Siemens TIA Portal Module 090-020 User Manual

SCE Training Curriculum

for Integrated Automation Solutions Totally Integrated Automation (TIA)

Siemens Automation Cooperates with Education

TIA Portal Module 090-020

WinCC Runtime Advanced Services

SCE Training Curriculum |

Page 1 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services

Industry Sector, IA&DT

Suitable SCE trainer packages for these training curriculums

SIMATIC controllers

SIMATIC S7-300 with CPU 314C-2PN/DP

Order no.: 6ES7314-6EH04-4AB3

SIMATIC S7-300 with CPU 314C-2PN/DP (upgrade)

Order no.: 6ES7314-6EH04-4AB4

SIMATIC S7-300 with CPU 315F-2PN/DP

Order no.: ES7315-2FH14-4AB1

SIMATIC ET 200S with CPU IM151-8 F PN/DP

Order no.: 6ES7151-8FB00-4AB1

SIMATIC HMI

SIMATIC TP700 Comfort Panel - Color

Order no.: 6AV2133-4AF00-0AA0

SIMATIC STEP 7 software for training

SIMATIC STEP 7 Professional V11 - Single license

Order no.: 6ES7822-1CC01-4YA5

SIMATIC STEP 7 Professional V11 - Classroom license (up to 12 users)

Order no.: 6ES7822-1AA01-4YA5

SIMATIC STEP 7 Professional V11 - Upgrade license (up to 12 users)

Order no.: 6ES7822-1AA01-4YE5

SIMATIC STEP 7 Professional V11 - Student license (up to 20 users)

Order no.: 6ES7822-1AC01-4YA5

Please note that these trainer packages may be replaced by successor trainer packages.

An overview of the currently available SCE packages is provided under: siemens.com/sce/tp

Advanced training

Please get in touch with your regional SCE contact for information on regional Siemens SCE advanced training siemens.com/sce/contact

Additional information regarding SCE

siemens.com/sce

Information regarding usage

This SCE training curriculum for the end-to-end automation solution Totally Integrated Automation (TIA) was prepared for the program "Siemens Automation Cooperates with Education (SCE)" specifically for educational purposes for public educational institutions and R&D facilities. Siemens AG does not make any guarantee regarding its contents.

This document may only be used for initial training on Siemens products/systems. That is, it may be copied in whole or in part and handed out to participants for use within the context of their education. Distribution and reproduction of this training curriculums and disclosure of its contents are permitted within public education and further education institutions for educational purposes.

Any exceptions require written consent from the Siemens AG contact person: Mr. Roland Scheuerer roland.scheuerer@siemens.com.

Offenders will be liable for damages. All rights reserved, including those relating to translation and in particular those rights created as a result of a patent being granted or utility model being registered.

Use for industry customers is expressly prohibited. We do not consent to any commercial use of the training curriculum.

We would like to thank Michael Dziallas Engineering and all those involved for their support in creating this training curriculum.

SCE Training Curriculum |

Page 2 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

|

|

Industry Sector, IA&DT |

|

|

PAGE: |

1. |

Preface.......................................................................................................................................................... |

4 |

2. |

Notes on programming the SIMATIC S7-300 ............................................................................................... |

6 |

2.1 |

SIMATIC S7-300 automation system ......................................................................................................... |

6 |

2.2 |

STEP 7 Professional V11 (TIA Portal V11) programming software ........................................................... |

6 |

2.3 |

Operator control and monitoring with WinCC ............................................................................................. |

7 |

3. |

Project description ........................................................................................................................................ |

8 |

3.1 |

Hardware configuration............................................................................................................................... |

8 |

3.2 |

Station description ...................................................................................................................................... |

9 |

3.3 |

Previous configuration .............................................................................................................................. |

10 |

3.4 |

Expanded configuration and task ............................................................................................................. |

10 |

4. |

Inserting an Operator PC in the Ink Mixing Station project ......................................................................... |

11 |

4.1 |

Loading and re-saving a project template ................................................................................................ |

12 |

5. |

Configuring on the operator PC .................................................................................................................. |

21 |

5.1 |

SIMATIC HMI HTTP connection ................................................................................................................ |

22 |

5.2 |

Tags on the PC-System_Advanced.......................................................................................................... |

24 |

5.3 |

Configuring the overview screen .............................................................................................................. |

25 |

5.4 |

Starting the PC-System_Advanced in Runtime ........................................................................................ |

29 |

5.5 |

Trend view of the ink mixing station ......................................................................................................... |

30 |

5.6 |

Trend view in runtime ............................................................................................................................... |

35 |

6. |

Remote Control of the TP700 Comfort with Sm@rtOptions ....................................................................... |

36 |

6.1 |

"Sm@rtServer" Runtime Service .............................................................................................................. |

37 |

6.2 |

Sm@rtClient application on the PC .......................................................................................................... |

38 |

6.3 |

Sm@rtClient via Web browser ................................................................................................................. |

40 |

7. |

Sm@art Options on the Operator_PC-System........................................................................................... |

43 |

7.1 |

Configuring the Sm@rtClient view............................................................................................................ |

43 |

7.2 |

Sm@artClient view in Runtime ................................................................................................................. |

45 |

7.3 |

Configuring the HTML browser................................................................................................................. |

46 |

7.4 |

HTML browser in Runtime ........................................................................................................................ |

48 |

SCE Training Curriculum |

Page 3 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

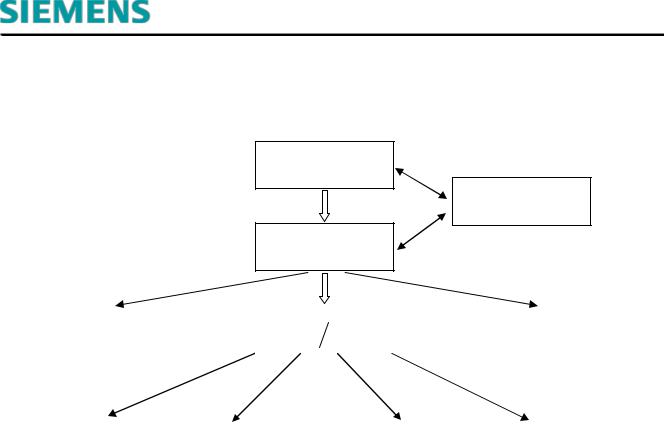

1.Preface

Regarding its content, module 090-020 is part of the 'Process visualization' training unit and demonstrates how to configure WinCC visualization between the TP700 Panel and a PC system.

Basics of PLC programming

Module 10, Module 20

Plant simulation with

SIMIT Module 150

Advanced functions for

PLC programming

Module 30

|

|

|

|

|

|

Other programming |

|

PROFIBUS |

PROFINET |

|

|

languages |

|

|

AS interface |

||

|

Module 60 |

Module 70 |

|

||

Module 40 |

|

|

Module 50 |

||

|

|

|

|

||

|

|

|

|

|

|

Safety technology |

|

Sensor technology |

|

Process visualization |

|

Drive technology |

Module 80 |

|

Module 110 |

|

(HMI) Module 90 |

|

Module 100 |

|

|

|

|

|

|

|

Learning objective:

This module describes the runtime services of the TP700 Panel and other functions of the WinCC

Advanced V11 software.

Typical tasks are performed at a sample plant.

"Open" and "Save as" of a STEP 7 project

Inserting an HMI station

Runtime services of the TP700 Comfort Panel

Configuring display and operating objects on the operator PC

HMI HTTP protocol

Trend view

Sm@rt Options

Requirements:

To successfully work through this module, the following knowledge is required:

Proficiency in working with Windows

Basics of PLC programming with the TIA Portal

(for example, module 020-010 – 'Startup' Programming the SIMATIC S7-300 with TIA Portal V11)

Blocks for SIMATIC S7-300

(for example, Module 030-010 – Block Types for SIMATIC S7-300)

WinCC Advanced with Runtime and TP700 Comfort Panel (e.g. Module 090-010 – S7-300 HMI TP700)

SCE Training Curriculum |

Page 4 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

Required hardware and software

1PC Pentium 4, 1.7 GHz 1 (XP) – 2 (Vista) GB RAM, approx. 2 GB of free hard disk space Operating system Windows XP Professional SP3 / Windows 7 Professional / Windows 7 Enterprise / Windows 7 Ultimate / Windows 2003 Server R2 / Windows Server 2008 Premium SP1, Business SP1, Ultimate SP1

2Software: STEP 7 Professional V11 SP2 (Totally Integrated Automation (TIA) Portal V11) and WinCC Advanced V11 SP2

3Ethernet connection between the PC and CPU 315F-2 PN/DP

4SIMATIC S7-300 PLC, e.g., CPU 315F-2PN/DP with 16DI/16DO signal module. The inputs must be fed out to a control panel.

5SIMATIC HMI TP700 Comfort Panel

|

|

|

|

|

|

|

|

|

|

2 STEP 7 Professional and |

|

|

|

|

|

|

|

|

|

|

WinCC Advanced V11 |

|

|

1 PC |

|

|

|

(TIA Portal V11 SP2) |

||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3 Ethernet connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 S7-300 with CPU 315F-2 PN/DP

5 SIMATIC HMI TP700

Comfort Panel

SCE Training Curriculum |

Page 5 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

2.Notes on programming the SIMATIC S7-300

2.1SIMATIC S7-300 automation system

The SIMATIC S7-300 automation system is a modular microcontroller system for the low and medium performance range.

A comprehensive range of modules is available to optimally adapt the system to the automation task The S7 controller consists of a power supply, a CPU, and input and output modules for digital and analog signals.

If necessary, communication processors and function modules are also used for special tasks such as stepper motor control.

The programmable logic controller (PLC) uses the S7 program to monitor and control a machine or a process. The S7 program scans the I/O modules via input addresses (%I) and addresses their output addresses (%Q).

The system is programmed with the STEP 7 software.

2.2STEP 7 Professional V11 (TIA Portal V11) programming software

The STEP 7 Professional V11 (TIA Portal V11) software is the programming tool for the following automation systems:

-SIMATIC S7-1200

-SIMATIC S7-300

-SIMATIC S7-400

-SIMATIC WinAC

STEP 7 Professional V11 provides the following functions for plant automation:

-Configuration and parameter assignment of the hardware

-Specification of the communication

-Programming

-Testing, commissioning, and servicing with operational/diagnostic functions

-Documentation

-Creation of visualizations for SIMATIC Basic Panels using the integrated WinCC Basic software.

-Visualization solutions for PCs and other panels can also be created with other WinCC software packages

Support is provided for all functions in a comprehensive online help system.

SCE Training Curriculum |

Page 6 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

2.3Operator control and monitoring with WinCC

System description

Since processes are becoming more and more multi-layered and the demands regarding the functionality of machines and plants are rising, the operator needs a powerful tool to control and monitor production systems. An HMI system (Human Machine Interface) represents the interface between the human being (operator) and the process (machine/system). The controller actually controls the process. That is, there is an interface between the operator and WinCC (on the HMI device) and an interface between WinCC and the controller.

WinCC is the software to handle all necessary configuring tasks. WinCC Advanced V11 Simulation is the software for process visualization.

WinCC handles the following tasks:

• Representing the process

The process is mapped to the HMI device. If, for example, a state changes in the process, the display is updated on the HMI device.

• Operating the process

The operator can use a graphic user interface to operate the process. The operator, for example, can enter a setpoint for the controller, or start a motor.

• Generating alarms

If critical process states occur in the process, an alarm is triggered automatically; for example, if a specified limit is exceeded.

• Logging process values and alarms

The HMI system is able to log alarms and process values. Thus, the process can be documented and older production data can later be accessed.

• Documenting process values and alarms

Alarms and process values can be read out by the HMI system as a log. After a shift, for example, you can have the production data read out.

• Managing process parameters and machine parameters

The HMI system is able to store parameters for processes and machines in recipes. These parameters can, for example, be transferred from the HMI device to the controller in one step in order to change production to another product type.

SCE Training Curriculum |

Page 7 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

3.Project description

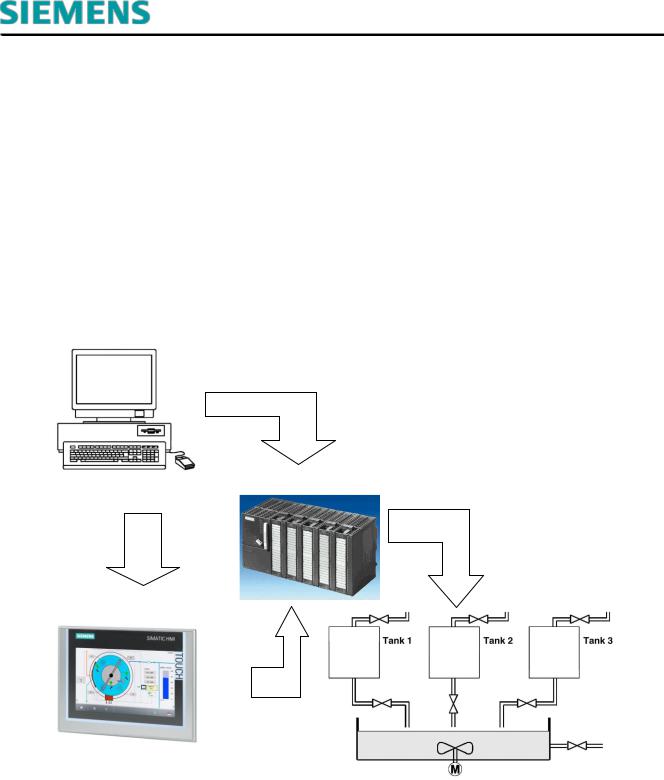

3.1Hardware configuration

In our sample program for an ink mixing station we use a programming device with WinCC Advanced V11 and the WinCC Advanced V11 Runtime.

The ink mixing station is controlled using a SIMATIC S7-300. The operator uses a Touch Panel (TP700) to operate the process via the graphical interface.

The operator, for example, can enter a setpoint for the controller, or start a motor.

The programming device, the SIMATIC S7-300 controller and the TP700 operator panel are interconnected via the Ethernet interface.

The ink mixing station is connected to the controller via digital and analog inputs and outputs.

PC

PC for configuration

Tank 1 |

|

Tank 2 |

|

Tank 3 |

TP700 as HMI device

SCE Training Curriculum |

Page 8 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

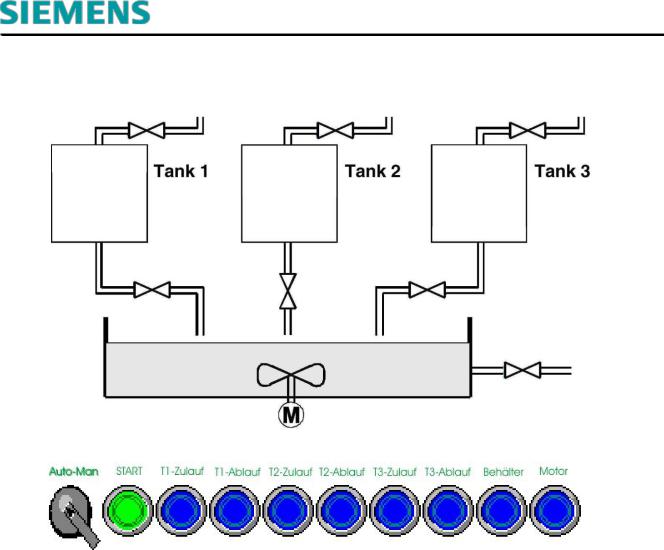

3.2Station description

Tank 1 |

|

Tank 2 |

|

Tank 3 |

|

|

|

|

|

Auto-Man |

START T1 supply |

T1 drain |

T2 supply |

T2 drain T3 supply |

T3 drain |

Container Motor |

An ink mixing station is controlled using a SIMATIC S7-300 in automatic or in manual mode. In the 'Automatic' mode, the three tanks are filled using a two-point control mechanism.

At minimum fill level the supply valve of the corresponding tank is opened automatically and only closed once the maximum fill level is reached.

The preset program is run when the Start button is pressed.

First, the drain valves are opened and the corresponding target quantities are filled into the container from the separate tanks.

After closing the drain valves, the mixer motor is started.

At the end of the mixing period and after a short rest period, the drain valve of the container opens and the finished color mixture is drained.

The start function is enabled as soon as the container is empty. The start button lamp is lit and a new color mixture can be started.

In "Manual" mode, the automatic drain is terminated; all valves and the mixer motor can then be operated manually.

The lamps in the buttons for manual operation are lit.

SCE Training Curriculum |

Page 9 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

3.3Previous configuration

The following requirements are to be met with the help of the Panel.

-It is now possible to operate the ink mixing station via the Panel as well.

-The fill levels of the tanks and of the container are to be indicated as bars and also as numerical value.

-The movement of the mixer motor is to be represented graphically.

-The target quantities are to be entered using the panel.

-The minimum and maximum fill levels of the three tanks can be specified on separate tank screens.

-The Panel can also be used to change operating modes.

-The finished color mixtures are saved as recipe in the Panel.

-The fill levels are monitored and alarms are generated in the event of danger.

-A password must be entered in order to operate the ink mixing station.

-The SIMATIC S7-300 controller communicates with the TP700 Comfort Panel and monitors it via PROFINET.

3.4Expanded configuration and task

On the programming device, the STEP 7 Professional V11 configuration software and WinCC Advanced V11 are used to create an additional process visualization for an operator PC.

The operator PC communicates with the operator panel via tags using an HMI HTTP connection. The S7-300 controller is accessed solely via the operator panel.

The value of a tag in the memory area (address) of the controller is read by the operator panel and transferred via an HMI HTTP connection to the operator PC.

The ink mixing station is remotely monitored and remotely operated using the visualization and the operating screens.

SCE Training Curriculum |

Page 10 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

4.Inserting an Operator PC in the Ink Mixing Station project

The software is used for project management and programming

'Totally Integrated Automation Portal V11'.

Components such as control, visualization, and networking of the automation solution are created, assigned parameters, and programmed here using a standard interface.

Online tools are available for the error diagnostics.

In the following section a project is to be opened for SIMATIC S7-300, the project is to be stored under a different name and adapted to the new requirements.

The central tool is the 'TIA Portal V11', which is opened here by double-clicking.

SCE Training Curriculum |

Page 11 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

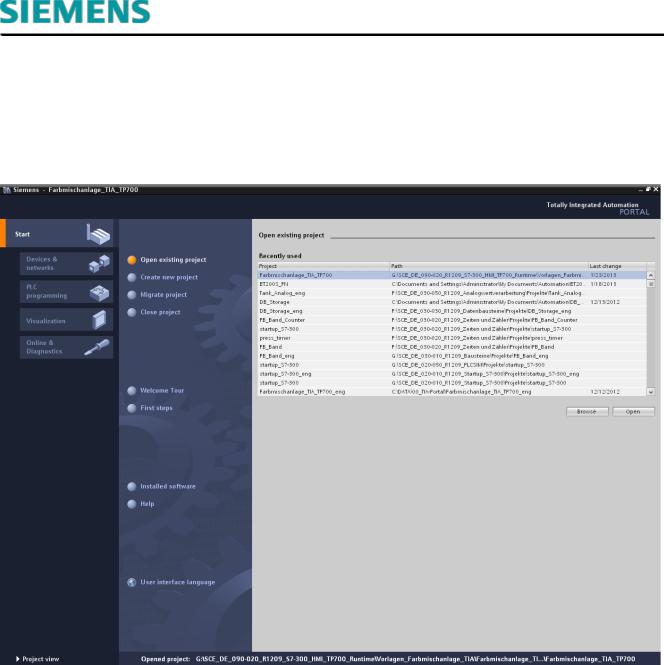

4.1Loading and re-saving a project template

The project "Ink mixing station_TIA_TP700'" from Module 090-010 is now opened as a template for

this program.

SCE Training Curriculum |

Page 12 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

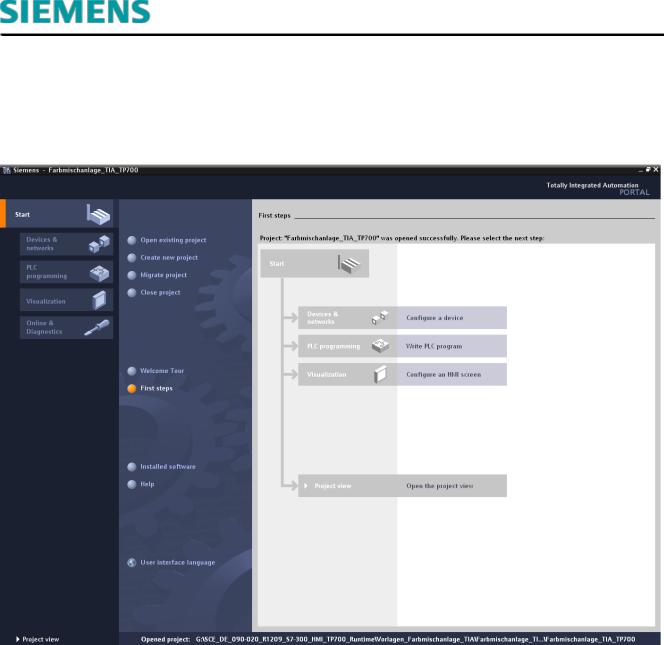

'First steps' for configuring are now suggested.

Click 'Open project view'.

SCE Training Curriculum |

Page 13 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

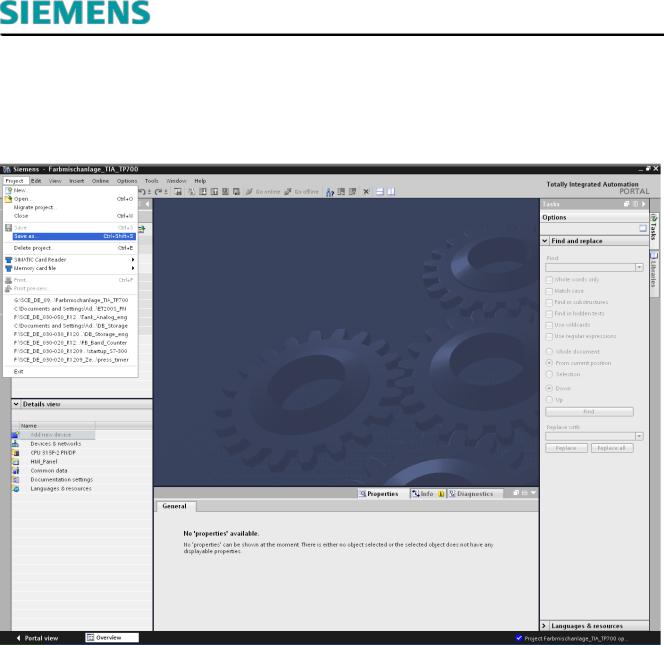

Start by saving the project under a different name.

In the Project menu click "Save as".

SCE Training Curriculum |

Page 14 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Industry Sector, IA&DT

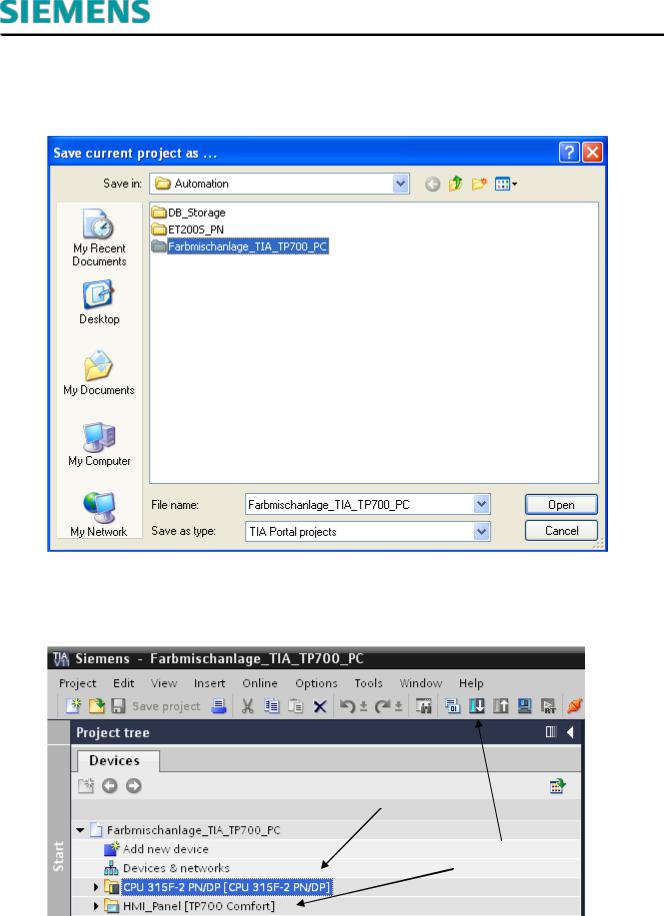

'Save' the project under the new name 'Ink mixing station_TIA_TP700_PC'.

Load the project to the S7-300 controller and to the HMI_Panel [TP700 Comfort].

SCE Training Curriculum |

Page 15 of 48 |

To be used only at Educational and R&D Facilities |

TIA Portal Module 090-020, Edition 03/2013 |

|

Unrestricted / © Siemens AG 2013. All Rights Reserved |

SCE_EN_090-020_R1209_ WinCC Advanced Runtime Services |

|

|

|

|

|

Loading...

Loading...