Siemens STC-ECO Technical data

Answers for energy.

Canned, clean and smart

STC-ECO hermetically sealed integrated motor compressor unit for dirty-gas applications onshore, offshore, and subsea

Answers for energy.

Canned, clean and smart

STC-ECO hermetically sealed integrated motor compressor unit for dirty-gas applications onshore, offshore, and subsea

The challenges of upstream dirty-gas compression together with other demanding applications which have traditionally suffered from poor seal reliability call for a radically different approach to the design of compression solutions.

Introducing the STC-ECO. Based on Siemens field-proven hermetically sealed technology, the STC-ECO is a compact, fully integrated, sealless motor-compressor unit of low complexity. It has been specifically designed to meet the requirements of the most demanding applications in the upstream business. These applications have either suffered from poor seal reliability — notably upstream of the glycol dehydrator — or involve hazardous and toxic gases, containing H2S, mercury, CO, etc.

After two years of field operation, the prototype of the STC-ECO has proven the credibility of its concept and design, which offers significant benefits for owners, operators and the environment.

Increased plant safety

The STC-ECO features a fully integrated, canned design. Compared to solutions consisting of discrete components, this represents a substantial reduction of interfaces and, hence, providing a major improvement in plant safety.

Increased uptime

The STC-ECO has been designed for ultimate ruggedness while at the same time reducing complexity. With 5+ years maintenance intervals, it offers superior availability and unparalleled lifetime value.

Zero emissions

The STC-ECO have been developed with special attention to applications involving hazardous and toxic gases. Its sealless, canned design means zero emissions for ultimate HSE compliance.

Compact footprint

The STC-ECO comes with a built-in variable-speed drive, offering maximum flexibility of operation. At the same time, the vertical, integrated concept enables a drastic reduction in the overall footprint, requiring minimal space in the plant layout.

STC-ECO — A fully proven solution

Representing a quantum leap in compressor technology, the STC-ECO has been co-developed by Shell and Siemens, two companies enjoying a long-standing mutually cooperative relationship. Key to the success of the project, the Shell research team has been part of the joint development group. To date, the STC-ECO is the only API-conforming sealless compression solution available for dirty-gas applications without need for clean-gas supply.

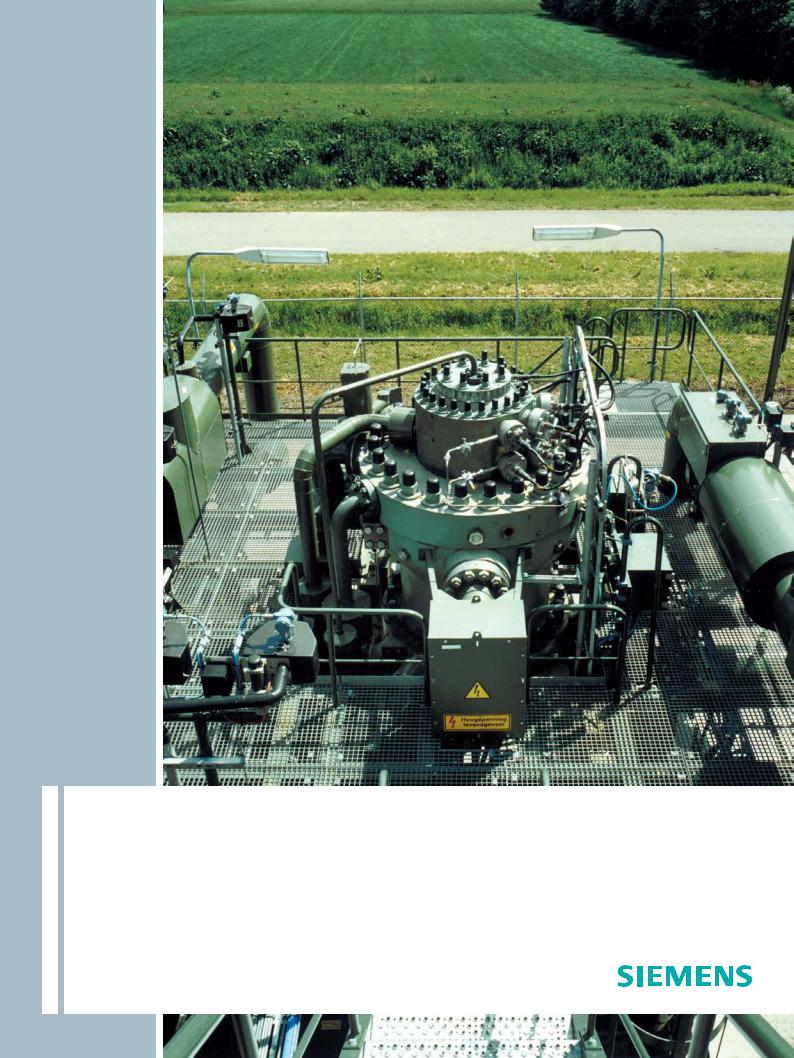

Preceded by months of extensive inhouse testing, in autumn 2006 the STC-ECO prototype was deployed at NAM’s Vries-4 gas gathering site near Groningen, Netherlands. For more than 20 months, it has operated with dirty process gas in modulating mode and under routine asset control. During this time, it was subjected to a wide range of contaminants, including sand, and water.

A scheduled inspection after its first year of general use-and-abuse operation in saturated gas confirmed that the STC-ECO prototype was in excellent condition. Not only did the test prove the suitability of the design for the intended applications, but additional tests also supported the confidence in achieving the desired 5-years maintenance interval, which had been among the key performance criteria in the development of the STC-ECO.

Following the completion of field testing, the STC-ECO prototype continued to operate as a standard machine, achieving some 10,000 operating hours by August 2008, effectively transforming the unit from prototype-under-test to an extension of normal production facilities.

The STC-ECO with its top being removed for inspection.

Loading...

Loading...