Honeywell MS4103 User Manual

Dampers, Actuators and Valves

control your environment with honeywell DAMPERS, valves and actuators

Application And Selection Guide

How to use this guide

All pages in this literature are constructed in one of two ways:

For unassembled product:

As a reference, pictures will represent the valves and actuators separately; and part numbers are highlighted in blue. To order a complete product one OS# must be chosen from each blue box.

For factory assembled product:

The complete assembled OS# will be displayed in the body of the chart (except for cartridge cage valves, both an actuator and valve must be chosen). Pictures will also reference the factory assembled configuration.

Additional product information

To find more detailed information on the individual products included in this document, go to: http://customer.honeywell.com and use the search text box to quickly locate product specific content.

Support

Contact Information |

Phone |

Fax |

Commercial Components |

|

|

Technical Hotline |

888-516-9347 |

|

Customer Care |

|

|

Order Entry |

888-793-8193 |

800-356-0149 |

Product Drop-Ship Team |

763-954-4140 |

800-356-0149 |

Butterfly & Flanged Control Ball Valve Ordering |

|

|

Take-Off Service |

888-664-4092 |

877-880-3386 |

Let Honeywell Take-Off Service provide a complete |

|

|

job schedule for your projects for dampers, actuators, |

|

|

valves and VFDs. |

|

|

Online Resources |

|

|

Honeywell Customer Web Site |

http://customer.honeywell.com |

|

A web site with a large amount of information, |

|

|

literature, pricing, and product selection tools |

|

|

that is available to you at any time. |

|

|

Honeywell Consulting Engineer Web Site |

http://specifyhoneywell.com |

|

A website developed for consulting engineers. Get |

|

|

product guide specs, wiring diagrams and more. |

|

|

Honeywell eLearning |

http://customer.honeywell.com/learning |

|

A convenient and smart way of learning about our |

|

|

products with 10 to 20 minute training modules. |

|

|

Register at the Honeywell customer website above for access. |

|

|

Table Of Contents

Section 1: DCA & Damper Selection |

|

Dampers....................................................................................... |

8 |

DCA............................................................................................ |

12 |

Fire and Smoke.......................................................................... |

14 |

Resilient Seat Butterfly Valves |

|

2-Way Electrically-Actuated Control....................................... |

66 |

3-Way Electrically-Actuated Control....................................... |

68 |

2-Way Pneumatically-Actuated Control................................. |

72 |

3-Way Pneumatically-Actuated Control................................. |

74 |

Section 2: Valve Selection |

|

Control Valve Applications .......................................................... |

17 |

Control Valve Selection Criteria .................................................. |

18 |

2-Way.................................................................................... |

18 |

3-Way.................................................................................... |

20 |

Fan Coil and Zone Valves........................................................... |

22 |

Cartridge Cage Valves................................................................ |

24 |

Cartridge Globe Valves............................................................... |

26 |

Control Ball Valves ½ - 3” |

|

2-Way NPT NEMA 2.............................................................. |

28 |

2-Way NPT NEMA 3R........................................................... |

30 |

Control Ball Valves ½ - 2 ½” |

|

3-Way NPT NEMA 2.............................................................. |

32 |

3-Way NPT NEMA 3R.......................................................... |

33 |

Flanged Control Ball Valves 4”- 6” |

|

2-Way Flanged NEMA 2+3R.................................................. |

34 |

3-Way Flanged NEMA 2+3R.................................................. |

35 |

NPT Globe Valves ½-3” |

|

With Dedicated Valve Actuators............................................. |

36 |

With Direct Coupled Actuators.............................................. |

38 |

Flanged Globe Valves 2 ½ -3” |

|

With Direct Coupled Actuators.............................................. |

42 |

Threaded and Flanged Globe Valves 2”-3” |

|

With Tandem Linked Direct Coupled Actuators.................... |

46 |

Flanged Globe Valves 2 ½ - 3” |

|

With Dedicated Valve Actuators............................................. |

48 |

Flanged Globe Valves 4”-6” |

|

With Tandem Linked Direct Coupled Actuators..................... |

52 |

With Dedicated Valve Actuators............................................. |

54 |

Flanged Cage Valves 2 ½ - 6”.................................................... |

55 |

NPT Globe Valves ½ -3” |

|

With Pneumatic Actuators..................................................... |

56 |

Flanged Globe Valves 2 ½ - 3” |

|

With Pneumatic Actuators..................................................... |

60 |

Flanged Globe Valves 4”- 6” |

|

With Pneumatic Actuators..................................................... |

64 |

Section 3: Submittal Sheets |

|

Rectangular Volume Control Dampers |

|

D1 Series.............................................................................. |

78 |

D2 and D3 Series.................................................................. |

79 |

Round Volume Control Dampers |

|

D690...................................................................................... |

80 |

DM7600................................................................................ |

81 |

Spring Return Direct Coupled Actuator |

|

S03 Series (MS4103; MS4603; MS7403; MS7503; MS8103).... |

82 |

S05 Series (MS4105; MS4605; MS7105; MS7405; MS7505; |

|

MS8105)................................................................... |

83 |

S05 Series (MS4105; MS7505; MS8105)................................... |

84 |

S10 Series (MS4110; MS7510; MS8110)................................... |

85 |

S20 Series (MS4120; MS7520; MS8120) .................................. |

86 |

ML4125; ML8125................................................................. |

87 |

Non-Spring Return Direct Coupled Actuator |

|

ML6161; ML7161.................................................................. |

88 |

ML6174; ML7174.................................................................. |

89 |

N05 Series (MN6105; MN7505)............................................. |

90 |

N10 Series (MN6110; MN7510)............................................. |

91 |

N20 Series (MN6120; MN7220)............................................. |

92 |

N34 Series (MN6134; MN7234)................................................. |

93 |

Fire And Smoke Actuators |

|

ML4115; ML8115 ................................................................. |

94 |

MS4209F; MS4309F; MS4709F; MS4809F; MS8209F; |

|

MS8309F............................................................................... |

95 |

MS4120F; MS4620F; MS8120F............................................ |

96 |

Pneumatic Damper Actuator |

|

MP909D................................................................................ |

97 |

MP909E, H............................................................................ |

98 |

MP913................................................................................... |

99 |

MP918A, B.......................................................................... |

100 |

MP920................................................................................. |

101 |

Pneumatic Valve Actuator |

|

MP953C, D.......................................................................... |

102 |

MP953E, F........................................................................... |

103 |

|

3 |

Table Of Contents

Section 3: Submittal Sheets (CONT.) |

|

MP958................................................................................. |

104 |

Modutrol IV Motor |

|

M4185; M8185.................................................................... |

105 |

M6184; M6194.................................................................... |

106 |

M6285 for slaving applications............................................ |

107 |

M6284; M6294 for slaving applications............................... |

108 |

M6274; M6284; M6285; M6294 Motors with |

|

Linear 10K Feedback........................................................... |

109 |

M7164 ................................................................................ |

110 |

M7274; M7284; M7285; M7286; M7294................................. |

111 |

M9164; M9174; M9182; M9184; M9194............................ |

112 |

M9175; M9185; M9186....................................................... |

113 |

Q7130; Q7230; Q7330........................................................ |

114 |

Unitary Valve Actuator |

|

VU443; VU444; VU843; VU844........................................... |

115 |

VC Series Two-position........................................................ |

116 |

VC Series Proportional......................................................... |

117 |

VC Series Fail Safe Proportional........................................... |

118 |

M6410; M7410.................................................................... |

119 |

M6435; M7435.................................................................... |

120 |

Direct Coupled Valve Actuator |

|

ML6420; ML7420................................................................ |

121 |

ML6421; ML7421................................................................ |

122 |

ML6425; ML7425................................................................ |

123 |

ML6984 .............................................................................. |

124 |

ML7984............................................................................... |

125 |

Unitary Valve |

|

VU52; VU53......................................................................... |

126 |

VU54................................................................................... |

127 |

VCZA; VCZB........................................................................ |

128 |

VCZM; VCZN....................................................................... |

129 |

V5852; V5862...................................................................... |

130 |

V5853; V5863...................................................................... |

131 |

Control Ball Valve |

|

VBN2................................................................................... |

132 |

VBN3................................................................................... |

133 |

VBF2.................................................................................... |

134 |

VBF3.................................................................................... |

135 |

NPT Globe Valve |

|

V5011F, G............................................................................ |

136 |

V5011N............................................................................... |

137 |

V5013N............................................................................... |

138 |

Flanged Cage Valve |

|

V5051A................................................................................ |

139 |

Flanged Globe Valve |

|

V5011A, B........................................................................... |

140 |

V5013B, C........................................................................... |

141 |

VGF2................................................................................... |

142 |

VGF2 Pressure Balanced..................................................... |

143 |

VGF3................................................................................... |

144 |

Resilient Seat Butterfly Valves |

|

VFF1.................................................................................... |

145 |

VFF2.................................................................................... |

146 |

VFF3.................................................................................... |

147 |

VFF6.................................................................................... |

148 |

Damper Linkage |

|

Q605................................................................................... |

149 |

Valve Linkage |

|

Q5001................................................................................. |

150 |

Q5020................................................................................. |

151 |

Q5022................................................................................. |

152 |

Section 4: Wiring Diagrams |

|

Actuator Wiring Diagrams ........................................................ |

154 |

Section 5: Guide Specifications |

|

Guide Specifications ............................................................... |

170 |

Section 6: Accessories |

|

Ball Joints, Push Rod Accessories............................................ |

186 |

Control, Positioning, Feedback Accessories............................. |

186 |

Mounting Accessories.............................................................. |

187 |

Rotational Limiters, Position Indicators..................................... |

188 |

Crankarms................................................................................ |

189 |

Shaft Adaptor Accessories....................................................... |

189 |

Enclosure Accessories.............................................................. |

190 |

Q7002 Interface Modules......................................................... |

190 |

Miscellaneous Accessories....................................................... |

190 |

Accessories for Obsolete Actuators.......................................... |

191 |

Valve Actuator Accessories....................................................... |

192 |

VU Series Fan Coil Actuator Accessories.................................. |

192 |

Pneumatic Damper Actuator Parts and Accessories................ |

193 |

4

Table Of Contents

Pneumatic Valve Actuator Parts and Accessories..................... |

196 |

Foot Mounted Motor Accessories............................................. |

198 |

Damper and Valve Linkage Accessories................................... |

200 |

Section 8: Competitive Cross Reference |

|

Direct Coupled Actuator........................................................... |

202 |

Control Ball Valve |

|

2-Way Valve ........................................................................ |

220 |

2-Way Valve + Non-Spring Return Floating Actuator........... |

221 |

2-Way Valve + Non-Spring Return Modulating Actuator...... |

222 |

2-Way Valve + Spring Return, 2-Position Actuator............... |

223 |

2-Way Valve + Spring Return Floating Actuator................... |

224 |

2-Way Valve + Spring Return Modulating Actuator.............. |

225 |

Threaded Globe Valves............................................................. |

226 |

Flanged Globe Valves............................................................... |

227 |

Pneumatics............................................................................... |

228 |

Modutrol IV Motor..................................................................... |

231 |

Section 8: |

|

APPENDIX A: |

|

Valve Selection & Sizing............................................................ |

244 |

APPENDIX B: |

|

NEMA Standard Classification Code for Enclosures ................ |

263 |

APPENDIX C: |

|

Best Practices for Low Power Control Signal Wiring................. |

264 |

Notes........................................................................................ |

265 |

Warranty................................................................................... |

267 |

5

6

GU Selection

Section 1: DCA & Damper Selection |

|

Dampers....................................................................................... |

8 |

DCA............................................................................................ |

12 |

Fire and Smoke.......................................................................... |

14 |

7

Damper And Actuator Sizing

Use the following guidelines to determine the actuator quantity and torque requirements for your damper configuration.

Determine Damper Actuator Locations

Use the following configuration to determine the amount of actuator locations your damper will require.

Single Section ≤ 48 x 74 D2, D3 ≤ 60 x 74 D1

Dampers will never ship more than 2 sections wide and one section high.

Configuration

A single section damper will have one actuator location.

A damper that is ≥ 48 x 74 ≤ 96 x 74 will have one actuator location. This is a two section damper jackshafted together.

A damper that is ≥ 96 x 74 ≤ 144 x 74 will have two actuator locations. This is a two section damper jackshafted together and a single section damper.

Exception: 3 section wide ≤ 42 SFT damper will have one actuator location.

If damper exceeds 74” height a second row is necessary. Apply same logic above to each row of dampers.

For dampers larger than 144 x 144, please contact the Take-Off Service (takeoff.service@honeywell.com) for a quote and actuator location.

Mounting

Internal Mount: Blade drive lever bracket provided only. Customer is responsible for providing mounting hardware.

External Mount: Actuator shaft will be provided as extension pin kit to be mounted on side or with jackshaft pre-mounted on damper.

Determining Damper Actuator Torque

Requirements

Use the following procedure to determine the required torque for your damper.

NOTE: Damper area is measured using the H and W dimensions.

H

W

M20587

Measuring Damper Area

1.Calculate the damper area in square feet by multiplying the H dimension by the W dimension.

2.Multiply the damper area by the lb-in. per square foot value from Table 2 on page 9.

NOTE: The minimum lb-in. per square foot value that can accommodate tight closeoff and no leakage applications is 5, regardless of the value shown in the table.

3.Select the highest actuator torque value than the calculated value.

EXAMPLE:

Low leakage, parallel blade damper: H dimension = 48 in.

W dimension = 96 in.

Static pressure (in. w.c.) = 2 in. w.c. Face Velocity = 1000 fpm

48 in. x 96 in. ÷ 144 = 32 sq. ft.

32 sq. ft. x 7 lb-in./sq. ft. = 244 lb-in. where 7 lb-in./sq. ft = value from Table 2.

In this case you would need an actuator with a minimum nominal torque of 224 lb-in.

8

DD&CA

Damper And Actuator Sizing

Table 2. Approximate industry standard damper lb-in. per sq ft value.

|

|

|

Face Velocity (fpm)/ |

|

||

|

|

|

Static Pressure (in. wc |

|

||

|

|

|

|

|

|

|

Leakage |

Damper |

500/ |

1000/ |

1500/ |

2000/ |

2500/ |

|

Blades |

1 |

2 |

3 |

4 |

5 |

|

|

|

|

|

|

|

Low |

Parallel |

4 |

7 |

10.5 |

12 |

14 |

|

|

|

|

|

|

|

Low |

Opposed |

3 |

5 |

7.5 |

8.5 |

10 |

|

|

|

|

|

|

|

Standard |

Parallel |

3 |

4.5 |

6.5 |

7 |

8 |

|

|

|

|

|

|

|

Standard |

Opposed |

2 |

3 |

4.5 |

5 |

6 |

|

|

|

|

|

|

|

Damper Sizing

Dampers can be sized using two different methods; actual sizing and nominal sizing. When actual sizing is used the damper dimensions will be the same as the sizes ordered. For example, when a 24 inch x 24 inch D640 damper is ordered, it will be made such that the height is 24 inches and the width is 24 inches. When nominal sizing is used, the damper dimensions will be ¼ inch smaller than the sizes ordered. For example, when a 24 inch x 24 inch D640 is ordered, it will be made such that the height is 23.75 inches and the width is 23.75 inches. No special allowances are required for dampers that are constructed of multiple sections. For example, a damper that is 24 inch x 60 inch will be constructed of two sections. When ordered using nominal sizing, the damper size will be 23.75 inches high by 59.75 inches wide.

Actual sizing is commonly used when the exact size of the opening is known or if the damper is not meant to be installed inside an opening or duct. Nominal sizing, with its ¼ inch undersizing is commonly used when the damper will be installed inside an opening or duct and space is needed for positioning or seal material.

Honeywell’s sizing default is nominal sizing. If actual sizing is required, please make sure this is specified on the order. For more information on ordering Honeywell dampers, please contact your local Honeywell distributor or sales representative.

9

Damper And Actuator Sizing

HVAC performance depends largely upon airflow, and Honeywell Volume Control Dampers are built for both improved airflow and heavy-duty use. Honeywell has long been the leading source for airflow

control, with Volume Control Dampers that meet AMCA-certified Air Performance Standards, the highest established standards for commercial control dampers. Designed to minimize leakage, Honeywell dampers will give you efficient, trouble-free operation for years to come.

Standard Rectangular Dampers

Durable construction details are the cornerstone of Honeywell D1, D2 and D3 Volume Control Dampers. They feature heavy-duty hat channel frames for dependable operation inside ductwork. And all models have low-profile top and bottom frames, creating more free area while reducing pressure loss and reducing actuator torque.

The Right Choice

There’s a Honeywell Volume Control Damper that’s just right for your application. The D1 airfoil extremely low leakage damper presents a lower resistance to airflow typically used in high pressure systems.

The D2 ultra-low leakage damper keeps leakage to a minimum with blade and jamb seals, and is designed for mediumto high-pressure and velocity systems. The D3 low leakage damper is ruggedly built for applications in medium pressure and velocity systems.

3-V Blades - D2 and D3 Dampers

Honeywell Volume Control Dampers feature a 3-V design that’s proven to

meet higher-level system requirements

while minimizing flow-through system loss. Blades are fabricated from a single thickness of 16-gauge galvanized steel with three horizontal structural V-grooves running the length of the blade.

Applications And Operation

Honeywell Volume Control Dampers are designed to control airflow volume in mediumto high-pressure and velocity HVAC systems. Typical applications include volume control of airflow in zoning, air handler unit or economizer applications. Dampers are designed to operate with a wide range of Honeywell electric and pneumatic actuators. Operating range is from 2000 to 4000 fpm, and 2.5 to 6

inch wg. Spring return and non-spring return actuators are available with a wide range of output torque ratings to deliver the precise power needed for your damper application.

Blade Design

Airfoil Blades - D1 Dampers

Honeywell Airfoil Volume Control Dampers feature blades constructed of double skin galvanized steel. This design presents a lower resistance

to airflow and has strength that is typically used in high pressure systems.

Certified Performance

Honeywell certifies that models D2 and D3 are licensed to bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 511 and comply with the requirements of the AMCA Certified Ratings Programs. The AMCA Certified Ratings Seal applies to air performance ratings only.

|

|

Material |

|

|

Frame |

|

Blade |

||||||

|

|

|

|

Gauge |

|

Seals |

|||||||

|

|

|

|

|

|

|

|

||||||

|

Galvanized |

|

Stainless |

|

Aluminum |

|

|

|

|

|

Vinyl |

|

Silicone |

S — Standard |

|

|

16 |

|

14 |

|

12 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O — Optional |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D1 Airfoil Extremely Low Leakage |

S |

|

O |

|

n/a |

S |

|

O |

|

O |

n/a |

|

S |

Volume Control Damper |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D2 Ultra-Low Leakage |

S |

|

O |

|

O |

S |

|

O |

|

O |

S |

|

O |

Volume Control Damper |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D3 Low Leakage Volume |

S |

|

O |

|

O |

S |

|

O |

|

O |

n/a |

|

n/a |

Control Damper |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bearings |

Axles |

Linkage |

|

|

Flange |

|

|

|||||||||

|

Material |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Synthetic |

|

Bronze |

|

Stainless |

Steel |

|

Stainless |

Steel |

|

Stainless |

None |

|

Single |

|

Double |

|

Reverse |

|

|

|

|

|

|

|

|||||||||||

S |

O |

|

O |

S |

|

O |

S |

|

O |

S |

|

O |

|

O |

|

O |

|

S |

O |

|

O |

S |

|

O |

S |

|

O |

S |

|

O |

|

O |

|

O |

|

S |

O |

|

O |

S |

|

O |

S |

|

O |

S |

|

O |

|

O |

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For a copy of the specification sheet the D1 (63-2671) or D2 and D3 (63-2398), visit customer.honeywell.com.

10

DD&CA

Damper And Actuator Sizing

Standard Round Dampers |

Custom Dampers |

D690 and DM7600 Round Dampers. The 6” to 16” round dampers are used in zoning systems to control airflow in a round duct. These dampers come with neoprene and silicone seals for tight close off and low leakage. The DM7600 includes an actuator that is already attached to the round damper.

Need a custom damper? Contact the Take-Off Service. Below is a sample list of the products we frequently quote.

Custom Rectangular Dampers

Number |

Description |

|

|

VCD34 |

Galvanized Insulated Airfoil Damper |

|

|

VCD40 |

Aluminum Narrow Frame Airfoil Damper |

|

|

VCD42 |

Aluminum Airfoil Damper (Galvanized Frame) |

|

|

VCD43 |

Aluminum Airfoil Damper |

|

|

VCD45 |

Aluminum thermally broken insulated Damper |

|

|

Custom Round Dampers

Number |

Description |

|

|

VCDR53 |

Galvanized Round Damper – to 24 inches |

|

|

VCDRM53 |

Galvanized Round Multi-Blade Damper – |

|

to 36 inches |

|

|

Specification Take-Off Service

1.Submit your information in one of the following ways:

a)Email to takeoff.service@honeywell.com (preferred)

b)Fax toll-free to 1-877-880-3386 (local: 1-612-951-1238)

2.Include your desired turn-around time.

3.Take-Off Service staff will send you a confirmation that your email or fax was received.

We always attempt to have your request finished as soon as possible. Please note, however, that the quality of the submitted information largely determines the turn-around time. We will work closely with you to ensure that we have enough information to move forward as quickly as possible.

4.A final product schedule document will be returned to you following take-off completion.

Included In the Final Take-Off Document

We send a comprehensive spreadsheet, which contains:

•A complete product schedule

•Base price

•Directions on how to order Honeywell products

•Links to product submittals

•Quote identification number

Questions

Don’t see what you need?

Take-Off Service Contact Information: Toll-free: 1-888-664-4092

Local: 1-612-951-1027

If you have questions about the Honeywell Take-Off Service, please call the dedicated Take-Off Service phone number or email us at takeoff.service@honeywell.com.

Direct Coupled Actuators

Spring Return,

Low Torque

Spring Return,

High Torque

Non-Spring Return,

Low Torque

Non-Spring Return,

High Torque

Direct coupled actuators quick selection guide

Precise, reliable performance. Lasting value. Ease of installation. Everything you look for in directcoupled actuators hinges on quality. And quality engineering is what makes Honeywell’s complete line of actuators the top performers in the industry. Our global engineering team designs and tests our direct-coupled actuators to exceed rigorous global standards — and to meet Honeywell’s own demanding life testing.

But we don’t stop there. Thanks to our continuous improvement process, Honeywell actuators are now easier than ever to install. You’ll also benefit from consistent wiring regardless of signal type, common accessories and a simplified selection process.

Honeywell’s complete line of building control products, including valves and actuators, are already proven in more than three million buildings worldwide. So when you need spring or nonspring return actuators for your damper and valve applications, specify Honeywell. We make precision easy.

Easy-to-select MODEL numbers

MS and MN Families

Improve Installation Time

•Self-centering shaft adapter provides mounting flexibility and greater clamping force.

•Common wiring among families for every signal saves installation time.

Decrease Material Cost

•Detachable access cover allows direct wiring without a junction box.

Reduce Inventory

•Signal mode switch adapts models to twoposition, floating (tri-state), or modulating (proportional) applications.

Increase Control and Accuracy

•More than 200 reposition steps for modulating models provide precise control.

MS 75 10 A 2 2 XX

Fail Safe Mode |

|

|

|

|

|

|

|

|

|

|

|

System Controlled Numbers |

||

• MS Spring Return |

|

|

|

|

|

Auxiliary Switches |

|

|||||||

• MN Non-Spring Return |

|

|

|

|

|

|||||||||

Input Signal Type |

|

|

|

|

|

|

|

|

|

• 0 No Internal Switches |

||||

|

|

|

|

• 2 Two Internal Switches |

||||||||||

• 41 Two-Position, 100-250 Vac |

|

|

|

|

|

|

Feedback |

|

||||||

• 61 Floating, 24 Vac/dc |

|

|

|

|||||||||||

• 75 Modulating/Floating, 24 Vac/dc |

|

|

|

• 1 No Feedback |

||||||||||

• 81 Two-Position, 24 Vac/dc |

|

|

• 2 Voltage Feedback |

|||||||||||

Torque |

|

|

Application Type |

|

||||||||||

• 03 Nm = 27 in-lb |

|

• A Standard Model |

||||||||||||

• 05 Nm = 44 in-lb |

|

• H Enhanced Model |

||||||||||||

• 10 Nm = 88 in-lb |

|

|

|

|

||||||||||

• 20 Nm = 175 in-lb |

|

|

|

|

||||||||||

• 34 Nm = 300 in-lb |

|

|

|

|

||||||||||

ML Family

ML 61 61 B 2 XXX |

|||||||||||

Fail Safe Mode |

|

|

|

|

|

|

|

|

|

System Controlled Numbers |

|

• ML Non-Spring Return |

|

|

|

|

|

|

|

Declutch |

|

||

|

|

|

|

|

|

|

|

|

|||

Input Signal Type |

|

|

|

|

|

|

|

• 1 Standard |

|||

• 61 Floating, 24 Vac |

|

|

|

|

|

|

|

• 2 Includes Declutch Function |

|||

• 71 Modulating, 24 Vac |

|

|

|

|

|

|

|

Feedback & Conduit |

|

||

|

|

|

|

|

|

|

|

|

|||

Torque |

|

|

|

|

|

|

|

• A Feedback w/Accessory |

|||

• 61 (4 Nm) = 35 in-lb |

|

|

|

|

|

|

|

• B Standard |

|||

• 74 (8 Nm) = 70 in-lb |

|

|

|

|

|

|

|

• C Feedback w/Accessory and |

|||

Cover w/Conduit Connections

• D Cover w/Conduit Connections

12

Direct Coupled Actuators

spring return

|

|

|

Running Time |

Power Supply |

|

|

Control Input/Output |

|

Auxiliary Knob |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adj. |

|

Internal |

|

Order |

Approximate |

|

Spring |

|

|

|

|

0/2-10 |

3 kOhm |

Feedback |

Zero |

SPDT |

Minimum |

|

Specification |

Area of Damper |

Drive |

Return |

24 |

120-230 |

VA Rating |

|

Vdc, |

NTC, |

(0/2-10 |

and |

Auxiliary |

Position |

|

Number |

(4.5 lb-in/sq. ft.) |

(seconds) |

(seconds) |

Vac/dc |

Vac |

(Running) |

On/Off |

Floating |

3-Position |

Vdc) |

Span |

Switches |

Potentiometer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S03 Series (3 Nm, |

27 lb-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

MS8103A1030 |

6 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

0 |

|

|

MS8103A1130 |

6 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

1 |

|

|

MS4103A1030 |

6 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

0 |

|

|

MS4103A1130 |

6 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

1 |

|

|

MS7503A2030 |

6 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

0 |

|

|

MS7503A2130 |

6 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

1 |

|

|

MS7403A2030 |

6 |

90 |

<25 |

• |

|

|

|

• |

• |

• |

|

0 |

• |

|

S05 Series (5 Nm, |

44 lb-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

MS8105A1030 |

10 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

0 |

|

|

MS8105A1130 |

10 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

1 |

|

|

MS4105A1030 |

10 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

0 |

|

|

MS4105A1130 |

10 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

1 |

|

|

MS7505A2030 |

10 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

0 |

|

|

MS7505A2130 |

10 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

1 |

|

|

MS7405A2030 |

10 |

90 |

<25 |

• |

|

|

|

|

• |

• |

|

0 |

• |

|

S10 Series (10 Nm, |

88 lb-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

MS8110A1008 |

20 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

0 |

|

|

MS8110A1206 |

20 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

2 |

|

|

MS4110A1002 |

20 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

0 |

|

|

MS4110A1200 |

20 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

2 |

|

|

MS7510A2008 |

20 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

0 |

|

|

MS7510A2206 |

20 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

2 |

|

|

MS7510H2209 |

20 |

90 |

<25 |

• |

|

|

|

|

|

• |

• |

2 |

|

|

S20 Series (20 Nm, |

175 lb-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

MS8120A1007 |

39 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

0 |

|

|

MS8120A1205 |

39 |

45 |

<25 |

• |

|

|

• |

|

|

|

|

2 |

|

|

MS4120A1001 |

39 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

0 |

|

|

MS4120A1209 |

39 |

45 |

<25 |

|

• |

|

• |

|

|

|

|

2 |

|

|

MS7520A2007 |

39 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

0 |

|

|

MS7520A2205 |

39 |

90 |

<25 |

• |

|

|

|

• |

|

• |

|

2 |

|

|

MS7520H2208 |

39 |

90 |

<25 |

• |

|

|

|

|

|

• |

• |

2 |

|

non-spring return

|

|

|

|

|

Power Supply |

|

|

Control Input/Output |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Order Specification |

|

Approximate Area of |

Running |

|

|

VA Rating |

On/Off, |

|

|

|

Feedback |

SPDT Auxiliary |

||||

|

Number |

|

Damper (4.5 lb-in/sq. ft.) |

Time |

24 Vac/dc |

24 Vac |

(Running) |

Floating |

0/2-10 Vdc |

2-10 Vdc |

|

(0/2-10 Vdc) |

|

|

|

Switches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N05 Series (5 Nm, 44 lb-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MN6105A1011 |

|

10 |

90 |

• |

|

|

• |

|

|

|

|

0 |

||||

|

MN6105A1201 |

|

10 |

90 |

• |

|

|

• |

|

|

|

|

2 |

||||

|

MN7505A2001 |

|

10 |

90 |

• |

|

|

|

|

|

|

• |

0 |

||||

|

MN7505A2209 |

|

10 |

90 |

• |

|

|

|

|

|

|

• |

2 |

||||

|

N10 Series (10 Nm, 88 lb- |

in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MN6110A1003 |

|

20 |

90 |

• |

|

|

• |

|

|

|

|

0 |

||||

|

MN6110A1201 |

|

20 |

90 |

• |

|

|

• |

|

|

|

|

2 |

||||

|

MN7510A2001 |

|

20 |

90 |

• |

|

|

• |

• |

|

|

• |

0 |

||||

|

MN7510A2209 |

|

20 |

90 |

• |

|

|

• |

• |

|

|

• |

2 |

||||

|

N20 Series (20 Nm, 175 lb |

-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MN6120A1002 |

|

39 |

90 |

• |

|

|

• |

|

|

|

|

0 |

||||

|

MN6120A1200 |

|

39 |

90 |

• |

|

|

• |

|

|

|

|

2 |

||||

|

MN7220A2007 |

|

39 |

90 |

• |

|

|

|

• |

|

|

• |

0 |

||||

|

MN7220A2205 |

|

39 |

90 |

• |

|

|

|

• |

|

|

• |

2 |

||||

|

N34 Series (34 Nm, 300 lb |

-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MN6134A1003 |

|

67 |

90 |

• |

|

|

• |

|

|

|

|

0 |

||||

|

MN7234A2008 |

|

67 |

90 |

• |

|

|

|

• |

|

|

|

2 |

||||

|

ML6161/7161 (4 Nm, 35 lb |

-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ML6161A2009 |

|

8 |

90 |

|

• |

1.8 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6161A2017 |

|

8 |

420 |

|

• |

1.8 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6161A2025 |

|

8 |

180 |

|

• |

1.8 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6161B2024 |

|

8 |

90 |

|

• |

1.8 |

• |

|

|

|

|

0 |

||||

|

MS6161B2032 |

|

8 |

420 |

|

• |

1.8 |

• |

|

|

|

|

0 |

||||

|

ML6161B2073 |

|

8 |

180 |

|

• |

1.8 |

• |

|

|

|

|

0 |

||||

|

ML6161C2007 |

|

8 |

90 |

|

• |

1.8 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6161D2006 |

|

8 |

90 |

|

• |

1.8 |

• |

|

|

|

|

0 |

||||

|

MS7161A2008 |

|

8 |

90 |

|

• |

5.4 |

|

|

• |

|

|

0 |

||||

|

ML6174/7174 (8 Nm, 70 lb |

-in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ML6174A2002 |

|

16 |

90 |

|

• |

2.4 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6174A2010 |

|

16 |

180 |

|

• |

2.4 |

• |

|

|

|

w/ accessory |

0 |

||||

|

ML6174B2019 |

|

16 |

90 |

|

• |

2.4 |

• |

|

|

|

|

0 |

||||

|

ML6174B2035 |

|

16 |

420 |

|

• |

2.4 |

• |

|

|

|

|

0 |

||||

|

ML6174D2009 |

|

16 |

90 |

|

• |

2.4 |

• |

|

|

|

|

0 |

||||

|

ML6174E2008 |

|

16 |

90 |

|

• |

2.4 |

• |

|

|

|

|

0 |

||||

|

ML7174A2001 |

|

16 |

90 |

|

• |

5.4 |

• |

|

|

|

|

0 |

||||

|

ML7174E2007 |

|

16 |

90 |

|

• |

5.4 |

• |

|

|

|

|

0 |

||||

1 Consult Tradeline catalog for additional models. |

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

2 Assumes standard 1000 fpm system with parallel blade damper. Approximate square foot. |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

||||||||||

SelectionDCA

Fire & Smoke Actuators

Honeywell’s complete line of two-position, fast-acting springreturn actuators meet all of your needs for fire and smoke control applications. All models are designed to meet the UL-555 and UL-555S high temperature requirements for fire dampers and combined fire and smoke dampers.

Safety First

As a life safety system component Honeywell is dedicated to meeting the UL-555 and UL-555S requirements. The elevated temperature test can be performed at the temperature ratings of 250ºF or 350ºF. Honeywell only offers models at 350ºF to

meet UL-555 and UL-555S for fire and combined fire and smoke applications to support the highest level of safety for building occupants.

Largest Torque Range in the Industry

Honeywell’s fire and smoke actuators are available in 30, 80 and 175 lb-in with the 175 lb-in being the highest torque commercial fire and smoke actuator available on the market today.

Key Features and Benefits

•Integral spring return that ensures the proper level of torque

•Patented design that eliminated limit switches, reducing power consumption

•Reliable service in smoke control systems requiring

Underwriter’s Laboratories Inc. UL-555 and UL-555S

•Robust die-cast aluminum housing ensures

•Full life of two-position spring return fire and smoke actuators rated up to 350ºF for all critical applications

•Fast acting with a maximum spring return timing of 15 seconds

•No audible noise during holding

|

Torque |

Voltage |

Spring Direction |

Description |

Number of internal |

Model Number |

|

|

Auxiliary Switch |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 Vac |

CCW |

|

External* |

ML4115A1009 |

|

|

|

CW |

Fire and smoke, fast acting, |

External* |

ML4115B1008 |

|

|

|

|

|

||||

|

|

|

|

CCW |

External* |

ML4115C1007 |

|

|

30 lb-in (3.4 Nm) |

230 Vac |

two position spring return, UL-555 |

||||

|

CW |

External* |

ML4115D1006 |

||||

|

|

|

|

and UL-555S ratings up to 350ºF |

|||

|

|

|

24 Vac |

CCW |

External* |

ML8115A1005 |

|

|

|

|

|

||||

|

|

|

CW |

|

External* |

ML8115B1004 |

|

|

|

|

|

|

|||

|

|

|

120 Vac |

CW |

|

External* |

MS4209F1007 |

|

|

|

CCW |

Fire and smoke, fast acting, |

External* |

MS4309F1005 |

|

|

|

|

|

||||

|

|

|

|

CW |

External* |

MS4709F1014 |

|

|

80 lb-in |

(9 Nm) |

230 Vac |

two position spring return, UL-555 |

|||

|

CCW |

External* |

MS4809F1012 |

||||

|

|

|

|

and UL555S ratings up to 350ºF |

|||

|

|

|

24 Vac |

CW |

External* |

MS8209F1003 |

|

|

|

|

|

||||

|

|

|

CCW |

|

External* |

MS8309F1001 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

120 Vac |

|

|

0 |

MS4120F1006 |

|

|

|

|

Fire and smoke, fast acting, |

2 SPST |

MS4120F1204 |

|

|

|

|

|

|

|||

|

|

|

|

|

0 |

MS4620F1005 |

|

|

175 lb-in |

(20 Nm) |

230 Vac |

Reversible Design |

two position spring return, UL-555 and |

||

|

2 SPST |

MS4620F1203 |

|||||

|

|

|

|

|

UL-555S ratings up to 350ºF |

||

|

|

|

24 Vac |

|

0 |

MS8120F1002 |

|

|

|

|

|

|

|||

|

|

|

|

|

2 SPST |

MS8120F1200 |

|

|

|

|

|

|

|

||

Note: Honeywell's spring return fire and smoke actuators are designed to pass UL-555 and UL-555S 350ºF requirements. They are not designed for HVAC applications. UL-555 and UL-555S requires that all new construction fire and smoke damper jobs have the actuator assembled and tested at the damper manufacturer. A like for like retrofit replacement or technically equal UL-555 and UL-555S approved device is recommended.

14

Section 2: Valve Selection |

|

Control Valve Applications .......................................................... |

17 |

Control Valve Selection Criteria .................................................. |

18 |

2-Way.................................................................................... |

18 |

3-Way.................................................................................... |

20 |

Fan Coil and Zone Valves........................................................... |

22 |

Cartridge Cage Valves................................................................ |

24 |

Cartridge Globe Valves............................................................... |

26 |

Control Ball Valves ½ - 3” |

|

2-Way NPT NEMA 2.............................................................. |

28 |

2-Way NPT NEMA 3R........................................................... |

30 |

Control Ball Valves ½ - 2 ½” |

|

3-Way NPT NEMA 2.............................................................. |

32 |

3-Way NPT NEMA 3R.......................................................... |

33 |

Flanged Control Ball Valves 4”- 6” |

|

2-Way Flanged NEMA 2+3R.................................................. |

34 |

3-Way Flanged NEMA 2+3R.................................................. |

35 |

NPT Globe Valves ½-3” |

|

With Dedicated Valve Actuators............................................. |

36 |

With Direct Coupled Actuators.............................................. |

38 |

Flanged Globe Valves 2 ½ -3” |

|

With Direct Coupled Actuators.............................................. |

42 |

Threaded and Flanged Globe Valves 2”-3” |

|

With Tandem Linked Direct Coupled Actuators.................... |

46 |

Flanged Globe Valves 2 ½ - 3” |

|

With Dedicated Valve Actuators............................................. |

48 |

Flanged Globe Valves 4”-6” |

|

With Tandem Linked Direct Coupled Actuators..................... |

52 |

With Dedicated Valve Actuators............................................. |

54 |

Flanged Cage Valves 2 ½ - 6”.................................................... |

55 |

NPT Globe Valves ½ -3” |

|

With Pneumatic Actuators..................................................... |

56 |

Flanged Globe Valves 2 ½ - 3” |

|

With Pneumatic Actuators..................................................... |

60 |

Flanged Globe Valves 4”- 6” |

|

With Pneumatic Actuators..................................................... |

64 |

Resilient Seat Butterfly Valves |

|

2-Way Electrically-Actuated Control....................................... |

66 |

3-Way Electrically-Actuated Control....................................... |

68 |

2-Way Pneumatically-Actuated Control................................. |

72 |

3-Way Pneumatically-Actuated Control................................. |

74 |

Selection Valve

15

16

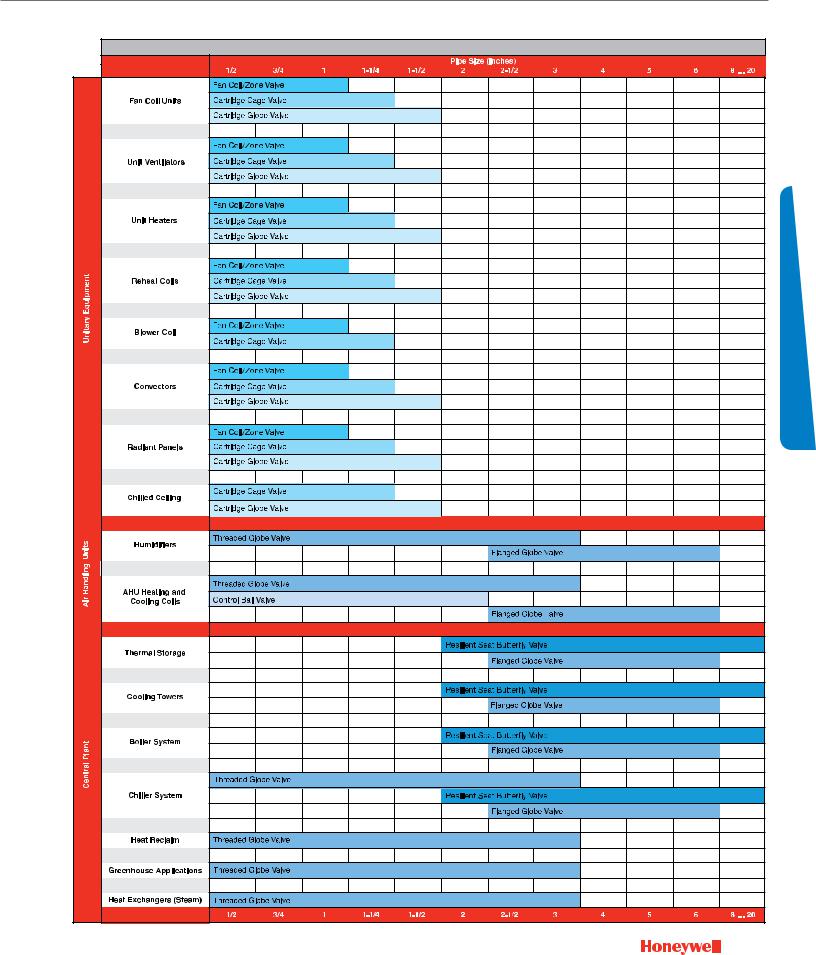

Control Valve Applications

Control Valve Applications |

Selection Valve |

17 |

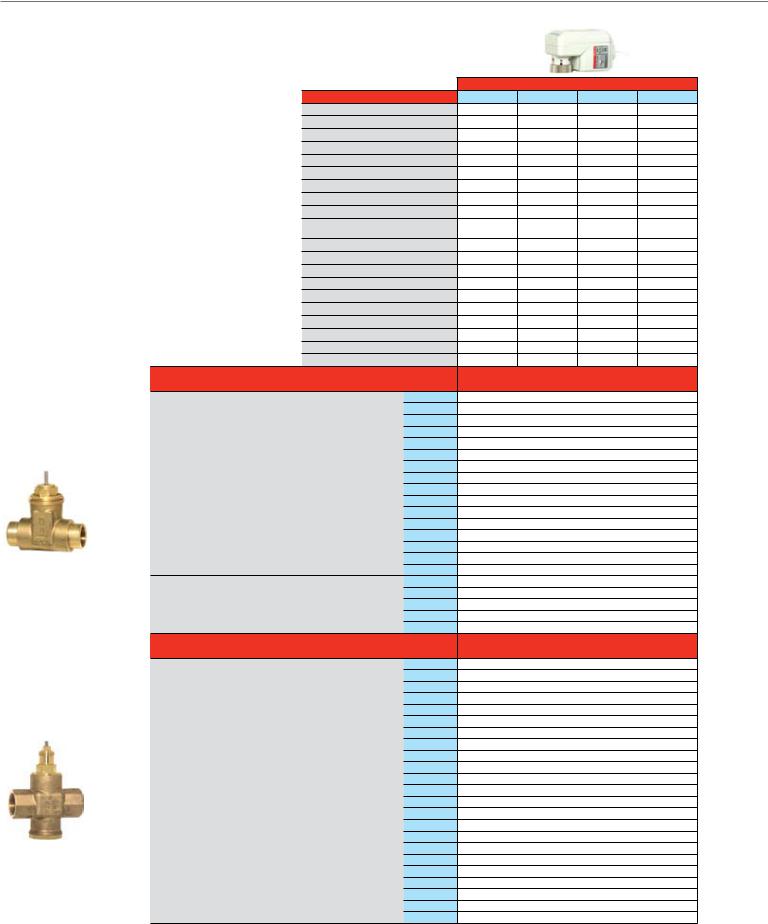

Control Valve Selection Criteria

2-Way

|

|

|

|

|

|

Unitary |

|

|

|

Globe |

|

|

||

|

|

|

|

Fan Coil |

|

Cartridge |

Cartridge |

|

Threaded |

|

|

Flanged |

|

|

|

|

|

|

|

Cage |

Globe |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Attribute |

Specification |

VU52 |

|

VU53 |

VCzA/B |

V58x2 |

V5011N... |

V5011F |

V5011G |

V5011A |

V5011B |

VGF2xS |

||

|

1/2" |

[DN15] |

• |

|

• |

• |

• |

• |

|

|

|

|

|

|

|

3/4" |

[DN20] |

• |

|

• |

• |

• |

• |

|

|

|

|

|

|

|

|

1" |

[DN25] |

• |

|

• |

• |

|

• |

|

|

|

|

|

|

1 1/4" |

[DN32] |

|

|

|

• |

|

• |

|

|

|

|

|

|

|

1 1/2" |

[DN40] |

|

|

|

|

|

• |

|

|

|

|

|

|

Pipe Size |

|

2" |

[DN50] |

|

|

|

|

|

• |

|

|

|

|

|

2 1/2" |

[DN65] |

|

|

|

|

|

|

• |

• |

• |

|

• |

||

|

|

|

|

|

|

|

|

|||||||

|

|

3" |

[DN80] |

|

|

|

|

|

|

• |

• |

• |

|

• |

|

|

4" |

[DN100] |

|

|

|

|

|

|

|

|

• |

• |

• |

|

|

5" |

[DN125] |

|

|

|

|

|

|

|

|

• |

• |

• |

|

|

6" |

[DN150] |

|

|

|

|

|

|

|

|

• |

• |

• |

|

Other |

(maximum size) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sweat |

• |

|

• |

• |

• |

|

|

|

|

|

|

|

Pipe Fittings |

NPT Internal Thread |

• |

|

• |

• |

• |

• |

• |

• |

|

|

|

||

Inverted Flare |

• |

|

• |

• |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||||

|

|

ANSI Flange |

|

|

|

|

|

|

|

|

• |

• |

• |

|

|

ANSI 125/150 |

|

|

|

|

|

• |

• |

• |

• |

• |

• |

||

Static Pressure |

ANSI 250/300 |

|

|

|

|

|

|

|

|

|

|

• |

||

|

|

|

Other |

300 psi |

|

300 psi |

230 psi |

|

|

|

|

|

|

|

|

|

Chilled Water |

• |

|

• |

• |

• |

• |

• |

• |

• |

• |

• |

|

Media |

|

Hot Water |

• |

|

• |

• |

• |

• |

• |

• |

• |

• |

• |

|

Low Pressure Steam |

|

|

|

|

|

N1, N3 |

• |

• |

• |

• |

• |

|||

|

|

|

|

|

|

|||||||||

|

High Pressure Steam |

|

|

|

|

|

N2 |

|

• |

|

|

• |

||

Flow Capacity, Cv |

Multiple ratings per pipe size |

• |

|

• |

• |

• |

• |

• |

• |

|

|

|

||

One rating/size above 1/2" |

|

|

|

|

|

• |

• |

• |

• |

• |

• |

|||

|

|

|

|

|

|

|||||||||

|

Direct Acting **** |

|

|

|

|

|

N1, N2 |

• |

• |

• |

|

• |

||

Valve Action |

Reverse Acting ***** |

|

|

|

• |

• |

N3 |

|

|

|

• |

|

||

|

Rotary N.O. |

• |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

Rotary N.C. |

|

|

• |

|

|

|

|

|

|

|

|

|

|

Equal Percentage |

|

|

|

|

• |

• |

• |

|

• |

• |

• |

||

Flow Characteristic |

Modified Equal Percentage |

|

|

|

• |

|

|

|

|

|

|

|

||

|

Linear |

|

|

|

• |

|

• |

|

• |

|

|

• |

||

|

|

|

|

|

|

|

|

|

||||||

|

|

Quick Open |

• |

|

• |

• |

|

|

|

|

|

|

|

|

Close-off |

High** |

(100 psid minimum) |

|

|

|

|

• |

|

|

|

|

|

|

|

Medium |

(40 psid minimum) |

|

|

|

• |

• |

|

|

|

|

|

|

||

pressure*** |

|

|

|

|

|

|

|

|

|

|||||

Varies with actuator |

• |

|

• |

|

|

• |

• |

• |

• |

• |

• |

|||

|

|

|

|

|||||||||||

|

ANSI Class III (0.10% Cv max.) |

|

|

|

|

0.02% |

0.05% |

|

|

|

|

• |

||

Maximum Seat |

ANSI Class IV (0.01% Cv max.) |

|

|

|

|

|

|

|

|

• |

• |

|

||

Leakage |

Bubble-tight design |

|

|

|

• |

|

|

|

|

|

|

|

||

|

Other (see product data literature) |

33 mL/m |

|

|

|

|

0.5% |

0.5% |

|

|

|

|||

|

High |

|

(50:1 minimum) |

|

|

|

|

• |

• |

• |

• |

• |

• |

• |

Rangeability |

Medium* |

(15~50:1) |

N/A |

|

• |

|

|

|

|

|

|

|

||

|

Low |

|

(under 15:1) |

|

|

|

|

|

|

|

|

|

|

|

|

Brass, plated brass, bronze |

|

|

|

|

|

N3 |

• |

|

• |

• |

|

||

Trim |

Brass plug /Stainless seat |

|

|

|

|

|

N1 |

|

|

|

|

|

||

Stainless Steel |

|

|

|

|

|

N2 |

|

• |

|

|

• |

|||

|

|

|

|

|

|

|

|

|

||||||

|

Resilient materials |

• |

|

• |

• |

• |

|

|

|

|

|

|

||

In-line |

|

Cartridge |

• |

|

• |

• |

• |

|

|

|

|

|

|

|

|

Packing |

|

|

|

|

|

• |

• |

• |

• |

• |

• |

||

Serviceability |

|

|

|

|

|

|

||||||||

|

Rebuild |

|

|

|

|

|

• |

• |

• |

• |

• |

|

||

|

|

|

|

|

|

|

|

|||||||

|

Electronic Modulating |

|

|

|

• |

• |

• |

• |

• |

• |

• |

• |

||

|

Tri-state floating |

|

|

|

• |

• |

• |

• |

• |

• |

• |

• |

||

|

Pulse Width Modulation |

|

|

|

• |

|

|

|

|

|

|

|

||

|

2-position low voltage |

• |

|

• |

• |

o |

• |

• |

• |

• |

• |

• |

||

Actuation Options |

2-position line voltage |

• |

|

• |

• |

|

• |

• |

• |

• |

• |

• |

||

Electric Spring Return |

• |

|

• |

|

• |

• |

• |

• |

• |

• |

• |

|||

|

|

|

||||||||||||

|

Electronic Fail Safe |

|

|

|

• |

|

|

|

|

|

|

|

||

|

Pneumatic, low pressure |

|

|

|

|

• |

• |

• |

• |

• |

• |

• |

||

|

Pnuematic bidirectional (Hi-Pr) |

|

|

|

|

|

|

|

|

|

|

|

||

|

Pnuematic spring return (Hi-Pr) |

|

|

|

|

|

|

|

|

|

|

|

||

Notes |

* Best used with supply water reset from outdoor air temperature. |

|

|

|

|

|

|

|

|

|||||

|

** Can dead-head pumps. Use with VFD-controlled pumps with maximum pressure cut-out |

|

|

|

|

|

|

|||||||

|

*** Maximum operating differential pressure. Static close-off pressure may be higher. Maximum pressure for quiet service may be less. |

|

|

|

||||||||||

18 |

**** Stem down to close |

|

|

|

|

|

|

|

|

|

|

|

||

***** Stem up to close |

|

|

|

|

|

|

|

|

|

|

|

|||

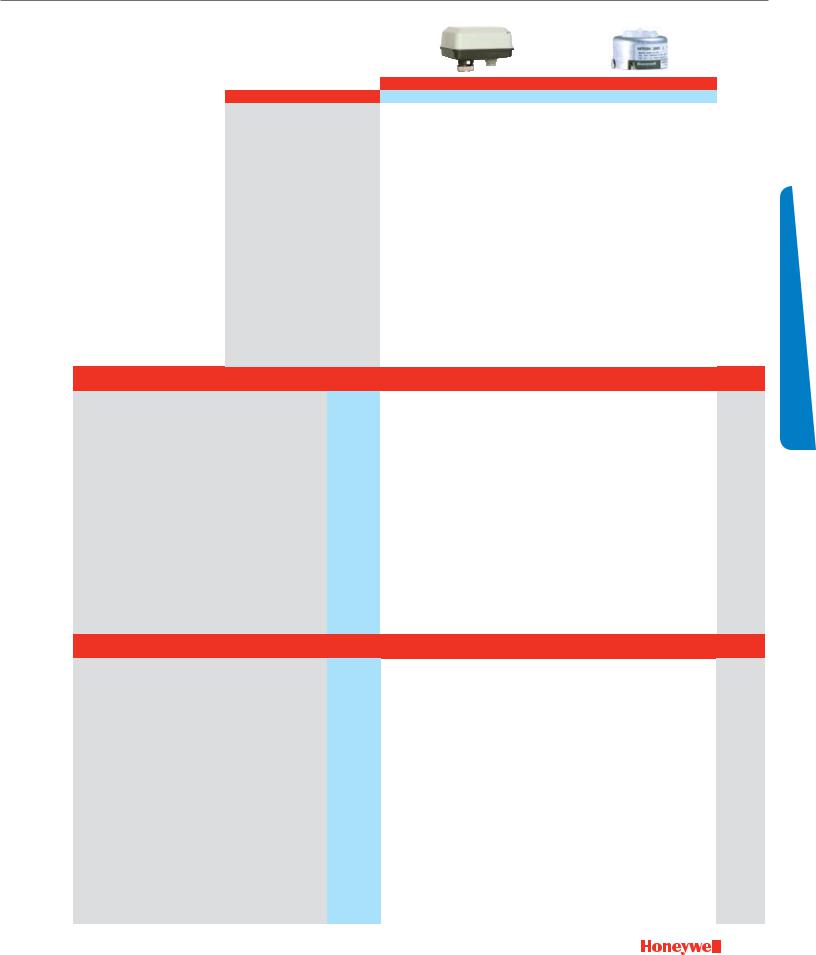

Control Valve Selection Criteria

2-Way

|

|

|

|

Globe |

Control Ball |

|

Butterfly |

|

||||||||

|

|

|

|

Pressure-Balanced |

Threaded |

Flanged |

Resilient Seat |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||||||

Attribute |

Specification |

V5862A3 |

VGF2xP |

VBN2 |

VBF2 |

VFF1 |

|

VFF2 |

|

|

|

|

|

|||

|

1/2" |

[DN15] |

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

3/4" |

[DN20] |

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

1" |

[DN25] |

• |

|

• |

|

|

|

|

|

|

|

|

|

|

|

1 1/4" |

[DN32] |

• |

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

1 1/2" |

[DN40] |

• |

|

• |

|

|

|

|

|

|

|

|

|

|

|

Pipe Size |

|

2" |

[DN50] |

|

|

• |

|

• |

|

|

• |

|

||||

2 1/2" |

[DN65] |

|

• |

• |

|

• |

|

|

• |

|

|

|

|

|

||

|

|

|

|

|

|

|||||||||||

|

|

3" |

[DN80] |

|

• |

• |

|

• |

|

|

• |

|

||||

|

|

4" |

[DN100] |

|

• |

|

• |

• |

|

|

• |

|

||||

|

|

5" |

[DN125] |

|

• |

|

• |

• |

|

|

• |

|

||||

|

|

6" |

[DN150] |

|

• |

|

• |

• |

|

|

• |

|

||||

|

Other |

(maximum size) |

|

|

|

|

|

20" [DN500] |

|

|||||||

|

|

Sweat |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pipe Fittings |

NPT Internal Thread |

• |

|

• |

|

|

|

|

|

|

|

|

|

|

||

Inverted Flare |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

ANSI Flange |

|

• |

|

• |

• |

|

|

• |

|

|||||

|

ANSI 125/150 |

|

• |

|

• |

|

|

|

|

|

|

|

|

|

||

Static Pressure |

ANSI 250/300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Other |

230 psi |

360 psi |

|

|

250 psi |

|

|||||||

|

|

Chilled Water |

• |

• |

• |

• |

• |

|

|

• |

|

|||||

Media |

|

Hot Water |

• |

• |

• |

• |

• |

|

|

• |

|

|||||

Low Pressure Steam |

|

• |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

High Pressure Steam |

|

• |

|

|

|

|

|

|

|

|

|

|

|

||

Flow Capacity, Cv |

Multiple ratings per pipe size |

• |

|

• |

• |

|

|

|

|

|

|

|

|

|

||

One rating/size above 1/2" |

|

• |

|

|

• |

|

|

• |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||||||||

|

Direct Acting **** |

• |

• |

|

|

|

|

|

|

|

|

|

|

|

||

Valve Action |

Reverse Acting ***** |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Rotary N.O. |

|

|

o |

o |

• |

|

|

o |

|

|

|

|

|

||

|

|

|

|

|

|

|

||||||||||

|

|

Rotary N.C. |

|

|

• |

• |

|

|

|

• |

|

|||||

|

Equal Percentage |

|

• |

|

|

|

|

|

|

|

|

|

|

|

||

Flow Characteristic |

Modified Equal Percentage |

|

|

• |

• |

• |

|

|

• |

|

||||||

|

Linear |

• |

• |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Quick Open |

|

|

|

|

|