Page 1

Operating Instructions

ND 1200

QUADRA-CHEK

Software Version

2.16

English (en)

4/2009

Page 2

Page 3

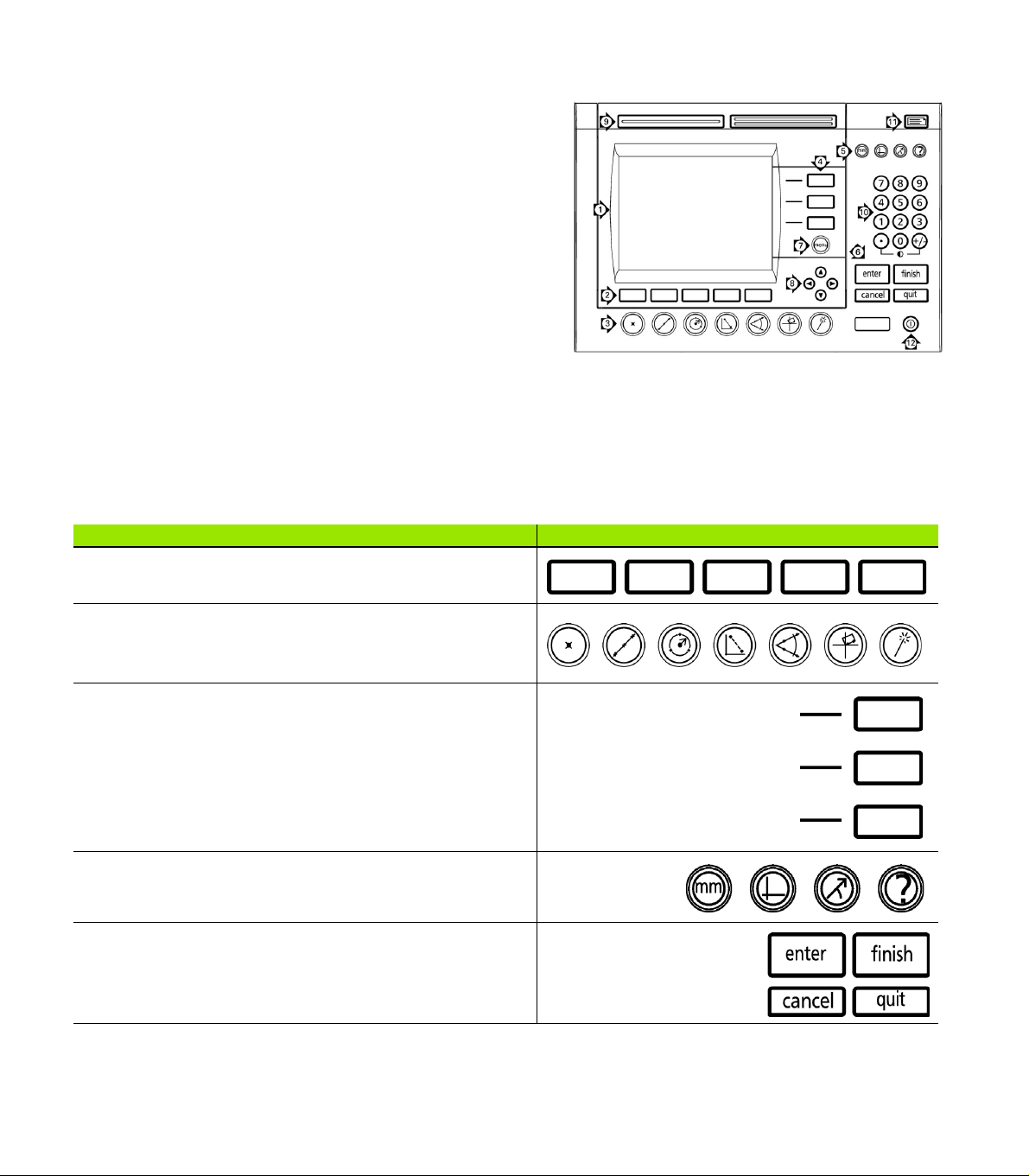

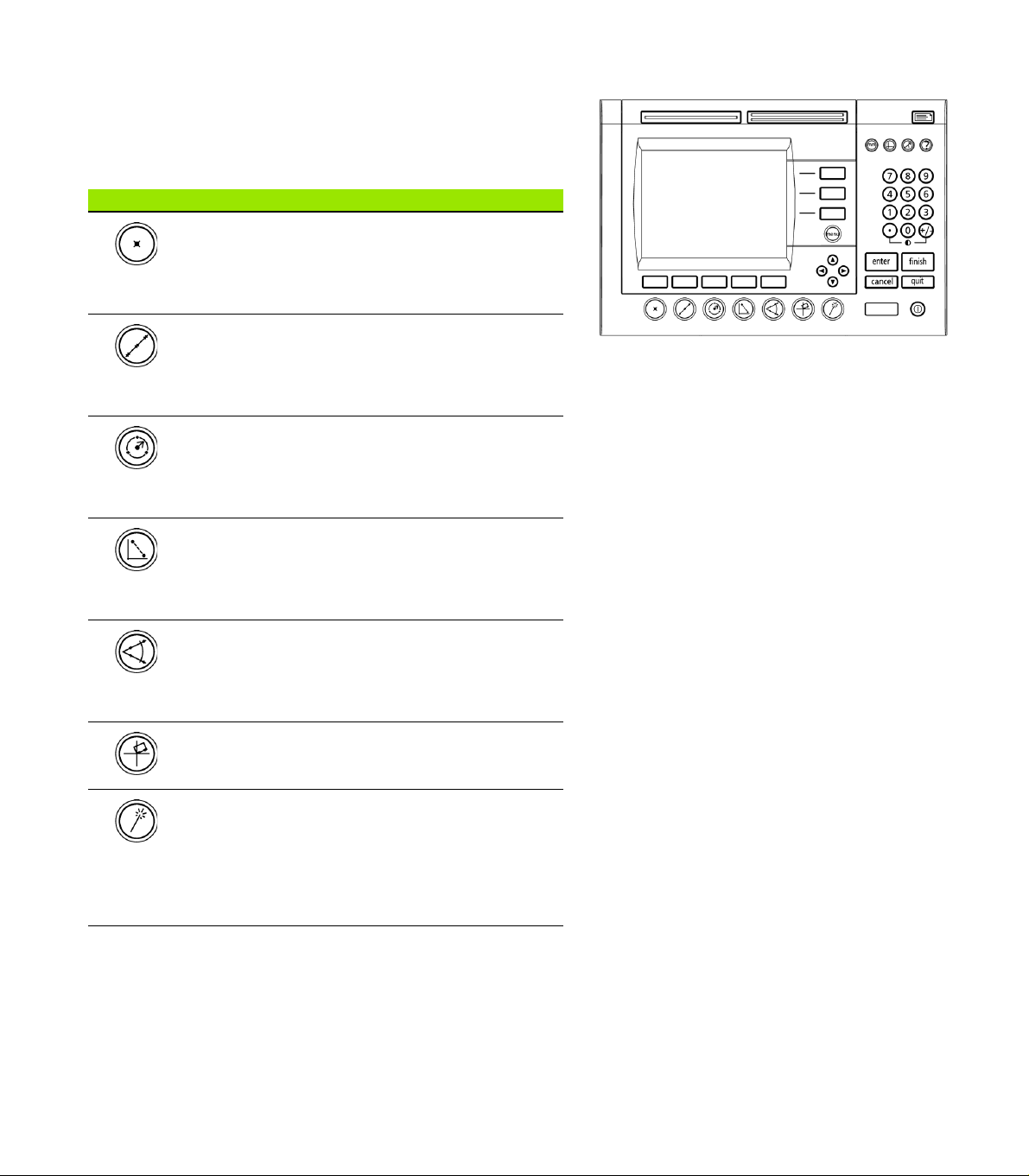

ND 1200 Introduction

1 LCD screen

2 Soft keys

3 Measurement function keys

4 Axis keys

5 Mode selection keys

6 Command keys

7 Menu key

8 Arrow cursor keys

9 Fast track keys

10 Numeric keypad

11 Send key

12 LCD On/Off key

ND 1200 panel keys

Panel keys are used to initiate feature measurements, apply

tolerances, send reports of measurement results and configure

operational parameters.

Panel function key Panel key

Soft keys: Functions change in support of the activities displayed

on the LCD.

Measure keys: Select a feature measurement type. Feature

measurement types include points, lines, circles distances,

angles, skew alignments and Measure Magic.

Axis keys: Select axes for zeroing or presetting datums prior to

measurements.

Mode keys: Select unit of measure, datum, cartesian or polar

coordinate system and help.

Command keys: Control measurement and data entry

processes.

ND 1200 QUADRA-CHEK 3

Page 4

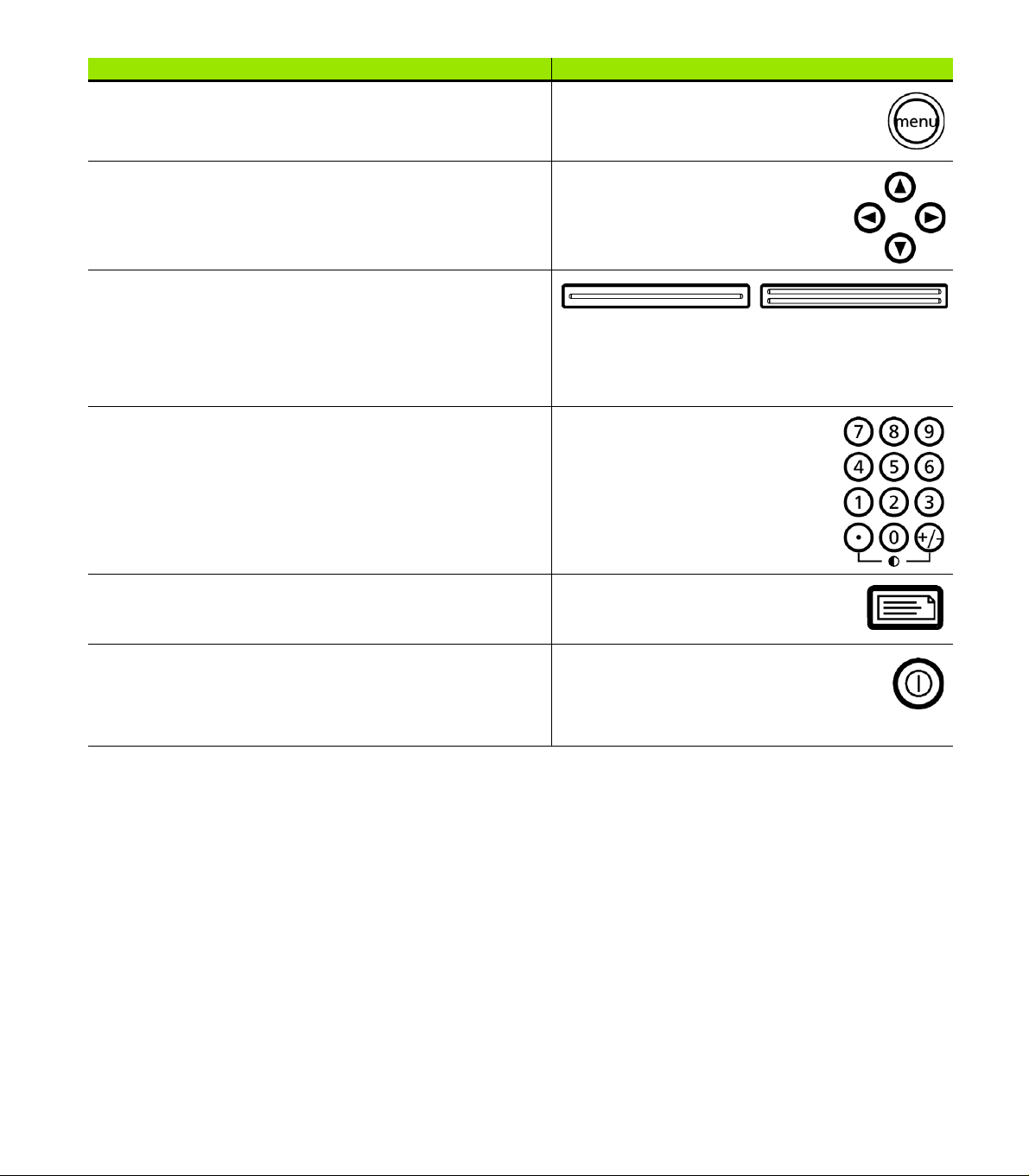

Panel function key Panel key

Menu key: Displays five soft key menus for system setup,

programming, extra functions clearing data and optional optical

edge detector functions.

Arrow cursor keys: Used to scroll through lists and navigate

menus and setup screen data fields. The up arrow cursor key is

also used to begin a feature construction process, as described

later in the feature Constructions portion of this chapter.

Fast track keys: Two programmable fast track keys are used to

perform frequently used functions. These keys can easily be

located by touch without taking your eyes off the part. By default

the left fast track key is assigned the Enter key function and the

right is assigned the Finish key function. Users can program

either fast track key as described later in the Hotkeys portion of

Chapter 2: Installation, Setup and Specifications.

Numeric keypad: Used to enter numeric data. Additionally, the

decimal point key and +/- key are used to adjust the contrast

of the LCD display.

Send key: Used to transmit measurement results to a computer,

USB printer or USB flash drive.

LCD On/Off key: Press the LCD on/off button to turn the LCD

display off without removing power from the ND 1200. Press the

button a second time to restore the LCD display. Additionally, the

LCD On/Off key can be used to clear feature data, datums and

skews.

4 Preface

Page 5

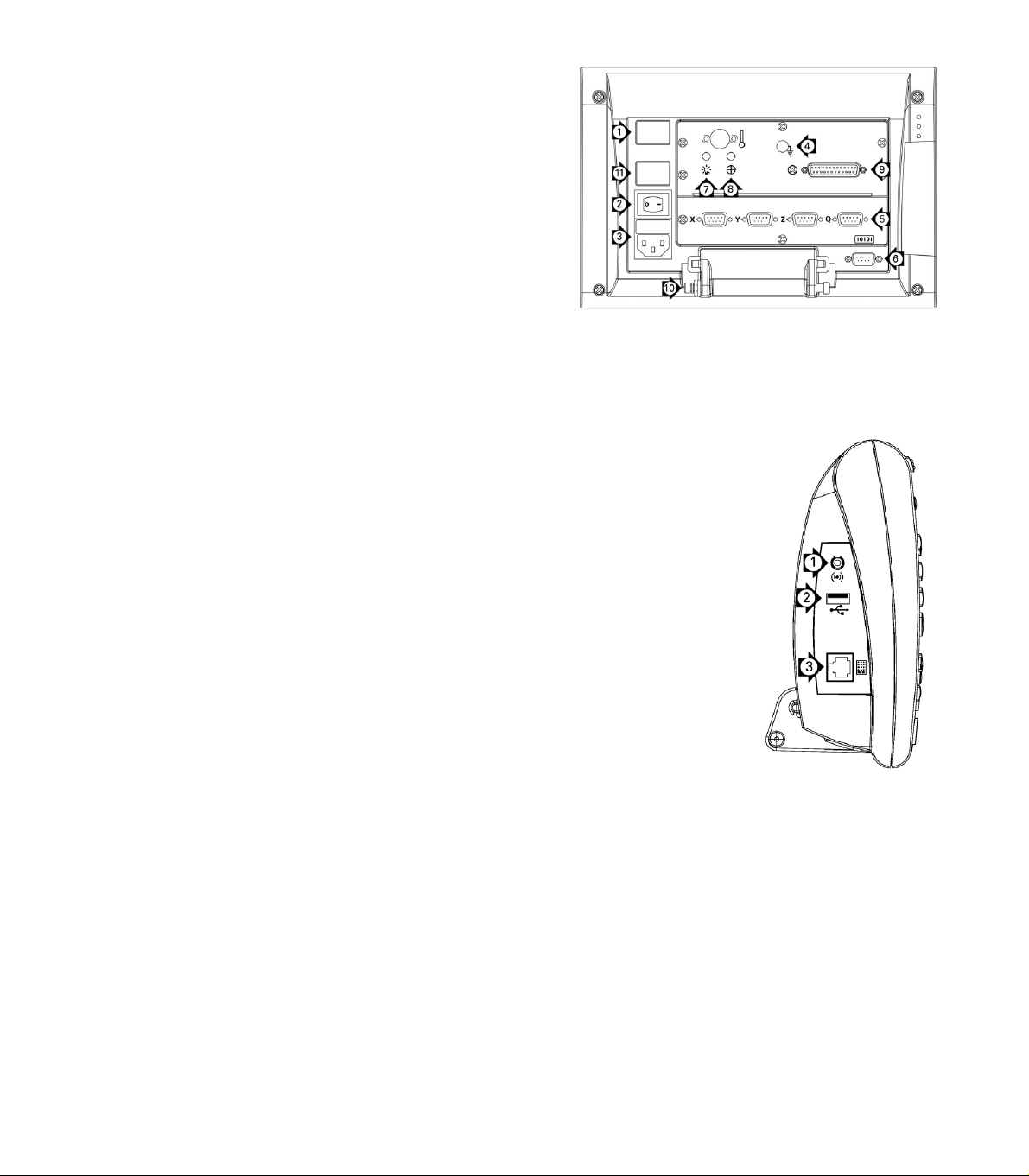

ND 1200 rear panel

1 Serial number label

2 Power switch

3 Power cord connector and fuse holder

4 Power ground access

5 Measurement axis connectors

6 RS-232 serial port connector

7 Optical reference cable connector

8 Optical sensor cable connector

9 Not supported in the ND 1200

10 Tilt base mechanical tightness adjustment

11 Electrical Ratings label

ND 1200 side panel

1 Speaker/headset jack

2 USB Type A connector

3 RJ-45 Foot switch/hand switch/keypad connector

ND 1200 QUADRA-CHEK 5

Page 6

Information contained in this manual

This User's manual covers the operation, installation, setup and

specifications of the ND 1200. Operating information is contained in

chapter 1. Installation, setup instructions and specifications are

contained in chapter 2.

Fonts used in this manual

The following fonts are used to indicate operator controls or to show

emphasis:

Operator controls - soft keys and other panel keys are shown in

upper case.

Emphasis - Items of special interest or concepts that are

emphasized to the user are shown in bold type.

Showing sequences of key presses

The ND 1200 user performs sequences of soft key and panel key

presses to measure part features and complete other tasks. These

sequences are indicated using text as shown in the following

example:

Press the MENU key, press the EDGE soft key and then press the

AUTO E soft key is sometimes abbreviated as:

Press MENU/EDGE/AUTO E

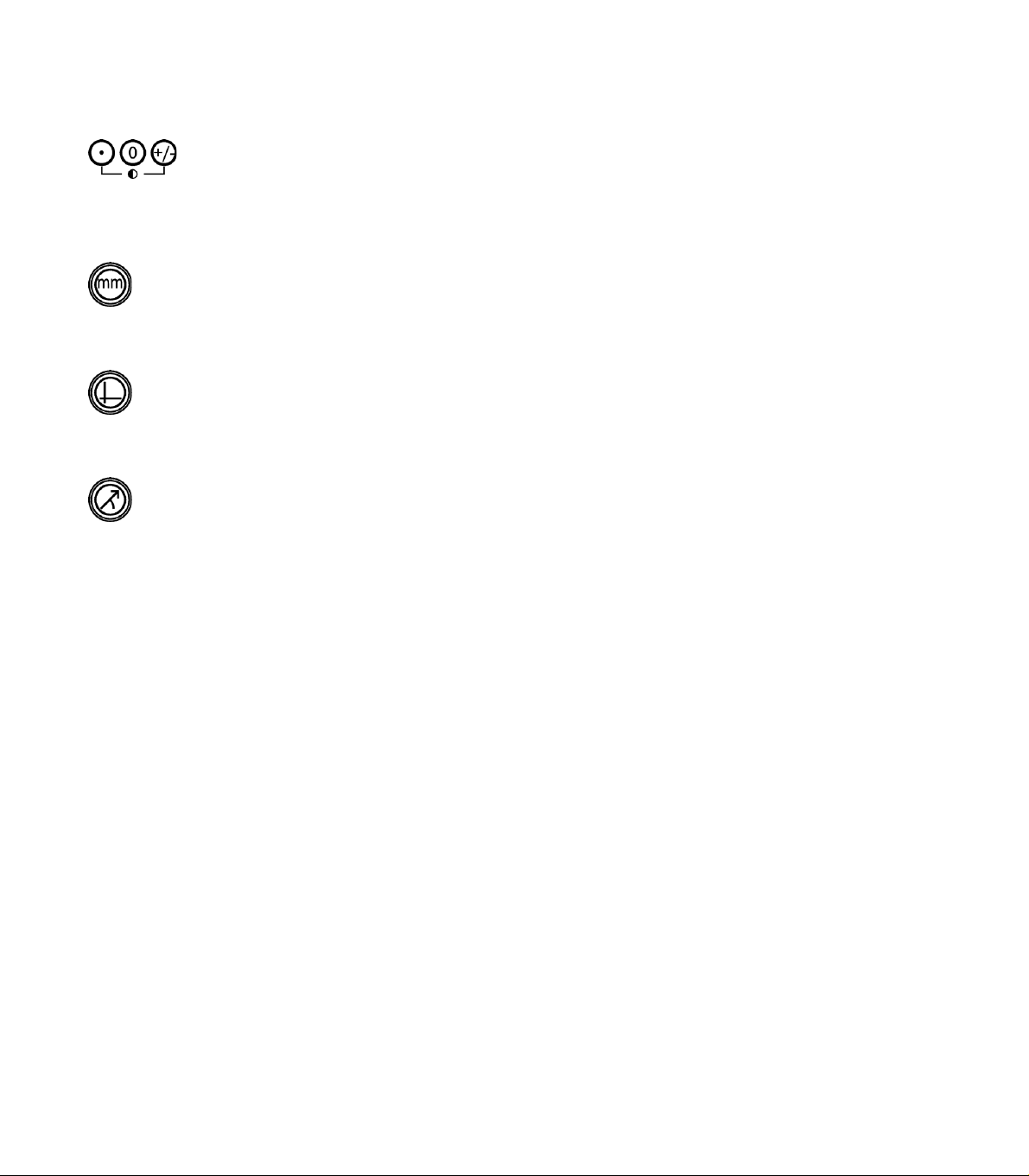

Symbols within notes

Notes are marked with symbols on the left indicating the type, or

potential severity of the information.

General Information

This is additional or supplementary information about an

activity or concept.

Warning

This warns of a situation or condition that could lead to

measurement errors, equipment malfunction or

equipment damage. Do not proceed until the message is

read and understood.

Caution - Risk of electric shock

This warns of a situation or condition that could lead to

electrical shock and to personal injury or death. Do not

proceed until the message is read and understood.

6 Preface

Page 7

Safety considerations

General accepted safety precautions must be followed when

operating the system. Failure to observe these precautions could

result in damage to the equipment, or injury to personnel. It is

understood that safety rules within individual companies vary. If a

conflict exists between the material contained in this manual and the

rules of a company using this system, the more stringent rules should

take precedence.

The ND 1200 is equipped with a 3-wire power plug that

includes a separate ground connection. Always connect

the power plug to a 3-wire grounded outlet. Use of 2-wire

power plug adapters or any other connection accessories

that remove the third grounded connection create a safety

hazard and should not be permitted.

Unplug the ND 1200 from the power outlet and seek the

assistance of a qualified service technician if:

The power cord is frayed or damaged or the power plug

is damaged

Liquid is spilled or splashed onto the enclosure

The ND 1200 has been dropped or the exterior has been

damaged

The ND 1200 exhibits degraded performance or

indicates a need for service some other way

ND 1200 measurement axes

The ND 1200 DRO can display 2, 3, or 4 axes depending on the model

purchased. DRO screen images used throughout this manual show

different numbers of axes and are for illustration only.

Software version

The software version is shown in the About setup screen discussed

later in chapter 2.

Cleaning

Use only a cloth dampened with water and a mild detergent for

cleaning the exterior surfaces. Never use abrasive cleaners, and never

use strong detergents or solvents. Only dampen the cloth, do not use

a cleaning cloth that is dripping wet.

ND 1200 QUADRA-CHEK 7

Page 8

8 Preface

Page 9

1 Operation ..... 13

1.1 ND 1200 Overview ..... 14

1.2 Basic Functions of the ND 1200 ..... 16

Switching on the ND 1200 ..... 16

Establishing a repeatable machine zero ..... 17

Switching off the ND 1200 ..... 17

Panel key descriptions ..... 18

LCD screen and soft key layout ..... 22

DRO mode screen and soft keys ..... 22

Feature evaluation mode screens and soft keys ..... 23

Feature measurement mode screen and soft keys ..... 24

ND 1200 Menus ..... 25

1.3 Preparing to Measure ..... 29

Power-up the ND 1200 ..... 29

Establish machine zero ..... 29

Adjust LCD screen contrast ..... 30

Select unit of measure ..... 30

Select a datum ..... 30

Select a coordinate system ..... 30

Select the desired annotation ..... 31

Toggle between forward and backward annotation ..... 31

Select a probe type ..... 32

Select crosshairs: ..... 32

Select an optical edge probe ..... 32

Calibrate the optical edge detector ..... 33

Perform a Teach ..... 33

Perform a D. Cal ..... 33

Perform an X Cal ..... 33

Align the part to a measurement axis ..... 34

Perform a part alignment (Skew) ..... 34

Establish a datum ..... 35

Probe skew and part edge lines for point construction ..... 35

Construct a datum point from line features ..... 36

Zeroing the datum ..... 36

Presetting the datum ..... 37

1.4 Measuring Part Features ..... 38

Part features ..... 38

Feature list ..... 38

Probing part features ..... 39

Probing with crosshairs ..... 39

Probing with optical edge detection ..... 39

Probing with Measure Magic ..... 40

Measuring features ..... 41

Auto repeat ..... 41

Measuring points ..... 42

Measuring lines ..... 43

Measuring circles ..... 44

Measuring distances ..... 45

Measuring angles ..... 46

ND 1200 QUADRA-CHEK 9

Page 10

1.5 Creating Part Features ..... 47

Created features ..... 47

Creating features ..... 47

Example of creating a feature ..... 48

1.6 Constructing Part Features ..... 49

Constructed features ..... 49

Constructing features ..... 49

Example of constructing a feature ..... 50

..... 51

More feature construction examples ..... 51

1.7 Tolerancing ..... 54

Feature tolerances ..... 54

Applying tolerances ..... 55

Example of applying a tolerance ..... 56

1.8 Programming ..... 58

ND 1200 programs ..... 58

Recording a program ..... 58

Example of recording a program ..... 59

Running a program ..... 60

Example of running a program ..... 61

Editing a program ..... 62

Displaying program steps ..... 62

Expanding and compressing a program steps ..... 63

Changing a program step ..... 64

Deleting a program step ..... 67

Inserting new program steps ..... 68

Copying a program ..... 69

Deleting a program ..... 70

Backing up programs ..... 71

1.9 Reporting ..... 72

Reporting ..... 72

Sending reports ..... 72

1.10 Error Indications ..... 73

Scale errors ..... 73

10

Page 11

2 Installation, Setup and Specifications ..... 75

2.1 ND 1200 Shipment Contents ..... 76

Items included with the ND 1200 ..... 76

Optional items possibly included ..... 76

Repackaging the ND 1200 ..... 77

2.2 Hardware Installation ..... 78

Assembling the mounting stand ..... 78

Benchtop location and mounting ..... 78

Arm mounting (optional) ..... 79

Connecting power ..... 80

Connecting encoders ..... 81

Connecting a computer ..... 82

Connecting a headphone ..... 82

Connecting a USB printer ..... 82

Connecting an optional foot switch or remote keypad ..... 83

Connecting and installing optical edge detection ..... 84

ND 1200 QUADRA-CHEK 11

Page 12

2.3 Software setup ..... 85

Setup menu ..... 86

Setup example: entering the supervisor password ..... 87

Order of setup ..... 88

Language selection and product version ..... 89

Supervisor password and program unlocking ..... 90

Loading settings files and startup screens ..... 91

Encoder configuration ..... 92

Encoders screen ..... 92

Misc screen ..... 95

Optical edge detection setup ..... 96

Edge menu tools ..... 96

Misc screen ..... 97

Stage squareness calibration ..... 98

Error correction ..... 99

Linear error correction (LEC) ..... 100

Segmented linear error correction (SLEC) ..... 102

Nonlinear error correction (NLEC) ..... 106

NLEC by measuring points on a calibration grid ..... 108

NLEC by importing an nlec.txt file ..... 110

Saving NLEC correction data as an nlec.txt file ..... 110

Measurement scaling for parts that expand or shrink ..... 111

Scale Factor screen ..... 111

Measurement configuration ..... 112

Measure screen ..... 112

Display formatting ..... 115

Display screen ..... 115

Hot key assignments ..... 118

Hot keys screen ..... 118

Print formatting ..... 122

Print screen ..... 122

Form chars screen ..... 125

RS-232 port configuration ..... 126

RS232 screen ..... 126

USB port configuration ..... 128

USB screen ..... 128

Audio configuration ..... 130

Sounds screen ..... 130

Key repeat rate adjustment ..... 131

Misc screen ..... 131

Time and date settings ..... 132

Clock screen ..... 132

Saving settings files and programs ..... 133

2.4 Specifications ..... 134

Dimensions ..... 135

Arm mount bracket ..... 136

12

Page 13

Operation

Page 14

1.1 ND 1200 Overview

The ND 1200® is an advanced digital readout (DRO) system for

performing high-precision 2, 3 or 4 axis measurements using analog or

TTL encoders. The ND 1200 can be used with optical comparators,

toolmaker’s microscopes or video measurement systems as part of inline production or in final quality inspection.

The following functions are available in the ND 1200:

Reference mark evaluations for distance-coded and single reference

encoders

Linear, segmented linear and optional nonlinear error correction

Scaling factor for parts that expand or shrink

1.1 ND 1200 Overview

Multilingual LCD user interface: language is selected by the user

soft key functions under LCD change to support different user

activities

Arrow cursor keys for easy navigation of lists and menus

Measurement support function keys clearly marked with:

Unit of measure: mm or inch

Datum 1 or datum 2

Cartesian or polar coordinate system

Skew compensation for part alignment prior to measurement,

eliminating the need for time-consuming fixturing

Two datums for absolute and incremental measurements

Axis zero and preset keys for establishing datums

Easy selection of feature measurement type using clearly marked

measure function keys:

Points, lines, circles, distances, angles

Skew for part alignment

Measure Magic

Feature measurement can include:

Dimensional measurements of geometric part features

Creation of features by entering dimensional data

Construction of new features from existing features

Applying tolerances

®

for automatic feature type identification

ND 1200 Front panel

14 1 Operation

Page 15

Number keypad with:

Number keys for data entry

Decimal point and +/- keys for data entry and LCD screen contrast

adjustment

User-defined hot keys that program panel and optional remote keys

to initiate commonly used functions.

User-defined programs made of the key-press sequences used to:

Perform measurements

Apply tolerances

Report results

Reports of measurement results printed to USB printer, sent to PC

over RS-232 connection or stored on USB drive

User-defined programs and system settings stored on USB drive

Speaker jack outputs for quiet or noisy environments

Optional optical edge detection probes and enters feature data

points at light to dark transitions on the comparator screen

Optional remote foot switch and keypad facilitate measurement

when the user is not close to the front panel

1.1 ND 1200 Overview

ND 1200 QUADRA-CHEK 15

Page 16

1.2 Basic Functions of the ND 1200

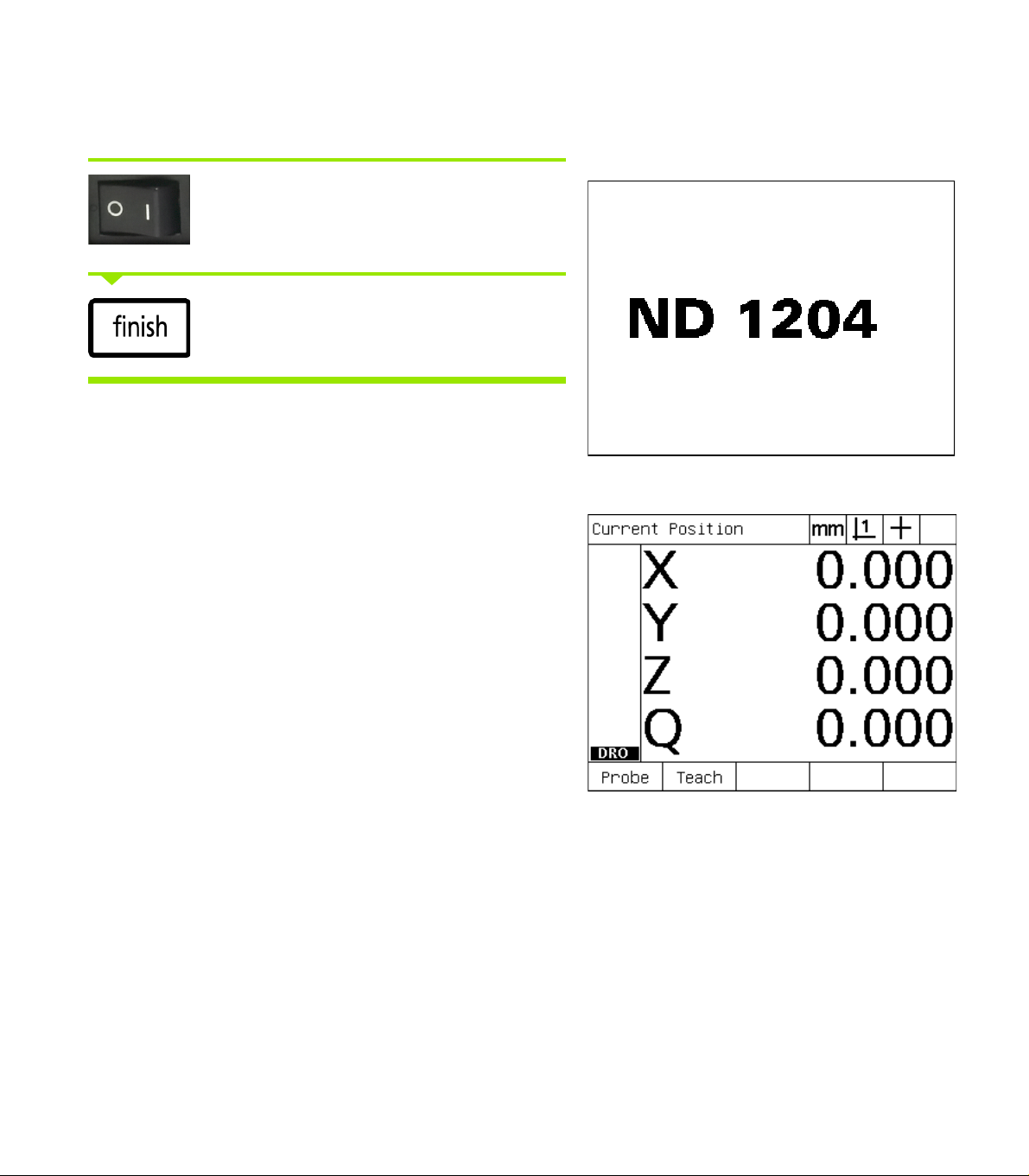

Switching on the ND 1200

Switch on the ND 1200. The POWER switch is

located on the rear of the enclosure. After switching

the power on, or after a power failure, the power-up

screen will be displayed.

Press the FINISH key to advance from the power-up

screen to the DRO.

Your ND 1200 is now ready for operation and is in the Current Position

operating mode. Encoder position values will be displayed for all axes.

1.2 Basic Functions of the ND 1200

Power-up screen

DRO screen

16 1 Operation

Page 17

Establishing a repeatable machine zero

If your ND 1200 was configured to establish a machine zero upon

power-up, a message will be displayed asking you to cross reference

marks or enter hard-stop axis reference positions. The machine zero is

used by the ND 1200 to apply error correction data as measurements

are performed. To establish a repeatable machine zero you must

either:

U Move the stage to have encoder reference mark crossings

recognized on each axis or

U move the stage to the hard-stop reference position and press

ENTER on each axis when no encoder reference marks are present.

If the requirement to cross reference marks is bypassed

by pressing the CANCEL soft key, error correction data

that might be stored in your ND 1200 will not be applied.

Switching off the ND 1200

Switch the ND 1200 off. The parameter settings,

error compensation tables and recorded programs

that have been saved during operation will be

retained in memory.

1.2 Basic Functions of the ND 1200

Your ND 1200 might also have been configured to retain

measurement results across power cycles

ND 1200 QUADRA-CHEK 17

Page 18

Panel key descriptions

Descriptions of panel key functions are provided in the following

pages for MEASUREMENT function, COMMAND, MODE selection,

AXIS, FAST TRACK, SEND, LCD ON/OFF, and MENU keys. Soft key

functions are also described later in the next section as part of screen

and soft key layout descriptions.

MEASURE keys Function

Measure point: Press the POINT key once to

measure one point, or twice to use auto

repeat to measure a series of points. A

minimum of one data point is required to

measure a point.

Measure line: Press the LINE key once to

measure one line, or twice to use auto repeat

to measure a series of lines. A minimum of

two data points are required to measure a

line.

Measure circle: Press the CIRCLE key once

to measure one circle, or twice to use auto

repeat to measure a series of circles. A

minimum of three data points are required to

1.2 Basic Functions of the ND 1200

measure a circle.

Measure distance: Press the DISTANCE key

once to measure one distance, or twice to

use auto repeat to measure a series of

distances. Two points are required to

measure a distance.

ND 1200 Panel keys

Measure angle: Press the ANGLE key once

to measure one angle, or twice to use auto

repeat to measure a series of angles. Collect

a minimum of two data points, then press the

ENTER key on each leg of an angle.

Align part: Press the SKEW key to

compensate electronically for non-square

part alignment on the primary axis.

Use Measure Magic: Press the MEASURE

MAGIC key to automatically measure any

geometric feature or twice to measure a

series of like features. Collect the desired

points and press the FINISH key; Measure

Magic analyzes the data and determines the

feature type.

18 1 Operation

Page 19

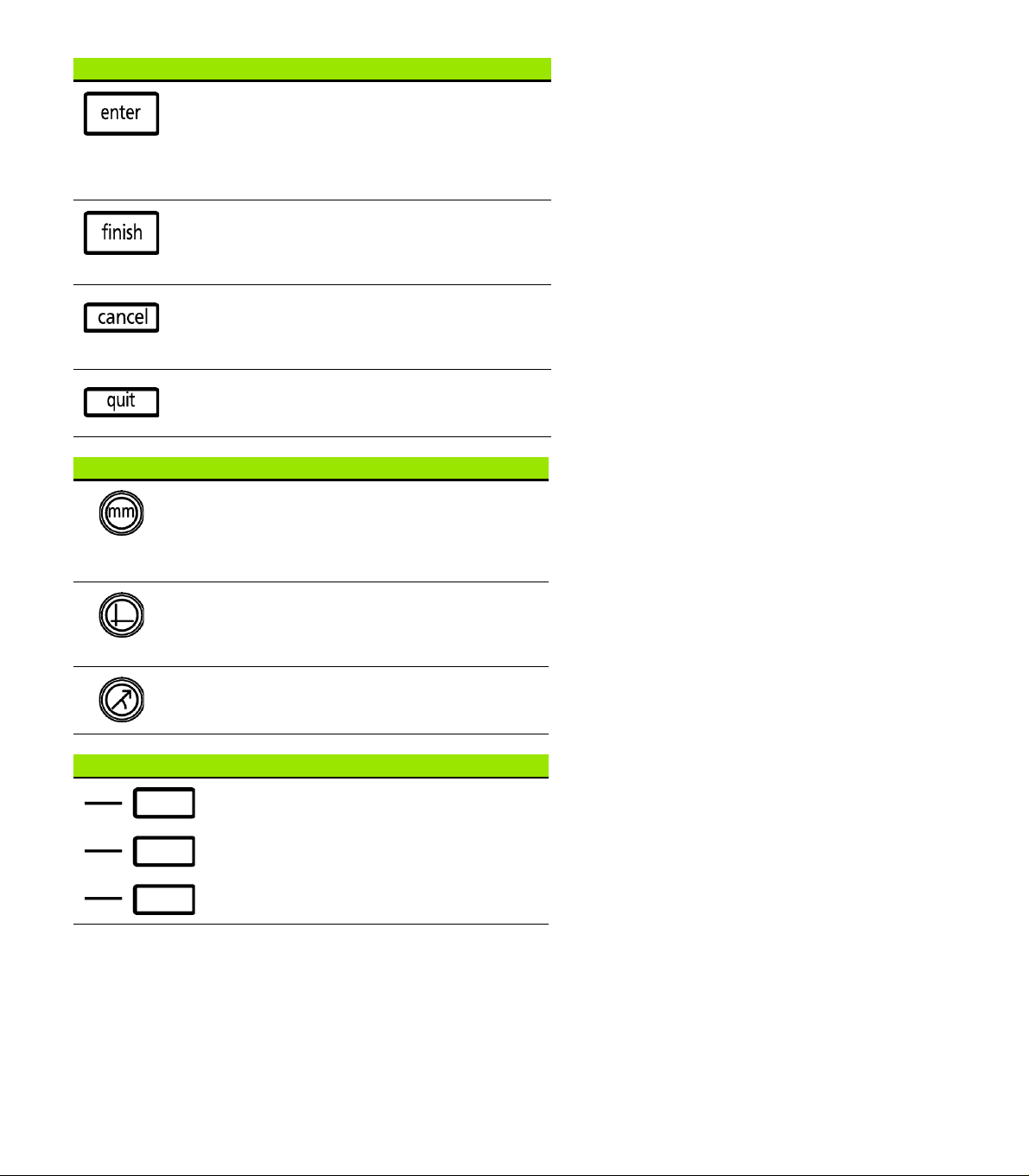

COMMAND keys Function

Enter data: Press the ENTER key to enter

points during feature measurements or to

enter values into configuration fields.

Pressing the ENTER key indicates that data

from a measurement or in a field is ready for

use.

Finish a measurement: Press the FINISH

key to complete a feature measurement.

Pressing the FINISH key a second time

returns the user to the DRO screen.

Delete data or features: Press the CANCEL

key to delete the last point entered, data in

configuration fields or any highlighted feature

from the feature list.

Quit current activity: Press the QUIT key to

abandon the current task and return to the

DRO screen or to exit the feature list.

MODE keys Function

Select unit of measure: Press the UNIT OF

MEASURE key to toggle between

millimeters and inches. The current unit of

measure is displayed in the upper right corner

of the screen.

1.2 Basic Functions of the ND 1200

Select a datum: Press the DATUM key to

toggle between datum 1 and datum 2.The

current datum number is displayed in the

upper right corner of the screen.

Select a coordinate system: Press the

COORDINATE key to toggle between

Cartesian and polar coordinate systems.

AXIS keys Function

Zero an axis: Press the axis key to the right

of the desired axis to zero the axis position

value when establishing a zero datum.

Preset an axis or axes: Press one or more

axis keys to the right of the desired axis or

axes when presetting axis position values for

a new datum.

ND 1200 QUADRA-CHEK 19

Page 20

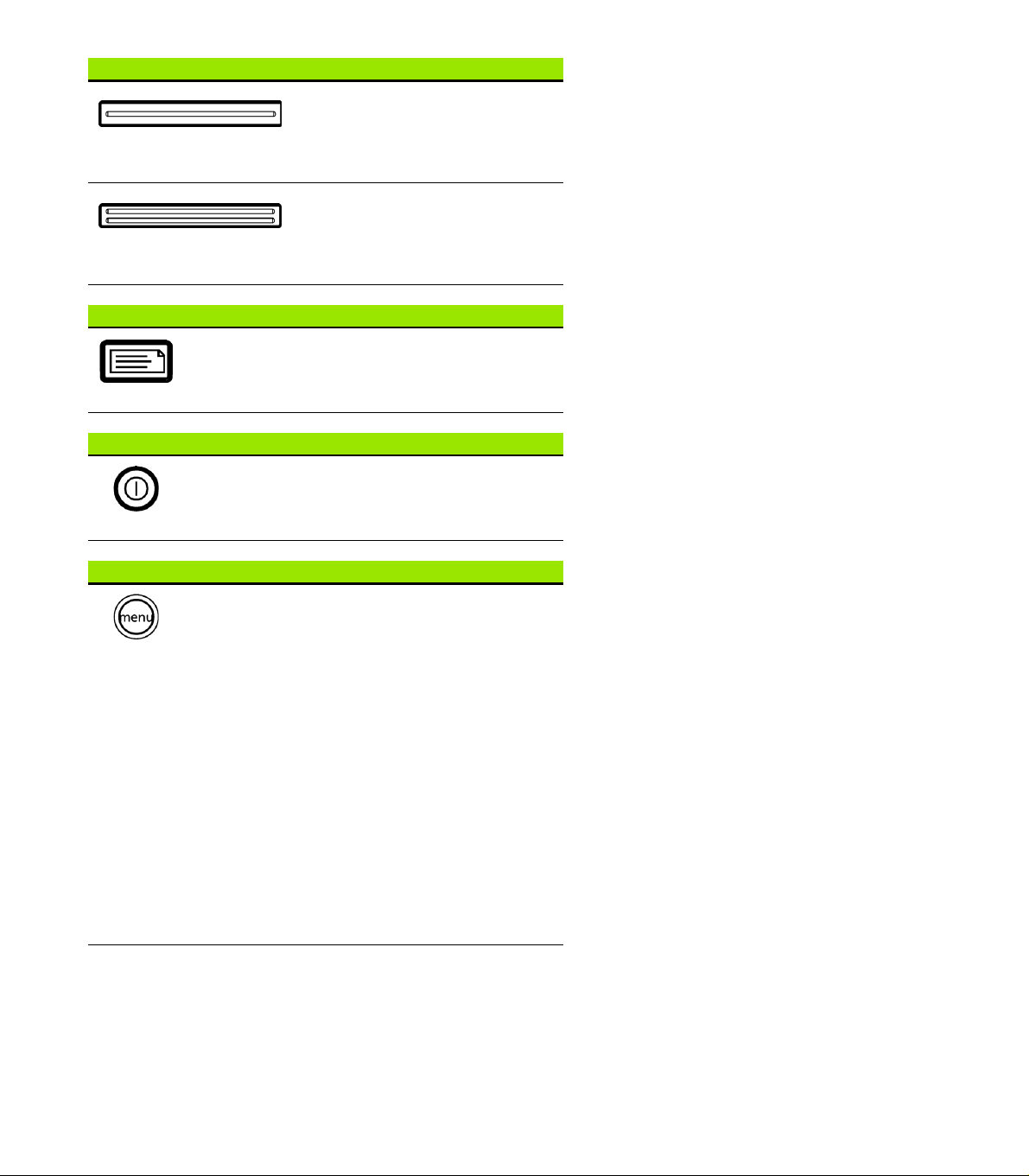

FAST TRACK keys Function

SEND key Function

Transmit measurement results: Press the

SEND key to transmit measurement data to a

computer, a USB printer or a USB memory

drive.

LCD ON/OFF key Function

Turn the LCD off or clear data: Press the

LCD ON/OFF key to toggle between LCD on

1.2 Basic Functions of the ND 1200

and LCD off, or to clear feature data, datums

and part alignments (skews).

Left frequently used function:

Press the left WIDE key to initiate

the function programmed for this

key. The factory default function for

this key is ENTER.

Right frequently used function:

Press the right WIDE key to initiate

the function programmed for this

key. The factory default function for

this key is FINISH.

MENU key Function

Display soft key menus: Press the MENU

key to display the titles of ND 1200 menus

above the soft keys. Menus include:

Setup: Used by supervisors to configure

the operational characteristics of the

system.

Prog: Used by operators and supervisors to

create and recall programs of recorded

measurement steps.

Extra: Used by operators to conduct

measurements and send measurement

result data.

Clear: Used by operators to clear

measurement data and datums.

Edge: Used by operators and supervisors

to install, calibrate and select optical edge

detectors.

20 1 Operation

Page 21

ARROW CURSOR keys Function

Navigate menus and setup screen

data fields. The up arrow cursor key is

also used to begin a feature

construction process.

1.2 Basic Functions of the ND 1200

ND 1200 QUADRA-CHEK 21

Page 22

LCD screen and soft key layout

ND 1200 LCD screens display information in one of four operating

modes:

DRO mode displays current positions of axes

Feature evaluation mode screens can be toggled between two

displays that show all measurement results and the data cloud of

collected points

Feature measurement mode displays feature type, points

collected and current positions of axes during measurements

Setup mode displays ND 1200 Installation and setup screens

Soft keys change to support activities shown on the screens.

Installation and setup screens and soft keys are described

later in Chapter 2: Installation, Setup and Specifications.

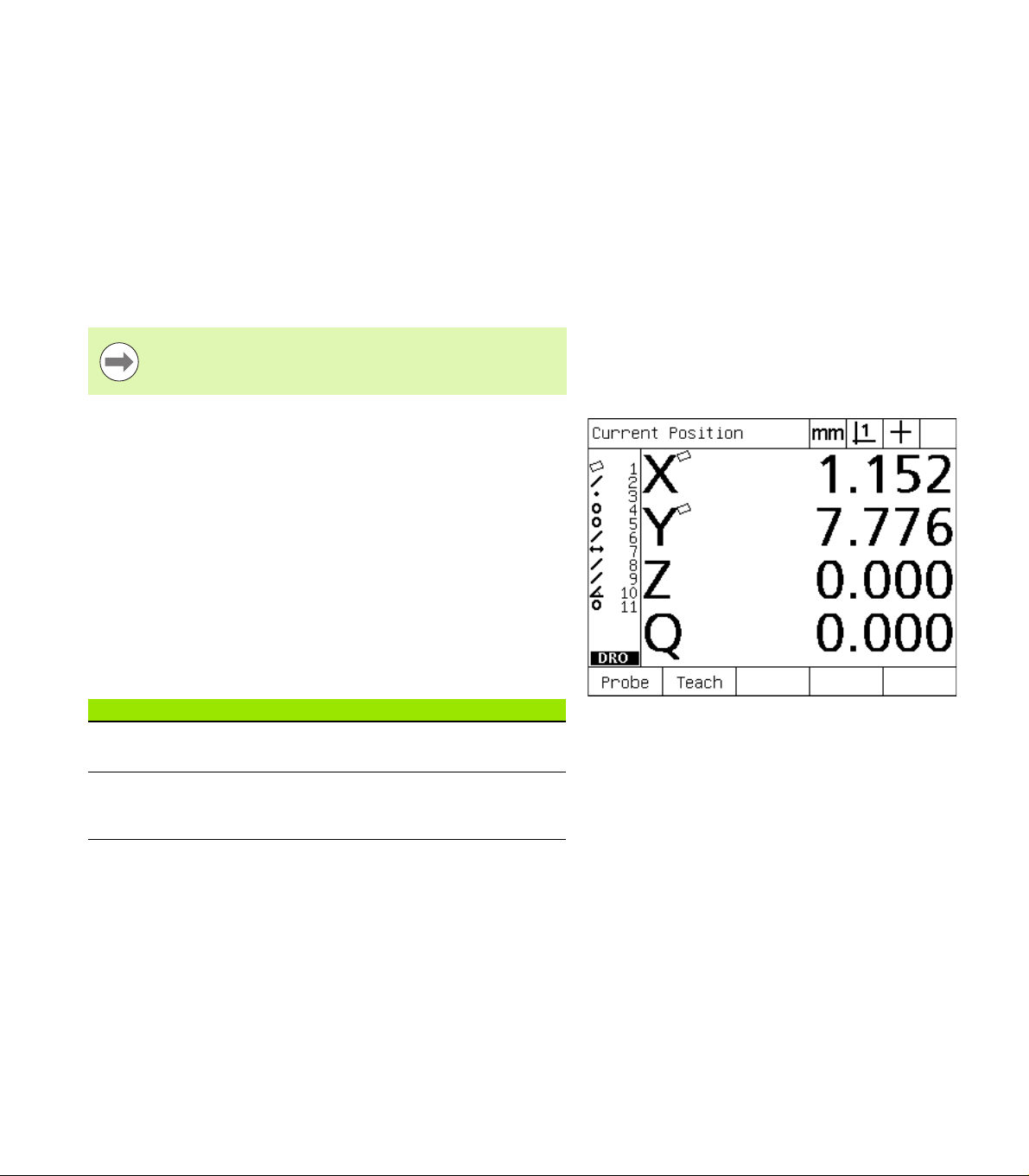

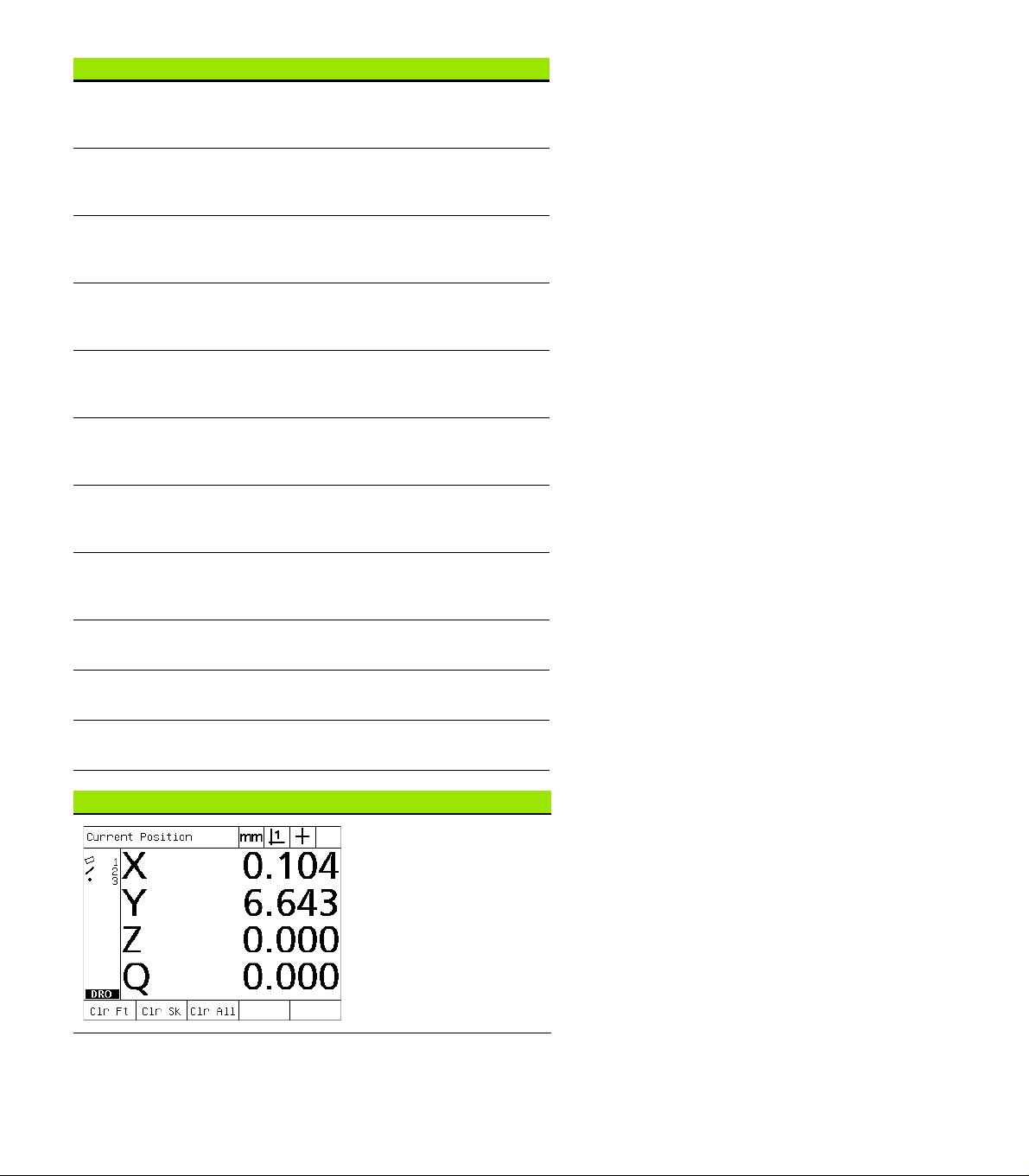

DRO mode screen and soft keys

The DRO screen shows:

Feature list of measured features on the left side

Unit of measure, current datum and probe type in the upper right

1.2 Basic Functions of the ND 1200

corner

The current positions of all axes

Part alignment status: a small rectangle over the axis letter indicates

that the part is aligned to a measurement axis (a skew was

performed)

Soft key functions for selecting a probe type and teaching

(calibrating) optical edge detection (optional)

DRO soft keys Function

Probe Toggles between crosshair and optical edge

detection probes

Teach Initiates the optical edge detection light-

calibration wizard. You will be guided through

the process by messages shown on the screen

22 1 Operation

DRO current position screen showing current axis

positions

Page 23

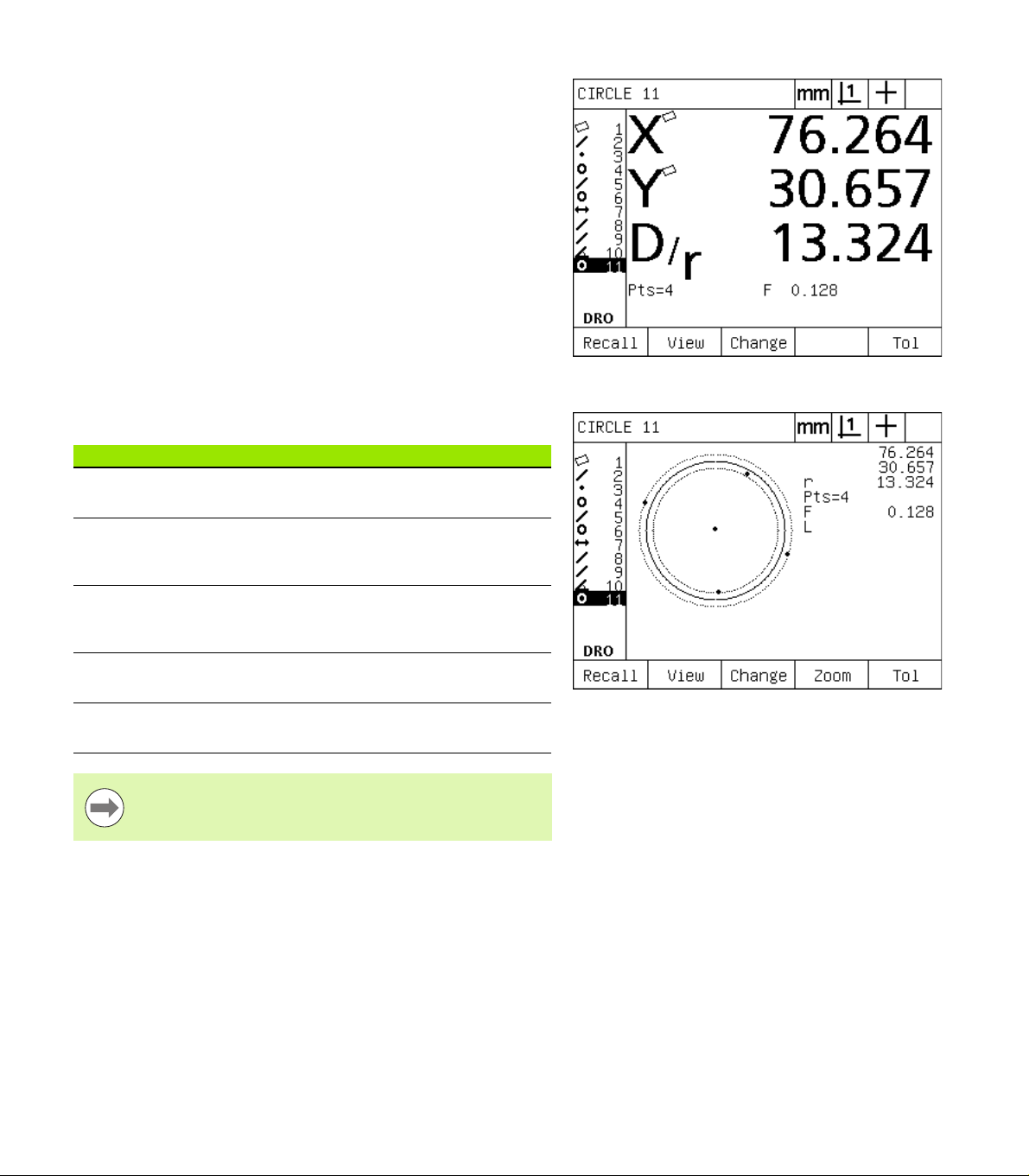

Feature evaluation mode screens and soft keys

The feature evaluation screens can be toggled between two displays

by pressing the VIEW soft key to show:

Feature list of measured features on the left side

Unit of measure, current datum and probe type in the upper right

corner

The feature type and number of the highlighted feature

Feature position

Geometric and dimensional values such as diameter, length or angle

Number of data points used to define the feature

Form error

Parent features used if the feature was constructed

An indication that the feature was created if applicable

Data cloud of collected data points used to define the feature

DRO soft keys Function

Recall Displays a different feature from the feature list

by specifying its feature number.

View Toggles between the default screen showing

axis values and the screen showing data points

collected to define the feature.

Feature evaluation mode screen showing feature

values

1.2 Basic Functions of the ND 1200

Change Shows alternative fit algorithms for the current

feature type, such as LSBF (least squares best

fit) and ISO.

Zoom Changes magnification when viewing the data

Tol Displays the alternative tolerances that can be

Tolerances are discussed later in this chapter.

ND 1200 QUADRA-CHEK 23

cloud of collected data points.

Feature evaluation mode screen showing data points

applied to the current feature.

Page 24

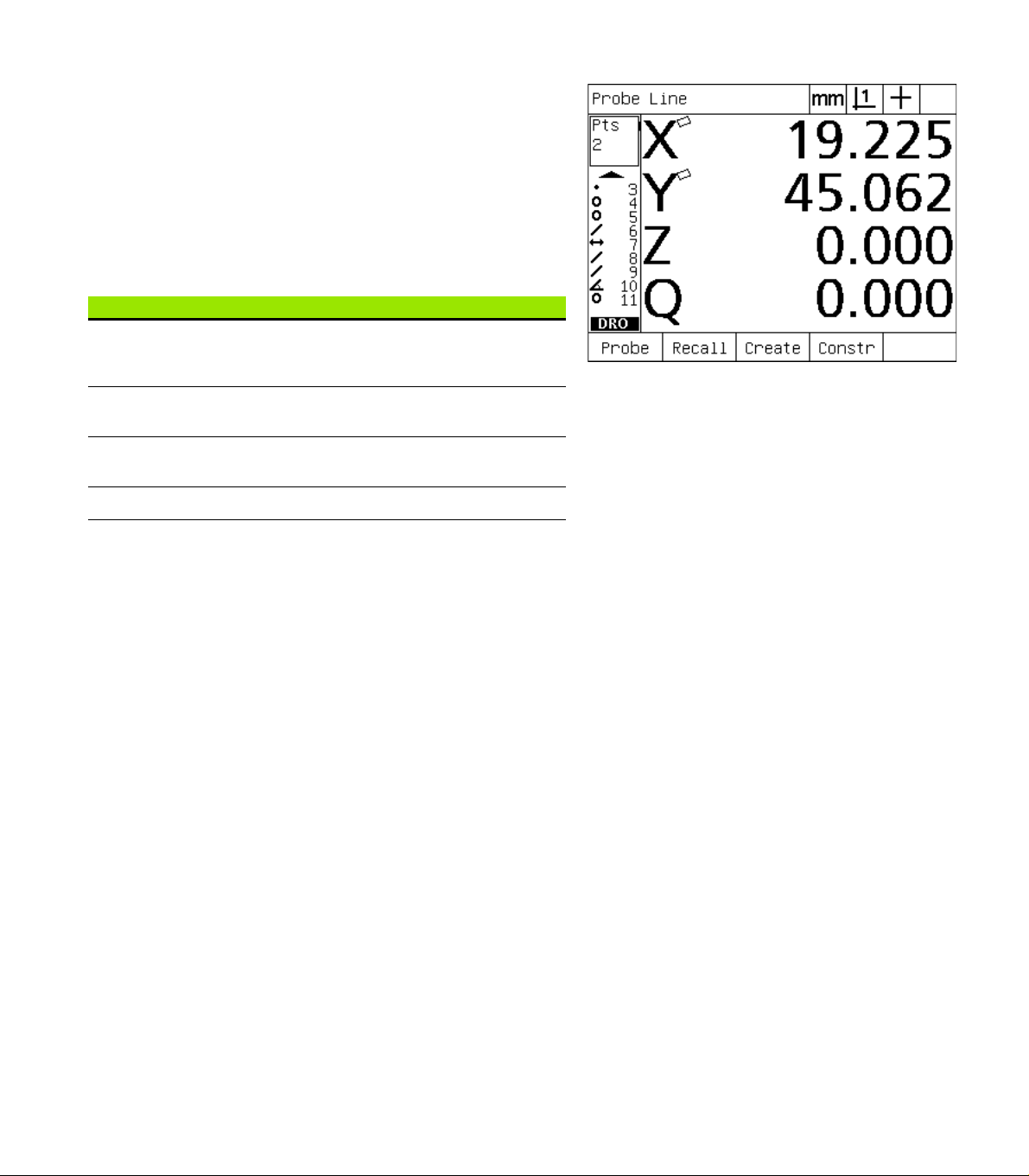

Feature measurement mode screen and soft keys

The feature measurement screen is displayed after initiating a feature

measurement by pressing a MEASUREMENT key and shows:

Feature list of measured features on the left side

Unit of measure, current datum and probe type in the upper right

corner

The feature type being probed and the number of collected data

points

The current positions of all axes

DRO soft keys Function

Probe Toggles between crosshair and optical edge

Recall Recalls the first parent feature of a new feature

Create Displays fields for entering data to create the

Const Initiates a new feature construction.

1.2 Basic Functions of the ND 1200

detection probes (available only with optical

edge detection option).

construction.

specified feature type.

Feature measurement mode screen showing feature

type and points collected

24 1 Operation

Page 25

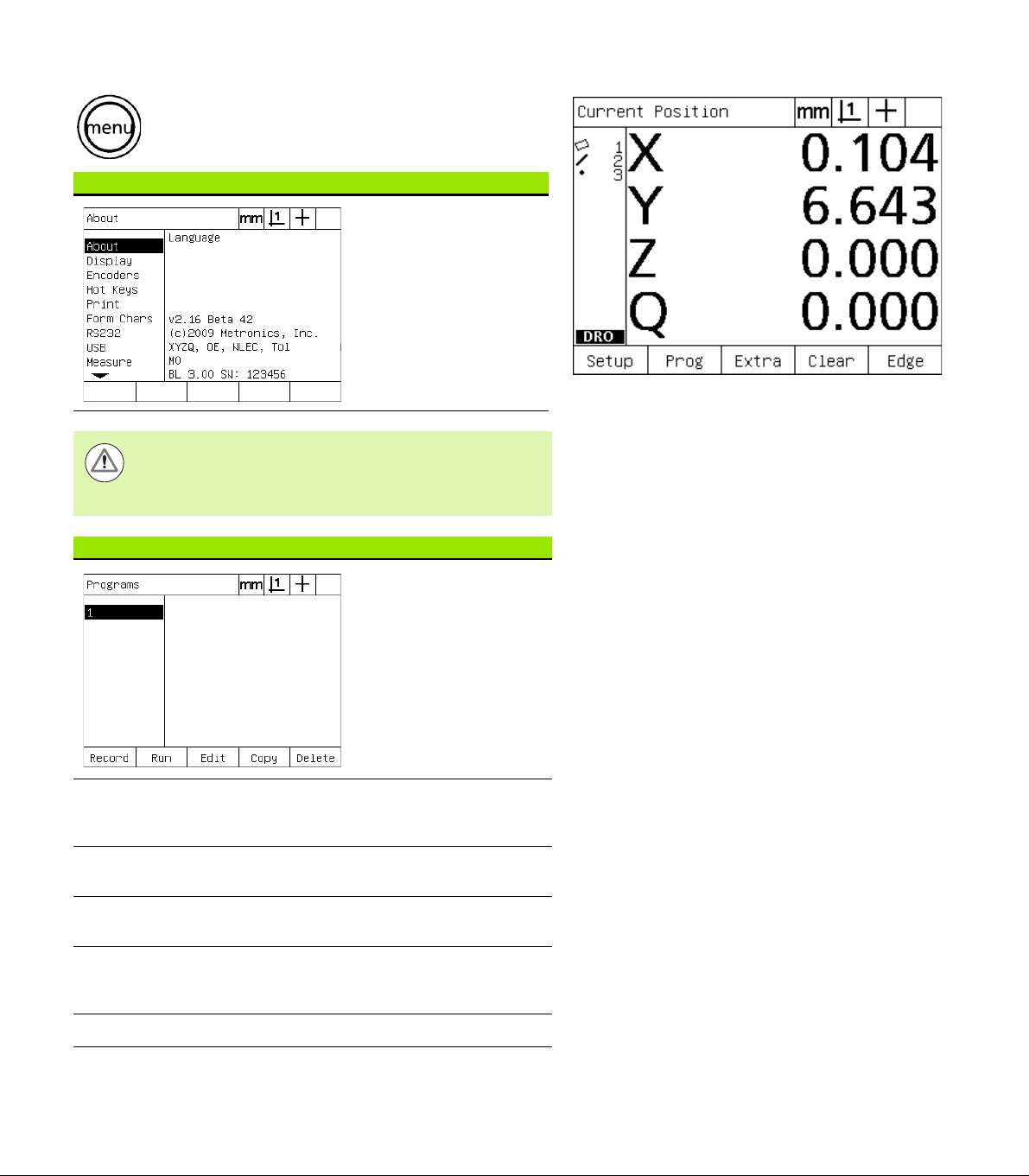

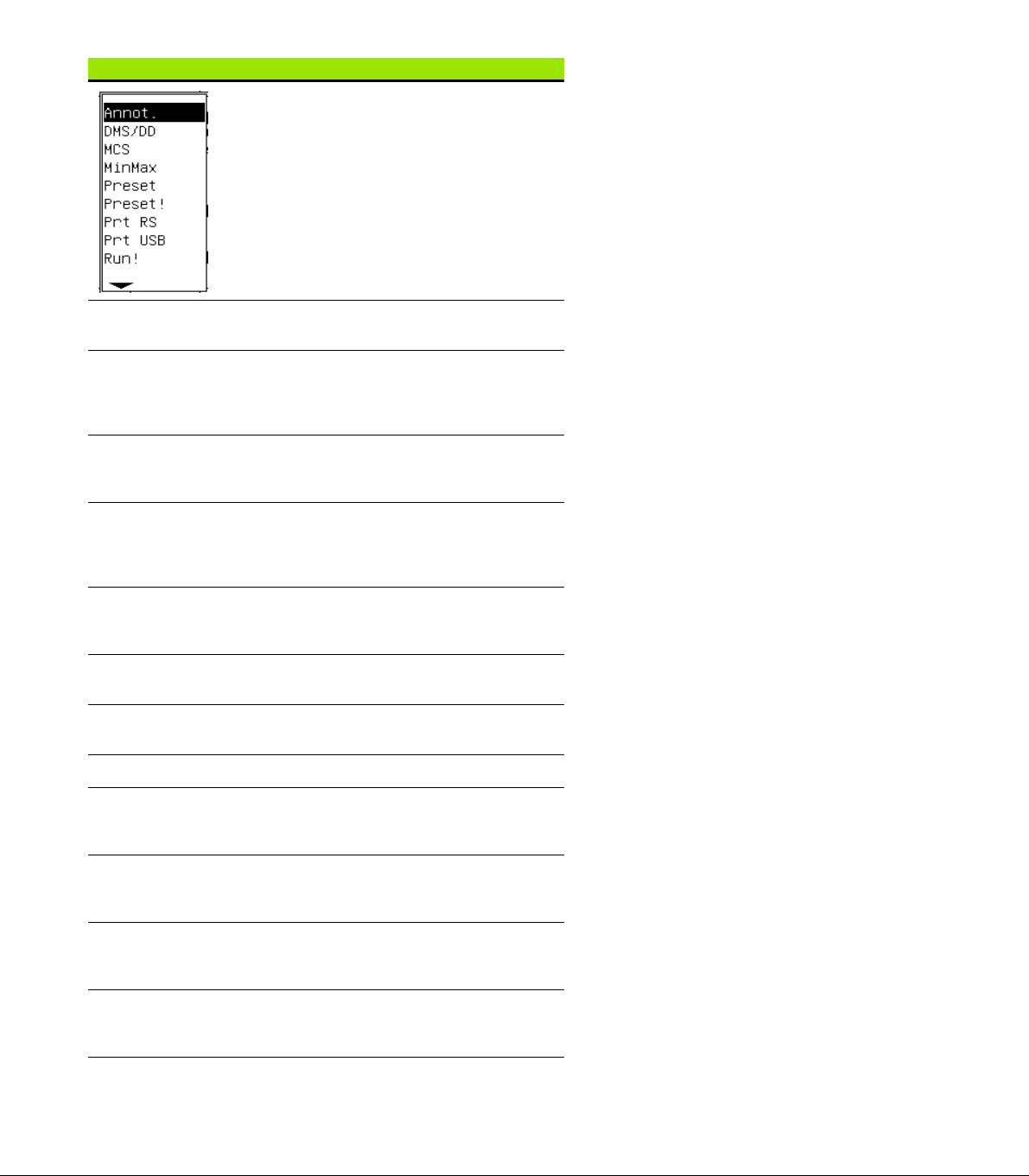

ND 1200 Menus

Press the MENU key to display menu titles over the soft

keys at the bottom of the LCD screen. Press a menu soft

key to display the corresponding menu screen. Menus

include:

SETUP menu SETUP functions

Press the SETUP menu

soft key to display the

collection of SETUP

screens used to configure

the ND 1200. Use of the

setup menu is explained

later in Chapter 2:

Installation, Setup and

Specifications.

Access to setup menu configuration data fields is

password restricted to supervisors and other technically

qualified personnel. Configuration mistakes can result in

serious measurement errors.

PROG menu PROG functions

Press the PROG soft key to

display the PROGRAMS

screen and soft keys for

program functions. Soft

keys include:

Menu titles are displayed over soft keys at the bottom

of the LCD screen

1.2 Basic Functions of the ND 1200

Record Records a program of user

Run Plays a program of

Edit Displays program steps for

Copy Copies a program to be

Delete Deletes a program.

ND 1200 QUADRA-CHEK 25

key presses that can be

played back later.

recorded key presses.

editing.

edited and saved under a

new name.

Page 26

EXTRA menu EXTRA functions

Press the EXTRA soft key

to display the EXTRA popup menu. The EXTRA

menu is used perform

many measurement and

data transmission

functions. Highlight a

function and then press the

ENTER key. EXTRA menu

functions include:

Annot Toggles between forward

and backward annotation.

DMS/DD Toggles between the

MCS Clears datums and re-

1.2 Basic Functions of the ND 1200

MinMax Collects and stores

Preset Sets the position of one or

Preset! Recalls the last preset

Prt RS Sends current data to the

Run Runs the last program.

Send 2 Sends current X, Y data to a

display of degrees,

minutes, seconds and

decimal degrees.

establishes machine

coordinates.

minimum and maximum

values until the FINISH key

is pressed.

more axes to specified

values.

position.

RS-232 serial port.

printer, USB drive or

computer.

Send 3 Sends current X, Y, Z data

Send 4 Sends current X, Y, Z, Q

Send D Sends current diameter to

26 1 Operation

to a printer, USB drive or

computer.

data to a printer, USB drive

or computer.

a printer, USB drive or

computer.

Page 27

EXTRA menu EXTRA functions

Send F Sends current form error to

a printer, USB drive or

computer.

Send L Sends current distance to a

printer, USB drive or

computer.

Send Q Sends current Q-axis value

to a printer, USB drive or

computer.

Send R Sends current radius to a

printer, USB drive or

computer.

Send X Sends current X-axis value

to a printer, USB drive or

computer.

Send Y Sends current Y-axis value

to a printer, USB drive or

computer.

Send Z Sends current Z-axis value

to a printer, USB drive or

computer.

Send < Sends current angle to a

printer, USB drive or

computer.

Time Displays the current date

and time.

1.2 Basic Functions of the ND 1200

Zero 2 Zeros X and Y axes in the

current datum.

Zero Q Zeros Q-axis protractor

CLEAR menu CLEAR functions

ND 1200 QUADRA-CHEK 27

value.

Press the clear soft key to

display soft key selections

for clearing data. Soft keys

include:

Page 28

CLEAR menu CLEAR functions

Clr Ft Clears feature data from

Clr Sk Clears the part alignment

the feature list.

(skew). Clearing the skew

does not clear any datums

that have been established.

Clr All Clears feature, datum and

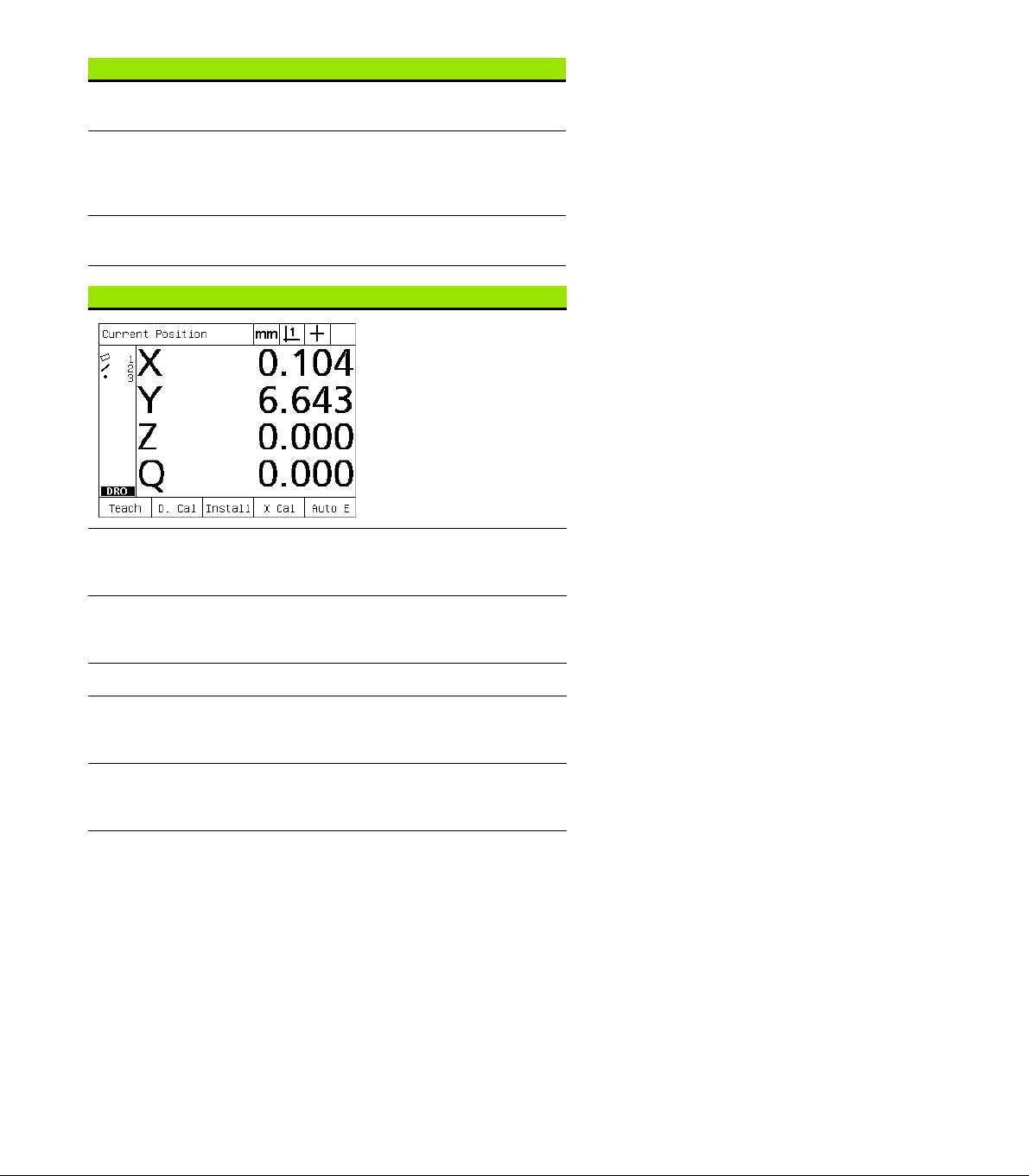

EDGE menu EDGE functions

part alignment data.

Press the EDGE soft key to

display edge detection soft

key functions. Soft keys

include:

1.2 Basic Functions of the ND 1200

Teach Calibrates edge detection

for typical light to dark edge

transitions.

D. Cal Calibrates edge detection

Install Installs edge detection.

X Cal Calibrates crosshair and

for fuzzy or irregular light to

dark edge transitions.

edge detector probes to

indicate identical positions.

Auto E Toggles between

automatic and manual edge

detection.

28 1 Operation

Page 29

1.3 Preparing to Measure

Power-up the ND 1200

U Switch on the ND 1200. The POWER switch is located on the rear

of the enclosure. After switching the power on, or after a power

failure, the power-up screen will be displayed. See "Switching on the

ND 1200" on page 16.

U Press the FINISH key to advance from the power-up screen to the

DRO.

If your ND 1200 was configured to establish a machine zero upon

powering up, a message will be displayed asking you to cross

reference marks or specify axis references manually.

Establish machine zero

A repeatable machine zero is required if you plan to retain feature

measurement results across a power cycle or if error correction will be

applied to your measurements.

Often feature data retention and error correction are not

desired. In these cases, it is not necessary to establish a

machine zero.

To establish a repeatable machine zero:

U Move the stage to have reference mark crossings recognized on

each axis or

U move the stage to the hard-stop reference position and press

ENTER on each axis when no encoder reference marks are present.

1.3 Preparing to Measure

ND 1200 QUADRA-CHEK 29

Page 30

Adjust LCD screen contrast

If necessary, adjust the LCD screen contrast using the decimal point

and +/- keys located on the numeric keypad.

U Press the DECIMAL POINT key to increase the

contrast

U Press the +/- key to decrease the contrast

Select unit of measure

U Press the UNIT OF MEASURE key to toggle between

millimeters and inches.

Select a datum

1.3 Preparing to Measure

U Press the DATUM key to toggle between Datum 1

and Datum 2.

Select a coordinate system

U Press the COORDINATE key to toggle between

Cartesian and polar coordinate systems.

30 1 Operation

Page 31

Select the desired annotation

Annotation determines the number of measurement points collected

for each feature type.

Forward annotation: Use forward annotation to require a

previously specified number of points for each feature type. When

using forward annotation, the number of required points is shown in

the top left corner of the screen. As points are entered, the number

of required points counts down. Since a fixed number of points is

required using forward annotation, the system automatically

completes the measurement and displays the feature after the last

required point is entered. It is not necessary to press the FINISH key

in forward annotation measurements to complete a measurement.

Backward annotation: Use backward annotation to allow the

operator to determine the number of points for each feature.

Backward annotation displays the total number of points collected

in the top left corner of the screen as they are entered. It is

necessary to press the FINISH key to complete backward

annotation measurements.

Toggle between forward and backward annotation

U Press MENU/EXTRA/ANNOT/ENTER

1.3 Preparing to Measure

ND 1200 QUADRA-CHEK 31

Page 32

Select a probe type

Features are probed with crosshairs or with optional optical edge

detection. Optical edge detection can be configured as manual or

automatic point entry.

Skip these probe selection instructions if your ND 1200

does not include the optical edge detection option.

Select crosshairs:

U Press the PROBE soft key if necessary to

select the crosshair probe. The crosshair

symbol will be shown in the upper right

corner of the screen.

Select an optical edge probe

1.3 Preparing to Measure

U Press the PROBE soft key if necessary to

display an optical probe symbol in the upper

right corner of the screen. The manual point

entry optical probe symbol is shown here.

U Toggle the optical probe between manual

and automatic point entry by pressing the

key sequence: MENU/EDGE/AUTO E.

Press the PROBE soft key to select a probe type

32 1 Operation

Page 33

Calibrate the optical edge detector

The optical edge detector must be calibrated to correctly recognize

light to dark part edge transitions. Calibration should be performed

after startup, when the part is changed, when magnification is

changed, when measuring a part with fuzzy or irregular edges, and

when the optical system is repositioned or replaced.

Skip these calibration instructions if your ND 1200 does

not include the optical edge detection option.

Three types of calibrations can be performed:

Teach: Teach calibration should be performed after each startup or

whenever the part or magnification level changes. Teach calibration

trains the ND 1200 to recognize the light to dark transitions on your

comparator. Any change in the comparator light conditions should

be followed by a teach calibration.

D. Cal: Distance Calibration should be performed when measuring

parts with poorly defined edges. Perform a distance calibration to

fine tune the edge detector for fuzzy or irregular edges and for thick

parts or parts with rounded edges.

X Cal: Cross calibration compensates for the position offset

between the crosshairs and the edge detector sensor to produce

consistent results for all measuring probes. Perform cross

calibrations each time the edge detector sensor is changed or

repositioned.

1.3 Preparing to Measure

Perform a Teach

U Press the TEACH soft key.

U Follow instructions displayed on the screen.

Perform a D. Cal

U Press MENU/EDGE/D. CAL

U Follow instructions displayed on the screen.

Perform an X Cal

U Press MENU/EDGE/X CAL

U Follow instructions displayed on the screen.

ND 1200 QUADRA-CHEK 33

Page 34

Align the part to a measurement axis

Accurate measurements require the part to be perfectly aligned along

a measurement axis. Misaligned parts result in cosine measurement

errors. Use the SKEW function to convert machine coordinates to part

coordinates and compensate for part misalignment. Measure a skew

each time a new part is mounted on the measuring system.

Measure a skew line by probing a straight edge of the part on a major

measurement axis. A minimum of two points is required for a line, but

probing more points will improve accuracy.

The alignment is performed on a part edge here as an

example. Part alignments can be made on part features

other than an edge. For example, a line constructed

between the centers of two holes could be aligned to a

measurement axis if desired.

1.3 Preparing to Measure

Perform a part alignment (Skew)

The skew alignment edge or line must be oriented within

45 degrees of the measurement axis.

U Press the SKEW key.

U Probe a minimum of two points along the part edge.

In the example shown here, the part is aligned to the

X-axis by probing three points along the bottom edge

of the part.

The part could alternately have been aligned along a

vertical edge to the Y-axis.

Three points are probed to align the bottom edge of a

part to the X-axis

34 1 Operation

Page 35

Establish a datum

Establish a reference datum once the part is skewed. Two datums can

be created in the ND 1200. Typically, datum 1 is a zero reference and

used as an absolute or primary datum, while datum 2 is used as an

incremental or temporary datum.

Datums can be set to zero or can be preset to specified values.

Two methods can be used to establish a datum:

Zero or preset the X and Y axes on a point or on the center point of

a circle

Zero or preset the X and Y axes on a point or on a center point

constructed from parent features

While the datum can be created from a probed point or from the

center point of a probed circle, it is more commonly created from a

point that has been constructed from important parent features, such

as the skew alignment line and a second part edge line. An example

of a datum created from a constructed point is shown below.

Constructions and the feature measurements necessary

for constructions are discussed in detail later in this

chapter. However, a brief example of constructions is

shown here to adequately cover the topic.

Probe skew and part edge lines for point construction

Probe a Skew alignment line along the bottom of the part and probe a

line on the left side of the part. These lines will be used to construct a

datum point.

Perform skew part alignment to the X-axis on the bottom edge

U Press the SKEW key.

U Probe 3 points along the bottom edge (points 1, 2

and 3).

U Press the FINISH key to create the skew line.

1.3 Preparing to Measure

Probe a line along the left edge

U Press the LINE key.

U Probe 3 points along the left edge (points 4, 5 and 6).

U Press the FINISH key to create the second line.

A skew is performed along the bottom and a line is

probed on the left side

The skew and left edge lines will now be shown in the feature list on

the left side of the DRO screen. The point construction using these

parent features is shown on the next page.

ND 1200 QUADRA-CHEK 35

Page 36

Construct a datum point from line features

Construct a point from the skew line and the left edge line to create a

datum.

U Press the POINT key. The Probe Point screen will be

displayed.

U Press UP ARROW/ENTER to start the construction

and select the line feature (2). The screen will change

to the Construct Point screen, feature 2 will be

checked and skew line feature 1 will become

highlighted.

U Press ENTER to check feature 1.

U Press the FINISH key to complete the point

construction from the intersection of the two

checked parent line features.

1.3 Preparing to Measure

POINT key is pressed Features are selected Point is constructed

Zeroing the datum

Datums can be zeroed or preset. This example creates a zero

reference datum from a point feature.

U With the datum point highlighted in the feature list,

press the DATUM key if necessary to select the

desired datum in the upper right corner of the screen.

U Press the X and Y AXIS keys to zero the point position.

Point is highlighted Point is zeroed as datum

36 1 Operation

Page 37

Presetting the datum

Datums can be zeroed or preset. This example creates a preset

reference datum from a point feature.

U With the datum point highlighted in the feature list,

press the DATUM key if necessary to select the

desired datum in the upper right corner of the screen.

U Press MENU/EXTRA/PRESET/ENTER to display the

preset screen.

U Press the desired AXIS key and enter the preset value

for the axis.

U Press another AXIS key if desired and enter the preset

value for that axis.

U Press the FINISH key to preset the datum to the

specified values.

1.3 Preparing to Measure

PRESET Selected from EXTRA menu Preset values are entered Point is preset as datum

ND 1200 QUADRA-CHEK 37

Page 38

1.4 Measuring Part Features

Part features

Features are measured by probing data points that characterize the

dimensional geometry of the part. For example, several points probed

around the circumference of a circle results in numeric and graphic

representations of the circle geometry. Throughout this manual, a

measured geometry is referred to as a feature and can alternately be

displayed numerically or graphically by pressing the VIEW soft key.

There are several types of features and each has different dimensional

information. For example, a circle has a center point position and a

radius, a point has a position, and an angle has degrees.

1.4 Measuring Part Features

Feature displayed numerically Feature displayed graphically

Feature list

Each feature is added to the feature list when it is measured. The

feature list shows all features measured on the left side of the LCD

screen and is visible in DRO and measuring modes. Each feature is

identified by a number and an icon indicating its type (i.e. circle, line,

etc.). Up to 100 features can be added to the feature list. Use the

ARROW CURSOR keys to scroll through the list. Highlight the desired

feature to recall, print or send the feature data to a computer or a USB

drive. Select parent features from the feature list to construct new

features. Delete features using the CANCEL key or the LCD ON/OFF

key. In general, the user should delete old features, datums, and

skews from the feature list before each new measurement session.

38 1 Operation

Page 39

Probing part features

Part features can be probed with crosshairs or with optional optical

edge detection. If optical edge detection is used, points can be

entered manually or automatically.

Probing with crosshairs

U Move the stage to position the crosshairs over the desired feature

point and press the ENTER key. The probed point will be added to

the points required for the feature.

Probing with optical edge detection

Probing with optical edge detection speeds the measurement process

and increases measurement consistency. Two general guidelines

should be followed when probing with optical edge detection:

Move the stage to make edge crossings as close to perpendicular

as possible.

Move the stage at slow to moderate speeds when possible. In

general, slower edge crossings are slightly more accurate.

To probe with edge detection:

Skip these probing instructions if your ND 1200 does not

include the optical edge detection option.

U Move the stage to pass the optical sensor over the edge.

U When manual point entry is used, the ND 1200 will beep when an

edge is recognized. Press the ENTER key to add the point to the

number required for the measurement.

U When automatic point entry (Auto E) is used, the ND 1200 will beep

when an edge is recognized and will add the point to the number

required for the feature measurement automatically.

1.4 Measuring Part Features

ND 1200 QUADRA-CHEK 39

Page 40

Probing with Measure Magic

Measure Magic analyzes feature data collected by part probing and

automatically determines the feature type. Measure Magic supports

the following feature types in the ND 1200:

Points

Lines

Circles

When Measure Magic is used, and more than the minimum number

of points required to define a feature type are collected, the feature

type can be changed manually by the user if the wrong feature type is

assigned.

To probe a feature using measure magic:

Press the MEASURE MAGIC MEASUREMENT key.

The Probe Feature screen will be displayed. Press the

key twice to measure a series of features using auto

1.4 Measuring Part Features

repeat.

Probe points on the desired feature and then press the

Finish key.

If the wrong feature type is shown on the screen:

Press the CHANGE soft key. The alternative feature types will be

shown over soft keys at the bottom of the screen.

Press the correct feature type soft key. The correct feature type will

be displayed in the feature list.

Press the CHANGE soft key Press the correct feature type soft key The correct feature type is displayed

40 1 Operation

Page 41

Measuring features

The ND 1200 measures point, line, circle, distance and angle features.

To measure a feature using backward annotation (See "Select the

desired annotation" on page 31):

U Press the desired feature MEASUREMENT key

U Probe the required points

U Press the FINISH key

Auto repeat

Use auto repeat to measure several features of the same type (such

as a series of circles). Press the desired feature MEASUREMENT key

twice to activate auto repeat. For example, press the CIRCLE

MEASUREMENT key twice to measure a series of circles. When auto

repeat is selected, the Probe feature screen becomes the Probe

features screen. For example, the Probe Circle screen becomes probe

Circles screens as shown below.

1.4 Measuring Part Features

Probe Circle screen Probe Circles screen

Use auto repeat and forward annotation to speed up repetitive

measurements. For example, the measurement of a dozen circles

requires the user to press the CIRCLE MEASUREMENT key before

measuring each circle and press the FINISH key for each

measurement. The same measurements using auto repeat and

forward annotation requires the user to press the CIRCLE

MEASUREMENT key twice before and the FINISH key once after

measuring all 12 circles. Pressing the FINISH key turns off auto repeat.

Examples of measurements are shown in the next few

pages and will use crosshairs to probe points on the 2-D

demo part shipped with each ND 1200.

Examples show feature probing and measurement using

forward annotation with the factory default minimum

points probed for each feature type. The number of

required points for each feature type can be changed in

the Measure setup screen discussed later in Chapter 2:

Installation, Setup and Specifications.

ND 1200 QUADRA-CHEK 41

Page 42

Measuring points

Points are the simplest features to measure. Only one point is required

to define the location of a point. A maximum of 100 points can be

probed and will be averaged by the system to measure a single point.

U Press the POINT MEASUREMENT key. The Probe

Point screen will be displayed. Press the key twice to

measure a series of points using auto repeat.

U Move the stage to position the crosshairs over the

desired point location and press the ENTER key.

U Press the FINISH key to complete the measurement.

The point position will be shown and the point feature

will be added to the feature list.

1.4 Measuring Part Features

A point is probed on the part

The point position is shown and the point feature is

added to the feature list

42 1 Operation

Page 43

Measuring lines

A minimum of 2 points are required to measure a line. A maximum of

100 points can be probed and will be processed by a fit algorithm to

define the line.

U Press the LINE MEASUREMENT key. The Probe Line

screen will be displayed. Press the key twice to

measure a series of lines using auto repeat.

U Move the stage to position the crosshairs over an end

point of the line and press the ENTER key.

U Move the stage to position the crosshairs over the

other end point of the line and press the ENTER key.

U Press the FINISH key to complete the measurement.

The line position and angle will be shown and the line

feature will be added to the feature list.

U Press the CHANGE soft key to change the line fit

algorithm if desired.

Line fit algorithms include:

LSBF: Fit determined by minimizing the sum of the squared point

deviations from the form fit.

ISO: Fit determined by minimizing the form deviation.

A line is probed on the part

1.4 Measuring Part Features

The line position and angle are shown and the line

feature is added to the feature list

ND 1200 QUADRA-CHEK 43

Page 44

Measuring circles

A minimum of 3 points are required to measure a circle. A maximum

of 100 points can be probed and will be processed by a fit algorithm to

define the circle.

U Press the CIRCLE MEASUREMENT key. The Probe

Circle screen will be displayed. Press the key twice to

measure a series of circles using auto repeat.

U Move the stage to position the crosshairs over a point

on the circumference of the circle and press the

ENTER key.

U Move the stage to position the crosshairs over two

other points evenly distributed around the

circumference, pressing the ENTER key to collect

each point.

U Press the FINISH key to complete the measurement.

The circle position and diameter will be shown and

the circle feature will be added to the feature list.

1.4 Measuring Part Features

U Press the D/R AXIS soft key to toggle the display

between Diameter and Radius if desired.

U Press the CHANGE soft key to change the circle fit

algorithm if desired.

Circle fit algorithms include:

LSBF: Fit determined by minimizing the sum of the squared point

deviations from the form fit.

ISO: Fit determined by minimizing the form deviation.

Outer: Yields the biggest circle.

Inner: Yields the smallest circle.

A circle is probed on the part

The circle position and diameter are shown and the

circle feature is added to the feature list

44 1 Operation

Page 45

Measuring distances

Two points are required to measure a distance.

U Press the DISTANCE MEASUREMENT key. The

Probe Distance screen will be displayed. Press the

key twice to measure a series of distances using auto

repeat.

U Move the stage to position the crosshairs over the

first of the two points, then and press the ENTER key.

U Move the stage to position the crosshairs over the

second of the two points, and then and press the

ENTER key.

U Press the FINISH key to complete the measurement.

The X, Y and vector distances will be shown and the

distance feature will be added to the feature list.

U When a Z-axis is used, press the L/Z AXIS soft key to

toggle the display between the vector distance (L)

and the Z height if desired. Z-axis height is not used in

the calculation of vector distance.

A distance is probed on the part

1.4 Measuring Part Features

The X, Y and vector distances are shown and the

distance feature is added to the feature list

ND 1200 QUADRA-CHEK 45

Page 46

Measuring angles

A minimum of 4 points evenly divided on two legs of an angle are

required to measure an angle. A maximum of 100 points can be

probed on the two angle legs. Once the minimum two points are

probed on each angle leg, additional points can be distributed between

the two legs in any proportion. For example, the first leg could be

defined by 4 points, and the second by 8.

U Press the ANGLE MEASUREMENT key. The Probe

Angle screen will be displayed. Press the key twice to

measure a series of angles using auto repeat.

U Move the stage to position the crosshairs over a

minimum of two points evenly distributed on one

angle leg, pressing the ENTER key to collect each

point.

U Press the finish key to complete the measurement of

the first leg.

U Move the stage to position the crosshairs over a

1.4 Measuring Part Features

minimum of two points evenly distributed on the

second angle leg, pressing the ENTER key to collect

each point.

U Press the FINISH key to complete the angle

measurement. The angle and angle vertex position

will be shown. The angle feature and two angle leg

features will be added to the feature list.

U Press the CHANGE soft key to change the angle type

if desired.

Slot features form an angle (

ø) on the part

Angle types include:

The two legs of an angle are probed on the part

INCLD: Included angle (A1).

360-A1: 360 degrees - included angle.

180+A1: 180 degrees + included angle.

180-A1: 180 degrees - included angle

INCLD (A1) 360 - A1 180 + A1 180 - A1

The angle and angle vertex position are shown. The

angle and angle legs are added to the feature list

46 1 Operation

Page 47

1.5 Creating Part Features

Created features

It can be useful to create features that are not found on the part

geometry. Created features can be used as reference points for

inspection purposes. For example, in order to measure a feature that

is referred to a point off the part geometry, the user could create the

reference point.

Users can create points, lines, circles, distances, angles, and part

skews. Created features are the same as probed features except that

the created features are geometrically perfect, so form error and

tolerance values do not apply.

Created features are not the same as constructed features, which are

discussed in the next section of this chapter. Created features are

defined by the user. For example, to create a circle, the user defines

the location of the center point and the diameter or radius.

Constructed features are built from previously measured or created

parent features. For example, the user could construct a line between

two or more points in the feature list. Constructed features can have

form errors and tolerance values.

Creating features

The method of creating a feature is identical for all feature types. To

create a feature:

U Press the desired feature MEASUREMENT key

U Press the CREATE soft key

U Enter the required feature data

U Press the FINISH key

1.5 Creating Part Features

An example of creating a feature is shown on the next

page.

ND 1200 QUADRA-CHEK 47

Page 48

Example of creating a feature

In this example, a circle is created:

U Press the feature MEASUREMENT key. In this

example, the CIRCLE MEASUREMENT key is

pressed and the Probe Circle screen is displayed.

U Press the CREATE soft key to display the Create data

entry screen. In this example, the Create Circle

screen is displayed.

U Enter the desired feature parameters. In this example,

the circle position and diameter (or radius) values are

entered into the X, Y, Z and D data fields.

U Press the FINISH key. The new feature will be shown

on the screen and added to the feature list.

1.5 Creating Part Features

CIRCLE MEASUREMENT key is pressed Circle position and diameter values are

entered

New circle is shown in the feature list

48 1 Operation

Page 49

1.6 Constructing Part Features

Constructed features

New features can be constructed from probed, created, or other

constructed features from the features list. Constructions are

frequently used to perform skew alignments, set datums and

measure relationships between parent features.

Users can construct points, lines, circles, distances, angles, and part

skews. Constructed features are the same as probed features. They

can have form errors and tolerances can be applied.

If a construction is requested that does not include the

required parent features or is not supported, an error

message is displayed indicating an “Invalid construction”.

Constructing features

The method of constructing a feature is identical for all feature types.

To construct a feature:

U Press the desired feature MEASUREMENT key

U Press the CONSTR soft key or the UP ARROW CURSOR key

U Highlight a required parent feature, then press the ENTER key to

select it

U Continue highlighting and selecting parent features until all the

required features are selected

U Press the FINISH key

1.6 Constructing Part Features

An example of constructing a feature is shown on the next

page.

ND 1200 QUADRA-CHEK 49

Page 50

Example of constructing a feature

In this example, a new point feature is constructed from two parent

circle features:

U Press the feature MEASUREMENT key corresponding to the

feature you want to construct. In this example, the POINT

MEASUREMENT key is pressed.

U Press the CONSTR soft key or press the up ARROW CURSOR key

to highlight the last feature in the feature list. If the last feature in

the feature list will not be one of the parent features, press the up

ARROW CURSOR key until the first parent feature is highlighted. In

this example, the first parent circle feature is at the bottom of the

feature list.

U Press the ENTER key to select the highlighted feature. A checkmark

will appear at the feature location in the list.

1.6 Constructing Part Features

POINT MEASUREMENT key is pressed First circle feature is highlighted First circle feature is selected as a parent

feature

U Continue highlighting and then selecting features until all the

required parent features are selected. In this example, the second

circle feature is highlighted and selected.

U Press the FINISH key to construct the new feature. The new feature

will be added to the feature list. In this example, a new point feature

is shown at the bottom of the feature list.

Second circle feature is highlighted Second circle feature is selected as a

parent feature

FINISH key is pressed to create new

point feature

50 1 Operation

Page 51

U Press the VIEW key to show a graphic image of the feature

construction. In this example the image shows that the Int 1 point

feature was constructed at the top intersection of the two circle

circumferences.

U Press the CHANGE soft key to show alternative point features that

can be constructed from the two parent circle features.

U Press the desired construction alternative soft key to change the

feature construction type. In this example, the Mid Pt point feature

was selected, and the point is constructed at the mid point between

the two circle center points.

VIEW soft key is pressed to show

graphic image of constructed feature

CHANGE soft key is pressed to show

alternative constructions

More feature construction examples

A collection of some typical feature constructions are shown here

graphically as examples. Many more constructions are possible.

Invalid construction requests will initiate an error message.

Construction Parent features Graphic

Point Two lines: intersection

Point Line and circle: intersection

Point Two circles: intersection

Point feature type is changed from Int 1

1.6 Constructing Part Features

to Mid Pt

ND 1200 QUADRA-CHEK 51

Page 52

Construction Parent features Graphic

Point Two points: mid point

Point Point and circle: mid point

Point Distance and point: offset

Point Circle: center point

1.6 Constructing Part Features

Point Line and point: perpendicular

Point Line and datum: perpendicular

Line Points: Best fit

Line Line and circle: perpendicular

Line Two lines: bisector

Line Line and distance: offset

52 1 Operation

Page 53

Construction Parent features Graphic

Circle Multiple circles: best fit

Circle Circle and distance: offset

Distance Two points: point to point

Distance Circle and circle: center to center

Distance Point and line: perpendicular

1.6 Constructing Part Features

Angle Two lines: vertex

ND 1200 QUADRA-CHEK 53

Page 54

1.7 Tolerancing

Feature tolerances

The following tolerances are available in the ND 1200.

Feature type To l e r a n c e

Point Bidirectional position

Point True position

1.7 Tolerancing

Line Bidirectional position

Line True position

Line Straightness

Line Perpendicularity

Line Parallelism

Line Angle

Circle Bidirectional position

Circle True position

Circle LMC: Least material condition

Circle MMC: Maximum material condition

Circle Roundness

Circle Concentricity

Circle Runout

Distance Width

Angle Angle

54 1 Operation

Page 55

Applying tolerances

The method of applying tolerances is identical for all feature types. To

apply a tolerance:

U Highlight a feature in the feature list using the ARROW CURSOR

keys.

U Press the TOL soft key to display the tolerance soft keys.

U Press the soft key corresponding to the desired tolerance type, such

as runout for a circle. A new screen will be displayed containing data

fields for nominal and tolerance values.

U Enter the nominal and tolerance values and then press the FINISH

key to display the tolerance results. Press the finish key again to

return to the DRO screen.

Measurements that pass tolerance tests are indicated by a checkmark

in the tol soft key box. Measurements that fail are indicated by a

crossed circle in the Tol soft key box and by outlined characters in the

DRO screen.

1.7 Tolerancing

Passed tolerance indicated by

checkmark in TOL soft key box

An example of applying a tolerance is shown on the next

page.

ND 1200 QUADRA-CHEK 55

Failed tolerance indicated by crossed

circle in TOL soft key box and outline

characters

Page 56

Example of applying a tolerance

In this example, a form tolerance (roundness) is applied to a circle

feature:

U Use the ARROW CURSOR keys to highlight the desired feature in

the feature list. In this example, the circle feature is highlighted.

U Press the TOL soft key to display the tolerance alternatives above

the soft keys at the bottom of the screen. In this example, the circle

tolerance alternatives are:

POS (Position)

1.7 Tolerancing

FORM

RUNOUT

CON (Concentricity)

U Press the soft key corresponding to the desired tolerance type to

display the data entry screen. In this example, the FORM soft key

was pressed and the data entry screen for specifying the roundness

tolerance is displayed. Initially, the tolerance data field (Tol. Zone)

contains the measured deviation from ideal roundness.

Circle feature is highlighted using

ARROW CURSOR keys

56 1 Operation

TOL soft key is pressed to display

tolerance soft keys

FORM soft key is pressed to display the

tolerance data entry screen

Page 57

U Enter the desired nominal and tolerance values into the data fields

provided. In this example of circle form tolerance, only the

roundness tolerance field is provided, and a tolerance of 0.15 is

entered.

U Press the FINISH key to display the tolerance result. The tolerance

and actual values will be displayed. In this example, the tolerance

value was greater than the actual value and the tolerance passed. A

checkmark is shown to indicate a passed test.

U Press the FINISH key again to return to the DRO screen. The

checkmark is shown again in the TOL soft key box.

1.7 Tolerancing

The form tolerance is entered The FINISH soft key is pressed to display

the tolerance test result

The FINISH key is pressed to return to

the DRO screen

ND 1200 QUADRA-CHEK 57

Page 58

1.8 Programming

ND 1200 programs

ND 1200 programs automate repetitive measurement and inspection

tasks. Programs are recorded sequences of measurement and other

operator key-press activities stored in the ND 1200 to be played back

later when inspecting identical parts. Any key-press activity can be

included. Programs save time and ensure greater consistency

because all parts are measured the same way.

When program recordings are run (played back) using the graphic

1.8 Programming

VIEW screen, a targeting image of part probing is displayed to assist

the operator. The targeting view displays a feature graphic showing

the next point to be probed and an arrow that represents the probe.

As the stage is moved to position the probe over the indicated point,

the arrow moves closer to the point shown on the part image.

ND 1200 programs can be:

Recorded

Run

Edited

Copied

Deleted

Recording a program

When the program is run, the VIEW soft key is

pressed to display the targeting graphic

To record a ND 1200 program:

U Press the MENU key.

U Press the PROG soft key. The Program screen will be displayed.

U Press the RECORD soft key. The program number dialog box will be

displayed.

U Enter the desired program number and press the OK soft key.

U Perform the desired measurement and other activities that you wish

to record.

U Press the MENU key.

U Press the PROG soft key.

U Press the END REC soft key to stop recording the program. The new

program will be added to the list of programs.

U Press the FINISH key to return to the DRO screen.

U Run and test the program to verify its correctness. Edit the program

if necessary.

An example of recording a program is shown on the next

page.

58 1 Operation

Page 59

Example of recording a program

In this example, a program is created to measure several features on

the 2-D demo part:

U Press the MENU soft key to display the menu soft key titles at the

bottom of the screen.

U Press the PROG soft key to display the Programs screen.

U Press the RECORD soft key to initiate the recording process and

display the program number dialog box.

U Enter the desired program number and press the OK soft key to

begin recording your activities. The DRO screen will be displayed

and a REC indication will be shown in the upper right corner of the

screen.

1.8 Programming

Menu key is pressed to show menu soft

key titles

U Perform all measurement and other inspection activities as usual.

PROG soft key is pressed to show

Programs screen

Program recording will continue in the background.

U When all part inspection activities are complete, press the MENU

soft key to display the menu soft key titles at the bottom of the

screen.

U Press the PROG soft key to display the Programs screen.

U Press the END REC soft key to stop recording and store the

program.

When recording begins, a REC indication

is shown in the upper right

When inspection is complete, the menu

key is pressed to show menu soft keys

RECORD soft key is pressed and the

program number is entered

The PROG and then END REC soft keys

are pressed to stop recording and store

the program

ND 1200 QUADRA-CHEK 59

Page 60

Running a program

To run (play back) a ND 1200 program:

U Press the MENU key.

U Press the PROG soft key. The Program screen will be displayed.

U Use the ARROW CURSOR keys to highlight the desired program

number.

U Press the RUN soft key. The DRO screen will be displayed and the

program will begin running. An indication of an active recording will

be shown in the upper right corner of the screen.

U Press the VIEW soft key to show the targeting graphic screen.

1.8 Programming

Do not use the targeting graphic to perform fine

positioning of the crosshair probe. The targeting graphic is

only provided to assist rough positioning.

U Perform the indicated measurements and other activities prompted

by the program. The program will stop running and the DRO screen

will be displayed automatically when all the program steps have

been completed.

An example of running a program is shown on the next

page.

60 1 Operation

Page 61

Example of running a program

In this example, the program recorded in the earlier example of

recording a program is run:

U Press the MENU soft key to display the menu soft key titles at the

bottom of the screen.

U Press the PROG soft key to display the Programs screen.

U Highlight the desired program number using the ARROW CURSOR

keys.

1.8 Programming

Menu key is pressed to show menu soft

key titles

U Press the RUN soft key to initiate the program play back and display

PROG soft key is pressed to show

Programs screen

the DRO screen.

U Press the view soft key to display the targeting graphic to assist

rough part positioning.

U Follow the program prompting messages to perform all

measurement and other inspection activities. When all the program

steps have been completed, the program will stop and the DRO

screen will be displayed.

The program begins running The targeting view is used for rough part

positioning

The desired program is selected

The program steps are complete and the

DRO screen is displayed

ND 1200 QUADRA-CHEK 61

Page 62

Editing a program

Programs can be edited to change, insert, or delete program steps.

There are a variety of reasons to edit programs. A program may

contain an error or omission. For example, a feature may have been

left out or measured using the wrong reference. Part specifications

might change and editing an existing program is often faster than

creating a new program. Edit programs to:

Expand or change a program step

Delete a program step

Insert a new program step

1.8 Programming

Use care when editing program steps, and store a backup

of the program first. Deleted steps cannot be restored.

To edit a program:

U Display the steps.

U Expand a step if necessary.

U Edit the program by:

Changing a step

Deleting a step

Inserting a new step

U Close the edit session and save edits by pressing the FINISH key.

Displaying program steps

To display program steps:

U Press the MENU soft key to display the menu soft key titles at the

bottom of the screen.

U Press the PROG soft key to display the Programs screen.

U Highlight the desired program number using the ARROW CURSOR

keys.

U Press the EDIT soft key to display the list of program steps. A EDT

indication will be shown in the upper right corner of the screen.

Menu key is pressed to show menu soft

key titles

PROG soft key is pressed to show

Programs screen

The EDIT soft key is pressed to show the

program steps

62 1 Operation

Page 63

Expanding and compressing a program steps

To expand or compress a program step:

U Use the ARROW CURSOR keys to highlight a compressed step.

Compressed steps are indicated by a + sign in a box in front of the

step.

U Press the ENTER key to toggle between expanding and

compressing the step.

1.8 Programming

A step is highlighted The ENTER key is pressed to expand the

step

The ENTER key is pressed to compress

the step

ND 1200 QUADRA-CHEK 63

Page 64

Changing a program step

Program steps can be edited to change:

Program properties

Settings

Tolerances

To change program steps:

U Use the ARROW CURSOR keys to highlight a step. Expand the step

if necessary.

1.8 Programming

U Press the ENTER key to cycle through the available alternatives and

select a new value for the highlighted the step.

U Press the FINISH key to change the step.

U Press the FINISH key again to leave the edit mode and return to the

programs screen.

Example of changing ND 1200 settings

In this example, ND 1200 settings will be edited to change the unit of

measure from mm to inches:

To change ND 1200 settings:

U Use the ARROW CURSOR keys to highlight the Settings step.

U Press the ENTER key to expand the Settings step.

U Use the ARROW CURSOR keys to highlight the Units step.

U Press the ENTER key to change the Units step value from mm to

inch.

U Press the FINISH key to save to change and return to the Programs

screen.

The Settings step is highlighted and

expanded

The Units step is highlighted The ENTER key is pressed to change

from mm to inch units

64 1 Operation

Page 65

Example of changing program properties

In this example, program properties will be edited to change the

behavior of the program when a tolerance fails. Initially, the program

pauses when a tolerance fails; after the change, the program will not

pause:

To change program properties:

U Use the ARROW CURSOR keys to highlight the Prg Properties step.

U Press the ENTER key to expand the Prg Properties step.

U Use the ARROW CURSOR keys to highlight the Pause Tol Results

step.

U Press the NEVER soft key and then the ENTER key to change the

Pause Tol Results step value from If Fail to Never.

U Press the FINISH key to save to change and return to the Programs

screen.

1.8 Programming

The Prg Properties step is highlighted

and expanded

The Pause Tol Results step is highlighted The NEVER soft key and then ENTER

key to change from If Fail to Never

ND 1200 QUADRA-CHEK 65

Page 66

Example of changing tolerances

In this example, a roundness form tolerance will be edited to be more

forgiving: