Honeywell R4140G User Manual

R4140G

Flame Safeguard Programming Controls

APPLICATION

The R4140G Flame Safeguard Programmers provide flameout protection plus automatic sequencing of the burner motor (blower), firing rate motor, ignition, pilot valve, and main fuel valve(s) for commercial and industrial burners using gas, oil, coal, or a combination of fuels.

FEATURES

•Approvals: Underwriters Laboratories Inc. listed or component recognized, Canadian Standards Association certified, and Factory Mutual approved for automatic fired burners.

•The R4140 directly replaces the R4150 for most applications and mounts on the same Q520A Wiring Subbase.

•Low-high-low purge programmers.

•Field selectable main burner flame-establishing period.

•Early spark termination (five-second ignition and fivesecond pilot only) available on some models.

•Plug-in, solid state, flame signal amplifiers are colorcoded and interchangeable to allow the use of any type of flame detector-flame rod, photocell, infrared detector, or ultraviolet detector.

•Amplifier capability includes three standard models, three Dynamic Self-Check models, and one Dynamic Ampli-Check® model.

PRODUCT DATA

•R7247C or R7476A Dynamic Self-Check Amplifier, when used with an ultraviolet flame detector with a self-checking shutter (R7247C with a C7012E or F; R7476A with a C7076), tests all electronic components in the flame detection system (amplifier and detector) 60 to 240 times a minute during burner operation and shuts down the burner if the detection system fails.

•R7247B Dynamic Self-Check Amplifier, when used with a rectifying flame rod (which is considered fail-safe), or R7248B Dynamic Ampli-Check Amplifier, when used with a C7015A Infrared (lead sulfide) Flame Detector, tests the flame signal amplifier at least 150 times a minute during burner operation and shuts down the burner if the amplifier fails.

•All models feature capability of proving low fire position of the firing rate motor before starting ignition trials.

•Provisions for connecting preignition or start interlocks (depending on model) to prove the proper conditions for startup, and for a combustion airflow switch to prove airflow throughout the operating cycle.

•All models have 4-wire firing rate switching circuitry— firing rate can be modulated while the burner is firing, and the firing rate motor can be driven to both low and high fire positions during prepurge.

•Safe start check at startup and during prepurge. If flame relay 2K is holding in at startup, the programmer cannot be started. If a flame (or a condition simulating a flame) is detected during prepurge, ignition trials cannot be started and the programmer recycles.

•Safety shutdown occurs on failure to ignite the pilot or main burner, on loss of flame during the Run period, or if the flame detection system fails (if a self-checking system is used).

•All relays are visible, labeled, and easily accessible.

•Alarm terminal is available to operate an external, line voltage alarm on safety shutdown.

|

Contents |

Application .......................................................................... |

1 |

Features .............................................................................. |

1 |

Specifications ...................................................................... |

2 |

Ordering Information ........................................................... |

2 |

Operation ............................................................................ |

6 |

Wiring .................................................................................. |

23 |

Copyright © 1996 Honeywell Inc. • All Rights Reserved

X-XX UL |

60-2337-3 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not include normal manufacturing tolerances. Therefore, this unit may not match the listed specifications exactly. Also, this product is tested and calibrated under closely controlled conditions, and some minor differences in performance can be expected if those conditions are changed.

MODELS:

R4140G Flame Safeguard Programming Controls—Flame Safeguard protection and sequencing controls for use on gas, oil, coal, or combination burners. See Table 1 for models available.

Interlock Circuits:

Start Interlocks (R4140G1049, G1056, G1064, G1114, G1122, G1148 and G1171)—System controls must be in proper positions or programmer will not start.

Preignition Interlocks (R4140G1007, G1015, and G1106)—Must be closed to start programmer. Prevent ignition trials if interlocks open during prepurge; timer recycles the programmer and system restarts if condition is self-correcting.

Running Interlocks (all models)—Must be closed (airflow must be proven, fuel pressure must not be too low or too high) within 9.5 seconds after startup or ignition trials cannot be started. Running interlocks must remain closed through the Run period or the automatic fuel valves de-energize, the burner flame(s) goes out, and the timer recycles the programmer.

Low Fire Interlock (all models)—Timer stops at 52 seconds until low fire proving switch closes, indicating damper is closed prior to ignition.

Table 1. Models Available.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flame-Establishing |

|

|

|

|

||

|

|

|

Timer |

|

|

|

Period (sec) |

|

|

|

Firing Rate |

|

|

|

With |

Cycle |

Prepurge |

Early Spark |

|

|

Main Burner |

|

Postpurge |

Interlock |

Switching |

|

Model |

Covera |

(sec) |

(sec) |

Terminationb |

Pilotc |

|

(Field Selectable)c |

|

(sec) |

Circuits |

Circuit |

|

R4140G1007 |

Yes |

120 |

60 |

No |

10 |

|

10 or 30 |

|

16 |

Preignition, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1015 |

No |

|

|

|

|

|

|

|

|

Running |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1106 |

No |

120 |

60 |

No |

10 |

|

10 or 15 |

|

16 |

(including |

|

|

|

|

|

|

|

|

|

|

|

|

Airflow |

|

|

|

|

|

|

|

|

|

|

|

|

Switch) and |

4-wire |

|

|

|

|

|

|

|

|

|

|

|

Low Fire |

common, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1049 |

No |

120 |

60 |

Yes |

10 |

|

10 or 30 |

|

16 |

Start, |

high fire, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1056 |

Yes |

120 |

60 |

Yes |

10 |

|

10 or intermittent |

|

16 |

Running |

low-fire, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1064 |

No |

120 |

60 |

Yes |

10 |

|

10 or intermittent |

|

16 |

(including |

modulate) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1114 |

No |

180 |

70 |

Yes |

10 |

|

10, 30, or 60 |

|

25 |

Airflow |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1122 |

No |

180 |

70 |

Yes |

10 |

|

10, 30 or 60 |

|

25 |

Switch) and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1148 |

No |

120 |

60 |

Yes |

10 |

|

10 or 15 |

|

16 |

Low Fire |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R4140G1171 |

No |

180 |

70 |

Yes |

10 |

|

10 or 15 |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

202050C Cover with reset button; heavy duty, metal cover for outside panel mounting. |

|

|

|

||||||||

b |

Early spark termination available on terminal 18 (5 second ignition and 5 second pilot only). |

|

|

|||||||||

c |

If used for direct spark ignition (oil or gas), the flame-establishing period is 10 seconds. |

|

|

|

||||||||

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number or specify order number. Order separately:

1.Flame detection system (amplifier and matching flame detector). See Table 4.

2.Q520A1089 or Q520A1121 Wiring Subbase.

3.Accessories, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1.Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.Home and Building Control Customer Logistics Honeywell Inc., 1885 Douglas Drive North Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2337—3 |

2 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

Safety Features:

Safe Start Check—For the presence of a flame (or a condition simulating a flame) provided at startup and during prepurge. If the flame relay 2K is pulled in at startup, 2K2 is open and the programmer cannot be started. If the flame relay 2K pulls in during prepurge (before 57.5 seconds), 2K2 opens, relay 1K drops out, and ignition trials cannot be started. Instead, the timer completes its revolution and stops at the standby position (zero seconds). If the flame relay 2K drops out by the end of the cycle, the programmer restarts the system.

Safety Shutdown—Ignition transformer and all automatic fuel valves de-energize. The lockout switch trips and locks out the programmer. If used, the external alarm is energized. The timer completes its revolution and locks up at the stand-by position (zero seconds). The lockout switch must be manually reset to restart the system.

Safety Shutdown occurs on:

•Failure to ignite the pilot (or first stage burner if using direct spark ignition).

•Failure to light the main burner (unless monitoring an intermittent pilot).

•Loss of flame during the Run period.

•Failure in the flame detection system (if a selfchecking system is used, see Table 4).

Flame Failure Response Time—2 to 4 seconds. Lockout Switch Timing—30 seconds (nominal).

Electrical Ratings:

Voltage and Frequency: 120 Vac (102V minimum to 132V

maximum), 50/60 Hz.

R4140G1114: 240 Vac, 60 Hz.

R4140G1122: 208 Vac, 60 Hz.

NOTE: Use of a 50 Hz power supply lengthens the sequence timings by a factor of 1.2.

Power Consumption (With No Loads Connected to Output Terminals): 13W maximum.

Maximum Total Connected Load: 2000 VA.

Terminal Ratings:

See Table 2.

Table 2. Terminal Ratings.

|

|

|

|

|

Maximum Rating at |

Terminal |

Typical Load |

120 Vac, 60 Hz |

|

|

|

5 or 6 |

Ignition |

4.5A ignition and 50 VA pilot duty or |

|

Transformer/Pilot |

2.5A ignition and 75 VA pilot duty |

|

Valve/First Stage |

|

|

Fuel Valve |

|

|

|

|

7 |

Main Fuel Valve(s) |

250 VA pilot duty or 65 VA pilot duty |

|

(solenoid/motorized |

in parallel with motorized valve(s) |

|

/diaphragm) and |

using a total of 1150 VA locked |

|

Vent Valve if |

rotor (inrush),460 VA to open, and |

|

required |

250 VA to hold or motorized |

|

|

valve(s) using a total of 1500 VA |

|

|

locked rotor (inrush), 600 VA to |

|

|

open, and 250 VA to hold |

|

|

|

8 |

Burner Motor |

9.8A full load, 58.8A locked rotor |

|

(blower) |

(inrush) |

|

|

|

9 |

120V Alarm |

75 VA pilot duty |

|

|

|

10, 11, 12, |

Firing Rate |

50 VA pilot duty |

and 14 |

(damper) Motor |

|

|

Contacts |

|

|

|

|

18 |

Ignition |

4.5A ignition |

(if available) |

Transformer |

|

|

|

|

NOTE: Allowable inrush can be up to ten times the pilot duty rating.

EXAMPLE: Pilot duty rating = 50 VA.

At 120V, running current is:

50

120 = 0.42A.

Maximum allowable inrush is ten times 0.42A = 4.2A.

Interlock Ratings:

See Table 3.

Table 3. Interlock Ratings.

|

Requirements must be abIe to |

Interlocks |

carry and break current to: |

|

|

Limits, Burner Controller, |

Ignition transformer, pilot valve, |

and Running Interlocks |

and main fuel valve(s). |

(including airflow switch) |

|

|

|

Start or Preignition |

Programmer relay 1K (5W max). |

Interlocks |

|

|

|

Ambient Operating Temperature Ratings:

Minimum: Minus 40°F (minus 40°C).

Maximum:

Programmer Mounting Position

Standard Vertical (With Handle Up) |

Any Other |

|

|

+150°F (+66°C) |

+135°F (+57°C) |

|

|

Storage Temperature Ratings:

Minus 60°F to plus 150°F (minus 51°C to plus 66°C).

Mounting:

3-sided Q520A1089 Wiring Subbase, or 4-sided Q520A1121 Wiring Subbase; both have 20 knife-blade contacts (subbase ordered separately).

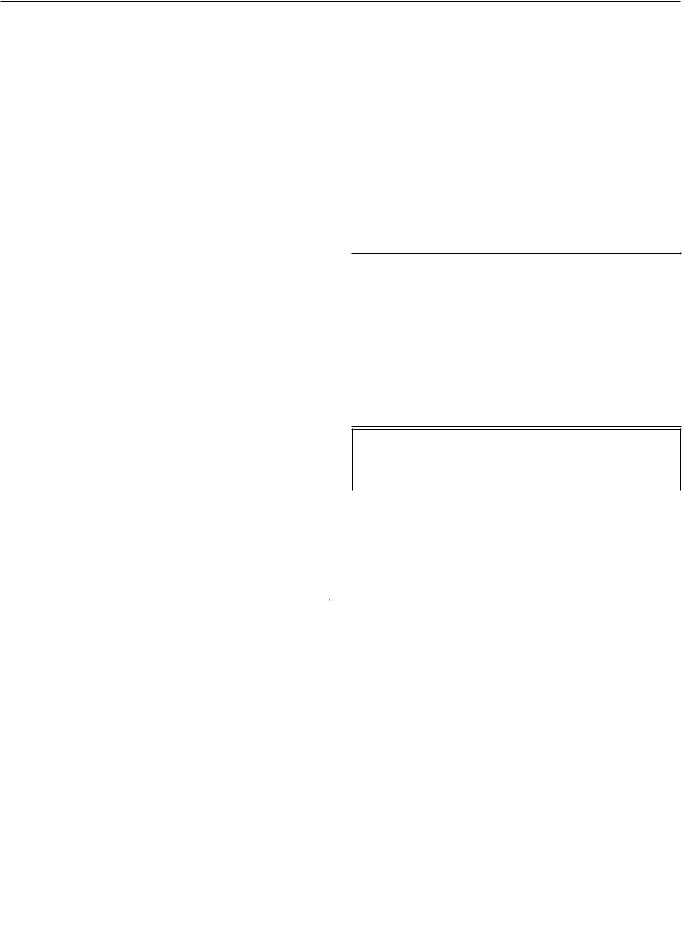

Dimensions:

See Fig. 1 and 2.

Weight (Without Plug-in Flame Signal Amplifier and 202050C Cover):

4 lb, 12 oz (2.15 kg).

Flame Detection System (Ordered Separately):

Plug-in Flame Signal Amplifier and matching Flame Detector; see Table 4.

Approvals:

Underwriters Laboratories Inc. Listed Section of Primary

Safety Control (120V Models With Covers): File No.

MP268; Guide No. MCCZ.

Underwriters Laboratories Inc. Component Recognized

(120V Models Without Covers): File No. MP268; Guide

No. MCCZ2.

Canadian Standards Association Certified: File No.

LR1620.

Factory Mutual Approved: Report No. 24180.

3 |

60-2337—3 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

2-3/8 (60)

2-3/8 (60)

2-11/32 (60)

2-11/32 (60)

7/8 (22) DIAMETER KNOCKOUT (2) |

|

|||

13/64 (5) DIAMETER (4) |

|

|

|

3/8 (10) (4) |

(FOR MOUNTING ON |

|

|

5/8 (16) (4) |

|

4 X 4 [102 X 102] JUNCTION BOX) |

|

|

||

|

|

|

||

|

3 |

|

|

5 |

|

4 |

L1 |

18 |

6 |

3-3/8 |

9 |

L2 |

17 |

7 |

(86) |

|

|

|

|

|

10 |

12 |

16 |

8 |

6-5/32 |

11 |

13 |

15 |

G |

(156) |

|

|

|

|

F |

14 |

1-3/4

(45)

|

31/32 |

7/8 (22) DIAMETER |

|

|

15/16 |

KNOCKOUT (2) |

1 |

||

(25) (2) |

||||

(24) (2) |

|

|

||

|

|

|

||

|

1-27/32 |

3-3/8 (86) |

|

|

|

(47) |

7 -1/16 (179) |

||

|

|

|||

|

7-3/16 (183) |

|

||

|

|

|

31/32 |

|

|

|

2-11/32 (60) |

(25) |

|

|

1-13/32 (36) |

1-13/32 (36) |

||

1-3/4

(45)

3/4

(19)

7/8 (22) DIAMETER KNOCKOUT (4)

1 OPEN ON 3-SIDED Q520A1089. |

M6776 |

Fig. 1. Mounting dimensions of the Q520A wiring subbase in in. (mm).

LOCKOUT SWITCH |

47/64 |

|

RESET BUTTON |

(19) |

|

202050C COVER |

35/64 |

|

(14) |

|

|

|

|

2-5/64 |

|

1-51/64 |

(53) |

|

|

|

|

(46) |

|

|

|

6-1/2 |

|

|

(165) |

7-3/16 (183)

202050C COVER

6

(152)

5-7/8

(149)

5-5/8

(143)

(ON Q520A1089 3-SIDED WIRING SUBBASE) |

M6777 |

Fig. 2. Mounting dimensions of the R4140 Programmer on the Q520A wiring subbase in in. (mm).

60-2337—3 |

4 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

Accessories:

W136A Test Meter (includes 117053 Meter Connector Plug); has SPL position with damping for testing selfchecking flame detection systems.

117053 Meter Connector Plug (for older W136A models).

123514A Flame Simulator (for use with R7247A Rectification Amplifiers).

123514B Flame Simulator (for use with R7249A Ultraviolet Amplifiers).

139695C (Series 1 and 2) Cover with reset button; heavy duty, metal cover for outside panel mounting.

202050C (Series 3) Cover with reset button; heavy duty, metal cover for outside panel mounting.

118760B (Series 1 and 2) Remote Reset Cover; heavy duty, metal cover with remote reset assembly; 120V, 60 Hz solenoid.

202051B (Series 3) Remote Reset Cover; heavy duty, metal cover with remote reset assembly; 120V, 60 Hz solenoid.

R1061012 Ignition Cable; for ignition installations in a high temperature environment; rated at 350°F (177°C) for continuous duty, and up to 500°F (260°C) for intermittent use; tested to 25,000V.

R1298020 Cable; for flame detector (F lead-wire) installations in a high temperature environment; rated up to 400°F (204°C) for continuous duty; tested for operation up to 600V and breakdown up to 7500V.

R1239001 High Tension Ignition Cable; for ignition installations in a contaminating environment; very resistant to severe conditions of oil, heat, and corona, and tested to withstand high voltages up to

25,000V rms in a salt bath for one minute without breakdown; rated at 200°F (93°C) for continuous duty, and up to 350°F (197°C) for intermittent use.

Q624A Solid State Spark Generator; prevents detection of ignition spark when properly applied with flame detection systems using C7027, C7035, or C7044 Minipeeper Ultraviolet Flame Detectors. For use only with gas pilots.

FSP5004 Tester; provides a quick operational check of most R4140 Flame Safeguard Programming Controls.

Q520E1002 Service Tool; allows any of the programmer terminals to be monitored while the programmer is operating.

Table 4. Flame Detection Systems

NOTE: Neither the R414G1114 or the R4140G1122 can be used with the C7012E or F Purple Peeper Ultraviolet Flame Detector and with the R7247C Dynamic Self-Check Amplifier.

|

|

|

|

|

|

|

|

|

Plug-In Flame Signal Amplifiers |

|

Applicable Flame Detectors |

||||

|

|

|

|

|

|

|

|

|

|

Self- |

|

Flame Failure |

|

|

|

Type |

Color |

Checking |

Model |

Response Time |

Fuel |

Type |

Models |

|

|

|

|

|

|

|

|

Rectification |

Green |

No |

R7247A |

2 to 4 sec |

Gas |

Rectifying |

Holdersa: C7004, C7007, C7011. |

|

|

|

|

|

|

Flame Rods |

Complete assemblies: C7005, |

|

|

|

|

|

|

|

C7008, C7009, Q179. |

|

|

|

|

|

|

|

|

|

|

|

R7247A, |

2 to 4 sec |

Oil |

Rectifying |

C7003, C7010, C7013, C7014. |

|

|

|

R7247Bb |

|

|

Photocellsc |

|

|

|

|

|

|

Gas, |

Ultraviolet |

C7012A or C. |

|

|

|

|

|

Oil, |

(Purple |

|

|

|

|

|

|

Coal |

Peeper) |

|

|

|

|

|

|

|

|

|

|

|

Dynamic |

R7147Bb |

2 to 4 sec |

Gas |

Rectifying |

Holdersa: C7004, C7007, C7011. |

|

|

Self- |

|

|

|

Flame Rods |

Complete Assemblies: C7005, |

|

|

Check |

|

|

|

|

C7008, C7009, Q179. |

|

|

|

|

|

|

|

|

|

|

|

R7247Cd |

2 to 4 sec |

Gas, |

Ultraviolet |

C7012E or F |

|

|

|

|

|

Oil, |

(Purple |

|

|

|

|

|

|

Coal |

Peeper) |

|

|

|

|

|

|

|

|

|

Infrared |

Red |

No |

R7248A |

2 to 4 sec |

Gas, |

Infrared |

C7015. |

|

|

|

|

|

Oil, |

(Lead |

|

|

|

|

|

|

Coal |

Sulfide) |

|

|

|

|

|

|

|

|

|

|

|

Dynamic |

R7248Bb |

2 to 4 sec |

Gas, |

Infrared |

C7015. |

|

|

Ampli- |

|

|

Oil, |

(Lead |

|

|

|

Check® |

|

|

Coal |

Sulfide) |

|

|

|

|

|

|

|

|

|

Ultraviolet |

Purple |

No |

R7249A |

2 to 4 sec |

Gas, |

Ultraviolet |

C7027, C7035, C7044. |

|

|

|

|

|

Oil |

(Minipeeper) |

|

|

|

|

|

|

|

|

|

|

Blue |

Dynamic |

R7476Ad |

2 to 4 sec |

Gas, |

Ultraviolet |

C7076. |

|

|

Self- |

|

|

Oil, |

(Adjustable |

|

|

|

Check |

|

|

Coal |

Sensitivity) |

|

|

|

|

|

|

|

|

|

a Order flame rod separately; see Instructions for the holder.

b Circuitry tests the flame signal amplifier at least 150 times a minute during burner operation and shuts down the burner if the amplifier fails.

c Use only Honeywell part no. 38316 Photocell.

dCircuitry tests all electronic components in the flame detection system (amplifier and detector) 60 to 240 times a minute during burner operation and shuts down the burner if the detection system fails.

5 |

60-2337—3 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

OPERATION

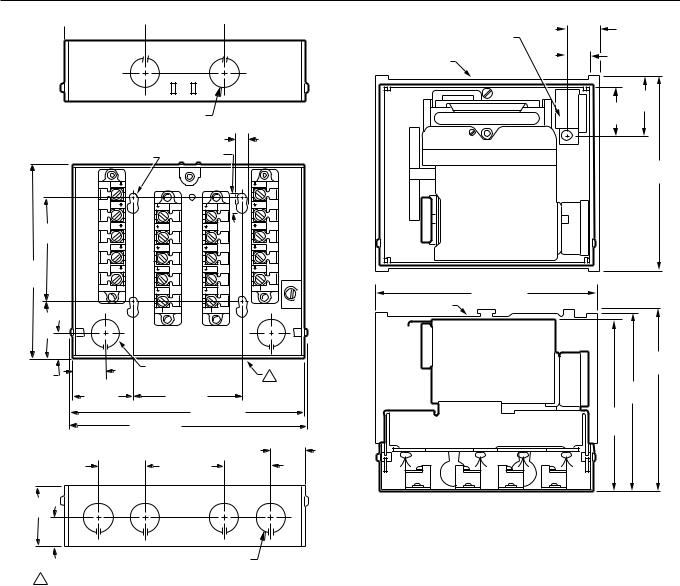

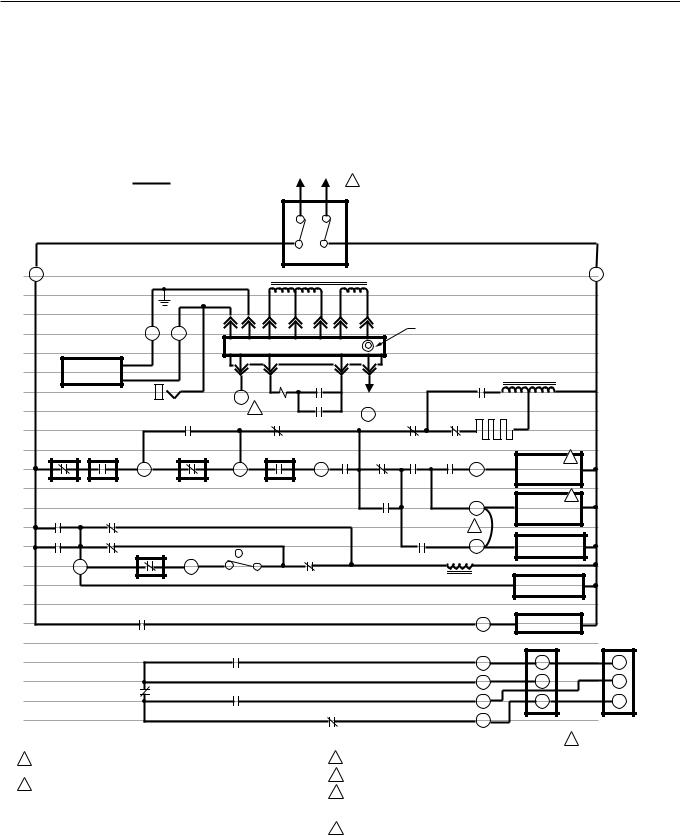

Models with Preignition Interlocks

Fig. 3 shows all contacts in the standby position (zero seconds). The opening and closing times are shown adjacent

to each timer contact. Refer to Fig. 4 and the Step-by-Step Operation section.

R4140G1007/G1015 SCHEMATIC |

120V, 60 HZ |

|||||

(WITH/WITHOUT HEAVY DUTY COVER) |

POWER SUPPLY |

|||||

L1 |

L2 |

|||||

|

|

|

|

|||

|

|

|

|

(HOT) |

1 |

|

|

|

INTERNAL |

EXTERNAL |

|

||

|

|

|

||||

O—OPENING TIME

C—CLOSING TIME

LS DENOTES LOCKOUT SWITCH; HTR DENOTES HEATER

MASTER

SWITCH

UNDERLINED O OR C DENOTES SNAP ACTION OF CONTACT. A TIMER CONTACTS SNAP CLOSED.

B CONTACTS SNAP OPEN.

1L1

L2

L2

2 |

|

|

|

|

|

|

|

|

|

|

|

NUMBERS BELOW |

3 |

|

|

3 |

9 |

13 |

5 |

8 |

12 |

10 |

|

|

DESIGNATE LINE |

|

|

|

|

LOCATIONS OF |

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

FLAME SIGNAL |

|

RELAY CONTACTS. |

|

4 |

|

G |

F |

|

|

|

|

|

|

(UNDERLINE |

||

|

|

|

|

|

|

METER JACK |

|

|||||

|

|

|

|

|

PLUG-IN AMPLIFIER |

|

|

INDICATES A |

||||

5 |

|

|

|

|

|

|

|

|

NORMALLY CLOSED |

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

CONTACT.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

FLAME |

|

|

7 |

M11B |

|

|

|

M9A |

1K |

|

|

DETECTOR |

|

17 |

|

11 |

16 |

|

||||||

|

|

|

C-15 O-70 |

C-57.5 O-109.5 |

2K - 13, 9, 8 |

|||||||

7 |

|

|

|

|

|

|

|

TO |

|

|

|

|

|

|

17 |

|

|

|

|

|

|

|

1K - 14, 14, 11 |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

2K |

|

|

TERMINAL |

|

|

|

||

8 |

|

TIP JACK |

2 |

|

|

|

|

|

||||

|

|

|

|

8 |

|

|

|

|

||||

|

|

|

|

|

|

LS2 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

2K3 |

|

|

|

|

||

9 |

|

|

|

|

|

|

|

|

|

LS - 19, 9 |

||

|

|

M7A |

M7B |

|

|

|

M2B |

|

|

|||

|

|

|

|

|

|

2K2 |

|

|

||||

|

|

BURNER |

C-57.5 O-111 |

O-9.5 C-116 |

|

|

|

|

||||

10 |

|

|

|

O-70 |

LS HTR |

|

|

|||||

LIMITS |

CONTROLLER |

|

|

|

|

1K3 |

|

|

||||

|

|

|

|

|

C-113.5 |

|

10 SECOND |

3 |

||||

11 |

|

|

|

|

|

|

|

|||||

|

4 |

16 |

|

|

|

3 |

|

|

5 |

INTERRUPTED |

||

|

|

|

|

|

|

|

|

|

M4A |

M6B |

PILOT/IGNITION |

|

12 |

|

|

PREIGNITION |

|

RUNNING |

|

|

|

|

|

||

|

|

|

|

|

|

C-60 |

C-50 O-80 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

INTERLOCKS |

|

INTERLOCKS |

|

|

2K1 O-85 |

|

30 SECOND |

4 |

|

13 |

|

|

|

|

(INCLUDING |

|

|

|

|

|

||

|

|

|

|

|

|

|

6 |

INTERRUPTED |

||||

14 |

1K1 |

1K2 |

|

|

AIRFLOW SWITCH) |

|

M2A |

|

PILOT/IGNITION |

|||

|

|

|

|

|

|

|

|

5 |

|

|

||

|

|

|

|

|

M5B |

|

|

C-70 |

|

|

||

|

|

|

|

|

|

|

|

O-109.5 |

|

|

||

15 |

|

|

|

|

|

O-104 |

|

|

MAIN FUEL |

|

||

|

|

|

|

|

|

|

|

7 |

|

|||

|

|

M3A |

NORM |

TEST |

C-108 |

|

|

|

|

VALVES (S) |

|

|

16 |

M1B |

O-52 C-66 |

|

|

|

|

|

|

|

|

|

|

C-4 |

8 |

13 |

|

|

|

|

|

|

|

|

|

|

|

LOW FIRE |

TIMER SWITCH |

|

|

|

|

|

|

|

|||

|

O-120 |

|

|

|

|

TIMER MOTOR |

|

|

||||

17 |

SWITCH |

|

|

|

|

BURNER MOTOR |

||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

(BLOWER) |

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

LS1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

120 V ALARM |

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

HIGH FIRE |

B |

B |

|

|

|

|

|

|

|

|

|

|

10 |

|||

22 |

|

|

M10A C-4 O-41 |

|

|

|

|

COMMON |

R |

R |

||

|

|

|

|

|

|

|

|

|||||

|

M10B O-4 C-45 |

|

|

|

|

|

|

|

11 |

|||

23 |

|

|

|

|

|

|

|

MODULATE |

|

|

||

|

|

|

|

|

|

|

|

W |

W |

|||

|

|

|

|

|

M8B O-100 |

C-116 |

12 |

|||||

|

|

|

M8A C-100 O-112 |

|

|

|

||||||

24 |

|

|

|

|

|

|

|

|

LOW FIRE |

FIRING |

|

|

|

|

|

|

|

|

|

|

|

14 |

SERIES 90 |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

RATE |

CONTROLLER |

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

6 |

1PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2TERMINAL 17 IS USED ONLY TO DRIVE THE SHUTTER ON A C7012E OR F OR A C7076A ULTRAVIOLET FLAME DETECTOR WITH SELF-CHECKING FEATURE. POWER TO DRIVE THE SHUTTER IS APPLIED TO TERMINAL 17 FROM TERMINAL 8 THROUGH A SOLID STATE SWITCH IN THE R7247C

OR R7476A DYNAMIC SELF-CHECK AMPLIFIER. REFER TO SAMPLE BLOCK DIAGRAM OF FIELD WIRING.

3 10 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

430 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

5FOR DIRECT SPARK IGNITION (GAS OR OIL,) A JUMPER IS INSTALLED BETWEEN TERMINALS 6 AND 7. REFER TO SAMPLE BLOCK DIAGRAM OF FIELD WIRING FOR HOOKUP.

6USE A SERIES 90 MODULATING MOTOR IF MODULATION IS REQUIRED.

M10149

Fig. 3. Simplified schematic diagram of R4140G1015 Programmer.

60-2337—3 |

6 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

TIMER |

0 |

|

10 |

20 |

|

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

|

SECONDS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREIGNITION INTERLOCKS |

|

|

|

|

|

|

6 |

|

5 |

|||

|

|

|

|

|

|

|

|

|

RUNNING INTERLOCKS (PROVEN AIRFLOW) |

|

|

|

RUN |

|||

|

|

|

|

|

|

|

|

|

|

|

|

PERIOD |

||||

TIMER DIAL |

|

|

|

|

PREPURGE |

|

|

|

IGN |

MAIN |

|

|

|

PURGE |

||

|

|

|

|

|

|

|

PILOT |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TIMER |

|

START |

|

|

|

|

3 |

STOP |

START |

|

|

|

5 |

STOP START |

|

STOP |

MOTOR |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

BURNER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

8 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

(BLOWER) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTERRUPTED |

|

5 |

|

|

|

|

|

|

|

10 SECONDS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PILOT/IGNITION |

|

6 |

|

|

|

|

|

|

|

30 SECONDS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

MAIN FUEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VALVE(S) |

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(GAS OR OIL) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH FIRE POSITION |

|

|

|

|

|

|

|

MODULATE |

|

|||

FIRING RATE |

|

|

|

10 |

TO 11 |

1 |

|

|

|

LOW FIRE POSITION |

|

|

12 |

TO 11 |

|

|

MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SWITCHING |

|

LOW |

|

|

|

|

|

|

|

14 TO |

11 |

|

|

|

|

LOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

2 |

|

|

|

|

2 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

ACTUAL |

|

|

|

|

|

|

MOTOR |

|

|

|

|

|

|

|

4 |

|

DAMPER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

|

DRIVES |

|

|

|

|

|

|

|

|

|

|

OPERATION |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

||

|

|

|

DRIVES |

|

|

DAMPER |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

MOTOR DRIVES |

|

||||

|

|

|

|

DAMPER |

|

|

CLOSED |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

DAMPER CLOSED |

|

||||

|

|

|

|

OPEN |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

TERMINAL NUMBERS (CIRCLED). |

4 |

FIRING RATE MOTOR MODULATES UNDER CONTROL OF SERIES 90 |

2 |

SLOPE DEPENDS ON MOTOR TIMING. |

|

CONTROLLER FROM 100 TO 112 SECONDS (INCLUDING RUN |

|

PERIOD WHILE BURNER IS FIRING). |

||

3 |

TIMER STOPS AT 52 SECONDS UNTIL LOW FIRE PROVING SWITCH CLOSES. |

5 |

TIMER STOPS AT 104 SECONDS FOR THE RUN PERIOD WITH THE |

|

|

|

BURNER FIRING. |

|

|

6 |

RUNNING INTERLOCKS (INCLUDING THE AIRFLOW SWITCH) |

|

|

|

MUST REMAIN CLOSED THROUGH THE RUN PERIOD. |

M10054

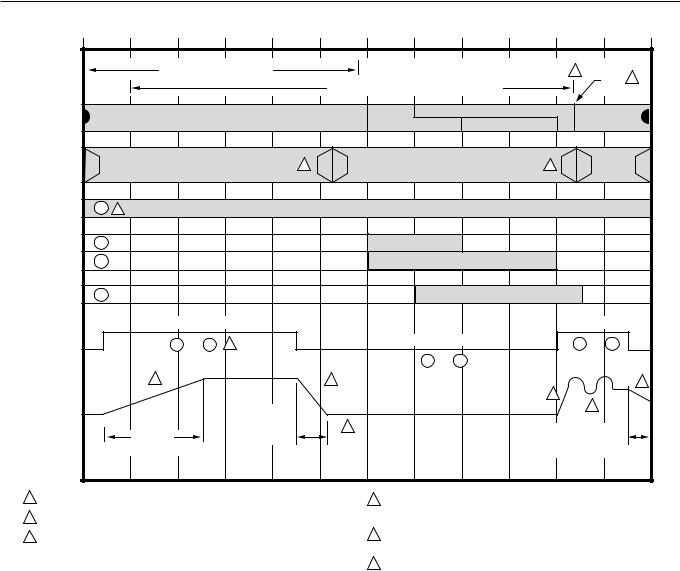

Fig. 4. Timer sequence for R4140G1015 Programmer.

Step-By-Step Operation (R4140G1015)

Start And Prepurge

0 seconds—On a call for heat, the burner controller contacts close. If the limits and preignition interlocks are closed and flame relay 2K is not holding in, relay 1K pulls in through M7B, LS2, 2K2, and the LS HTR (lockout switch heater—thus proving its continuity).

—1K1 closes and 1K2 opens, timer motor starts (through 1K1, M3A, and M5B), power is applied to terminal 8, starting the burner motor (blower); 1K3 closes.

—Prepurge begins.

4 seconds—M10A closes, M10B opens; firing rate motor drives toward high fire position (open).

—M1B closes, bypassing 1K1; the timer can complete its revolution if shutdown occurs.

9.5 seconds—M7B opens; running interlocks must close (airflow must be proven) or 1K drops out, 1K3 opens,

and ignition trials cannot be started. Running interlocks must remain closed through the Run period or the system shuts down; the timer completes its revolution and recycles the programmer.

15 seconds—M11B closes; flame relay 2K can pull in if a flame (or a condition simulating a flame) is detected. If detected during prepurge (until 57.5 seconds), 2K pulls in, 2K2 opens, 1K drops out, and the system shuts down; the timer completes its revolution and recycles the programmer (if 2K dropped out).

45 seconds—M10B closes; firing rate motor drives toward low fire position (closed).

52 seconds—M3A opens; timer stops until the low fire proving switch closes; timer can be stopped by opening the timer switch (until 66 seconds when M3A closes again).

57.5 seconds—M9A closes; the LS HTR (lockout switch heater) begins heating in preparation for ignition trials.

—M7A closes, bypassing the preignition interlocks.

7 |

60-2337—3 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

Ignition Trials

60 seconds—M4A closes; power is applied to terminals 5 and 6, energizing the ignition transformer and pilot valve (or main fuel valve(s) on terminal 7 if using direct spark ignition).

—When a flame is detected, relay 2K pulls in, 2K2

opens, and the LS HTR stops heating; 2K1 and 2K3 close.

66 seconds—M3A closes, bypassing the low fire switch and the timer switch.

70 seconds—M2B opens; pilot or ignition trial ends; a flame must be detected by this time (2K pulled in and 2K1 closed) or safety shutdown occurs and the lockout switch trips.

—M2A closes; power is applied to terminal 7, energizing the main fuel valve(s).

—M11B opens; prevents 2K from pulling in after this time.

80 seconds—M6B opens; 10 second interrupted pilot/ ignition (terminal 5) is de-energized.

100 seconds—M4A opens; 30 second interrupted pilot/ ignition (terminal 6) is de-energized.

—M8A closes, M8B opens; firing rate motor is released to modulate under control of the Series 90

Controller.

104 seconds—M5B opens; timer stops with the system in the Run condition.

Run Period (Burner is Firing) Postpurge And Stop

104 seconds—When the operating setpoint is reached, the burner controller contacts open; relay 1K and the main fuel valve(s) (terminal 7) de-energize.

—1K2 closes; timer motor starts; postpurge begins.

—When the flame goes out, relay 2K drops out. 112 seconds—M8A opens; firing rate motor stops

modulating under control of the Series 90 Controller. 116 seconds—M8B closes; firing rate motor drives toward

low fire position (closed).

120 seconds—M1B opens; timer and burner motor stop; cycle ends.

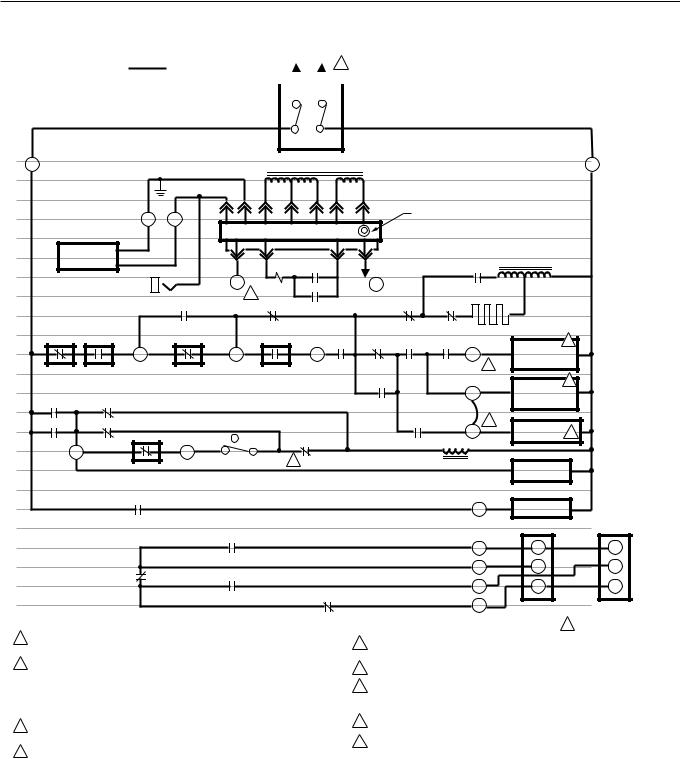

Fig. 5 shows all contacts in the standby position (zero seconds). The opening and closing times are shown adjacent to each timer contact. Refer to Fig. 6 and the Step-by-Step Operation section.

60-2337—3 |

8 |

R4140G FLAME SAFEGUARD PROGRAMMING CONTROLS

R4140G1106 SCHEMATIC |

|

120V, 60 HZ |

|||||

|

POWER SUPPLY |

||||||

|

|

|

|

L1 |

L2 |

||

|

|

|

|

(HOT) |

1 |

||

|

|

INTERNAL |

EXTERNAL |

||||

|

|

|

|

||||

O—OPENING TIME |

|

|

|

|

|

||

|

|

|

|

|

|||

C—CLOSING TIME |

|

|

|

|

|

||

LS DENOTES LOCKOUT SWITCH; HTR DENOTES HEATER |

|

|

|||||

MASTER

SWITCH

UNDERLINED O OR C DENOTES SNAP ACTION OF CONTACT. A TIMER CONTACTS SNAP CLOSED.

B CONTACTS SNAP OPEN.

1L1

L2

L2

2 |

|

|

|

|

|

|

|

|

|

|

|

|

NUMBERS BELOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

3 |

9 |

13 |

5 |

8 |

12 |

10 |

|

|

|

DESIGNATE LINE |

|

|

|

|

|

|

|

|

|

|

|

|

LOCATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

G |

F |

|

|

|

|

|

FLAME SIGNAL |

|

|

RELAY CONTACTS. |

|

|

|

|

|

|

|

METER JACK |

|

|

(UNDERLINE |

||||

5 |

|

|

|

|

PLUG-IN AMPLIFIER |

|

|

|

|

|

INDICATES A |

||

|

|

|

|

|

|

|

|

|

|

|

|

NORMALLY CLOSED |

|

6 |

FLAME |

|

|

|

|

|

|

|

|

|

|

CONTACT.) |

|

|

|

7 |

M11B |

|

|

|

M9A |

|

1K |

|

|||

DETECTOR |

|

17 |

|

11 |

16 |

|

|

||||||

|

|

|

C-15 O-70 |

C-57.5 O-109.5 |

2K - 16, 10, 8 |

||||||||

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

|

|

|

|

TO |

8 |

|

|

|

1K - 17, 17, 12 |

|

|

|

|

|

2K |

|

|

|

|

|

|

|||

8 |

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

TIP JACK |

|

|

|

|

LS2 |

|

|

|

|

|||

|

|

|

|

2K3 |

|

|

|

|

|

||||

9 |

|

|

|

|

|

|

|

|

|

|

LS - 22, 8 |

||

|

|

M7A |

M7B |

|

|

|

M2B |

|

|

|

|||

|

|

|

|

|

|

2K2 |

|

|

|

||||

|

|

BURNER |

C-57.5 O-111 |

O-9.5 C-116 |

|

|

|

|

|

||||

10 |

|

|

|

O-70 |

LS HTR |

|

|

||||||

LIMITS |

CONTROLLER |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

1K3 |

C-113.5 |

|

|

10 SECOND |

8 |

|||

|

|

|

|

|

|

|

|

|

|||||

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

16 |

|

|

|

3 |

|

|

5 |

|

INTERRUPTED |

||

|

|

|

|

|

|

|

|

|

M4A |

M6B |

3 |

PILOT/IGNITION |

|

12 |

|

|

PREIGNITION |

|

RUNNING |

|

|

|

|

||||

|

|

|

|

|

C-60 |

C-50 O-80 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

INTERLOCKS |

|

INTERLOCKS |

|

|

2K1 O-85 |

|

|

15 SECOND |

9 |

|

13 |

|

|

|

|

(INCLUDING |

|

|

|

|

|

|||

|

|

|

|

|

|

|

6 |

|

INTERRUPTED |

||||

14 |

1K1 |

1K2 |

|

|

AIRFLOW SWITCH) |

|

M2A |

|

PILOT/IGNITION |

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

M5B |

|

|

C-70 |

7 |

|

|

||

|

|

|

|

|

|

|

|

O-109.5 |

|

|

|||

15 |

|

|

|

|

|

O-104 |

|

|

MAIN FUEL |

|

|||

|

|

|

|

|

|

|

|

7 |

|

4 |

|||

|

|

M3A |

NORM |

TEST |

C-108 |

|

|

|

|

|

VALVES (S) |

||

16 |

M1B |

O-52 C-66 |

|

|

|

|

|

|

|

|

|

|

|

C-4 |

B |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

LOW FIRE |

TIMER SWITCH |

5 |

|

|

|

|

|

|

|

|||

|

O-120 |

|

|

|

TIMER MOTOR |

|

|

|

|||||

17 |

SWITCH |

|

|

|

|

BURNER |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

LS1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

ALARM |

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

|

HIGH FIRE |

|

B |

B |

|

|

|

|

|

|

|

|

|

10 |

|

|||

22 |

|

|

M10A C-4 O-41 |

|

|

|

|

|

COMMON |

|

R |

R |

|

|

|

|

|

|

|

|

|

|

|

||||

|

M10B O-4 C-45 |

|

|

|

|

|

|

|

11 |

|

|||

23 |

|

|

|

|

|

|

|

|

MODULATE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

W |

||

|

|

|

|

|

M8B O-100 |

C-116 |

12 |

|

|||||

24 |

|

|

M8A C-100 O-112 |

LOW FIRE |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

FIRING |

|

||

|

|

|

|

|

|

|

|

|

14 |

|

SERIES 90 |

||

|

|

|

|

|

|

|

|

|

|

|

|

RATE |

CONTROLLER |

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

6 |

1PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED

2TERMINAL 17 IS USED ONLY TO DRIVE THE SHUTTER ON A C7012E OR F PURPLE PEPPER ULTRAVIOLET FLAME DETECTOR WITH SELF-CHECKING FEATURE. POWER TO DRIVE THE SHUTTER IS APPLIED TO TERMINAL 17 FROM TERMINAL 8 THROUGH A SOLID STATE SWITCH IN THE R7247C DYNAMIC SELF-CHECK AMPLIFIER. REFER TO SAMPLE BLOCK DIAGRAM OF FIELD WIRING.

3FOR DIRECT SPARK IGNITION OR OIL, REFER TO SAMPLE BLOCK DIAGRAM OF FIELD WIRING FOR HOOKUP OF IGNITION AND MAIN OIL VALVE SOLENOID.

4SOME AUTHORITIES HAVING JURISDICTION PROHIBIT THE WIRING OF ANY LIMIT OR OPERATING CONTACTS IN SERIES WITH THE MAIN FUEL VALVE(S).

5TIMER SWITCH IS SHOWN IN "NORM" POSITION; IT IS OPEN IN "TEST" POSITION.

6USE A SERIES 90 MODULATING MOTOR IF MODULATION IS REQUIRED.

7FOR DIRECT SPARK IGNITION (OIL OR GAS), A JUMPER IS INSTALLED BETWEEN TERMINALS 6 AND 7. REFER TO SAMPLE BLOCK

DIAGRAM OF FIELD WIRING FOR HOOKUP.

810 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

915 SECOND MAIN BURNER FLAME-ESTABLISHING PERIOD.

M10044

Fig. 5. Simplified schematic diagram of R4140G1106 Programmer.

9 |

60-2337—3 |

Loading...

Loading...