MTS Insight - 1kN to 300kN User Manual

MTS Insight™ Material Testing Systems

Product Information

1kN to 300kN

l

100-146-666 E

Copyright information Trademark information

Contact information

© 2007 MTS Systems Corporation. All rights reserved.

MTS and TestWorks are registered trademarks of MTS Systems Corporation.

MTS Insight is a Trademark of MTS Systems Corporation.

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada) Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515 E-mail: info@mts.com http://www.mts.com

ISO 9001 Certified

Publication information

Manual Part Number |

Publication Date |

|

|

100-146-666 A |

January 2006 |

|

(build 041306) |

|

|

100-146-666 B |

June 2006 |

|

|

100-146-666 C |

June 2006 |

|

(build 081006) |

|

|

100-146-666 D |

December 2006 |

|

(build 051007) |

|

|

100-146-666 E |

May 2007 |

|

|

2 |

Insight Material Testing System |

Contents

Preface 5

About This Manual |

6 |

|

|

|

||

Conventions |

7 |

|

|

|

|

|

Technical Support |

9 |

|

|

|

|

|

EC Declaration of Conformity 13 |

|

|||||

MTS Insight 1 kN to 100 kN |

13 |

|||||

MTS Insight 150 kN to 300 kN |

14 |

|||||

Introduction |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

Description |

18 |

|

|

|

|

|

Specifications |

20 |

|

|

|

|

|

General Specifications |

20 |

|

|

|||

Model Specifications |

21 |

|

|

|||

Crosshead Detail |

34 |

|

|

|

||

Baseplate Detail |

35 |

|

|

|

||

Installation |

39 |

|

|

|

|

|

|

|

|||||

Moving the 1 kN and 2 kN Frames |

40 |

|||||

Moving the 5 kN and Higher Frames |

42 |

|||||

Machine location and ventilation |

43 |

|||||

Controller Connections 44 |

|

|

||||

Connecting the main power |

44 |

|

||||

Transformer Requirements for MTS Insight 150, 200 and 300 Machines 48 |

||||||

Installing cables |

50 |

|

|

|

||

Controller Connectors |

50 |

|

||||

Operation |

57 |

|

|

|

|

|

|

|

|

|

|

|

|

Hazard Icons |

58 |

|

|

|

|

|

Main Power Switch (I/O) and E-Stop |

59 |

|||||

Insight Material Testing System |

Contents |

3 |

Travel Limit Switches (Physical Limits) 60

Crush Zone Hazards |

62 |

|

Fixture Mounting |

63 |

|

Load Cell Mounting |

64 |

|

Handset Control |

68 |

|

Maintenance |

71 |

|

|

|

|

Appendix 73

Additional Digital I/O Information 73

4 |

Contents |

Insight Material Testing System |

Preface

Safety first! Before you attempt to use your MTS equipment in your test system, read and understand the Safety manual. Like an automobile, your test system is very useful—but if misused, it is capable of deadly force. You should not be afraid of your test system, but you should always maintain a healthy respect for it.

Improper installation, operation, or maintenance of MTS equipment in your test system can result in hazardous conditions that can cause severe personal injury or death, and damage to your equipment and specimen. Again, read and understand the Safety manual before you continue. It is very important that you remain aware of hazards that apply to your test system.

Contents |

About This Manual |

6 |

|

|

Conventions 7 |

|

|

|

Technical Support |

9 |

|

|

EC Declaration of Conformity |

13 |

|

|

MTS Insight 1 kN to 100 kN |

13 |

|

MTS Insight 150 kN to 300 kN 14

Insight Material Testing System |

Preface |

5 |

About This Manual

About This Manual

Purpose This manual provides detailed information about the MTS Insight™ Material Testing Systems. The information includes an overview of all the models available, installation, operation, and maintenance.

Summary This manual includes the following sections.

Introduction This section reviews the MTS Insight material testing system models, gives you a description of a typical frame, and lists the environmental specifications. This section also provides the technical frame specifications of each MTS Insight frame model and line drawings of the crosshead and baseplate details.

Installation This section gives you specific instructions for properly moving MTS Insight frames, cable installation, and line drawings of the basic controller.

Operation This section provides a graphic of the manual handset control and handset functions. Other areas such as travel limit switches and fixture and load cell mounting are reviewed.

Maintenance This section gives you a complete guide to the preventive maintenance schedule for all MTS Insight frames.

6 |

Preface |

Insight Material Testing System |

Conventions

Conventions

Hazard conventions

Danger notices

The following paragraphs describe some of the conventions that are used in your MTS manuals.

Hazard notices are embedded in this manual and contain safety information that is specific to the task to be performed. Hazard notices immediately precede the step or procedure that may lead to an associated hazard. Read all hazard notices carefully and follow the directions that are given. Three different levels of hazard notices may appear in your manuals. Following are examples of all three levels.

Note For general safety information, see the Safety manual included with your system.

Danger notices indicate the presence of a hazard which will cause severe personal injury, death, or substantial property damage if the danger is ignored. For example:

DANGER

DANGER

Warning notices

High intensity light and dangerous radiation are emitted by class 3B lasers.

Viewing a class 3b laser directly or viewing it using optical instruments will cause immediate and severe injury.

Avoid eye or skin exposure to the laser beam. Ensure that all power to the laser is off before attempting any maintenance, service, or adjustment procedure.

Warning notices indicate the presence of a hazard which can cause severe personal injury, death, or substantial property damage if the warning is ignored. For example:

WARNING |

Hazardous fumes can accumulate in the test chamber as a result of |

|

|

|

testing. |

Breathing hazardous fumes can cause nausea, fainting, or death.

Ensure the chamber is properly ventilated before you open the chamber door or put your head or hands into the chamber. To do this, ensure the temperature controller is off and allow sufficient time for the ventilation system to completely exchange the atmosphere within the chamber.

Insight Material Testing System |

Preface |

7 |

Conventions

Caution notices Caution notices indicate the presence of a hazard which will or can cause minor personal injury, cause minor equipment damage, or endanger test integrity if the caution is ignored. For example:

CAUTION

CAUTION

Other conventions

Notes

This specimen can develop sharp edges as a result of testing.

Handling the specimen with unprotected hands can result in cuts and slivers.

Always wear protective gloves when you handle the specimen.

Other conventions used in your manuals are described below:

Notes provide additional information about operating your system or highlight easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be aware that these illustrations are examples only and do not necessarily represent your actual system configuration, test application, or software.

Electronic manual conventions

Hypertext links

This manual is available as an electronic document in the Portable Document File (PDF) format. It can be viewed on any computer that has Adobe Acrobat Reader installed.

The electronic document has many hypertext links displayed in a blue font. All blue words in the body text, along with all contents entries and index page numbers are hypertext links. When you click a hypertext link, the application jumps to the corresponding topic.

8 |

Preface |

Insight Material Testing System |

Technical Support

Technical Support

Start with your manuals

Technical support numbers

MTS web site

www.mts.com

E-mail:

Telephone

Fax

The manuals supplied by MTS provide most of the information you will need to use and maintain your equipment. If your equipment includes MTS software, you should look for README files for additional product information.

If you cannot find answers to your technical questions from these sources, you can use the internet, telephone, or fax to contact MTS for assistance. You can also fill out the Problem Submittal Form that is available on the MTS web site and in the back of many MTS manuals that are distributed in paper form.

MTS provides a full range of support services after your system is installed. If you have any questions about a system or product, contact MTS in one of the following ways.

The MTS web site gives you access to our technical support staff by means of a Problem Submittal Form and a Technical Support link.

•Problem Submittal Form:

www.mts.com > Contact MTS > Problem Submittal Form

•Technical Support:

www.mts.com > Contact MTS > Service & Technical Support

General information: info@mts.com

Technical support: em.techsupport@mts.com

HELPLine 800-328-2255

Weekdays 7:00 A.M. to 6:00 P.M.,

Central Time

952-937-4515

Please include an MTS contact name if possible.

Insight Material Testing System |

Preface |

9 |

Technical Support

Before you MTS can help you more efficiently if you have the following information contact MTS available when you contact us for support.

Know your site number The site number contains your company number and identifies your

and system number equipment type (material testing, simulation, and so forth). The number is usually written on a label on your MTS equipment before the system leaves MTS. If you do not have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system project number identifies which system you are calling about. You can find your project number in the papers sent to you when you ordered your system.

Know information from prior technical assistance

Example system project number: US1.30123

If you have contacted MTS about this problem before, we can recall your file. You will need to tell us the:

•MTS notification number

•Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the following questions.

•How long has the problem been occurring?

•Can you reproduce the problem?

•Were any hardware or software changes made to the system before the problem started?

•What are the model and serial numbers of the suspect equipment?

Know relevant computer information

If you are experiencing a computer problem, have the following information available.

•Manufacturer’s name and model number

•Operating software type and service patch information. Examples:

–Windows XP Service Pack 1 (SP1)

–Windows 2000 Service Pack 3 (SP3)

•Amount of system memory. Example: 512 MB of RAM.

•Amount of free space on the hard drive in which the application resides. Example: 11.2 GB free space, or 72% free space.

•Current status of hard-drive fragmentation. Example: 3% total fragmentation.

10 |

Preface |

Insight Material Testing System |

Know relevant software information

If you contact MTS by phone

Identify system type

Be prepared to troubleshoot

Technical Support

For MTS software application problems, have the following information available.

•TestWorks 4 version; for example Version 4.09

•Names of other non-MTS applications that are running on your computer, such as screen savers, keyboard enhancers, print spoolers, and so forth

Your call will be registered by a HELPLine agent if you are calling within the United States or Canada. Before connecting you with a technical support specialist, your agent will ask you for your site number, name, company, company address, and the phone number where you can normally be reached.

To assist your HELPLine agent with connecting you to the most qualified technical support specialist available, identify your MTS Insight system as an electromechanical materials test system.

Prepare yourself for troubleshooting while on the phone.

•Call from a telephone close to the system so that you can try implementing suggestions made over the phone.

•Have the original operating and application software media available.

•If you are not familiar with all aspects of the equipment operation, have an experienced user nearby to assist you.

Insight Material Testing System |

Preface |

11 |

Technical Support

Write down relevant Prepare yourself in case we need to call you back.

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action is taken regarding your problem or request. If you have questions about the status of your problem or have additional information to report, please contact MTS again.

Problem Submittal Form in MTS manuals

In addition to the Problem Submittal Form on the MTS web site, there is also a paper version of this form (postage paid) in the back of many MTS manuals. Use this form to forward problems you are experiencing with your MTS equipment, whether it be software, hardware, manuals, or service. This form includes check boxes that allow you to select when you expect us to respond to your input. We guarantee a timely response—your feedback is important to us.

12 |

Preface |

Insight Material Testing System |

EC Declaration of Conformity

EC Declaration of Conformity

MTS Insight 1 kN to 100 kN

Description of Model

Manufacturer

Directives

Standards

MTS Insight Material Testing System 1 kN to 100 kN. This includes the following sub-systems of the machine: Frame, Motor, Amplifier, Controller, Transformer (1 kN to 50 kN only), Handset and Cables (guard is customer option).

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN, USA 55344-2290

Phone: 952-937-4000

Low Voltage directive 73/23/EEC, the EMC directive 89/336/EEC and the Machinery Safety Directive 98/37/EC.

EN 61010-1: Safety requirements for electrical equipment for measurement, control and laboratory use, Part 1: General requirements

EN 61326-1: Electrical equipment for measurement, control and laboratory use, EMC requirements.

EN 55011: Specification for limits and methods of measurement of radio disturbance characteristics of industrial, scientific and medical (ISM) radio frequency equipment (1991). Group 1, class A (non-domestic where RF is NOT used in the treatment of material).

Description |

Basic Standard |

Test specification |

|

|

|

Limits for harmonic current emissions |

EN 61000-3-2 |

Class A |

|

|

|

Limits for voltage fluctuations and flicker |

EN 61000-3-3 |

Class A |

|

|

|

Electrostatic discharge |

EN 61000-4-2 4 kV contact discharge |

|

|

|

4 kV air discharge |

|

|

|

Radio frequency electromagnetic field, |

EN 61000-4-3 |

3 V/m |

amplitude modulated |

|

|

|

|

|

Electrical fast transient |

EN 61000-4-4 |

0.5 kV control and signal |

|

|

1 kV mains |

|

|

|

Insight Material Testing System |

Preface |

13 |

EC Declaration of Conformity

Description |

Basic Standard |

Test specification |

|

|

|

Surge immunity test |

EN 61000-4-5 |

0.5 kV line to line |

|

|

1 kV line to ground |

|

|

|

Radio frequency common mode, amplitude |

EN 61000-4-6 |

3 V (rms) |

modulated |

|

|

|

|

|

Power frequency magnetic field |

EN 61000-4-8 |

30 A (rms)/m |

|

|

|

Voltage dips, short interruptions and voltage |

EN 61000-4-11 |

1 cycle/100% |

variations |

|

|

|

|

|

Radiated emissions |

EN 55011 |

|

|

|

|

Conducted emissions |

EN 55011 |

|

|

|

|

MTS Insight 150 kN to 300 kN

Description of Models

Manufacturer

Directives

Standards

MTS Insight Material Testing System 150kN, 200 kN and 300 kN. This includes the following sub-systems of the machine: Frame, Motor, Amplifier, Controller, Handset and Cables (guard is customer option).

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN, USA 55344-2290

Phone: 952-937-4000

Low Voltage directive 73/23/EEC, the EMC directive 89/336/EEC and the Machinery Safety Directive 98/37/EC.

EN 61010-1: Safety requirements for electrical equipment for measurement, control and laboratory use, Part 1: General requirements

EN 61326-1: Electrical equipment for measurement, control and laboratory use EMC requirements Part 1: General requirements.

EN 55011: Specification for limits and methods of measurement of radio disturbance characteristics of industrial, scientific and medical (ISM) radio frequency equipment (1991). Group 1, class A (non-domestic where RF is NOT used in the treatment of material).

14 |

Preface |

Insight Material Testing System |

|

|

EC Declaration of Conformity |

Description |

Basic Standard |

Test specification |

Electrostatic discharge |

EN 61000-4-2 |

4 kV contact discharge |

|

|

4 kV air discharge |

Radio frequency electromagnetic field, |

EN 61000-4-3 |

3 V/m |

amplitude modulated |

|

|

Electrical fast transient |

EN 61000-4-4 |

0.5 kV control and signal |

|

|

1 kV mains |

Surge immunity test |

EN 61000-4-5 |

Mains 0.5 kV line to line |

|

|

1 kV line to ground |

Radio frequency common mode, amplitude |

EN 61000-4-6 |

3 V (rms) |

modulated |

|

|

Power frequency magnetic field |

EN 61000-4-8 |

30 A (rms)/m |

Voltage dips, short interruptions and voltage |

EN 61000-4-11 |

1 cycle/100% |

variations |

|

|

Radiated emissions |

EN 55011 |

|

Conducted emissions |

EN 55011 |

|

Signed:

Name: Phil Leise

Title: Product Manager

Date: 01 December 2006

Insight Material Testing System |

Preface |

15 |

EC Declaration of Conformity

16 |

Preface |

Insight Material Testing System |

Introduction

Contents

Inappropriate use

The MTS Insight™ product series is the latest generation of electromechanical material testing equipment from MTS. The purpose of this manual is to help you understand your testing system, its capabilities, and operating requirements. This manual provides technical information for all MTS Insight material testing frames; from the lowest force model (1 kN), to the highest (300 kN). Read each section carefully and refer to the manual whenever you need assistance.

Description 18

Specifications 20

Model Specifications 21

Crosshead Detail 34

Baseplate Detail 35

Before you attempt to use the Insight Material Testing System, read and understand your manual that accompanies this product. Improper installation or operation of this product can result in hazardous conditions that can cause severe personal injury or death, and damage your equipment and specimen.

Insight Material Testing System |

Introduction |

17 |

Description

Description

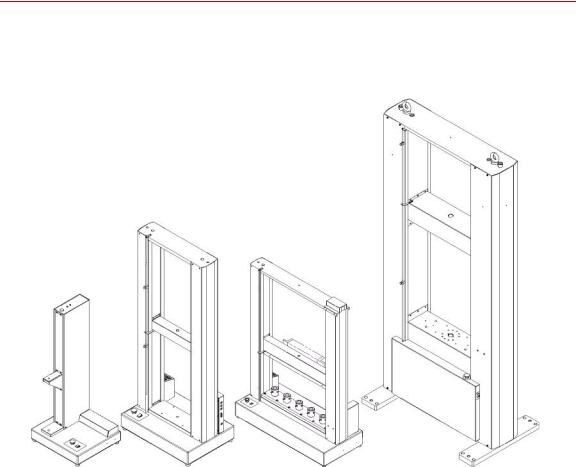

Every MTS Insight material testing system is comprised of a load frame,

electronic frame controller, and TestWorks® software. The following figure shows the external features of the various MTS Insight load frames.

1 kN and 2 kN |

2 kN EL High-Speed and |

50 kN W and |

100 kN through 300 kN |

|

5 kN through 50 kN |

50 kN W Mulihead (shown) |

|

The personal computer is also an integral part of the system. It runs TestWorks software which provides full machine control, data acquisition and management, and advanced data analysis and presentation. MTS has minimized the amount of custom electronics required for your system, thereby making it flexible and reliable. This is done by connecting the frame and the computer via standard USB 2.0 connectors.

18 |

Introduction |

Insight Material Testing System |

Frame controller

Software

Description

The load frame has a rectangular shape and includes a base unit and one or two vertical columns. The two column models have a fixed upper transverse member. The moving crosshead is driven by precision ball screws on the load frame. The crosshead is coupled to the ball screw(s) with high-strength, precision ball nuts and rides on the ball bearings. This configuration is very efficient in minimizing friction and wear. The ball screws are anti-backlash. This feature removes the backlash so that position can be measured with increased accuracy over nonpreloaded ball screws.

The screws are driven by a series of pulleys and belts which in turn are driven by a precision dc servo motor on the MTS Insight 1 through MTS Insight 50 models and an ac brushless motor on the higher force models. The ball screw is connected to an optical encoder for precise position and velocity control.

The frame controller is responsible for the following:

•Provides main data and signal processing power

•Detects the activation of limit switches

•Provides the interface between the software (computer) and the frame

•Provides digital servo control—for speed and position accuracy

•Responsible for self-ID load cell and frame

•Handset interface

•Programmable, 1000 Hz maximum, data acquisition rate

•Management of frame power

TestWorks 4 is a versatile software program offering you a host of features that will make the material testing process fast and easy to use. The software has various method templates available. The method templates in the General Testing Package provide a starting point in configuring test methods that conform with your testing needs. The General Testing Package is separated into 4 specific testing categories.

•MTS Tensile

•MTS Compression

•MTS Flex

•MTS Peel-Tear

Many additional features can be purchased to meet your company’s specific needs. Some of these features might already be part of the system you ordered, or they can be added to your system as your requirements change. Refer to the TestWorks manual for additional information.

Insight Material Testing System |

Introduction |

19 |

Specifications

Specifications

This section provides general specifications for the MTS Insight Material Testing System frames and illustrations of the crosshead and baseplate threaded hole patterns for mounting fixtures.

Note At the time of this printing, some specifications have not been tested and calculated specifications are provided in the following tables. Consequently, specifications are subject to change without notice. Contact MTS for verification if critical specifications.

General Specifications

The following specifications are for all MTS Insight frames. Specifications for the specific models and in the following tables.

Parameter |

Specification |

|

|

Environmental |

For indoor use only |

Temperature |

5 to 40 °C |

Relative humidity |

10 to 85%, noncondensing |

Altitude |

For use at altitudes up to 2000 m |

|

(6500 ft) |

|

|

Power |

|

Insulation over voltage |

Category II |

Pollution degree |

2 |

|

|

20 |

Introduction |

Insight Material Testing System |

Specifications

Model Specifications

Specifications for MTS Insight 1 and MTS Insight 1 EL

Specifications |

MTS Insight 1 |

MTS Insight 1 EL |

Force Capacity |

1 kN (225 lbf) |

1 kN (225 lbf) |

|

|

|

Minimum Test Speed |

0.001 mm/min. (0.00004 in./min.) |

0.001 mm/min (0.00004 in./min.) |

|

|

|

Maximum Test Speed |

1500 mm/min. (59 in./min.) |

1500 mm/min. (59 in./min.) |

|

|

|

Force Capacity |

1 kN (225 lbf) |

1 kN (225 lbf) |

@ max. test speed |

|

|

|

|

|

Maximum Test Speed |

1500 mm/min. (59 in./min.) |

1500 mm/min. (59 in./min.) |

@rated force capacity |

|

|

|

|

|

Crosshead Return Speed |

1500 mm/min. (59 in./min.) |

1500 mm/min. (59 in./min.) |

|

|

|

Vertical Test Space |

750 mm (29.5 in.) |

1000 mm (39.5 in.) |

(crosshead travel) |

|

|

|

|

|

Horizontal Test Space |

104 mm (4.1 in.) |

104 mm (4.1 in.) |

(centerline to rear column) |

|

|

|

|

|

Position Resolution |

0.001 mm (0.00004 in.) |

0.001 mm (0.00004 in.) |

|

|

|

Position Accuracy |

0.01 mm (0.0004 in.) |

0.01 mm (0.0004 in.) |

|

|

|

Speed Accuracy % of set speed |

±0.05 |

±0.05 |

|

|

|

Motor Type |

Precision DC Servo Motor |

Precision DC Servo Motor |

|

|

|

Drive System Type |

DC 4 Quadrant Motor Drive |

DC 4 Quadrant Motor Drive |

|

|

|

Position Measurement |

Optical Encoder |

Optical Encoder |

|

|

|

Ball Screw Type |

Anti-backlash |

Anti-backlash |

|

|

|

Height/Width/Depth |

1136 X 490 X 450 mm |

1394 X 490 X 450 mm |

|

(45 X 19 X 18 in.) |

(55 X 19 X 18 in.) |

|

|

|

Weight |

50 kg (110 lb) |

55 kg (122 lb) |

|

|

|

Power |

5/3 Amps |

5/3 Amps |

|

120/220-240 Vac |

120/220-240 Vac |

|

50/60 Hz |

50/60 Hz |

|

Single phase |

Single phase |

|

|

|

Insight Material Testing System |

Introduction |

21 |

Specifications

Specifications for MTS Insight 2 and MTS Insight 2 EL

Specifications |

MTS Insight 2 |

MTS Insight 2 EL |

Force Capacity |

2 kN (450 lbf) |

2 kN (450 lbf) |

|

|

|

Minimum Test Speed |

0.001 mm/min. (0.00004 in./min.) |

0.001 mm/min. (0.00004 in./min.) |

|

|

|

Maximum Test Speed |

1000 mm/min. (39.4 in./min.) |

1000 mm/min. (39.4 in./min.) |

|

|

|

Force Capacity |

2 kN (450 lbf) |

2 kN (450 lbf) |

@ max. test speed |

|

|

|

|

|

Maximum Test Speed |

1000 mm/min. (39.4 in./min.) |

1000 mm/min. (39.4 in./min.) |

@rated force capacity |

|

|

|

|

|

Crosshead Return Speed |

1500 mm/min. (59 in./min.) |

1500 mm/min. (59 in./min.) |

|

|

|

Vertical Test Space |

750 mm (29.5 in.) |

1000 mm (39.5 in.) |

(crosshead travel) |

|

|

|

|

|

Horizontal Test Space |

104 mm (4.1 in.) |

104 mm (4.1 in.) |

(centerline to rear column) |

|

|

|

|

|

Position Resolution |

0.001 mm (0.00004 in.) |

0.001 mm (0.00004 in.) |

|

|

|

Position Accuracy |

0.01 mm (0.0004 in.) |

0.01 mm (0.0004 in.) |

|

|

|

Speed Accuracy % of set speed |

±0.05 |

±0.05 |

|

|

|

Motor Type |

Precision DC Servo Motor |

Precision DC Servo Motor |

|

|

|

Drive System Type |

DC 4 Quadrant Motor Drive |

DC 4 Quadrant Motor Drive |

|

|

|

Position Measurement |

Optical Encoder |

Optical Encoder |

|

|

|

Ball Screw Type |

Anti-backlash |

Anti-backlash |

|

|

|

Height/Width/Depth |

1136 X 490 X 450 mm |

1394 X 490 X 450 mm |

|

(45 X 19 X 18 in.) |

(55 X 19 X 18 in.) |

|

|

|

Weight |

50 kg (110 lb) |

55 kg (119 lb) |

|

|

|

Power |

5/3 Amps |

5/3 Amps |

|

120/220-240 Vac |

120/220-240 Vac |

|

50/60 Hz |

50/60 Hz |

|

Single phase |

Single phase |

|

|

|

22 |

Introduction |

Insight Material Testing System |

Specifications

Specifications for MTS Insight 2 EL High-Speed

Specifications |

MTS Insight 2 EL High Speed |

|

|

Force Capacity |

2 kN (450 lbf) |

|

|

Minimum Test Speed |

0.003 mm/min. (0.00012 in./min.) |

|

|

Maximum Test Speed |

2540 mm/min. (100 in./min.) |

|

|

Force Capacity |

2 kN (450 lbf) |

@ max. test speed |

|

|

|

Maximum Test Speed |

2540 mm/min. (100 in./min.) |

@rated force capacity |

|

|

|

Crosshead Return Speed |

2540 mm/min. (100 in./min.) |

|

|

Vertical Test Space |

1400 mm (55 in.) |

(crosshead travel) |

|

|

|

Horizontal Test Space |

405 mm (15.9 in.) |

(space between columns) |

|

|

|

Position Resolution |

0.003 mm (0.00012 in.) |

|

|

Position Accuracy |

0.03 mm (0.0012 in.) |

|

|

Speed Accuracy % of set speed |

±0.05 |

|

|

Motor Type |

Precision DC Servo Motor |

|

|

Drive System Type |

DC 4 Quadrant Motor Drive |

|

|

Position Measurement |

Optical Encoder |

|

|

Ball Screw Type |

Anti-backlash |

|

|

Guide Columns |

Two |

|

|

Height/Width/Depth |

1900 X 650 X 450 mm |

|

(74.75 X 26 X 18 in.) |

|

|

Weight |

123 kg (261 lb) |

|

|

Power |

5/3 Amps |

|

120/220-240 Vac |

|

50/60 Hz |

|

Single phase |

|

|

Insight Material Testing System |

Introduction |

23 |

Loading...

Loading...