Honeywell S8610U User Manual

69-1955-01

®

Automatic Ignition Systems

ANSI Z21.20

S8610U Universal Intermittent

WARNING

Pilot Gas Ignition Control

SUPER TRADELINE

APPLICATION

The SUPER TRADELINE® S8610U Universal

Intermittent Pilot Gas Ignition Control Module is designed

to provide easy field replacement of a wide range of

intermittent pilot ignition modules manufactured by

Honeywell, Robertshaw, Johnson Controls, and others.

The S8610U control provides ignition sequence, flame

monitoring, and safety shutoff for intermittent pilot central

furnaces, residential boilers, and other heating

appliances. The S8610U replaces existing flame

rectification type, intermittent pilot ignition modules with

the following characteristics:

• Single rod (local sense) or two rod (remote sense)

flame sensing

• Non-100 percent shutoff, 100 percent shutoff/lockout,

or 100 percent shutoff/continuous retry

• Natural or LP gas

• Shutoff/lockout times of 15 seconds or longer

• Prepurge configurable to 30 seconds or no prepurge

• Pilot burners with flow rates of 1,500 Btuh or less

• With or without integral damper connector

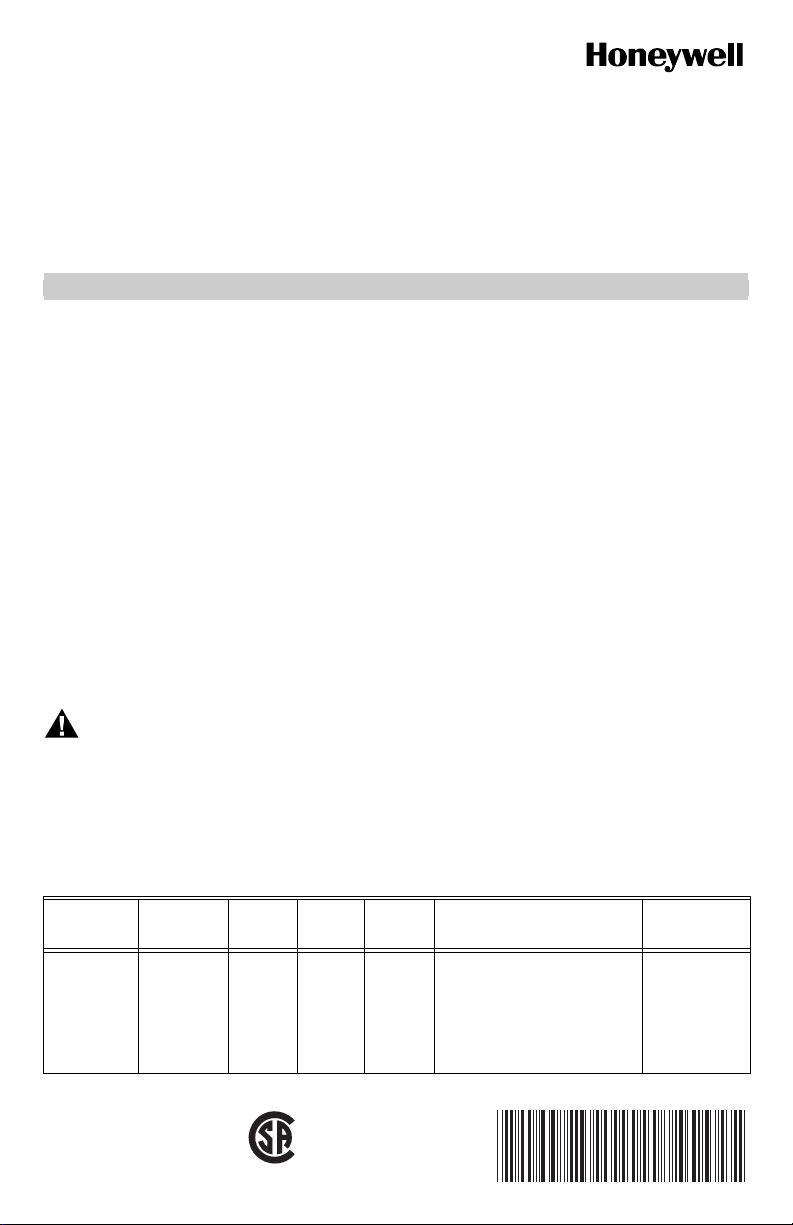

Table 1 describes the key features of the S8610U control.

Check Table 2 on page 2 before replacing an

existing intermittent pilot control with the S8610U.

If the existing control is not listed, do not use the

S8610U to replace it unless you are certain the

specifications match those of the existing control.

Table 1. S8610U Universal Intermittent Pilot Gas Ignition Control.

Igniter-Sensor

Typ e

Separate

(two rod; remote

flame sensing)

or

Combination

(one rod; local

flame sensing)

Valve Current

Rating

@ 24 Vac

1.0 A Pilot

and

2.0 A Main

Prepurge

Timing

None or 30

seconds

(field

selectable)

Trial fo r

Pilot

Ignition

15 or 90

seconds

(field

selectable)

®

INSTALLATION INSTRUCTIONS

A complete list of the specific Honeywell and other

modules that the SUPER TRADELINE

designed to replace is provided in Table 2 on page 2.

The SUPER TRADELINE® S8610U package contains

complete, easy-to-use instructions, plus the accessories

required to adapt the existing spark cable (Rajah, stud,

nail, or other) to the spark terminal on the control module.

It also help assure proper marking of the wires attached

to the existing control and a label with LED code

information that can be affixed in the appliance.

IMPORTANT

The S8610U control module is not designed to

replace controls with:

— Flame sensing other than by flame rectification

(White Rodgers Cycle-Pilot

thermal sensing)

— Standing pilot appliances

— Direct main burner ignition

The S8610U provides:

• Natural or LP gas

• Pilot burner ignition using an internally generated high

voltage spark

• Flame rectification circuit to monitor flame presence

• Monitoring of 24 Vac, pilot, and main gas valve

• LED indicator for flame presence/strength and system

status/errors

• Vent Damper connection

• Connections for flame reading via standard microammeter.

The S8610U is designed for a wide variety of natural or

liquid propane fueled applications.

Ignition

Sequence

Typ e

Retry Spark and pilot gas ON until lightoff or trial

Ignition Sequence

(After prepurge, if prepurge is

selected)

for ignition ends.

• If established flame is lost, trial for

ignition restarts immediately.

• If pilot fails to light, pilot gas and spark

Off (100% shutoff). After 5 minute delay,

a new trial for ignition is initiated. This

sequence continues until lightoff or “Call

for Heat” is removed.

®

S8610U is

®

, or Robertshaw

Included for use as

needed.

• If initially installed

Integral

Damper

Connector

and powered up

with damper

attached, unit

must always have

a vent damper

connected.

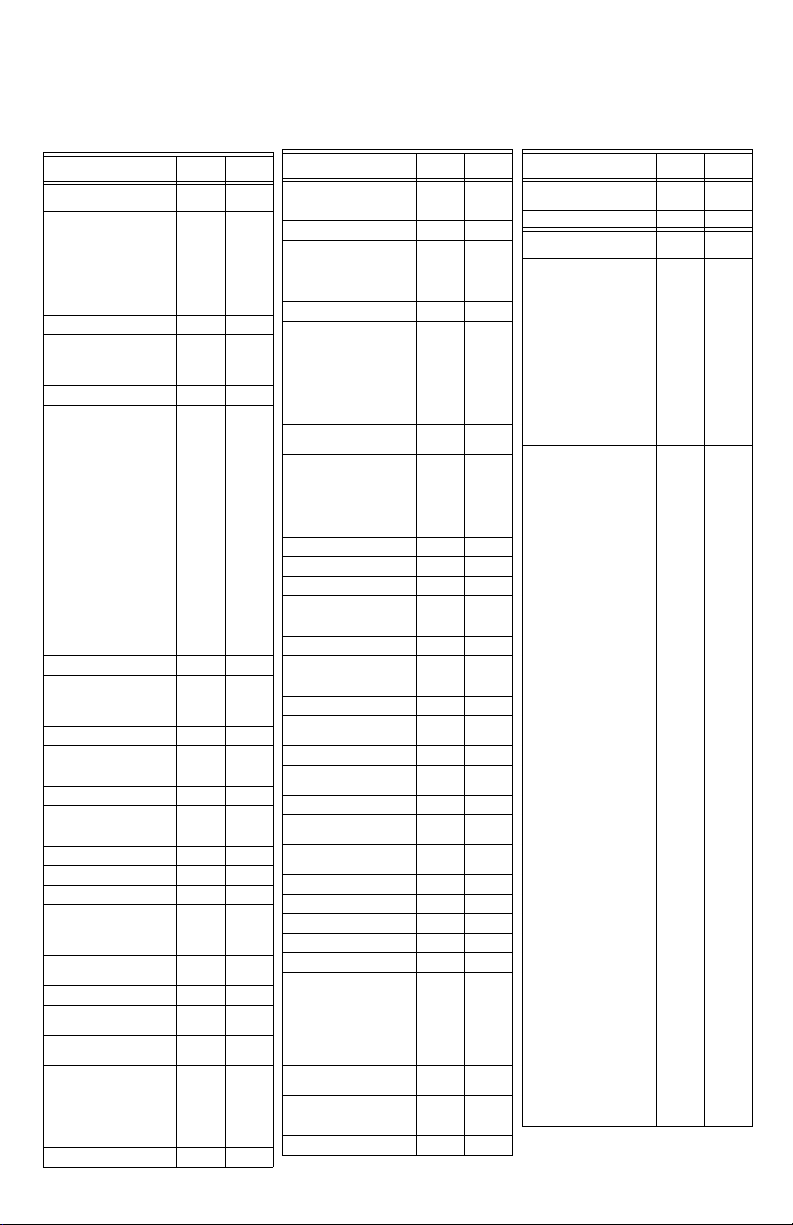

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

For module replacement, the following table indicates the proper Dip Switch settings for Prepurge timing (SW1) and

Trial For Ignition timing (SW2). See “Settings and Adjustments” on page 15 for Dip Switch information.

Table 2. S8610U Replaces These

Modules

Vendor / Model SW1 SW2

Honeywell

S86A1001

S86A1019

S86A1027

S86A1035

S86B1009

S86B1017

S86B1025

S86C1007

S86C1015

S86C1023 OFF ON

S86C1031

S86C1049

S86C1056

S86D1005

S86D1013 OFF ON

S86D1021

S86E1002

S86E1010

S86E1028

S86E1036

S86E1044

S86E1051

S86E1069

S86E1077

S86E1101

S86 E1119

S86E1127

S86F1000

S86F1018

S86F1026

S86F1042

S86F1059

S86F1067

S86F1075

S86F1083

S86F1091

S86G1008

S86G1016

S86G1024 OFF ON

S86G1032

S86G1057

S86G1073

S86H1006

S86H1014 OFF ON

S86H1022

S86H1048

S86H1055

S86H1063 OFF ON

S86H1089

S86H1097

S86H1105

S86H1113 OFF ON

S86H1121 OFF OFF

S86H1139 OFF ON

S86H1147

S90A1005

S90B1003

S90B1011

S860C1000

S860D1009

S860D1017 ON ON

S8600A1001

S8600B1009

S8600B1025

S8600B3005

S8600B3013

S8600C1015

S8600C3003

S8600F1000

S8600F1034

S8600F1042

S8600H1006

S8600H1014 OFF ON

69-1955—01 2

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

ON OFF

OFF OFF

OFF ON

OFF OFF

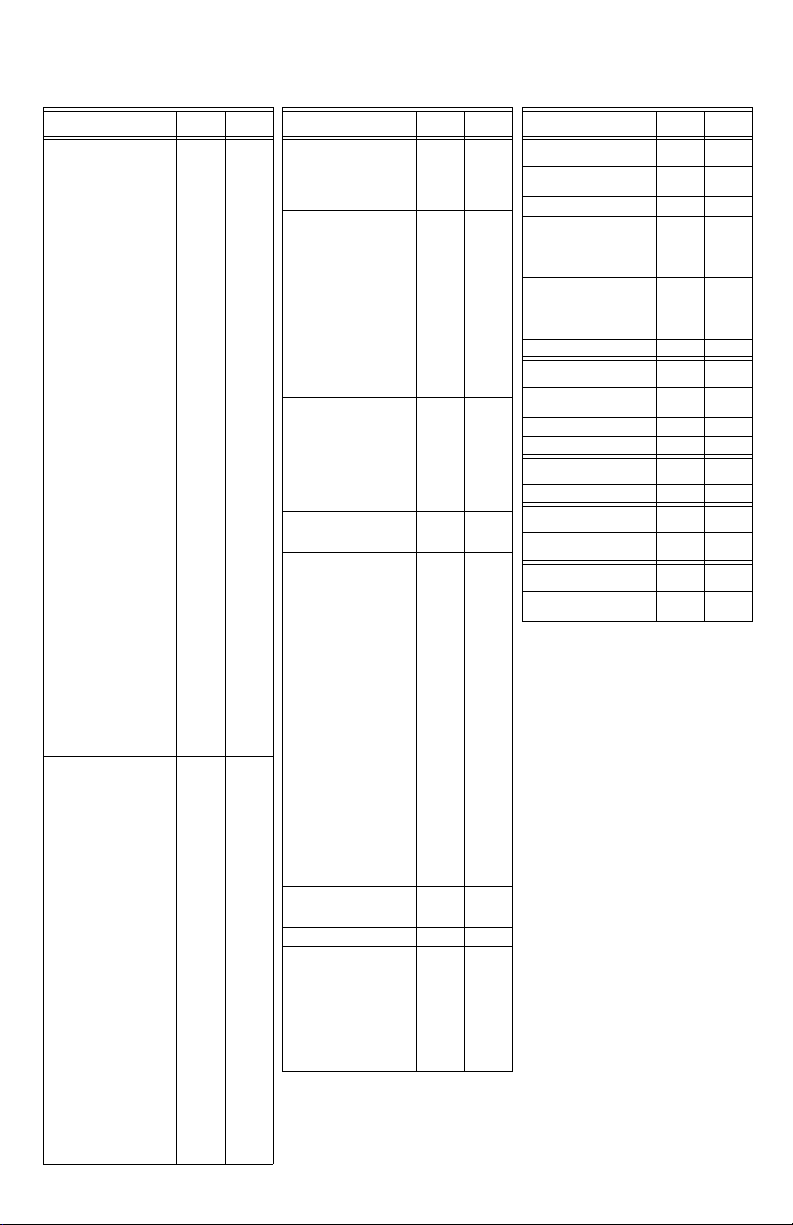

Table 2. S8610U Replaces These

Modules (Continued)

Vendor / Model SW1 SW2

S8600H1022

S8600H1048

S8600H1055

S8600H1063 OFF ON

S8600H1071

S8600H1089

S8600H1097

S8600H1105

S8600H3002

S8600H3010 OFF ON

S8600M1005

S8600M1013

S8600M1021

S8600M2003

S8600M3001

S8600M4009

S8610A1009

S8610B1007

S8610B1015

S8610B1023

S8610B3003

S8610C1005

S8610C1013

S8610C3001

S8610F1008

S8610F1016

S8610F1024

S8610F1032

S8610H1004 OFF ON

S8610H1012 OFF OFF

S8610H1020 OFF ON

S8610H1038

S8610H1046

S8610H1053

S8610H1061 OFF ON

S8610H1079

S8610H1095

S8610H3000

S8610H3018 OFF ON

S8610H3026

S8610M1003

S8610M1011 OFF ON

S8610M1029

S8610M3009

S8610M3017 OFF ON

S8610U1003

S8610U1011

S8620C1003

S8620C1011

S8620H1002 OFF OFF

S8620H1010 OFF ON

S8620H1028 OFF OFF

S8660D1002 ON OFF

S8660D1010 ON ON

S8660J1008

S8660J1016

S8660J1024

S8660K1006

S8660K1014

S8660K1022

S8670D1000

S8670D1018

S8670D1026

S8670D3006

S8670D3014

S8670E1007

S8670E3003

S8670J3002 ON ON

OFF OFF

OFF OFF

OFF OFF

OFF ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF ON

ON OFF

ON ON

ON OFF

Table 2. S8610U Replaces These

Modules (Continued)

Vendor / Model SW1 SW2

S8670J3010

S8670K3000

S8680J1004 ON ON

ON OFF

Johnson Controls

CSA35A-617R

CSA35A-618R

CSA42A-600R

CSA42A-601R

CSA42A-602R

CSA42A-603R

CSA42A-604R

CSA43A-600R

CSA44A-600R

CSA45A-601R

CSA45A-602R

CSA46A-600R

CSA48A-600R

CSA49A-600R

CSA49A-605R

CSA51A-601R

CSA52A-600R

G60AAA-1

G60AAG-1

G60AAG-2

G60AAG-3

G60AAG-4

G60AAG-5

G60AAG-6

G60AAG-7

G60CAA-1

G60CAA-3

G60CAG-1

G60CAG-2

G60CAG-3

G60CAG-4

G60CAG-5

G60CAG-6

G60CAG-7

G60CAG-8

G60CAG-9

G60CBA-1

G60CBA-2

G60CBA-3

G60CBG-1

G60CBG-2

G60CBG-3

G60CBG-4

G60CBG-5

G60CBG-6

G60CBG-7

G60CBG-8

G60CBG-9

G60CBG-10

G60CBG-11

G60CBG-12

G60CBG-13

G60CBG-14

G60CBG-15

G60CBG-16

G60CBG-17

G60CCA-1

G60CCG-1

G60CPG-1

G60DBG-1

G60DCG-1

G60DCG-2

G60DCG-3

G60DCG-4

G60PAG-1

G60PAG-2

G60PAG-3

G60PAG-4

G60PAG-5

G60PAG-6

G60PAJ-1

G60PAK-1

G60PAK-2

G60PFH-1

G60PFH-2

G60PFL-1

G60PFQ-1

G60PVL-1

G60QAG-1

G60QAG-2

G60QAG-3

OFF OFF

OFF OFF

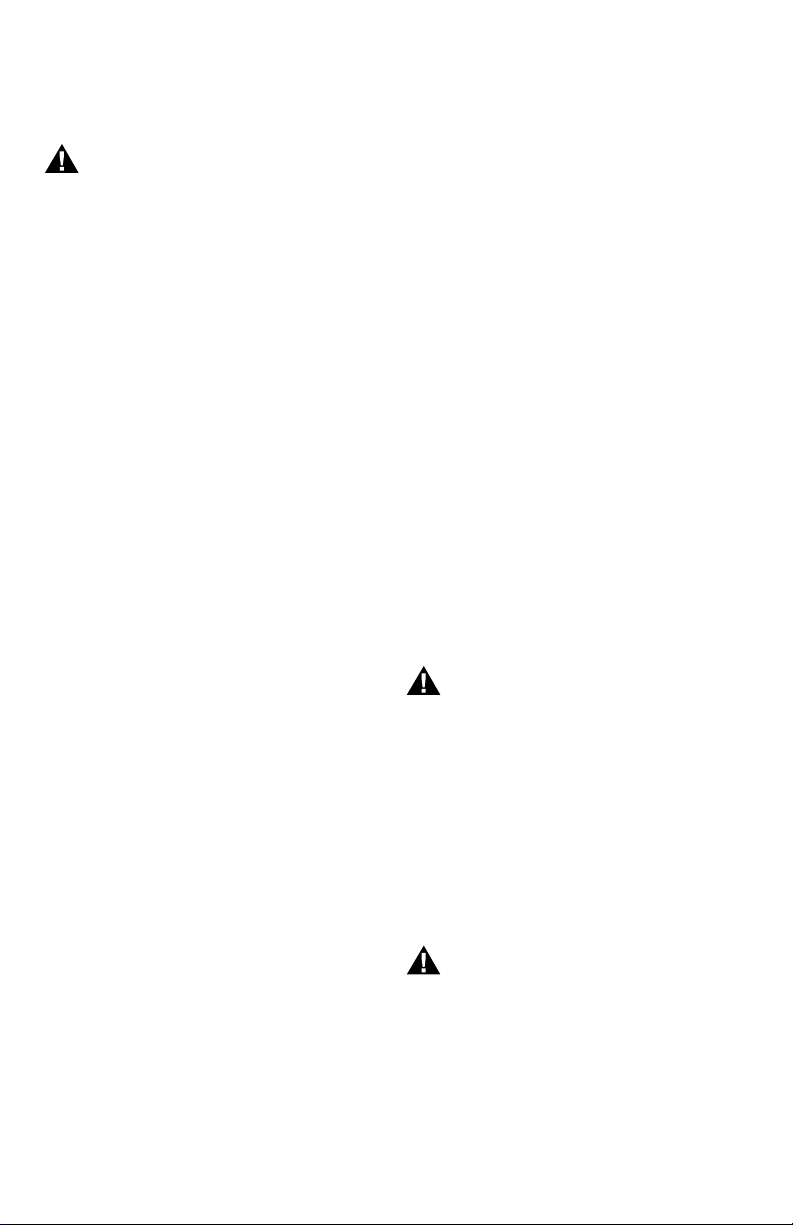

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

Table 2. S8610U Replaces These

Modules (Continued)

Vendor / Model SW1 SW2

G60QAG-4

G60QAK-1

G60QBG-1

G60QBG-2

G60QBG-3

G60QBG-4

G60QBG-5

G60QBG-6

G60QBG-7

G60QBG-8

G60QBG-9

G60QBH-1

G60QBK-1

G60QBK-2

G60QBK-3

G60QBL-1

G60QBL-2

G60QCG-1

G60QCJ-1

G60QCL-1

G60QDG-1

G60QFL-1

G60QGH-1

G60QHL-1

G60QHL-2

G60QJL-1

G60QLG-1

G60QLK-1

G60QPL-1

G60QRH-1

G60QRH-2

G60QRH-3

G60QRL-1

G60QRL-2

G60QRL-3

G60QSL-1

G60QTH-1

G60QTL-1

G60RAG-1

G60RAK-1

G60RBG-1

G60RBG-2

G60RBG-3

G60RBK-1

G60RBK-2

G60RCG-1

G60RCG-2

G60RCJ-1

G60RDG-1

G60RDK-1

G60RGL-1

G60RHL-1

G60RHP-1

G60RPL-1

G60RSL-1

G60TTL-1

G60ZAG-1

G60ZAG-2

G65BBG-1

G65BBG-2

G65BBG-3

G65BBG-4

G65BBG-5

G65BBG-6

G65BBG-7

G65BBG-8

G65BBM-1

G65BBM-2

G65BBM-3

G65BBM-4

G65BCG-1

G65BCM-1

G65BFG-1

G65BFM

G65BKG-1

G65BKG-2

G65BKG-3

G65BKM-1

G65BKM-2

G65BKM-3

G65BLG-1

G65BLG-2

G65DBG

G65DBM-1

G65DBM-2

G65DBM-3

G65DCM-1

G65DFG

G65DFM-1

G65DKG

G65DKM

G65DKM-1

G65DLM-1

G65FBG

G65FFG

G65FKG

OFF OFF

OFF OFF

Table 2. S8610U Replaces These

Modules (Continued)

Vendor / Model SW1 SW2

G66AG-1

G66AG-2

G66BG-1

G66MG-1

G66MG-2

G66NG-1

G67AG-3

G67AG-4

G67AG-7

G67AG-8

G67AG-9

G67AG-10

G67AG-11

G67BG-2

G67BG-3

G67BG-4

G67BG-5

G67MG-1

G67MG-2

G67MG-3

G67MG-4

G67NG-2

G67NG-4

G600AX-1

G600AX-2

G600AX-3

G600AY-1

G600LX-1

G600LX-2

G600LY-1

G600MX-1

G600NX-1

G600RX-1

G670AW-1

G670AW-2

G670GA-1

G770LGA-1

G770LGA-2

G770LGC-1

G770LGC-2

G770LGC-3

G770LGC-4

G770LHA-1

G770LHA-2

G770LHC-1

G770MGA-1

G770MGA-2

G770MGA-3

G770MGC-1

G770MGC-2

G770MGC-3

G770MGC-4

G770MGC-5

G770MGC-6

G770MHA-1

G770MHA-2

G770MHC-1

G770NGA-1

G770NGC-4

G770NGC-5

G770NGC-6

G770NGC-7

G770NHA-1

G770NHC-1

G770RGA-1

G770RHA-1

G770RHA-2

G775RGA-1

G775RHA-1

G775RHA-2

G779 OFF OFF

Y79ABC-1

Y79ABC-2

Y79ABC-3

Y79ABC-4

Y79ABC-5

Y79ABC-6

Y79ABC-7

Y79ABD-1

Y79ABCD-2

Y79BBA-1

Y79BBA-2

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFF OFF

Table 2. S8610U Replaces These

Modules (Continued)

Vendor / Model SW1 SW2

RobertShaw

780-001

780-002

780-003 ON OFF

780-845

780-715

780-735

780-736

780-737

SP715

SP715A

SP735

SP735D

SP735L

USI715U OFF OFF

OFF OFF

OFF OFF

OFF OFF

White-Rodgers

50D49-350

50D49-360

50D49-361 ON OFF

50D49-401 OFF OFF

OFF OFF

Camstat

IPI-24-00 OFF OFF

Fenwal

05-203025-005

05-203026-005

OFF OFF

HSC

1003-3

1003-300

OFF OFF

SPECIFICATIONS

Control Voltage:

Line 24 V (18-30 Vac) 50/60 Hz

Anticipator Setting:

0.1 A plus valve load @ 24 Vac

Trial for Ignition:

See Table 1 on page 1

Prepurge: See Table 1 on page 1

Flame Failure Response Time:

2 seconds maximum

LED:

The green Status LED provides

system status, error codes, and

flame strength when in run

mode.

Typical Gas Control: Honeywell

models VR8204 and VR8304

Operating Temperature:

Minimum ambient temperature

rating is -40°F (-40°C)

Maximum ambient rating when

used with 2.0 A main valve is

165°F (74°C)

Relative Humidity:

0% to 95% non condensing

3 69-1955—01

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

WARNING

WARNING

WARNING

PLANNING THE INSTALLATION

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. Plan the installation as outlined below.

2. Plan for frequent maintenance as described in

the Maintenance section.

Intermittent pilot systems are used on a wide variety of

central heating equipment and on heating appliances

such as commercial cookers, agricultural equipment,

industrial heating equipment and pool heaters. Some of

these applications may make heavy demands on the

controls, either because of frequent cycling, or because of

moisture, corrosive chemicals, dust or excessive heat in

the environment. In these situations, special steps may be

required to prevent nuisance shutdowns and premature

control module failure. These applications require special

Honeywell review; contact your Honeywell Sales

Representative for assistance.

Review the following conditions that can apply to your

specific installation and take the precautionary steps

suggested.

Frequent Cycling

These controls are designed for use on appliances that

typically cycle three to four times an hour only during the

heating season. In year-round applications with greater

cycling rates, the control module can wear out more

quickly; perform a monthly checkout.

suspended in air, as in some industrial or agricultural

applications, use a NEMA 4 enclosure for the ignition

control module.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause

controls to malfunction. Where dust or grease can be a

problem, provide covers for the ignition control module

and the gas control to limit contamination. A NEMA 4

enclosure is recommended for the ignition control module.

Heat

Excessively high temperatures can damage controls.

Make sure the maximum ambient temperature at the

control module does not exceed the rating of the control

module. If the appliance operates at very high

temperatures, use insulation, shielding, and air

circulation, as necessary, to protect the controls. Proper

insulation or shielding should be provided by the

appliance manufacturer; verify proper air circulation is

maintained when the appliance is installed.

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in these instructions to

make sure the S8610U module is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out operation

as provided in these instructions.

Water or Steam Cleaning

If the control module gets wet, replace it. If the appliance

is likely to be cleaned with water or steam, protect (cover)

the controls and wiring from water or steam flow. Mount

the controls high enough above the bottom of the cabinet

so they do not get wet during normal cleaning procedures.

Use a NEMA 4 enclosure for the ignition control module.

High Humidity or Dripping Water

Dripping water can cause the control module to fail. Never

install an appliance where water can drip on the controls.

In addition, high ambient humidity can cause the gas

control to corrode and fail.

If the appliance is in a humid atmosphere, make sure air

circulation around the controls is adequate to prevent

condensation. Also, regularly check out the system. A

NEMA 4 enclosure is recommended for the ignition

control module.

Corrosive Chemicals

Corrosive chemicals can attack the ignition control

module and gas control, eventually causing a failure. If

chemicals are used for routine cleaning, make sure they

do not reach the controls. Where chemicals are

69-1955—01 4

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. The ignition control module can malfunction if it

gets wet, leading to accumulation of explosive

gas.

—Never install where water can flood, drip or

condense on the ignition control module.

—Never try to use an ignition control module

that has been wet; replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not naturally vent upward.

—Do not operate electric switches, lights, or

appliances until you are sure the appliance

area is free of gas.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

or making wiring connections to prevent electrical

shock or equipment damage.

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

CAUTION

CAUTION

WARNING

1. If a new gas control is to be installed, turn off

the gas supply before starting installation.

Conduct a Gas Leak Test according to the gas

control manufacturer instructions after the gas

control is installed.

2. Wiring errors can cause improper appliance

operation and dangerous conditions such as

bypassing safety features.

Equipment Damage Hazard.

Water can cause equipment damage or

malfunction.

If ignition control module must be mounted where

there is the potential for exposure to water or

moisture, provide a suitable waterproof enclosure.

Maintenance Requirements in Severe Environments

Regular preventive maintenance is important in any

application, but especially so in commercial cooking,

agricultural, and industrial applications because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000-200,000 cycles

per year. Such heavy cycling can wear out the gas control

in one to two years. A normal forced air furnace, for which

the controls were originally intended, typically operates

less than 20,000 cycles per year.

• Exposure to water, dirt, chemicals, and heat can

damage the ignition control module or the gas control and

shut down the control system. A NEMA 4 enclosure can

reduce exposure to environmental contaminants.

The maintenance program should include regular

checkout of the system as outlined under “Checkout” on

page 15.

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to take the ignition control module

apart or to clean it. Improper reassembly and

cleaning may cause unreliable operation.

Maintenance frequency must be determined individually

for each application. Some considerations are:

• Cycling frequency – Appliances that may cycle more

than 20,000 times annually should be checked

monthly.

• Intermittent use – Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown – Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

• Dusty, wet, or corrosive environment – Since these

environments can cause the controls to deteriorate

more rapidly, the system should be checked more

often.

Any ignition control module should be replaced if it does

not perform properly on checkout or troubleshooting. In

addition, replace any ignition control module if it is wet or

looks like it has ever been wet. Protective enclosures as

outlined under “Planning the Installation” are

recommended regardless of checkout frequency.

Perform Pre-Installation Safety Check

The pre-installation checks described below must be

done before the replacement ignition control module is

installed. If a condition that could result in unsafe

operation is detected, the appliance should be shut off

and the owner advised of the unsafe condition. Correct

any potentially unsafe condition before proceeding with

the installation.

The following safety checklist should be followed in

making the safety inspection:

1. Conduct a Gas Leakage Test of the appliance piping and control system downstream of the shutoff

valve in the supply line to the appliance.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restrictions, leakage or corrosion or

other deficiencies that could cause an unsafe condition.

3. Shut off all gas to the appliance and shut off any

other fuel-burning appliance within the same room.

Use the shutoff valve in the supply line to each

appliance.

4. Inspect burners and crossovers for blockage and

corrosion.

5. Applicable only to warm air heating appliances.

Inspect heat exchangers for cracks, openings or

excessive corrosion.

6. Applicable only to boilers. Inspect for evidence of

water or combustion product leaks.

7. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliance is located and other spaces of the

building. Turn on clothes dryers. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed.

Do not operate a summer exhaust fan.

Close fireplace dampers.

If, after completing steps 7 through 12 in this safety

checklist, it is believed sufficient combustion air is

not available, refer to section 1.3.4 of the National

Fuel Gas Code (Z223.1) for guidance.

8. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

a. Determine that the pilot is burning properly and

that main burner ignition is satisfactory by interrupting and reestablishing the electrical supply

to the appliance in any convenient manner.

b. Determine manifold pressure in order to match

input after the new control is installed.

c. Visually determine that main burner gas is burn-

ing properly; i.e., no floating, lifting or flashback.

Adjust the primary air shutter(s) as required.

d. If appliance is equipped with high and low flame

control or flame modulation, check for proper

main burner operation at low flame.

9. Test for spillage at the draft hood relief opening after

five minutes of main burner operation. Use a draft

gauge, the flame of a match or candle, or smoke

from a cigarette, cigar or pipe.

5 69-1955—01

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

CAUTION

10. Return doors, windows, exhaust fans, fireplace

dampers and all other fuel-burning appliances to

their previous conditions of use.

11. Applicable only to warm air heating appliances.

Check both limit controller and fan controller for

proper operation. Limit controller operation can be

checked by temporarily disconnecting the electrical

supply to the blower motor and determining that the

limit control acts to shut off the main burner gas.

12. Applicable only to boilers:

a. Determine that the circulating water pumps are

in operating condition.

b. Test low water cutoffs, automatic feed controls,

pressure and temperature limit controls and

relief valves in accordance with the manufacturer’s recommendations and instructions to

determine they are in operating condition.

Remove Old Ignition Control Module

Disconnect power supply before doing any work on the

unit. Disconnect and tag the wires from the old module.

Remove the old module from its mounting location.

Wire the System

M29889

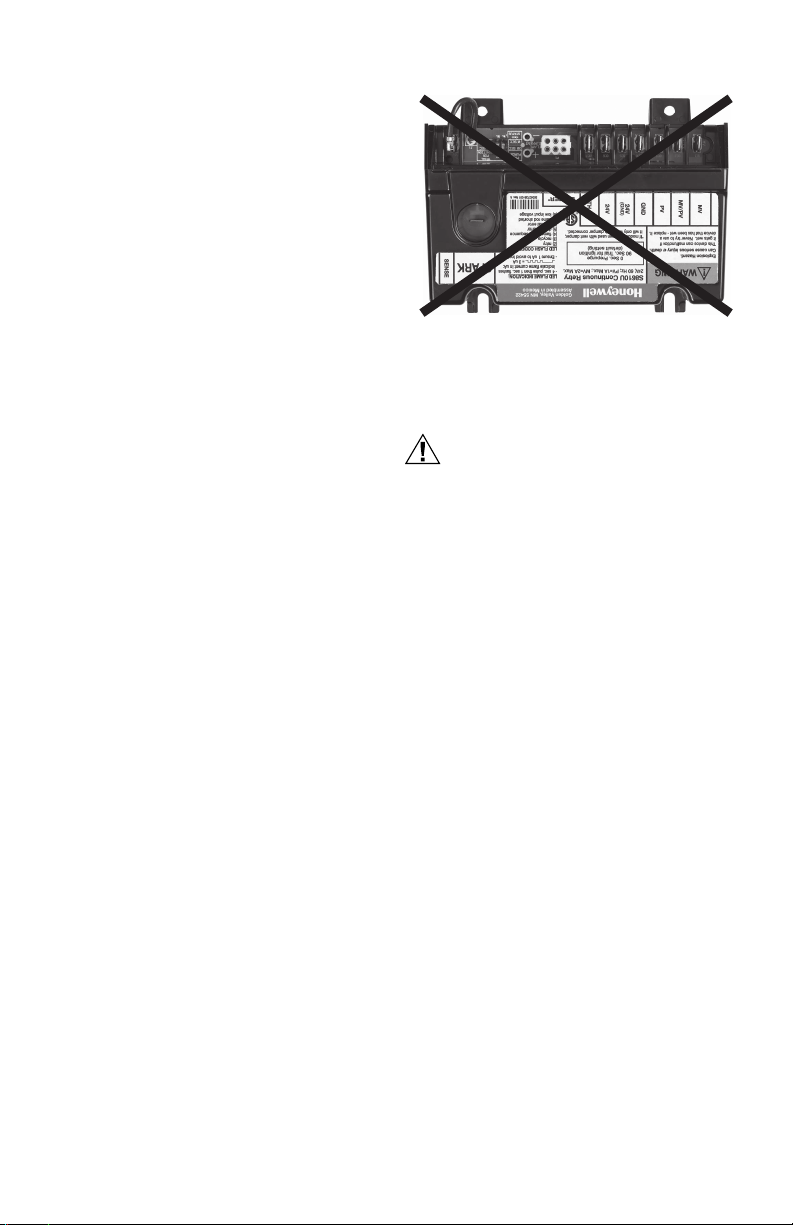

Fig. 1. Incorrect Mounting.

Mount New Ignition Control Module

The recommended mounting for the S8610U ignition

control module is the same location as the old control

module. Otherwise, select a location close enough to the

burner to allow a short (3 ft. [0.9 m] maximum), direct

cable route to the pilot burner. Ambient temperature at the

control module must be within the range listed in the

“Specifications” on page 3.

Mount the ignition control module with the terminals down

to protect them from dripping water and dust. The control

module can also be mounted with the terminals on either

side. Do not mount with the terminals pointing up. Fig. 1

on page 6 illustrates the incorrect mounting position.

When it is necessary to drill new mounting holes, use the

S8610U as a template to mark the mounting hole pattern.

Drill new holes, as required. Fasten securely with four —

No. 6-32 machine screws, or No. 8 sheet metal screws, or

8-18 x 5/8 Pan Head tapping screws.

Location

The mounting location must provide:

— Good, clear access to the field wiring terminals.

— Operating ambient temperatures between

-40°F (-40°C) and 165°F (74°C).

— Relative humidity below 95% non condensing.

— Protection from water, steam or corrosive chemicals

that are used to clean the appliance.

— Protection from dripping water, such as from an

overfilled humidifier or from condensation.

— Protection from dust or grease accumulation.

IMPORTANT

Do not mount with terminals facing up.

69-1955—01 6

Equipment Damage Hazard.

Disconnect power supply before beginning wiring

or making wiring connections to prevent electrical

shock or equipment damage.

All wiring must comply with local codes and ordinances.

Refer to Fig. 2 and Table 9 on page 11 for typical

connections.

IMPORTANT

1. As shown in the wiring diagrams, a common

ground is required on:

The pilot burner mounting bracket, and the GND

(BURNER) terminal on the ignition control module. Failure to use the GND (BURNER) terminal

may result in intermittent loss of spark and/or

loss of flame current sensitivity.

2. Make sure the transformer has adequate VA.

The ignition control module requires at least

0.1 A at 24 Vac. Add the current draws of all

other devices in the control circuit, including the

pilot and main valves in the gas control, and multiply by 24 to determine the total VA requirement

of these components. Add this total to 2.4 VA (for

the ignition control module). The result is the

minimum transformer VA rating. Use a Class II

transformer if replacement is required.

Connect Vent Damper (Optional)

If the ignition control module is to be used with a damper

connected to the module’s integral damper connector in

an atmospheric appliance, perform the following to

connect it to the module:

IMPORTANT

After the initial power-up, the ignition control

module senses the presence of the vent damper

connection. If the vent damper is connected for

10 ignition cycles, the ignition control module

permanently configures itself to operate only

with the damper connected.

Once an ignition control module completes 10

ignition cycles with a vent damper connected,

the module will not function without a vent

damper being connected.

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

CAUTION

1. Using the wiring harness on the appliance, insert

the matching 6-pin plug into the connector (labeled

P1; see Fig. 2 on page 11) on the S8610U ignition

control module and connect the other end to the

vent damper.

NOTE: The connector (P1) accepts a Molex 03-06-2061

plug.

Connect Ignition Cable

Use existing ignition cable if it is in good condition. If the

existing ignition cable does not have a 1/4 in. quick

connect on the module end, either use the Rajah adapter

or strip the wire and replace with the 1/4 in. insulated

quick connect supplied. If the cable must be replaced,

order a Honeywell ignition cable (Table 3) or refer to Table

4. It might be necessary to replace the connector at the

pilot burner end to match the pilot burner spark

termination.

NOTE: When using an S8610U to replace an S86, use

the enclosed adapter to convert the S86 Ignition

Cable to an S8610U Ignition Cable. Then, install

the adapter and cable to the S8610U Ignition

Module.

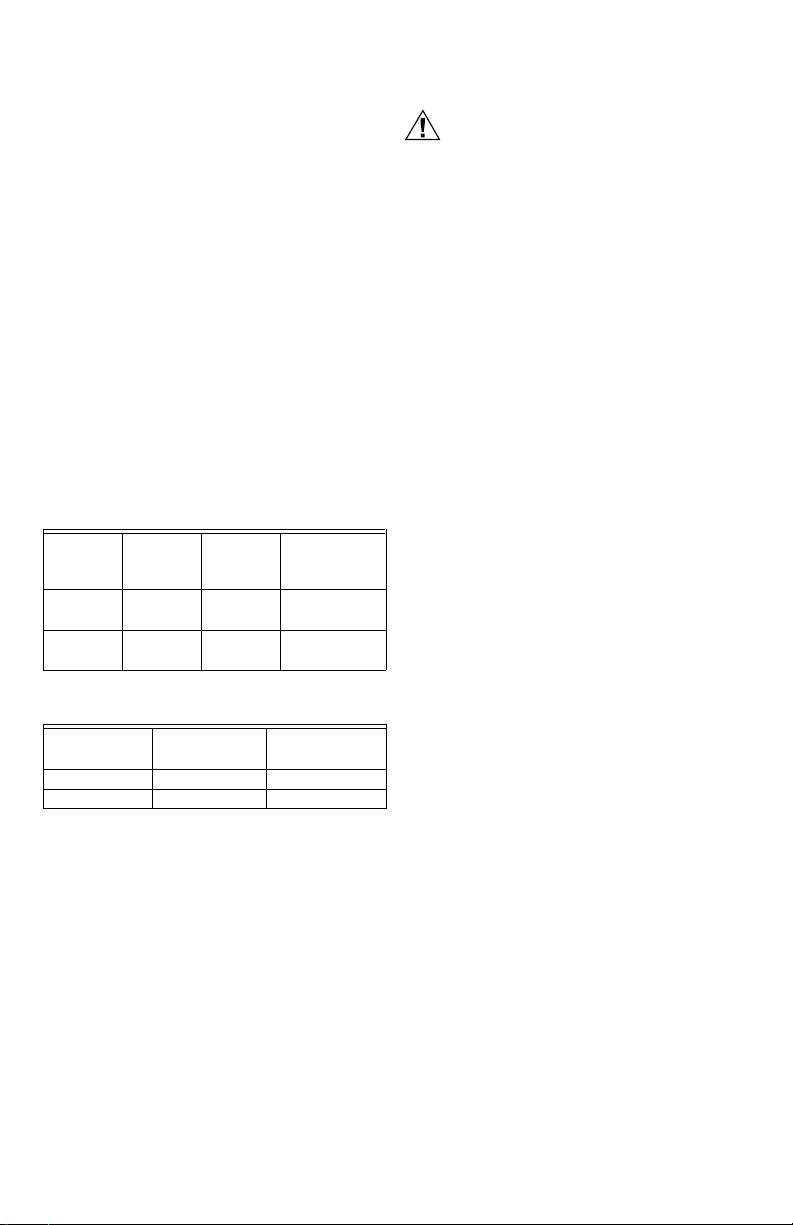

Table 3. Honeywell Pre-assembled Ignition Cables

CABLE

PAR T

NUMBER LENGTH

394800-30 30 inches 1/4 inch quick

394801-30 30 inches 1/4 inch quick

(UL Style 3257).

MODULE

END PILOT BURNER

connect,

insulated

connect,

insulated

Rajah connector

receptacle, 90

degree rubber boot

Rajah connector

receptacle, straight

rubber boot

Connect Ignition Control Module

Equipment Damage Hazard.

Check the wiring diagram provided on the

appliance and compare with Table 5 through Table

8 beginning on page 8. Carefully follow any

special instructions affecting the general wiring

procedures outlined in this section.

1. Connect the wires to the module as shown in the

wiring tables (Table 5 through Table 8). Make sure

that adequate system ground is provided as indicated in the wiring tables.

(Refer to Fig. 2 and Table 9 on page 11 for wiring

connections on the S8610U module.)

2. Verify the thermostat anticipator setting as

explained in the Important notes in the wiring tables.

NOTE: Refer to Fig. 2 and Table 9 on page 11 for the

location of each connection on the S8610U module.

The wiring diagrams in Fig. 3 through Fig. 5 beginning on

page 12 describe typical hookups with the S8610U

module and should be used for reference only.

• Fig. 3 shows a basic circuit used only for heating

systems with atmospheric burners and damper control.

(Shown with local and remote flame sensing.)

• Fig. 4 shows a basic circuit used only for heating

systems with atmospheric burners without damper

control. (Shown with local and remote flame sensing.)

• Fig. 5 shows a circuit for power assisted combustion

applications.

Table 4. Recommended Ignition Cable for Field

CABLE TYPE

UL Style 3217 10,000 302°F (150°C)

UL Style 3257 10,000 484°F (250°C)

Cable must be no longer than 36 in. (0.9 m). Solid

conductor cable recommended. To construct a cable, fit

one end of ignition cable with 1/4 in. diameter Rajah

connector receptacle and the other with a 1/4 in. female

quick connect. Protect both ends with insulated boots.

NOTE: The cable must not run in continuous contact

with a metal surface or spark voltage may be

greatly reduced. Use ceramic or plastic standoff

insulators as required. Resistive spark cable

reduces spark voltage and may impact appliance

performance.

Assembly.

VOLTAGE RATING

(rms)

TEMPERATURE

RATING

To install:

1. Connect one end of the cable to the male quick

connect SPARK terminal on the ignition module.

2. Connect the other end of the cable to the igniter or

igniter-sensor stud on the pilot burner/ignitersensor.

7 69-1955—01

S8610U UNIVERSAL INTERMITTENT PILOT GAS IGNITION CONTROL

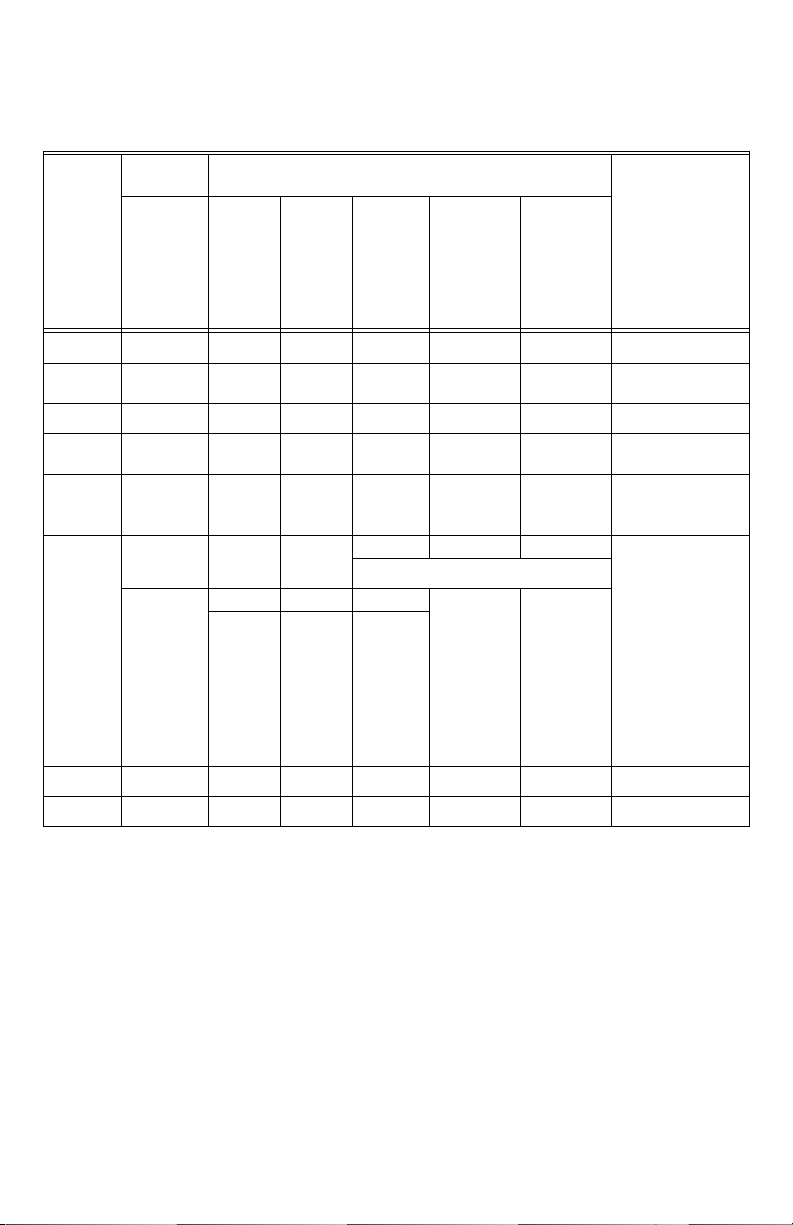

The following four tables describe the wiring connections necessary for conversion:

Table 5. Conversion from Honeywell Intermittent Pilot Modules.

Replacement

Control Old Control

S90A,B

S8600A,B,C

S8610A,B,C

S8610U1003

S8620C,

Ter min al

Function

Main Valve

Operator

Main Valve

and Pilot

Common

Pilot Valve

Operator

Burner

Ground

Connection

Transformer

Secondary

(unswitched

leg)

Transformer

Secondary

(switched

leg)

Flame

Sensor

Igniter /

Sensor

a

Terminals may be marked 25V on some models and 24V on later models. These are functionally equivalent.

b

If 25V (2) and TH-R have wires connected, disconnect and splice together with solderless connector.

c

If TH-R and TH-W are jumpered together, connect 25V (2) lead from S86 to TH-W on S8610U.

d

On dual igniter and sensor models, remove jumper wire quick connect from S8610U Remote Sense terminal, then cut

jumper wire at circuit board and discard.

e

Leave black jumper connected.

f

Use Rajah to quick connector adapter (supplied) or cut Rajah connector off ignition cable at module end and attach

insulated quick connect for connection to S8610U.

MV

MV/PV MV/PV MV/PV MV/PV MV/PV MV/PV —

PV PV PV PV PV PV —

GND

(BURNER)

24V GND

24V *25V (2) 25V

TH-W

d

SENSE

SPARK

MV

GND GND GND

25V (2)

b

TH-R

c

TH-W

e

IGN COIL

f

MV

MV

(BURNER)

25V

TH-R

TH-W

ee

25V (2)

25V (2) a *24V * 24V *

25V (2) or 24V used only in systems where plug-in

cable connects damper to module

b

TH-R

TH-W

b

c

IGN COIL fIGN COIL fSPARK

S8660D,J

S8670D,J

S8680D,J

MV

GND (BURNER) GND (BURNER) —

a

24V GND

TH-W

(This terminal is

not included on

S90.)

de

SENSE

S8600F,H,M

S8610F,H,M

S8660E,K

S8670E,K

MV

24V GND

TH-W

Procedural NotesS8610U S86A,C S86B,D S86E,F,G,H

—

—

* IMPORTANT

If the old module had a

vent damper connector but

a vent damper was not

installed, or if it did not

have a vent damper

connector, then connect

the 25V (2) or 24V wire

from the old module to the

TH-W terminal on the

S8610U. Do not use the

24V terminal on the

S8610U.

If the old module had a

vent damper, connect it to

the P1 connector on the

module, and wire the

terminals as indicated in

the table.

—

SPARK

—

69-1955—01 8

Loading...

Loading...