Bosch Therm 4000 S, GWH 12 CTDE 23 F5 S7805, GWH 12 CTDE 31 F5 S7805 Installation And Operating Instructions Manual

Installation and operating instructions

Balanced flue gas instantaneous water heater

Therm 4000 S

GWH 12 CTD E.. F5..

6 720 815 298 (2017/05) GB

2

Table of Contents

Therm 4000 S – 6 720 815 298 (2017/05)

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . 3

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 EC declaration of type conformity . . . . . . . . 6

2.3 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 Description of the device . . . . . . . . . . . . . . . 6

2.7 Accessories (not included within the

scope of delivery) . . . . . . . . . . . . . . . . . . . . . .6

2.8 Dimensions and minimum clearances . . . . . 7

2.9 Layout of device . . . . . . . . . . . . . . . . . . . . . . 8

2.10 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . 9

2.11 Technical specifications . . . . . . . . . . . . . . . 10

2.12 Product data on energy consumption . . . . 11

2.13 Flue accessories . . . . . . . . . . . . . . . . . . . . . 12

2.13.1 Vertical flue gas routing . . . . . . . . . . . . . . . . 13

2.13.2 Horizontal flue gas routing . . . . . . . . . . . . . 13

3 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Digital display - Description . . . . . . . . . . . . 14

3.2 Before commissioning the device . . . . . . . 14

3.3 Device ON/OFF . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Setting the temperature . . . . . . . . . . . . . . . 14

3.5 Program key . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Draining the device . . . . . . . . . . . . . . . . . . . 15

3.7 Error codes on the display . . . . . . . . . . . . . 15

3.8 Cleaning the casing of the device . . . . . . . . 15

4 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Installation (only for approved contractors) . . . . . 16

5.1 Important information . . . . . . . . . . . . . . . . . 16

5.2 Selecting the installation location . . . . . . . 17

5.2.1 Regulations for the installation location . . . 17

5.2.2 Total length of the flue system (Type C

devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Minimum clearances . . . . . . . . . . . . . . . . . . 17

5.4 Fitting the wall mounting bracket . . . . . . . . 18

5.5 Installing the device . . . . . . . . . . . . . . . . . . 19

5.6 Water connection . . . . . . . . . . . . . . . . . . . . 19

5.7 Gas connection . . . . . . . . . . . . . . . . . . . . . . 20

5.8 Installation of the flue gas/air accessories . 20

5.9 Altitude of installation location . . . . . . . . . . 21

5.10 Starting the device . . . . . . . . . . . . . . . . . . . 21

6 Electrical connection (only for approved

contractors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.1 Power cable . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Replacing power cable . . . . . . . . . . . . . . . . 22

7 Gas regulating (only for approved contractors) . . 22

7.1 Factory setting . . . . . . . . . . . . . . . . . . . . . . 22

7.2 Service mode . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 Gas supply with propane gas . . . . . . . . . . . 23

7.4 Setting the device . . . . . . . . . . . . . . . . . . . . 23

7.4.1 Access to the pressure test ports . . . . . . . . 23

7.4.2 Setting the maximum gas volume

(parameter P1) . . . . . . . . . . . . . . . . . . . . . . .23

7.4.3 Setting the minimum gas volume

(parameter P2) . . . . . . . . . . . . . . . . . . . . . . .24

7.4.4 Adjustment of the burner nozzle pressure

(parameter P0) . . . . . . . . . . . . . . . . . . . . . . .24

7.4.5 Factory setting (parameter P4) . . . . . . . . . 24

7.5 Converting gas type . . . . . . . . . . . . . . . . . . 25

8 Maintenance (only for approved contractors) . . . 25

8.1 Removing the casing . . . . . . . . . . . . . . . . . . 25

8.2 Regular maintenance . . . . . . . . . . . . . . . . . 25

8.3 Replacing the fuses (control device) . . . . . 26

8.4 Putting into operation after maintenance . 26

8.5 Safe operation/ risk for prolonged use . . . 26

9 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Environmental protection/disposal . . . . . . . . . . . . 28

3

Key to symbols and safety instructions

Therm 4000 S – 6 720 815 298 (2017/05)

1 Key to symbols and safety instructions

1.1 Explanation of symbols

Warnings

The following signal words are defined and can be used in this

document:

• NOTICE indicates that material damage may occur.

• CAUTION indicates that minor to medium personal injury

may occur.

• WARNING indicates that severe or life-threatening

personal injury may occur.

• DANGER indicates that severe to life-threatening personal

injury will occur.

Important information

Additional symbols

1.2 General safety instructions

These installation instructions are

directed to the owner of the device as

well as to approved gas, water and

heating engineers and electricians.

▶ Read and retain the operating

instructions (device, heating

controller, etc.) prior to operation.

▶ Read the installation instructions

(device, heating controller, etc.) prior

to operation.

▶ Observe safety instructions and

warnings.

▶ Observe national and regional

regulations, technical rules and

guidelines.

▶ Keep a record of all work carried out.

If you smell gas

A gas leak could potentially cause an

explosion. Observe the following rules if

you smell gas.

▶ Avoid producing flames or sparks:

– Do not smoke, do not use a lighter

or strike matches.

– Do not operate any electrical

switches or pull out any plugs.

– Do not use the telephone or ring

doorbells.

▶ Turn off the gas supply at the main

shut-off valve or at the gas meter.

▶ Open windows and doors.

▶ Warn your neighbours and leave the

building.

▶ Prevent anyone from entering the

building.

▶ Stay well away from the building: call

the emergency services and the gas

supplier.

Intended use

The device may only be used for DHW

heating for domestic use or for similar

Warnings in the text are indicated by a

warning triangle.

In addition, signal words are used to indicate

the type and seriousness of the ensuing risk

if measures for minimising the danger are

not taken.

Important information where there is no

danger to people or property is indicated

with the adjacent symbol.

Symbol Meaning

▶Step

Cross-reference to another part of the document

• List/list entry

– List/list entry (second level)

Table 1

4

Key to symbols and safety instructions

Therm 4000 S – 6 720 815 298 (2017/05)

purposes, and it may only be operated

on an intermittent basis.

Any other type of use is considered as

improper. Any damage that may result is

excluded from liability.

Installation, commissioning and

maintenance

Installation, commissioning and

maintenance may only be carried out by

an approved contractor.

▶ Check all connections on the device

for leaks (gas, water and flue gas).

▶ In the case of open flue operation:

▶ Ensure that the installation location

meets the ventilation requirements.

▶ Only install original spare parts.

Inspection and maintenance

Regular inspection and maintenance are

prerequisites for safe and

environmentally compatible operation

of the heating system.

We recommend arranging an annual

inspection and maintenance contract

with the manufacturer.

▶ Have work carried out only by an

approved contractor.

▶ All defects that are detected must be

eliminated immediately.

Every situation, which does not

correspond to the conditions described

in the manual, must be evaluated by an

approved technician. If there is approval

for this, the contractor must specify a

catalogue of maintenance

requirements, which take wear and the

particular operating conditions into

account, and which comply with the

standards and requirements of the

country.

Conversion and repairs

Unprofessional modifications to the

device or other parts of the installation

can result in personal injury and/or

material damage.

▶ Have work carried out only by an

approved contractor.

▶ Never remove the panelling of the

device.

▶ Never carry out any modifications to

the device or to other parts of the

installation.

Electrical work

Electrical work may only be carried out

by qualified and approved electricians.

▶ Before starting electrical work:

– Isolate all poles of the mains

voltage and secure against

reconnection.

– Using suitable means, test that the

power supply is disconnected.

▶ Also observe the connection

diagrams of other system

components.

Open flue operation

The installation location must be

adequately ventilated, if the device

draws its combustion air from the room.

▶ Never cover or reduce the size of

5

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

ventilation openings in doors,

windows and walls.

▶ Consult an approved contractor in the

following cases to ensure that the

ventilation requirements are met:

– If structural modifications are

made (e.g. replacing windows and

doors)

– If devices with an air discharge

outside are subsequently installed

(e.g. extractor or circulation fans,

kitchen fans or air conditioning

units).

Combustion air/ambient air

The air in the installation location must

be free of flammable or chemically

aggressive substances.

▶ Do not store or use any highly

flammable or explosive materials

(paper, petrol, thinners, paints etc.)

within the vicinity of the heat source.

▶ Do not store or use any corrosive

substances (solvents, adhesives,

chlorinated cleaning agents, etc.)

within the vicinity of the heat source.

Handover to the user

Instruct the user in the operation and

operating conditions of the product.

▶ Explain the operation - with particular

emphasis on all safety-related

actions.

▶ Explain that conversions or repairs

must only be carried out by an

approved contractor.

▶ Point out the need for regular

inspections and maintenance for safe

and environmentally compatible

operation.

▶ The installation and operating

instructions must be given to the user

for keeping.

Safety of electrical devices for

domestic use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

prevent hazards when using electrical

devices:

“This device may be operated by

children aged 8 or over, by people with

physical, sensory and mental

disabilities, and by people who have no

experience with this type of device,

provided they are supervised or

instructed on how to use the device

safely and on the associated risks.

Children must not play with the device.

Children must not clean or service the

device without supervision.”

“In order to prevent hazards, damaged

power cables must be replaced by the

manufacturer, the service department

or an approved contractor, who has

been authorised by the manufacturer.”

2 Product details

GWH devices are for DHW heating. They can be started up by simply pressing a key.

6

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

2.1 Intended use

The device may only be used for DHW heating.

The device may only be installed in mobile homes.

Any other use is considered inappropriate. Any damage that

may result is excluded from liability.

2.2 EC declaration of type conformity

This device complies with the requirements of European

Directives 2009/142/EC, 2006/95/EC, 2004/108/EC and

the model described in the EC type-examination certificate.

The device is tested in accordance with EN 26.

2.3 Type overview

[GWH]Gas instantaneous water heater

[12] DHW output (l/min)

[CT] Thermostatically controlled

[D] Digital user interface

[E] Electrical ignition

[23] Device set for natural gas

[31] Device set for butane

[F5] Air box

[S...] Special number

Test gas details with code number and gas category in

accordance with EN 437:

2.4 Scope of delivery

• Balanced flue gas instantaneous water heater

•Fixing materials

• Documents about the device

• Water connection accessories

• Connection accessories

• Gas isolator

2.5 Data plate

The data plate is located on the outside at the bottom of the

device.

At the relevant location there is information about the

output, type approvals and serial number of the device.

2.6 Description of the device

• Device for wall-mounted installation, irrespective of

chimney and room size

• Multi-function display

• Device for operation with natural gas or LPG

• Electronic ignition

•Flow meter

• Temperature sensor for monitoring the water temperature

at the water inlet and outlet of the device.

• Safety equipment:

– Ionising electrode

–Thermal fuse

– Hot water temperature sensor

–Switch box

–Air temperature sensor

• Electrical connection: 230 V, 50 Hz.

2.7 Accessories (not included within the scope of

delivery)

•Gas conversion kits

• Flue accessories

• Frost protection accessories

• Remote control.

Type Country Category

GWH 12 PT, ES, IT, GB II

2R3R

NL II

2L3B/P (25; 30)

DE II

2ELL3B/P (20; 50)

FR II

2ESi3B/P (20/25; 30)

BE I

2E(S), I3B

AT-CH II

2H3B/P (20; 50)

HR II

2H3B/P (20; 30)

LU I

2E

Installation type B23, C13, C33, C43, C53, C

83

Table 2

GWH12 CT D E 23 F5 S....

GWH12 CT D E 31 F5 S....

Table 3

Code

numbers

Wobbe index

(W

S

) (15 °C)

Gas family

23 12.7-15.2 kWh/m

3

Natural gas group 2

31 20.2-21.3 kWh/m

3

LPG group 3

Table 4

7

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

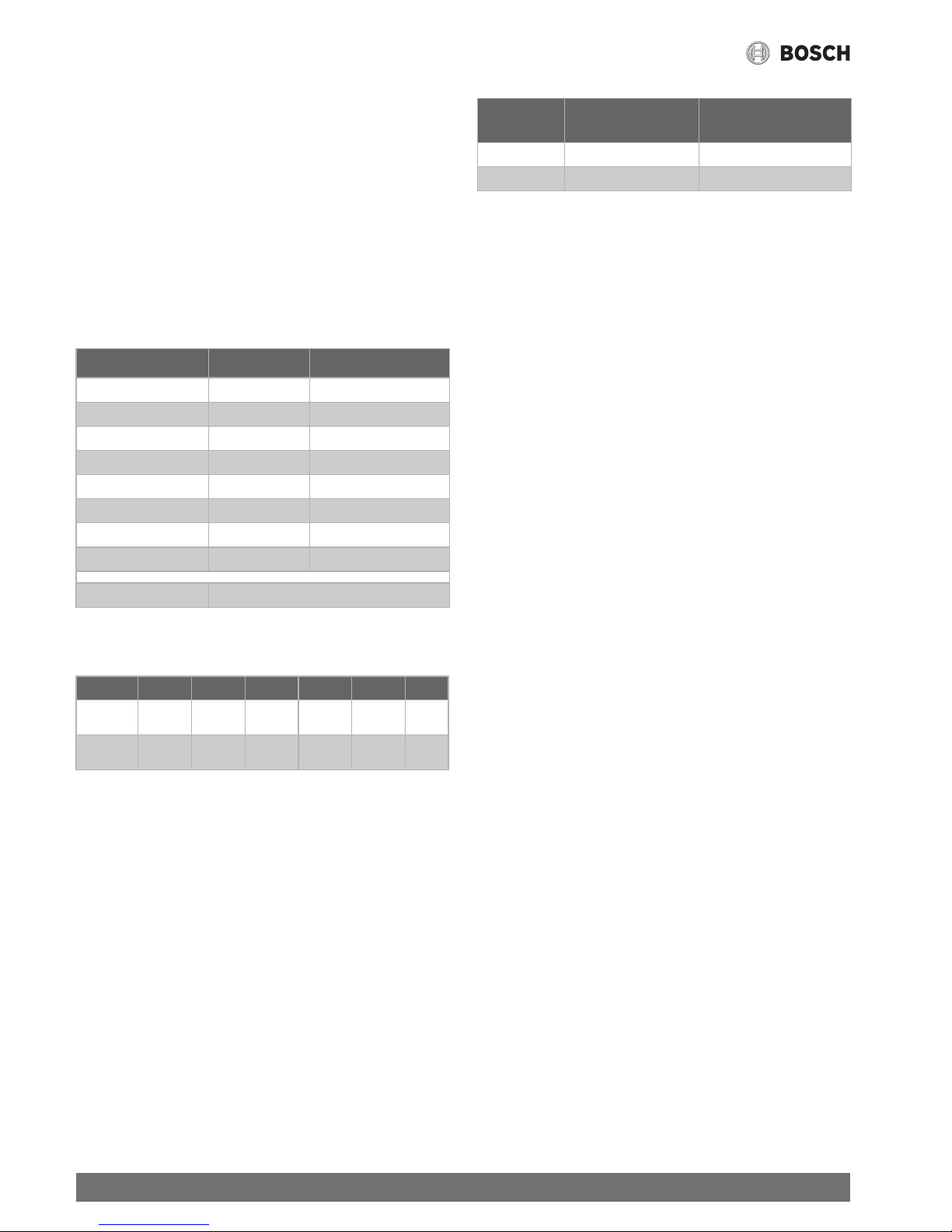

2.8 Dimensions and minimum clearances

Fig. 1 Dimensions (in mm)

Connection

Water Gas

A B C Cold water Domestic hot Natural gas LPG

GWH 12... 300 568 170 ¾ “ ½ “ ½ “ ½ “

Table 5 Dimensions (in mm)

8

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

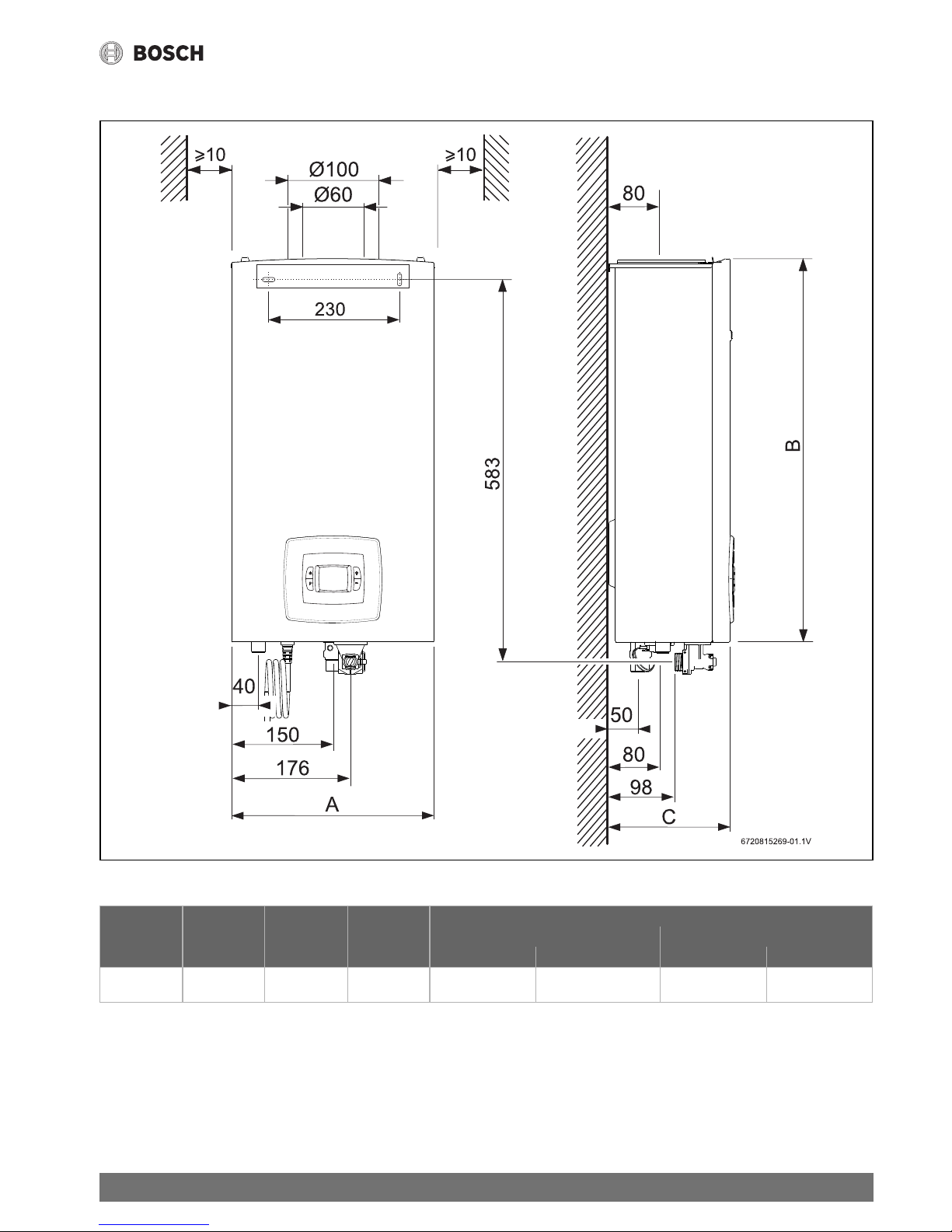

2.9 Layout of device

Fig. 2

[3] Combustion chamber

[4] Ionising electrode

[5] Burner

[6] Test port for air pressure in the casing

[7] Fan

[8] Air temperature sensor in the casing

[9] Thermal fuse

[10] Hot water temperature sensor

[11] DHW outlet

[12] Connecting lead with plug

[13] Combustion air test port

[14] Flue gas collector

[15] Ignition electrode

[16] Test port for gas pressure in the burner

[17] Flow meter

[18] Switch box

[19] Cold water temperature sensor

[20] Gas isolator

[21] Water inlet

[22] Test port for gas pressure at the gas connection

[23] Gas

9

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

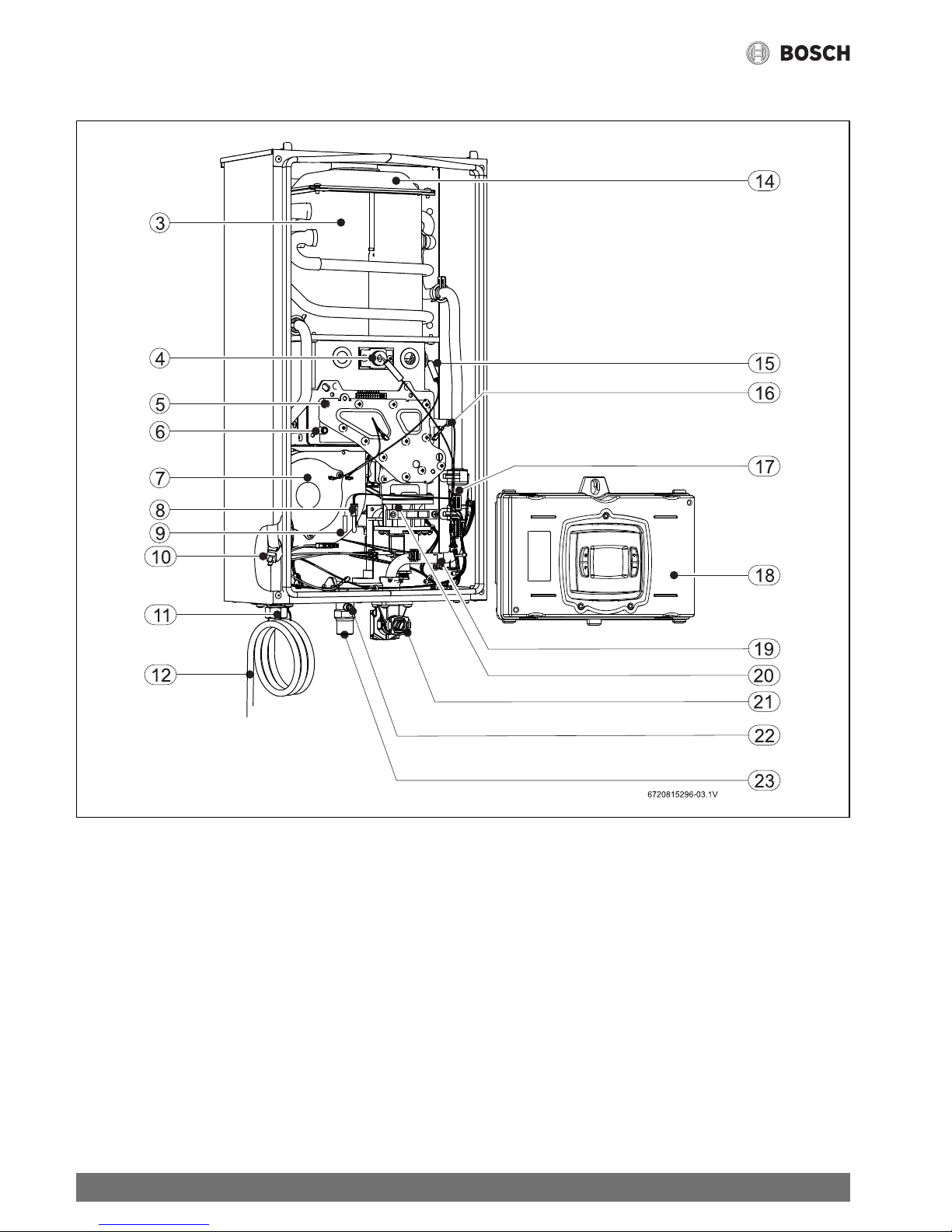

2.10 Wiring diagram

Fig. 3 Wiring diagram

[1] Ionising electrode

[2] Fan

[3] Ignition electrode

[4] Power supply

[5] Connection for frost protection accessories

[6] Connection for remote control

[7] Solenoid valve 1

[8] Solenoid valve 2

[9] Solenoid valve 3

[10] Solenoid valve 4

[11] Thermal fuse

[12] Flow meter

[13] Air temperature sensor in the casing

[14] Hot water temperature sensor

[15] Cold water temperature sensor

6720804089-10.1V

1 32

4

6

7

8

9

10

11

12

13

14

15

230 V

AC

M1

5

10

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

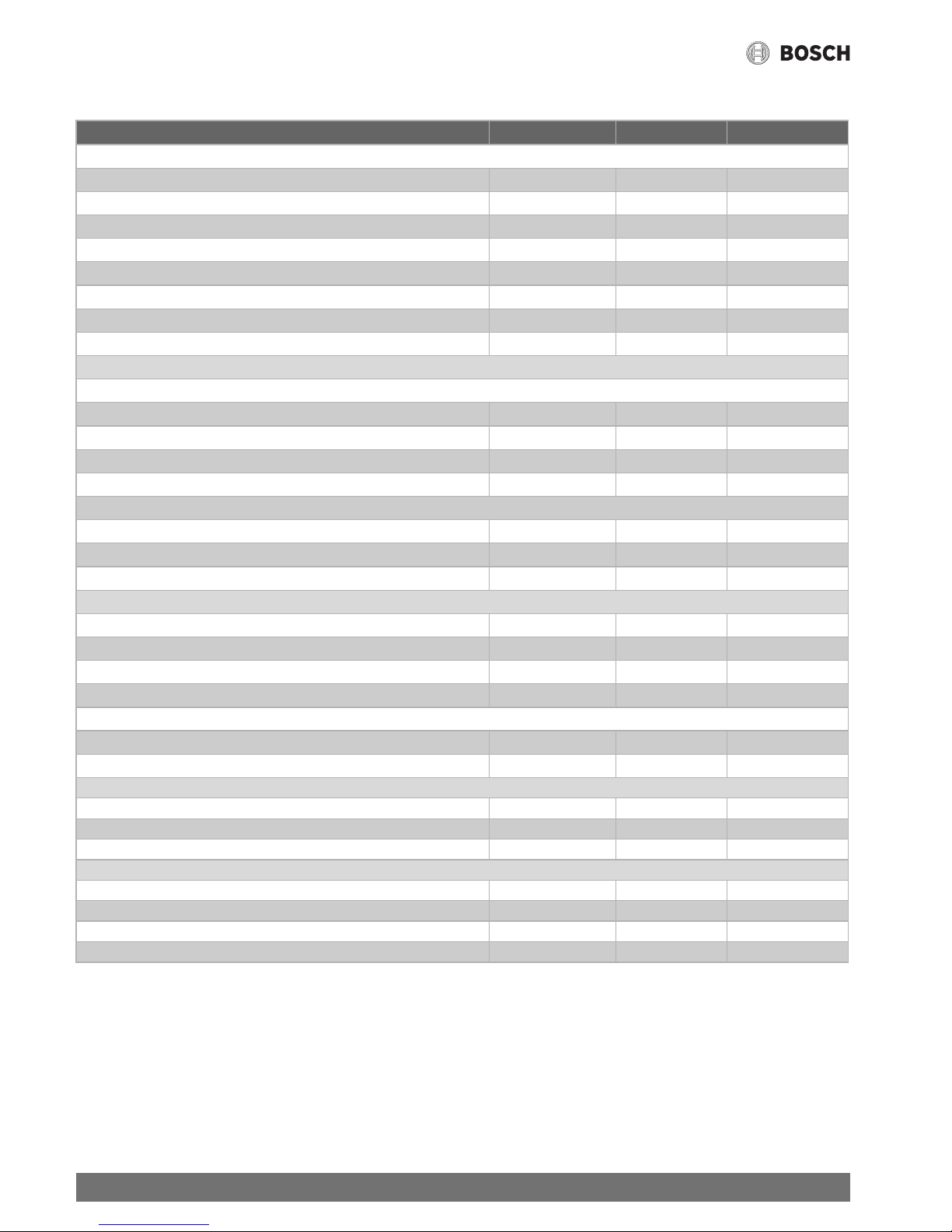

2.11 Technical specifications

Technical properties Symbols Unit GWH12

Output

1)

1) Hi 15- 1013 mbar - dry: Natural gas (G20) 34.02 MJ/m3 (9.5 kWh/m3) / Natural gas (G25) 37.38 MJ/m3 (10.38 kWh/m3)

Butan 45,65 MJ/kg (12,7 kWh/kg) - Propan 46,34 MJ/kg (12,9 kWh/kg) °C

Max. rated output (G20 / G31 / G25) Pn kW 20.8

Max. rated output (G25)

2)

2) G25: Category E(S), ESi

Pn kW 16.6

Minimum rated output (G20 / G31 / G25) Pmin kW 2.9

Minimum rated output (G25)

2)

Pmin kW 2.3

Heat load Qn kW 22.5

Minimum rated heat load Qmin kW 3.0

Efficiency at 100% of the rated heat load % 91.5

Efficiency at 30% of the rated heat load % 94

Gas specification

Permitted gas supply pressure

Natural gas G20 mbar 20

Natural gas G25 mbar 25

Butane G30 mbar 28-30 / 50

Propane G31 mbar 30 / 37 / 50

Gas supply value

Natural gas G20 m

3

/h 2.4

Butane G30 kg/h 1.8

Propane G31 kg/h 1.7

Water specification

Max. permitted pressure

3)

3) Allowing for water expansion, this value must not be exceeded.

pw bar 12

Minimum operating pressure pwmin bar 0.1

Switch-on flow rate l/min 2.2

Max. water volume at a l/min 9.0

Flue gas specification

Flow rate of the combustion products

4)

4) At rated heat output

kg/h 50

Flue gas temperature at the test points °C 170

Electrical specification

Power supply V 230

Max. power consumption W 100

IP rating IPX4D

General information

Weight (excl. packaging) kg 10

Height mm 570

Width mm 300

Depth mm 170

Table 6

11

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

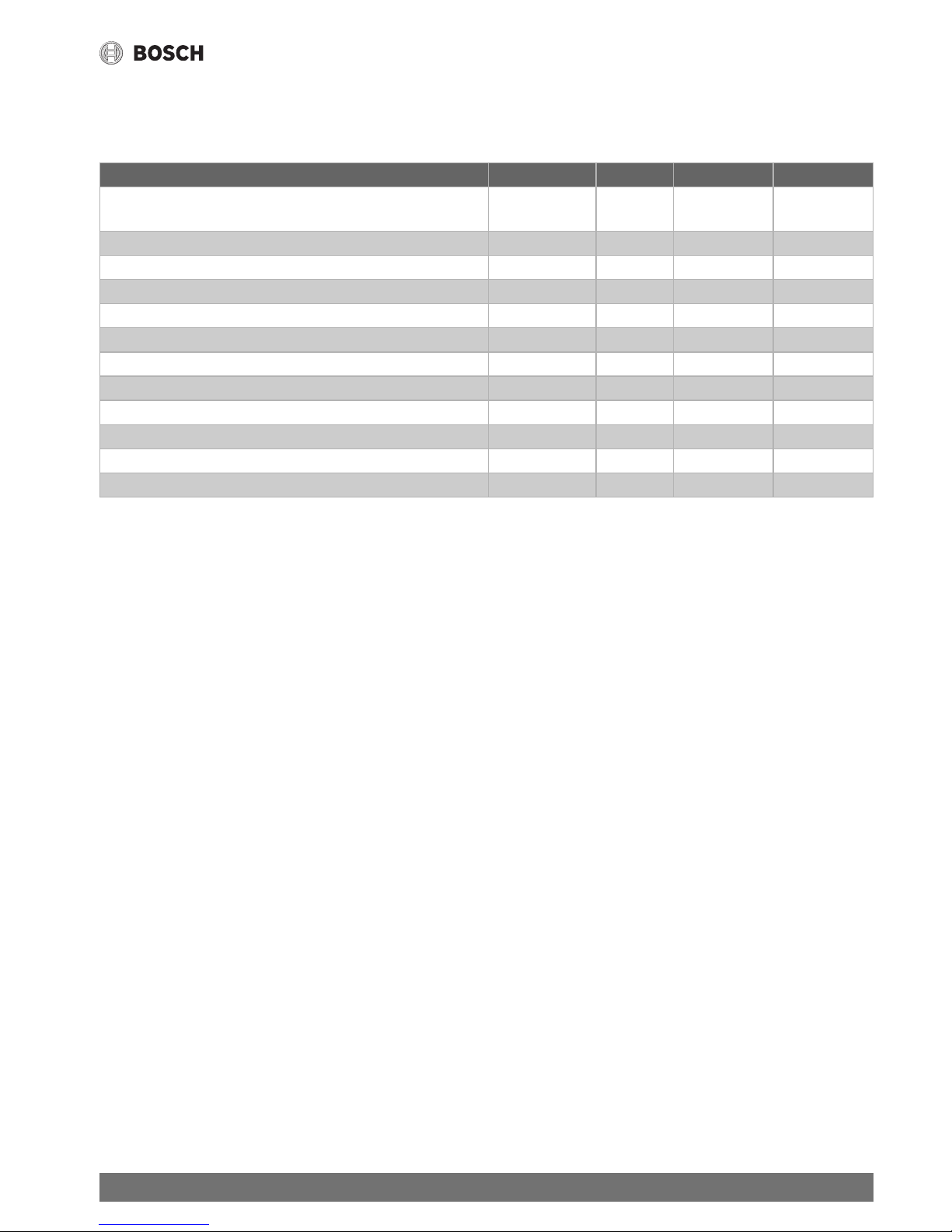

2.12 Product data on energy consumption

The following product data complies with the requirements of EU Regulations 811/2013, 812/2013, 813/2013 and 814/2013

as supplement to the Directive 2010/30/EU.

Product data Symbol Unit 7736503028 7736503029

Product type – – GWH 12 CTDE

23 F5 S7805

GWH 12 CTDE

31 F5 S7805

Emissions of nitrogen oxides NO

x

mg/kWh 127 127

Sound power level, indoors L

WA

dB(A) 67 67

Declared load profile – – M M

Water heating energy efficiency class – – A A

Water heating energy efficiency

wh

% 73 73

Annual electricity consumption AEC kWh 15 15

Daily electricity consumption (average climate conditions) Q

elec

kWh 0,068 0,068

Annual fuel consumption AFC GJ 6 6

Daily fuel consumption Q

fuel

kWh 8,439 8,439

Smart control enabled? – – No No

Thermostat temperature (factory setting) T

set

°C 60 60

Table 7 Product data on energy consumption

12

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

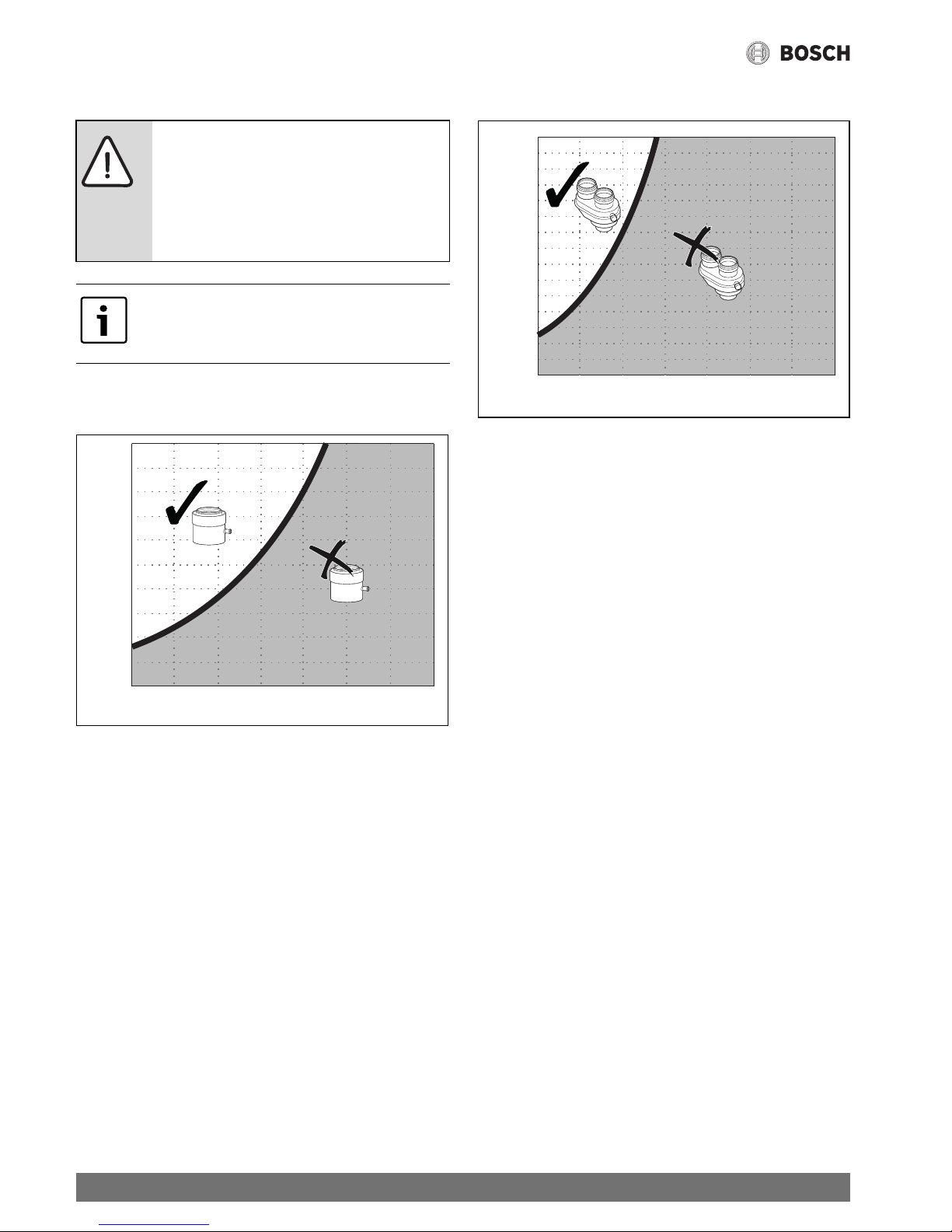

2.13 Flue accessories

Condensate trap

We recommend the use of a condensate trap.

Fig. 4 Concentric pipes

[A] Running length of the flue

[B] Temperature of the suction air

Fig. 5 Separate pipes

[A] Running length of the flue

[B] Temperature of the suction air

DANGER: The flue must not have any leaks

after it has been installed.

▶ Should this requirement not be met, flue

gas could enter the installation room,

which could result in severe injury or

death.

See accessories list below. For the correct

operation of the device use only genuine

accessories.

(A)

10 m

9 m

7 m

6 m

8 m

5 m

4 m

3 m

2 m

1 m

0 m

0°C-5°C-10°C 5°C 10°C 15°C 20°C 25°C

(B)

6720809968-04.3V

0°C-5°C-10°C 5°C 10°C 15°C 20°C 25°C

(B)

6720809968-03.3V

(A)

0 m

2 m

4 m

1 m

3 m

6 m

5 m

9 m

7 m

8 m

10 m

15 m

11 m

14 m

12 m

13 m

13

Product details

Therm 4000 S – 6 720 815 298 (2017/05)

Concentric pipes

The concentric pipes of the flue accessories have an internal

diameter of 60 mm and an external diameter of 100 mm.

Separate pipes

The separate pipes of the flue accessories have an internal

diameter of 80 mm.

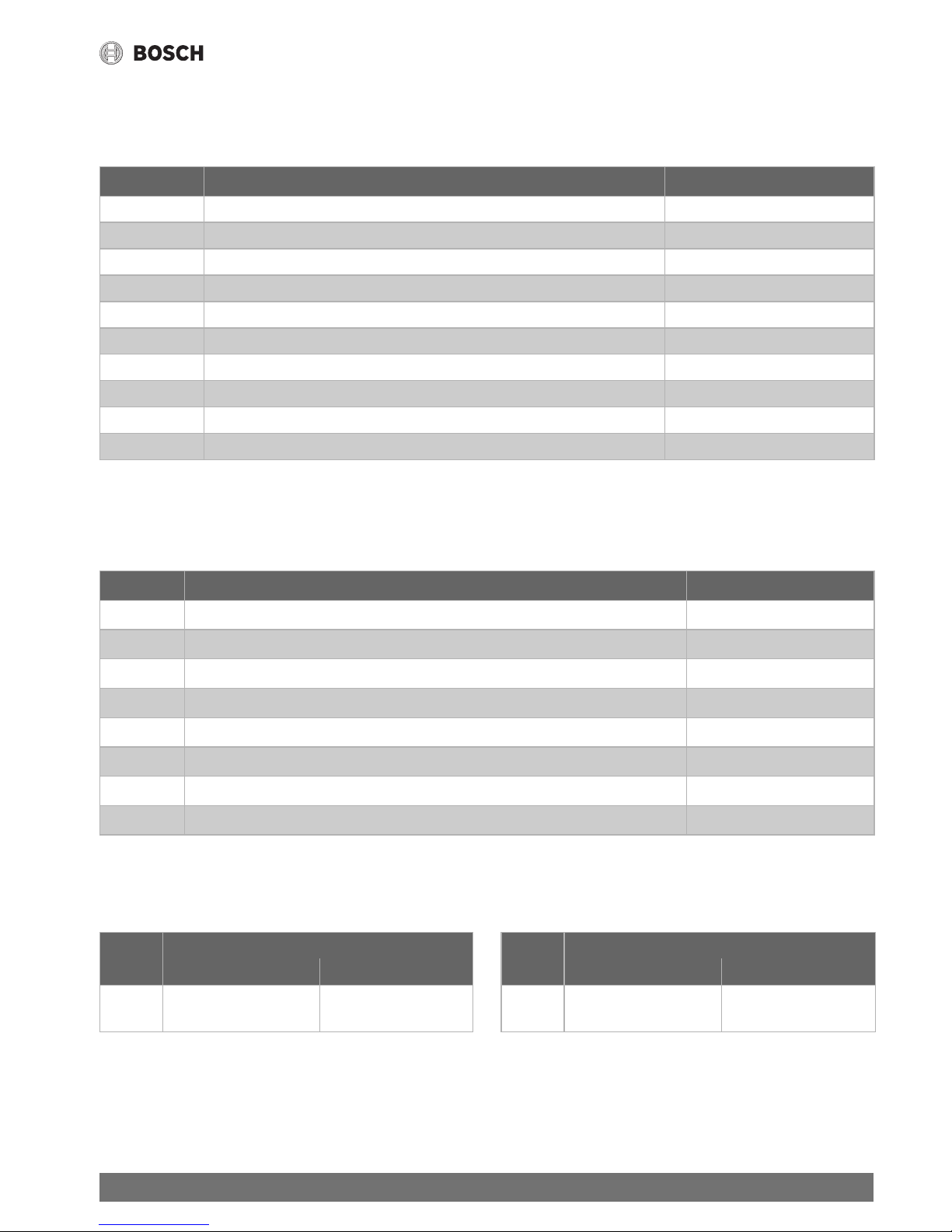

2.13.1 Vertical flue gas routing

Maximum lengths (Lmax)

2.13.2 Horizontal flue gas routing

Maximum lengths (Lmax)

Type Description Item number

AZ369 Set for vertical flue gas routing 7 716 050 044

AZ361 Set for horizontal telescopic connection (425-725 mm) 7 716 050 036

AZ362 Set for horizontal flue gas routing 7 716 050 037

--- 90° bend 7 736 995 079

--- 45° bend 7 736 995 071

--- Straight section 350 mm 7 736 995 059

--- Straight section 750 mm 7 736 995 063

--- Straight section 1500 mm 7 736 995 067

--- Condensate trap for horizontal flue gas routing 7 736 995 087

--- Condensate trap for vertical flue gas routing 7 736 995 089

Table 8 Flue accessories Ø 60-100 mm

Type Description Item number

----- Adaptor for concentric pipe (Ø 60/100 ->Ø 80-Ø 80) 7 736 995 095

----- 90° bend 7 736 995 107

----- 45° bend 7 736 995 106

----- Straight section 500 mm 7 736 995 100

----- Straight section 1000 mm 7 736 995 101

----- Straight section 2000 mm 7 736 995 102

----- Straight section 1000 mm + pipe bottoms 7 736 995 105

----- Straight section 135 mm with condensate collector 7 736 995 103

Table 9 Flue accessories Ø 80 mm

Lmax

Concentric pipes Separate pipes

GWH12 12 m 15 m + 15 m

Table 10

Lmax

Concentric pipes Separate pipes

GWH12 10 m 15 m + 15 m

Table 11

14

Operating instructions

Therm 4000 S – 6 720 815 298 (2017/05)

3 Operating instructions

3.1 Digital display - Description

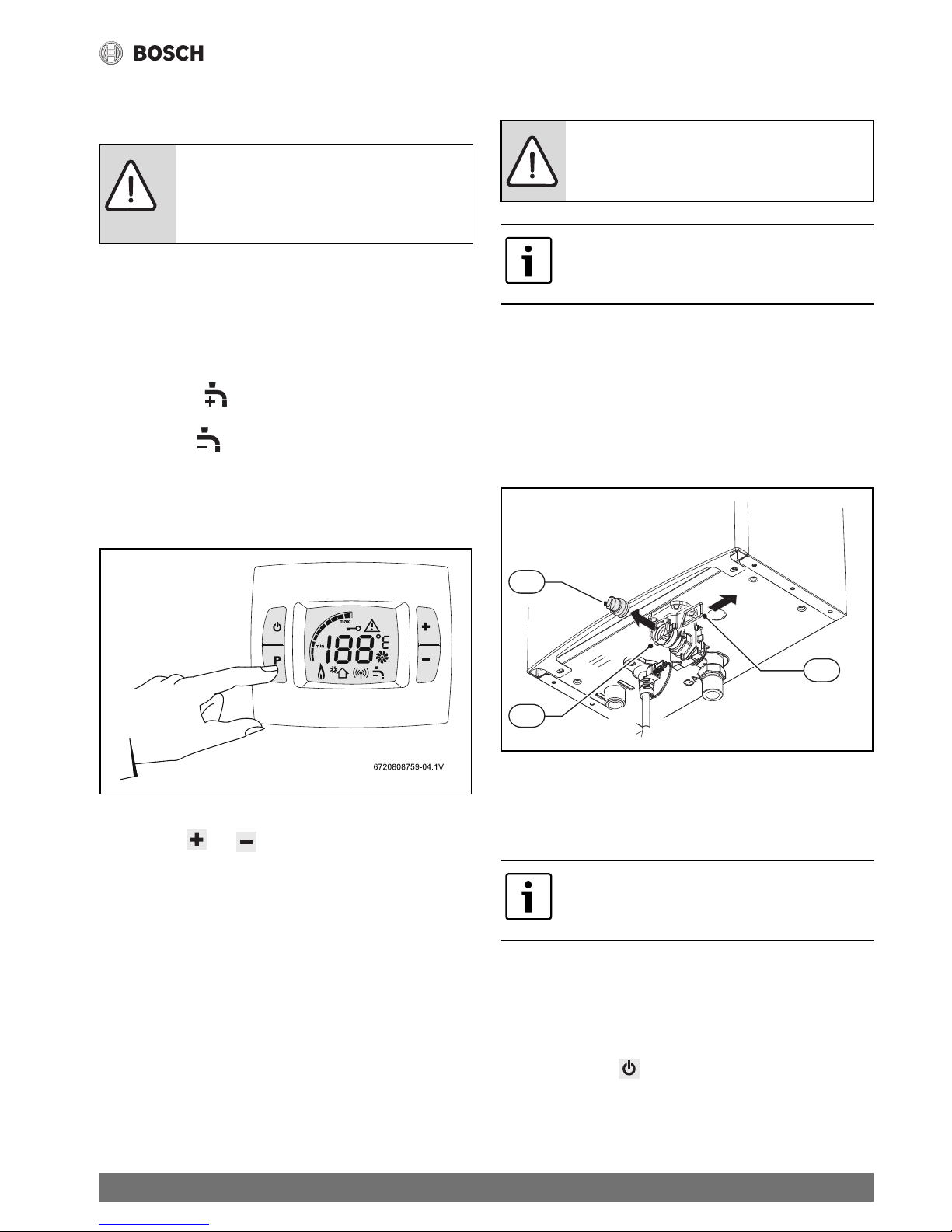

Fig. 6 Digital display

[1] ON/OFF key

[2] Program key

[3] LCD display

[4] Forwards key

[5] Backwards key

3.2 Before commissioning the device

▶ It must be ensured that the gas type, which is given on the

data plate, corresponds to that which is available at the

installation location.

▶ Connect the device to the power supply.

▶ Open the gas isolator on the system.

▶ Open the water tap on the system.

3.3 Device ON/OFF

Switching on

▶ Press the key.

The display shows the desired DHW temperature.

Fig. 7

Switching off

▶ Press the key.

3.4 Setting the temperature

▶ Press the or keys, until the desired value is set.

Fig. 8

If the temperature is set to the lowest possible value in line with

the particular requirement, the energy and water consumption

Open all shut-off valves for gas and water.

CAUTION: Risk of burns!

The front can become very hot in the area of

the burner, and there is a risk of burns if it is

touched.

CAUTION:

▶The instantaneous water heater must be

commissioned for the first time by an

approved contractor, who should

provide the customer with all the

required information for proper

operation of the device.

The DHW temperature is set as standard to

42 °C.

The temperature shown on the display

corresponds to the preset temperature.

15

Operating instructions

Therm 4000 S – 6 720 815 298 (2017/05)

will be reduced, and it will be easier to prevent any possible

limescale deposits in the internal body of the device.

Water flow rate

The temperature, which is shown on the display, flashes until

the set value is reached.

If the set temperature is not reached after 30 seconds, the

symbol of a water tap appears on the display to show that the

water volume has to be matched correctly.

▶ Increase the water volume to reach the set

temperature.

▶ Reduce the water volume to reach the set

temperature.

3.5 Program key

Saving the DHW outlet temperature

Fig. 9

▶ Press the or keys to set the temperature that is

to be saved.

▶ Press the program key and hold it down for 3 seconds to

save the temperature.

The set temperature is saved, when the display no longer

flashes.

Selecting the saved temperature

To select the saved temperature:

▶ Hold the program key down for 1 second.

The display shows the previously saved temperature. This is

now the selected temperature.

3.6 Draining the device

If there is a danger of frost:

▶ Close the water shut-off valve, which is upstream of the

device.

▶ Open one hot water tap.

▶ Remove the fixing ring [2] from the cold water pipe [1].

▶ Remove the holder [3].

▶ Allow the water inside the device to flow out completely.

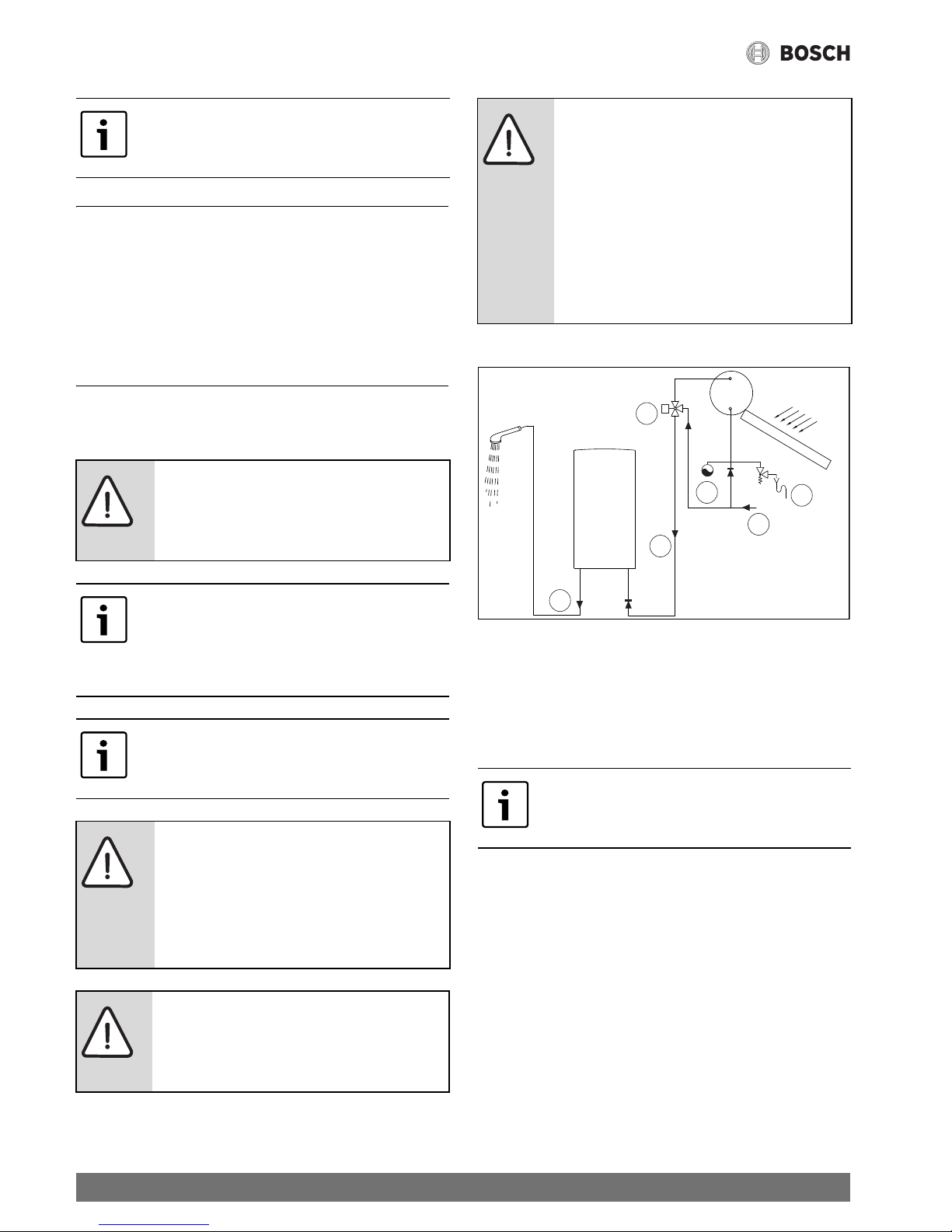

Fig. 10 Drain screw

[1] Water inlet

[2] Fixing ring

[3] Cap

3.7 Error codes on the display

See Tab. 18 on page 27.

Resetting the device

Many faults can be eliminated by resetting the device:

▶ Hold down the key for 3 seconds.

3.8 Cleaning the casing of the device

▶ If required, clean the casing with a damp cloth.

CAUTION: The temperature indicator on the

display shows an approximate value. Always

test the temperature with your hand before

bathing.

NOTICE:

Frost can result in damage to the device: drain

the device if there is a danger of frost.

Place a container under the device to

completely catch the water flowing out.

Installing a frost protection accessory protects

the device from freezing.

6720804089-07.1V

3

1.

2.

2

1

16

Regulations

Therm 4000 S – 6 720 815 298 (2017/05)

4Regulations

The currently applicable European standards must be

observed. Installation, repairs and maintenance must only be

carried out by approved contractors.

The appliance installation must meet the requirements of

EN1949 standard.

5 Installation (only for approved

contractors)

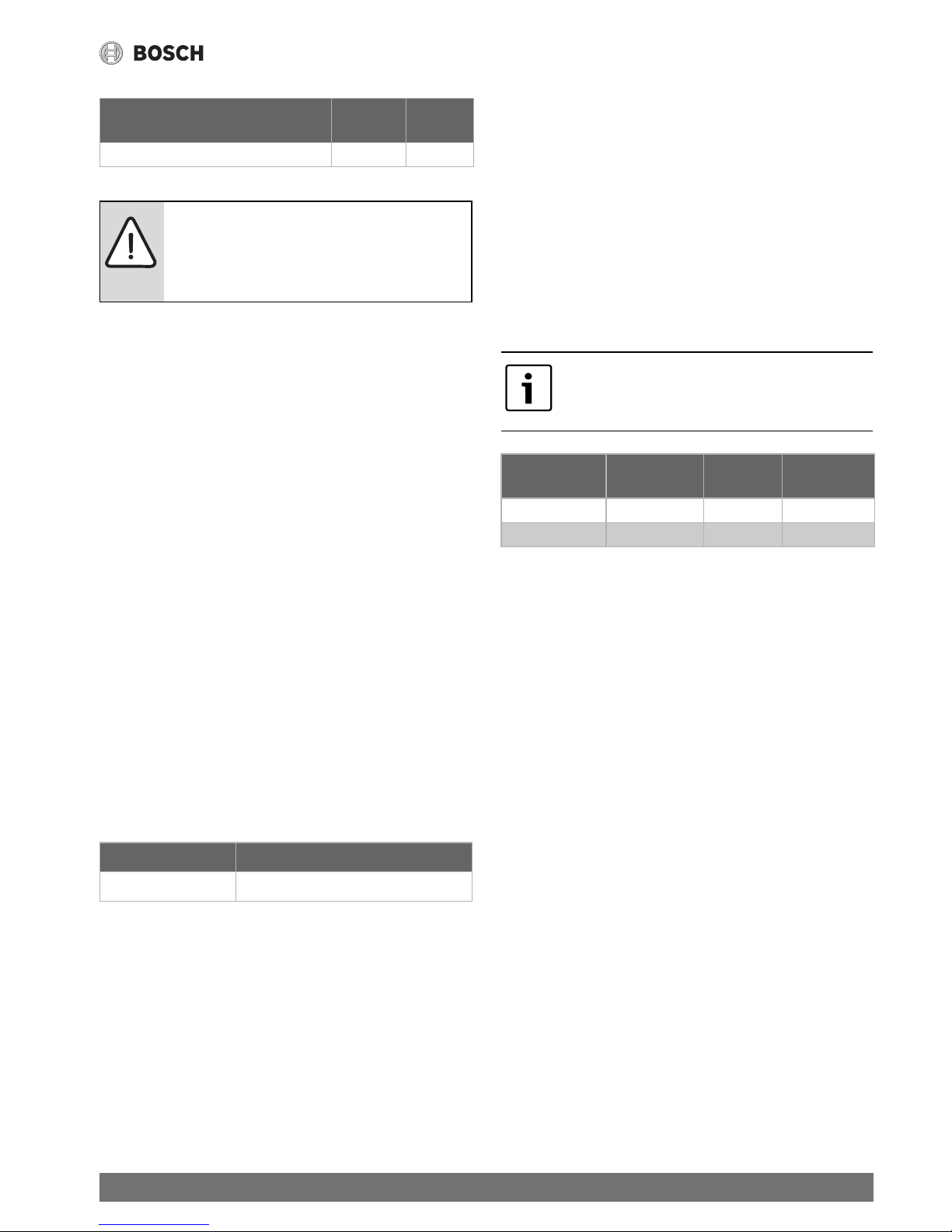

Solar system (thermosiphon)

Fig. 11 Solar system

[1] Cold water

[2] Water inlet

[3] Thermostatic valve

[4] Expansion vessel

[5] Safety assembly

5.1 Important information

▶ Prior to installation, consult your gas supplier about wall-

mounted gas boilers and ventilation at the installation

location, and also observe all the relevant standards.

Water quality

The device is used for DHW heating for domestic purposes in

accordance with the relevant regulations. Use of a water

treatment system is recommended in areas with a high level of

water hardness. The water parameters, which have an effect on

limescale, must generally comply with the values given in

Tab. 12.

Never use aggressive or corrosive cleaning

agents.

DANGER: Risk of explosion!

▶ Always close the gas isolator prior to

commencing any work on gas-carrying

components.

The installation, electrical connection, gas

connection and the connection of the air

suction and flue pipes, as well as the initial

commissioning, must only be carried out by

approved contractors.

The device may only be used in the countries

that are given on the data plate.

NOTICE: Damage to the device!

Leaking connections.

▶ Do not put the device down on the floor

with the connections facing

downwards, so that the metal threads

are not damaged.

NOTICE: Appliance malfunction!

▶ Always place the appliance front cover

after installation or after maintenance

work.

CAUTION:

▶ The water inlet temperature for the

device must not exceed 60 °C.

▶ If the water inlet temperature reaches

higher values, a 3-way valve or a

thermostatic valve (set for values below

60 °C) must be fitted upstream of the

device.

▶ In the case of solar systems, ensure that

the system has an expansion vessel.

In the case of water outlet temperatures

above 45 °C, the use of a decalcification

system is recommended.

2

2

1

3

6720608999-11.6V

T

5

4

17

Installation (only for approved contractors)

Therm 4000 S – 6 720 815 298 (2017/05)

5.2 Selecting the installation location

5.2.1 Regulations for the installation location

General notes

▶ Observe country-specific requirements.

▶ Never install the instantaneous water heater above a heat

source.

▶ Maintain the minimum clearances specified in Fig. 12.

▶ Never install the device in rooms, where the temperature

can fall below freezing point (0 °C). When there is a danger

of frost, switch the device OFF and drain it ( Fig. 10).

-or-

▶ Installing frost protection accessories.

▶ It must be ensured that at the installation location there is a

socket available, which is easily accessible after the

instantaneous water heater has been installed.

Type B devices

▶ Only install the device in rooms with a minimum size of

8m

3

. The furniture should not comprise more than 2 m3.

Air supply (Type B devices)

Depending on the type of device, the location intended for the

installation of the device must have the area for air supply that

is listed in the table.

In addition to the above minimum requirements, countryspecific requirements must also be observed.

Combustion air

The air grille for the air suction must be located in a well

ventilated room.

Keep the supply of combustion air free of corrosive substances

to prevent corrosion.

Corrosive substances include halogenated hydrocarbons

which contain chlorine and fluoride compounds. These could

be contained in, for example, solvents, paints, adhesives,

propellants and domestic cleaning agents.

If these conditions cannot be met, another location must be

selected for the air supply.

5.2.2 Total length of the flue system (Type C devices)

The total length of the flue system must not exceed the values

given in Tabs. 10 and 11, and it must not be smaller than the

values (Lmin) given in Tab. 14.

The equivalent length (Leq) must be taken into account for

each accessory used, when determining the overall length of

the system.

Surface temperature

The maximum surface temperature of the device is less than

85 °C. In accordance with TRGI or TRF, it is not therefore

necessary to observe safety clearances for combustible

construction materials and installed furniture. Country-specific

guidelines must be observed.

5.3 Minimum clearances

When selecting the installation location for the device, the

following restrictions must be observed:

▶ Maximum clearance for all protruding parts, such as hoses,

pipes etc.

▶ Ensure easy accessibility for maintenance and observe the

minimum clearances shown in Fig. 12.

TDS (Total dissolved solids) (mg/l) Hardness

(mg/l)

PH

0 - 600 0 - 180 6.5 - 9.0

Table 12

NOTICE: Damage to the device!

If these values are not observed, it can result in

partial blockage and faster ageing of the

internal body of the device.

Device Minimum effective area

GWH12... 60 cm

2

Table 13 Effective area for the air supply

If the flue gas routing is horizontal, the first

bend after the outlet from the device must

not be taken into account for the calculation.

Ø Accessory

part

Leq Lmin

Ø 80 90 ° bend 1.5 m 0.5 m

Ø 60/100 90 ° bend 2m 0.375 m

Table 14 Equivalent lengths

18

Installation (only for approved contractors)

Therm 4000 S – 6 720 815 298 (2017/05)

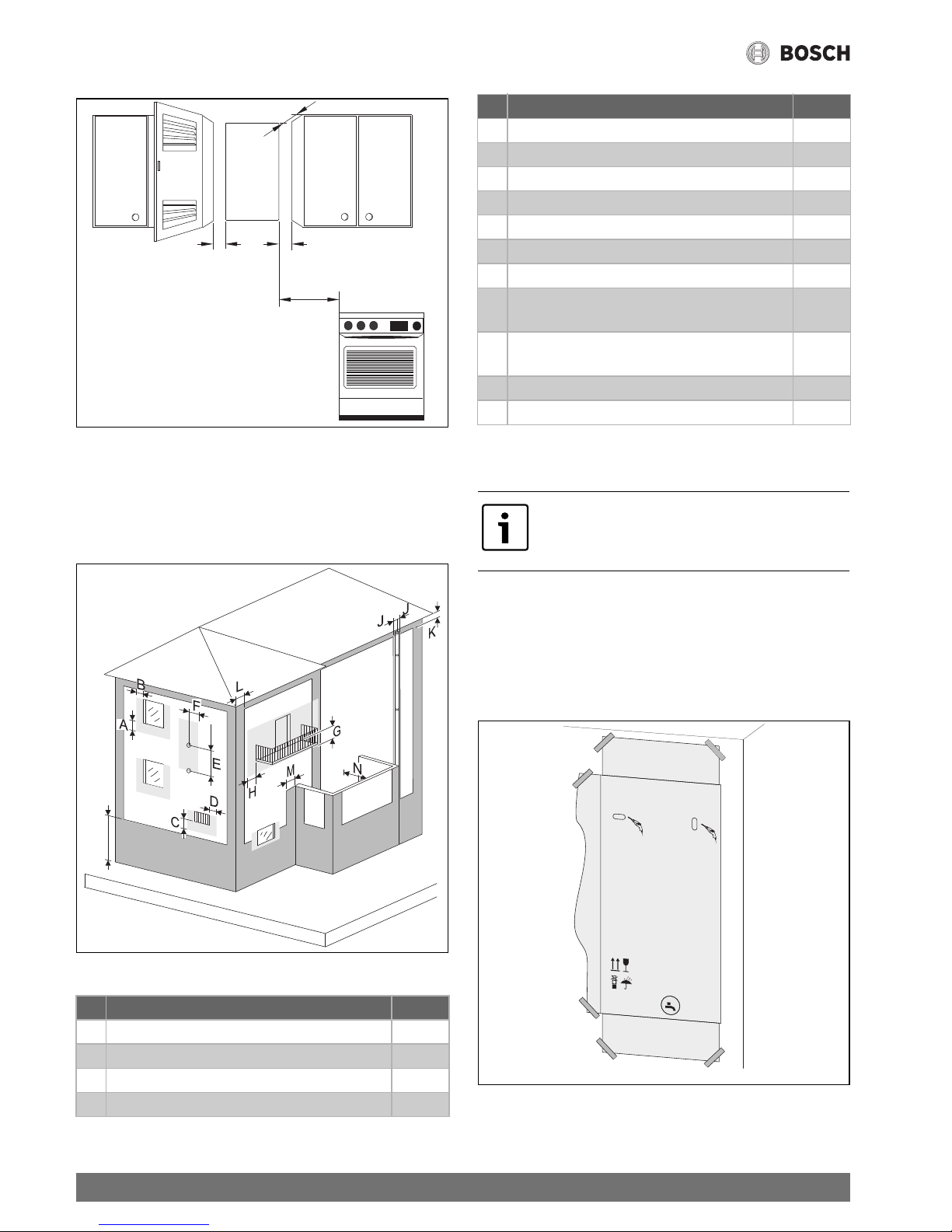

Fig. 12 Minimum clearances

[A] At the side 1cm

[B] 40 cm

[C] At the front 2cm

Minimum clearances for the flues

Fig. 13 Minimum clearances for the flues

5.4 Fitting the wall mounting bracket

No special wall protection is required. The wall must be even

and with sufficient load-bearing capacity to hold the weight of

the device.

▶ Remove the device from the packaging.

▶ Fasten the packaging to the wall to mark the position of the

holes.

Fig. 14 Mounting template

▶ Remove the mounting template from the wall.

Minimum clearances for the flues (mm)

A Below a window 600

B Beside a window 400

C Below an air inlet or outlet opening 600

D Beside an air inlet or outlet opening 600

Table 15

C

AA

B

6720804089-14.1V

I

6720806426-05.2V

E Vertical clearance between two flues 1 500

F Horizontal clearance between two flues 600

G Below a balcony 300

H Beside a balcony 1 000

I To the floor or another floor of the building 2 200

J To vertically or horizontally running flues 300

K Below the roof edge 300

L To the wall / internal corner / external corner in

the case of buildings without windows

300

M To the wall / internal corner / external corner in

the case of buildings with windows

1 000

N To the front wall with windows 3 000

N To the front wall without windows 2 000

Prior to fitting the wall mounting bracket,

check whether the connections for water,

gas and flue accessories are available.

Minimum clearances for the flues (mm)

Table 15

Ø8mmØ

8

mm

Ø8mmØ

8

mm

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

c

s

lt

l

v

p

l

e

n

d

z

e

s

n

l

m

a

p

t

d

e

f

r

i

t

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Pe

d

in

s

t

a

la

c

řč

řš

ě

ňš

ě

ř

šm

o

n

t

u

o

ja

n

t

p

e

rs

k

a

it

y

ti

m

o

n

ta

v

im

o

in

s

tr

u

k

c

i

j

ą!

šžp

e

r

s

k

a

ity

t

i

im

o

in

s

t

r

u

k

c

ij

ą!

žąą

ā

ž

a

s

iz

la

s

īt ža

s

ža s

iz

la

s

š

ādī

š

a

n

a

s

t

e

lp

a

i

j

ān

o

d

r

o

šin

a

v

ēd

in

ā

š

a

n

a

s

p

r

a

s

īb

a

s

!

ćę

ćęł

żłć ą

í

p

ro

s

tu

d

u

jte

in

s

ta

la

n

í

n

á

v

o

d

!

Pe

d

s

p

u

tn

í

m

p

r

o

s

tu

d

u

jt

e

n

á

v

o

d

p

r

o

o

b

s

lu

h

u

!

M

ís

tn

o

s

t

in

s

t

a

la

c

e

m

u

s

í

s

p

l

o

v

a

t

p

o

d

m

ín

k

y

p

r

o

z

a

ji

tn

í

p

ív

o

d

u

s

p

a

lo

v

a

n

é

h

o

v

z

d

u

c

h

u

!

P

r

ie

P

r

ie

p

a

le

id

ia

n

t

n

a

u

d

o

j

P

a

ta

lp

o

je

,

k

u

r

io

je

d

irb

s

r

e

n

g

in

y

s

,

u

tik

r

in

t

i

r

e

ik

ia

m

v

e

n

t

ilia

c

ij

!

P

ir

m

s

m

o

n

t

m

o

n

t

in

s

t

r

u

k

c

iju

!

li

e

to

a

n

a

s

in

s

t

r

u

k

c

iju

!

U

z

s

t

Vo

o

r

h

e

t

in

s

ta

lle

re

n

,

in

s

ta

lla

t

ie

v

o

o

r

s

c

h

r

if

t

d

o

o

r

le

z

e

n

!

Vo

o

r

h

e

t

in

b

e

d

r

ijft

n

e

m

e

n

,

b

e

d

ie

n

in

g

s

v

o

o

r

s

c

h

r

ift

d

o

o

rle

z

e

n

!

D

e

o

p

s

t

e

llin

g

s

r

u

im

t

e

d

ie

n

t

a

a

n

d

e

d

a

a

v

o

o

r

g

e

ld

e

n

d

e

v

o

o

r

s

c

h

rif

te

n

t

e

v

o

ld

o

e

n

!

P

r

z

e

d

z

a

in

s

t

a

lo

w

a

n

ie

m

p

r

z

e

c

z

y

ta

in

s

t

r

u

k

c

j

in

s

ta

la

c

ji!

P

rz

e

d

u

ru

c

h

o

m

ie

n

ie

m

p

r

z

e

c

z

y

ta

in

s

tr

u

k

c

j

o

b

s

u

g

i!

M

ie

js

c

e

m

o

n

t

a

u

m

u

s

i

s

p

e

n

ia

w

y

m

a

g

a

n

ia

d

o

t

y

c

z

c

e

w

e

n

ty

la

c

ji!

į

ā

āīt

R

e

a

d

in

s

ta

lla

t

io

n

m

a

n

u

a

l

p

r

io

r

to

in

s

ta

lla

tio

n

o

f

th

is

u

n

it

!

R

e

a

d

u

s

e

r

m

a

n

u

a

l

b

e

fo

r

e

p

u

tt

in

g

th

is

u

n

it

in

o

p

e

r

a

tio

n

!

T

h

e

in

s

ta

lla

t

io

n

ro

o

m

m

u

s

t

fu

lf

ill

th

e

v

e

n

tila

tio

n

r

e

q

u

ir

e

m

e

n

ts

!

L

e

e

r

la

s

in

s

tr

u

c

c

io

n

e

s

te

c

n

ic

a

s

a

n

t

e

s

d

e

in

s

t

a

la

r

e

l

a

p

a

r

a

to

!

L

e

e

r

la

s

in

s

t

r

u

c

c

io

n

e

s

p

a

r

a

e

l

u

s

u

a

r

io

a

n

t

e

s

d

e

p

o

n

e

r

e

n

f

u

n

c

io

n

a

m

ie

n

t

o

e

l

a

p

a

r

a

to

!

E

l

c

a

le

n

ta

d

o

r

s

o

lo

p

u

e

d

e

s

e

r

in

s

t

a

la

d

o

e

n

u

n

lo

c

a

l

q

u

e

c

u

m

p

la

lo

s

r

e

q

u

is

ito

s

d

e

v

e

n

t

ila

c

io

n

a

d

e

c

u

a

d

o

s

!

P

ir

m

s

ie

d

a

r

b

in

n

a

L

e

r

a

s

in

s

t

r

u

ç

õ

e

s

d

e

in

s

ta

la

ç

ã

o

a

n

t

e

s

d

e

in

s

t

a

la

r

o

a

p

a

r

e

lh

o

!

A

n

te

s

d

e

c

o

lo

c

a

r

o

a

p

a

r

e

lh

o

e

m

f

u

n

c

io

n

a

m

e

n

to

,

le

r

a

s

in

s

tr

u

ç

õ

e

s

d

e

u

tiliz

a

ç

ã

o

!

O

lo

c

a

l

d

e

in

s

t

a

la

ç

ã

o

d

e

v

e

c

u

m

p

r

ir

a

s

e

x

ig

ê

n

c

ia

s

d

e

v

e

n

t

ila

ç

ã

o

!

Vo

r

In

s

ta

lla

tio

n

In

s

ta

lla

t

io

n

s

a

n

le

it

u

n

g

le

s

e

n

!

Vo

r

I

n

b

e

t

r

ie

b

n

a

h

m

e

B

e

d

ie

n

u

n

g

s

a

n

le

itu

n

g

le

s

e

n

!

D

e

r

A

u

fs

t

e

llr

a

u

m

m

u

s

s

d

ie

B

e

lu

ftu

n

g

s

a

n

fo

r

d

e

ru

n

g

e

n

e

rfu

lle

n

!

L

ir

e

la

n

o

t

ic

e

t

e

c

h

n

iq

u

e

a

v

a

n

t

d

'in

s

ta

lle

r

l

'a

p

p

a

r

e

il!

L

ir

e

la

n

o

t

ic

e

d

'u

til

is

a

tio

n

a

v

a

n

t

la

m

is

e

e

n

fo

n

c

tio

n

n

e

m

e

n

t

d

e

l

'a

p

p

a

r

e

il!

L

e

lie

u

d

'in

s

ta

lla

tio

n

d

o

it

r

e

p

o

n

d

r

e

a

u

x

p

r

e

s

c

r

ip

t

io

n

s

d

e

v

e

n

tila

t!

P

r

im

a

d

i

e

f

fe

tt

u

a

re

l

'in

s

ta

lla

z

io

n

e

d

e

ll

'a

p

p

a

r

e

c

c

h

io

le

g

g

e

r

e

le

is

t

r

u

z

io

n

i

d

i

in

s

t

a

lla

z

io

n

e

!

P

rim

a

d

i

e

f

f

e

tt

u

a

r

e

la

m

e

s

s

a

in

s

e

r

v

iz

io

le

g

g

e

re

le

is

tr

u

z

io

n

i

d

'u

s

o

!

L

e

c

a

r

a

t

te

r

is

t

ic

h

e

d

i

v

e

n

til

a

z

io

n

e

d

e

l

lo

c

a

le

n

e

l

q

u

a

le

e

in

s

t

a

lla

t

o

l

'a

p

p

a

r

e

c

c

h

io

d

e

v

o

n

o

e

s

s

e

r

e

c

o

n

f

o

r

m

i

a

lle

n

o

r

m

a

tiv

e

v

ig

e

n

ti!

ز

ﺎﻬ

ﺟ

ﻟ

ﻛ

ﺗ

ﺑﻗ

ﺗﻛ

ﻟ

ﻗ

ﺟ

ز

ﺎﻬ

ﺟ

ﻟ

ﻐ

ﺷ

ﺗ

ﺑﻗ

ﺎﻣ

ﻌ

ﺗﺳ

ﻻ

ﺔ

ﻔ

ﻛ

ﻗ

ﺟ

ز

ﺔ

ﻬ

ﺗﻟ

ﺷ

ﻟ

ﺟ

ﺗﺳ

ﺟ

ز

ﺎﻬ

ﺟ

ﻟ

ﻛ

ﺗ

ﺎﻛ

ﻣ

ﺔ

ﻟﻵ

ﻛ

ﺗ

ﺑﻗ

ﻗ

ﻘ

ﺗﻟ

ت

ﺎﻣ

ﻠﻌ

ﺗﻟ

ﻗ

ﻰ

ﺟ

ﺔ

ﺔ

ﻟﻵ

ﻐ

ﺷ

ﺗ

ﺑﻗ

ﺎﻣ

ﻌ

ﺗ

ﺳ

ﻻ

ت

ﺎﻣ

ﻠﻌ

ﺗ

ﻗ

ﻰ

ﺟ

ﻟﺔ

ﻛ

ﺗﻟ

ﺎﻛ

ﻣ

ﻲ

ﻓ

ﺔ

ﻬ

ﺗﻠﻟ

ﺔ

ﻣ

ز

ﻼ

ﻟ

ﺷ

ﻟ

ﻛ

ﻓ

ﺗ

ﺟ

3

6720804089-12.1V

Loading...

Loading...