Honeywell S7800A2142 4-Line LCD User Manual

7800 SERIES

32-00110-07

S7800A2142 4-Line LCD

Keyboard Display Module

PRODUCT DATA

The S7800A2142 is required to program

the Valve Proving feature of selected 7800

Series devices.

The S7800A2142 KDM offers the following

technical advancements to the 7800

SERIES devices:

• Compatible with installed Honeywell

7800 SERIES systems.

• When used with the new 7800 SERIES

with Valve Proving Feature, the KDM

allows for programming the Valve

Proving Control feature and timing (Pass

APPLICATION

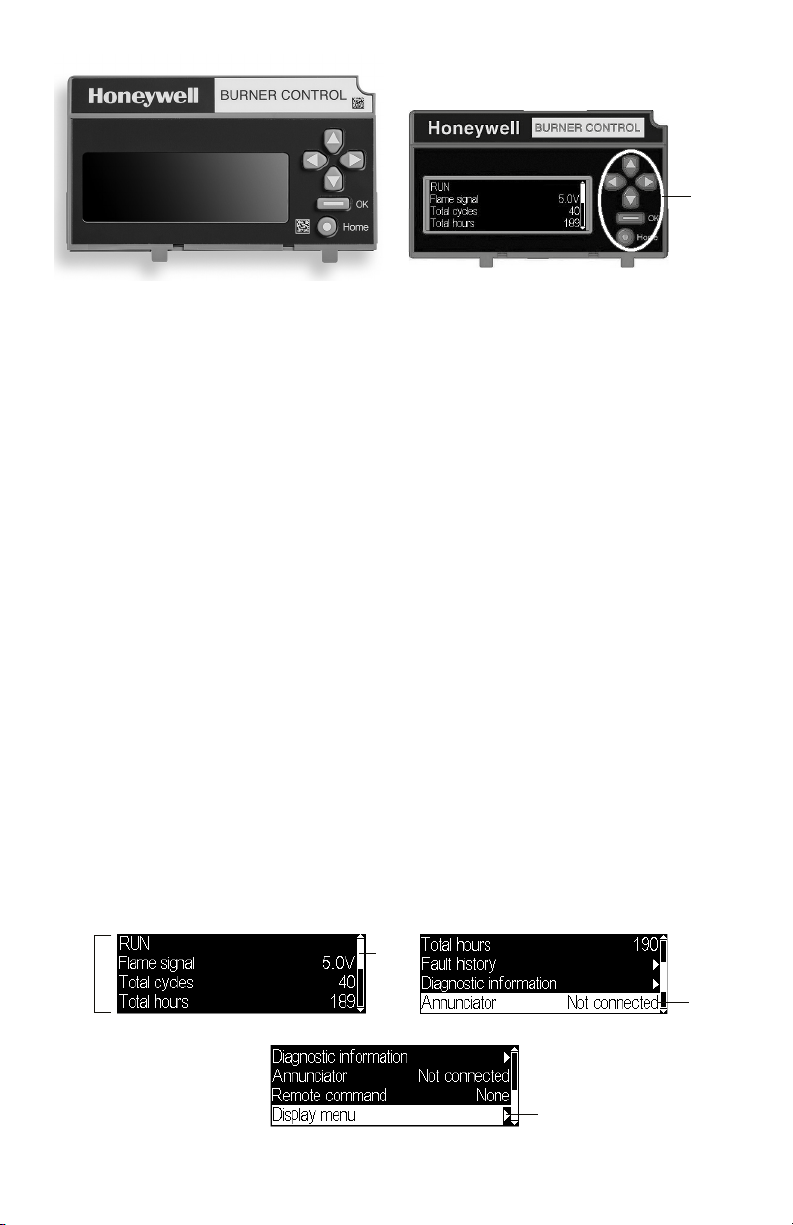

The S7800A2142 Keyboard Display Module

(KDM) provides current system status along

with first-out annunciation and system

diagnosis using a five-row by 64 column

readout (Main screen shows 4 rows of text

for better long-distance legibility, all other

screens show 5 rows of text). The KDM

provides local or remote annunciation of

operation and fault information, remote

reset, report generation, burner control data

and diagnostic information. The KDM is

part of the 7800 SERIES of microprocessorbased burner controls for gas, oil, coal

or combination fuel single burner

applications.

The 7800 SERIES is programmed to provide

a level of safety, functional capabilities

and features beyond the capacity of

conventional controls.

Contents

FEATURES 2

SPECIFICATIONS 2

INSTALLATION 3

WIRING 5

TROUBLESHOOTING 10

APPENDIX A: DISPLAY SETUP 28

Code protected feature).

• When used with the new 7800 SERIES

with Postpurge feature, the KDM allows

for programming the Postpurge time

(Pass Code protected feature).

• Allows for naming the S7830 Expanded

Annunciator terminals to match your

system drawings. (Displayed message

only.) (Pass Code protected feature.)

• An eight line (available by scrolling)

by twenty column readout set of “Call

Service” (Business Card) alpha/numeric

directions can be displayed instead of the

standard lockout display message. (Pass

Code protected feature).

• Enable ModBus communication feature.

• Configure language for English, Spanish,

or French.

• On-line troubleshooting guide.

APPENDIX B: BURNER CONTROL

COMMISSIONING 43

APPENDIX C: DIAGNOSTICS 48

APPENDIX D: ANNUNCIATOR TERMINAL

MESSAGES 50

APPENDIX E: MODBUS FUNCTION 51

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

The Business Card (Call Service) and

Expanded Annunciator can be made up

using:

• Capital letters (A through Z in configured

language).

• Lower case letters (a through z in

configured language).

• Numbers (0 through 9).

• Symbols (!, @, #, $,%, etc.).

Programming can be done with the S7800

KDM mounted on a 7800 SERIES Relay

Module or with a 13 Vdc power source

connected to the KDM through the 203541

5-wire connector.

Since your Business Card (Call Service)

S7800A2142 will be left at the job site,

programming your personal three-number

password and personal lockout message

can be set up ahead of time without being

connected to a 7800 SERIES device.

FEATURES

• Application flexibility.

• Communication interface capability.

– Through Q7700 Network Interface Unit

– Through 203541 Connector on the

ModBus data high- way.

• Dependable, long-term operation

provided by microcomputer technology.

• First-out annunciation and system

diagnostics provided by a 5-line by

64-character display.

• First-out expanded annunciation with 24

limit and interlock Light Emitting Diodes

(LEDs).

• Local or remote annunciation of

operation and fault information.

• UL NEMA Class 4 rating when p/n

204729A,C NEMA 4 cover is used.

• Remote reset.

• Report generation.

• On-line troubleshooting guide.

• Burner controller data:

– Sequence status.

– Sequence time.

– Hold status.

– Lockout/alarm status.

– Flame signal strength.

– Expanded annunciator status.

– Total cycles of operation.

– Total hours of operation.

– Fault history of six most recent faults:

• Cycles of operation at time of fault.

• Expanded annunciator data at time

of fault.

• Fault message and code.

• Hours of operation at time of fault.

• Sequence status at time of fault.

• Sequence time at time of fault

– Diagnostic information:

320011007 2

• Device type.

• Flame amplifier type.

• Flame failure response time (FFRT).

• Manufacturing code.

• On-Off status of all digital inputs and

• Prepurge time

• Postpurge time

• Valve Proving mode

• Valve Proving time

• Software revision and version of 7800

• Relay Module and KDM.

• Status of configuration jumpers.

• Status of Run/Test Switch.

• Reset count

• Reset reason

SPECIFICATIONS

Electrical Ratings:

Voltage and Frequency: 13 Vdc peak full

wave rectified (+20%/- 15%).

Power Dissipation: 7W maximum. VA

consumption: 2 VA maximum.

Terminal Ratings:

Power: 13 Vdc peak full wave rectified.

Earth Ground.

Environmental Ratings:

Ambient Temperature Ranges:

Operating: 0 °F (-18 °C) to +140 °F (+60 °C).

Storage: -22 °F (-30 °C) to +158 °F (+70 °C).

Humidity: 85% relative humidity

continuous, noncondensing.

NOTE: UL NEMA Class 4 rating when P/N

Vibration: 0.5G environment.

Mechanical:

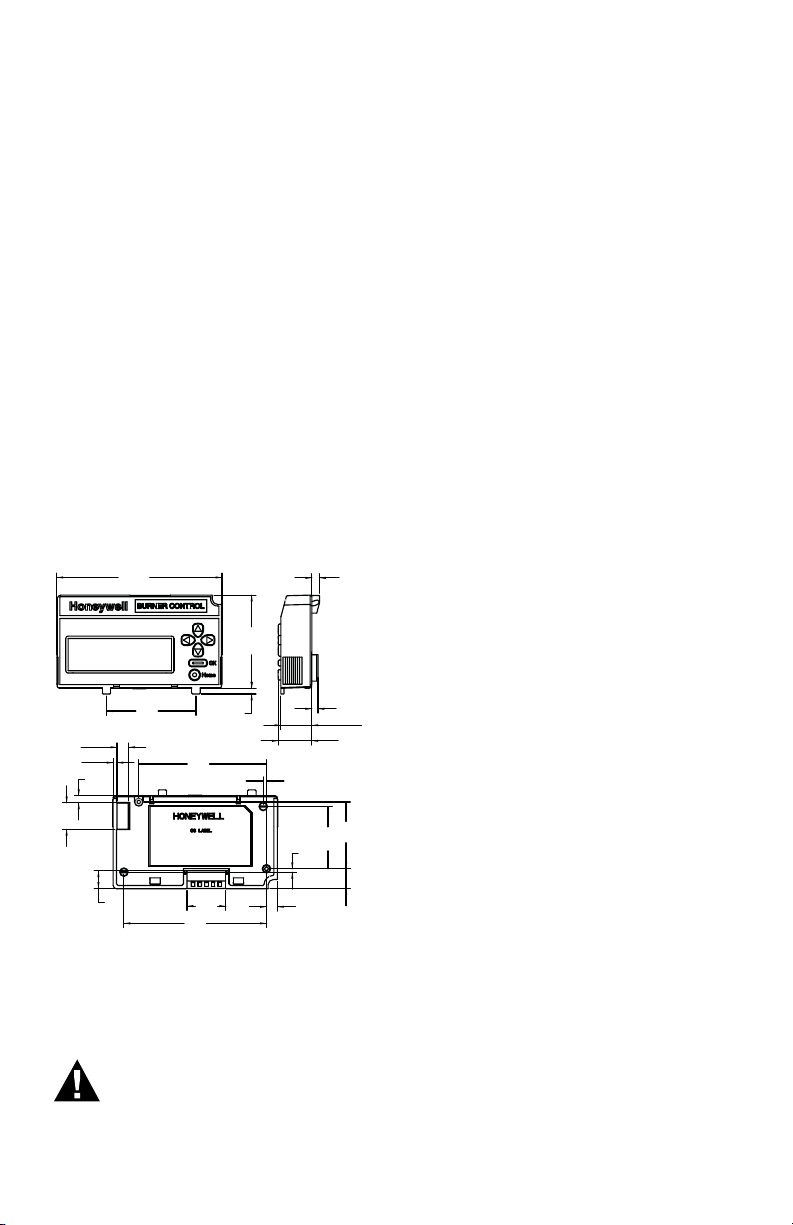

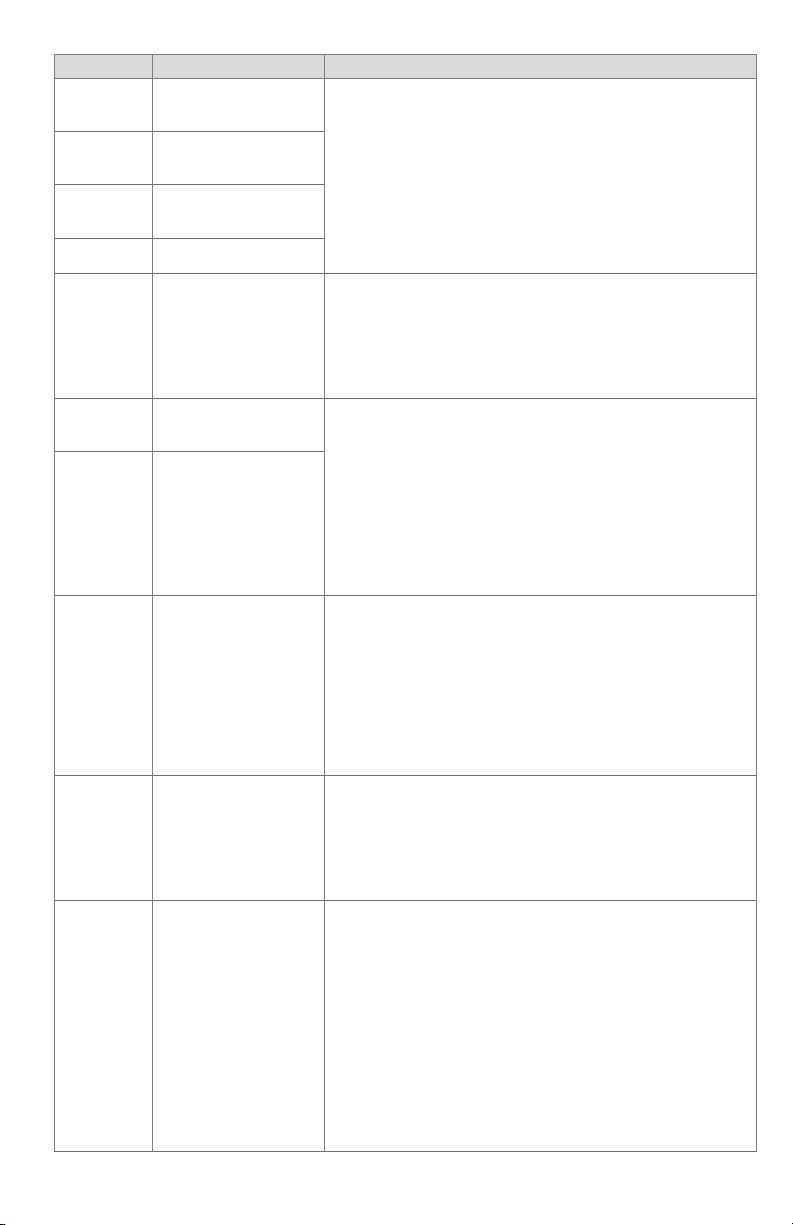

Dimensions: See Fig. 1.

Weight: 4 oz. (124 grams), unpacked.

Display:

5 rows by 64 columns with title and

navigation bar.

Languages:

S7800A2142 English/Spanish/French

Language display.

Approvals:

Underwriters Laboratories Inc. Listed: File

No. MP268, guide No. MCCZ.

Factory Mutual Approved: Report No.

J.I.1V9A0.AF. IRI: Acceptable.

Federal Communications Commission: Part

15, Class B emissions.

outputs.

SERIES.

204729A,C NEMA 4 Cover is used.

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

4.85

(123.3)

2.75

(69.8)

.17

(4.3)

2.63

(66.8)

.18

(4.6)

.91

(23.1)

.99

(25.1)

.22

(5.7)

.59

(15)

.32

(8.1)

3.76

(95.4)

.21

(5.4)

.78

(19.8)

.11

(2.9)

.34

(8.8)

.52

(13.2)

1.14

(29)

4.19

(106.4)

1.97

(50)

.10

(2.5)

.10

(2.4)

1.84

(46.7)

EN60730: For compliance with remote

KDM mounting require- ments, provide

electrical insulation separation by

insulation using double or reinforced

insulation. Do this by: Optically isolating the communication or remote

reset lines from the control cabinet, or

provide physical separation from the

communication or remote display cover

assembly (part number 204729A) or other

suitable enclosure that meets the IP40

class of protection.

Accessories:

203541 ControlBus™ 5-wire Electrical

Connector.

S7810A1009 Data ControlBus™ Module.

203765 Remote Display Mounting Bracket.

221818A 60 in. (1.5 m) Extension Cable

Assembly.

221818C 120 in. (3 m) Extension Cable

Assembly.

204729A NEMA 4 Cover Assembly for

S7800A KDM.

204729C NEMA 4 Cover Assembly for

S7800A KDM with reset button.

205321B Remote Display Flush Mount Kit.

Disconnect the power supply before

beginning installation to prevent

electrical shock and equipment

damage. More than one power

supply disconnect can be involved.

When Installing This Product…

1. Read these instructions carefully.

Failure to follow them could damage the

product or cause a hazardous condition.

2. Check the ratings given in the

instructions and marked on the product

to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced,

flame safeguard service technician.

4. After installation is complete, check out

the product operation as provided in

these instructions.

5. Be sure wiring complies with all

applicable codes, ordinances and

regulations.

6. See Fig. 3 for S7800A unique wiring

connections.

IMPORTANT

1. This equipment generates, uses and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, can cause interference to radio

communications. It has been tested and

found to comply with the limits for a Class

B computing device of Part 15 of FCC rules

which are designed to provided reasonable

protection against such interference when

operated in a commercial environment.

Operation of this equipment in a residential

area can cause interference, in which case,

users, at their own expense, can be required

to take whatever measures are required to

correct this interference.

2. This digital apparatus does not exceed

the Class B limits for radio noise for digital

Fig. 1. Approximate dimensions of S7800A2142

in. (mm).

INSTALLATION

WARNING

Electrical Shock Hazard.

Can cause severe injury, death

apparatus set out in the Radio Interference

Regulations of the Canadian Department of

Communications.

Humidity

Install the S7800A where the relative

humidity never reaches the saturation

point. The S7800 is designed to operate

in a maximum 85% RH continuous,

noncondensing, moisture environment.

Vibration

Do not install the S7800A where it can be

subjected to vibration in excess of 0.5G

continuous maximum vibration.

or property damage.

3 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

Temperature

Temperatures below 32 °F (0 °C) may cause

a slow screen refresh rate and ghosting.

This effect will be most evident during cold

start-up (display has not been operating

and is in a < 32 °F (0 °C) environment). This

is due to the time required for the display to

warm up. The display has a heater feature

which can be set to automatic/ON/OFF

(refer to page 42 Heater Mode)

If the display does not fully recover within 5

minutes, then check the systems line input

voltage to insure it is within specifications.

For certain RM/ EC7800xx models the

display heater (used to improve display

legibility in colder temperatures) will not be

available and will not function regardless

of what the setting is in the display module

Heater Mode.

Refer to page 43 Models that do not

use the Heater Function for a list of relay

models that do not use the heater function.

Weather

The S7800A is not designed to be weather

tight. If installed outdoors, the S7800A

must be protected by an approved

weather-tight enclosure such as the

204729A or 204729C NEMA 4 Enclosure

listed in Accessories.

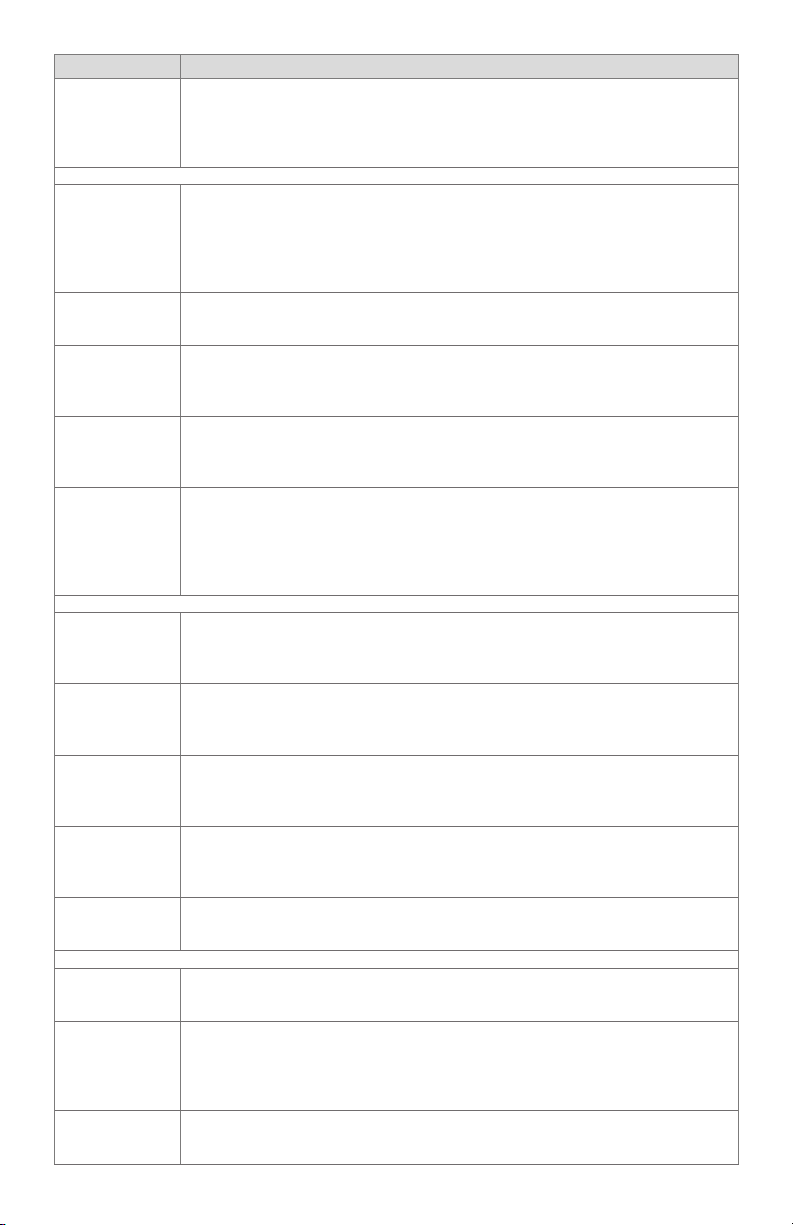

S7800A2142 Embedded Features

See Appendix A to set up the following

features:

• Call Service (Business Card) information

displayed when burner system is in

Lockout of the 7800 SERIES device.

• Customizing of Expanded Annunciator

(S7830) message to match a given

installed limit string. If ModBus Feature

is required, use S7810M1003 ModBus

Module.

• ModBus communication setup and

enable feature: Note that this will

occupy terminals 1, 2, 3 of the 203541

Connector on the KDM, which disables

the Expanded Annunciator Features.

SERVICE NOTE:

The S7800A2142 can either do the

Expanded Annunciator Feature or

ModBus -- not both. If BOTH are

required, order the S7810M1003

ModBus Module for the ModBus

option.

B. The S7800A2142 KDM is also used to

program the Valve Prov- ing and Postpurge feature of Select RM7800 SERIES

devices. See Appendix B.

320011007 4

Mounting KDM on 7800 SERIES

Relay Module.

1. Align the two interlocking ears of the

KDM with the two mating slots on the

7800 SERIES Relay Module. See Fig. 2.

Fig. 2. Keyboard Display Module mounting.

2. Insert the two interlocking ears into

the two mating slots and, with a hinge

action, push on the lower corners of the

KDM to secure it to the 7800 SERIES

Relay Module.

3. Make sure the KDM is firmly in place.

Remote Mounting KDM

The KDM can be mounted either on the

face of a panel door or on other remote

locations. When mounting the KDM on the

face of a door panel, closely follow these

instructions:

1. Select the location on the door panel for

flush mounting.

2. Pay attention to the insertion

dimensions of the two KDM screws, two

interlocking ears, and the two plugin connections to allow for sufficient

clearance.

3. Use the KDM or Data ControlBus

Module™ as a template (Fig. 28)

and mark the two screw locations,

interlocking ear locations and the two

plug-in connector locations.

4. Drill the pilot holes for the mounting

screws.

5. Cut holes in the door panel for the

interlocking ears and the two plug-in

connectors.

6. Mount the KDM, securing it with the

two screws provided in the KDM bag

assembly.

Remote Display Mounting Bracket

Use the 203765 Remote Display Mounting

Bracket when mounting the KDM on a wall

or remote location:

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

1. Use the 203765 Remote Display

Mounting Bracket as a template to mark

the four screw locations.

2. Drill the pilot holes for the four

mounting screws.

3. Mount the 203765 Remote Display

Mounting Bracket by securing the four

no. 6 screws (M3.5 x 0.6).

4. Mount the KDM by aligning the two

interlocking ears with the two mating

slots on the remote mounting bracket.

5. Insert the two interlocking ears into the

two mating slots.

6. Push on the lower corners of the KDM

to secure it to the remote mounting

bracket.

7. Make sure the KDM is firmly in place.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury or

death.

To prevent electrical shock and

equipment damage, disconnect

the power supply from the main

disconnect before beginning

installation. More than one

disconnect can be involved.

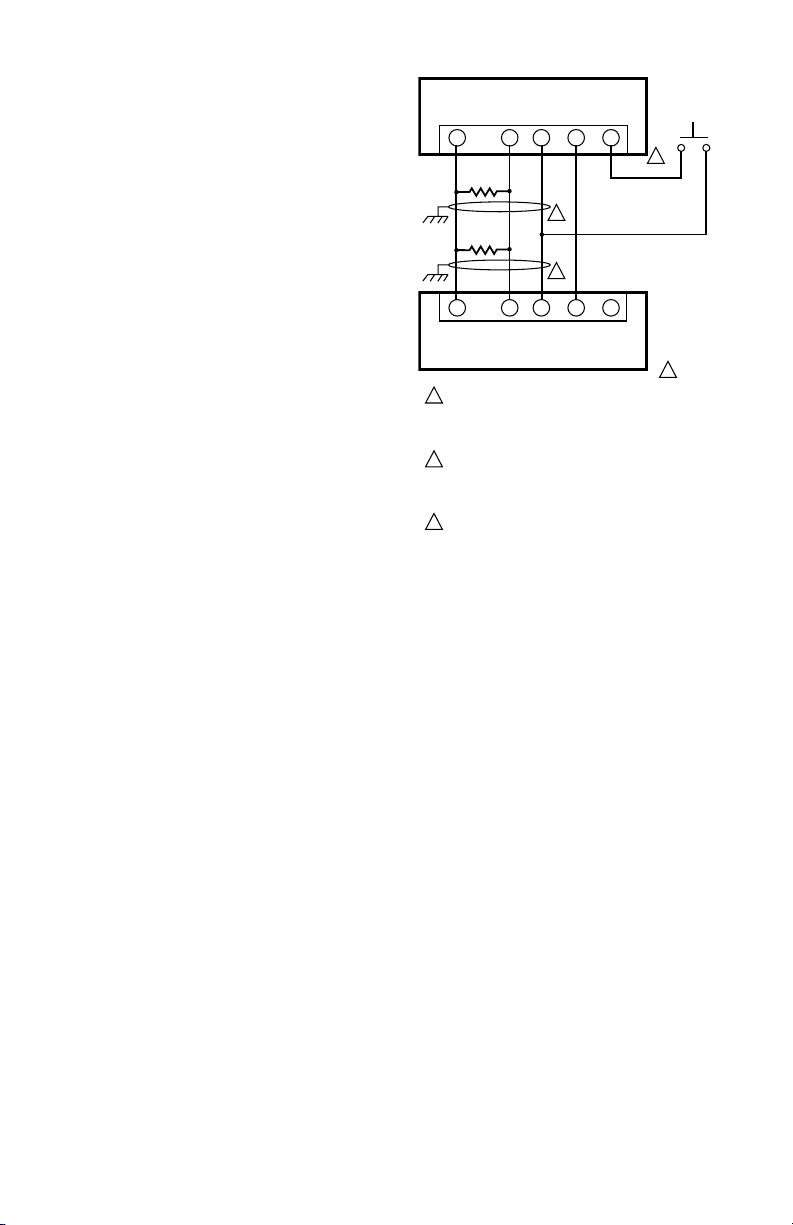

1. Refer to Fig. 3 for proper wiring.

2. Make sure all wiring complies with all

applicable electrical codes, ordinances

and regulations.

3. For recommended wire size and type,

see Table 1.

4. For Recommended grounding practices,

see Table 2.

5. For KDM: The KDM is powered from a

low voltage, energy- limited source. It

can be mounted outside of a control

panel if it is protected from mechanical

damage.

NOTE: A 13 Vdc power supply must be

used any time more than one

KDM is used. A maximum of two

KDM, Data ControlBus™ Modules

or S7810B Multi-Drop Switch

Modules are allowed in any

combination.

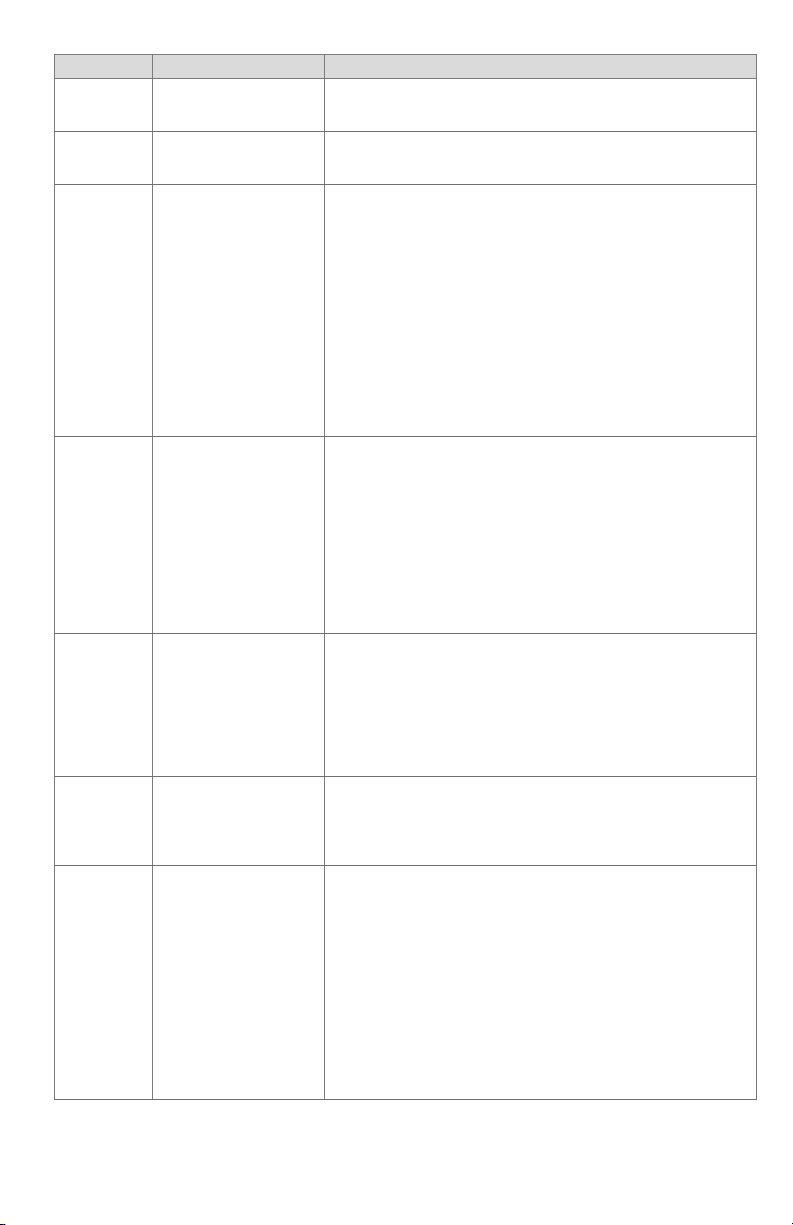

Application

Keyboard Display Module

Data ControlBus™ Module

Remote Reset

Module

Communications

Interface

ControlBus

Module™

13 Vdc full

wave rectified

transformer

power input.

Table 1. Recommended Wire Size and Part Number.

Recommend-

ed Wire Size

22 AWG twowire twisted pair

with ground, or

five-wire.

22 AWG twowire twisted pair

with ground, or

five-wire.

22 AWG twowire twisted pair,

insulated for low

voltage.

22 AWG two-wire

twisted pair with

ground.

18 AWG wire,

insulated for

voltages and

temperatures for

given applications.

Ground Type Recommended Practice

Signal ground

(KDM, Data ControlBus™ Module,

Communications Interface

ControlBus

Module™).

Table 2. Recommended Grounding Practices.

Use the shield of the signal

wire to ground the device to

the signal ground terminals

[3(c)] of each device. Connect the shield at both ends

of the daisy chain to ground.

6. Recommended wire routing:

a. ControlBus:

(1) Do not route the ControlBus cable

in conduits that carry line voltage

circuits.

(2) Avoid routing the ControlBus cable

close to ignition transformer leadwires.

(3) Route the ControlBus cable outside

of conduit if properly supported and

protected from damage.

b. Remote Reset:

(1) Do not run high voltage ignition

transformer wires in the same conduit

with the Remote Reset wiring.

(2) Do not route Remote Reset wires in

conduit with line voltage circuits.

Recommended

Part Num-

ber

Belden 8723

shielded

cable or

equivalent.

Belden 8723

shielded

cable or

equivalent.

—

Belden 8723

shielded

cable or

equivalent.

TTW60C,

THW75C,

THHN90C

7. Maximum wire lengths:

(a) KDM: The maximum length

interconnecting wire is 4000 ft

(1219m).

5 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

S7810 DATA CONTROLBUS MODULEª

A CABINET DOOR.

(b) Remote Reset leadwires: The

maximum length wire is 1000 ft

(MOUNTED ON 7800 SERIES RELAY MODULE)

(300m) to a Remote Reset pushbutton.

8. Install all electrical connectors.

1

9. Restore power to the panel.

KDM Display

The first line of the KDM display provides

current status of the burner sequence

(STANDBY, PURGE, PILOT IGN, MAIN IGN,

RUN and POSTPURGE), timing information

(PURGE, PILOT IGN, MAIN IGN and

POSTPURGE) in minutes and seconds, hold

information (PURGE HOLD), and lockout

information (Lockout, Fault Code, Message

and Sequence). The second line will display

selectable or preemptive messages. A

selectable message supplies information

for flame strength, system status

indication, system or self-diagnostics and

troubleshooting. A preemptive message

has parentheses around the message and

supplies a detailed message to support the

sequence status information. A preemptive

message can also be a lockout message. A

preemptive message replaces a selectable

message to support the sequence status

information. The 7800 SERIES Relay

Module LED provide positive visual

indication of the Relay Module sequence.

The LED is energized simultaneously with

the correct sequence description.

1

THREE WIRE SHIELDED CABLE MAY BE REQUIRED. TWO 120

1

OHM TERMINATING RESISTORS ARE REQUIRED FOR

CONNECTIONS OVER 100 FEET. CABLE SHIELD MUST BE

TERMINATED TO EARTH GROUND AT BOTH ENDS. IF SHIELDED

CABLE IS NOT USED, TWISTED PAIR WIRE MUST BE USED.

2

WHEN CONNECTING THE KEYBOARD DISPLAY MODULE DATA

CONTROLBUS MODULEª, OR REMOTE RESET MODULE

EXTERNAL FROM THE CONTROL CABINET, APPROPRIAT E

MEASURES MUST BE TAKEN TO MEET EN60730 SAFETY

LOW VOLTAGE REQUIREMENTS (SEE APPROVALS).

3

221818A OR C EXTENSION CAN BE USED IN PLACE OF THE

S7810 DATA CONTROLBUS MODULEª IF DISPLAY IS TO

Fig. 3. Wiring Keyboard Display Module for remote

mounting.

A

B

C (GND)

2345

120 OHM

RESISTOR

120 OHM

RESISTOR

2345

A

B

C (GND)

7800 REMOTE KEYBOARD DISPLAY MODULE

RESET

+13 VDC

1

1

RESET

+13 VDC

MOMENTARY

PUSH BUTTON

SWITCH

3

2

M5285C

320011007 6

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

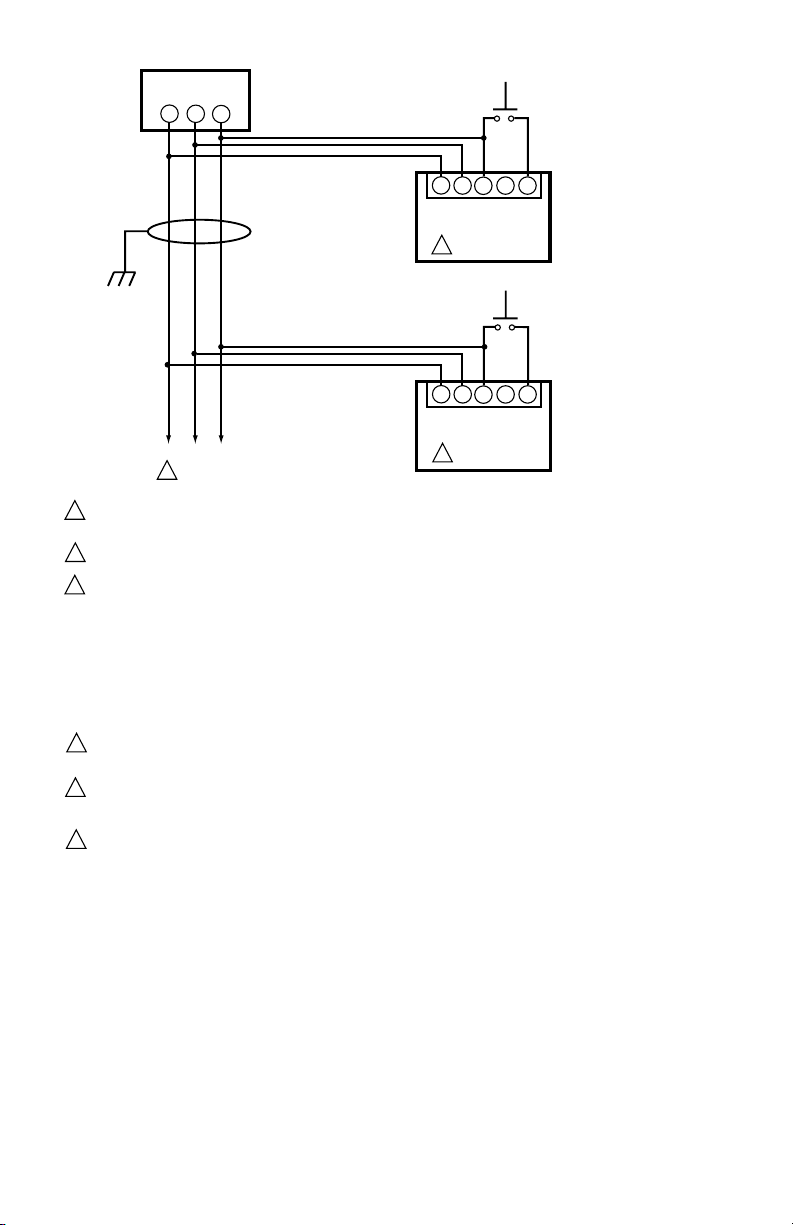

23

23

B

C (GND)

23

23

B

C (GND)

MOMENTARY

PUSHBUTTON

SWITCH

5

4

5

4

+13 VDC

RESET

MOMENTARY

PUSHBUTTON

SWITCH

5

4

5

4

+13 VDC

RESET

RM78xx SERIES DEVICE

WITH S7800 SERIES 5

OR GREATER DISPLAY.

RM78xx SERIES DEVICE

WITH S7800 SERIES 5

OR GREATER DISPLAY.

PC/PLCGND

-

+

B

1

MULTI-DROP RS-485 COMMUNICATION BUS. UP TO 31 S7800 SERIES 5 OR GREATER DISPLAYS CAN BE CONNECTED TO A SINGLE BUS

1

WITHOUT AN RS-485 REPEATER. UP TO 99 MODBUS™ (SUBNETWORKS) CAN BE CONNECTED TO A BUS WITH RS-485 REPEATERS. WHEN

USING AN RS-485 REPEATER, THE REPEATER MUST BE INSTALLED EVERY 30TH MODULE.

THE SUBNETWORKS MUST BE WIRED IN A DAISY CHAIN CONFIGURATION. RECOMMEND THAT THE PC/PLC BE AT ONE END OF THE

2

DAISY CHAIN.

MODBUS™ COMMUNICATION BUS TERMINATION RESISTORS:

3

A. WITHOUT RS-485 REPEATER:

MODULES AT THE CLOSEST AND FARTHEST END OF THE DAISY CHAIN REQUIRE TERMINATION RESISTORS.

INSTALL A 120 OHM, 1/4 WATT RESISTOR BETWEEN TERMINALS A AND B OF THE PC/PLC (IF INSTALLED AT ONE END THE DAISY CHAIN).

INSTALL A 120 OHM, 1/4 WATT RESISTOR BETWEEN TERMINALS 7 AND 8 OF THE LAST S7810M MODBUS™ MODULE IN THE DAISY CHAIN.

B. WITH RS-485 REPEATER:

WHEN AN RS-485 REATER IS USED, TWO DAISY CHAIN CONFIGURATIONS ARE EFFECTIVELY FORMED. MODULES AT THE

CLOSEST AND FARTHEST ENDS OF EACH DAISY CHAIN REQUIRE TERMINATION RESISTORS. INSTALL A 120 OHM, 1/4 WATT

RESISTOR BETWEEN TERMINALS A AND B OF THE PC/PLC (IF INSTALLED AT THE END OF THE DAISY CHAIN. INSTALL A 120

OHM, 1/4 WATT RESISTOR BETWEEN INPUT TERMINALS DATA+ AND DATA- OF THE RS-485 REPEATER. INSTALL A 120 OHM,

1/4 WATT RESISTOR BETWEEN TERMINALS 7 AND 8 OF THE LAST S7810M MODBUS™ MODULE IN THE ADDITIONAL DAISY CHAIN.

LOCAL RS-485 COMMUNICATIONS BUS. THE DEVICES ON THIS BUS MUST BE WIRED IN A DAISY CHAIN CONFIGURATION. THE ORDER OF

4

INTERCONNECTION IS NOT IMPORTANT. THE MODULES ON THE CLOSEST AND FARTHEST ENDS OF THE DAISY CHAIN REQUIRE A 120 OHM,

1/4 WATT TERMINATION RESISTOR BETWEEN TERMINALS 1 AND 2 OR A AND B.

THREE WIRE SHIELDED CABLE (BELDEN 8723 SHIELDED OR EQUIVALENT) IS RECOMMENDED AND SHOULD BE GROUNDED AS

5

FOLLOWS: IF NO INTERFERENCE IS PRESENT, OR TO REDUCE CAPA CITIVE INTERFERENCE, THE SHIELD SHOULD BE GROUNDED

AT ONE END. WHEN GROUNDING ONLY ONE END OF THE THE SHIELD, THE SHIELD END CLOSEST TO THE S7810M MODBUS™

MODULE SHOULD BE ATTACHED TO EARTH GROUND. TO REDUCE INDUCTIVE INTERFERENCE (RF INTERFERENCE), THE SHIELD

SHOULD BE GROUNDED AT BOTH ENDS.

6

TERMINAL NUMBERS ARE ON 203541 5-WIRE CONNECTOR (SUPPLIED WITH REMOTE MOUNTING BRACKET).

RS-485

BUS

CA

1

1

A

6

1

1

A

6

M24190

Fig. 4. Wiring for ModBusTM Feature.

NOTE: LED has been replaced by block characters visible on the MB address setup menu.

7 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

KEYBOARD

4 LINES

LINE WITH

doesn’t make sense for the button action,

selecting the button is ignored.

BUTTONS

Fig. 5. S7800 Keyboard Display Module

Keyboard Functions

The keyboard contains six push-buttons

that are used to navigate on each page and

between pages on the display module (see

Fig. 6). These buttons generally have the

following functions:

• Up arrow - move up on a page or

increment a value for an input control

• Down arrow - move down on a page or

decrement a value for an input control

• Left arrow - move to the left on a page

(tab left) or go to a previous page

• Right arrow - move to the right on a page

(tab right) or go to the next page when

applicable

• OK - approve/accept the highlighted item

or go to the next page when applicable

• Home - go to the Home (Main Status)

page

When the burner control module is in a

Lockout condition the “Home” button

navigates to the Lockout page instead of

the Home page to display the lockout.

These buttons are acted on when they

are pressed and released. In some cases

a button can be pressed and held, i.e., not

released, for repeated execution of the

button (arrow buttons). Buttons are active

on some pages only when the action for the

button makes sense for the position of the

input focus on the page. If the input focus

Fig. 6. Keyboard buttons.

Page Structure

The Home and Lockout pages display text

using a larger font size than all other pages

so that information on them can be more

easily viewed from distances farther away

from the display module (see Fig. 7 and Fig.

8).

Up to 4-5 lines of text are displayed

(dependent on font size) at a time on the

page. When the page has more than 4 lines

of text to display a scroll bar is present on

the right-hand side of the page to indicate

this situation. The “Up arrow” and “Down

arrow” buttons are used to scroll up and

down the lines of the page. Each line is

highlighted with a white background to

indicate that it currently has input focus for

any button actions. The scroll bar adjusts to

give a relative position of the current view

with respect to all lines that the page can

display.

When a line has a right arrow symbol

positioned on the righthand side it

indicates that this line can navigate to

another page, “Next page”, related to the

subject of the line when that line has input

focus. A “Right arrow” or “OK” button can

be pressed when the focus is on this line to

navigate to the next page.

Fig. 7. Home page

320011007 8

SCROLL

BAR

RIGHT ARROW SYMBOL INDICATES

“NEXT” PAGE IS AN OPTION

INPUT

FOCUS

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

4 LINES

TION

BAR

W INPUT

MENU

GO TO

LOCKOUT

DETAIL

Fig. 8. Lockout page

For pages other than Home and Lockout a

smaller font size is used to display the text

and pages have a format like the one shown

in Fig. 9.

TITLE BAR

MAIN

BODY

NAVIGA

Fig. 9. Page structure

The top line of the page is a title that

describes the context or purpose of the

page (see Fig. 9).The bottom line of the

page is a navigation bar which indicates

the more important button actions that can

be performed for the current input focus

(see Fig. 10). The middle or main body

of the page contains the lines that show

information or allow for user input. Up to 5

lines of text may be displayed in the main

body. Solid lines separate the title and

navigation bar from the main body.

INPUT FOCUS

Home Page

The Home page is the main status page

that displays primary status of the burner

control operation (see Fig. 11). This page is

intended to be the primary one displayed

most often when the user is not specifically

looking for other information or configuring

the display. The following information is

displayed by default:

• Burner control sequence or lockout state

• Flame signal strength

• Total cycles count

• Total run-time hours count

• Annunciator connection status

• Remote command status

The burner control sequence state may

be displayed in one or two lines due to the

length of the text. In case of two lines the

remaining lines are pushed down to make

room for the second line.

This page also permits navigation to the

following pages:

• Lockout message (when burner control is

in a lockout condition)

• Fault history

• Burner control diagnostic status

• Annunciator diagnostic status (when

annunciator is connected)

• Burner control commissioning

(supported models only)

• Display menu

MAY BE 1 OR 2

LINES (SEQUENCE

STATE)

NE

FOCUS

Fig. 10. Input focus

An item on a page that has input focus

is usually highlighted with an inverse

look (black text on white background) to

distinguish it from the rest of the page.

The arrow buttons move the input focus

to another selectable item if another one

exists on the page (some pages may only

have a single focus item).

For pages that allow user input (see Fig.

10) the input value is edited on the page

and then is acknowledged or confirmed at

another tab position on the page (“Yes” tab

Fig. 11. Home page status

An additional status line can be displayed

between the burner control sequence line(s)

and the flame signal strength line when

configured (see “Selected Status Message”

on page 30). Fig. 12 shows an example

with the T6 terminal (“Demand”) status

displayed.

in the above example). This confirmation

action permits the user to cancel the editing

and not commit to the change or to accept

the edited value.

Fig. 12. Home page status

9 320011007

GO TO FAULT

HISTORY

GO TO BURNER

DIAGNOSTICS

GO TO

COMISSIONING (ONLY

SOME MODELS)

GO TO DISPLAY

OPTIONAL

SELECTED

STATUS

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

The lines are scrollable using the up and down arrows. For lines that navigate to another

page the right arrow or OK button is pressed when the line has input focus (highlighted) to

go to the new page.

TROUBLESHOOTING

After the KDM is installed, return the 7800 SERIES to normal operation, restore power

and run the system through at least one complete automatic cycle. For complete

Troubleshooting and System Checkout information, see form 65-0229.

7800 SERIES System Diagnostics

Troubleshooting control system equipment failures is made easier with the 7800 SERIES

self-diagnostics and first-out annunciation. The S7800 provides visual annunciation by

displaying a fault code and fault or hold message on the display.

Self-diagnostics of the 7800 SERIES enables it to detect and annunciate both external

and internal system problems. Internal faults and external faults such as interlock failures,

flame failures and false flame signals are annunciated by the KDM via the 7800 SERIES

Relay Module.

The KDM displays a sequence status message indicating STANDBY, PREPURGE, PREIGNITION, SAFETY 1, PILOT IGN, PILOT STAB., MAIN IGN, RUN or POSTPURGE, as

appropriate. The selectable messages also provide visual indication of current status and

historical status of the equipment, such as: Flame Signal, Total Cycles, Total Hours, Fault

History, Diagnostic Information and Expanded Annunciator terminal status (if used).

With this information, most problems can be diagnosed without extensive trial-and-error

testing.

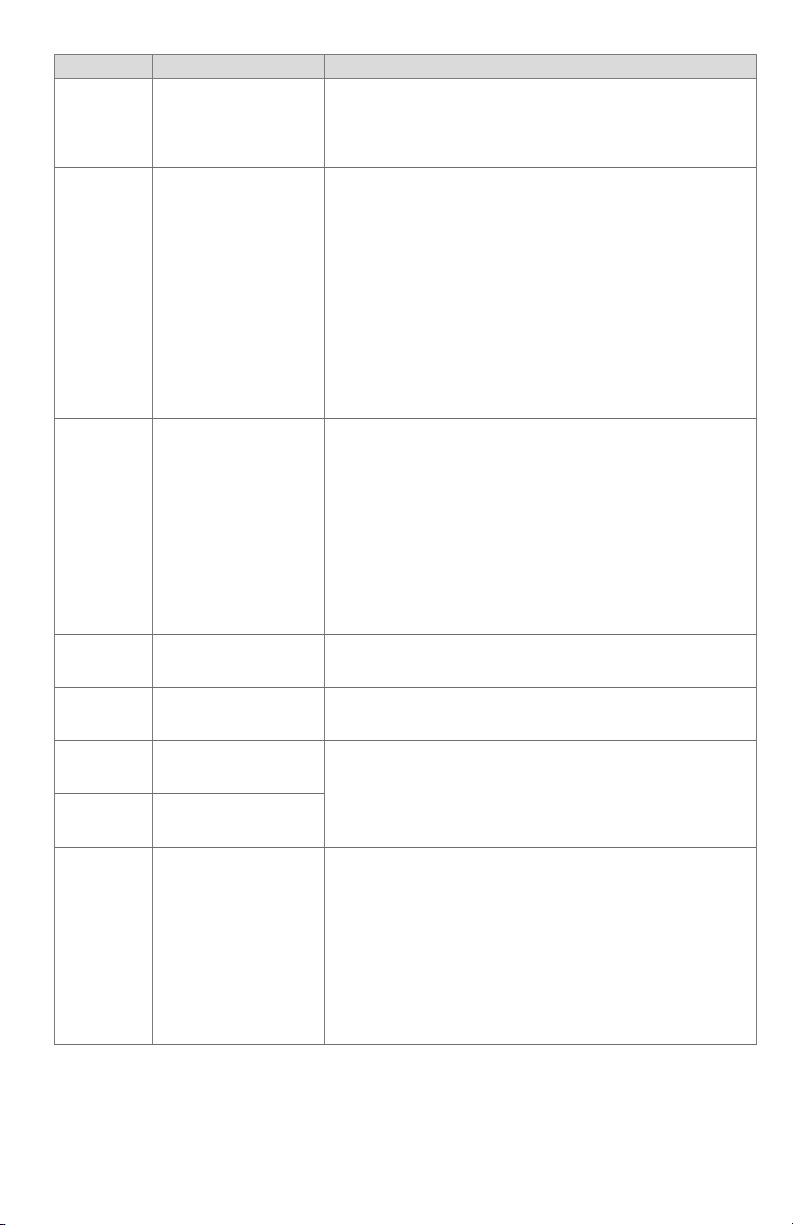

Table 3 provides the sequence and status hold messages. These messages along with the

fault messages (Table 5) can be viewed on-line in the KDM.

320011007 10

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

Sequence Status

The Keyboard Display Module (KDM) indicates the burner status, INITIATE, a

stabilization period for the relay module to check for any fluctuations in ac line

INITIATE mm:ss

voltage inputs or control inputs on power up or during normal operation. The

timing of the INITIATE period is either two seconds or ten seconds, depending

on the model, before entering STANDBY.

If the relay module is in an INITIATE HOLD status, the following conditions could exist:

The KDM indicates the burner status and that it is waiting for excess line noise

INITIATE HOLD:

(AC Frequency/

Noise)

to clear up, which prevents sufficient reading of the line voltage inputs. The

burner sequence does not advance into STANDBY until the excess line noise

ceases or a line frequency error occurs; this is caused by using a 60 Hz device

on a 50 Hz line, or vice versa on devices with a date code earlier than 9804, is

corrected.

INITIATE HOLD:

(AC Line Dropout)

The KDM indicates the burner status and that ac line power has momentarily

dropped out. The burner sequence does not advance into STANDBY until the ac

line voltage has stabilized throughout the INITIATE sequence.

The KDM indicates the burner status and that line frequency is faster than the

INITIATE HOLD:

(AC Frequency)

expected value. The burner sequence does not advance into STANDBY until the

line frequency returns to the proper value; this is perhaps caused by using a 60

Hz device on a 50 Hz line for devices with a date code earlier than 9804.

INITIATE HOLD:

(Low Line Voltage)

The KDM indicates the burner status and that low line voltage (10% lower

than rated voltage) has occurred. The burner sequence does not advance

into STANDBY until the line voltage is at a sufficient level for proper operating

parameters.

The KDM indicates the burner status, STANDBY. The burner can be placed in

STANDBY by opening the burner switch or if the operating controller indicates

STANDBY

its setpoint is satisfied. If a demand is present for burner operation, the burner

sequence does not advance from STANDBY to PURGE until the recycle limits

close. If an Expanded Annunciator is connected, the display messages are

enhanced.

If the relay module is in a STANDBY HOLD status, the following conditions could exist:

STANDBY HOLD:

F/G (Flame

Detected)

STANDBY HOLD:

T20(Pre-Ignition

Interlock)

STANDBY HOLD:

T7(Lockout

Interlock)

STANDBY HOLD:

T7 (Running

Interlock) EC/

RM7850

The KDM indicates the burner status and that a flame is detected. A demand

is present for burner operation. The sequence does not advance to PREPURGE

until the flame signal clears. If the flame signal does not clear within 40 sec-

onds, the relay module locks out.

The KDM indicates the burner status and that the Pre-Ignition Interlock is not

closed. A demand is present for burner operation, but the burner sequence does

not advance to PREPURGE until the Pre-Ignition Interlock proves closed. If this

time exceeds a 30 second hold, the relay module locks out.

The KDM indicates the burner status and that the Lockout Interlock is closed.

A demand is present for burner operation, but the burner sequence does not

advance to PREPURGE until the Lockout Interlock proves open. If this time

exceeds the 120 second hold, the relay module locks out.

The KDM indicates the burner status and that the Running Interlock is closed.

A demand is present for burner operation, but the burner sequence does not

advance to PREPURGE until the Running Interlock proves open. If this time

exceeds the 120 second hold, the relay module locks out.

The KDM indicates the burner status, PURGE, which is the period of time the

PURGE

blower motor is running before the Ignition period. The timing of the PURGE

period is selectable.

If the relay module is in a PURGE HOLD status, the following conditions could exist:

PURGE HOLD:

T19 (High Fire

Switch)

PURGE DELAY:

T19 (High Fire

Switch Jumpered)

PURGE HOLD:

TEST (Run/Test

Switch)

11 320011007

The KDM indicates the burner status and that the High Fire Switch is not closed.

The firing rate motor is driving to its PURGE rate position. If this time exceeds

four minutes and fifteen seconds, the relay module locks out.

The KDM indicates the burner status and that the High Fire Switch is jumpered.

The High Fire Switch is bypassed, welded or otherwise prematurely closed. The

system automatically adds 30 seconds to allow the firing rate motor additional

drive time to reach or near the open damper position before starting the PURGE

sequence.

The KDM indicates the burner status and that the Run/Test Switch is in the

TEST position. The sequence does not continue until the Run/Test Switch is

placed in the RUN position.

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

Sequence Status

PURGE HOLD:

T18 (Low Fire

Switch Jumpered)

PURGE HOLD:

F/G(Flame Detected)

PURGE HOLD:

T18 (Low Fire

Switch)

PURGE HOLD:

T7 (Running

Interlock)

PILOT IGN

mm:ss

The KDM indicates the burner status and that the Low Fire Switch is jumpered.

The Low Fire Switch is bypassed, welded or otherwise prematurely closed. The

system automatically adds 30 seconds to allow the firing rate motor addition-

al drive time to reach or near the closed damper position before starting the

ignition sequence.

The KDM indicates the burner status and that a flame is detected. The burner

sequence does not advance through PREPURGE because a flame is detected

as being present. The sequence holds waiting for the flame signal to clear. If the

time exceeds 30 seconds, the relay module locks out.

The KDM indicates the burner status and that the Low Fire Switch is not closed.

The firing rate motor is driving to its Low Fire position in preparation for Ignition

Trials. If this time exceeds four minutes and fifteen seconds, the relay module

locks out.

The KDM indicates the burner status and that the Running Interlock is not

closed. The sequence does not advance to ignition until the Running Interlock

proves closed. If this time exceeds 30 seconds, the relay module locks out.

The KDM indicates the burner status, PILOT IGN, and the timing of the PILOT

IGN trial begins, in seconds. During this period, the relay module permits the

pilot valve to open and the pilot flame to establish.

If the relay module is in a PILOT HOLD status, the following conditions could exist:

PILOT HOLD:

TEST (Run/Test

Switch)

The KDM indicates the burner status, PILOT IGN, and that the Run/Test Switch

is in the TEST position. The sequence does not continue until the Run/Test

Switch is placed in the RUN position.

The KDM indicates the burner status, MAIN IGN, and the timing of the MAIN

MAIN IGN mm:ss

IGN trial begins, in seconds. During this period, the relay module permits the

main valve to open and the main flame to establish.

The KDM indicates the burner status, RUN, which is the period of time after the

RUN

Ignition Trials and before the operating controller setpoint is reached. During

this time, the burner is firing under control of the firing rate control.

If the relay module is in a RUN HOLD status, the following condition could exist:

RUN LOWFIRE:

TEST (Run/Test

Switch)

POSTPURGE

mm:ss

Waiting for connection...

The KDM indicates the burner status and that the Run/Test Switch is in the

TEST position. Normal modulation or operation does not continue until the

Run/Test Switch is placed in the RUN position.

The KDM indicates the burner status, POSTPURGE, which is the period of time

after the RUN period when the blower motor continues to run. The timing of the

POSTPURGE period is fifteen seconds.

The KDM has power but is waiting to receive a signal from the relay module to

continue operation.

The KDM indicates the burner status, RESET/ALARM TEST. This condition inRESET/ALARM

TEST

dicates that the reset button is pressed. If it is held for more than four seconds,

the alarm output is energized. The alarm output is de-energized when the reset

button is released.

Additional Sequence Status Information When An Expanded Annunciator is Connected to the

Relay Module:

BURNER OFF: T6

(Burner Switch)

The KDM indicates the Burner Switch is not closed. The burner sequence does

not advance to PREPURGE until the Burner Switch closes.

The KDM indicates the burner status, STANDBY, and that the Operating Control

STANDBY

is not closed. The burner sequence does not advance to PREPURGE until the

Operating Control closes.

STANDBY HOLD:

T6 (EA Hold

Message)

STANDBY HOLD:

T6 (Circuit Fault)

Table 3. Keyboard Display Module Sequence and Status Hold Messages .

The KDM indicates the burner status, STANDBY, and that a limit is not closed.

The burner sequence does not advance to PREPURGE until one or all limits

close downstream from the Operating Control.

The KDM indicates the burner status, STANDBY, and that the control input is not

closed. The burner sequence does not advance to PREPURGE until the control

input closes.

320011007 12

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

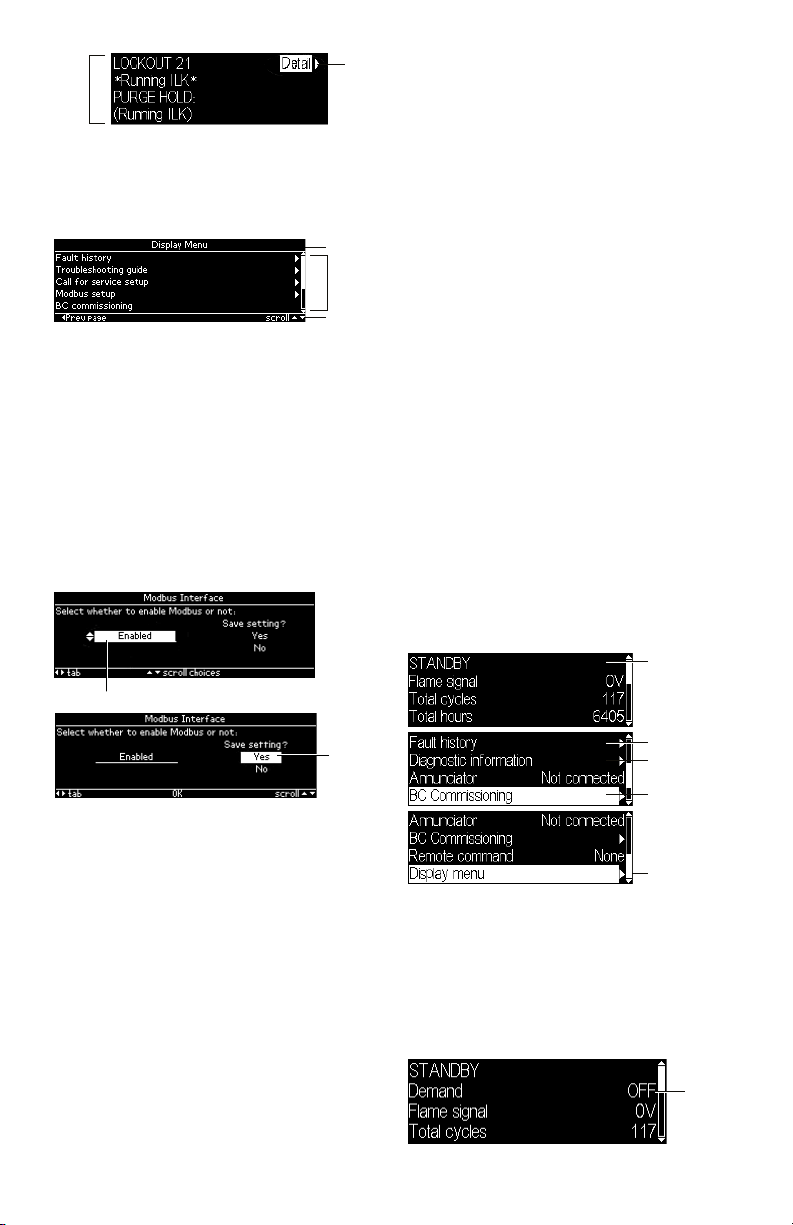

The S7800 provides diagnostic information to aid the service mechanic in obtaining

information when troubleshooting the system. See Table 4 for information on accessing

historical and diagnostic selectable messages. Information available in the Diagnostic

Information includes Device Type, Software Revision, Manufacturing Code, Flame Amplifier

Type, Flame Failure Response Time (FFRT), Selectable Jumper Configuration Status, Run/

Test Switch Status and Terminal Status.

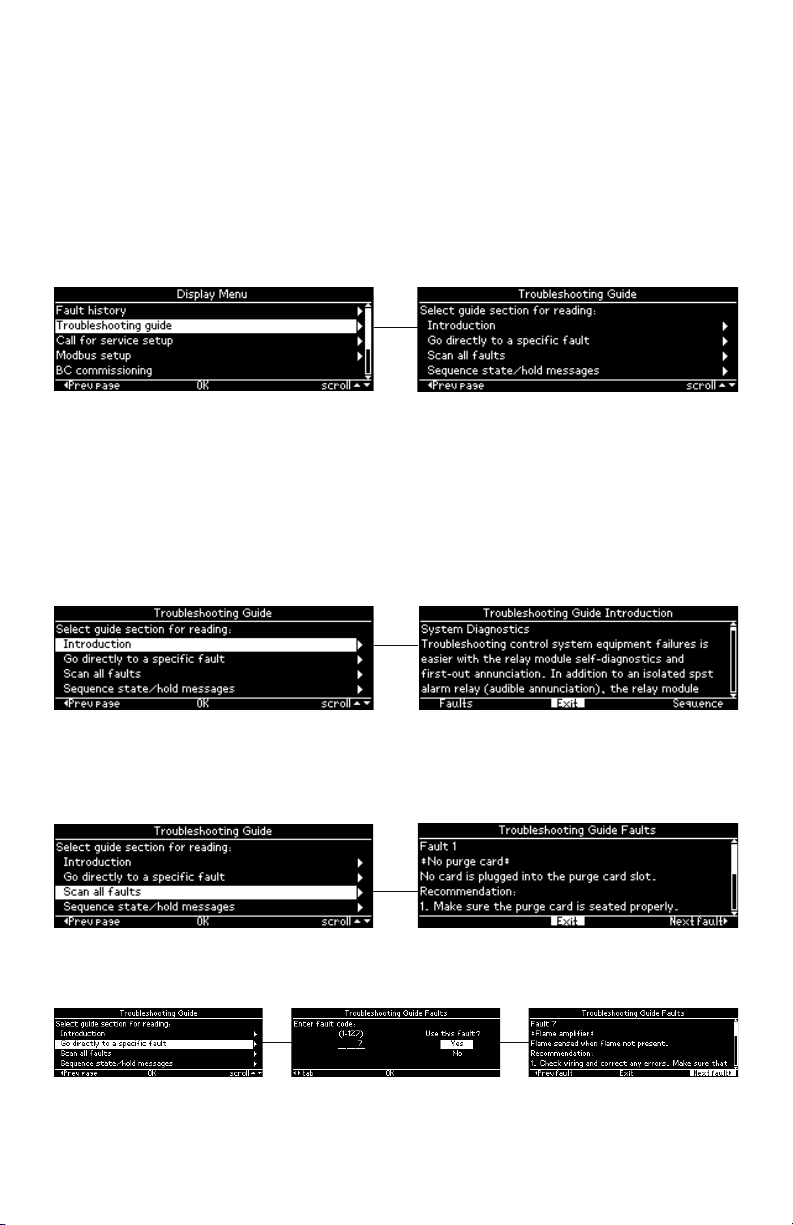

Information from the above table and Table 5 are viewable in the display module. The

troubleshooting guide can be accessed from the Display Menu (see Fig. 13). A menu is

displayed that permits access to these different sections of the guide:

• Introduction

• Faults

• Sequence and Status Hold messages

Fig. 13. Troubleshooting guide menu

The Introduction section contains brief troubleshooting tips and is presented in a scrollable

paragraph form for reading using the up and down arrow buttons (see Fig. 14). The

navigation bar contains the following commands that can be selected using the right and

left arrow buttons:

• “Faults” – go to Troubleshooting guide Faults section

• “Exit” – exit Introduction section and return back to Troubleshooting guide menu

• “Sequence” – go to Troubleshooting guide Sequence/Status Hold section

Pressing the OK button executes the command with the current input focus.

Fig. 14. Troubleshooting guide introduction

The Faults section presents a description and recommended actions for each fault that

the burner control module may have (see Fig. 15). The information is presented for a single

fault code and when more lines are needed to display the information than can fit on the

page, the up and down arrow buttons are used to scroll through the lines.

Fig. 15. Troubleshooting guide faults section

The Faults section can be accessed starting at the beginning (see Fig. 15) or by going

directly to a specific fault code (see Fig. 16).

Fig. 16. Troubleshooting guide direct fault access

13 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

The Faults navigation bar contains the following commands that can be selected using the

right and left arrow buttons:

• “Prev fault” – go to previous fault code

• “Exit” - exit Faults section and return back to Troubleshooting guide menu

• “Next fault” – go to next fault code

Pressing the OK button executes the command with the current input focus.

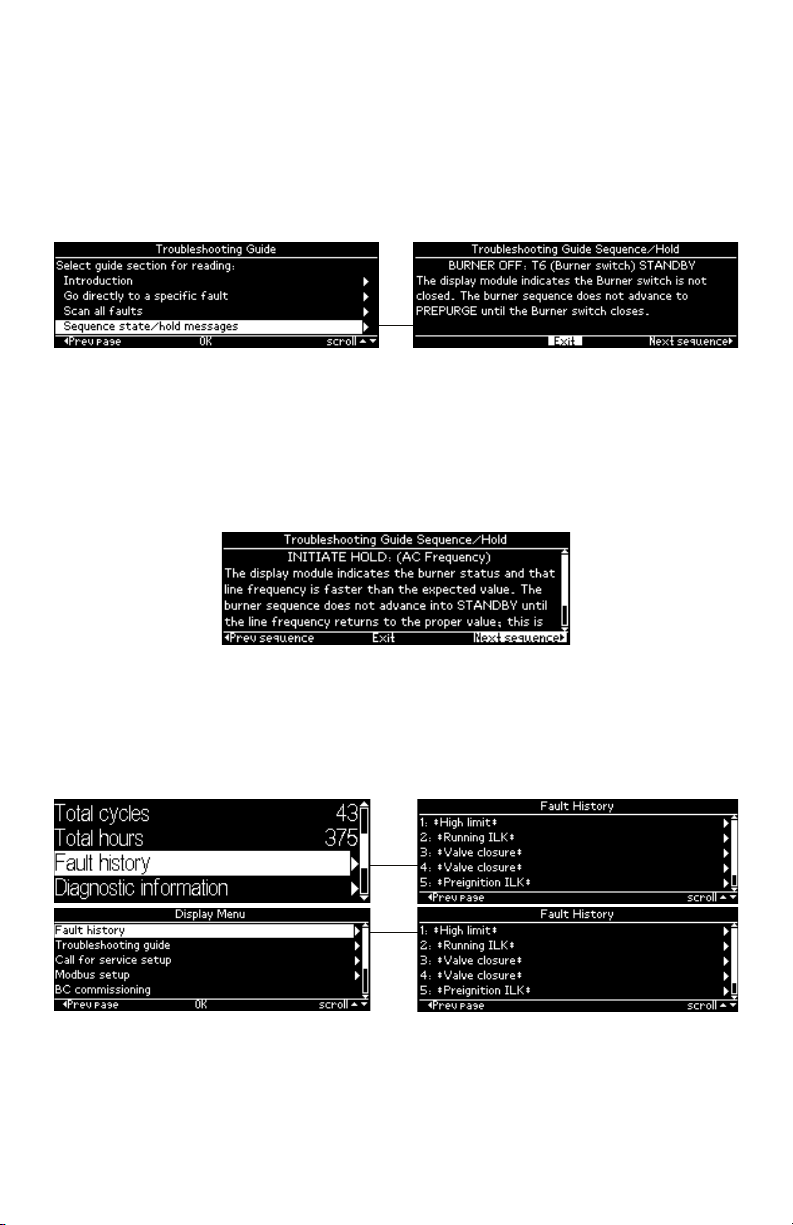

The Sequence and Status Hold section explains the meaning of different sequence state

and status hold messages that can display for a burner control on the display module (see

Fig. 17). The up and down arrow buttons are used to scroll the lines of the explanation.

Fig. 17. Troubleshooting guide sequence section

The Sequence/Status Hold navigation bar (see Fig. 18) contains the following commands

that can be selected using the right and left arrow buttons:

• “Prev sequence” – go to previous sequence/status hold message

• “Exit” - exit Sequence/Status Hold section and return back to Troubleshooting guide

menu

• “Next sequence” – go to next sequence/status hold message

Pressing the OK button executes the command with the current input focus.

Fig. 18. Troubleshooting guide sequence section (continued)

Historical Information Index

The S7800 displays historical information for the six most recent lockouts. Each of the six

lockout records retains the cycle when the fault occurred, a fault code, a fault message, and

burner status when the fault occurred. The fault history can be accessed from either the

Home or Display Menu pages (see Fig. 19).

Fig. 19. Fault history menu

The fault history is displayed in order from most recent lockout, #1, on the first line to the

oldest lockout on the last line. The up and down arrow buttons are used to scroll to the

lockout desired and the right arrow or OK button is pressed to view the fault information

(see Fig. 20) for that lockout.

320011007 14

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

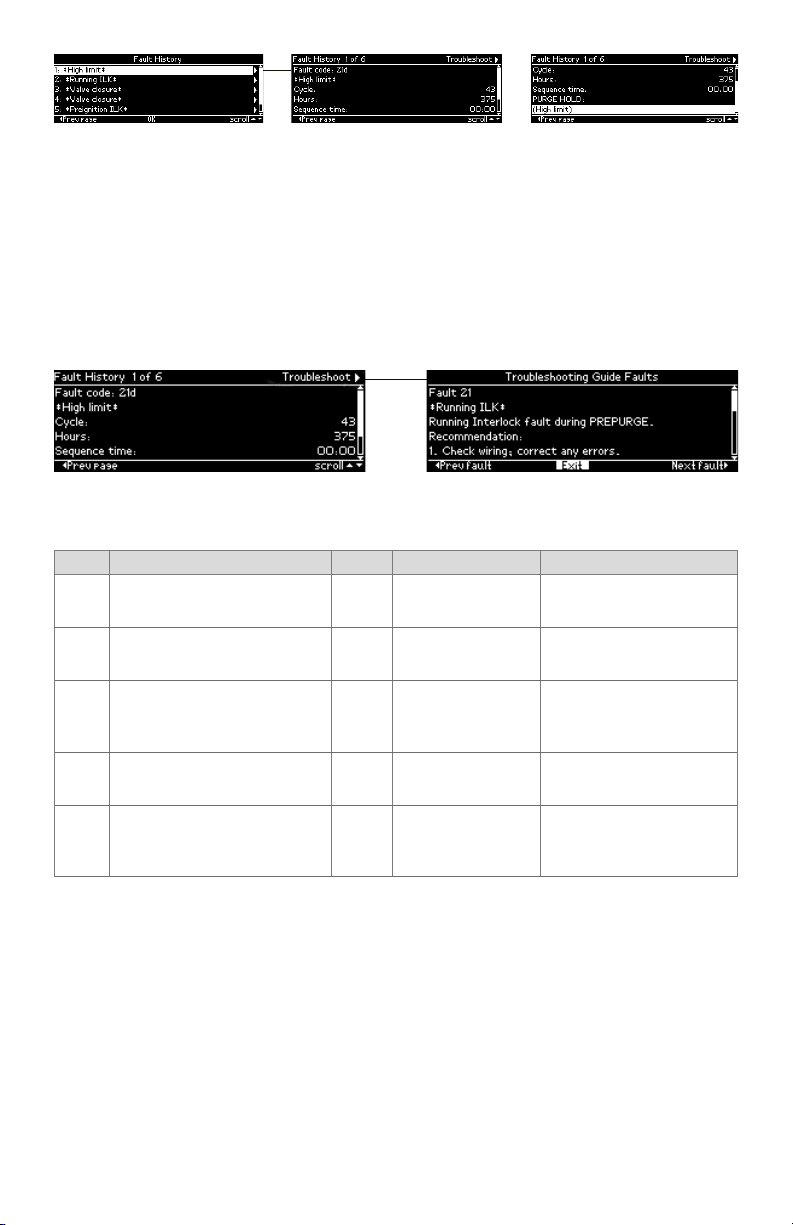

Fig. 20. Fault history record

The fault record is scrollable using the up and down arrow buttons to see all lines of the

information. The fault description can take 1 or 2 lines to display and is presented on the

line(s) below the fault code line. Below the sequence time line is displayed the sequence

state that the burner control was in at the time of the fault. This state description may take

1 or 2 lines to display also.

The left arrow button can be pressed to exit this fault record and go back to the Fault

history menu (previous page).

The title bar displays which fault history record is displayed and indicates that the

Troubleshooting guide can be navigated to using the “Next page” (right arrow) button (see

Fig. 21).

GO TO

TROUBLESHOOTING

GUIDE

Fig. 21. Troubleshooting guide from fault history record

When the “Exit” command in the troubleshooting guide has input focus and the OK button

is pressed control returns back to the fault history record.

Step Operation Press Display Comments

Press hi buttons to access

1.

Diagnostic Information.

Press u button to access Diag-

2.

nostic Information.

hi

t u

STANDBY Diagnostic Information>

STANDBY Diagnostic Information>

Use the Down/Up arrow

buttons to access the "Diagnostic information" line.

Use the right arrow or OK

button to access the Diagnostic Information.

Push the Down/Up arrow

Continue display of Diagnostic

3.

Information.

hi

Device RM7800<

buttons to scroll through

the burner control diagnostic status.

Continue through remaining

4.

diagnostic information display

— — —

following step 3 as required.

Another display can be

Press the t arrow button to

5.

return to the Home page

t u

STANDBY Diagnostic Information>

selected or discontinue

accessing Diagnostic Information review.

Table 4. Accessing Historical and Diagnostic Selectable Messages.

SERVICE NOTE: If the Keyboard Display Module screen is scrambled, remove and reinstall

the Keyboard Display Module and reset the 7800 SERIES Relay Module.

SERVICE NOTE: Reset the 7800 SERIES Relay Module by pressing the reset push button

on the relay module or pressing a remote reset push button wired through the

Keyboard Display Module, Data ControlBus™ Module or Remote Reset Module. A

power-up reset will cause an electrical reset of the 7800 SERIES Relay Module but

will not reset a lockout condition.

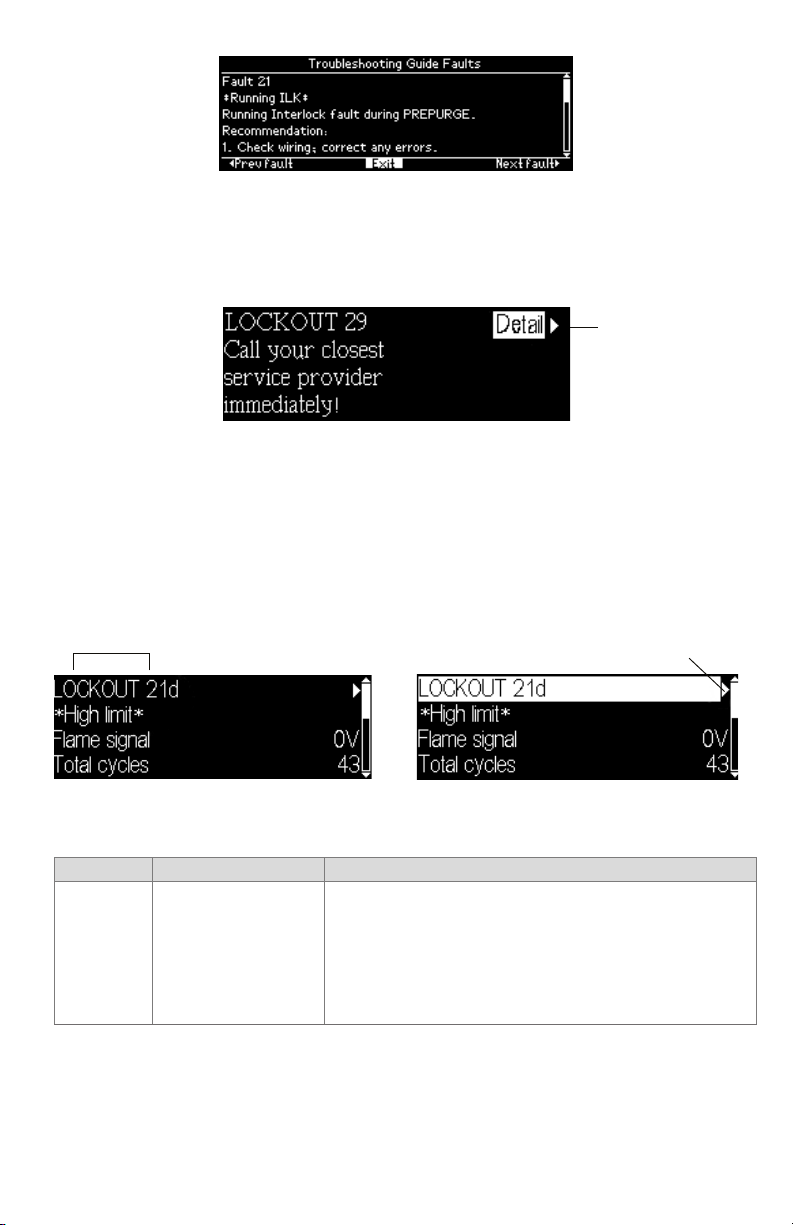

Lockout Messages

When the 7800 SERIES is locked out, a standard lockout message is displayed unless the

Call for Service feature is enabled. When the Call for Service feature is enabled a custom

lockout message is displayed instead. The standard lockout message (see Fig. 22) is

automatically displayed when the lockout initially occurs unless the user happens to be

15 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

ANNUNCIATED

editing a parameter on a page. In this case the lockout message waits until the user is done

editing and exits the page.

FAULT CODE

DESCRIPTION

STATE AT TIME

OF FAULT

GO TO

LOCKOUT

DETAIL

Fig. 22. Lockout message

Up to 4 lines are displayed in the standard lockout message. The top line shows the

numeric fault code that determined the lockout. A description of this fault is shown on the

second line and possibly on the third line if the description requires two lines to display

it (only one line needed in the above example). On the next line(s) the burner control

sequence state at the time of the lockout is displayed. The sequence state may need 1 or 2

lines to display (Fig. 22 required two lines). Since a maximum of 4 lines are displayed in this

message, in the case when both the fault description and sequence state each need 2 lines

to display their text, the second line of the sequence state is dropped to make room.

FAULT CODE

ANNUNCIATED

DESCRIPTION

Fig. 23. Annunciated lockout message

When an annunciator is connected to the burner control system it may annunciate the

lockout to provide more detailed information regarding the lockout. In this case the fault

code is annunciated with a fault code letter and the fault description identifies more

specifically the cause of the fault (see Fig. 23 for an example).

On the top line of the message the input focus is on a flashing “Detail” tab that permits

the user to view more details about the lockout. Pressing the “Right arrow” or “OK” button

navigates to a Lockout Detail page (see the following figure) that provides the following

information:

• Fault code

• Fault description

• Cycle count at the time of the fault

• Run-time hours at the time of the fault

• Sequence time at the time of the fault

• Operation sequence state at the time of the fault

Fig. 24. Lockout detail

The information may take more lines to display than can fit on the 5 main body lines. In this

case the a scroll bar is displayed, and the up and down arrow buttons can be used to scroll

to view all lines.

A flashing “Troubleshoot” tab is displayed in the title bar that has input focus to indicate

that the troubleshooting guide can be navigated to display what is recommended for this

fault (see Fig. 25).

320011007 16

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

LOCKOUT

Fig. 25. Troubleshooting guide

When the Call for Service feature is enabled a custom message up to 8 lines is displayed

instead of the standard lockout message (see Fig. 26 for an example). Only 4 lines of the

custom message are displayed at a time; the first 4 lines are displayed for 2 seconds,

followed by the remaining lines for 2 seconds. The page alternates between these two sets

of lines continuously. If the custom message is 4 lines or less, no alternation is needed.

GO TO

LOCKOUT

DETAIL

Fig. 26. Call for Service lockout message

The first or top line of the message is not custom and is the same as the top line in the

standard lockout message. This line permits the user to navigate to the Lockout Detail

page.

The lockout message (standard or custom) displays continuously while the lockout

condition persists. The user may elect to exit the message to view other pages by pressing

the “Left arrow” or “Home” button which navigates to the Home page. The lockout

condition is displayed on the Home page (see Fig. 27) which permits the user to re-display

the lockout message. Pressing the “Right arrow” button when the lockout fault code line

has input focus causes the lockout message to be re-displayed.

C0NDITION

GO TO

LOCKOUT

MESSAGE

Fig. 27. Lockout indication on Home page

The following table describes the possible faults a burner control may have and the

recommended action.

Fault Code System Failure

Make sure the purge card is seated properly.

Inspect the purge card and connector on the relay module for

damage or contaminants.

Fault 1 *No

Purge Card*

No card is plugged into

the purge card slot.

Reset and sequence the relay module.

If the fault code reappears, replace the purge card.

Reset and sequence the relay module.

f the fault persists, replace the relay module.

17 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

Fault Code System Failure

Fault 2 *AC

Frequen/

Noise*

Fault 3 *AC

Line Dropout*

Fault 4

*AC Frequency*

Fault 5*Low

Line Voltage*

Excess noise or device

running on slow AC.

AC line dropout detected.

Device running on fast

AC.

Low AC line detected.

Check the relay module and display module connections.

Reset and sequence the relay module.

Check the relay module power supply and make sure that

both frequency and voltage meet the specifications.

Check the backup power supply, as appropriate.

Make sure the purge card is seated properly.

Inspect the purge card and connector on the relay module for

Fault 6

*Purge Card

Error*

Purge card timing

changed since card was

initially read.

damage or contaminants.

Reset and sequence the relay module.

If the fault code reappears, replace the purge card.

Reset and sequence the relay module.

If the fault persists, replace the relay module.

Fault 7

*Flame Amplifier*

Flame sensed when

flame not present.

Check wiring and correct any errors. Make sure that flame

sensor wires are in separate conduits. Check for noise cou-

pling into the flame detector leadwires.

Make sure that flame detector and flame amplifier are com-

patible.

Fault 8

*Flame Amp/

Shutter*

Flame sensed when no

signal expected during

shutter-check or Ampli-Check versions.

Remove the flame amplifier and inspect connections. Reseat

the amplifier.

Reset and sequence the relay module.

If the code reappears, replace the amplifier and/or the flame

detector.

If the fault persists, replace the relay module.

Check that flame is not present in the combustion chamber;

correct any errors.

Check wiring and correct any errors. Make sure that flame

Fault 9

*Flame

Detected*

Flame sensed when

shutter open and no

flame is expected

during STANDBY.

sensor wires are in separate conduits. Check for noise cou-

pling into flame detector leadwires.

Remove the flame amplifier and inspect its connections.

Reseat the amplifier. Reset and sequence the relay module.

If the code reappears, replace the amplifier and/or the flame

detector.

If the fault persists, replace the relay module.

Check wiring and correct any errors.

Fault 10

*Pre-Ignition

ILK*

Pre-Ignition Interlock

fault during STANDBY

*(EC/RM7800, 7840,

7838B only).

Check Pre-Ignition Interlock switches to assure proper func-

tioning.

Check fuel valve operation.

Reset and sequence the relay module; monitor the Pre-Igni-

tion Interlock status.

If the code persists, replace the relay module.

Check wiring to make sure that interlocks are connected

properly between terminals 6 and 7. Correct any errors.

Reset and sequence the relay module.

If the fault persists, measure the voltage between terminals 6

and G (ground), then terminals 7 and G. If there is line supply

Fault 11

*Running ILK

On*

Running Interlock

powered at improper

sequence point.

voltage present at terminal 6 when the controller is off, the

controller switch may be bad or is jumpered.

If steps 1 through 3 are correct and there is line supply volt-

age present at terminal 7 when the controller is closed and

the fault persists, check for a welded or jumpered Running

Interlock, Lockout Interlock, or Airflow Switch. Correct any

errors.

If steps 1 through 4 are correct and the fault persists, replace

the relay module.

320011007 18

Fault Code System Failure

Fault 12

*Lockout ILK

On*

Fault 13

*Airflow Sw.

On*

Fault 14

*High Fire

Sw.*

Fault 15

*Flame

Detected*

Fault 16

*Flame-Out

Timer*

Fault 17

*Main Flame

Failure*

Fault 18

*Flame

Detected*

Lockout Interlock powered at improper point

in sequence.

Combustion airflow

interlock fault during

STANDBY.

High Fire Interlock

Switch failure to close

during PREPURGE.

Flame sensed when

no flame is expected

during STANDBY.

No flame detected

during Pilot Flame

Establishing Period.

Main flame failure

during RUN after flame

is established and on

for at least 10 seconds.

Flame sensed when

shutter is open and

no flame is expected

during PREPURGE.

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

-

-

Check wiring and correct any errors.

Reset and sequence the relay module.

Use either the manual motor potentiometer to drive the motor

to the High Fire position or use the Run/Test Switch option, if

available. Sequence to Prepurge drive to High Fire and place

in the Test position. Adjust the High Fire Switch while in this

state to make sure that it closes properly.

Measure the voltage between terminal 19 and G (ground)

while in the Prepurge drive to High Fire state. Line supply

voltage should be present. If not, the switch adjustment is

incorrect and/or the switch is defective and needs replacing.

Reset and sequence the relay module. If line supply voltage

was present between the High Fire Switch and terminal 19,

and the fault still persists, replace the relay module.

Check that the flame is not present in the combustion cham-

ber; correct any errors.

Make sure that the flame amplifier and flame detector are

compatible.

Check wiring and correct any errors.

Remove the flame amplifier and inspect the connections.

Reseat the amplifier.

Reset and sequence the relay module.

If the code reappears, replace the amplifier and/or the flame

detector.

If the fault persists, replace the relay module.

Measure the flame signal. If one exists, make sure it meets

specifications.

Make any necessary burner adjustments using manufacturer

instructions. Make sure that the flame amplifier and flame

detector are compatible.

If the code reappears, replace the amplifier and/or the flame

detector.

If the fault persists, replace the relay module.

Inspect the main fuel valve(s) and connection(s).

Make sure that the fuel pressure is high enough to supply fuel

to the combustion chamber.

Check the flame detector sighting for adequate flame signal

throughout the burner firing rate.

Check that flame is not present in the combustion chamber.

Correct any errors.

Make sure that the flame amplifier and flame detector are

compatible.

Check the wiring and correct any errors. Make sure F and

G wires are in individual conduits and protected from stray

noise pickup.

Remove the flame amplifier and inspect the connectors.

Reseat the flame amplifier.

Reset and sequence the relay module.

If the code reappears, replace the flame amplifier and/or the

flame detector.

If the fault persists, replace the relay module.

19 320011007

7800 SERIESS7800A2142 4Line LCD Keyboard Display Module

Fault Code System Failure

Fault 19

*Main Flame

Ignition*

Flame was lost during

MFEP or the first 10

seconds of the RUN

state.

Inspect the main fuel valve(s) and connection(s).

Make sure that the fuel pressure is high enough to supply fuel

to the combustion chamber.

Make sure the flame detector is positioned to obtain the

required flame signal strength; reset and recycle.

Check wiring and correct any errors.

Reset and sequence the relay module.

Use either the manual motor potentiometer to drive the motor

to the Low Fire position or use the Run/Test Switch option, if

available. Sequence to Prepurge drive to Low Fire and place in

Fault 20

*Low Fire

Switch Off*

Low Fire Interlock

switch failure to close

during PREPURGE.

the Test position. Adjust the Low Fire Switch to make sure that

it closes properly.

Measure the voltage between terminal 18 and G (ground)

while in the Prepurge drive to Low Fire state. Line supply

voltage should be present. If not, the switch adjustment is

incorrect and/or the switch is defective and needs replacing.

Reset and sequence the relay module. If line supply voltage

was present between the Low Fire Switch and terminal 18,

and the fault still persists, replace the relay module.

Check wiring; correct any errors.

Inspect the fan; make sure there is no blockage of the air

intake and that it is supplying air.

Make sure the Interlock Switches are working properly and

Fault 21

*Running

ILK*

Running Interlock fault

during PREPURGE.

that all switch contacts are free of contaminants.

Reset and sequence the relay module to PREPURGE (place

the

Run/Test Switch in the Test position, if available). Measure

the voltage between terminals 7 and G (ground). Line voltage

should be present.

If steps 1 through 4 are correct and the fault persists, replace

the relay module.

Fault 22

*Lockout

ILK*

Fault 23 *Airflow Switch*

Fault 24 *Internal fault*

Fault 25 *Internal fault*

Lockout Interlock fault

during PREPURGE.

Combustion airflow

interlock fault during

PREPURGE.

The flame interlock

(relay module) was on

when it should be off.

The flame interlock

(relay module) was off

when it should be on.

-

-

Check for F leadwire routing. Make sure routing is in its con-

duit and isolated from noise-producing circuits.

Check wiring and correct any errors.

Make sure that the Manual Open Valve Switch is fully open.

Make sure that the Manual Open Valve Switch is functioning

Fault 26

*Man-Open

Sw. Off*

The Manual Open

Valve Switch was off

when it should be on

(RM7838B only).

properly and that the switch contacts are free from contam-

inants.

Reset and sequence the relay module.

Make sure that the Manual Open Valve Switch provides an

electrical path when closed. Verify that the relay module is

receiving power at terminal 17.

If steps 1 through 5 are correct and the fault persists, replace

the relay module.

320011007 20

Loading...

Loading...