEMBLY ...................................................... |

293 |

How to Select Piston and Bearing ....................... |

297 |

DESCRIPTION ................................................. |

297 |

HOW TO SELECT PISTON ............................. |

297 |

HOW TO SELECT CONNECTING ROD BEAR- |

|

ING ................................................................... |

298 |

HOW TO SELECT MAIN BEARING ................. |

299 |

Inspection After Disassembly .............................. |

300 |

CRANKSHAFT SIDE CLEARANCE ................. |

300 |

CONNECTING ROD SIDE CLEARANCE ........ |

300 |

PISTON TO PISTON PIN CLEARANCE .......... |

301 |

PISTON RING SIDE CLEARANCE .................. |

301 |

PISTON RING END GAP ................................. |

302 |

CONNECTING ROD BEND AND TORSION ... 302 |

|

CONNECTING ROD BIG END INNER DIAME- |

|

TER .................................................................. |

302 |

CONNECTING ROD BUSHING OIL CLEAR- |

|

ANCE (SMALL END) ........................................ |

303 |

CYLINDER BLOCK TOP SURFACE DISTOR- |

|

TION ................................................................. |

303 |

MAIN BEARING HOUSING INNER DIAMETER. 304 |

|

PISTON TO CYLINDER BORE CLEARANCE . 304 |

|

CRANKSHAFT JOURNAL OUTER DIAMETER. 305 |

|

CRANKSHAFT PIN OUTER DIAMETER ......... |

305 |

CRANKSHAFT OUT-OF-ROUND AND TAPER. 305 |

|

CRANKSHAFT RUNOUT ................................. |

306 |

CONNECTING ROD BEARING OIL CLEAR- |

|

ANCE ............................................................... |

306 |

MAIN BEARING OIL CLEARANCE ................. |

306 |

MAIN BEARING CRUSH HEIGHT ................... |

307 |

MAIN BEARING CAP BOLT DEFORMATION . 307 |

|

CONNECTING ROD BOLT DEFORMATION ... |

307 |

OIL JET ............................................................ |

308 |

OIL JET RELIEF VALVE ................................... |

308 |

MOVEMENT AMOUNT OF FLYWHEEL .......... |

308 |

SERVICE DATA AND SPECIFICATIONS (SDS) ... |

310 |

Standard and Limit ............................................... |

310 |

GENERAL SPECIFICATIONS .......................... |

310 |

INTAKE MANIFOLD AND EXHAUST MANI- |

|

FOLD ................................................................ |

310 |

DRIVE BELTS .................................................. |

310 |

CYLINDER HEAD ............................................ |

311 |

VALVE .............................................................. |

311 |

CAMSHAFT AND CAMSHAFT BEARING ....... |

315 |

CYLINDER BLOCK .......................................... |

315 |

PISTON, PISTON RING AND PISTON PIN ..... |

316 |

CONNECTNG ROD ......................................... |

317 |

CRANKSHAFT ................................................. |

317 |

AVAILABLE MAIN BEARING ........................... |

318 |

AVAILABLE CONNECTING ROD BEARING ... |

318 |

MISCELLANEOUS COMPONENTS ................ |

318 |

Tightening Torque ................................................ |

319 |

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-5

|

PRECAUTIONS |

|

[QG] |

|

|

PRECAUTIONS |

PFP:00001 |

Precautions for Drain Coolant |

EBS00GUD |

●Drain coolant when engine is cooled.

Precautions for Disconnecting Fuel Piping |

EBS00GUE |

●Before starting work, make sure no fire or spark producing items are in the work area.

●Release fuel pressure before disassembly.

●After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and Disassembly |

EBS00GUF |

●When instructed to use special service tools, use the specified tools. Always be careful to work safely, avoid forceful or uninstructed operations.

●Exercise maximum care to avoid damage to mating or sliding surfaces.

●Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

●Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

●When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and Replacement |

EBS00GUG |

●Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and replace if necessary.

Precautions for Assembly and Installation |

EBS00GUH |

●Use torque wrench to tighten bolts or nuts.

●When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified, do exactly as specified.

●Replace with new gasket, packing, oil seal or O-ring.

●Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction and blockage.

●Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

●Release air within route after draining coolant.

●After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems for leakage.

Parts Requiring Angular Tightening |

EBS00GUI |

●Use an angle wrench for the final tightening of the following engine parts.

–Cylinder head bolts

–Lower cylinder block bolts

–Connecting rod cap bolts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angular tightening)

●Do not use a torque value for final tightening.

●The torque value for these parts are for a preliminary step.

●Ensure thread and seat surfaces are clean and coated with engine oil.

EM-6

PRECAUTIONS

|

[QG] |

|

Precautions for Liquid Gasket |

EBS00GUJ |

|

REMOVAL OF LIQUID GASKET SEALING |

|

A |

●After removing the mounting bolts and nuts, separate the mating surface using a seal cutter and remove the liquid gasket.

CAUTION:

Be careful not to damage the mating surfaces.

●In areas where the cutter is difficult to use, use a plastic hammer to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed screwdriver is used, be careful not to damage the mating sur-

faces.

PBIC0275E

LIQUID GASKET APPLICATION PROCEDURE

1.Using a scraper, remove the old liquid gasket adhering to the gasket application surface and the mating surface.

●Remove the liquid gasket completely from the groove of the gasket application surface, mounting bolts, and bolt holes.

2.Wipe the gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

3.Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

PBIC0003E

4.Apply the gasket without breaks to the specified location with the specified dimensions.

●If there is a groove for the liquid gasket application, apply the gasket to the groove.

●As for the bolt holes, normally apply the gasket inside the holes. If specified, it should be applied outside the holes. Make sure to read the text of service manual.

●Within five minutes of gasket application, install the mating component.

● If the liquid gasket protrudes, wipe it off immediately. |

EMA0622D |

|

●Do not retighten after the installation.

●After 30 minutes or more have passed from the installation, fill the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe them.

EM

C

D

E

F

G

H

I

J

K

L

M

EM-7

|

PREPARATION |

|

|

|

[QG] |

|

|

|

PREPARATION |

|

PFP:00002 |

Special Service Tools |

|

EBS00GWK |

|

|

|

Tool number |

|

Description |

Tool name |

|

|

|

|

|

|

|

|

ST0501S000 |

|

Disassembling and assembling |

Engine stand assembly |

|

|

1 ST05011000 |

|

|

Engine stand |

|

|

2 ST05012000 |

|

|

Base |

|

|

|

NT042 |

|

|

|

|

Engine attachment assembly |

|

Overhauling engine |

|

||

1 KV10106500 |

|

|

Engine attachment |

|

|

2 KV10113300 |

|

|

Sub-attachment |

|

|

|

NT029 |

|

|

|

|

|

|

|

ST10120000 |

|

Loosening and tightening cylinder head bolt |

|

||

Cylinder head bolt wrench |

|

a: 13 mm (0.51 in) dia. |

|

|

b: 12 mm (0.47 in) |

|

|

c: 10 mm (0.39 in) |

|

NT583 |

|

|

|

|

|

|

|

KV10116200 |

|

Disassembling valve mechanism |

|

||

Valve spring compressor |

|

|

1 KV10115900 |

|

|

Attachment |

|

|

|

NT022 |

|

|

|

|

|

|

|

KV10115600 |

|

Installing valve oil seal |

Valve oil seal drift |

|

|

|

NT024 |

|

|

KV10107902 |

Displacement valve lip seal |

Valve oil seal puller |

|

|

NT011 |

|

|

KV101151S0 |

Changing shims |

Lifter stopper set |

|

1 KV10115110 |

|

Camshaft pliers |

|

2 KV10115120 |

|

Lifter stopper |

|

|

NT041 |

EM-8

|

PREPARATION |

|

|

[QG] |

|

|

|

|

|

|

|

Tool number |

Description |

|

Tool name |

||

|

||

|

|

|

EM03470000 |

Installing piston assembly into cylinder bore |

|

Piston ring compressor |

|

|

NT044 |

|

|

|

|

KV10107400 |

|

Disassembling and assembling piston pin |

Piston pin press stand |

|

|

1 KV10107310 |

|

|

|

|

|

Center shaft |

|

|

2 ST13040020 |

|

|

Stand |

|

|

3 ST13040030 |

|

|

Spring |

|

|

4 KV10107320 |

|

|

Cap |

NT013 |

|

5 ST13040050 |

|

|

Drift |

|

|

|

|

|

KV10111100 |

|

Removing oil pan |

Seal cutter |

|

|

|

NT046 |

|

|

WS39930000 |

Pressing the tube of liquid gasket |

Tube presser |

|

|

NT052 |

|

|

KV10112100 |

Tightening bolts for bearing cap, cylinder |

Angle wrench |

head, etc. |

|

NT014 |

|

|

ST16610001 |

Removing pilot bushing |

Pilot bushing puller |

|

|

NT045 |

|

|

KV101056S0* |

Preventing crankshaft from rotating |

Rear gear stopper |

|

1 KV10105630 |

|

Adapter |

|

2 KV10105610 |

|

Plate assembly |

|

|

NT773 |

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-9

|

PREPARATION |

|

[QG] |

|

|

Commercial Service Tools |

EBS00GWL |

|

|

Tool name |

Description |

|

|

Spark plug wrench |

Removing and installing spark plug |

NT047

Valve seat cutter set |

Finishing valve seat dimensions |

NT048

Piston ring expander |

Removing and installing piston ring |

|

NT030 |

|

|

|

|

Valve guide drift |

|

Removing and installing valve guide |

|

||

|

|

Intake & Exhaust: |

|

|

a: 9.5 mm (0.374 in) dia. |

|

|

b: 5.5 mm (0.217 in) dia. |

|

NT015 |

|

|

|

|

|

|

|

Front (heated) oxygen sensor wrench |

|

Loosening or tightening heated oxygen |

|

|

sensor with 22 m (0.87 in) hexagon nut |

|

NT379 |

|

|

|

|

Valve guide reamer |

Reaming valve guide 1 or hole for oversize |

|

|

valve guide 2 |

|

|

Intake & Exhaust: |

|

|

d1 |

: 5.5 mm (0.217 in) dia. |

|

d2 |

: 9.685 mm (0.3813 in) dia. |

|

NT016 |

|

EM-10

PREPARATION |

|

[QG] |

||

|

|

|||

|

|

|

|

|

|

|

|

|

|

Tool name |

Description |

|

|

A |

|

|

|

|

|

Front oil seal drift |

Installing front oil seal |

|

|

|

|

a: 52 mm (2.05 in) dia. |

|

|

|

|

b: 40 mm (1.57 in) dia. |

|

|

EM |

|

|

|

|

|

|

|

|

|

|

NT049 |

|

|

|

C |

|

|

|

|

|

Rear oil seal drift |

Installing rear oil seal |

|

|

|

|

a: 103 mm (4.06 in) dia. |

|

|

D |

|

b: 84 mm (3.31 in) dia. |

|

|

|

|

|

|

|

E |

NT049 |

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

G |

|

|

|

|

H |

|

|

|

|

I |

|

|

|

|

J |

|

|

|

|

K |

|

|

|

|

L |

|

|

|

|

M |

EM-11

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

|

[QG] |

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING |

PFP:00003 |

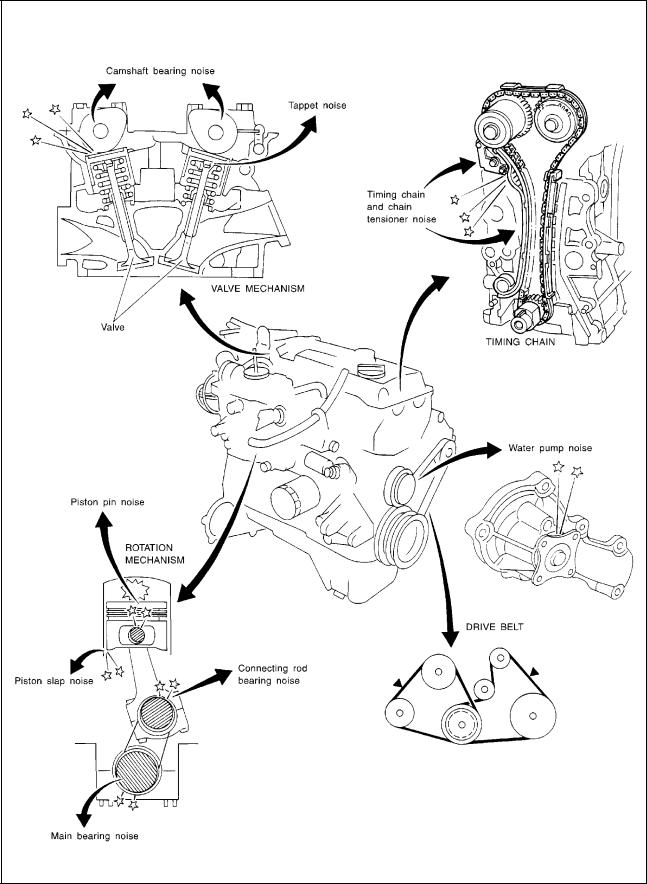

NVH Troubleshooting —Engine Noise |

EBS00GX9 |

SEM937F

EM-12

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[QG]

Use the Chart Below to Help You Find the Cause of the Symptom. |

EBS00GXA |

1.Locate the area where noise occurs.

2.Confirm the type of noise.

3.Specify the operating condition of engine.

4.Check specified noise source.

If necessary, repair or replace these parts.

|

|

|

|

Operating condition of engine |

|

|

|

|

||||

Location |

Type of |

|

|

|

|

|

|

|

|

Source of |

|

Refer- |

|

Before |

After |

When |

|

When |

When |

While |

Check item |

||||

of noise |

noise |

|

noise |

ence page |

||||||||

warm- |

warm- |

start- |

|

|||||||||

|

|

|||||||||||

|

idling |

racing |

driving |

|

||||||||

|

|

|

|

|

|

|

||||||

|

|

|

up |

up |

ing |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Top of |

Ticking or |

C |

A |

— |

|

A |

B |

— |

Tappet |

Valve clearance |

EM-140 |

|

engine |

clicking |

|

noise |

|||||||||

|

|

|

|

|

|

|

|

|

||||

Rocker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Camshaft |

Camshaft journal clear- |

|

|

cover |

|

|

|

|

|

|

|

|

|

EM-42 |

||

Rattle |

C |

A |

— |

|

A |

B |

C |

bearing |

ance |

|||

Cylinder |

|

|||||||||||

|

EM-42 |

|||||||||||

|

|

|

|

|

|

|

|

|

noise |

Camshaft runout |

||

head |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Piston and piston pin |

|

|

Slap or |

— |

A |

— |

|

B |

B |

— |

Piston pin |

clearance |

EM-85 |

|

|

knock |

|

noise |

Connecting rod bush- |

EM-88 |

|||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

ing clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Piston-to-bore clear- |

|

Crank- |

|

|

|

|

|

|

|

|

|

|

ance |

EM-89 |

|

|

|

|

|

|

|

|

|

|

Piston ring side clear- |

||

Slap or |

|

|

|

|

|

|

|

Piston |

EM-86 |

|||

shaft pul- |

|

|

|

|

|

|

|

|||||

A |

— |

— |

|

B |

B |

A |

ance |

|||||

rap |

|

slap noise |

EM-86 |

|||||||||

ley |

|

|||||||||||

|

|

|

|

|

|

|

Piston ring end gap |

|||||

|

|

|

|

|

|

|

|

|

|

EM-87 |

||

Cylinder |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Connecting rod bend |

||

|

|

|

|

|

|

|

|

|

|

|

||

block |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and torsion |

|

|

(Side of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connecting rod bush- |

|

|

engine) |

|

|

|

|

|

|

|

|

|

Connect- |

|

|

|

|

|

|

|

|

|

|

|

ing clearance (Small |

|

||

Oil pan |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

ing rod |

EM-88 |

||

Knock |

A |

B |

C |

|

B |

B |

B |

end) |

||||

|

|

|||||||||||

|

|

bearing |

EM-87 |

|||||||||

|

|

|

|

|

|

|

|

|

|

Connecting rod bear- |

||

|

|

|

|

|

|

|

|

|

|

noise |

|

|

|

|

|

|

|

|

|

|

|

|

ing clearance (Big end) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Main |

Main bearing oil clear- |

EM-92 |

|

Knock |

A |

B |

— |

|

A |

B |

C |

bearing |

ance |

||

|

|

EM-91 |

||||||||||

|

|

|

|

|

|

|

|

|

|

noise |

Crankshaft runout |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Front of |

|

|

|

|

|

|

|

|

|

Timing |

Timing chain cracks |

|

engine |

|

|

|

|

|

|

|

|

|

chain and |

|

|

Tapping or |

|

|

|

|

|

|

|

and wear |

EM-53 |

|||

Timing |

A |

A |

— |

|

B |

B |

B |

chain ten- |

||||

ticking |

|

Timing chain tensioner |

EM-49 |

|||||||||

chain |

|

|

|

|

|

|

|

sioner |

||||

|

|

|

|

|

|

|

|

|

operation |

|

||

cover |

|

|

|

|

|

|

|

|

|

noise |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Squeak- |

|

|

|

|

|

|

|

Drive belts |

|

|

|

|

|

|

|

|

|

|

|

(Sticking |

|

|

||

|

ing or fizz- |

A |

B |

— |

|

B |

— |

C |

Drive belts deflection |

|

||

|

|

or slip- |

|

|||||||||

|

ing |

|

|

|

|

|

|

|

|

EM-14 |

||

|

|

|

|

|

|

|

|

ping) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Front of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive belts |

Idler pulley bearing |

|

|

engine |

Creaking |

A |

B |

A |

|

B |

A |

B |

|

|||

|

(Slipping) |

operation |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Squall |

|

|

|

|

|

|

|

Water |

|

CO-18, |

|

|

A |

B |

— |

|

B |

A |

B |

pump |

Water pump operation |

"WATER |

||

|

Creak |

|

||||||||||

|

|

|

|

|

|

|

|

noise |

|

PUMP" |

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

A: Closely related B: Related C: Sometimes related |

—: Not related |

|

|

|

|

|||||||

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-13

|

DRIVE BELTS |

|

[QG] |

|

|

DRIVE BELTS |

PFP:02117 |

Checking Drive Belts |

EBS00GWM |

PBIC0764E

●Before inspecting the engine, make sure the engine has cooled down; wait approximately 30 minutes after the engine has been stopped.

●Visually inspect all belts for wear, damage, or cracks on contacting surfaces and edge areas.

●When measuring deflection, apply 98 N (10 kg, 22 lb) at the ▼ marked point.

CAUTION:

When measuring belt tension immediately after belt is installed, first set the tension to the standard. Then, rotate crankshaft for more than two turns in order to eliminate variance in belt deflection between the pulleys. Re-measure and adjust the tension to the standard.

|

|

Deflection adjustment Unit: mm (in) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

Used belt |

|

|

|

|

|

|

|

|

|

|

New belt |

|

|

|

Limit |

|

After adjustment |

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Without air conditioner compressor |

10.2 (0.402) |

|

6.5 |

- 7.0 |

5.5 |

- 6.1 |

|

|

(0.256 |

- 0.276) |

(0.217 |

- 0.240) |

||

Alternator |

|

|

|

||||

|

|

|

|

|

|

|

|

With air conditioner compressor |

8.1 (0.319) |

|

5.3 |

- 5.7 |

4.5 |

- 5.0 |

|

|

|

||||||

|

|

(0.209 |

- 0.224) |

(0.177 |

- 0.197) |

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

Power steering oil pump |

10.8 (0.425) |

|

6.6 |

- 7.5 |

6.0 |

- 6.6 |

|

|

(0.260 |

- 0.295) |

(0.236 |

- 0.260) |

|||

|

|

|

|

||||

|

|

|

|

|

|

||

Applied pushing force |

|

|

98 N (10 kg, 22 lb) |

|

|

||

|

|

|

|

|

|

|

|

EM-14

|

|

DRIVE BELTS |

|

[QG] |

|

|

|

|

|

|

|

|

|

|

|

Tension Adjustment |

|

|

EBS00GWN |

|

|

|

|

|

|

Portion |

Belt tightening method for adjustment |

|

|

|

|

|

|

|

|

Power steering pump and water pump |

Adjusting bolt on power steering pump |

|

|

|

belt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternator and air conditioner compressor |

Adjusting bolt on idler pulley |

|

|

|

belt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION: |

|

|

|

|

● When belt is replaced with a new one, tighten it a little |

|

|

|

|

stronger than current one to accommodate for insufficient |

|

|

|

|

adaptability with pulley grooves. |

|

|

|

|

● When tension of belt being used exceeds “Retightening |

|

PBIC0531E |

|

|

limit”, adjust it to value for “Used belt”. |

|

|

|

●When installing belt, make sure that it is correctly engaged with pulley groove.

●Keep oil and water away from belt.

●Do not twist or bend belt excessively.

●When adjusting belt, remove snap retainer from adjusting bolt thread (to prevent the retainer from becoming pinched or missing).

●After adjustment, be sure to install snap retainer to adjusting bolt thread.

NOTE:

Snap retainer can prevent adjusting bolt from dropping due to vibration during driving.

POWER STEERING PUMP AND WATER PUMP BELT

1.Loosen lock nut (A) and power steering pump mounting nut (B).

2.Turn adjusting bolt (C) to adjust. Refer to EM-14, "Checking Drive Belts" .

3.Tighten lock nut (A) and power steering pump mounting nut (B) in this order.

Nut A :

: 16.7 - 23.5 N·m (1.7 - 2.3 kg-m, 13 - 17 ft-lb)

: 16.7 - 23.5 N·m (1.7 - 2.3 kg-m, 13 - 17 ft-lb)

Nut B :

: 26.5 - 36.3 N·m (2.7 - 3.7 kg-m, 20 - 26 ft-lb)

: 26.5 - 36.3 N·m (2.7 - 3.7 kg-m, 20 - 26 ft-lb)

PBIC0532E

ALTERNATOR AND AIR CONDITIONER COMPRESSOR BELT

1.Remove RH splash cover (with undercover attached).

2.Loosen lock nut (G).

3.Turn adjusting bolt (H) to adjust.

Refer to EM-14, "Checking Drive Belts" .

4.Tighten lock nut (G).

Nut G :

: 24.5 - 31.4 N·m (2.5 - 3.2 kg-m, 18 - 23 ft-lb)

: 24.5 - 31.4 N·m (2.5 - 3.2 kg-m, 18 - 23 ft-lb)

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-15

DRIVE BELTS

[QG]

Removal and Installation |

EBS00GWO |

REMOVAL

●Loosen each belt while referring to “Tension Adjustment”, and remove them one by one starting from the one in front.

INSTALLATION

1.Install belts to pulley in reverse order of removal.

2.Adjust belt tension.

CAUTION:

●When checking belt tension immediately after installation, first, adjust to specified value. Then, after turning crankshaft more than two turns, re-adjust to specified value to avoid variation in deflection between pulleys.

●Tighten idler pulley lock nut by hand and measure tension without looseness.

3.Tighten each adjusting bolt and nut to the specified torque.

4.Make sure that tension of each belt is within the standard.

EM-16

AIR CLEANER AND AIR DUCT

|

|

[QG] |

|

||

AIR CLEANER AND AIR DUCT |

PFP:16500 |

||||

Removal and Installation |

|

|

|

A |

|

EBS00GUS |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EM |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

D |

|

|

|

|

|

E |

|

|

|

|

|

F |

|

|

|

|

|

G |

|

|

|

|

|

H |

|

|

|

|

|

I |

|

|

PBIC0533E |

|

||

|

|

|

|

|

|

1 |

Air cleaner case (upper) |

2 |

Resonator |

3 |

Air duct |

4 |

Mass air flow sensor |

5 |

O-ring |

6 |

Air cleaner case (lower) |

7 |

Grommet |

8 |

Air cleaner element |

9 |

Bracket |

REMOVAL

1.Remove air cleaner case assembly, air duct and resonator.

●Add marks as necessary for easier installation.

2.Remove harness connector from mass air flow sensor.

3.Remove mass air flow sensor.

CAUTION:

Handle mass air flow sensor with following cares.

●Do not shock it.

●Do not disassembly it.

●Do not touch its sensor.

●Do not deform mass air flow sensor's wire mesh.

4.Remove left fender protector and resonator.

INSTALLATION

1.Attach each joint aligning marks put at removal. Screw clamps firmly.

2.Install in the reverse order of removal.

J

K

L

M

EM-17

AIR CLEANER AND AIR DUCT

[QG]

Changing Air Cleaner Element |

EBS00GV2 |

The viscous paper type filter does not need cleaning between renewals.

SMA373C

EM-18

|

INTAKE MANIFOLD |

|

[QG] |

|

|

INTAKE MANIFOLD |

PFP:14003 |

Removal and Installation |

EBS00GWP |

|

|

|

|

|

PBIC0528E |

|

|

|

|

|

|

1 |

Gasket |

2 |

Harness bracket |

3 |

Intake manifold |

4 |

Electric throttle control actuator |

5 |

Fuel feed hose |

6 |

Intake manifold support (engine rear) |

7 |

Intake manifold support (rear) |

8 |

Intake manifold support (front) |

9 |

Air hose |

10 |

Vacuum hose |

11 |

EVAP canister purge volume control |

12 |

PCV hose |

solenoid valve |

|||||

13 |

Bracket |

|

|

|

|

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the coolant when the engine is hot.

1.Release fuel pressure.

Refer to EC-58, "FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-591, "FUEL PRESSURE RELEASE" (WITHOUT EURO-OBD).

2.Remove air duct and air cleaner case. Refer to EM-17, "Removal and Installation" .

3.Remove fuel hose.

4.Separate harness and pipings from intake manifold.

5.Remove mounting nuts from canister purge control valve to make it movable.

A

EM

C

D

E

F

G

H

I

J

K

L

M

EM-19

INTAKE MANIFOLD

[QG]

6.Loosen mounting bolts in reverse order shown in figure to remove electric throttle control actuator.

7.Remove all intake manifold supports (front, rear, engine mount, engine rear).

8.Remove mounting bolts from support on cylinder head side of intake manifold assembly.

PBIC0534E

9.Loosen mounting nuts and bolts in reverse order shown in figure to remove intake manifold assembly.

PBIC0535E

INSPECTION AFTER REMOVAL

Surface Distortion

●Using straightedge and feeler gauge, inspect surface distortion of intake manifold collector and intake manifold surface.

Limit : 0.1 mm (0.004 in)

PBIC0536E

INSTALLATION

●Install in the reverse order of removal paying attention to the following.

Tightening Intake Manifold Bolts and Nuts

●Tighten in numerical order as shown in the figure.

NOTE:

Installation direction (fore and aft) for gasket is not specified (symmetrical).

PBIC0535E

EM-20

INTAKE MANIFOLD

Installation of Electric Throttle Control Actuator

●Tighten mounting bolts for electric throttle control actuator in two steps in order shown in figure.

1st step : 8.8 - 10.8 N·m (0.9 - 1.1 kg-m, 6.5 - 7.9 ft-lb)

1st step : 8.8 - 10.8 N·m (0.9 - 1.1 kg-m, 6.5 - 7.9 ft-lb)

2nd step : 17.7 - 21.6 N·m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

2nd step : 17.7 - 21.6 N·m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

CAUTION:

When electric throttle control actuator is replaced, perform idle air volume learning.

●Refer to BASIC SERVICE PROCEDURE, EC-55, "Idle Air Volume Learning" (WITH EURO-OBD), EC-589, "Idle Air Volume Learning" (WITHOUT EURO-OBD).

[QG]

A

EM

C

PBIC0534E D

Disassembly and Assembly |

EBS00GWQ |

PBIC0529E

1 |

Intake manifold |

2 |

Gasket |

3 Fuel tube and injectors |

4 |

Intake manifold collector |

5 |

Electric throttle control actuator |

|

INTAKE MANIFOLD COLLECTOR

●Loosen and remove mounting nuts and bolts in reverse order shown in figure.

●Tighten mounting nuts and bolts in order shown in figure.

PBIC0537E

E

F

G

H

I

J

K

L

M

EM-21

INTAKE MANIFOLD

[QG]

THROTTLE POSITION SENSOR

●When installing throttle position sensor, insert connector into electric throttle control actuator facing direction shown in figure. Rotate it to the direction shown by arrow, and temporarily tighten mounting screws.

●After the repair, adjust it on vehicle.

PBIC0538E

CAUTION:

Do not touch the engine immediately after stopped as engine becomes extremely hot.

●Perform procedures for “Throttle Valve Closed Position Learning” after finishing repairs. Refer to BASIC SERVICE PROCEDURE, EC-55, "Throttle Valve Closed Position Learning" (WITH EURO-OBD), EC589, "Throttle Valve Closed Position Learning" (WITHOUT EURO-OBD).

●If electric throttle control actuator is replaced, perform procedures for “Idle Air Volume Learning” after finishing repairs. Refer to BASIC SERVICE PROCEDURE, EC-55, "Idle Air Volume Learning" (WITH EURO-OBD), EC-589, "Idle Air Volume Learning" (WITHOUT EURO-OBD).

EM-22

EXHAUST MANIFOLD AND CATALYTIC CONVERTER

|

|

|

|

|

|

[QG] |

|

|||

EXHAUST MANIFOLD AND CATALYTIC CONVERTER |

PFP:14004 |

|||||||||

Removal and Installation |

|

|

|

|

|

|

A |

|||

|

|

|

EBS00GWR |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

J |

|

|

|

|

|

|

|

PBIC0539E |

|

|||

|

|

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

||

1 |