Siemens STC-GV, STC-GVT User Manual

STC-GV, STC-GVT Siemens Turbocompressor – Integrally Geared, Vertically split volute casing

A success story since 1948

Since its inception 60 years ago, the STC-GV compressor series has been meeting demands for compression solutions with high efficiencies and pressures up to 200 bar. STC-GV compressors, designed according to customer specifications and in accordance with both API 617 and

API 672, guarantee the highest quality and technical standards for a broad range of industrial application.

An innovative and compact design allows for an integrated turbine drive within STC-GV, where compressor stages and turbine are mounted on the same gear (STC-GVT).

Highlights

The perfect match for all air separation and process industry requirements

The perfect match for all air separation and process industry requirements

High efficiency and outstanding operating range

High efficiency and outstanding operating range

Powerful and robust design, with integrated turbine or expander options

Powerful and robust design, with integrated turbine or expander options

Flexible design concepts combining custom-tailored design with standardized components for maximum reliability

Flexible design concepts combining custom-tailored design with standardized components for maximum reliability

Siemens is the only compressor manufacturer who also develops and supplies proprietary gear technology

Siemens is the only compressor manufacturer who also develops and supplies proprietary gear technology

Fields of application

Air separation

Air separation

Ammonia

Ammonia

Carbon capture and storage

Carbon capture and storage

Ethylene oxide

Ethylene oxide

Flare mitigation

Flare mitigation

Fuel gas

Fuel gas

Hydrocarbons

Hydrocarbons

Metallurgy

Metallurgy

-Direct reduction

-Direct smelting

Petrochemicals

Petrochemicals

Phenol

Phenol

Refineries

Refineries

Synthetic fibers

Synthetic fibers

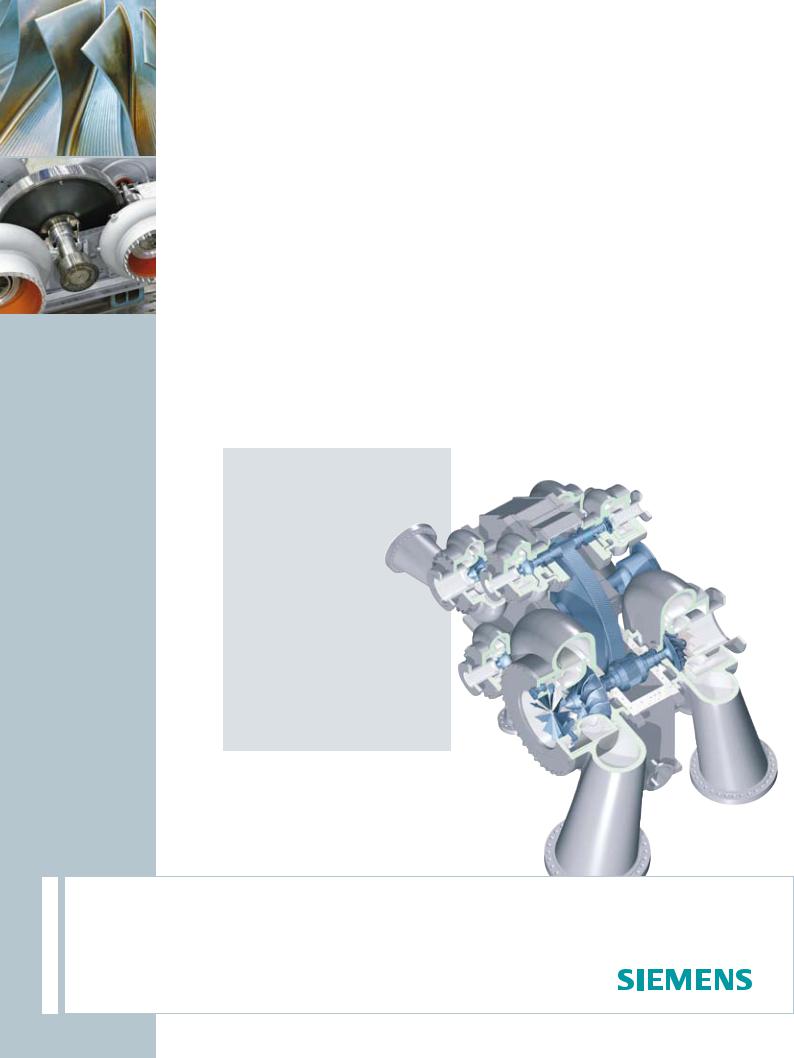

Integrally geared centrifugal compressor with vertically split volute casing (STC-GV)

Siemens Turbocompressors

Answers for energy.

Design Concept

Powerful, robust and reliable

The STC-GV integrally geared centrifugal compressors feature a multi-shaft arrangement with different speeds. All shafts are mounted in maintenance-free, oil-lubri- cated hydrodynamic bearings. With up to eight compressor stages around a central bull gear, the STC-GV compressor series forms a compact unit for the multi-stage compression of a wide range of gases.

Optimized shaft speeds, modern impellers, tailored aerodynamics and mechanics along with optimized auxiliaries guarantee the highest efficiency. Adjustable guide vane units at the first and/or any other compression stage optimize the operating range. External cooler arrangements allow for operation at extreme site conditions.

Package and driver options

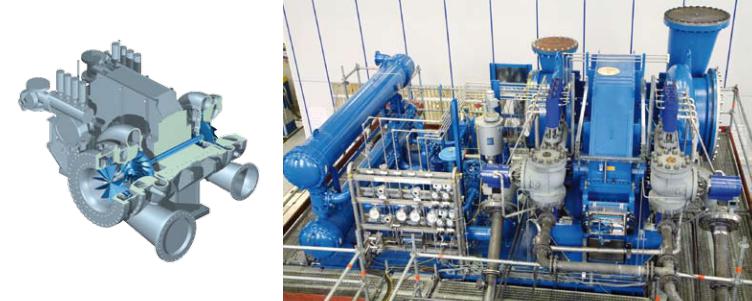

For most STC-GV compressor sizes, Siemens offers a package design. The package includes the compressor, driver, process gas coolers, lube oil console, process piping and all tubing and wiring. The package design leads to significantly reduced on-site installation time. These compressor types are also suitable for direct turbine-drive or integrated turbine design (STC-GVT).

Driver: depending on process and energy resources: steam turbine, gas turbine or electric motor.

Siemens also offers variants of the STC-GV:

STC-GV (H): this compressor is designed for high-pressure application with suction pressures higher than 5 bar, especially booster air in air separation.

STC-GV (H): this compressor is designed for high-pressure application with suction pressures higher than 5 bar, especially booster air in air separation.

STC-GVT: a new and compact design, STC-GV is also available with integrated turbine drive, compressor stages and turbine being mounted on the same gear.

STC-GVT: a new and compact design, STC-GV is also available with integrated turbine drive, compressor stages and turbine being mounted on the same gear.

STC-GT: singleor multi-stage expanders enable power recovery from process gases.

STC-GT: singleor multi-stage expanders enable power recovery from process gases.

STC-GVT: with its single or multiple expander stages, STC-GVT is the ideal solution for simultaneous gas compression and expansion of process gas.

STC-GVT: with its single or multiple expander stages, STC-GVT is the ideal solution for simultaneous gas compression and expansion of process gas.

|

|

Integrally geared turbocompressor with |

STC-GVT on testbed |

integrated steam turbine (STC-GVT) |

|

Loading...

Loading...