Honeywell RV283P User Manual

EN0H-1203GE23 R0514 • Subject to change

RV283P

Controllabel anti-pollution check valve with flanges

Product specification sheet

Construction

The check valve comprises:

•Housing with flanges

•Housing end casing with flanges

•Test and drain plugs

CERT

Application

Check valves are preferably for use as an independent means of preventing reverse water flow and are for installing directly after a water meter, but also for application in transfer pipes on district water supply systems.

They can also be used for industrial, commercial and similar systems where back pressure, back flow and back syphonage must be prevented.

The types of safety devices required for these purposes are specified in EN 1717.

Special Features

•DIN/DVGW-certified where applicable (for DN40-DN150)

•Universal application

•High temperature resistance

•Create no shock pressure loadings

•Powder coated inside and outside

•Meets KTW regulations for potable water

•Disc, spring and lip seal ring are exchangeable

•Low pressure loss

Range of Application |

|

Medium |

Drinking water |

Inlet pressure |

max. 16.0 bar |

Technical Data |

|

Operating temperature |

65 °C |

Opening pressure |

approx. 0.05 bar |

• |

Disc and disc guide |

Connection size |

DN40 - DN300 |

• |

Spring |

|

|

• Disc lip seal ring |

|

|

|

Materials

•Grey cast iron housing end and housing

o Powdercoated with:

High-performance polyamide (DN50 - DN100) High-performance epoxy resin (DN125 - DN300)

•Stainless steel screws and nuts

•Stainless steel disc (red bronze for DN 40 and DN 50)

•Stainless steel spring

•EPDM for lip seal ring

http://ecc.emea.honeywell.com 1

RV283P Controllabel anti-pollution check valve with flanges

Method of Operation

Spring loaded check valves have a moving seal disc which is lifted off the seat by a greater or lesser amount depending on the flow rate through the valve. If the flow falls towards zero, then the spring pushes the disc back onto the seat and seals the waterway.

To ensure continuing correct function it is recommended that check valves be regularly checked and maintained (as specified in EN 1717).

Options

RV283P-... A = With drilled flanges, PN16, ISO 7005-2,

EN 1092-1, DN40 - DN300,

EPDM lip seal ring

Connection size

Connection size |

R |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

Weight |

approx. kg |

9 |

11 |

17 |

21 |

29 |

37 |

62 |

78 |

155 |

180 |

|

|

|

|

|

|

|

|

|

|

|

|

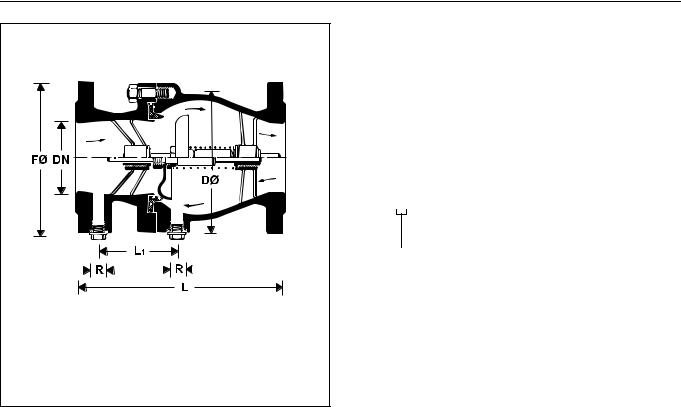

Dimensions |

mm |

|

|

|

|

|

|

|

|

|

|

|

L |

180 |

200 |

240 |

260 |

300 |

350 |

400 |

500 |

600 |

700 |

|

L1 |

37.5 |

36.5 |

89 |

107 |

111.5 |

131.5 |

149 |

163 |

186 |

218 |

|

F |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

405 |

460 |

|

D |

150 |

165 |

185 |

200 |

220 |

250 |

285 |

345 |

420 |

475 |

|

|

|

|

|

|

|

|

|

|

|

|

Test and drain plugs |

R |

1/4" |

1/4" |

1/2" |

1/2" |

1/2" |

3/4" |

3/4" |

3/4" |

3/4" |

3/4" |

kvs-value |

m3/h |

39 |

62 |

110 |

170 |

240 |

420 |

760 |

1400 |

2100 |

3000 |

Nominal flow rate in m3/h |

15.1 |

24.0 |

43.0 |

66.0 |

93.0 |

163.0 |

295.0 |

542.0 |

813.0 |

1162.0 |

|

at p = 0.15 bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIN/DVGW Registration No. |

|

|

NW - 6310 BU 0492 |

|

|

Approval not compulsory |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

EN0H-1203GE23 R0514 • Subject to change

2 http://ecc.emea.honeywell.com

Loading...

Loading...