MTS 647 User Manual

Series 647 Hydraulic Wedge Grips Reference

Manual

Axial Grips Axial-Torsional Grips All-Temperature Grips

100-027-131 N be certain.

© 2013 MTS Systems Corporation. All rights reserved.

Original Instructions (English): 100-027-131 N

Trademark Information

MTS, be certain., Bionix, ElastomerExpress, FlatTrac, FlexTest, Just In Case, LevelPlus, MTS Criterion, MTS

EM Extend, MTS Insight, MTS Landmark, RPC, ServoSensor, SWIFT, Temposonics, TestWare, TestWorks are

registered trademarks of MTS Systems Corporation within the United States. Acumen, Advantage, Aero ST,

Aero-90, AeroPro, Criterion, CRPC, Echo, Flat-Trac, Landmark, MAST, MicroProfiler, MPT, MTS Acumen, MTS

Echo, MTS Fundamentals, MTS TestSuite, ReNew, SilentFlo, TempoGuard, TestLine, and Tytron are trademarks

of MTS Systems Corporation within the United States. These trademarks may be registered in other countries.

All other trademarks are property of their respective owners.

Proprietary Software

Software use and license is governed by the MTS End User License Agreement which defines all rights retained

by MTS and granted to the End User. All Software is proprietary, confidential, and owned by MTS Systems

Corporation and cannot be copied, reproduced, disassembled, decompiled, reverse engineered, or distributed

without express written consent of MTS.

Software Verification and Validation

MTS software is developed using established quality practices in accordance with the requirements detailed in

the ISO 9001 standards. Because MTS-authored software is delivered in binary format, it is not user accessible.

This software will not change over time. Many releases are written to be backwards compatible, creating another

form of verification. The status and validity of the MTS operating software is also checked during system verification

and routine calibration of MTS hardware. These controlled calibration processes compare the final test results

after statistical analysis against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet exacting quality standards when initially installed

and will continue to perform as intended over time.

Manual Part Number—Publication Date—Release

100-027-131 M—April 2011

100-027-131 L—April 2010

100-027-131 K—April 2009

100-027-131 J—March 2008

100-027-131 H—Mat 2007

100-027-131 G—November 2006

100-027-131 F—July 2005

100-027-131 E—February 2003

100-027-131 D—October 2001

100-027-131 C—June 2011

100-027-131 B—December 2011

100-027-131 A—February 2000

Contents

Technical Support 7

Preface 11

Introduction 13

How to Get Technical Support.................................................................................................................7

Before You Contact MTS.........................................................................................................................7

If You Contact MTS by Phone.................................................................................................................9

Problem Submittal Form in MTS Manuals............................................................................................10

Before You Begin...................................................................................................................................11

Documentation Conventions..................................................................................................................11

Overview Reference...............................................................................................................................14

Series 647 Hydraulic Wedge Grips Component Identication..............................................................16

Series 647 Hydraulic Wedge Grips Functional Description...................................................................19

About Gripping Specimens....................................................................................................................20

About Wedges........................................................................................................................................20

About Spiral Washers.............................................................................................................................21

About Couplings....................................................................................................................................21

About All Temperature Grips.................................................................................................................21

About Environmental Chambers............................................................................................................22

Hydraulic Fluid Recommendations........................................................................................................23

Cooling Water Specications.................................................................................................................23

Series 647 Wedge Grip Temperature Ranges.........................................................................................23

Series 647 Hydraulic Wedge Grip Force and Torque Capacities...........................................................24

Safety 29

General Safety Practices: Grips and Fixtures.........................................................................................30

Read all manuals........................................................................................................................31

Avoid Pinch and Crush Points....................................................................................................31

Locate and read hazard placards/labels......................................................................................31

Know facility safe procedures....................................................................................................32

Know controls............................................................................................................................32

Know Specimen Properties........................................................................................................32

Have rst aid available...............................................................................................................32

Be aware of component movement with hydraulics off.............................................................32

Keep bystanders safely away.....................................................................................................32

Wear proper clothing..................................................................................................................32

Remove ammable uids..........................................................................................................32

Check bolt ratings and torques...................................................................................................33

Lift Equipment Safely................................................................................................................33

Series 647 Hydraulic Wedge Grips Reference Manual 3

Practice good housekeeping.......................................................................................................33

Do not exceed the Maximum Supply Pressure..........................................................................33

Do not disable safety devices.....................................................................................................33

Provide adequate lighting...........................................................................................................33

Provide means to access out-of-reach components....................................................................34

Wear appropriate personal protection.........................................................................................34

Handle chemicals safely ............................................................................................................34

Know system interlocks.............................................................................................................34

Know system limits....................................................................................................................34

Do not disturb sensors ...............................................................................................................34

Ensure secure cables...................................................................................................................34

Stay alert ....................................................................................................................................35

Contain small leaks ...................................................................................................................35

Stay clear of moving equipment/avoid crush points .................................................................35

Know the causes of unexpected actuator motions .....................................................................35

General Precautions for Environmental Components............................................................................35

Hazard Placard Placement......................................................................................................................36

Installation 37

Series 647 Hydraulic Grip Lift Points....................................................................................................38

Install Axial Grips..................................................................................................................................39

About the Installation of Axial Grips.........................................................................................39

Install Axial Grip........................................................................................................................42

Install Axial-Torsional Grips..................................................................................................................44

About the Installation of Axial-Torsional Grips.........................................................................44

Install Axial-Torsional Grip.......................................................................................................46

Install 647.250 Grips..............................................................................................................................50

Install the Grips in an Environmental Chamber.....................................................................................50

About Installation of the Grips in an Environmental Chamber .................................................50

Install Environmental Chambers with U-Plugs..........................................................................51

Install Environmental Chambers Without U-Plugs....................................................................55

Install Extension Rods............................................................................................................................66

About Extension Rod Installation..............................................................................................66

Install Extension Rods................................................................................................................67

Align the Wedge Openings.....................................................................................................................71

Preload the Spiral Washers.....................................................................................................................72

Grip Water Cooling Congurations.......................................................................................................74

Grip Water Cooling Assembly Conguration for Electromechanical Frames...........................74

Operation 77

Basic Operation......................................................................................................................................78

About Grip Controls...............................................................................................................................78

Determine Gripping Pressure.................................................................................................................79

4 Series 647 Hydraulic Wedge Grips Reference Manual

About Grip Pressure Determination...........................................................................................79

Determine Gripping Pressure -Axial for Round Specimens (and Axial/Torsional for Flat Specimens).81

Determine Gripping Pressure - Axial-Torsional for Round Specimens Only............................82

Change/Install Wedges...........................................................................................................................83

Change Model 647.02 - 647.100 Wedges..................................................................................83

Change Standard Wedges...........................................................................................................83

Change Wide Wedges.................................................................................................................84

Wedges and Inserts for Rebar and Wire Rope............................................................................85

Install Model 647.250 Wedges and Liners.................................................................................86

Install Model 647.250 Wedges.......................................................................................86

Install Model 647.250 Wedge Liners.............................................................................87

Install/Remove Test Specimen...................................................................................................88

Install a Specimen..........................................................................................................88

Remove a Specimen.......................................................................................................90

Maintenance 93

Hydraulic Hoses and Fittings.................................................................................................................94

Wedges...................................................................................................................................................94

Water Cooling Components...................................................................................................................94

Daily Inspections....................................................................................................................................94

Series 647 Hydraulic Wedge Grips Reference Manual 5

Technical Support

How to Get Technical Support

Start with your manuals

The manuals supplied by MTS provide most of the information you need to use and maintain your equipment.

If your equipment includes software, look for online help and README files that contain additional product

information.

Technical support methods

MTS provides a full range of support services after your system is installed. If you have any questions about

a system or product, contact Technical Support in one of the following ways.

Web site

Outside the U.S.

For technical support outside the United States, contact your local sales and service office. For a list of

worldwide sales and service locations and contact information, use the Global MTS link at the MTS web site:

www.mts.com > Global Presence > Choose a Region

www.mts.com > Contact Us (upper-right corner) > In the Subject field, choose

To escalate a problem; Problem Submittal Form

Worldwide: tech.support@mts.comE-mail

Europe: techsupport.europe@mts.com

Worldwide: 1 800 328 2255 - toll free in U.S.; +1 952 937 4000 - outside U.S.Telephone

Europe: +800 81002 222, International toll free in Europe

Before You Contact MTS

MTS can help you more efficiently if you have the following information available when you contact us for

support.

Know your site number and system number

The site number contains your company number and identifies your equipment type (such as material testing

or simulation). The number is typically written on a label on your equipment before the system leaves MTS.

If you do not know your MTS site number, contact your sales engineer.

Example site number: 571167

Series 647 Hydraulic Wedge Grips Reference Manual 7

When you have more than one MTS system, the system job number identifies your system. You can find

your job number in your order paperwork.

Example system number: US1.42460

Know information from prior technical assistance

If you have contacted MTS about this problem before, we can recall your file based on the:

• MTS notification number

• Name of the person who helped you

Identify the problem

Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Know relevant computer information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant software information

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if available) software patch number.

This information can typically be found in the About selection in the Help menu.

• The names of other applications on your computer, such as:

• Anti-virus software

• Screen savers

• Keyboard enhancers

• Print spoolers

• Messaging applications

8 Series 647 Hydraulic Wedge Grips Reference Manual

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical support specialist. The agent

asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue will be assigned a unique

notification number.

Identify system type

To enable the Call Center agent to connect you with the most qualified technical support specialist available,

identify your system as one of the following types:

• Electrodynamic material test system

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to troubleshoot

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an experienced user nearby to

assist you.

Write down relevant information

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

Series 647 Hydraulic Wedge Grips Reference Manual 9

After you call

MTS logs and tracks all calls to ensure that you receive assistance for your problem or request. If you have

questions about the status of your problem or have additional information to report, please contact Technical

Support again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software, hardware, manuals, or service

that are not resolved to your satisfaction through the technical support process. The form includes check

boxes that allow you to indicate the urgency of your problem and your expectation of an acceptable response

time. We guarantee a timely response—your feedback is important to us.

You can access the Problem Submittal Form at www.mts.com > Contact Us (upper-right corner) > In the

Subject field, choose To escalate a problem; Problem Submittal Form

10 Series 647 Hydraulic Wedge Grips Reference Manual

Preface

Before You Begin

Safety first!

Before you use your MTS product or system, read and understand the safety information provided with your

system. Improper installation, operation, or maintenance can result in hazardous conditions that can cause

severe personal injury or death, or damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very important that you remain

aware of hazards that apply to your system.

Other MTS manuals

In addition to this manual, you may receive additional manuals in paper or electronic form.

You may also receive an MTS System Documentation CD. It contains an electronic copy of the manuals that

pertain to your test system.

Controller and application software manuals are typically included on the software CD distribution disc(s).

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your MTS manuals.

Hazard conventions

Hazard notices may be embedded in this manual. These notices contain safety information that is specific to

the activity to be performed. Hazard notices immediately precede the step or procedure that may lead to an

associated hazard. Read all hazard notices carefully and follow all directions and recommendations. Three

different levels of hazard notices may appear in your manuals. Following are examples of all three levels. (for

general safety information, see the safety information provided with your system.)

DANGER:

Danger notices indicate the presence of a hazard with a high level of risk which, if

ignored, will result in death, severe personal injury, or substantial property damage.

WARNING:

Warning notices indicate the presence of a hazard with a medium level of risk which,

if ignored, can result in death, severe personal injury, or substantial property damage.

CAUTION:

Series 647 Hydraulic Wedge Grips Reference Manual 11

Caution notices indicate the presence of a hazard with a low level of risk which, if

ignored, could cause moderate or minor personal injury or equipment damage, or

could endanger test integrity.

Other special text conventions

Important:

Important notices provide information about your system that is essential to its proper

function. While not safety-related, if the important information is ignored, test results may

not be reliable, or your system may not operate properly.

Note:

Notes provide additional information about operating your system or highlight easily

overlooked information.

Recommended:

Recommended notes provide a suggested way to accomplish a task based on what MTS

has found to be most effective.

Tip:

Tips provide helpful information or a hint about how to most efficiently accomplish a task.

Access:

Access provides the route you should follow to a referenced item in the software.

Example:

Examples show specific scenarios relating to your product and appear with a shaded

background.

Special terms

The first occurrence of special terms is shown in italics.

Illustrations

Illustrations appear in this manual to clarify text. They are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual conventions

This manual is available as an electronic document in the Portable Document File (PDF) format. It can be

viewed on any computer that has Adobe Acrobat Reader installed.

Hypertext links

The electronic document has many hypertext links displayed in a blue font. All blue words in the body text,

along with all contents entries and index page numbers, are hypertext links. When you click a hypertext link,

the application jumps to the corresponding topic.

12 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

Topics:

•

Overview Reference..............................................................................................................................14

•

Series 647 Hydraulic Wedge Grips Component Identification...............................................................16

•

Series 647 Hydraulic Wedge Grips Functional Description...................................................................19

•

About Gripping Specimens....................................................................................................................20

•

About Wedges.......................................................................................................................................20

•

About Spiral Washers............................................................................................................................21

•

About Couplings.....................................................................................................................................21

•

About All Temperature Grips..................................................................................................................21

•

About Environmental Chambers............................................................................................................22

•

Hydraulic Fluid Recommendations........................................................................................................23

•

Cooling Water Specifications.................................................................................................................23

•

Series 647 Wedge Grip Temperature Ranges.......................................................................................23

•

Series 647 Hydraulic Wedge Grip Force and Torque Capacities..........................................................24

Series 647 Hydraulic Wedge Grips Reference Manual 13

Introduction

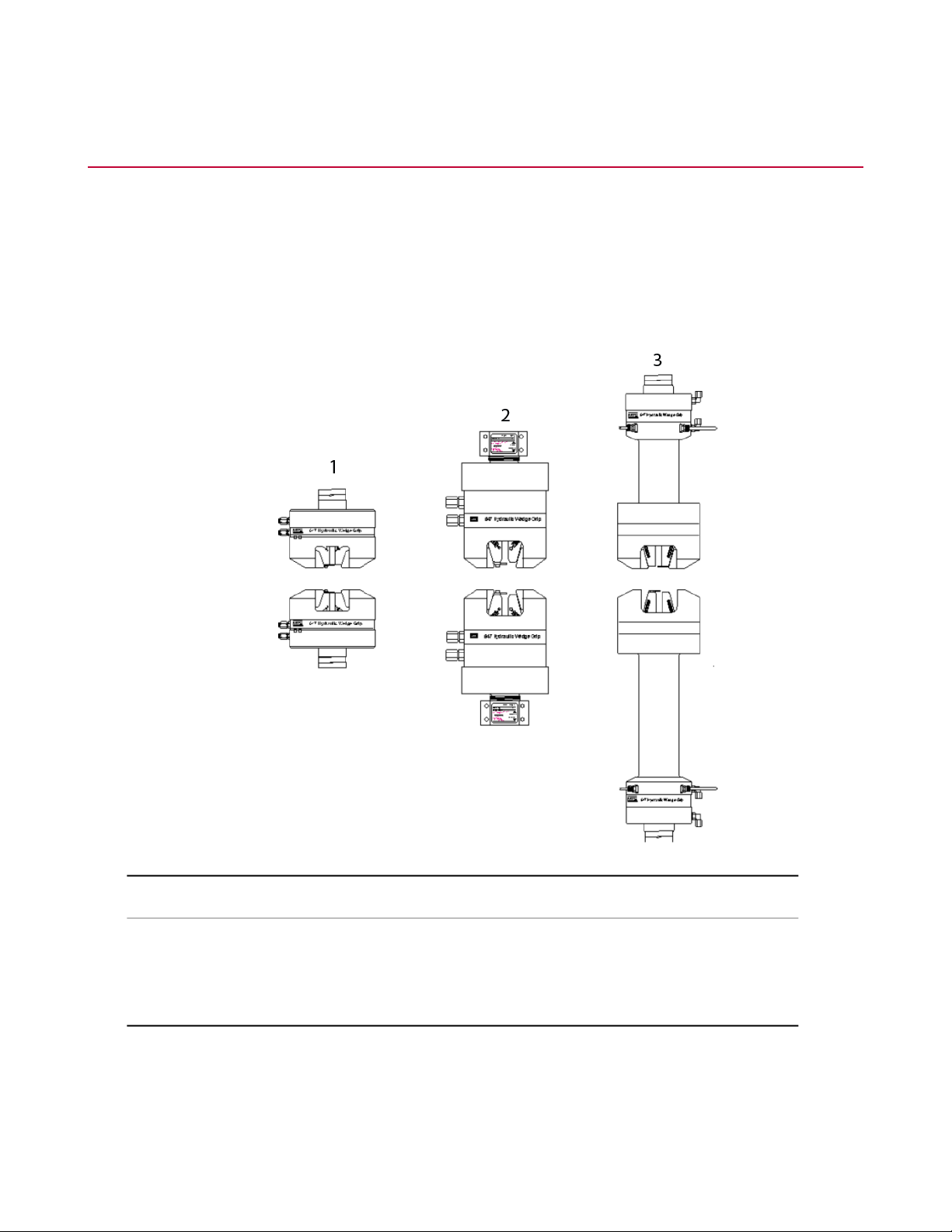

Overview Reference

The MTS Series 647 Hydraulic Wedge Grips grasp and hold a specimen in place during testing, and provide

a constant, hydraulically actuated gripping force regardless of the applied test loads. The grips are specifically

designed for static or fatigue testing applications in MTS testing systems. A variety of wedges allow the grips

to be used to test a variety of materials. Optional equipment includes a cooling/warming kit and an external

hydraulic grip supply.

The size and shape of the Series 647 Hydraulic Wedge Grips vary among the models.

Grip TypeItem

Axial1

Axial-Torsional2

All Temperature3

What you need to know

MTS Systems Corporation assumes that you know how to use your controller. See the appropriate manual

for information about performing any controllerrelated step in this manual’s procedures. You are expected to

know how to perform the following procedures:

14 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

• Turn hydraulic pressure on and off.

• Select a control mode.

• Manually adjust the actuator position.

• Monitor a sensor signal.

Related products

See the following product information manuals for information about the related products.

• The hydraulic controls for the Series 647 Hydraulic Grips can be located on the front panel of the load unit

or on an external unit (controls and a hydraulic power unit for the grips).

• If hydraulic grip controls are located on the load unit, see your load unit product information manual.

• If hydraulic grip controls are added to your load unit, see the 685.53 Hydraulic Grip Kit Product

Information manual (MTS part number 015-029-701).

• If you have a dedicated hydraulic supply for the grips, see the Series 685 Hydraulic Grip Supply Product

Information manual (MTS part number 015-205-001).

• If you are using an environmental chamber, see the Series 651 Environmental Chambers Product

Information manual (MTS part number 015-205-001).

Series 647 Hydraulic Wedge Grips Reference Manual 15

Introduction

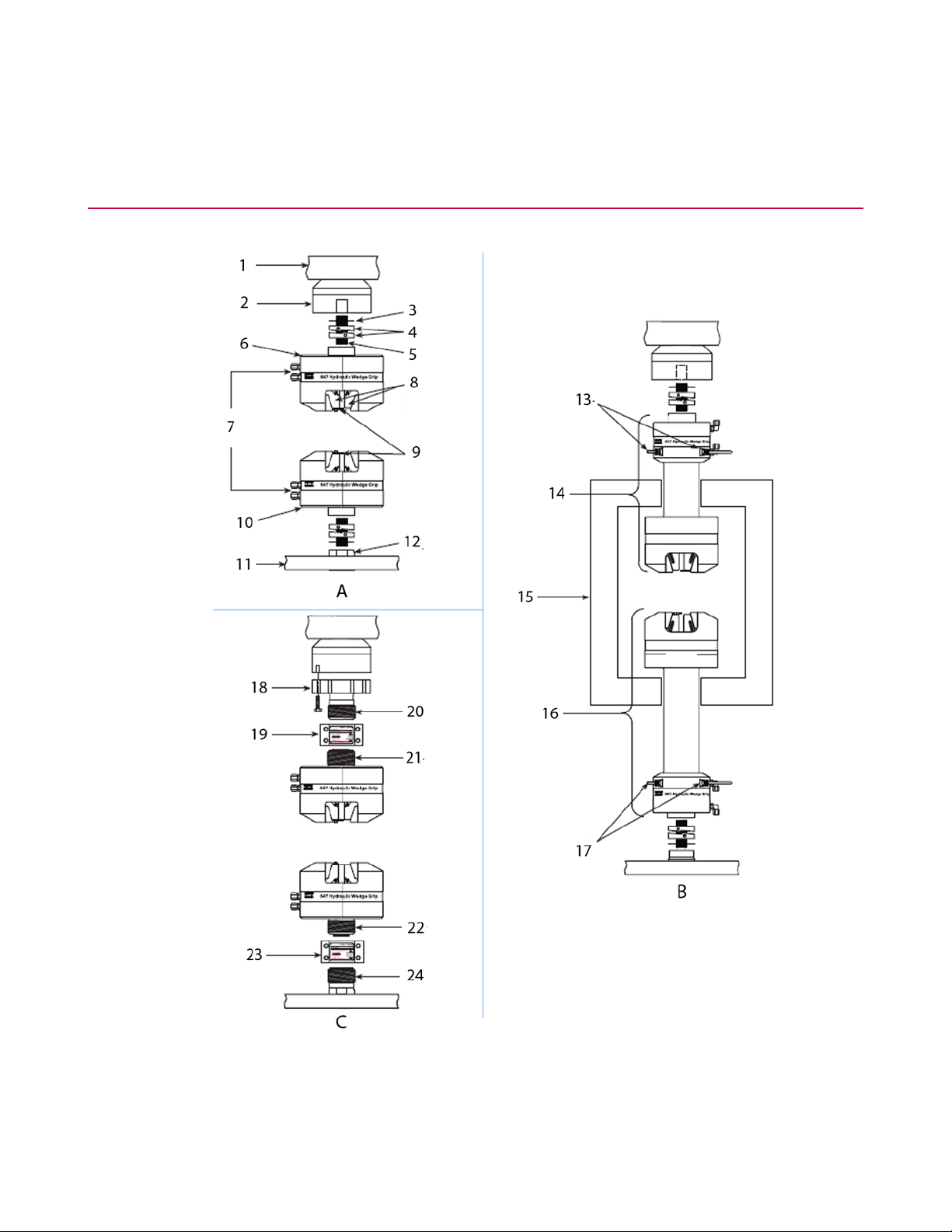

Series 647 Hydraulic Wedge Grips Component Identification

Series 647 Hydraulic Grip Components

16 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

DescriptionItemDescriptionItem

All Temperature GripsBAxial GripsA

Water Cooling Lines13Load Unit Crosshead1

Upper Grip Assembly14Force Transducer2

Environmental Chamber15Shim3

Lower Grip Assy16Spiral Washer Set4

Water Cooling Lines17Connector Stud5

Axial/Torsional GripsCUpper Grip6

Adapter Plate18Hydraulic Pressure and return Lines7

8

liners)

Load unit

• Crosshead and Base

Plate

Upper Coupling19Wedges (647.250 includes wedge

Left Hand Thread20Specimen Guide9

Right Hand Thread21Lower Grip10

Left Hand Thread22Load Unit Base11

Lower Coupling23Actuator Rod12

Right Hand Thread24

DescriptionItem

Provides the structure to mount the grips and other components in

the force train. It is also the reaction mass for the force train. The grips

are mounted to the force transducer and actuator rod in the load unit.

• Some load units have the actuator mounted in the base plate and

the force transducer mounted to the crosshead.

• Some load units have the force transducer mounted in the base

plate and the actuator mounted to the crosshead.

Force Transducer

Upper and lower grips

Hydraulic pressure and

return lines

Measures the axial forces applied to the specimen. An axial-torsional

version also measures the rotational forces applied to the specimen.

Clamps a specimen in place. The grips house the wedges and the

hydraulic components that operate the grips.

The grip assemblies of the all-temperature grips have the components

separated so those components most affected by extreme

temperatures are located outside the extreme environment.

Ports the hydraulic fluid to and from the grips. The hydraulic fluid

comes from a system hydraulic power unit (HPU) or a dedicated

Series 647 Hydraulic Wedge Grips Reference Manual 17

Introduction

DescriptionItem

hydraulic grip supply. Each grip has two hydraulic lines connected to

it; a hydraulic pressure port and a hydraulic return port.

Wedges

Specimen guide

Actuator rod

Water cooling lines

Environmental chamber

Contacts and holds the specimen in place. A variety of wedges are

available, for flat specimens, round specimens, hard specimens, and

soft specimens. Wedges are available as matched sets of four.

Each model has wedges that are designed for its use. The 647.250

grips have permanent wedges and use wedge liners to accommodate

various specimen shapes.

Helps align the specimen when it is installed. The specimen guide

can only be used with flat specimens.

Applies axial or axial and torsional forces to specimens. The actuator

is a hydraulically powered device that provides linear displacement

of (or forces into) a specimen. For axial-torsional systems, the actuator

applies both axial and torsional forces to the specimen.

The end of the actuator rod is threaded so that a grip can be mounted

to it. The actuator rod can be located in the base or the crosshead of

the load unit.

Provides the source of water for heating or cooling. The water is

circulated through the grips to keep them warm or cool when operating

in a cold or hot environmental chamber.

Allows a specimen to be tested at different temperatures (hot or cold).

Environmental chambers are insulated boxes that surround the

specimen and grips.

Axial attachment kit

• Shims

• Spiral washers

• Connector stud

Axial-torsional attachment

kit

Includes the required components to install the grips. The attachment

kit contains shim washers, spiral washers, and connector studs. Each

grip model/load unit model combination has a unique attachment kit.

Allows the upper and lower grips to be aligned. When the grips are

installed, the upper and lower grips might not be aligned. Shims can

be added so that the grips are aligned when they are tightened on

the connector stud. The shims are available in thicknesses that

correspond with 1/8 to 1/2 turns.

Ensures preloading without inducing offsets in the force train. They

provide a backlash-free union of threaded components. They preload

the connecting stud to a minimum axial load that is 110% of the test

maximum.

Mounts the grips to the other components in the force train. Connector

studs are threaded rods that connect the grips with an actuator rod

or force transducer.

Includes the required components to install the grips. The attachment

kit contains an adapter plate, an upper coupling, and a lower coupling.

Each grip model/load unit model combination has a unique attachment

kit.

18 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

DescriptionItem

• Adapter plate

• Upper and lower

couplings

Allows axial-torsional grips to be mounted to a force transducer. The

adapter provides the thread needed to use the couplings.

Clamps the grips to the to the actuator and force transducer (via an

adapter). The couplings have left and right handed threads that

preloads the grip connection and prevents offsets in the force train.

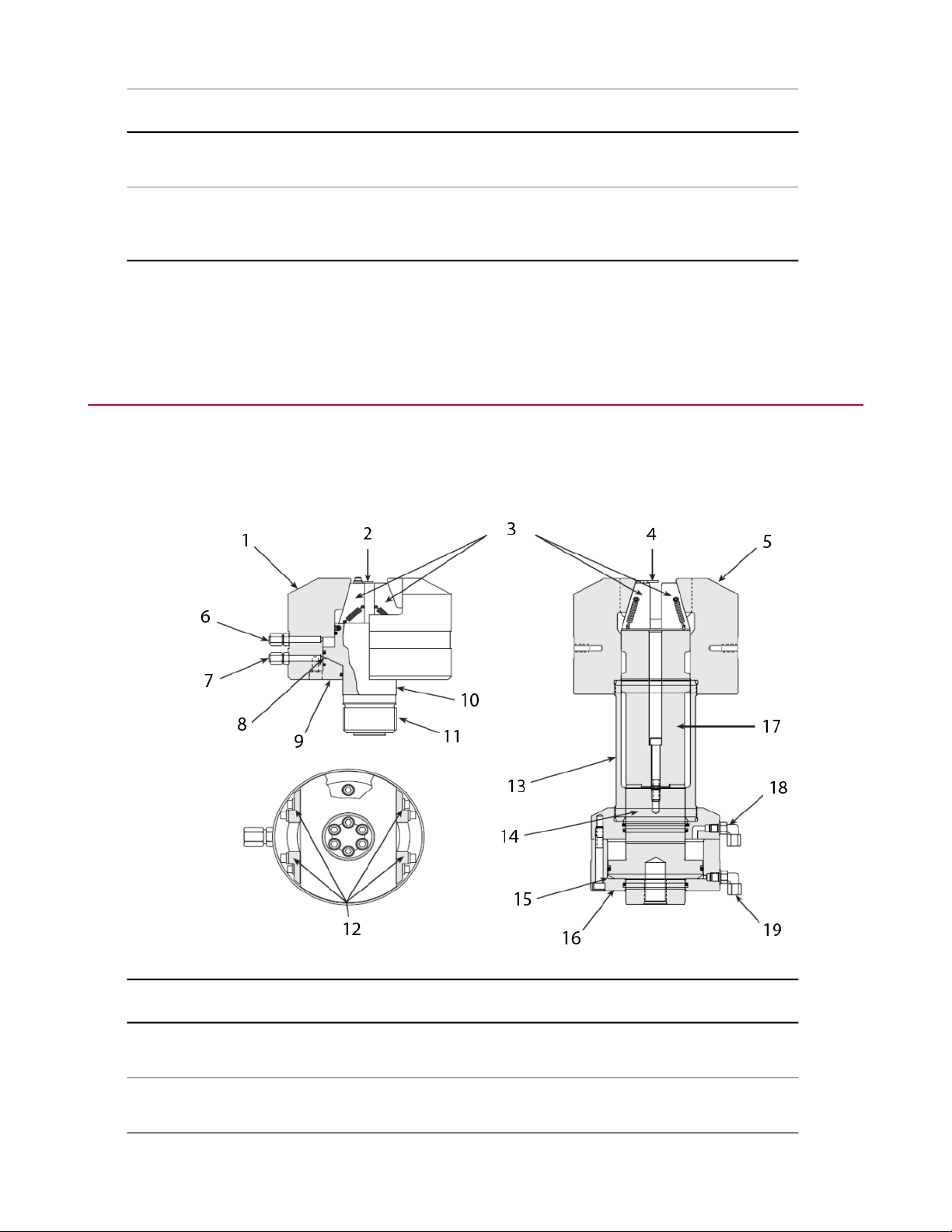

Series 647 Hydraulic Wedge Grips Functional Description

The Series 647 Hydraulic Wedge Grips are typically mounted in an MTS load unit to secure the specimen

under test. Hydraulic pressure to the grips is supplied by and adjusted at an external hydraulic grip supply.

The grips have a side loading design for quick and easy specimen installation.

DescriptionItemDescriptionItem

11Wedge Chamber1

2

only)

12Specimen Guide (flat specimens

Series 647 Hydraulic Wedge Grips Reference Manual 19

Anti-Rotate Adapter (Axial-Torsional

Only)

Anti-Rotate Blocks (Axial-Torsional

Only)

Introduction

DescriptionItemDescriptionItem

Cylinder13Wedges3

4

only)

Grip Piston10

Grip Piston14Specimen Guide (flat specimens

Preload Chamber15Wedge Chamber5

End Cap16Hydraulic Release6

Piston Extension17Hydraulic Pressure7

Hydraulic Release18Preload Chamber8

Hydraulic Pressure19End Cap9

About Gripping Specimens

The grips provide a constant, hydraulically actuated gripping force regardless of the applied test loads. The

specimen gripping force is adjustable to prevent specimen damage by the grips or specimen slippage during

the test. Each grip (upper and lower) is independently actuated. When actuated, the preload chamber locks

all moving grip parts in position, thus eliminating backlash when cycling between tension and compression.

The specimen can then be cycled from full tension through zero to full compression with no backlash.

Once a specimen is positioned between the grip wedges, hydraulic pressure is applied to the preload chamber.

This pressure pulls the wedge chamber toward the piston, forcing the wedges to clamp the specimen. The

pressure applied to the preload chamber can be adjusted to a level which clamps the specimen securely, but

does not damage the specimen by applying excessive gripping force.

About Wedges

Each grip model has its own selection of wedges. Not all wedge options are available for all grip models.

Three types of wedges are available for use with the grips: flat wedges, round wedges, and vee-notched

wedges.

• Flat wedges grip flat specimens. Both narrow and wide wedges are available.

• Round wedges can only grip a round specimen of a specific diameter.

• Vee-notched wedges can grip a range of round specimens.

Flat wedge surfaces can be finished with diamond serrations, with a Surfalloy coating, or a smooth finish.

• Diamond serrated surfaces can grip materials such as soft steels and plastics.

• Surfalloy surfaces can grip hard or brittle materials. Surfalloy incorporates a grit onto the wedge surface.

20 Series 647 Hydraulic Wedge Grips Reference Manual

• Smooth surfaces can grip specimens that cannot tolerate imperfections on the grip surface. This surface

also has a lower force rating.

Water-cooled wedges are available for applications where the specimen is heated. A water cooling kit includes

the parts to connect the wedges to a water source and regulate the water flow.

About Spiral Washers

The optional Model 601 Spiral Washers are commonly used when installing axial grips. They provide

fatigue-resistant connections between elements of the force train and minimize the effects of backlash.

The spiral washers are placed over the connector studs at each connection and adjusted to place a constant

preload on the stud. The spiral washers also minimize the possibility of backlash due to loose-fitting or worn

stud threads. When cyclic loads below the tensile force level of the preload are applied to the connections,

the load is distributed between the surfaces of the spiral washers and the stud in a ratio of the relative stiffness

of the parts. The spiral washers have a large surface area and therefore greater stiffness. They react to most

of the load and keep the stress in the stud below its fatigue runout level.

Introduction

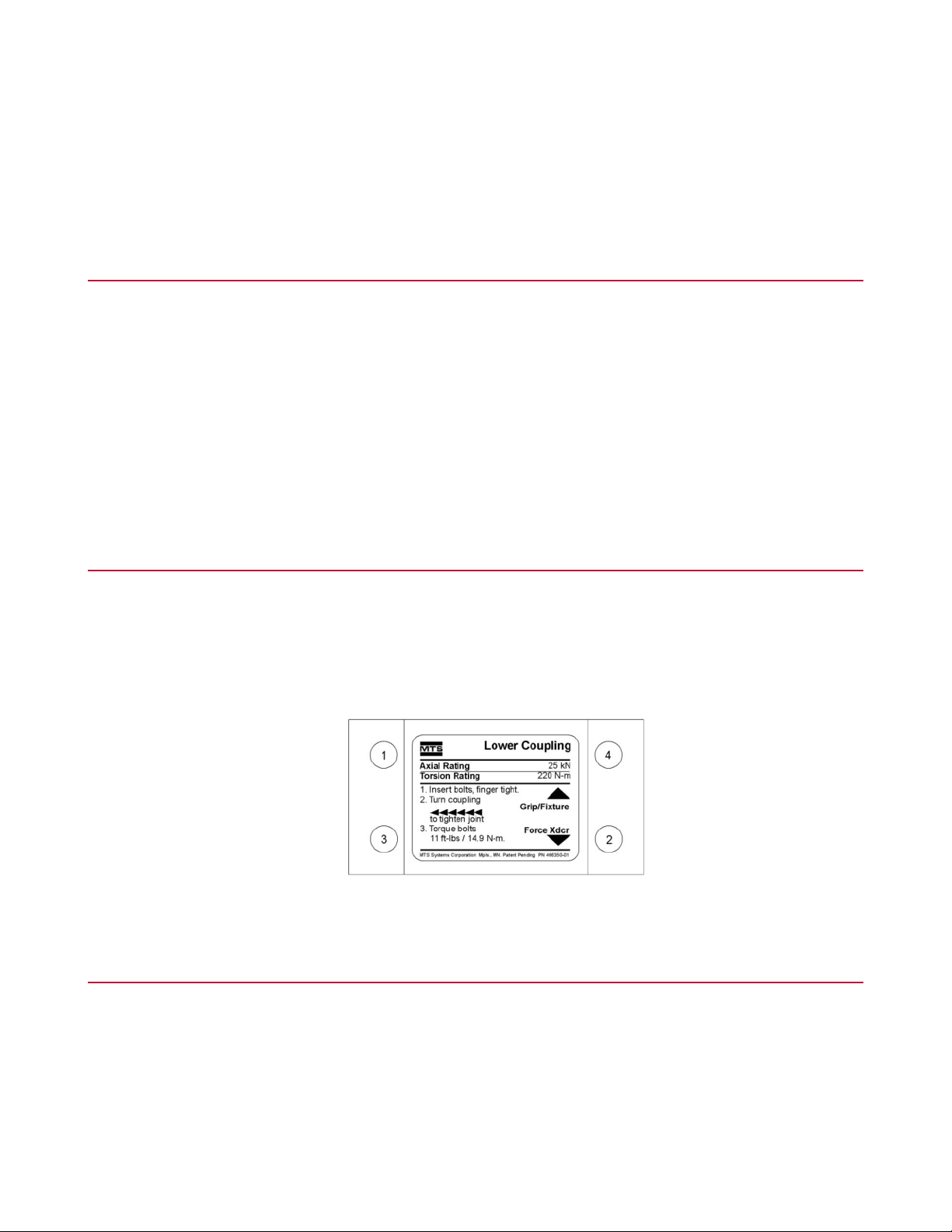

About Couplings

Special upper and lower couplings clamp the grips to the actuator and force transducer for axial-torsional

grips. Each coupling has two different thread patterns—a right-hand thread with a 3 mm pitch, and a left-hand

thread with a 2 mm pitch. Half of the coupling matches the thread of the grip, and the other half matches the

thread of the actuator or force transducer adapter. A label on each coupling indicates the direction to tighten,

torque rotation, and torque requirements. Here is an example:

About All Temperature Grips

The grip mechanism (the wedge chamber and wedges) is fully enclosed in the environmental chamber to

secure the specimen under test. The grip actuating mechanism (the end cap, preload chamber, and piston)

is outside the environmental chamber, eliminating the need for high-temperature hydraulic fluid and allowing

a broader temperature range for testing—from -129° to +315°C (-200° to +600°F) or -129° to +540°C (-200°

to +1000°F) depending on the grip model. With the grip mechanism inside the environmental chamber, the

thermal stresses caused by temperature gradients along the length of the specimen are minimized. The grip

actuating mechanism is water cooled/warmed to further protect it from temperature extremes.

Series 647 Hydraulic Wedge Grips Reference Manual 21

Introduction

About Environmental Chambers

The grips can be mounted for room temperature testing or testing in an environmental chamber. The

temperature range of the grips is determined by the type of seals used in the grips and the type of fluid used

for the grips. There are two methods for using grips in an environmental chamber (as shown in the following

figure).

DescriptionItem

Using Extension Rods with Axial GripsA

Using All Temperature GripsB

22 Series 647 Hydraulic Wedge Grips Reference Manual

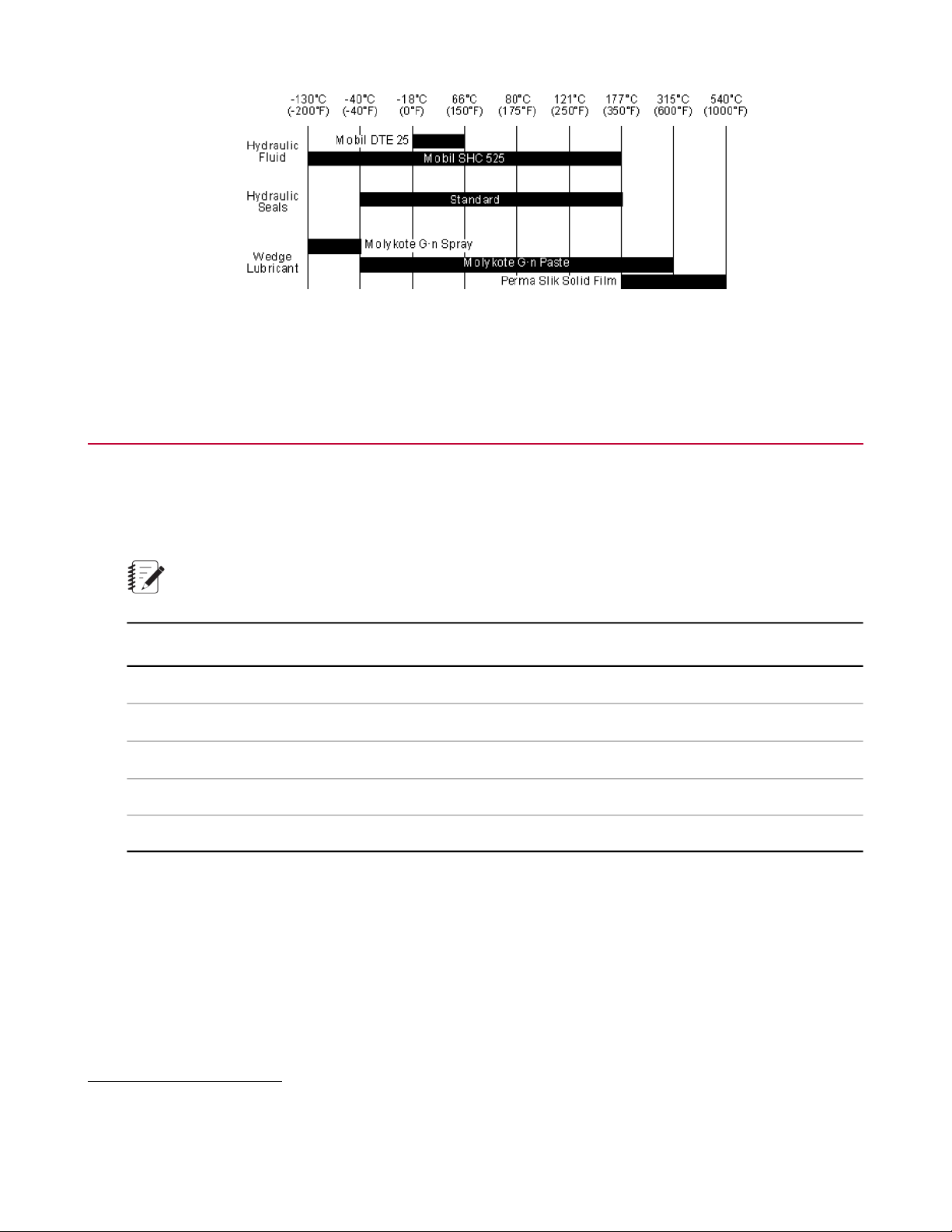

Hydraulic Fluid Recommendations

All frame mounted 3000 psi and 10,000 psi grip supplies use standard Mobile DTE-25 hydraulic fluid from

the HPU. The grips that use this fluid are rated to 65 °C (150 °F) maximum. All other hydraulic grips that are

used within a chamber are rated to maximum of 177 °C (350 °F). These grips require the use of a stand alone

grip supply that uses Mobile SHS 525 hydraulic fluid. This fluid has a flash point and overall temperature

rating higher than 177 °C (350 °F). MTS does not recommend the use of hydraulic grips that have hydraulic

fluid inside chambers rated at higher temperatures.

Cooling Water Specifications

SpecificationParameter

35°C (95°F) maximumTemperature

Introduction

3.8 L/min (1 gpm) minimum, at 0.276 MPa (40 psi)Flow

Quality

Water chemistry is critical for a successful grip cooling. Generally speaking, municipal

drinking water that is pollution free, bacteriologically safe, and has a neutral pH is

perfectly acceptable for grip cooling.

Series 647 Wedge Grip Temperature Ranges

The temperature range of the grips is determined by the type of seals used in the grips and the type of

hydraulic fluid used with the grips. The grips are available in the following temperature ranges:

• -40°C to 177°C (-40°F to 350°F)

• -130°C/315°C (-200°F/600°F)

• -130°C/540°C (-200°F/1000°F)

Not all grip models are available in all temperature ranges.

Series 647 Hydraulic Wedge Grips Reference Manual 23

Introduction

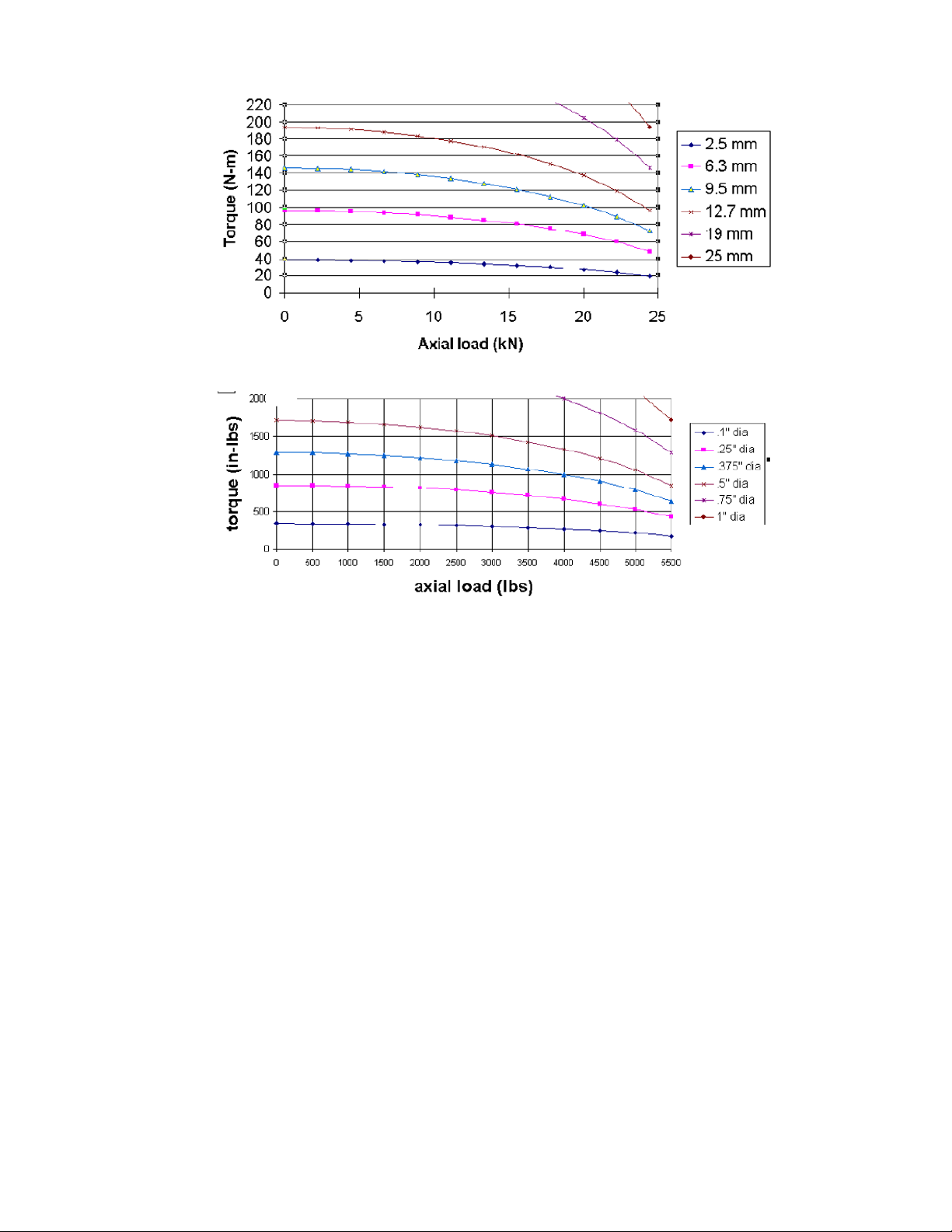

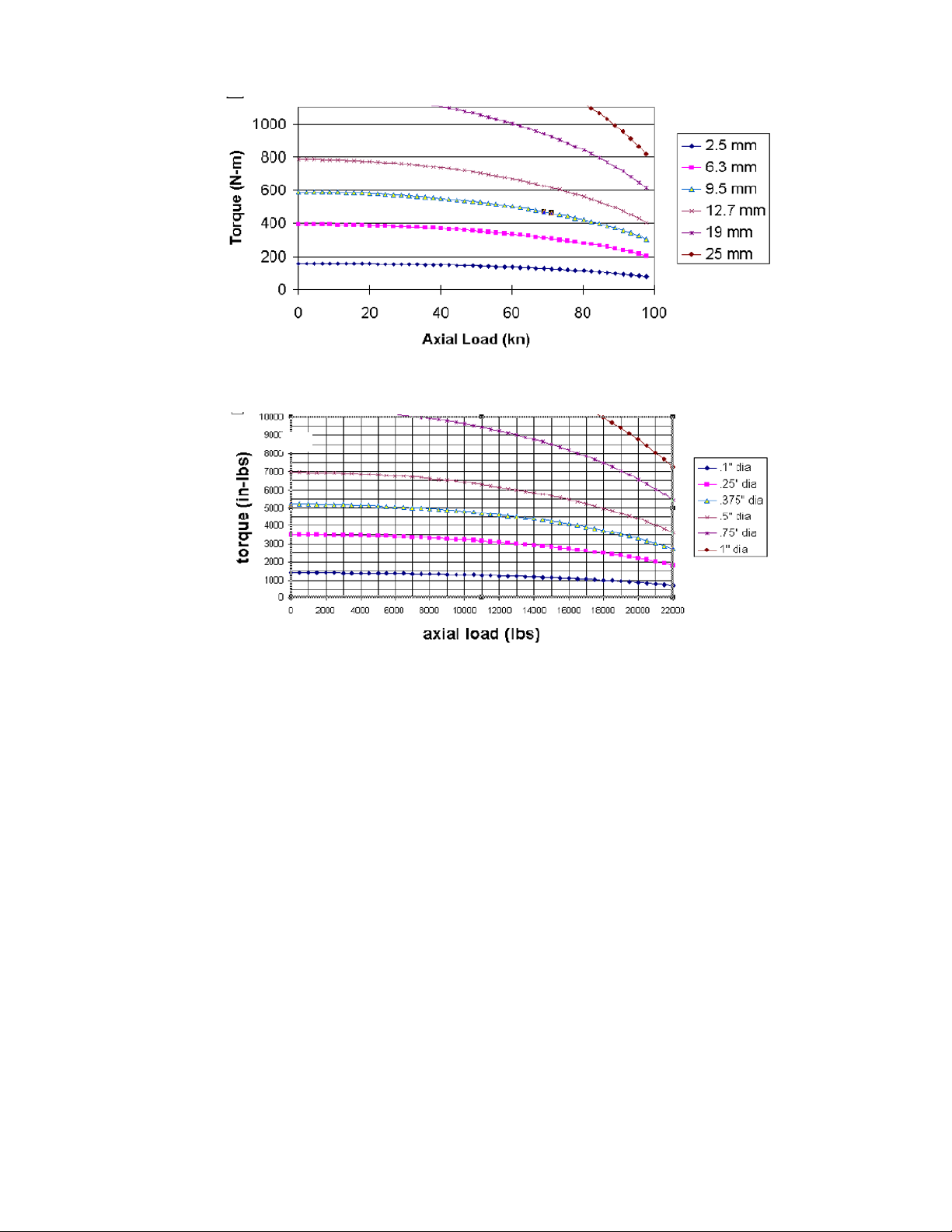

Series 647 Hydraulic Wedge Grip Force and Torque Capacities

The amount of torque the grips can produce is reduced with biaxial operation. The amount of torque is affected

by the amount of axial force and the diameter of the specimen. The graphs, which follow the table, illustrate

the axial-torsional performance envelope of the Model 647.02B and Model 647.10 Hydraulic Wedge Grips

and the Model 647.25 Axial-Torsional Wedge Grips.

Note:

Charts assume that edges for RND specimens are diamond face vee or RND wedges.

Grip PressureDynamic ForceStatic ForceModel

1

2

3

21 MPa (3,000 psi)25 kN (5.5 kip)31 kN (7 kip)647.02B

21 MPa (3,000 psi)100 kN (22 kip)120 kN (27 kip)647.10

69 MPa (10,000 psi)250 kN (55 kip)333 kN (75 kip)647.25

69 MPa (10,000 psi)500 kN (110 kip)550 kN (120 kip)647.50

69 MPa (10,000 psi)1000 kN (220 kip)1200 kN (264 kip)647.100

1

Torsional force for the axial-torsional version is 220 N·m (2,000 in·lb).

2

Torsional force for the axial-torsional version can be 550 N·m (5,000 in·lb) or 1100 N·m (10,000 in·lb).

3

Torsional force for the axial-torsional version is 2200 N·m (20,000 in·lb).

24 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

Model 647.02B Grip Maximum Torque versus Axial Load

Series 647 Hydraulic Wedge Grips Reference Manual 25

Introduction

Model 647.10 Grip Maximum Torque versus Axial Load

26 Series 647 Hydraulic Wedge Grips Reference Manual

Introduction

Model 647.25 Grip Maximum Torque versus Axial Load

Series 647 Hydraulic Wedge Grips Reference Manual 27

Safety

Topics:

•

General Safety Practices: Grips and Fixtures........................................................................................30

•

General Precautions for Environmental Components...........................................................................35

•

Hazard Placard Placement....................................................................................................................36

Series 647 Hydraulic Wedge Grips Reference Manual 29

Loading...

Loading...