Honeywell N10010, N05010 PRODUCT DATA

N05010/N10010

NON-SPRING RETURN DIRECT-COUPLED DAMPER ACTUATORS FOR

MODULATING AND FLOATING / 2-POSITION CONTROL

PRODUCT DATA

SPECIFICATIONS

Supply voltage 24 Vac/dc -15%/+20%, 50/60 Hz

Nominal voltage 24 Vac/dc, 50/60 Hz

All values stated hereinafter apply to operation under

nominal voltage conditions.

Power consumption

N05010 5 VA / 2 W

N10010 5 VA / 2 W

Control signal

Modulating 0...10 V

Floating/2-Position 24 Vac/dc

Ambient limits

Ambient operating limits -20...+60 °C (-5...+140 °F)

Ambient storage limits -30...+80 °C (-22...+176 °F)

Relative humidity 5...95%, non-condensing

Safety

GENERAL

This non-spring return direct-coupled damper actuator

provides modulating and floating/2-position control for:

• air dampers,

• VAV units,

• air handlers,

• ventilation flaps,

• louvers, and

• reliable control for air damper applications with up to 1 m

/ (5 Nm) and 2 m

friction-dependent).

2

(10 Nm) (seal-less damper blades; air

FEATURES

• Declutch for manual adjustment

• Adjustable mechanical end limits

• Removable access cover for direct wiring

• Mountable in any orientation

• Function selection switch for selecting modulating or

floating/2-position control

Protection standard IP54

Protection class II as per EN 60730-1

Overvoltage category II

Lifetime

Full strokes 60000

Repositions 1.5 million

Mounting

Round damper shaft 8...16 mm

Square damper shaft 6...13 mm; 45° steps

Shaft length min. 41 mm

2

End switches (when included)

Rating 5 A (resistive), 3 A (inductive)

Triggering points 5° / 85°

Torque rating 5 Nm / 10 Nm

Runtime for 90°

mod. (dc / 50/60 Hz ac) 90 sec

floating (dc / 60 Hz ac) 90 sec

floating (50 Hz ac) 110 sec

Rotation stroke 95° ± 3°

Dimensions see "Dimensions" on page 8

Weight (without cables) 450 g

Noise rating 35 dB(A) max. at 1 m

® U.S. Registered Trademark EN0B-0478GE51 R0408

Copyright © 2008 Honeywell Inc. • All rights reserved

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

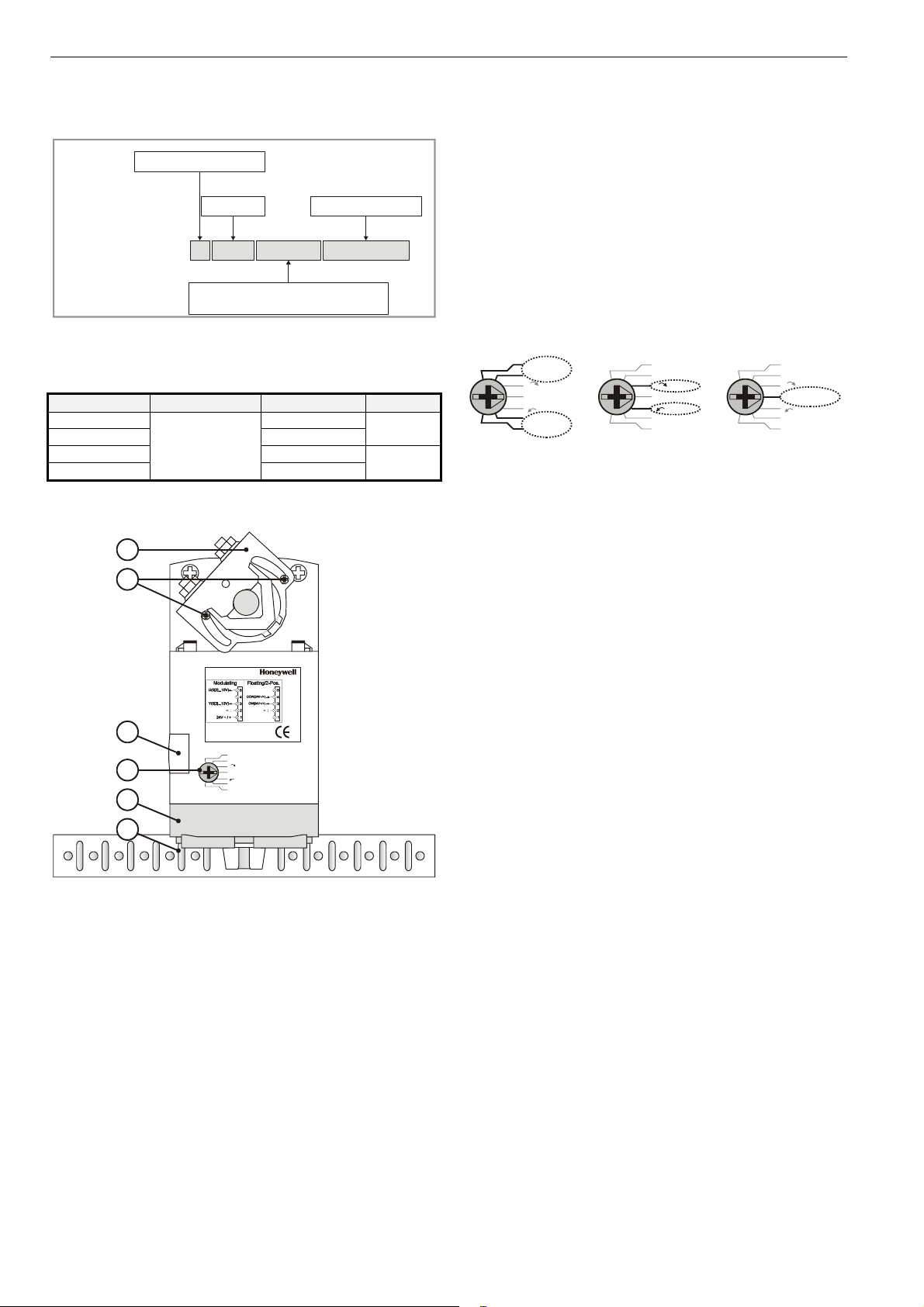

PRODUCT IDENTIFICATION SYSTEM

Contents of Package

The delivery package includes the actuator, parts 1 through 6

N = non-spring return

S = spring return

(see Fig. 2), plus two cable grommets and a spare cable

grommet.

05 = 5 Nm

10 = 10 Nm

equipped with two

end switches

RUN MODES

The function selection switch (see Fig. 3) can be used to

W

SmartAct

N

5

0

0-0

010 = modulating + floating

24 = 24 V floating + ON/OFF

230 = 230 V ON/OFF

S

+ ON/OFF

21

Fig. 1. Product Identification System

place the actuator into any one of three different modes:

• Service/Off;

• the floating/2-position run mode ("Dir" for CCW-closing

dampers or "Rev" for CW-closing dampers); and

• the modulating run mode.

modulating

MODELS

order no. supply voltage end switches torque

N05010 -N05010-SW2 2

N10010 -N10010-SW2

24 Vac/dc

2

BASIC FEATURES

1

2

N05010

3

2...10 V

0...10 V

Dir

4

5

6

Fig. 2. Setting units and control elements

Legend for Fig. 2:

1) Universal shaft adapter

2) Mechanical end limits

3) Declutch button

4) Function selection switch

5) Removable access cover

6) Anti-rotation bracket

Service/Off

Rev

10...0 V

10...2 V

5 Nm

10 Nm

Power-Off Behavior

If power is removed, the shaft adapter remains in position.

Service/Off

If the function selection switch is set to the "Service/Off"

position, then all rotary movement is cancelled, and all control

signals are ignored, thus allowing the actuator to be manually

operated safely.

Floating/2-Position Run Mode

Without Feedback Signal

If, however, the function selection switch has been set to one

of the two floating/2-position control settings – but the

actuator has not been wired for a feedback signal (see Fig. 12

and Fig. 13) – then as soon as operating power is applied, the

shaft adapter will run according to the control signals applied.

With Feedback Signal

If the function selection switch has been set to one of the two

floating/2-position control settings – and if the actuator has

been wired for a feedback signal (see Fig. 12 and Fig. 13) –

then as soon as operating power is applied, the shaft adapter

will likewise run first completely counterclockwise and then

completely clockwise (see also section "Adaption"), after

which it will run according to the control signals applied.

Modulating Run Mode

If the function selection switch has been set to one of the four

modulating control settings – and if the actuator is wired

correspondingly (see Fig. 11) – then as soon as operating

power is applied, the shaft adapter will run first completely

counterclockwise and then completely clockwise (see also

section "Adaption"), after which it will run according to the

control signals applied.

floating/2-position

2...10 V

0...10 V

Dir

Service/Off

Rev

10...0 V

10...2 V

2...10 V

0...10 V

Dir

Service/Off

Rev

10...0 V

10...2 V

Fig. 3. Function selection switch

Service/Off

2...10 V

0...10 V

Service/Off

Rev

10...0 V

10...2 V

Dir

EN0B-0478GE51 R0408

2

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

Table 1 describes, for the floating mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

Table 2 describes, for the 2-position mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

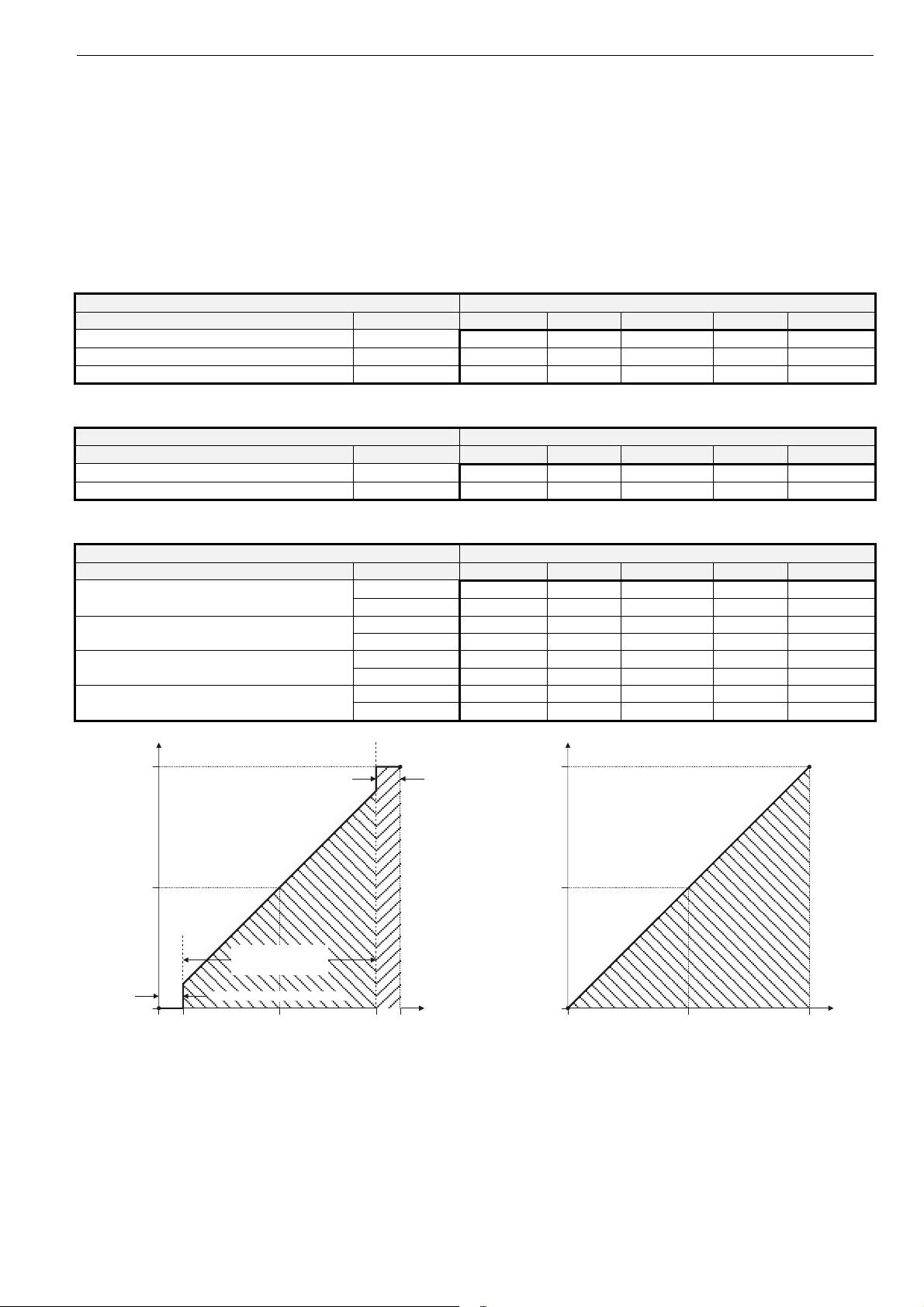

Table 1. Shaft adapter behavior in the floating mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

open open

open 24 Vac/dc

24 Vac open

Table 2. Shaft adapter behavior in the 2-position mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

24 Vac open

24 Vac 24 Vac/dc

Table 3. Shaft adapter behavior in the modulating mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

open

< min. control signal plus 0.24 V

between min. control signal plus 0.24 V

and max. control signal minus 0.24 V

> max. control signal minus 0.24 V

open

24 Vac/dc

open

24 Vac/dc

open

24 Vac/dc

open

24 Vac/dc

Table 3 describes, for the modulating mode, the shaft adapter

behavior ("stops," rotates "totally CCW," rotates "totally CW,"

runs to "proportional" position, or runs to "50%" of max.

stroke) in dependence upon the control signals applied to

terminals 3 and 4 and upon the function selection switch

setting.

-- stops stops stops --

-- CCW stops CW --

-- CW stops CCW --

-- CW stops CCW --

-- CCW stops CW --

totally CCW -- stop -- totally CCW

50% -- stop -- 50%

totally CCW -- stop -- totally CW

50% -- stop -- 50%

proportional -- stop -- proportional

50% -- stop -- 50%

totally CW -- stop -- totally CCW

50% -- stop -- 50%

final position of shaft adapter (% of max. stroke)

100

50

0

upper dead band (9.76 to 10.0 V)

range of proportional

actuator movement

(0.24 to 9.76 V)

lower dead band (0 to 0.24 V)

00.24

control signal (V)

5.0 10.09.76

Fig. 4. Final shaft adapter position in dependence upon

control signal (example function selection switch setting

of 0...10 V)

100

50

0

0

current position of shaft adapter (% of max. stroke)

feedback signal (V)

510

Fig. 5. Feedback signal in dependence upon current

position of shaft adapter (example function selection

switch setting of 0...10 V)

3 EN0B-0478GE51 R0408

Loading...

Loading...