MTS 793 User Manual

m

be certain.

MTS Series 793 Controller Overview

100-162-928 H

Copyright information

Trademark information

Proprietary information

Software validation and verification

© 2011 MTS Systems Corporation. All rights reserved.

MTS, FlexTest, RPC, Temposonics, and TestWare are registered trademarks of MTS Systems Corporation; MPT, Station Builder, Station Manager, and TestStar are trademarks of MTS Systems Corporation within the United States. These trademarks may be protected in other countries.

Microsoft, Windows, and Windows NT are registered trademarks of Microsoft Corporation. All other trademarks or service marks are property of their respective owners.

Software use and license is governed by MTS’ End User License Agreement which defines all rights retained by MTS and granted to the End User. All Software is proprietary, confidential, and owned by MTS Systems Corporation and cannot be copied, reproduced, disassembled, decompiled, reverse engineered, or distributed without express written consent of MTS.

MTS software is developed using established quality practices in accordance with the requirements detailed in the ISO 9001 standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This software will not change over time. Many releases are written to be backwards compatible, creating another form of verification.

The status and validity of MTS’ operating software is also checked during system verification and routine calibration of MTS hardware. These controlled calibration processes compare the final test results after statistical analysis against the predicted response of the calibration standards. With these established methods, MTS assures its customers that MTS products meet MTS’ exacting quality standards when initially installed and will continue to perform as intended over time.

Publication information |

MANUAL PART NUMBER |

PUBLICATION DATE |

MTS 793 SOFTWARE RELEASE |

|

|

|

|

|

100-162-928 H |

July 2011 |

Version 5.35 or later |

|

|

|

|

MTS Series 793 Controller Overview

Contents

Technical Support |

7 |

|

|

|

|

|

|

||

How to Get Technical Support |

7 |

|

||

Before You Contact MTS 8 |

|

|

||

If You Contact MTS by Phone |

9 |

|

||

Problem Submittal Form in MTS Manuals 10 |

||||

Preface 13 |

|

|

|

|

|

|

|

|

|

Before You Begin |

13 |

|

|

|

Conventions |

14 |

|

|

|

Documentation Conventions |

14 |

|

||

Chapter 1 |

Introduction |

17 |

||

|

|

|||

Learn About Your Controller Here |

17 |

|||

New Features in Version 5.30 |

17 |

|

||

Chapter 2 |

Controller Hardware 19 |

|||

|

|

|

|

|

Controller Overview |

19 |

|

About MTS FlexTest Models 40/60/100/200 Controllers 20 |

||

FlexTest GT Controller Description |

22 |

|

FlexTest SE Controller Description |

25 |

|

FlexTest IIm Controller Description |

30 |

|

Controller Hardware Options 32 |

|

|

About TEDS Sensors |

34 |

|

MTS Series 793 Controller Overview |

Contents |

3 |

Chapter 3 |

Controller Software |

|

35 |

|||||

|

|

|

|

|||||

Model 793.00 System Software Bundle |

35 |

|

|

|||||

Software Options Available with Key Codes |

37 |

|||||||

Software Options Available on Separate Media |

42 |

|||||||

Chapter 4 |

Operation Concepts |

|

43 |

|||||

|

|

|

|

|

|

|

||

Operational Overview |

43 |

|

|

|

|

|

||

About Projects 46 |

|

|

|

|

|

|

|

|

Understanding Projects |

46 |

|

|

|

|

|

||

Using Project Manager to Modify Projects |

48 |

|

||||||

About Hardware Interface Files |

49 |

|

|

|

|

|||

Understanding Hardware Interface Files 49 |

|

|||||||

About Station Configurations 51 |

|

|

|

|

||||

About the Station Builder Application |

51 |

|

|

|||||

Using the Station Builder Application to Create Station Configurations 52 |

||||||||

Station Builder Application Window 53 |

|

|

||||||

About Assigning Parameters to Station Configurations 54 |

||||||||

About Parameter Sets |

54 |

|

|

|

|

|

||

Using the Station Manager Application to Create Parameter Sets 55 |

||||||||

Station Manager Application Windows |

58 |

|

|

|||||

About Compensators |

59 |

|

|

|

|

|

||

About Test Designs |

64 |

|

|

|

|

|

|

|

Understanding Test Design Files |

64 |

|

|

|

||||

Designing Tests with the Basic TestWare Application 65 |

||||||||

Designing Tests with MultiPurpose TestWare |

66 |

|||||||

MPT Process Types 69 |

|

|

|

|

|

|||

MultiPurpose TestWare Windows |

73 |

|

|

|

||||

About Running Tests |

76 |

|

|

|

|

|

|

|

Understanding Files Used for Testing |

76 |

|

|

|||||

Test Desktop |

77 |

|

|

|

|

|

|

|

Monitoring Test Information |

78 |

|

|

|

|

|||

4 |

Contents |

MTS Series 793 Controller Overview |

Chapter 5 |

Installed 793 Files 83 |

|

||

|

|

|

||

File Types and Locations |

83 |

|

||

About System Information |

83 |

|

||

About Controller Information 84 |

|

|||

About Project Information |

85 |

|

||

About Program Information 86 |

|

|||

Chapter 6 |

Perform a Practice Test |

87 |

||

|

|

|||

About Setting Up a Practice Test 87 |

|

|||

Steps to Run a Test 89 |

|

|

|

|

Chapter 7 |

Documentation 97 |

|

||

|

|

|||

Series 793 Controller Manuals 97 |

|

|||

Other 793 Documents |

99 |

|

|

|

Other MTS Documents Included with Your System |

100 |

|||

|

Index |

101 |

|

|

|

|

|

|

|

MTS Series 793 Controller Overview |

Contents |

5 |

6 |

Contents |

MTS Series 793 Controller Overview |

Technical Support

How to Get Technical Support

Start with your manuals

Technical support methods

www.mts.com

Telephone

Fax

Outside the U.S.

The manuals supplied by MTS provide most of the information you need to use and maintain your equipment. If your equipment includes software, look for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If you have any questions about a system or product, contact Technical Support in one of the following ways.

The web site provides access to our technical support staff by means of an online form:

www.mts.com > Contact MTS > Service & Technical Support button

tech.support@mts.com

MTS Call Center 800-328-2255

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

952-937-4515

Please include “Technical Support” in the subject line.

For technical support outside the United States, contact your local sales and service office. For a list of worldwide sales and service locations and contact information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand column) > (choose the location closest to you)

MTS Series 793 Controller Overview |

Technical Support |

7 |

Before You Contact MTS

Know your site number and system number

Know information from prior technical assistance

Identify the problem

MTS can help you more efficiently if you have the following information available when you contact us for support.

The site number contains your company number and identifies your equipment type (such as material testing or simulation). The number is typically written on a label on your equipment before the system leaves MTS. If you do not know your MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies your system. You can find your job number in your order paperwork.

Example system number: US1.42460

If you have contacted MTS about this problem before, we can recall your file based on the:

•MTS notification number

•Name of the person who helped you

Describe the problem and know the answers to the following questions:

•How long and how often has the problem occurred?

•Can you reproduce the problem?

•Were any hardware or software changes made to the system before the problem started?

•What are the equipment model numbers?

•What is the controller model (if applicable)?

•What is the system configuration?

8 |

Technical Support |

MTS Series 793 Controller Overview |

Know relevant computer information

Know relevant software information

For a computer problem, have the following information available:

•Manufacturer’s name and model number

•Operating software type and service patch information

•Amount of system memory

•Amount of free space on the hard drive where the application resides

•Current status of hard-drive fragmentation

•Connection status to a corporate network

For software application problems, have the following information available:

•The software application’s name, version number, build number, and (if available) software patch number. This information can typically be found in the About selection in the Help menu.

•The names of other applications on your computer, such as:

–Anti-virus software

–Screen savers

–Keyboard enhancers

–Print spoolers

–Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical support specialist. The agent asks you for your:

•Site number

•Name

•Company name

•Company address

•Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue will be assigned a unique notification number.

MTS Series 793 Controller Overview |

Technical Support |

9 |

Identify system type

Be prepared to troubleshoot

Write down relevant information

After you call

To enable the Call Center agent to connect you with the most qualified technical support specialist available, identify your system as one of the following types:

•Electromechanical material test system

•Hydromechanical material test system

•Vehicle test system

•Vehicle component test system

•Aero test system

Prepare to perform troubleshooting while on the phone:

•Call from a telephone close to the system so that you can implement suggestions made over the phone.

•Have the original operating and application software media available.

•If you are not familiar with all aspects of the equipment operation, have an experienced user nearby to assist you.

In case Technical Support must call you:

•Verify the notification number.

•Record the name of the person who helped you.

•Write down any specific instructions.

MTS logs and tracks all calls to ensure that you receive assistance for your problem or request. If you have questions about the status of your problem or have additional information to report, please contact Technical Support again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software, hardware, manuals, or service that are not resolved to your satisfaction through the technical support process. The form includes check boxes that allow you to indicate the urgency of your problem and your expectation of an acceptable response time. We guarantee a timely response—your feedback is important to us.

10 Technical Support |

MTS Series 793 Controller Overview |

Access the Problem Submittal Form:

•In the back of many MTS manuals (postage paid form to be mailed to MTS)

•www.mts.com > Contact Us > Problem Submittal Form button (electronic form to be e-mailed to MTS)

MTS Series 793 Controller Overview |

Technical Support |

11 |

12 Technical Support |

MTS Series 793 Controller Overview |

Preface

Before You Begin

Safety first!

Other MTS manuals

Before you use your MTS product or system, read and understand the Safety manual and any other safety information provided with your system. Improper installation, operation, or maintenance can result in hazardous conditions that can cause severe personal injury or death, or damage to your equipment and specimen. Again, read and understand the safety information provided with your system before you continue. It is very important that you remain aware of hazards that apply to your system.

In addition to this manual, you may receive additional manuals in paper or electronic form.

You may also receive an MTS System Documentation CD. It contains an electronic copy of the manuals that pertain to your test system, such as:

•Hydraulic and mechanical component manuals

•Assembly drawings

•Parts lists

•Operation manual

•Preventive maintenance manual

Controller and application software manuals are typically included on the software CD distribution disc(s).

MTS Series 793 Controller Overview |

Preface 13 |

Conventions

Conventions

Documentation Conventions

Hazard conventions

Notes

Special terms

The following paragraphs describe some of the conventions that are used in your MTS manuals.

Hazard notices may be embedded in this manual. These notices contain safety information that is specific to the activity to be performed. Hazard notices immediately precede the step or procedure that may lead to an associated hazard. Read all hazard notices carefully and follow all directions and recommendations. Three different levels of hazard notices may appear in your manuals. Following are examples of all three levels.

Note For general safety information, see the safety information provided with your system.

DANGER

DANGER

Danger notices indicate the presence of a hazard with a high level of risk which, if ignored, will result in death, severe personal injury, or substantial property damage.

WARNING

WARNING

Warning notices indicate the presence of a hazard with a medium level of risk which, if ignored, can result in death, severe personal injury, or substantial property damage.

CAUTION

CAUTION

Caution notices indicate the presence of a hazard with a low level of risk which, if ignored, could cause moderate or minor personal injury or equipment damage, or could endanger test integrity.

Notes provide additional information about operating your system or highlight easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of the list.

The first occurrence of special terms is shown in italics.

14 Preface |

MTS Series 793 Controller Overview |

Illustrations

Electronic manual conventions

Hypertext links

Conventions

Illustrations appear in this manual to clarify text. They are examples only and do not necessarily represent your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document File (PDF) format. It can be viewed on any computer that has Adobe Acrobat Reader installed.

The electronic document has many hypertext links displayed in a blue font. All blue words in the body text, along with all contents entries and index page numbers, are hypertext links. When you click a hypertext link, the application jumps to the corresponding topic.

MTS Series 793 Controller Overview |

Preface 15 |

Conventions

16 Preface |

MTS Series 793 Controller Overview |

Learn About Your Controller Here

Chapter 1

Introduction

Learn About Your Controller Here

Software is introduced in the order you use it

Practice test procedure

MTS Series 793 Controllers are supplied with several manuals—each pertaining to a primary attribute of the Controller, such as hardware, control software, application software, utility software, and more.

This manual integrates descriptions of all of these attributes to help you learn about your Controller as efficiently as possible. It is a not a “how-to” manual, it is a learning manual.

In this manual, the various software applications included with your Controller are described in the order you typically use them to perform tests.

For instance, the section that describes station configurations introduces the Station Builder application; the section that describes test designs introduces the Basic TestWare and MultiPurpose TestWare applications.

This manual includes a practice test procedure. By performing this procedure you will become familiar with many of the activities typically performed while testing.

New Features in Version 5.35

If you are an existing user of Series 793 Controllers, you will find several enhancements and additions included in Version 5.30.

•Added support for CANdb databases to the 793.25 CANBus interface option.

•Added Series 793 Software support for 2500 processors.

•Added several enhancements for the Model 793.100 Hybrid Simulation (Internal Model) and Model 793.101 Hybrid Simulation (External Model) options.

MTS Series 793 Controller Overview |

Introduction 17 |

New Features in Version 5.35

18 Introduction |

MTS Series 793 Controller Overview |

Controller Overview

Chapter 2

Controller Hardware

Controller Overview

Types of MTS Series

793 Controllers

MTS controllers equipped with Series 793 Software are referred to as MTS Series 793 Controllers.

MTS offers several types of Series 793 Controllers. This manual pertains to the following:

•MTS FlexTest Series 40/60/100/200 Controllers

•FlexTest GT Controllers

•FlexTest SE Controllers (Basic, Plus, and 2-Channel models)

•FlexTest IIm Controllers

For information about the hardware included in FlexTest GT, FlexTest SE, and FlexTest IIm Controllers, see the MTS Models FlexTest IIm/GT/SE Controller Hardware manual (PN 100-147-133). For more information on Series 494 controllers, see the MTS Models FlexTest®40/60/100/200 Controller Hardware manual (PN 100-187-204).

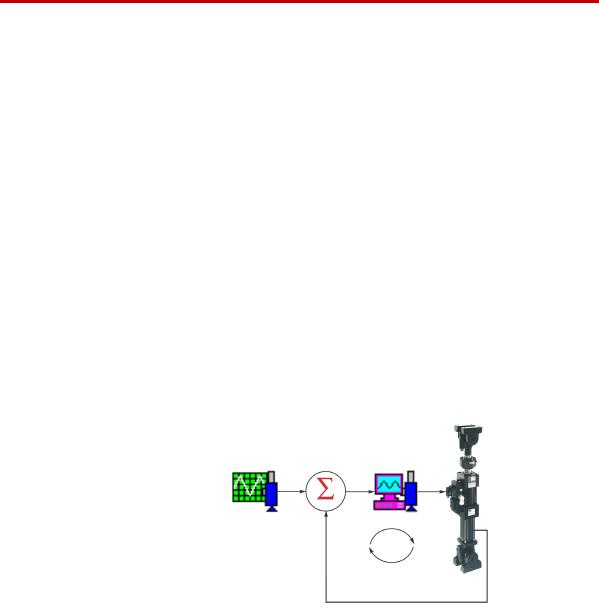

Closed loop control MTS Series 793 Controllers provide closed-loop control of the mechanical and hydraulic components of a test system.

Simple Control diagram

When reduced to its basic form, a Series 793 test system typically includes these elements. (The command can also be provided by the function generator or MultiPurpose TestWare).

Basic |

Station |

TestWare |

Manager |

application |

application |

Command |

Feedback |

|

Source |

||

Source |

||

|

||

|

Summing and |

|

|

Conditioning |

MTS Series 793 Controller Overview |

Controller Hardware 19 |

About MTS FlexTest Models 40/60/100/200

Types of MTS Series

793 Controllers

MTS offers several types of Series 793 Controllers. This manual pertains to the following:

•MTS FlexTest Series 40/60/100/200 Controllers

•FlexTest GT Controllers

•FlexTest SE Controllers (Basic, Plus, and 2-Channel models)

•FlexTest IIm Controllers

Note For information about the hardware included in FlexTest GT, FlexTest SE, and FlexTest IIm Controllers, see the MTS Series 793 Controller Hardware manual (PN 100-147-133). For more information on Series 494 controllers, see the Series 494 Controller Hardware manual (PN 100-187-204).

About MTS FlexTest Models 40/60/100/200 Controllers

MTS FlexTest Models 40/60/100/200 Controllers are generally used in servohydraulic test systems. They provide real-time closed-loop control, with transducer conditioning and function generation to drive various types of servoactuators.

A FlexTest Controller consists of:

•One or more Series 494 Hardware chassis that contain controller hardware.

•A computer workstation that runs MTS controller applications.

Controller capabilities

PARAMETER |

FLEXTEST |

FLEXTEST |

FLEXTEST FLEXTEST |

|

|

40 |

60 |

100 |

200 |

|

|

|

|

|

Test Stations |

2 |

Up to 6* |

Up to 8 |

Up to 8 |

|

|

|

|

|

Control Channels |

Up to 4 |

Up to 8 |

Up to 16 |

Up to 40 |

|

|

|

|

|

Conditioned |

Up to 12 |

Up to 24 |

Up to 40 |

Up to 80 |

Transducer Inputs |

|

|

|

|

|

|

|

|

|

Auxiliary Data Inputs |

Up to 16 |

Up to 32 |

Up to 64 |

Up to 96 |

*With On/Off Hydraulic Service Manifolds only

20 Controller Hardware |

MTS Series 793 Controller Overview |

About MTS FlexTest Models 40/60/100/200

FlexTest 40 |

FlexTest 60 |

Back

(3 VME slots)

FlexTest 100

Front |

Back |

(6 VME slots) |

(8 transition slots, |

|

7 powered) |

Front |

Back |

(10 VME slots) |

(12 transition slots, 10 powered) |

FlexTest 200

Front |

Back |

(20 VME slots) |

(20 transition slots, 19 powered) |

FlexTest Models 40/60/100/200 Controllers

MTS Series 793 Controller Overview |

Controller Hardware 21 |

FlexTest GT Controller Description

FlexTest GT Controller Description

FlexTest GT Controllers are PC-based multi-station digital controllers consisting of:

•A PC running Series793 Software

•A FlexTest GT Controller chassis equipped with Series 493 electronics

•An optional Handset

These components work together to control up to eight channels on up to four independent stations.

Typical FlexTest GT configuration

FlexTest GT Controllers are typically used for component or structural testing applications.

22 Controller Hardware |

MTS Series 793 Controller Overview |

Typical FlexTest GT

configuration

About DUCs

FlexTest GT Controller Description

The controller chassis is typically equipped with the following Series 493 Plug-In Modules (32 maximum):

•One valve driver module per control channel (two-stage or three-stage)

•Two digital universal conditioners (DUCs) per control channel

•Hydraulic service manifold (HSM) and hydraulic power unit (HPU) interlock modules

The Model 494.25 Digital Universal Conditioners (DUCs) condition AC and DC transducers. You can use the same DUC to condition an LVDT (AC transducer) for one test, and then to condition a load cell (DC transducer) for another test.

Model 494.25 DUCs are full range conditioners. This means DUCs accurately cover the full scale of the transducer, which eliminates the need to select between ranges for transducers. DUCs also provide the resolution and repeatability required for measuring small percentages of their total range.

MTS Series 793 Controller Overview |

Controller Hardware 23 |

FlexTest GT Controller Description

Hardware options |

• |

Additional Model 494.25 DUCs |

|

• |

Model 494.26 Dual DUC |

|

• |

Model 494.21 Multi-Range DUC with Acceleration Compensation, which |

|

|

provides conditioning and accelerometer compensation in a single card |

|

• |

Auxiliary analog-to-digital (A/D) inputs |

|

• |

Set of 16 digital inputs and 16 digital outputs for user-defined operation |

|

• |

Encoders |

|

|

Controller |

|

|

backpanel |

FlexTest GT Controller chassis

24 Controller Hardware |

MTS Series 793 Controller Overview |

FlexTest SE Controller Description

FlexTest SE Controller Description

The FlexTest SE Controller is a fully-digital PIDF controller that is available in three configurations:

•FlexTest SE Basic

•FlexTest SE Plus

•FlexTest SE 2-Channel

FlexTest SE Basic The FlexTest SE Basic is a stand-alone controller equipped with a multicolor display panel and direct-access menu keys. It does not require a PC to operate; a special form of MTS Series 793 Software is stored directly on its internal flash memory.

The FlexTest SE Basic Controller is equipped with its own manual (FlexTest SE

User Information and Software Reference, PN 100-149-574).

FlexTest SE Controller

With the FlexTest SE Basic model, you perform all operations from the front panel controls shown here.

For the FlexTest SE Plus and FlexTest SE 2-Channel models, you typically perform most operations from a PC loaded with Series 793 Software.

MTS Series 793 Controller Overview |

Controller Hardware 25 |

FlexTest SE Controller Description

Automated FlexTest

SE Controllers

The FlexTest SE is available in two automated configurations, the FlexTest SE Plus and the FlexTest SE 2-Channel.

The FlexTest SE Plus and FlexTest SE 2-Channel Controllers include:

•A PC with Series 793 Software

•FlexTest SE Controller equipped with Series 493 Electronics

FlexTest SE Plus

The FlexTest SE Plus provides one control channel, as shown in this axial load unit example.

FlexTest SE 2-Channel

The FlexTest SE 2-Channel provides two control channel, as shown in this axial-torsional load unit example.

26 Controller Hardware |

MTS Series 793 Controller Overview |

Using Plus and 2-

Channel Controllers in

the Basic mode

Supplemental interface for specimen handling

FlexTest SE Controller Description

If desired, the FlexTest SE Plus and FlexTest SE 2-Channel Controllers can also be used without PCs (in the FlexTest Basic configuration). The Controller is fully capable of system control without the PC.

For FlexTest SE Plus and FlexTest SE 2-Channel controllers you typically use:

•The FlexTest SE front panel controls to facilitate specimen loading

•The Station Manager application running on the PC as the primary test interface

You can position the FlexTest SE Controller near your load frame or test fixture with an adjustable arm or a portable test stand. This eliminates the need for a Remote Station Controller (RSC).

MTS Series 793 Controller Overview |

Controller Hardware 27 |

FlexTest SE Controller Description

Booting the controller in the automated mode disables several of the menus on the front panel of the controller. These menus are used for testing in nonautomated FlexTest SE Basic models. To compensate for the disabled front-panel menus, you use the Station Manager application interface on the PC to set up and run tests.

The PC manages testing. You use a PC loaded with Series 793 Software to design and run tests.

The FlexTest Controller manages specimen installation. You use the FlexTest SE Controller to position the actuator when loading specimens.

28 Controller Hardware |

MTS Series 793 Controller Overview |

Typical FlexTest SE

Plus configuration

Options

FlexTest SE Controller Description

FlexTest SE Plus Controllers typically support one channel on one station, and include the following:

•VME processor capable of an update rate of 6kHz, along with a two-stage or three-stage valve driver, and two digital universal conditioners

•One analog input and three analog outputs

•Digital inputs and outputs (for interlocks or user-defined purposes)

•Serial interface for temperature control

•Up to three additional DUCs

•Six auxiliary analog-to-digital input channels

•Test stand (adjustable arm or portable stand) for the FlexTest SE Controller

FlexTest SE Controller backpanel

Typical FlexTest SE 2- Channel configuration

The FlexTest SE 2-Channel Controller is designed for two-channel, singlestation test applications. FlexTest 2-Channel Controllers include the following additions to the FlexTest SE Plus configuration:

•Two two-stage or three-stage valve drivers

•Four digital universal conditioners (DUCs)

For more information For more information on DUCs, see “About DUCs” on page 23.

MTS Series 793 Controller Overview |

Controller Hardware 29 |

FlexTest IIm Controller Description

FlexTest IIm Controller Description

FlexTest IIm Controllers are PC-based multistation digital controllers consisting of two major hardware components:

•A PC running Series 793 Software

•A FlexTest IIm Controller chassis, equipped with Series 497 Electronics

FlexTest IIm Controllers support up to sixteen control channels on up to four independent stations.

Typical FlexTest IIm configuration

FlexTest IIm Controllers are typically used for component or structural testing applications that require higher channel counts.

30 Controller Hardware |

MTS Series 793 Controller Overview |

Loading...

Loading...