Siemens UL1066, UL 489 User Manual

WL Trip Unit, MODBUS Communication

and Electronic Accessories Application

Guide

powerful ideas

RELIABLE SOLUTIONS

WL Low Voltage Power

Circuit Breaker

ANSI / UL1066 & UL 489

ANSI / UL1066 & UL 489

Global network of innovation

Communication-capable Circuit Breakers

WL Circuit Breaker

Technological Leader Among Circuit Breakers: WL Communication

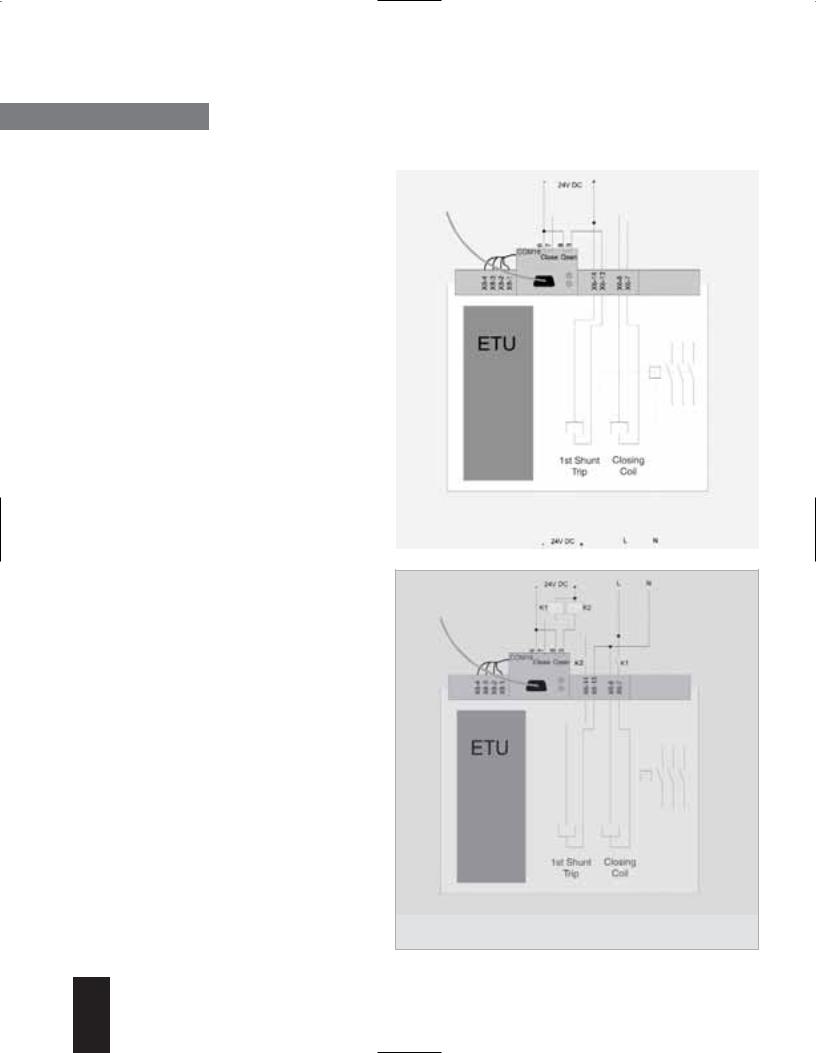

Connection Diagram |

|

|

1 Breaker Data Adapter |

13 |

13 |

(BDA) |

|

|

2Browser-capable input and output device (e.g. notebook)

3 WL Circuit Breaker

4COM16 MODBUS module or COM 15 PROFIBUS module

5Breaker Status Sensor (BSS)

6 |

Electronic Trip Unit |

|

|

|

|

|

7 |

Metering function PLUS |

15 |

||||

8 |

Zone Selective |

14 |

|

|

|

|

|

Interlocking (ZSI) module |

|

|

|

|

|

9 |

Digital output module |

4 |

|

|

|

|

|

|

|

|

|||

|

with relay or optocoupler |

5 |

|

|

|

|

|

|

|

|

|

||

|

outputs |

2 |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

10 |

Digital output module |

7 |

|

|

|

|

|

|

|

||||

|

with relay or optocoupler |

|

|

|

|

|

|

outputs, remotely |

|

|

|

|

|

|

configurable |

|

|

|

|

|

11Analog output module

12Digital input module

13WinPM.Net on PC

14PLC (e.g. SIMATIC S7)

15BDA Plus

* The Siemens BDA Plus or meters, 9330, 9350, 95/9600 can be used as a gateway to enable Ethernet communication to the WL Circuit Breaker.

The 9500 meter can also be used as a central display unit for multiple WL breakers with metering capability.

Communication-capable

Circuit Breaker

Introduction and Overview

WL Circuit Breaker

MODBUS Profile for WL Circuit Breaker

Breaker Data Adapter (BDA)

Breaker Data Adapter Plus (BDA Plus)

1

2

3

4

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle and are marked as follows according to the level of danger. This equipment contains hazardous voltages. Death, serious personal injury or property damage can result if safety instructions are not followed.

Only qualified personnel should work on or around this equipment after becoming thoroughly familiar with all warnings, safety notices, and maintenance procedures contained herein. The successful

and safe operation of this equipment is dependent upon proper handling, installation, operation and maintenance.

Danger

For the purpose of this manual and product labels, DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning

For the purpose of this manual and product labels, WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Caution

For the purpose of this manual and product labels, CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Attention

Draws your attention to particularly important information on the product, handling the product or to a particular part of the documentation.

Qualified Personnel

For the purpose of this manual and product labels, a qualified person is one who is familiar with the installation, construction and operation of the equipment, and the hazards involved. In addition, he or she has the following qualifications:

(a)Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in accordance with established safety practices.

(b)Is trained in the proper care and use of protective equipment, such as rubber gloves, hard hat, safety glasses or face shield, flash clothing, etc., in accordance with established safety practices.

(c)Is trained in rendering first aid.

Correct Usage

Note the following:

Warning

This device and its components may only be used for the applications described in the catalog or the technical descriptions, and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

Registered Trademarks

WinPM.Net is a registered trademark of Siemens Energy & Automation. MODBUS® is a registered trademark of MODICON. Some other designations used in these documents are also brands;

the owner's rights may be violated if they are used by third parties for their own purposes. Excel and Explorer are registered trademarks of Microsoft Corporation. Java is a registered trademark of Sun Microsystems. Netscape is a registered trademark of AOL Time Warner.

WL MODBUS Communication and Electronic Accessories • January 2005

Introduction and

Overview

1

Content of the Manual

Overview of the Bus Systems

Communicating with the Circuit Breaker

WL MODBUS Communication and Electronic Accessories • January 2005

Introduction and Overview

WL Circuit Breaker

General

This manual is aimed at those who want to find out more about the different applications of communications-capable circuit breakers in power distribution systems.

It contains a detailed guide to commissioning, operating, diagnosing and maintaining the new communications-capable WL Circuit Breaker.

Content of the Manual

Chapter 1 contains a short introduction to communications in power distribution systems, and provides an overview of the benefits and applications of communicationscapable circuit breakers. The chapter concludes with a short description of the most important communication bus systems.

Chapter 2 contains a general description of the WL Circuit Breaker. It includes information on configuration data and provides commissioning instructions.

Chapter 3 explains how the circuit breakers are integrated in a power management system and describes the supported function codes, register maps and exception codes.

WL is the first circuit breaker that can be configured, diagnosed and maintained remotely without the use of field bus systems and higher-level operator control and monitoring

systems. These procedures are carried out using the breaker data adapter (BDA), a state-of-the-art Internetcapable configuration device for circuit breakers, which is described in Chapter 4.

Introduction

The demand for communicationscapable systems, data transparency and flexibility in industrial automation systems is growing all the time. Bus systems and intelligent switchgear are vital to ensure that industrial power systems can meet these demands, since industrial production and building management are now inconceivable without communications technology.

The evermore-stringent requirements placed on the electrical and mechanical aspects of circuit breakers, the growing need for flexibility and efficiency, and increasing cost pressure and automation have contributed to the recent major innovations in circuit breaker technology. In power distribution systems, the WL Circuit Breaker uses industry-standard bus systems to transmit key information for warnings, commissioning and load shedding to a central control room. The wide range of applications ensure that these circuit breakers are more than just simple switching and protective devices.

Point-to-point communication, as well as data entry, transmission, analysis and visualization are only possible if the automation and lowvoltage switchgear technology components can be easily integrated in a communication solution to leverage the full range of functions available.

1/1

WL MODBUS Communication and Electronic Accessories • January 2005

In this way, status information, alarms, trip information and setpoints (e.g. overcurrent, phase unbalance, overvoltage) increase transparency in power distribution systems, enabling these situations to be dealt with quickly. A communication host can send short text messages to the cell phones of maintenance personnel. Prompt analysis of this data enables targeted intervention in the process and helps reduce system down time.

Information for preventive maintenance (e.g. the number of operating cycles or hours) enables timely personnel and material scheduling, which increases system availability and helps prevent sensitive system components from being damaged.

Communication helps provide rapid and targeted information on the location and cause of power failures. The cause of the fault can be determined by recording the phase currents (e.g. trip as a result of a short-circuit of 2317 A in phase L2 on 08/27/2002 at 14:27). This information can be used to quickly rectify the fault and reduces downtime for quicker recovery.

Measuring and communicating power, power factor and energy allows an even greater number of applications. The availibility of power consumption data on a targeted basis for business analysis enables power profiles to be created and costs to be clearly assigned. In this way, energy costs can be allocated and optimized by balancing the peak loads.

Introduction and Overview

WL Circuit Breakers—Modular and

Intelligent

Thousands of options with just a few components: That's the WL. A new generation of circuit breakers – from 200A to 5000A – with a modular design to support every conceivable application in power distribution systems – cost effective and flexible, its communication functionality enables it to be integrated in

system solutions.

Cost Saving

Whatever the configuration, the WL Circuit Breaker does the job where it matters. Advantages include simple retrofitting and a compact design benefiting everyone who uses WL Circuit Breakers, whether in planning, business, or whether they develop or operate switchgear systems.

Easy Planning

WL Circuit Breaker

Graphic Saving costs increases 1-1 productivity.

The WL Circuit Breaker and EasyTCC together provide a convenient software package for coordinating multiple circuit breakers.

Graphic Simplified planning every

1-2 |

step of the way. |

|

System Solutions

By integrating WL Circuit Breakers in a higher-level communication system, they can be configured via MODBUS, Ethernet or the Internet; an integrated power management system allows you to optimize power distribution across the board.

System solutions - Supports Graphic energy management through

1-3 advanced metering and communications.

1/2

WL MODBUS Communication and Electronic Accessories • January 2005

Introduction and Overview

WL Circuit Breaker

Communication Bus Systems

Communication bus systems are used to connect distribution devices with varying levels of intelligence. With their different structures and mechanisms, certain bus systems are designed for highly specific applications, while others are better suited for more open applications. The following section describes the most important bus systems used in automation and power distribution systems.

MODBUS

MODBUS is an open, serial communications protocol based on a master-slave architecture. Since it is very easy to implement on any kind of serial interface, it can be used in a wide range of applications. MODBUS comprises a master and several slaves, whereby communication is controlled exclusively by the master. MODBUS features two basic communication mechanisms:

•Question/answer (polling): The master sends an inquiry to a station and waits for a response.

•Broadcast: The master sends a command to all the network stations, which execute the command without confirmation.

The messages enable process data (input/output data) to be written to and read from the slaves either individually or in groups.

The data can either be transmitted in ASCII or as a package in RTU format. MODBUS can be used over a wide range of transmission media, normally, on an RS 485 physical bus, a twisted, shielded two-wire cable with terminating resistors.

The MODBUS protocol was originally developed for networking control systems, and is often used for connecting input/output modules to a central PLC. Due to the low transmission rate of 38.4 kBaud max., MODBUS is particularly recommended for applications with a low number of stations or low response time requirements.

1/3

WL MODBUS Communication and Electronic Accessories • January 2005

Introduction and Overview

WL Circuit Breaker

Communication Structure of the

WL Circuit Breakers

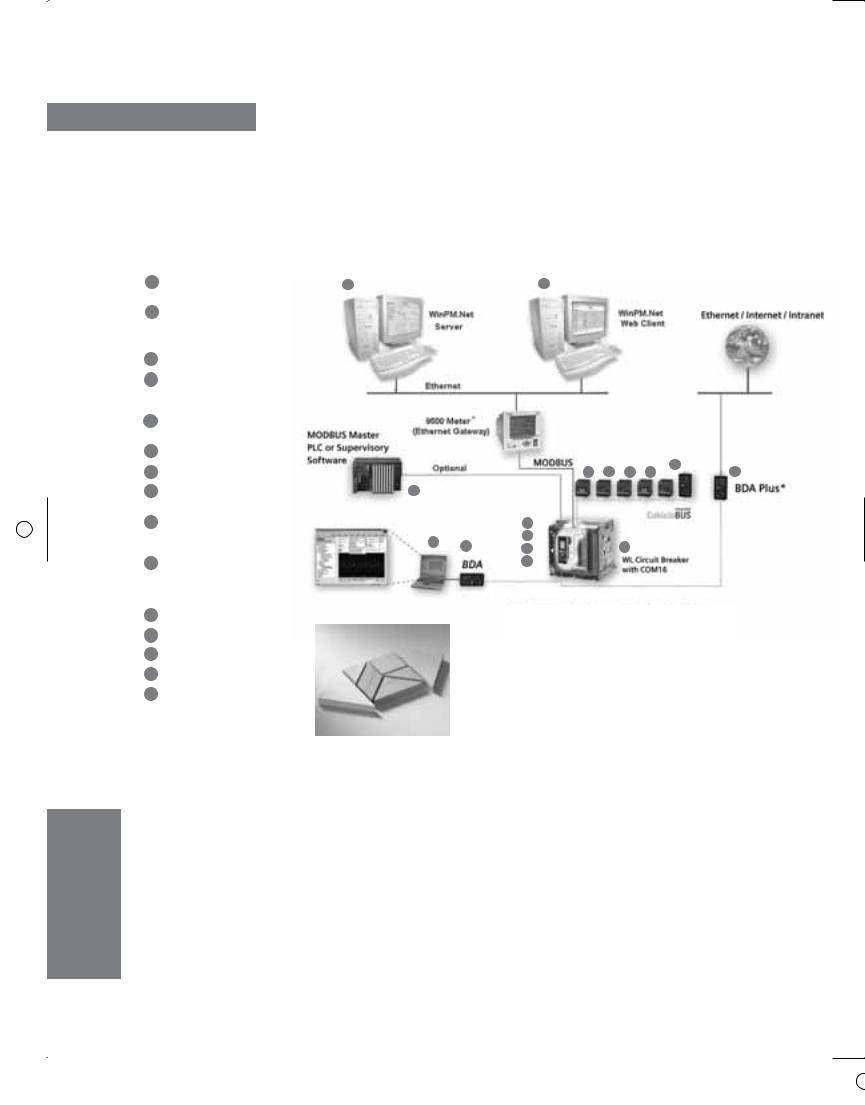

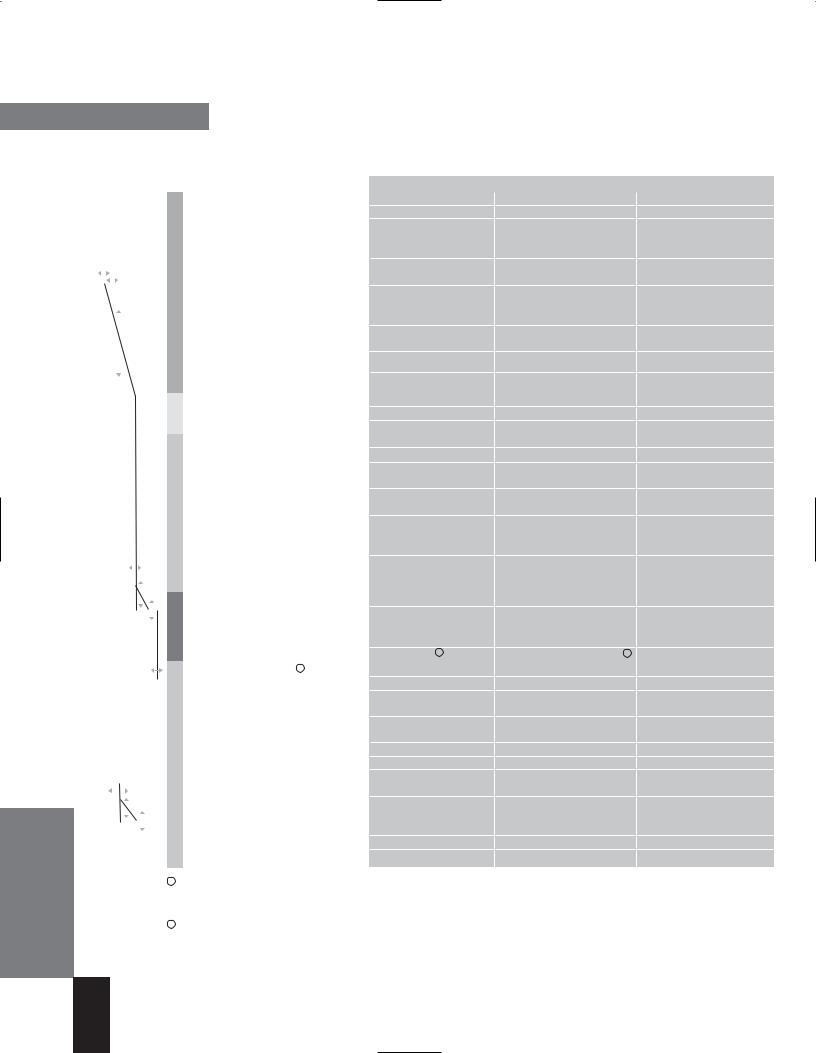

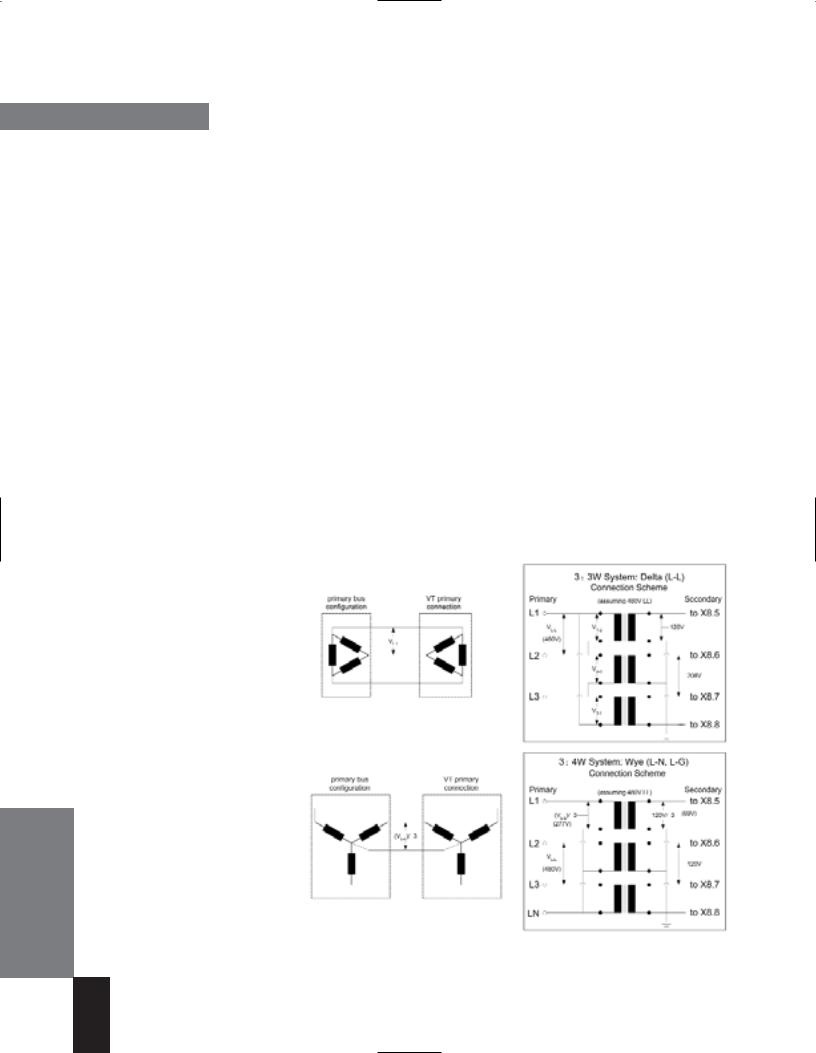

The following diagram:

•Provides an overview of the different communication options available with WL Circuit Breakers and their modules.

•Illustrates the high level of system flexibility, enabling new and innovative ideas to be implemented.

Starting at the lowest level with simple configuration of the circuit breakers, to the field level with

a PLC and WinPM.Net software tool, to a connection to the Intranet/Internet, the potential for saving on power costs by means of intelligent power management is achieveable.

The individual circuit breakers and their modules are described in the following chapters.

Connection Diagram |

|

|

1 Breaker Data Adapter |

13 |

13 |

(BDA) |

|

|

2Browser-capable input and output device (e.g. notebook)

3 WL Circuit Breaker

4COM16 MODBUS module or COM 15 PROFIBUS module

5Breaker Status Sensor (BSS)

6 |

Electronic Trip Unit |

|

|

|

|

|

7 |

Metering function PLUS |

15 |

||||

8 |

Zone Selective |

14 |

|

|

|

|

|

Interlocking (ZSI) module |

|

|

|

|

|

9 |

Digital output module |

4 |

|

|

|

|

|

|

|

|

|||

|

with relay or optocoupler |

5 |

|

|

|

|

|

|

|

|

|

||

|

outputs |

2 |

|

|

|

|

|

Digital output module |

6 |

|

|

|

|

|

|

|

|

|

||

10 |

7 |

|

|

|

|

|

|

|

|

||||

|

with relay or optocoupler |

|

|

|

|

|

|

outputs, remotely |

|

|

|

|

|

|

configurable |

|

|

|

|

|

11Analog output module

12Digital input module

13WinPM.Net on PC

14PLC (e.g. SIMATIC S7)

15BDA Plus

* The Siemens BDA Plus or meters, 9330, 9350, 95/9600 can be used as a gateway to enable Ethernet communication to the WL Circuit Breaker.

The 9500 meter can also be used as a central display unit for multiple WL breakers with metering capability.

1/4

WL MODBUS Communication and Electronic Accessories • January 2005

Introduction and Overview

WL Circuit Breaker

Ethernet

The Industrial Ethernet is a highperformance network that conforms to IEE 802.3 (ETHERNET). The highly successful 10Mbit/s technology, which has been used for over a decade, and the new 100Mbit/s technology (Fast Ethernet to IEEE 802.3u) in conjunction with Switching Full Duplex and Autosensing enable the required network performance to be adapted to different requirements. The appropriate data rates are selected as required because complete compatibility enables the technology to be implemented on

a step-by-step basis.

Used in 80% of networks, Ethernet is currently the best of its kind in LAN environments.

Ethernet does not function according to a master-slave principle. All the stations have equal priority on the bus, which means that any station can be the sender or receiver. A sender can only send on the bus if no other station is sending at that time. This is due to the fact that the stations are always "listening in" to find out whether any messages are being sent to them or any senders are currently active. If a sender has started sending, it checks that the message it has sent is not corrupt. If the message is not changed, the send operation continues.

If the sender detects that its data is corrupt, another sender must have already started sending data. In this case, both senders abort their respective send operations.

After a random time has elapsed, the sender restarts the send operation. This is known as CSMA/CD and, as a "random" access procedure, does not guarantee a response within a certain time frame. This largely depends on the bus load, which means that realtime applications cannot yet be implemented with Ethernet.

1/5

WL MODBUS Communication and Electronic Accessories • January 2005

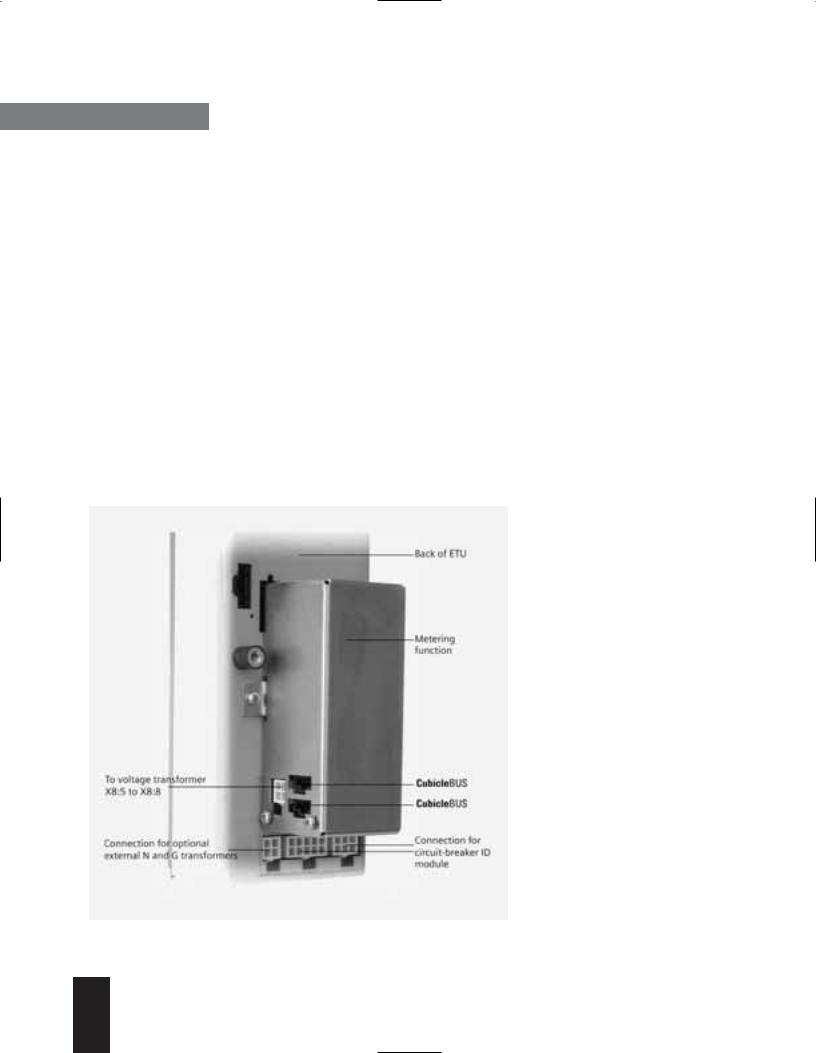

WL Circuit Breaker

Short description of WL Circuit Breaker |

2 |

The CubicleBUS |

|

Communication Function of the Trip Units |

The COM16 MODBUS Module

Metering and Metering Plus

Description of Important Functions/Parameters for Communication

External CubicleBUS Modules

External Power Consumption of a WL Circuit Breaker with CubicleBUS

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

Introduction and Overview

The demands regarding communications capability, data transparency, flexibility and integration in power distribution systems are increasing all the time. The WL Circuit Breaker

is a modular circuit breaker that fulfills the requirements of the future today.

Brief Description of the

WL Circuit Breaker

Circuit breakers today are no longer simply devices for protecting plants, transformers, generators and motors. Many users now require a complete overview of the plant from a central control room and round-the-clock access to all available information. Modern power distribution systems are characterized by the methods used to network circuit breakers— both with each other and other components. The circuit breakers in the

WL Circuit Breaker family have a lot to offer:

It is possible to carry out analysis and maintenance procedures remotely via the Internet. Operating staff can be given immediate access to information on system status and alarms. This is not just a vision of the future, but reality.

The WL Circuit Breaker covers the entire range from 200A to 5000A. The devices are available with different interrupting ratings, allowing shortcircuit currents of up to

200kA to be interrupted reliably.

WL Circuit Breakers can be adapted to different system conditions, which means that a rating plug can be used to adapt each circuit breaker to the appropriate rated current. This ensures that optimum protection is provided, even if changes have been made in the system. The modules (reference Graphic 2-1) can be replaced without the need for the transformer to be changed.

Note: Installation instructions related to the communication modules described in this section can be found in the individual instruction sheets and/or Section 9 of the Operator's Manual

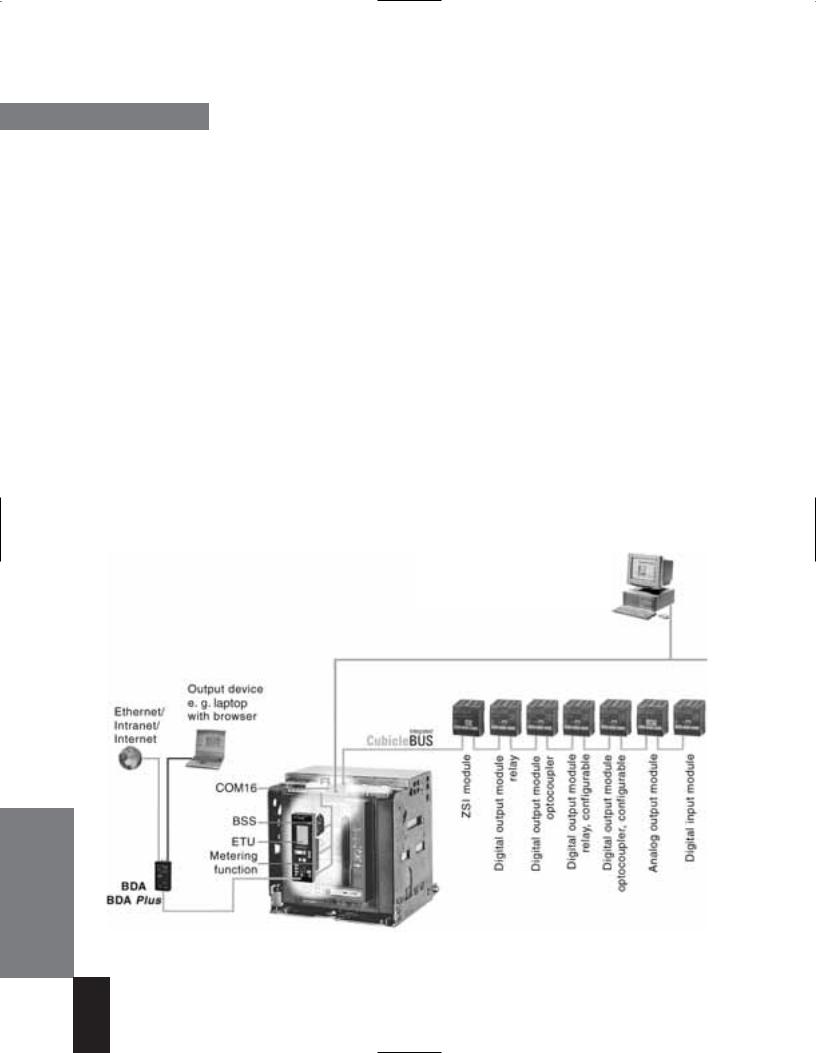

PC with WinPM.Net

WL Circuit Breaker configuration and monitoring software

Graphic 2-1 The system architecture of the WL Circuit Breaker with CubicleBUS enables simultaneous communication via MODBUS and BDA with a laptop or Ethernet/Intranet/Internet.

2/1

WL MODBUS Communication and Electronic Accessories • January 2005

The ability to change between two different parameter sets is also possible. This function is particularly useful in the event of a power failure when an automatic transfer is made from utility to generator power, a process which can

involve changing many of the trip unit parameters.

A wide range of lock-out systems are available to improve reliability during critical processes. All accessories, such as shunt trips, motor operators and communication components, can be installed quickly and easily; this is made easier because the accessories are identical across the entire product line. The commitment to reducing the overall number of parts results in fewer spares to be ordered and lower inventory costs.

The heart of each circuit breaker is the electronic trip unit (ETU). Several versions are available to adapt the protective, metering, and alarm functions to the system requirements: from simple overload and short-circuit protection to trip units that can be configured remotely and which feature a wide range of metering and alarm functions.

All circuit breakers with ETU745, ETU748, ETU755 and ETU776 trip units are communications capable, and allow additional components to be internally networked via the CubicleBUS.

The circuit breaker is connected to MODBUS via the RS485 interface on the COM16 module.

The breaker data adapter (BDA) (see Chapter 4) also supports higher-level networking/ communication (Intranet/Internet).

Communication-capable Circuit Breakers

WL Circuit Breaker

The CubicleBUS

The CubicleBUS, which connects all the intelligent components within the WL Circuit Breaker and enables additional external components to be connected quickly and reliably, forms the backbone of the modular architecture of the WL. The CubicleBUS is already integrated in and connected to all assembled circuit breakers with the ETU745, ETU748, ETU755, and ETU776

trip units.

The high level of system modularity enables communication functions (e.g. metering function) to be retrofitted at any time. A WL Circuit Breaker that is not communications capable can be upgraded (e.g. by exchanging ETU725 for ETU745 with CubicleBUS) quickly and easily on site. All CubicleBUS modules can access the existing data of the circuit breaker directly, thereby ensuring rapid access to information and speedy responses to events.

By connecting additional, external modules to the CubicleBUS, costeffective solutions for communicating data from other devices in the cubicle can be implemented.

Communications Capability of the

Electronic Trip Units (ETUs)

The electronic trip units ETU745, ETU748, ETU755, and ETU776 are all communications capable. The CubicleBUS is connected to the circuit breaker terminals X8.1(-) to X8.4(+)

Different versions of communications-capable trip units are available.

The front of the ETU745 has rotary switches for setting protective parameters. These can be read via the communication device. The ETU745 can also be installed with a four-line display for the measured values.

The ETU755 does not have rotary switches or a display. The protective parameters can only be changed via communications. This trip unit with remote-only parameter setting is for special application demands.

The ETU776 features a graphical display with a clearly structured, key-driven menu. This not only enables operators to display measured values, status information, and maintenance information, but also to read all the existing parameters and make password-protected changes.

2/2

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

Functional overview of the trip unit system

Basic Functions |

|

|

ETU725 |

ETU727 |

ETU745 |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long-time overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range IR = In x … |

0.4, 0.45, 0.5, 0.55, |

0.4, 0.45, 0.5, 0.55, |

0.4, 0.45, 0.5, 0.55, 0.6, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6, 0.65, 0.7, 0.8, |

0.6, 0.65, 0.7, 0.8, |

0.65, 0.7, 0.8, 0.9, 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.9, 1 |

0.9, 1 |

|

In |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch-selectable overload protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

(I2t or I4t dependent function) |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay class tR at I2t |

10s, set at 6 x Ir |

10s, set at 6 x Ir |

2, 3.5, 5.5, 8, 10, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay tR at I 4t |

|

|

14, 17, 21, 25, 30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

– |

– |

1, 2, 3, 4, 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thermal memory |

– |

– |

(via slide switch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase loss sensitivity |

at tsd=20 ms (M) |

at tsd=20 ms (M) |

at tsd=20 ms (M) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

Neutral protection |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF |

– |

(via slide switch) |

(via slide switch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N-conductor setting range IN = In x … |

– |

1 |

0.5 … 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short-time delayed overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF |

– |

– |

(via rotary switch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range Isd = In x … |

1.25, 1.5, 2, 2.5, |

1.25, 1.5, 2, 2.5, |

1.25, 1.5, 2, 2.5, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3, 4, 6, 8, 10, 12 |

3, 4, 6, 8, 10, 12 |

3, 4, 6, 8, 10, 12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

Setting range of time delay tsd, fixed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

0, 0.02 (M), 0.1, |

0, 0.02 (M), 0.1, |

0.02 (M), 0.1, 0.2, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.2, 0.3, 0.4 |

0.2, 0.3, 0.4 |

0.3, 0.4, OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch-selectable short-time delay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

short-circuit protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(I2t dependent function) |

– fixed only |

– fixed only |

(via rotary switch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay tsd at I2t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

– |

– |

0.1, 0.2, 0.3, 0.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zone Selective Interlocking (ZSI) function |

– |

– |

per CubicleBUS module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instantaneous overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

Extended Instantaneous Protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is enabled when OFF |

– |

– |

(via rotary switch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range Ii = In x … |

Ii = 0.8 x Icw |

Ii = 0.8 x Icw |

1.5, 2.2, 3, 4, 6, 8, 10, 12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50kA max |

50kA max |

0.8 x Icw = max, OFF=I cw=EIP 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground fault protection 2 |

– |

(standard) |

O (field installable module) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Trip and alarm function |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detection of the ground fault current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

by residual summing method |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detection of the ground fault current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

by direct sensing method |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

Setting range of the Ig for trip |

– |

A, B, C, D, E |

A, B, C, D, E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of the Ig for alarm |

– |

– |

A, B, C, D, E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of the time delay tg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

– |

0.1, 0.2, 0.3, 0.4, 0.5 |

0.1, 0.2, 0.3, 0.4, 0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch-selectable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ground fault protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(I2t / fixed) |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range time delay tg at I2t |

– |

– |

0.1, 0.2, 0.3, 0.4, 0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ZSI ground function |

– |

– |

per CubicleBUS module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1Extended Instantaneous Protection (EIP) allows the WL breaker to be applied at the withstand rating of the breaker with minus 0% tolerance; that means no instantaneous override whatsoever. EIP further enables the circuit breaker to be applied up to the full instantaneous rating of the breaker on systems where the available fault current exceeds the withstand rating.

2 Ground Fault Module cannot be removed after installation.

available

– not available

Ooptional

2/3

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

|

|

Basic Functions |

|

|

|

|

|

ETU725 |

|

ETU727 |

ETU745 |

|||||||||||||

|

|

Parameter sets |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Selectable between |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

parameter set A and B |

|

|

– |

|

– |

– |

|||

|

|

LCD |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LCD, alphanumeric (4-line) |

|

|

– |

|

– |

O |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LCD, graphic |

|

|

– |

|

– |

– |

|||

|

|

Communication |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CubicleBUS integrated |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Communication capability via |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODBUS or PROFIBUS |

|

|

– |

|

– |

|

|||

|

|

Metering function |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metering function capability with |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metering Function PLUS |

|

|

– |

|

– |

|

|||

|

|

Display by LED |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Trip unit active |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alarm |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ETU error |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L trip |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S trip |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I trip |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N trip |

|

|

– |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G trip |

|

|

– |

|

|

(only with ground fault module) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G alarm |

|

|

– |

|

– |

(only with ground fault module) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tripped by extended protection or |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

protective relay function |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Communication |

|

|

– |

|

– |

|

|||

|

|

Signal contacts with external CubicleBUS modules |

|

|

|

|

|

|||||||||||||||||

|

|

(Opto or relay) |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overcurrent warning |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Load shedding ON/OFF |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early signal of long-time trip (200 ms) |

– |

|

– |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature alarm |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase unbalance |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instantaneous trip |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short-time trip |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long-time trip |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Neutral conductor trip |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground fault protection trip |

|

|

– |

|

– |

(only with ground fault module) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground fault alarm |

|

|

– |

|

– |

(only with ground fault module) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auxiliary relay |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ETU error |

|

|

– |

|

– |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Step for Settings via Communications or ETU Key Pad |

Setting range of the Ig |

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

from … to |

|

step |

from … to |

step |

|

|

Frame Size II |

Frame Size III |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 … 1 |

|

0.1 |

1000 … 1600 |

50 |

|

A |

100 A |

400 A |

|

|||||||||||||

|

|

1 … 100 |

1 |

|

1600 … 10000 |

100 |

|

B |

300 A |

600 A |

|

|||||||||||||

|

|

100 … 500 |

5 |

|

10000 … max |

1000 |

|

C |

600 A |

800 A |

|

|||||||||||||

|

|

500 … 1000 |

10 |

|

|

|

|

|

D |

900 A |

1000 A |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

1200 A |

1200 A |

|

|

|

available |

– |

not available |

O |

optional |

2/4

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

Functional overview of the trip unit system

Basic Functions |

|

|

ETU748 |

ETU755 |

ETU776 |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long-time overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF |

– |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range IR = In x … |

0.4, 0.45, 0.5, 0.55, |

0.4 … 1 (step: 1A) |

0.4 … 1 (step: 1A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6, 0.65, 0.7, 0.8, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.9, 1 |

|

|

In |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch-selectable overload protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

(I2t or I4t dependent function) |

|

(via communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay class tR at I2t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

2, 3.5, 5.5, 8, 10, |

2 … 30 (step: 0.1s) |

2 … 30 (step: 0.1s) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay tR at I4t |

14, 17, 21, 25, 30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

1, 2, 3, 4, 5 |

1 … 5 (step: 0.1s) |

1 … 5 (step: 0.1s) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Thermal memory |

(via slide switch) |

(on/off via communications) |

(on/off via key pad |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase loss sensitivity |

at tsd=20ms (M) |

(on/off via communications) |

(on/off via key pad |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Neutral protection |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

Function can be switched ON/OFF |

– |

(via communications) |

(via key pad or communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N-conductor setting range IN = In x … |

0.5, 1, OFF |

0.5, 1, OFF |

0.5 … 2, OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short-time delayed overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF |

– |

(via communications) |

(via key pad or communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range Isd = In x … |

1.25, 1.5, 2, 2.5, |

1.25 … 0.8 x Icw = max |

1.25 … 0.8 x Icw = max |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3, 4, 6, 8, 10, 12 |

(step: 10A) |

(step: 10A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

Setting range of time delay tsd, fixed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

M, 0.1, 0.2, 0.3, 0.4 |

M, 0.08 …0.4, OFF (step: 0.001s) |

M, 0.08 …0.4, OFF (step: 0.001s) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch-selectable short -time delay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

short-circuit protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(I2t dependent function) |

(via rotary switch) |

(via communications) |

(via key pad or communications) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting range of time delay tsd at I2t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(seconds) |

0.1, 0.2, 0.3, 0.4 |

0.1 … 0.4 (step: 0.001s) |

0.1 … 0.4 (step: 0.001s) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zone Selective Interlocking (ZSI) function |

per CubicleBUS module |

per CubicleBUS module |

per CubicleBUS module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instantaneous overcurrent protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Function can be switched ON/OFF, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IExtended Instantaneous Protection

|

|

|

|

|

is enabled when OFF |

– |

|

|

|

|

(via communications) |

|

(via key pad or communications) |

||||||||||||

|

|

|

|

|

Setting range I |

i |

= I |

n |

x … |

– I |

i |

= I |

cw |

= EIP 1 |

1.5 x I |

n |

… 0.8 x I |

cs |

= max, OFF=I =EIP |

1 |

1.5 x I |

n |

… 0.8 x I |

cs |

= max, OFF=I =EIP |

|

|

|

|

|

|

|

|

|

|

|

|

|

cw |

|

|

|

cw |

||||||||

|

|

|

|

|

Ground fault protection 2 |

O (field installable module) |

O (field installable module) |

|

O (field installable module) |

||||||||||||||||

|

|

|

|

|

Trip and alarm function |

|

|

|

|

|

(via communications) |

|

(via key pad or communications) |

||||||||||||

|

|

|

|

|

Detection of the ground fault current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

by residual summing method |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Detection of the ground fault current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

by direct sensing method |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Setting range of the Ig for trip |

A, B, C, D, E |

A … E (step: 1A) |

|

A … E (step: 1A) |

||||||||||||||||

|

|

|

|

|

G Setting range of the Ig for alarm |

A, B, C, D, E |

A … E (step: 1A)- |

|

A … E (step: 1A) |

||||||||||||||||

|

|

|

|

|

Setting range of the time delay tg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

(seconds) |

|

|

|

|

0.1, 0.2, 0.3, 0.4, 0.5 |

0.1 … 0.5 (step: 0.001s) |

|

0.1 … 0.5 (step: 0.001s) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

Switch-selectable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

ground fault protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

(I2t / fixed) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Setting range time delay tg at I2t |

0.1, 0.2, 0.3, 0.4, 0.5 |

0.1 … 0.5 (step: 0.001s) |

|

0.1 … 0.5 (step: 0.001s) |

||||||||||||||||

|

|

|

|

|

ZSI ground function |

|

per CubicleBUS module |

per CubicleBUS module |

|

per CubicleBUS module |

|||||||||||||||

|

|

|

|

|

1 Extended Instantaneous Protection (EIP) allows the WL breaker to be applied at the withstand rating of |

available |

|

|

|||||||||||||||||

|

|

|

|

|

the breaker with minus 0% tolerance; that means no instantaneous override whatsoever. EIP further |

– |

not available |

|

|||||||||||||||||

|

|

|

|

|

enables the circuit breaker to be applied up to the full instantaneous rating of the breaker on systems |

|

|||||||||||||||||||

|

|

|

|

|

O |

optional |

|

|

|||||||||||||||||

|

|

|

|

|

where the available fault current exceeds the withstand rating. |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

2 Ground Fault Module cannot be removed after installation.

Notes:

M = Indicates phase loss sensitivity is enabled. LT pickup reduced 80% when phase unbalance > 50%. ST delay = 20ms

Communications = Setting the parameters of the trip unit via the Breaker Data Adapter, MODBUS, or PROFIBUS

Key pad = Direct input at the trip unit

2/5

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

|

Basic Functions |

ETU748 |

ETU755 |

ETU776 |

||||||||||||

|

Parameter sets |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Selectable between |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

parameter set A and B |

– |

|

|

|

|

LCD |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

LCD, alphanumeric (4-line) |

O |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

LCD, graphic |

– |

– |

|

|

|

Communication |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

CubicleBUS integrated |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Communication capability via |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODBUS or PROFIBUS |

|

|

|

|

|

Metering function |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Metering function capability with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metering Function PLUS |

|

|

|

|

|

Display by LED |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Trip unit active |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alarm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ETU error |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I trip |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G trip |

(only with ground fault module) |

(only with ground fault module) |

(only with ground fault module) |

|

|

|

|

|

|

|

|

|

|

|

|

|

G alarm |

(only with ground fault module) |

(only with ground fault module) |

(only with ground fault module) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Tripped by extended protection or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

protective relay function |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Communication |

|

|

|

|

|

Signal contacts with external CubicleBUS modules |

|

|

|

|

|||||||||||

|

(Opto or relay) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Overcurrent warning |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Load shedding ON/OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early signal of long-time trip (200 ms) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Temperature alarm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase unbalance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Instantaneous trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Short-time trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long-time trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Neutral conductor trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground fault protection trip |

(only with ground fault module) |

(only with ground fault module) |

(only with ground fault module) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Ground fault alarm |

(only with ground fault module) |

(only with ground fault module) |

(only with ground fault module) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Auxiliary relay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ETU error |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

available |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

not available |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

optional |

2/6

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

WL Circuit Breaker

Data Availability on the CubicleBUS

All modules connected to the CubicleBUS can request data from other modules via the bus and generate data themselves that can be read by other modules.

Each data point in the comprehensive WL Circuit Breaker data dictionary can only be generated by a single module—the data source. If this data source (module) exists, the data points assigned to it also exist.

This information is described and communicated in the property bytes.

If a data source (module) does not exist, the data point does not exist either.

Again, the relevant property byte contains this information.

The following table provides an overview of the internal CubicleBUS modules and the data point groups (collection of several data points) assigned to them.

See Chapter 3 Register List for a detailed description of the individual data points.

|

|

|

CubicleBUS Modules |

|

Data point group |

ETU745, 748, |

BSS |

COM16 |

Metering |

Data points with the same source |

755 or 776 |

|

|

Function Plus |

Protection parameter set A |

|

|

|

|

Protection parameter set B (N/A for ETU745 or 748) |

|

|

|

|

Extended protection parameters |

|

|

|

|

Parameter for setpoints |

|

|

|

|

MODBUS communication parameters |

|

|

|

|

Parameters for metering settings |

|

|

|

|

Device identification data |

|

|

|

|

Circuit breaker position specifications |

|

|

|

|

Status info. (circuit breaker open/closed, storage spring, etc.) |

|

|

|

|

Alarms |

|

|

|

|

Trip log |

|

|

|

|

Setpoint messages |

|

|

|

|

Maintenance information |

|

|

|

|

Circuit breaker temperature |

|

|

|

|

Temperature in the cubicle |

|

|

|

|

3-phase currents |

|

|

|

|

Current in neutral, ground-fault current; equip. spec. |

|

|

|

|

3-phase voltage |

|

|

|

|

Power KW, KVAR, KVA |

|

|

|

|

Power factor |

|

|

|

|

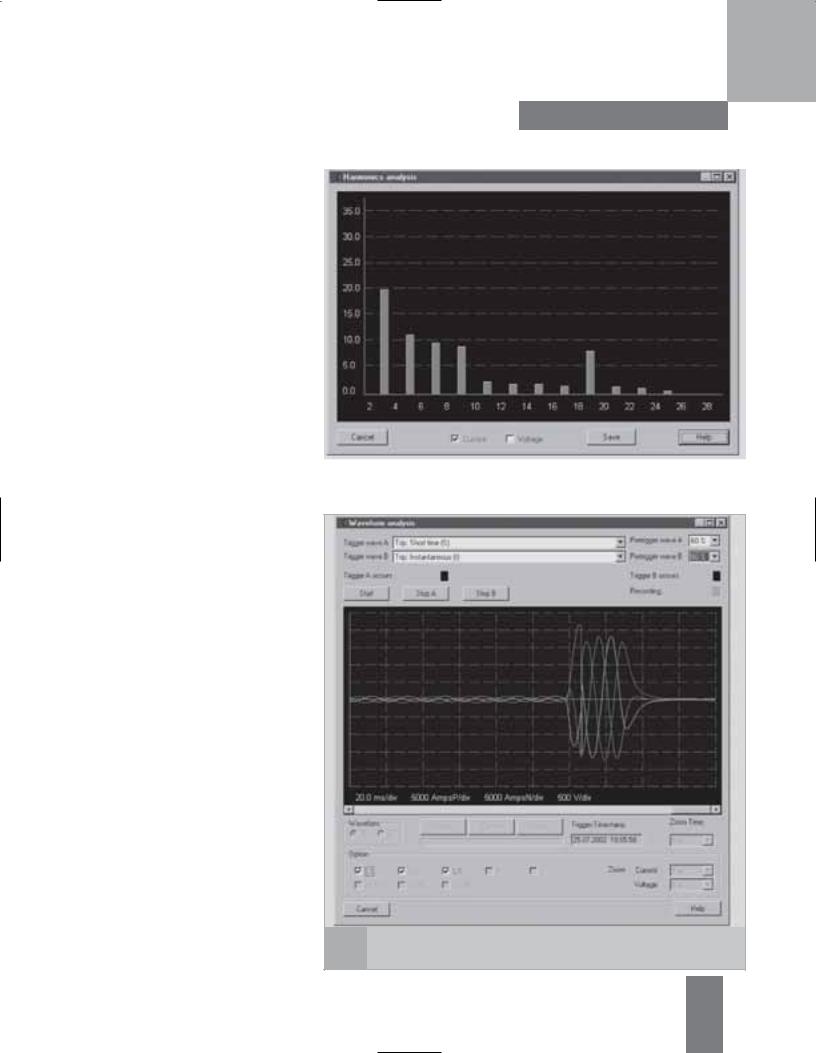

Frequency, total harm. distortion, form factor, crest factor |

|

|

|

|

Harmonic analysis |

|

|

|

|

Waveform buffer |

|

|

|

|

Event log |

|

|

|

|

System time |

|

|

|

|

Table 2-2 The table shows which data points from the data dictionary are generated by which CubicleBUS module, enabling you to quickly find out which modules are required for which system.

2/7

WL MODBUS Communication and Electronic Accessories • January 2005

Communication-capable Circuit Breakers

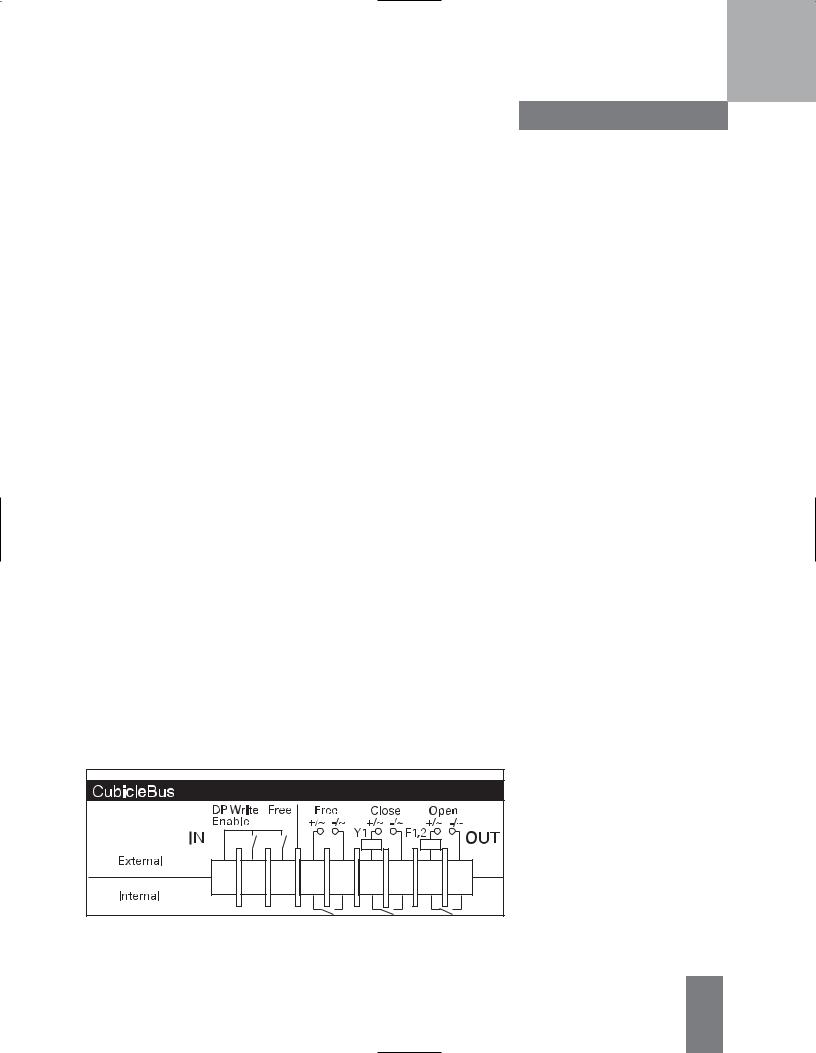

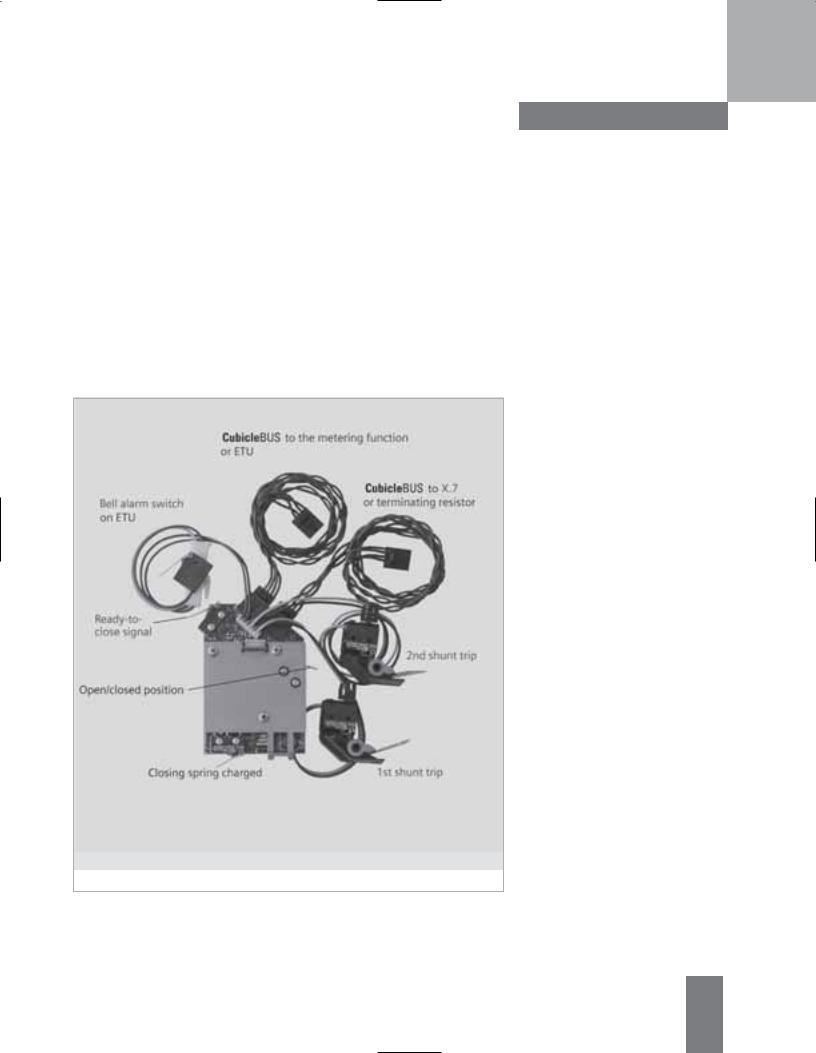

The MODBUS COM16 Module and the BSS

The COM16 module enables the WL Circuit Breaker to exchange data via MODBUS to supervisory systems and MODBUS masters. The COM16 module retrieves some of the key data on the status of the circuit breaker (circuit breaker open/closed, closing spring charged, ready-to- close, etc.) via the CubicleBUS from the BSS (breaker status sensor). Both modules are, therefore, offered together as

a MODBUS communication package.

MODBUS Module COM16

The COM16 module for the WL enables the circuit breaker to be connected to any MODBUS master network. This makes it easy to add WL and a COM16 to existing MODBUS networks.

If required, control/write access to the circuit breaker can be locked using hardware and software to prevent any switching operations

taking place via MODBUS (manual or automatic operation) or parameters from being changed.

All key events are assigned a time stamp from the integrated clock to enable operators to keep track of alarms. This device clock can be synchronized with the clock in the automation system.

A temperature sensor integrated in the COM16 module measures the temperature surrounding the breaker in the switchgear cubicle.

Three integrated microswitches located in the COM16 module are used to detect the position of the circuit breaker (connect, test, disconnect and not present) and communicate via MODBUS. The circuit breaker can be remotely operated only in the test or connect position.

Pin Configuration

The COM16 module is connected to the auxiliary conductor plug-in system at X7.