Honeywell Sensepoint XCD RFD Operating Manual

Technical Handbook

Sensepoint XCD RFD

(Remote Flammable Detector)

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

1 Safety

Ensure that this Operating Manual is read and understood BEFORE installing / operating / maintaining the equipment. Pay particular attention to Warnings and Cautions. All document Warnings are listed here and repeated where appropriate at the start of the relevant chapter(s) of this Operating Manual. Cautions appear in the sections/sub-sections of the document where they apply

WARNINGS

Sensepoint XCD RFD is designed for installation and use in Zone 1 or 2 hazardous areas in many countries including Europe, and for Class I, Division 1, Groups B, C & D Hazardous Areas in the Americas.

Installation must be in accordance with the recognized standards of the appropriate authority in the country concerned.

Access to the interior of the detector, when carrying out any work, must only be conducted by trained personnel.

Before carrying out any work ensure local regulations and site procedures are followed.

Appropriate standards must be followed to maintain the overall certiication of the detector.

If using an anti-seize compound, the threads should be thinly coated with an approved silicone free compound e.g. petroleum jelly

To reduce the risk of ignition of hazardous atmosphere, de-classify the area or disconnect the equipment from the supply circuit before opening the detector enclosure. Keep assembly tightly closed during operation.

Never attempt to open a junction box/enclosure or replace/reit the sensor in potentially hazardous atmospheres while power is still applied to the transmitter.

The detector must be earthed/grounded for electrical safety and to limit the effects of radio frequency interference. Earth/ground points are provided inside and outside the unit. The internal grounding shall be used as the primary equipment ground. The external terminal is only a supplemental bonding connection where local authorities permit or require such a connection.

Ensure that all screens/instrument earth/clean earth wiring is earthed/grounded at a single point (either at the controller or detector - BUT NOT BOTH) to prevent false readings or alarms that may occur due to potential earth/ground loops.

Take care when handling sensors as they may contain corrosive solutions. Do not tamper with or in any way disassemble the sensor.

Do not expose to temperatures outside the recommended ranges.

Do not expose sensors under storage conditions to organic solvents or lammable liquids.

Refer to the local or national regulations relative to the installation at the site. For Europe see EN60079-29-2, EN60079-14 and EN61241-14.

Only assessed for ATEX for ignition hazards.

This equipment is designed and constructed as to prevent ignition sources arising, even in the event of frequent disturbances or equipment operating faults. Note: The control card must have a suitably rated fuse.

The sensor head must be itted with the supplied weather protection, and mounted so that the sinter is pointing downward to provide ingress protection IPX6.

The weather protection is a potential electrostatic charging hazard. The manufacturer’s instructions should be observed.

For Safety reasons, this equipment must be operated and serviced by qualified personnel only

(Pour des raisons de securite, Cet equipment doit etre utilise,

Entretenu et repare uniquement par un personnel qualifie) EMI signal may cause incorrect operations.

Any rapid upscale reading followed by a declining or erratic reading may indicate a gas concentration beyond the upper scale limit which may be hazardous.

2

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

2 Information

This manual is for use with the Sensepoint XCD RFD range transmitters only.

The Start-up/Surge/In rush current is dependant on the type of power supply used. The typical start-up current for Sensepoint XCD RFD is less than 800mA. Measure the startup current using the specific power supply before installation to ensure suitability for your application.

Honeywell Analytics can take no responsibility for installation and/or use of its equipment if not done so in accordance with the appropriate issue and/or amendment of the Technical Manual.

The reader of this Operating Manual should ensure that it is appropriate in all details for the exact equipment to be installed and/or operated. If in doubt, contact Honeywell Analytics for advice.

The following types of notices are used throughout this Operating Manual:

WARNING

Identifies a hazardous or unsafe practice which could result in severe injury or death to personnel.

Caution: Identifies a hazardous or unsafe practice which could result in minor injury to personnel, or product or property damage.

Note: Identifies useful/additional information.

Every effort has been made to ensure the accuracy of this document; however, Honeywell Analytics can assume no responsibility for any errors or omissions in this document or their consequences.

Honeywell Analytics would greatly appreciate being informed of any errors or omissions that may be found in the content of this document.

For information not covered in this document, or if there is a requirement to send comments/corrections about this document, please contact Honeywell Analytics using the contact details given on the back page.

Honeywell Analytics reserve the right to change or revise the information supplied in this document without notice and without obligation to notify any person or organization of such revision or change. If information is required that does not appear in this document, contact the local distributor/agent or Honeywell Analytics.

3

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

3 Table of contents |

|

1 Safety................................................................................................................................ |

2 |

2 Information....................................................................................................................... |

3 |

4 Introduction...................................................................................................................... |

6 |

4.1 Transmitter.................................................................................................................. |

7 |

4.2 Flammable Gas sensors............................................................................................. |

7 |

4.2.1 Sensepoint XCD flammable gas sensors ............................................................... |

8 |

4.2.2 Sensepoint LEL Flammable gas sensors ............................................................... |

8 |

4.2.3 705 LEL flammable gas sensors (UL approved)...................................................... |

9 |

4.3 Accessories................................................................................................................. |

9 |

4.4 Options ..................................................................................................................... |

11 |

4.4.1 Modbus® ................................................................................................................ |

11 |

5 Installation...................................................................................................................... |

13 |

5.1 Mounting and location............................................................................................... |

14 |

5.2 Mounting the transmitter ........................................................................................... |

14 |

5.3 Installing the sensor.................................................................................................. |

15 |

6 Electrical connections ................................................................................................. |

17 |

6.1 Transmitter Wiring..................................................................................................... |

18 |

6.2 Terminal connections ................................................................................................ |

19 |

6.3 Power........................................................................................................................ |

20 |

6.4 Cabling...................................................................................................................... |

21 |

6.5 Cable and Earth/Ground regimes ............................................................................. |

21 |

6.6 Ground Terminal Wiring ............................................................................................ |

22 |

7 Default configuration .................................................................................................... |

23 |

8 Normal Operation .......................................................................................................... |

24 |

8.1 Display Screen.......................................................................................................... |

24 |

8.2 System Status........................................................................................................... |

25 |

8.3 Magnetic Wand Activation......................................................................................... |

26 |

8.4 Operation Mode Structure ........................................................................................ |

26 |

9 First time switch on (Commissioning) ........................................................................ |

27 |

10 Response Check and Calibration .............................................................................. |

29 |

10.1 Zeroing and span calibration ................................................................................. |

29 |

11 General Maintenance................................................................................................... |

33 |

11.1 Operational Life....................................................................................................... |

33 |

12 Servicing ...................................................................................................................... |

34 |

12.1 Sensor replacement................................................................................................ |

34 |

12.2 Replacing Modules within the Transmitter .............................................................. |

36 |

12.3 Faults and Warnings............................................................................................... |

37 |

13 Menu’s and Advanced Configuration........................................................................ |

38 |

13.1 Abort Function......................................................................................................... |

38 |

13.2 Configuration Mode ................................................................................................ |

38 |

13.3 Sensor / Gas Selection ........................................................................................... |

44 |

13.4 Review Mode .......................................................................................................... |

46 |

14 General specification.................................................................................................. |

49 |

4

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

||

15 Ordering information.................................................................................................. |

|

50 |

|

16 Warranty statement .................................................................................................... |

|

52 |

|

17 Installation Drawing ................................................................................................... |

|

53 |

|

17.1 |

Mechanical Installation Drawing ........................................................................... |

|

53 |

17.2 |

Electronic Connection Drawing.............................................................................. |

|

54 |

17.3 |

Duct Mounting Drawing ......................................................................................... |

|

56 |

17.4 |

Collecting Cone Drawing ....................................................................................... |

|

57 |

17.5 |

Mounting Bolt Assy Drawing .................................................................................. |

|

58 |

17.6 |

Mounting Bracket Drawing..................................................................................... |

|

55 |

17.7 |

Sensepoint XCD RFD Sensor ............................................................................... |

|

59 |

17.8 |

Control Drawing ..................................................................................................... |

|

61 |

18 Certification................................................................................................................. |

|

63 |

|

18.1 China GB Ex and PA.............................................................................................. |

|

63 |

|

18.2 |

Korea KTL.............................................................................................................. |

|

66 |

18.3 |

European ATEX ..................................................................................................... |

|

67 |

18.4 |

International IEC .................................................................................................... |

|

69 |

18.5 |

Sensepoint XCD ATEX Name Plate ...................................................................... |

|

71 |

18.6 |

Sensor Cartridges Label ........................................................................................ |

|

72 |

19 Cross Interference and Cross Calibration ............................................................... |

|

73 |

|

19.1 |

Cross Calibration Flammable Gas Detector .......................................................... |

|

73 |

19.2 Meter Multiplication Factors for Sensepoint XCD-IR Propane............................... |

76 |

||

19.2 Meter Multiplication Factors for Sensepoint XCD-IR Propane............................... |

76 |

||

A.1 Modbus® and the XCD .............................................................................................. |

|

77 |

|

A.2 Modbus® Registers ................................................................................................... |

|

78 |

|

5

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

4 Introduction

The Sensepoint XCD RFD (“Exceed RFD”) transmitter allows the user to either directly or remotely mount a flammable gas sensor from the Sensepoint XCD , Sensepoint and

705 sensor ranges. The remote sensor can be located up to 30 meters (100 feet) from the transmitter. The transmitter features a display and three programmable relays for controlling external equipment e.g. alarms, sirens, valves or switches. The transmitter provides an industry standard 3-wire, 4-20mA source or sink output for connection to a dedicated gas detection control system or PLC.

The construction of Sensepoint XCD RFD allows it to be used in hazardous area locations; it may also be used in other areas not classified as hazardous. Sensepoint XCD RFD is suitable for use in Zone 1 or 2 hazardous areas (International).

Calibration and maintenance is carried out using a Magnetic Wand, this allows a single user to undertake routine maintenance without needing to access internal components.

Sensepoint XCD RFD comprises of the main parts as shown below.

M20 or 3/4"NPT cable/conduit entries

Display Module |

(x2) |

Certification Label |

|

Integral |

|

Ex d Plug |

|

|

|

mounting plate |

|

Cover |

|

|

|

|

|

Internal Earth |

|

|

|

|

Point |

|

|

|

Terminal Module |

External Earth |

|

Locking |

Seal |

Point (x2) |

||

|

||||

|

|

|||

Grub |

|

|

Enclosure |

|

screw |

|

|

M25 or 3/4"NPT entry for

Flammable Sensor or Remote Sensor Cable Gland

Diagram 1. – Exploded View

6

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

4.1 Transmitter

The transmitter enclosure has three threaded entries. The two cable entries either side of the upper part of the transmitter housing are for connecting the power source, signal output and relay contacts to associated signalling equipment. The bottom entry allows local (direct) mounting of the appropriate sensor, or cable entry when using a remotely mounted sensor. These three entries are ¾” NPT for the Americas. For Europe and most other regions of the world, the two cable entries are provided with an M20 thread and the bottom entry is M25 for the sensor.

A local LCD provides gas type, concentration, alarm and operating status. The display provides numerical, bar graph and icon information.

Diagnostic information may also be displayed when the transmitter is interrogated using a magnet. The transmitter cover has a glass window which allows use of the Magnetic Wand to activate the three user interface magnetic switches that are located on the front of the display module. The magnet also enables a non intrusive, one-man calibration and configuration facility for the Sensepoint XCD RFD.

Magnetic

MENU/ENTER

Switch

Full Scale

Bar Graph

Gas Type

Gas Reading

Magnetic

DOWN

Switch

Magnetic Wand

activation Icon

Calibration Icon

Test Pass Icon

Warning/

Fault Icon

Inhibit Icon

Alarm Icon

Measuring

Units

|

Magnetic |

|

XCD RFD |

||

UP Switch |

||

|

Diagram 2: Sensepoint XCD RFD Display and Magnetic Switches

4.2 Flammable Gas sensors

Sensepoint XCD RFD is designed to work with the flammable sensors from the Sensepoint XCD, 705 and Sensepoint sensor ranges. Sensepoint XCD sensors use NDIR infrared and electro-catalytic technologies. The Sensepoint XCD range is ATEX approved for use throughout Europe and many parts of the world.

Please refer to chapter 15 ‘Ordering information’ for more detail information.

7

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

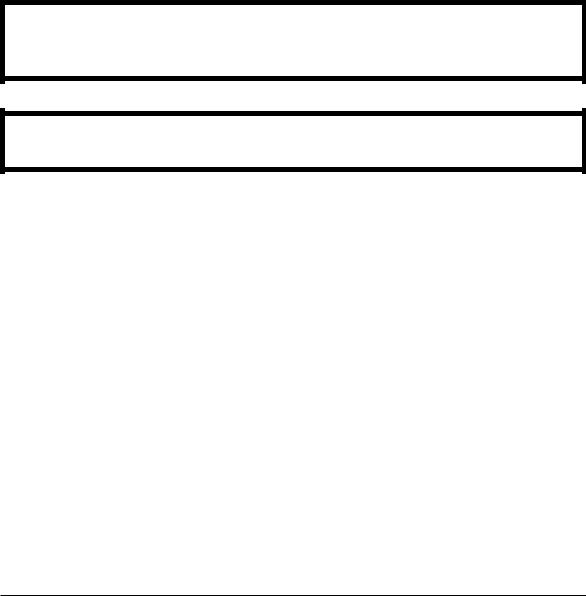

4.2.1 Sensepoint XCD flammable gas sensors

Sensepoint XCD flammable gas sensors are ATEX approved for use in Zone 1 or 2 hazardous areas. Two versions are available: IR and CAT versions. For more sensor specific details, refer to the Quick Start Guide of Sensepoint XCD Remote Flammable Sensor (PN: 3001M5022_1). These sensors are not approved for use in the Americas or Canada.

Diagram 3: Sensepoint XCD Flammable Sensor and Plug-in Cartridge

4.2.2 Sensepoint LEL Flammable gas sensors

Standard LEL Version

The standard LEL sensor is available for use in temperatures up to 80°C (remote mounting only) and detects gas concentrations up to 100% LEL of a target gas with a resolution in the region of 1% LEL, depending on the gas being detected. The sensor is available with M25 thread. M20 or ¾” NPT threads are options.

High temperature LEL Version

The high temperature version is available for use in temperatures up to 150°C (remote mounting only) and ranges of 0-20%LEL or 0-100%LEL depending on transmitter or controller. The sensor is available with M25 thread. M20 or ¾” NPT threads are options.

Details of connecting these sensors with the Sensepoint XCD RFD transmitter are given in sections 5 and 6. For more sensor specific details, refer to the Technical Handbook Part

No. 2106M0502 or their individual manuals (Sensepoint HT Sensor Quick Start Guide Part No: 2106M0523, Sensepoint LEL Operating Instructions Part No: 2106M0501). These sensor are not approved for use in the Americas or Canada.

Standard LEL version |

High Temperature LEL version |

Diagram 4: Sensepoint LEL flammable sensors

8

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

4.2.3. 705 LEL Flammable gas sensors (UL Approved)

Standard LEL version

The standard LEL sensor is available for use in temperatures up to 80°C (remote mounting only) and detects gas concentrations up to 100% LEL of a target gas with a resolution in the region of 1% LEL, depending on the gas being detected. The sensor is available with ¾”NPT thread only.

High Temperature LEL version

The high temperature version is available for use in temperatures up to 150°C (remote mounting only) and detects gas concentrations up to 100% LEL of a target gas with a resolution in the region of 1% LEL, depending on the gas being detected. The sensor is available with ¾”NPT thread only.

Details of connecting these sensors with the Sensepoint XCD RFD transmitter are given in sections 5 and 6. For more sensor specific details, refer to the 705 Combustible Gas

Sensor Operating Instructions Part No: 00705M5002.

Standard LEL version |

High Temperature LEL version |

705 LEL flammable sensors

9

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

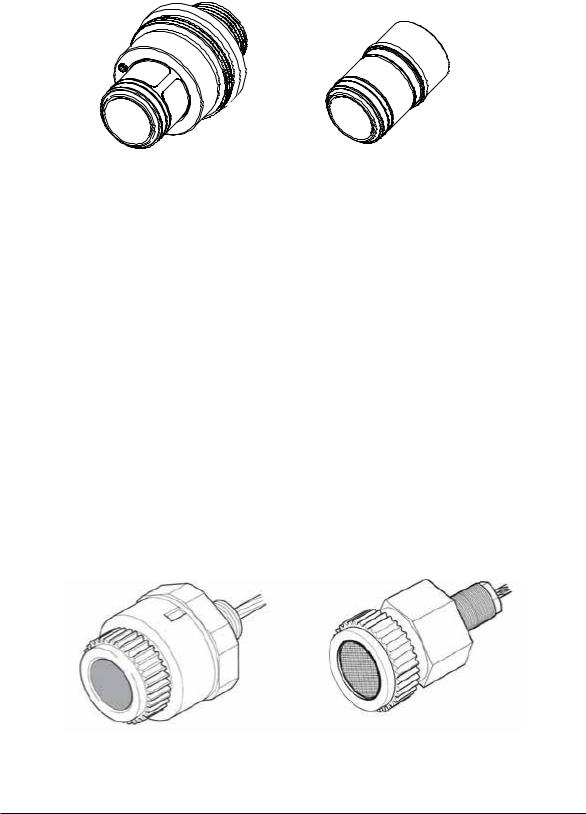

4.3 Accessories

A range of accessories are available to allow use of Sensepoint XCD RFD in a wide variety of applications. These include Pipe mounting bracket, Sunshade deluge cover, Sensor collecting cone, Sensor flow Housing and Remote sensor mounting junction boxes.

For Sensepoint XCD |

For Sensepoint / 705 |

(P/N: SPXCDWP) |

(P/N: 02000-A-1640/1635) |

Standard Weather Protection

The Standard Weather Protection is designed to protect the sensor from changes in environmental conditions. This is recommended to be fitted to a Sensepoint XCD sensor and Sensepoint / 705 sensors.

For UL/CSA Junction Box |

For ATEX Junction Box |

(P/N: 2430-0021) |

(P/N: 00780-A-0100) |

Remote Sensor Mounting

UL aluminum junction box,ATEX standard junction box and

ATEX High temperature junction box (P/N: 2052D0001) are optional accessories that can be used for remote sensor mounting. Make the connection from the junction box to the transmitter using suitable cable and cable glands.

Sensepoint Filter and Filter Housing

Sensepoint Stainless steel filter (P/N: 00780-

F-0018) and Filter Housing (P/N: 00780-C-

0038) is an optional accessory can be used to offer additional protection to the Sinter in dry, and dusty applications.

Calibration Cup

The Gassing Cap (P/N: S3KCAL) is an optional accessory that may be temporarily fitted to

Sensepoint XCD flammable sensors for Gas

Response checking during commissioning and routine maintenance.

For Sensepoint XCD |

For Sensepoint / 705 |

(P/N: SPXCDCC) |

(P/N: 02000-A-1642) |

Collecting Cone

The Collecting Cone is an optional accessory that may be fitted to the Weather Protection of XCD and Sensepoint / 705 sensors.

The collecting cone is designed for use with gases that are lighter than air.

Calibration Gas Flow Housing

The Calibration Gas Flow Housing (P/N: 02000-

A-1645) may be used for either calibration of the

Sensepoint / 705 sensor or if the Sensepoint / 705 sensor is to be used as part of a Aspirated Sampling System.

10

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

4.4 Options

4.4.1 Modbus®

One of the most common field buses in the industry, the optional Modbus® interface allows the XCD to connect to a bus of devices and transmit data to PLCs or controllers (see Appendix A). Connections to the XCD are made through a pluggable terminal block on the Modbus® interface circuit board. Modbus® RTU protocol uses ASCII/Hex protocols for communication. And allows all transmitter/sensor front panel functions to be transmitted using this industrial fieldbus.

Modbus® protocol is a Master-Slaves protocol. Only one master (at the same time) is connected to the bus and one or up to 32 slave nodes are also connected to the same serial bus. Modbus® communication is always initiated by the master. The slave nodes will never transmit data without receiving a request from the master node. The slave nodes will never communicate with each other. The master node initiates only one Modbus® transaction at the same time.

The MODBUS® may only be used for data collection or record keeping with regard to combustible gas detection and not for performance verification.

Modbus® option is available only for selected gases. Please refer to chapter 15 Ordering information.

To find out if a unit has the Modbus® option fitted, look at the part number on the product label. Units fitted with Modbus® have the letter “M” at the end of the part number.

Note: MODBUS® is a registered trademark of Schneider Automation Inc.

11

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

(MODBUS ID SETTING)

Set id>>Set Modbus slave ID>>Set Baud rate>>Set Parity

1)Slave ID shall be set 1~247

2)Baud rate setting 9600 or 19200

3)Parity setting (No, Even, Odd)

From the Configuration Mode screen, select‘’. To set the Modbus Slave ID, use the up-down ‘’switches to move to the desired position and use ‘’to select it. Again, using the‘’switches, increment or decrement the value until the desired value appears, selects the value and moves to the next setting.

The communications baud rate and Parity Setting can also be set from this screen by using the‘’ switches to navigate to the baud rate display then selecting ‘’. Using the

‘’switches, highlight the proper baud rate or parity setting and select‘’. Default is Slave ID 1, 19200bps and even parity.

Note: Set ID menu is available only for XCD equipped with Modbus® option.

12

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

5 Installation

Refer to the Sensepoint XCD RFD Control Drawing 3001EC091 for CSA applications shown in section 17.

WARNINGS

Sensepoint XCD RFD is designed for installation and use in Zone 1 or 2 hazardous areas in many countries including Europe, and for Class I, Division 1, Group B,C & D Hazardous Areas in the Americas.

Installation must be in accordance with the recognized standards of the appropriate authority in the country concerned.

Access to the interior of the detector, when carrying out any work, must only be conducted by trained personnel.

Before carrying out any work ensure local regulations and site procedures are followed.

Appropriate standards must be followed to maintain the overallcertification of the detector.

Care should be taken when removing and refitting the SensepointXCD plug-in Sensor to the

Sensor Socket so that damage to the connection pins can be avoided.

If using an anti-seize compound, the threads should be thinly coated with an approved silicone free compound e.g. petroleum jelly

To reduce the risk of ignition of hazardous atmosphere, de-classify the area or disconnect the equipment from the supply circuit before opening the detector enclosure. Keep assembly tightly closed during operation.

Never attempt to open a junction box/enclosure or replace/refitthe sensor in potentially hazardous atmospheres while power is still applied to the transmitter.

The detector must be earthed/grounded for electrical safety and to limit the effects of radio frequency interference. Earth/ground points are provided inside and outside the unit. Ensure that all screens/instrument earth/clean earth wiring is earthed/grounded at a single point (either at the controller or detector - BUT NOT BOTH) to prevent false alarms due to earth/ ground loops.

Take care when handling sensors as they may contain corrosive solutions. Do not tamper with or in any way disassemble the sensor.

Do not expose to temperatures outside the recommended ranges.

Do not expose sensors under storage conditions to organic solvents or flammable liquids.

Refer to the local or national regulations relative to the installation at the site. For Europe see EN60079-29-2, EN60079-14 and EN61241-14.

Only assessed for ATEX for ignition hazards.

This equipment is designed and constructed as to prevent ignition sources arising, even in the event of frequent disturbances or equipment operating faults. Note: The control card must have a suitably rated fuse.

The sensor head must be fitted with the supplied weather protection, and mounted so that the sinter is pointing downward to provide ingress protection IPX6.

The weather protection is a potential electrostatic charging hazard. The manufacturer’s instructions should be observed.

The Sensepoint sensor is a possible Electrostatic risk - Do not rub or clean with solvents.

Clean with a damp cloth. High velocity airflows and dusty environments can cause hazardous electrostatic charges.

13

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

5.1 Mounting and location

Caution: The location of gas detectors should be made in accordance with any relevant local and national legislation, standards or codes of practice. Always replace sensors with a sensor of the same type.

Gas detectors should be mounted where a potential hazard of gas is most likely to be present. The following points should be noted when locating gas sensors.

•When locating detectors consider the possible damage caused by natural events e.g. rain or flooding.

•Consider ease of access to the gas detector for functional testing and servicing.

•Consider how escaping gas may behave due to natural or forced air currents.

Note: The placement of gas detectors should be determined following the advice of experts having specialist knowledge of gas dispersion, experts having knowledge of the process plant system and equipment involved, safety and engineering personnel. The agreement reached on the location of detectors should be recorded.

5.2 Mounting the transmitter

The Sensepoint XCD RFD transmitter has an integral mounting plate consisting of four mounting holes on the transmitter body. The transmitter may be fixed directly to a surface mounting, or to a horizontal or vertical pipe/structure, 40.0-80.0mm (1.6 to 3.1 inches) in diameter/cross section. The Pipe Mounting Bracket accessory (optional accessory) may be used for this purpose.

M20 or 3/4 NPT entries

All dimensions are shown in mm.

Diagram 5: Outline and mounting dimensions

14

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

5.3 Installing the sensor

WARNINGS

Care should be taken when removing and refitting the SensepointXCD plug-in Sensor to the Sensor Socket so that damage to the connection pins can be avoided.

If using an anti-seize compound, the threads should be thinly coated with an approved silicone free compound e.g. petroleum jelly

Take care when handling old sensors as they may contain corrosive solutions.

Take care when removing or replacing the Sensor Retainer as there may be sharp edges present on the adjoining threads.

The equipment is designed and constructed as to prevent ignition sources arising, even in the event of frequent disturbances or equipment operating faults.

Only assessed for ATEX for ignition hazards.

The sensor head must be fitted with the supplied weather protection, and mounted so that the sinter is pointing downward to provide ingress protection IPX6.

The weather protection is a potential electrostatic charging hazard. The manufacturer’s instructions should be observed.

A remotely mounted sensor should be mounted using a suitable junction box . For further details regarding mounting sensors to suitable junction boxes refer to the relevant sensor manual.

1.Connect the remote sensor/junction box to the Sensepoint XCD RFD transmitter using suitable cable with wires of diameter 0.5 - 2.5mm2 (20AWG - 13AWG).

2.Connect the cable to the transmitter enclosure via the bottom entry.

3.Cable (non conduit) based installations must use appropriately certified cable glands.

Refer to the Sensepoint XCD RFD Control Drawing 3001EC091 shown in section 17 for conduit based installation in the Americas.

Note: The maximum cable length between the remotely mounted sensor and the Sensepoint XCD RFD transmitter is 30 meters (100 feet). The maximum loop resistance is 17 Ω.

4.Terminate the wires from the sensor in the transmitter as shown in chapter 6.2.

5.Select sensor type at configuration menu after remote sensor mounting. Refer to the chapter 12.1 Sensor Replacement and the chapter 13.3.1 Sensor Selection.

Sensepoint XCD RFD with Sensepoint Remote Sensor

Transmitter |

Junction Box |

Cable Gland |

Sensor |

15

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

Sensepoint XCD RFD with Sensepoint XCD remote plug-in sensor

It is necessary to use a ferrite filter at the remote sensor to reduce electromagnetic interference. The ferrite filter (supplied) should be fitted as follows:

1.Screw the sensor into the remote junction box.

2.Open the ferrite filter.

3.Wind the sensor leads 2 turns round the ferrite filter.

4.Close the ferrite filter.

5.Follow instructions in the individual sensor manuals to complete installation.

16

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

6 Electrical connections

WARNINGS

Sensepoint XCD RFD is designed for installation and use in Zone 1 or 2 hazardous areas in many countries including Europe, and for Class I, Division 1, Group B,C & D Hazardous Areas in the Americas.

Installation must be in accordance with the recognized standards of the appropriate authority in the country concerned.

Access to the interior of the detector, when carrying out any work, must only be conducted by trained personnel.

Before carrying out any work ensure local regulations and site procedures are followed.

Appropriate standards must be followed to maintain the overallcertification of the detector.

Care should be taken when removing and refitting the SensepointXCD Sensor Cartridge to the Sensor Socket so that damage to the connection pins can be avoided.

If using an anti-seize compound, the threads should be thinly coated with an approved silicone free compound e.g. petroleum jelly

To reduce the risk of ignition of hazardous atmosphere, de-classify the area or disconnect the equipment from the supply circuit before opening the detector enclosure. Keep assembly tightly closed during operation.

Never attempt to open a junction box/enclosure or replace/refitthe sensor in potentially hazardous atmospheres while power is still applied to the transmitter.

The detector must be earthed/grounded for electrical safety and to limit the effects of radio frequency interference. Earth/ground points are provided inside and outside the unit. Ensure that all screens/instrument earth/clean earth wiring is earthed/grounded at a single point (either at the controller or detector - BUT NOT BOTH) to prevent false alarms due to earth/ground loops.

Take care when handling sensors as they may contain corrosive solutions. Do not tamper with or in any way disassemble the sensor.

Do not expose to temperatures outside the recommended ranges.

Do not expose sensors under storage conditions to organic solvents or flammable liquids.

Refer to the local or national regulations relative to the installation at the site. For Europe see EN60079-29-2, EN60079-14 and EN61241-14. For the Americas refer to the Sensepoint XCD RTD Control Drawing 3001EC091 shown in section 17.

17

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

6.1 Transmitter Wiring

Caution: All electrical connections should be made in accordance with any relevant local or national legislation, standards or codes of practice.

The Sensepoint XCD RFD transmitter may be wired in either Current SOURCE or Current SINK configuration. These two options are offered to allow greater flexibility in the type of control system that it can be used with. SOURCE/SINK is selectable via the switch located on the back side of the display module; accessible by removing the display module during installation / commissioning (see section 9).

Controller |

|

|

Detector |

+VE |

1 |

1 |

+VE |

|

|

||

Signal |

2 |

3 |

Signal |

|

|

||

RL |

|

|

|

-VE |

3 |

2 |

-VE |

|

|

XCD Source 3 Wire 4-20mA (Source) |

|||

Controller |

|

|

Detector |

+VE |

1 |

1 |

+VE |

|

|

||

RL |

|

|

|

Signal |

2 |

3 |

Signal |

|

|

||

-VE |

3 |

2 |

-VE |

|

|

||

XCD Sink 3 Wire 4-20mA (Sink)

Note: Terminate cable screen at detector or controller, not both.

Caution: 250ohm load resistor (RL) is installed in the factory, In case of connection with controller, this resistor should be removed because controller has load resistor internally.

18

Sensepoint XCD RFD Technical Manual SPXCDHMRFEN Issue 4_08-2016

6.2 Terminal connections

Note: Ensure that none of the wires in the terminal area cause an obstruction when refitting the Display Module. Ensure that the socket on the Display Module is fully engaged in the Display Module Connector on the Terminal Module.

|

Ground/Earth |

|

|

|

|

Point |

|

|

|

Terminal Block |

|

Terminal Block |

||

Power & Signal |

|

for Relays |

||

Display Module |

|

Display Module |

||

|

Alignment Pin |

|||

Connector |

|

|||

|

Locator |

|||

|

|

|

||

|

|

|

Note: Terminal |

|

Terminal block for |

|

Blocks are |

||

|

plug/socket type |

|||

Sensepoint or 705 |

|

|||

|

and may be |

|||

Flammable sensor |

|

removed to ease |

||

|

|

|

wiring. |

|

|

Diagram 6: Sensepoint XCD RFD Terminal module |

|||

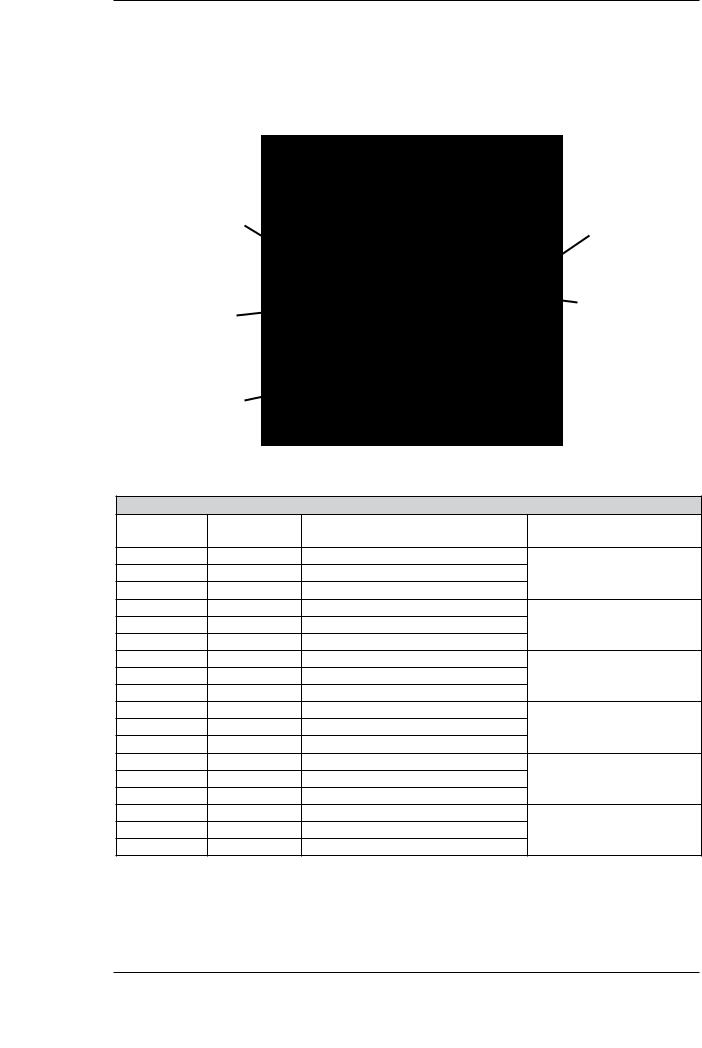

Terminal |

|

Terminal Module Connections |

|

|

Marking |

Connection |

Description |

||

Number |

||||

|

|

|

||

1 |

24V |

+VE Supply(12-32VDC) |

|

|

2 |

0V |

-VE Supply(0VDC) |

Controller Connections |

|

3 |

4~20mA |

Current Output Signal |

||

|

||||

4 |

COM |

Common |

MODBUS RTU. RS485 |

|

5 |

TxD |

MODBUS A(+) |

||

(Optional) |

||||

6 |

RxD |

MODBUS A(-) |

||

|

||||

7 |

RLY1/NC |

Normally Closed |

Programmable Relay 1 |

|

8 |

RLY1/COM |

Common |

||

(Default A1) |

||||

9 |

RLY1/NO |

Normally Open |

||

|

||||

10 |

RLY2/NC |

Normally Closed |

Programmable Relay 2 |

|

11 |

RLY2/COM |

Common |

||

(Default A2) |

||||

12 |

RLY2/NO |

Normally Open |

||

|

||||

13 |

RLY3/NC |

Normally Closed |

Programmable Relay 3 |

|

14 |

RLY3/COM |

Common |

||

(Default Fault) |

||||

15 |

RLY3/NO |

Normally Open |

||

|

||||

16 |

+VE |

Sensitive (Sensor Brown Wire) |

|

|

17 |

-VE |

Non-Sensitive (Sensor Blue Wire) |

RFD Sensor Connection |

|

18 |

01 |

Signal (Sensor White Wire) |

|

|

Table 1: Transmitter terminal connections

Note: The Sensepoint HT sensor and 705 HT sensor (not covered by the CSA certification) must be earthed either at the remote junction box or at the transmitter as appropriate. Avoid earth loops.

19

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

6.3 Power for UL/CSA Version

The Sensepoint XCD transmitter(UL/CSA versions)requires a power supply from the controller of between 12Vdc and 32Vdc. Ensure that a minimum supply of 12Vdc is measured at the sensor, taking into account the voltage drop due to cable resistance.

The maximum loop resistance in the field cable is calculated as follows

R loop = (V controller – V detector min) / I detector

Example;

The controller is supplying a nominal 24Vdc (V controller), the detector minimum allowable

voltage is 12Vdc (V detector min), therefore the maximum allowable voltage drop between the controller and detector is 12Vdc; this means a voltage drop of 6V in each core (+ve core

and -ve core).

+18V |

+24V |

(wrt Controller 0V) |

12V (min) |

4-20mA |

Signal |

XCD |

Controller |

|

|

|

|

|

|

Field Cable (L) |

|

+6V |

0V |

(wrt Controller 0V) |

Diagram 7: Power Connection |

Power consumption of the detector is 5.0W. The current required to drive the detector at the minimum voltage is (I = P / V), 5.0 / 12 = 416.7 mA (I detector).

So, the maximum ieldcable loop resistance (R loop) = 12 / 0.42 = 28.8 Ohms, or 14.4 Ohms per core, (allowing for component variations, losses, etc.).

The following tables show the maximum cable distances between the controller and transmitter assuming a voltage drop of 4V in each core and for different cable parameters. The tables are examples only and actual cable parameters and source power supply voltage for the application should be used to calculate the maximum cable distance allowed at the installation site.

Typical cable data |

Maximum Cable length (L) |

|||

Cable size |

Cable resistance |

Meters |

Feet |

|

(cross sectional area) |

Ω/km (Ω/mi) |

|||

|

|

|||

0.5mm2 (20AWG*) |

36.8 (59.2) |

353 |

1158 |

|

1.0mm2 (17AWG*) |

19.5 (31.4) |

666 |

2185 |

|

1.5mm2 (16AWG*) |

12.7 (20.4) |

1023 |

3356 |

|

2.0mm2 (14AWG*) |

10.1 (16.3) |

1287 |

4222 |

|

2.5mm2 (13AWG*) |

8.0 (12.9) |

1621 |

5318 |

|

*nearest equivalent |

**example for 24Vdc |

supply voltage |

|

|

Table 2: Maximum cable distances

20

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

6.4 Cabling

The use of industrial grade, suitably armoured field cable is recommended.

For example, screened 3 cores (plus screen 90% coverage), suitably mechanically protected copper cable with a suitable M20 explosion-proof gland with 0.5 to 2.5 mm2 (20 to 13 AWG) conductors. Ensure the cable gland is installed correctly and fully tightened.

All unused cable entries must be sealed with a suitable certified sealing plug (one plug is supplied).

Remote Mounting Cable Details

Type |

Cable Spec |

Max Length |

|

|

|

RFD Remote |

AWM2464 AWG20~AWG14 Shield |

30meters |

|

|

|

Note: The Sensepoint HT sensor requires an earth core if the remote junction box does not have a suitable earth point.

6.5 Cable and Earth/Ground regimes

Effective Earth/Ground bonding is important to ensure good EMC and RFI immunity.

The following diagrams show examples of how to earth/ground bond the cable at enclosures. These bonding techniques provide good RFI/EMC performance. Earth/ground loops must be avoided to prevent the risk of false signal variation.

Controller

Clean / Instrument

Earth Screen

Cable to Transmitter

|

|

|

|

|

|

|

|

|

Cable outer sheath |

|

Cable inner sheath |

||||||

|

|

|

|

|

|

|||

|

|

Diagram 8: Controller Grounding |

||||||

Transmitter |

|

|

|

Controller |

||||

Power & Signal |

||||||||

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earth Screen

Diagram 9: System grounding

21

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

The Earth Screen of the field cable should be “tied to Earth” or connected to Ground at one point only. It is common practise to adopt a STAR EARTH connection regime where all instrumentation Screens are connected at one common point.

The Screen at the other end of the cable should be “parked” or terminated into a blank terminal.

The following diagrams show how to install the wire into the ground screw of the enclosure.

Loosen the bolt |

Insert cable |

Fasten the bolt |

6.6 Ground Terminal Wiring

Internal Ground connection: Utilize the shield of the wiring cable recommended in the wiring instructions. For connection to this terminal. Twist the shield wire to avoid stray shield wires, Loosen the screw sufficiently and wrap the wire around the screw in a “U” shape. Raise the clamp and place the wire between the clamp and ground base, lower the clamp and tighten the screw to 6.9lb-in torque.

External Ground Connection: If required by local authority, Utilize a No 14 AWG copper,

(Stranded or Solid), wire. Loosen the screw sufficiently to enable ‘wrapping the wire around the screw in a “U” shape. Raise the clamp and place the wire between the clamp and ground base, lower the clamp and tighten the screw to10.4lb-in torque. A suitable Ring or Spade type insulated crimp terminal may also be used to accommodate the M4 size external earth screw.

22

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

7 Default configuration

The Sensepoint XCD RFD transmitter is supplied with the following default configuration.

Function |

Value/Setting |

Meaning |

|

|

Automatic for Sensepoint XCD RFD |

XCD RFD recognizes the XCD RFD sensor cartridge |

|

|

according to the gas type within its own sensor family |

||

Sensor Type |

sensors. Must be set for Sensepoint |

i.e. mV. For a Sensepoint and 705 sensor the user |

|

|

and 705 sensors. |

must set the sensor type. |

|

|

|

||

|

≥0.0<1.0 mA |

Fault (refer to table 9 section 12.3 for details) |

|

Signal output |

2.0 mA or 4.0 mA |

Inhibit (during configuration/user settings) |

|

4.0 mA to 20.0 mA |

Normal gas measurement |

||

|

|||

|

22.0 mA |

Maximum over range |

|

|

Value is sensor dependant |

Lower alarm level |

|

Alarm Relay 1* |

De-energized |

Energizes on alarm |

|

|

Contact Normally Open (NO) |

Closes on alarm |

|

|

Value is sensor dependant |

Higher alarm level |

|

Alarm Relay 2* |

De-energized |

Energizes on alarm |

|

|

Contact Normally Open (NO) |

Closes on alarm |

|

|

<1mA |

Detector Fault |

|

Fault Relay |

Energized |

De-energizes on alarm |

|

|

Contact Normally Open (NO) |

Closes on alarm |

|

|

|

Signal output inhibited during menu use |

|

Inhibit |

2.0 mA (default) |

If any relay is set to inhibit relay, then inhibit relay will |

|

|

|

be activated. |

|

|

|

No inhibit timeout. The detector waits for a button |

|

Timeout |

Disabled |

press before returning to the previous state/setting |

|

Timeout period can be set in ‘Configure Inhibit’ menu |

|||

|

|

||

|

|

in Configuration Mode. |

|

Password |

0000 (Disabled) |

0000 (Password disabled). If changed then password |

|

is activated. |

|||

|

|

||

Location |

0000 |

Optional feature to identify the location or User’s “Tag” |

|

(Tag Number) |

number of the XCD |

||

|

|||

|

|

|

|

Temperature |

oC |

Option to have oC or oF |

|

Modbus |

|

ID : 1 |

|

ID, baud rates and Parity bit |

Baud rates : 19,200 |

||

|

|

Parity bit : EVEN |

* Alarm relays automatically reset when reading falls within alarm thresholds. If relay configured to LATCH, then relays must be reset using the Magnetic Wand.

Table 3: Default configuration

Gas Name |

Default Range |

Lower Alarm |

Lower Alarm |

Higher Alarm |

Higher Alarm |

|

|

|

Type |

|

Type |

Sensepoint Flammable |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

Sensepoint HT Flammable |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

Sensepoint HT Flammable |

20%LEL |

10%LEL |

Rising |

15%LEL |

Rising |

705 Flammable |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

705 HT Flammable |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

XCD Flammable CB* |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

XCD Methane IR |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

XCD Propane IR* |

100%LEL |

20%LEL |

Rising |

40%LEL |

Rising |

Carbon Dioxide* |

2.00%Vol |

0.40%Vol |

Rising |

0.80%Vol |

Rising |

*Contact Honeywell Analytics for availability

For details of how to change the configuration of the Sensepoint XCD please refer to section 13.

23

Sensepoint XCD RFD Technical Manual |

SPXCDHMRFEN Issue 4_08-2016 |

|

|

8 Normal Operation

Sensepoint XCD RFD is supplied configured and ready for use according to the “Default

Settings” table shown above. However these setting may be tailored to a specific application requirement using the Sensepoint XCD RFD configuration menu system.

Access to the Sensepoint XCD RFD transmitter’s configuration menus system is via the

Magnetic Activation Tool.

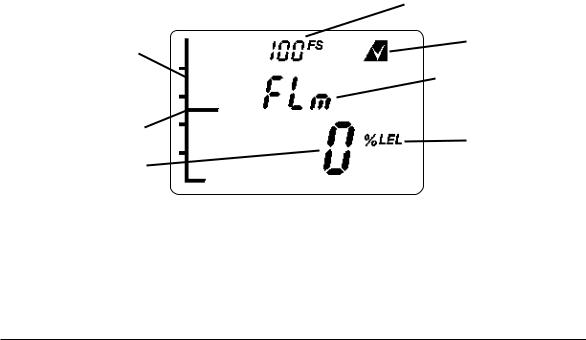

8.1 Display Screen

The Sensepoint XCD RFD display features an LCD with Numeric and bar-graph gas concentration data, alpha-numeric warning and status indication, a target for magnetic switch activation and the UP/DOWN/ESC/ENTER zones for remote configuration. The

LCD is also backlit with hi-intensity multi-colour LED indicator to show NORMAL, ALARM and FAULT status.

During normal operation the instrument display shows a steady GREEN backlight.

During Low and High Gas Alarm it displays a flashing RED backlight

During Fault condition the instrument display shows a flashing YELLOW backlight.

The screen is visible through the window of the transmitter’s cover. The display shows the gas concentration (both graphically and numerically), range, units, alarm/

fault status, etc.

Note: The detector display may become sluggish in sub-zero temperatures and possibly unclear at temperatures below -40 °C, but the detector continues its gas monitoring function. The display is not damaged and recovers when the temperature increases.

Full Scale

Bar Graph

(Proportional Test Pass Icon

to gas reading)

Gas Type

Peak Reading bar |

Measuring |

|

|

Gas Reading |

Unit |

|

Diagram 10: Example of a Flammable Transmitter Display screen – Normal Operation

24

Loading...

Loading...