MTS 632-85 User Manual

m

be certain.

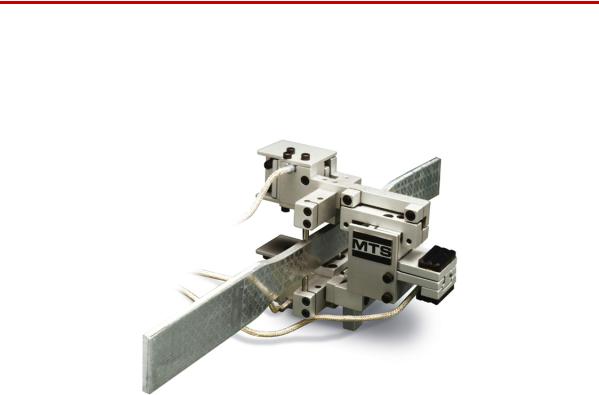

Model 632.85 Biaxial Extensometer

Product Information

011565200 B

Copyright information Trademark information

© 2014 MTS Systems Corporation. All rights reserved.

MTS is a registered trademark of MTS Systems Corporation within the United States. These trademarks may be protected in other countries.

All other trademarks or service marks are property of their respective owners.

Publication information |

Manual Part Number |

Publication Date |

|

|

|

|

011565200 A |

July 1986 |

|

|

|

|

011565200 B |

July 2014 |

|

|

|

2 |

Model 632.85 Biaxial Extensometer |

Contents

Introduction |

5 |

|

|

|

|

|

|

Specifications 7 |

|

|

|

Safety Information |

9 |

|

|

|

|

||

Safety Information Overview |

9 |

||

Read all manuals |

9 |

|

|

Personnel Qualifications 10 |

|

||

System Hazard Zones 10 |

|

||

Avoid Pinch and Crush Points |

10 |

||

Installation |

11 |

|

|

|

|

|

|

Specimen Mounting 11

Cabling 13

Maintenance 15

Model 632.85 Biaxial Extensometer |

3 |

4 |

Model 632.85 Biaxial Extensometer |

Introduction

The Model 632.85 Biaxial Extensometer provides axial and transverse outputs from a single extensometer. The biaxial extensometer is typically used when performing Poisson ratio testing, composites testing and metal formability testing.

The extensometer consists of three sensor units. Each sensor unit uses precision resistance-type, foil strain gages bonded to a metallic element to form a Wheatstone bridge circuit. Each axial sensor unit uses either a half or full Wheatstone bridge (depending upon the option selected) to measure axial deflection. The transverse sensor unit uses a full Wheatstone bridge to measure the transverse deflection.

Model 632.85 Biaxial Extensometer |

Introduction |

5 |

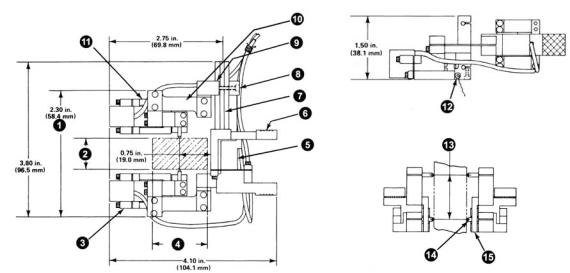

The design of the conical contact points allows the extensometer to be used on a wide variety of specimens. These same conical points are usable on specimens with circular as well as rectangular cross sections.

Item Description

1Plus specimen dimension R

2Specimen dimension R

3Axial sensor unit A

4Specimen dimension S

5Transverse sensor unit

6Grip pads

7Positioning arm

8Loosen these screws to adjust for specimen dimension R

9Slide bracket

10Compliance flexure

11Axial sensor unit B

12Zero set pin

13Axial gage length

14Conical point

15Overtravel stop plate

6 |

Introduction |

Model 632.85 Biaxial Extensometer |

Loading...

Loading...