SHARP XG-C40XU(XE) Service Manual

1

XG-C40XU/XE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische T eile verwendet

werden.

CONTENTS INHAL T

Page

» SPECIFICATIONS...................................................... 2

» INPORTANT SERVICE SAFTY NOTES(for USA)...... 3

» OPERATION MANUAL ............................................... 7

» REMOVING OF MAJOR P ARTS.............................. 13

» RESETTING THE TOTAL LAMP TIMER.................. 18

» THE OPTICAL UNIT OUTLINE ................................ 19

» CONVERGENCE AND FOCUS ADJUSTMENT ........ 20

» ELECTRICAL ADJUSTMENT................................... 25

» ADJUSTING THE PC BOARD ................................. 31

» TROUBLE SHOOTING TABLE ................................ 32

» CHASSIS LAYOUT ................................................... 92

» BLOCK DIAGRAM .................................................... 94

» OVERALL WIRING DIAGRAM .................................. 96

» DESCRIPTION OF SCHEMATIC DIAGRAM............. 98

» WAVEFORMS........................................................... 99

» SCHEMATIC DIAGRAM......................................... 100

» PRINTED WIRING BOARD ASSEMBLIES ............ 148

» PARTS LIST

Ë

ELECTRICAL PARTS ........................................ 158

Ë

CABINET AND MECHANICAL PARTS .............. 178

Ë

ACCESSORIES PARTS .................................... 184

Ë

PACKING PARTS............................................... 184

» PACKING OF THE SET.......................................... 185

Seite

» TECHNISCHE DATEN ............................................. 48

» HINWEISE FÜR DAS WARTUNGSPERSONAL...... 49

» BEDIENUNGSANLEITUNG ..................................... 50

» ENTFERNEN DER HAUPTTEILE............................ 56

» NULLSTELLUNG DES LAMPEN-

BETRIEBSSTUNDENZÄHLERS (GESAMTZEIT).... 61

» ÜBERSICHT DER OPTIKEINHEIT .......................... 62

» EINSTELLUNG VON KONVERGENZ UND

BRENNPUNKT ......................................................... 63

» ELEKTRISCHE EINSTELLUNG............................... 68

» EINSTELLUNG DER PC-PLATINE .......................... 74

» FEHLERSUCHTABELLE.......................................... 75

» CHASSIS-ANORDNUNG ......................................... 92

» BLOCKSCHALTBILD................................................ 94

» GESAMTSCHALTPLAN ........................................... 96

» BESCHREIBUNG DES SCHEMATISCHEN

SCHALTPLANS ........................................................ 98

» WELLENFORMEN ................................................... 99

» SCHEMATISCHER SCHALTPLAN ........................ 100

» LEITERPLATTENEINHEITEN ................................ 148

» ERSATZTEILLISTE

Ë

ELEKTRISCHE BAUTEILE................................ 158

Ë

GEHÄUSE UND MECHANISCHE BAUTEILE... 178

Ë

ZUBEHÖRTEILE................................................ 184

Ë

VERPACKUNGSTEILE...................................... 184

» VERPACKEN DES GERÄTS.................................. 185

SHARP CORPORATION

SERVICE MANUAL

SERVICE-ANLEITUNG

LCD PROJECTOR

LCD PROJEKTOR

MODELS

MODELLE

XG-C40XU/XE

S01B4XG-C40XU

2

XG-C40XU/XE

Product type

Model

Video system

Display method

LCD panel

Lens

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Horizontal resolution

Audio output

Computer RGB input signal

Pixel clock

Vertical frequency

Horizontal frequency

Computer control signal

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Laser pointer of remote control

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

LCD Projector

XG-C40XU/XE

PAL/SECAM/NTSC 3.58/NTSC 4.43/DTV 480P/DTV 720P/DTV 1080I

LCD panel × 3, RGB optical shutter method

Panel size: 22.9 mm (0.9") (13.9 [H] × 18.5 [W] mm)

Display method: Translucent TN liquid crystal panel

Drive method: TFT (Thin Film Transistor) Active Matrix panel

No. of dots: 786,432 dots (1,024 [H] × 768 [V])

1–1.3 × zoom lens, F1.7–2.0, f = 33–43 mm

DC 200 W lamp

250:1

RCA Connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75 Ω terminated

RCA Connector: AUDIO, 0.5 Vrms more than 22 kΩ (stereo)

4-pin Mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

560 TV lines (video input), 750 TV lines (DTV 720P input, Dot by Dot)

3 W (monaural)

15-

PIN

MINI

D-

SUB

CONNECTOR

(INPUT 1, 2):

RGB separate/composite sync/sync on green type analog input: 0–0.7 Vp-p, positive,

75 Ω terminated

S

TEREO

M

INIJACK

: AUDIO, 0.5 Vrms, more than 22 kΩ (stereo)

H

ORIZONTAL

SYNC

.

SIGNAL

: TTL level (positive/negative) or composite sync (Apple only)

V

ERTICAL

SYNC

.

SIGNAL

: Same as above

12–230 MHz

43–200 Hz

15–126 kHz

9-pin Mini DIN female connector (RS-232C Input Port)

8 cm (3

3

⁄

32

") round

AC 100–240 V

3.3 A

50/60 Hz

300 W

41°F to + 104°F (+ 5°C to + 40°C)

-4°F to + 140°F (– 20°C to + 60°C)

Plastic

38 kHz

Wave length: 650 nm / Max. output: 1 mW / Class II Laser Product

9

1

/

64

"

(W) × 4

49

/

64

"

(H) × 12

13

/

64

"

(D) (229 × 121 × 310 mm) (main body only)

9

19

/

32

"

(W) × 5

9

/

32

"

(H) × 14

7

/

64

"

(D) (243.5 × 134 × 358.4 mm) (including adjustment feet

and projecting parts)

10.6 lbs. (4.8 kg)

Remote control, Two AA size batteries, Power cord (11' 10" 3.6m), Computer RGB cable

(9' 10" 3 m), Computer audio cable (9' 10" 3 m), USB mouse control cable (3' 3" 1 m),

DIN-D-sub RS-232C cable (6

45

/

64

" 15 cm), Remote mouse receiver, Extra air filter, Lens cap

(attached), CD-ROM, LCD projector operation manual, LCD projector quick references,

Sharp Advanced Presentation Software operation manual

Lamp unit (Lamp/cage module) (BQC-XGC40XU/1), Remote control (RRMCG1579CESA),

(RRMCG1584CESA),AA size batteries, Power cord (QACCU5013CEZZ(XG-C40XU),

QACCB5024CENA(XG-C40XE),QACCV4002CEZZ(XG-C40XE)), Computer RGB cable

(QCNWG0002CEZZ), Computer audio cable (QCNW-4870CEZZ), USB mouse control

cable (QCNWG0007CEPZ), DIN-D-sub RS-232C cable (QCNW-5288CEZZ), Remote mouse

receiver (RUNTK0673CEZZ), Air filter (PFILD0076CEZZ), Lens cap (GCOVH1307CESB),

CD-ROM (UDSKA0053CEN1),(UDSKA0057CEN1), LCD projector operation manual

(TINS-7482CEZZ),(TINS-7533CEZZ), LCD projector quick references (TINS-7483CEZZ),

(TINS-7534CEZZ, TINS-7535CEZZ, TINS-7536CEZZ), Sharp Advanced Presentation

Software operation manual (TINS-7538CEZZ),(TINS-7537CEZZ)

This unit has some inactive TFTs within acceptable tolerances which

may result in illuminated or inactive dots on the picture screen. This

will not affect the picture quality or the life expectancy of the unit.

This SHARP projector uses LCD (Liquid Crystal Display) panels. These

very sophisticated panels contain 786,432 pixels (

×

RGB) TFTs (Thin

Film Transistors). As with any high technology electronic equipment

such as large screen TVs, video systems and video cameras, there

are certain acceptable tolerances that the equipment must conform

to.

Specifications are subject to change without notice.

Specifications

3

XG-C40XU/XE

INPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

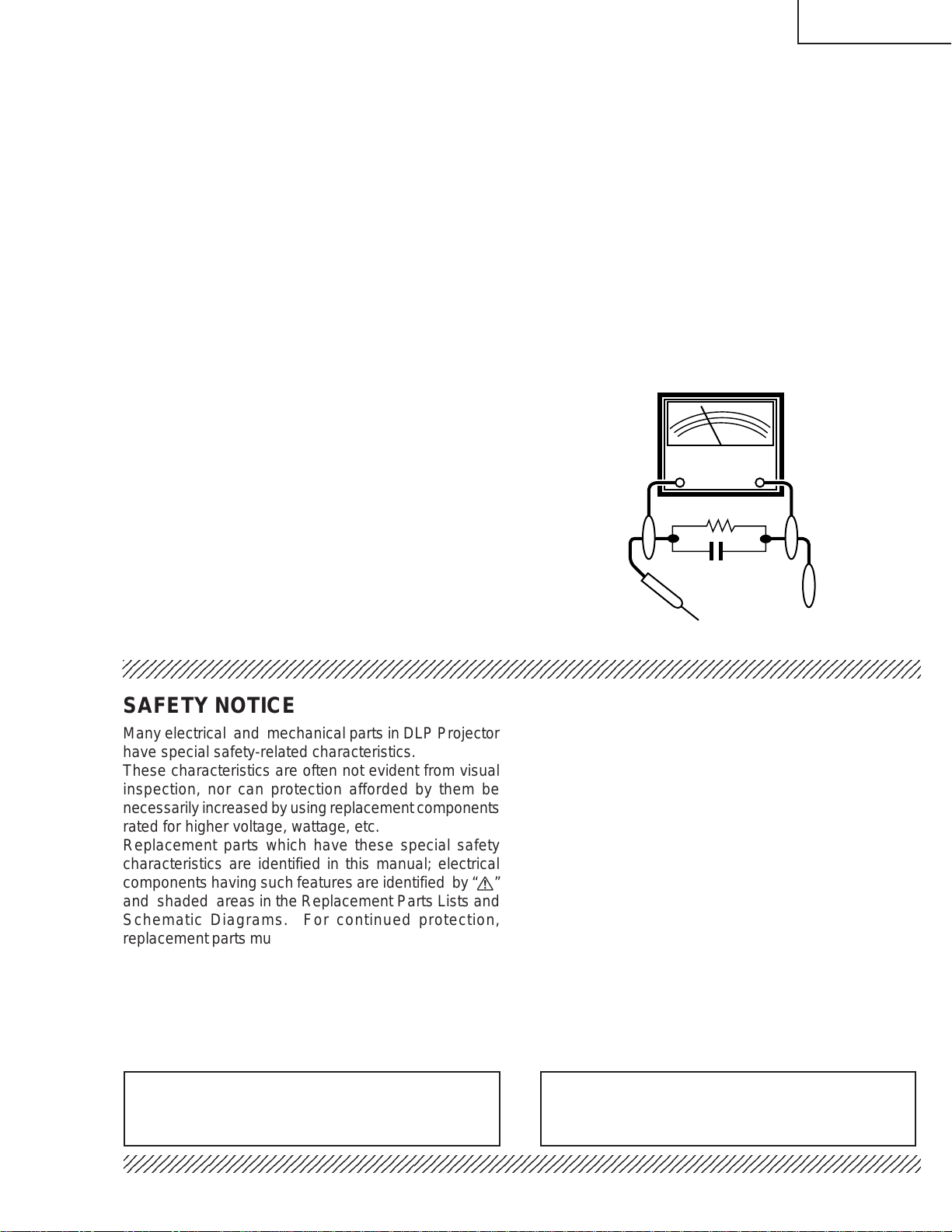

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary , a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

SAFETY NOTICE

Many electrical and mechanical parts in DLP Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DLP présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

4

XG-C40XU/XE

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe mètal halide , dans le

projecteur LCD émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type CLMPF0075CE01 or BQC-XGC40XU/1,

caractéristique 85V/200W.

4. La lampe émet de petites quantités de radiation UV -

éviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

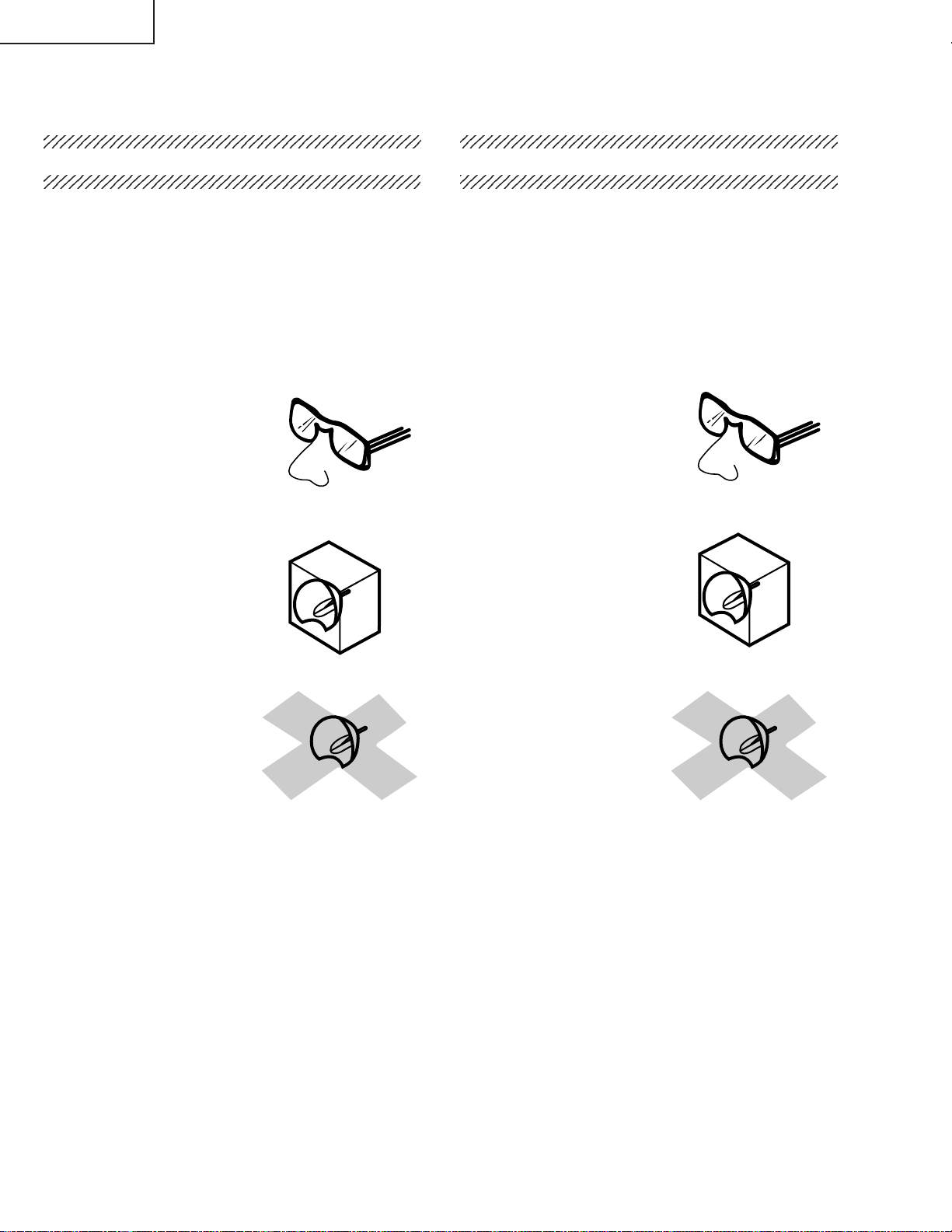

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0075CE01 or BQC-XGC40XU/1 rated 85V/

200W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

5

XG-C40XU/XE

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du con-

duit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle

XG-C40XU qui est livré sans.

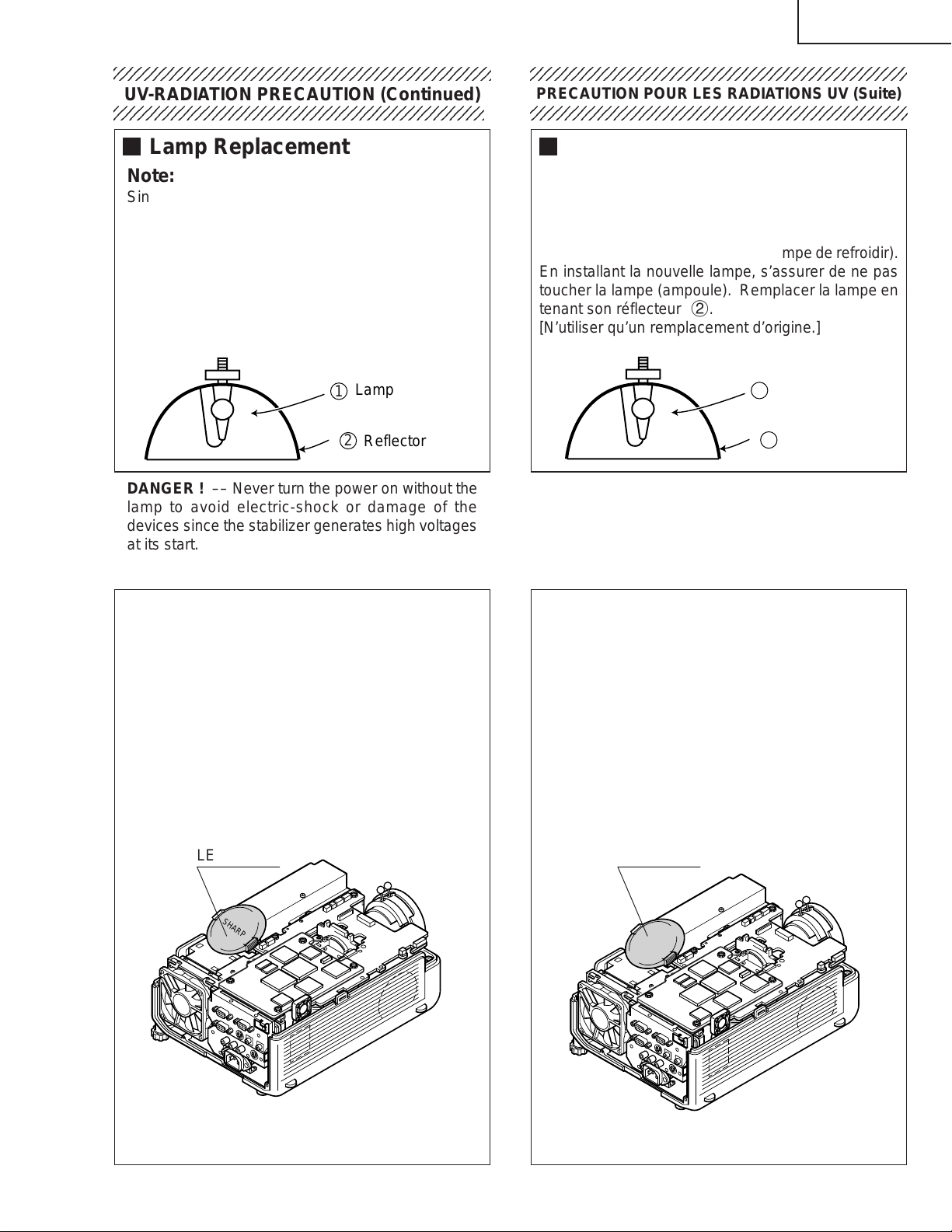

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Note: Please obtain a lens cap before servicing a

model XG-C40XU that is received without

one.

23456789012345678901234567890121234567890123

4

1

2

Lamp

Reflector

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

UV-RADIATION PRECAUTION (Continued)

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

234567890123456789012345678901212345678901234

5

1

2

Lamp

Reflector

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

PRECAUTION POUR LES RADIATIONS UV (Suite)

SHARP

LENS CAP

Figure 1.

SHARP

LENS CAP

Figure 1.

6

XG-C40XU/XE

WARNING: High brightness light source, do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE P ARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

A VERTISSEMENT : Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE P AS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REP ARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

PRECAUTION

(Unite d’admission)

CAUTION

(INLET Unit)

For continued protection

against a risk of fire,

replace only with same

type 5A 250V fuse.

(F761)

Pour une protection continue

contre les risques d’incendie,

ne remplacer qu’avec un

fusible 5A 250V du même

type.

(F761)

5A 250V

5A 250V

7

XG-C40XU/XE

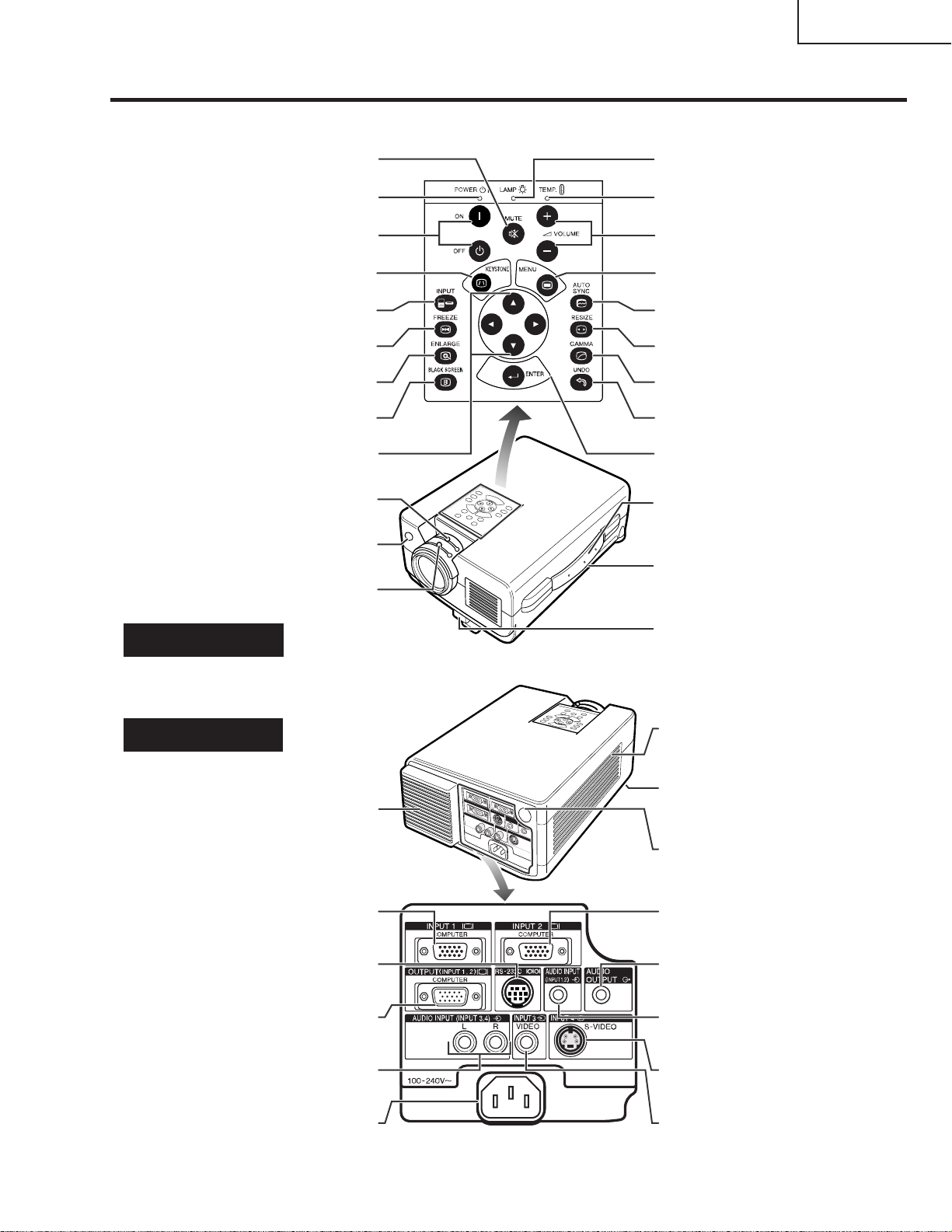

Location of Controls

Projector

Foot release

VOLUME buttons (+ / – )

MENU button

ENTER button

UNDO button

GAMMA button

RESIZE button

AUTO SYNC button

MUTE button

KEYSTONE button

BLACK SCREEN button

ENLARGE button

FREEZE button

INPUT button

POWER buttons (ON/OFF)

POWER indicator

ADJUSTMENT buttons

TEMPERATURE WARNING

indicator

LAMP REPLACEMENT

indicator

Carrying handle

Zoom knob

Remote control sensor

Kensington Security Standard

connector

Front and Top View

Side and RearView

INPUT 1 port (HD 15)

Cooling fan (Exhaust vent)

RS-232C port (9-pin Mini DIN)

AUDIO INPUT 3 terminals (RCA)

OUTPUT port for INPUT 1, 2 (HD 15)

Speaker

AC socket

INPUT 2 port (HD 15)

AUDIO OUTPUT terminal

(3.5mm stereo minijack)

AUDIO INPUT terminal

for INPUT 1, 2

(3.5 mm stereo minijack)

S-VIDEO INPUT 4 terminal

(4-pin Mini DIN)

VIDEO INPUT 3 terminal

(RCA)

Focus knob

Air filter/Cooling fan (Intake vent)

Remote control sensor

('/"/\/|)

OPERATION MANUAL

8

XG-C40XU/XE

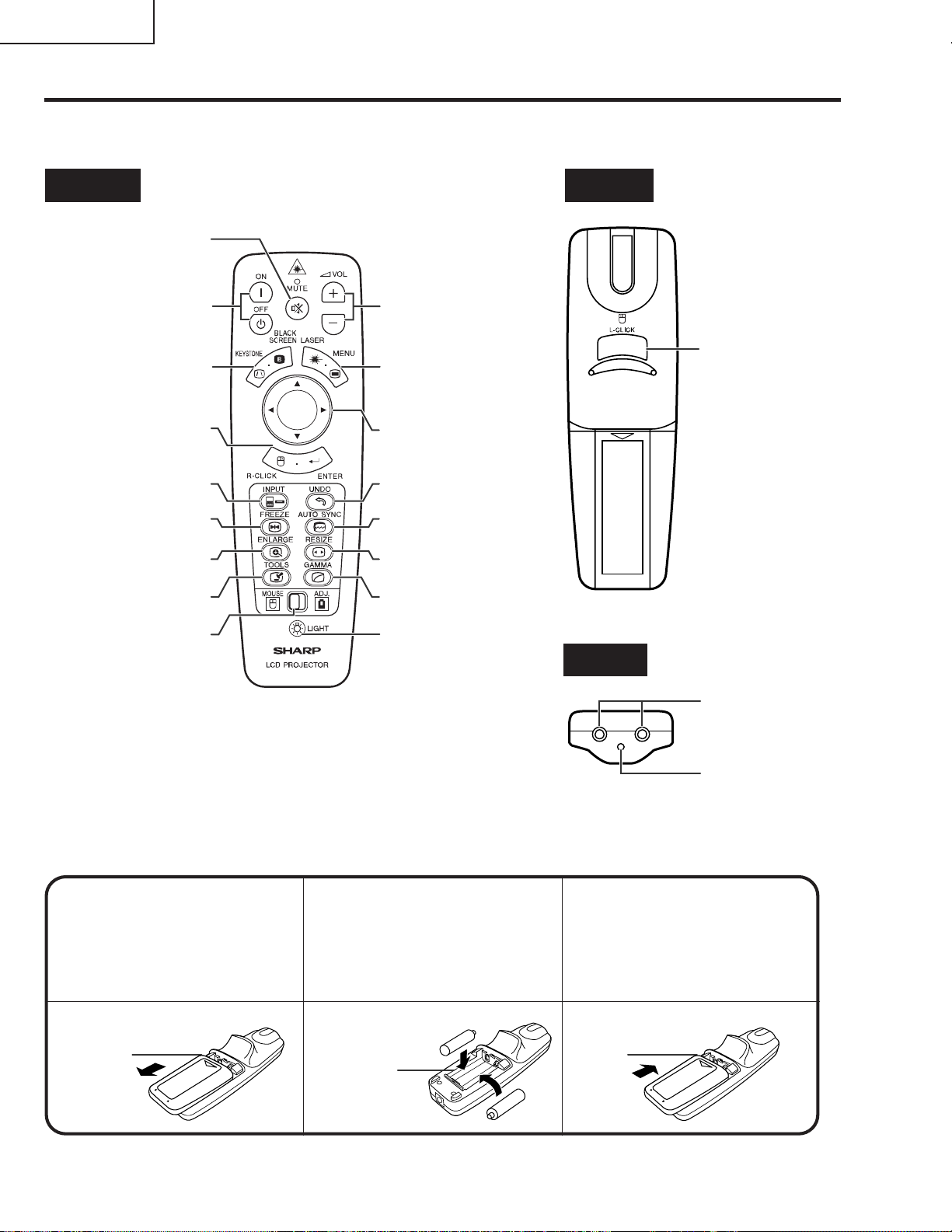

Front View Rear View

Inserting the batteries

1

Press in on the arrow

mark and slide in the

direction of the arrow to

remove the battery cover.

2

Insert two AA size

batteries, making sure

their polarities match the

+ and – marks inside

the battery compartment.

Insert the side tabs of

the battery cover into

their slots and press the

cover in until it is

properly seated.

VOLUME buttons

( + / – )

BACKLIGHT button

MUTE button

POWER buttons

(ON/OFF)

LASER POINTER/

MENU button

KEYSTONE/BLACK

SCREEN button

RIGHT-CLICK/

ENTER button

UNDO button

INPUT button

AUTO SYNC button

FREEZE button

RESIZE button

ENLARGE button

GAMMA button

TOOLS button

MOUSE/

ADJUSTMENT

switch

LEFT-CLICK

button

MOUSE/

ADJUSTMENT

buttons ('/"/\/|)

Battery

compartment

Battery

cover

Battery

cover

Operating the Wireless Mouse Remote Control

Remote Control

Top View

Remote control

signal transmitter

Laser

pointer

window

3

9

XG-C40XU/XE

MOUSE

ADJ.

MOUSE/ADJUSTMENT switch

(Remote control)

MOUSE

ADJ.

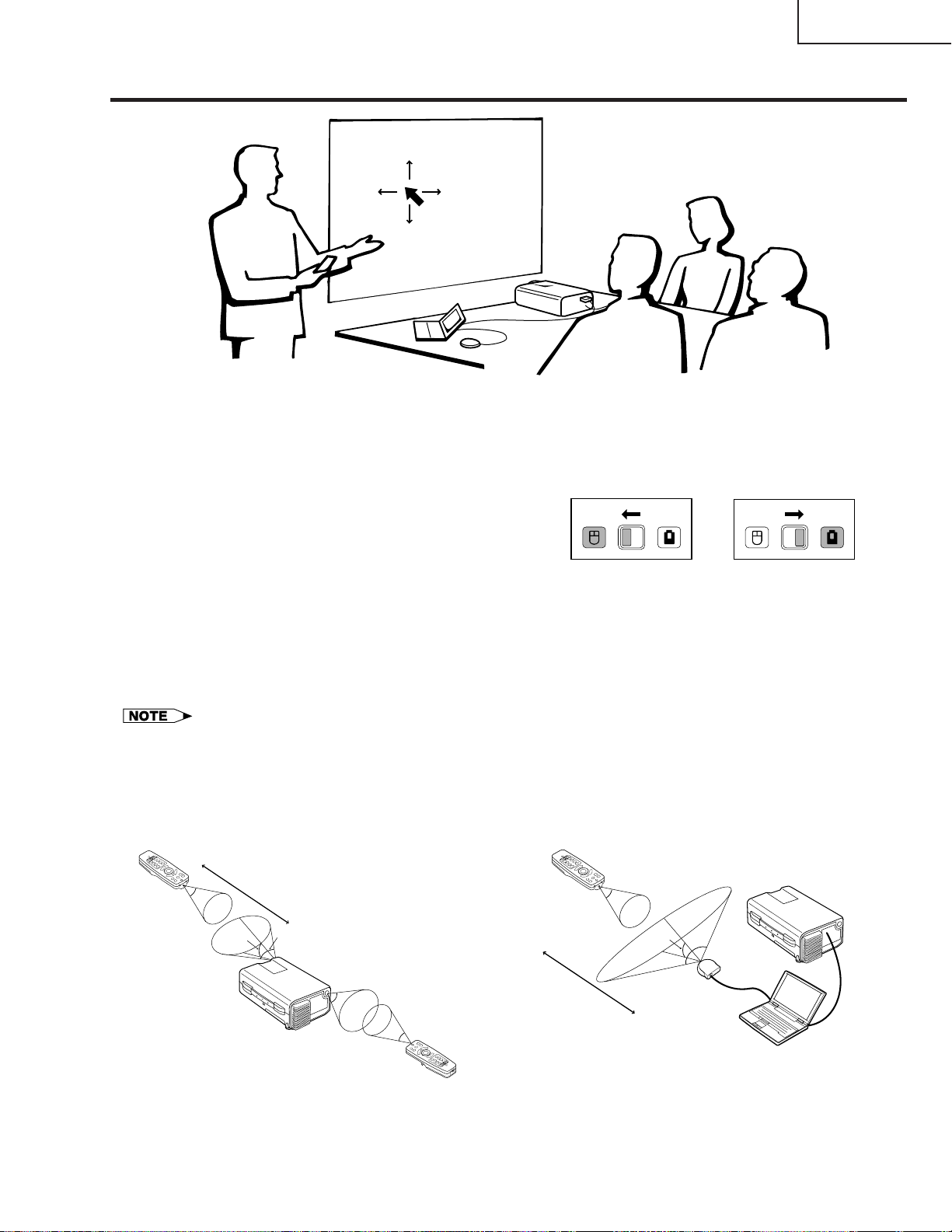

Using the Wireless Mouse

Remote control

Using the Remote Control as a Wireless Mouse

Remote Control/Mouse Receiver Positioning

The remote control has the following three functions:

• Projector control

• Wireless mouse

• Laser pointer

• The remote control can be used to control the projector within the ranges shown below.

• The remote mouse receiver can be used with the remote control to control the mouse functions of a connected

computer within the ranges shown below.

• The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the

signal may differ due to the screen material.

Wireless mouse

Laser pointer

Projector control

Controlling the Projector

Remote control

4 m

30˚

30˚

120˚

Remote

mouse

receiver

30˚

45˚

7 m

30˚

30˚

45˚

Remote control

10

XG-C40XU/XE

Use as a Wireless Mouse

Be sure the supplied remote mouse receiver is

connected to your computer.

(Slide the MOUSE/ADJUSTMENT switch on

the remote control to the MOUSE position.)

• The wireless mouse may not operate correctly if your

computer serial port is not correctly set up. Refer to the

computer’s operation manual for details of setting up/

installing the mouse driver.

• For one-button mouse systems, use either the LEFT-CLICK

or RIGHT-CLICK button.

Using the remote control in a dark room

Press BACKLIGHT, and the buttons will light up. Green

lights refer to mouse operations, and red lights to

projector adjustments.

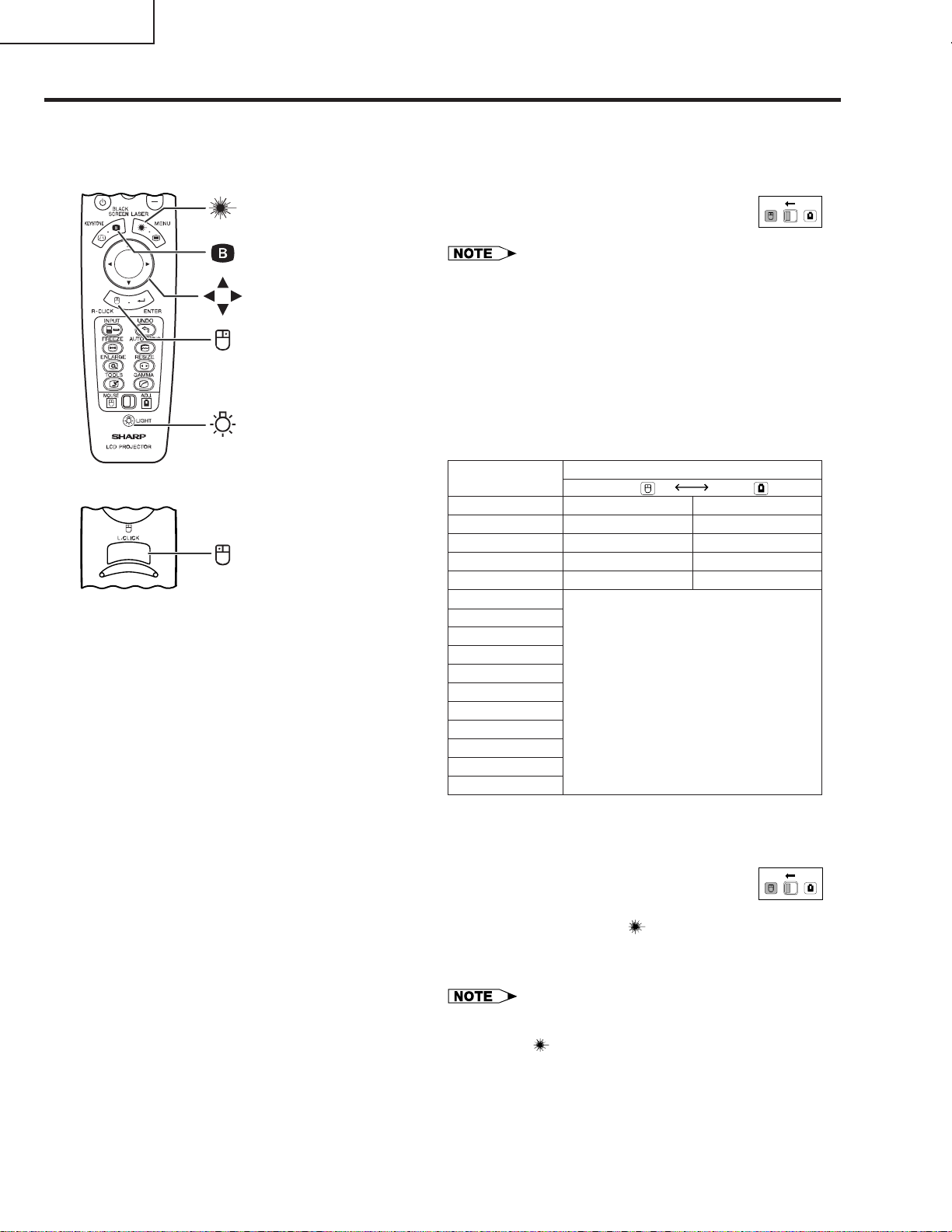

Position of MOUSE/ADJUSTMENT switch

MOUSE

LASER POINTER (GREEN)

BLACK SCREEN (GREEN)

RIGHT-CLICK (GREEN)

MOUSE (NOT LIT)

ON (NOT LIT)

ADJ.

MENU (RED)

KEYSTONE

(RED)

ENTER (RED)

ADJUSTMENT (NOT LIT)

—

Button name

LASER POINTER/MENU

BLACK SCREEN/KEYSTONE

RIGHT-CLICK/ENTER

MOUSE/ADJUSTMENT

LEFT-CLICK

POWER ON/OFF

VOLUME + / –

MUTE

INPUT

UNDO

FREEZE

AUTO SYNC

ENLARGE

RESIZE

TOOLS

GAMMA

Use as a Laser Pointer

(Slide the MOUSE/ADJUSTMENT switch on

the remote control to the MOUSE position.)

Press LASER POINTER ( ) to activate the laser

pointer. When the button is released, the light

automatically goes off.

• For safety, the laser pointer automatically goes off after 1

minute of continuous use. To turn it on, release LASER

POINTER ( ) and press again.

MOUSE

ADJ.

Effective buttons in MOUSE mode

Remote control

(Front view)

Remote control

(Rear view)

LASER POINTER

BLACK SCREEN

MOUSE

RIGHT-CLICK

BACKLIGHT

LEFT-CLICK

MOUSE

ADJ.

ON (RED)

11

XG-C40XU/XE

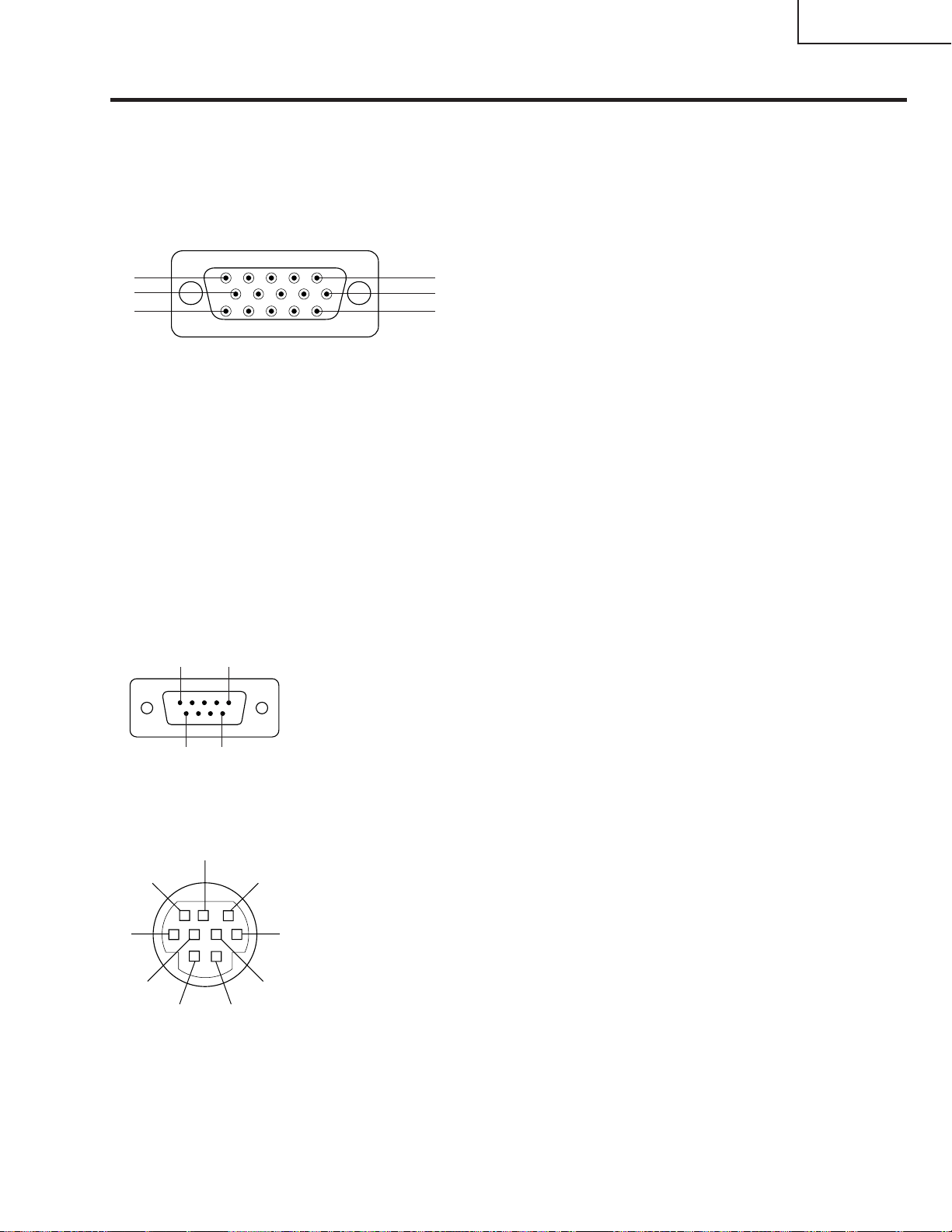

Analog Computer 1 and 2 Signal Input Ports: 15-pin mini D-sub female connector

Computer Input

Analog

1. Video input (red)

2. Video input

(green/sync on green)

3. Video input (blue)

4. Reserve input 1

5. Composite sync

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. Not connected

10. GND

11. GND

12. Bi-directional data

13. Horizontal sync signal

14. Vertical sync signal

15. Data clock

1

15

5

6

11

10

Pin No. Signal Name I/O Reference

1 CD Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 ER Not connected

5 SG Signal Ground Connected to internal circuit

6 DR Data Set Ready Output Not connected

7 RS Request to Send Output Connected to internal circuit

8 CS Clear to Send Input Connected to internal circuit

9 CI Not connected

Pin No. Signal Name I/O Reference

1 VCC + 3.3V (Reserved) Output Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 EXIR Detector of Option Unit Input Not connected

(Reserved)

5 SG Signal Ground Connected to internal circuit

6 ERX IR Receive Signal from Input Not connected

IR Amplifier (Reserved)

7 RS Request to Send Output Connected to internal circuit

8 CS Clear to Send Input Connected to internal circuit

9 ETX IR Transmit Signal Output Not connected

(Reserved)

RS-232C Terminal: 9-pin Mini DIN female connector

6

8

4

9

7

3

5

2

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

1

5

6

9

1

Component Input

1. P

R

(C

R

)

2. Y

3. P

B

4. Not connected

5. Not connected

6. Earth (P

R

)

7. Earth (Y)

8. Earth (P

B

)

9. Not connected

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15. Not connected

Connection Pin Assignments

12

XG-C40XU/XE

Units: inches (mm)

Top View

Side View

Front View

Bottom View

10

5

/

16

(262)

2

13

/

32

(61)5

19

/

32

(142)

9

11

/

32

(237.5)

1

5

/

16

(33.5)

12

13

/

64

(310)5

9

/

32

(134)

5

/

8

(16)

29

/

32

(23)

1

5

/

64

(27.5)

14

7

/

64

(358.4)

2

13

/

32

(61)4

49

/

64

(121)

3

21

/

32

(93)

3

17

/

64

(83)

1

13

/

16

(30)

9

19

/

32

(243.5)

9

1

/

64

(229)

63

/

64

(25)

7

/

16

(11)

13

/

32

(10.5)

1

11

/

16

(43)

2

63

/

64

(76)

3

17

/

64

(83)

3

51

/

64

(96.5)

3

53

/

64

(97.5)

25

/

64

(10)

23

/

64

(9)

23

/

64

(9)

17

/

32

(13)

54

33

/

64

(138.5) 49

1

/

64

(124.5)

Rear Vie

w

Dimensions

13

XG-C40XU/XE

SHARP

Lamp unit

Lamp cover

1-2

Intake cover

1-1

1-3

1-3

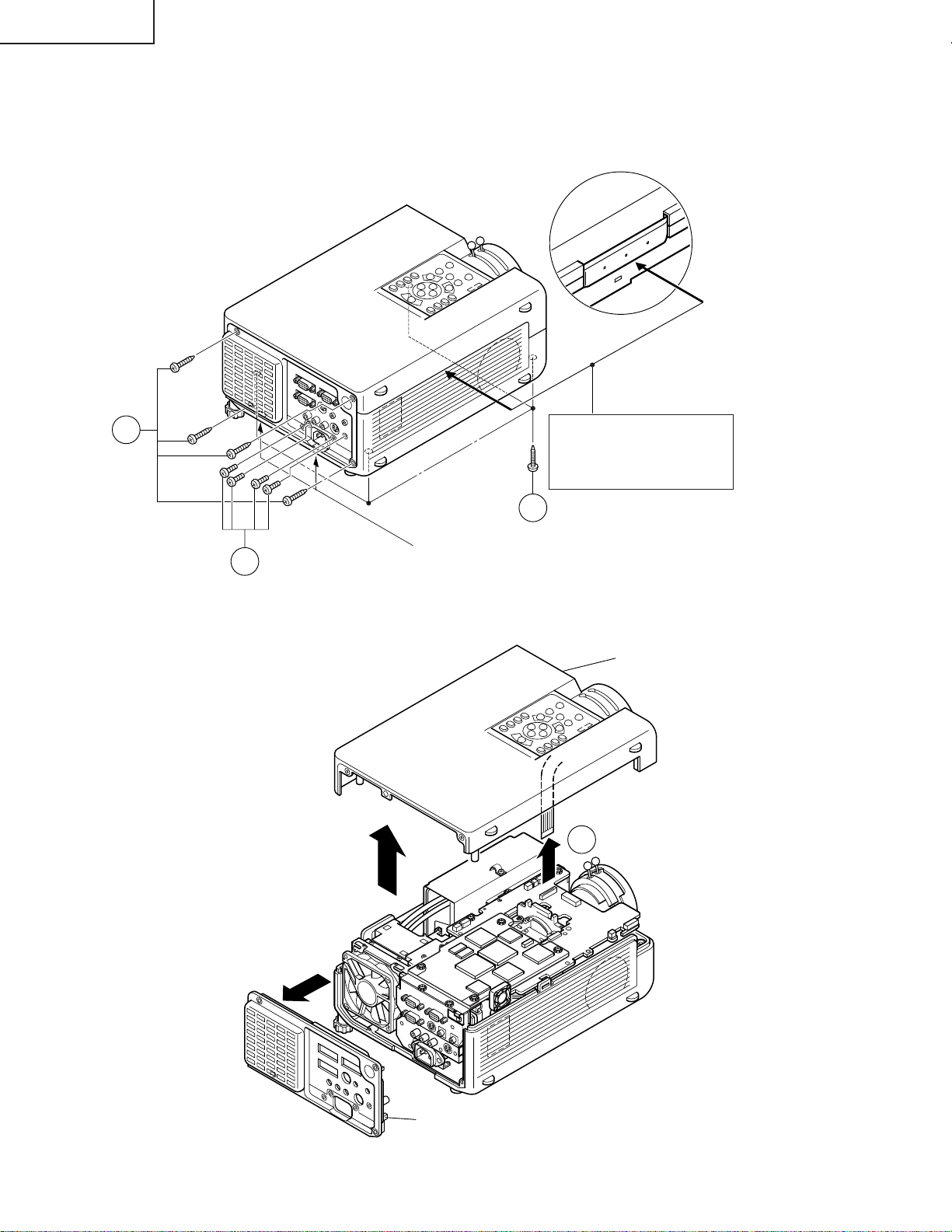

REMOVING OF MAJOR PARTS

1.Removing the Intake cover and lamp unit

1-1. Detach the Intake cover.

1-2. Loosen the lamp cover screw and draw out the lamp cover in the direction of arrow (toward yourself).

1-3. Remove the two lamp unit lock screws. Detach the lamp unit.

Note:

When replacing the lamp, make sure

that there is a clearance of over

8mm between the terminal and the

lamp snap-on spring (and other

metallic parts).

14

XG-C40XU/XE

SHARP

Press both sides of the bottom

cabinet in the directions of

arrow to undo the hooks. Lift

and detach the top cabinet.

Hook

2-1

2-2

2-3

(KY)

Top cabinet

Rear cabinet

2-4

2.Removing the top and rear cabinets

2-1. Remove the four rear cabinet lock screws.

2-2. Remove the four terminal board lock screws off the rear cabinet. Unhook and detach the rear cabinet from

below.

2-3. Remove the four top cabinet lock screws from below.

2-4. Slowly lift the top cabinet and disconnect the operation key unit connector (KY). Then take away the top

cabinet.

15

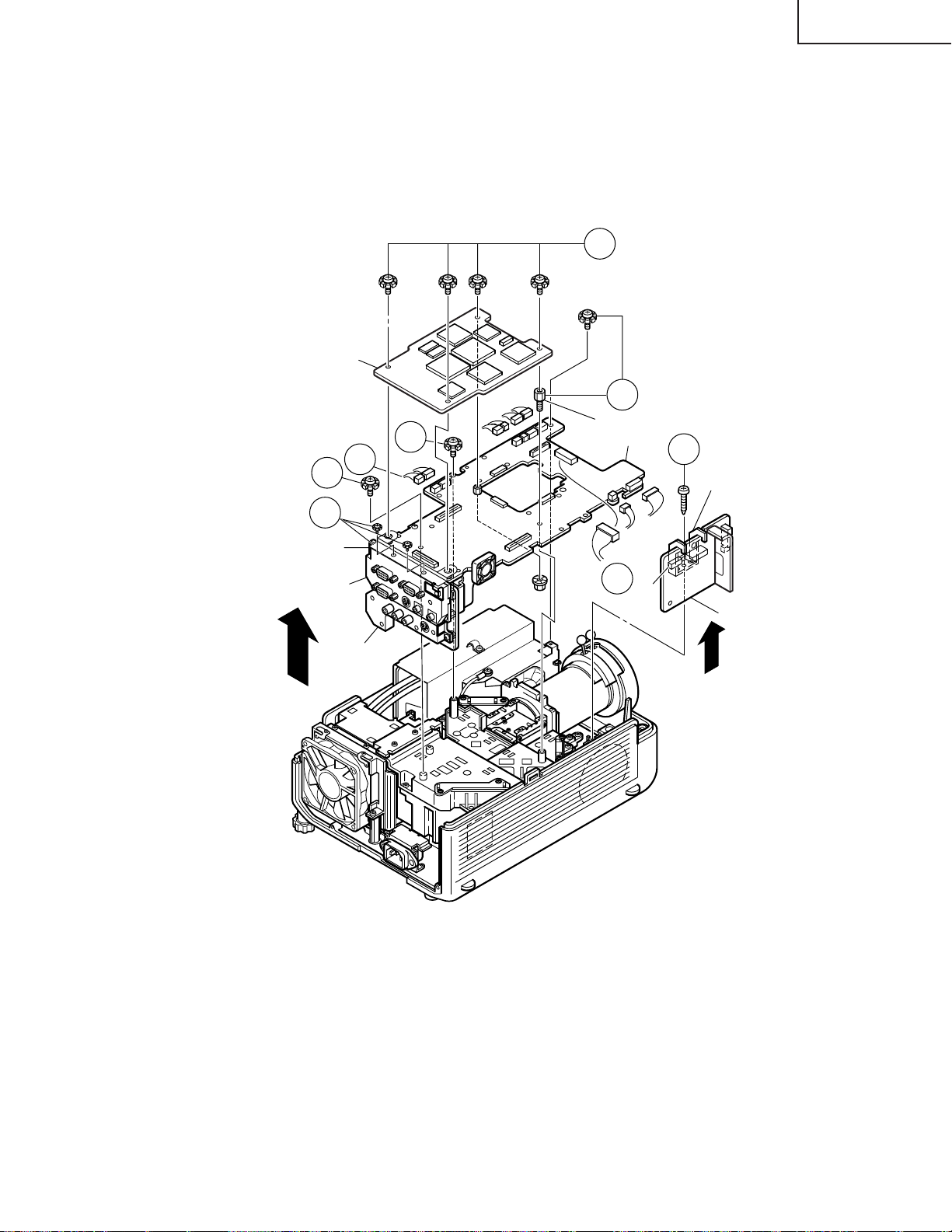

XG-C40XU/XE

PC Terminal Unit

Video Unit

Signal Unit

PC I/F Unit

Spacer (stud bolt)

Output Unit

S-out/REG Unit Angle

S-out/REG Unit

3-1

3-1

3-2

3-2

3-3

3-3

3-3

3-4

(FP)

(FS)

(Q)

(FN)

(TP)

(EB)

(EB)

(SO)

(SP)

(EA)

(SO)

(F)

(L)

3. Removing the PWB units

3-1. Disconnect the connectors from the output unit.

3-2. Remove the four PC I/F unit lock screws.

Remove the two screws and the earth shield, and take out the PC I/F unit.

3-3. Remove the spacer (stud bolt) and the three screws off the output unit. Lift the output unit, together with the

signal unit, off the position.

3-4. Remove the S-out/REG unit angle lock screw and take out the S-out/REG unit.

16

XG-C40XU/XE

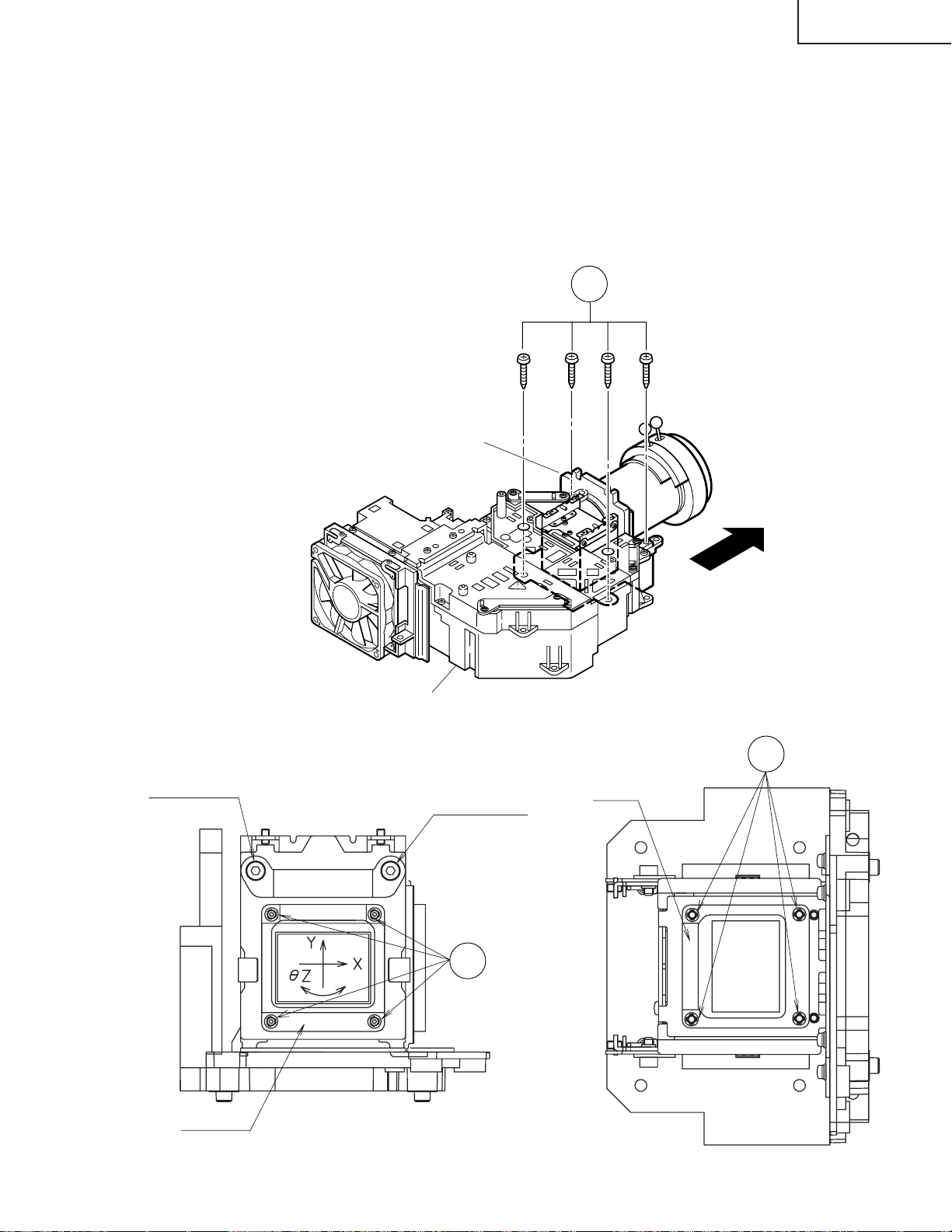

4-1

Optical Mechanism Unit

Duct Fan Unit

4-2

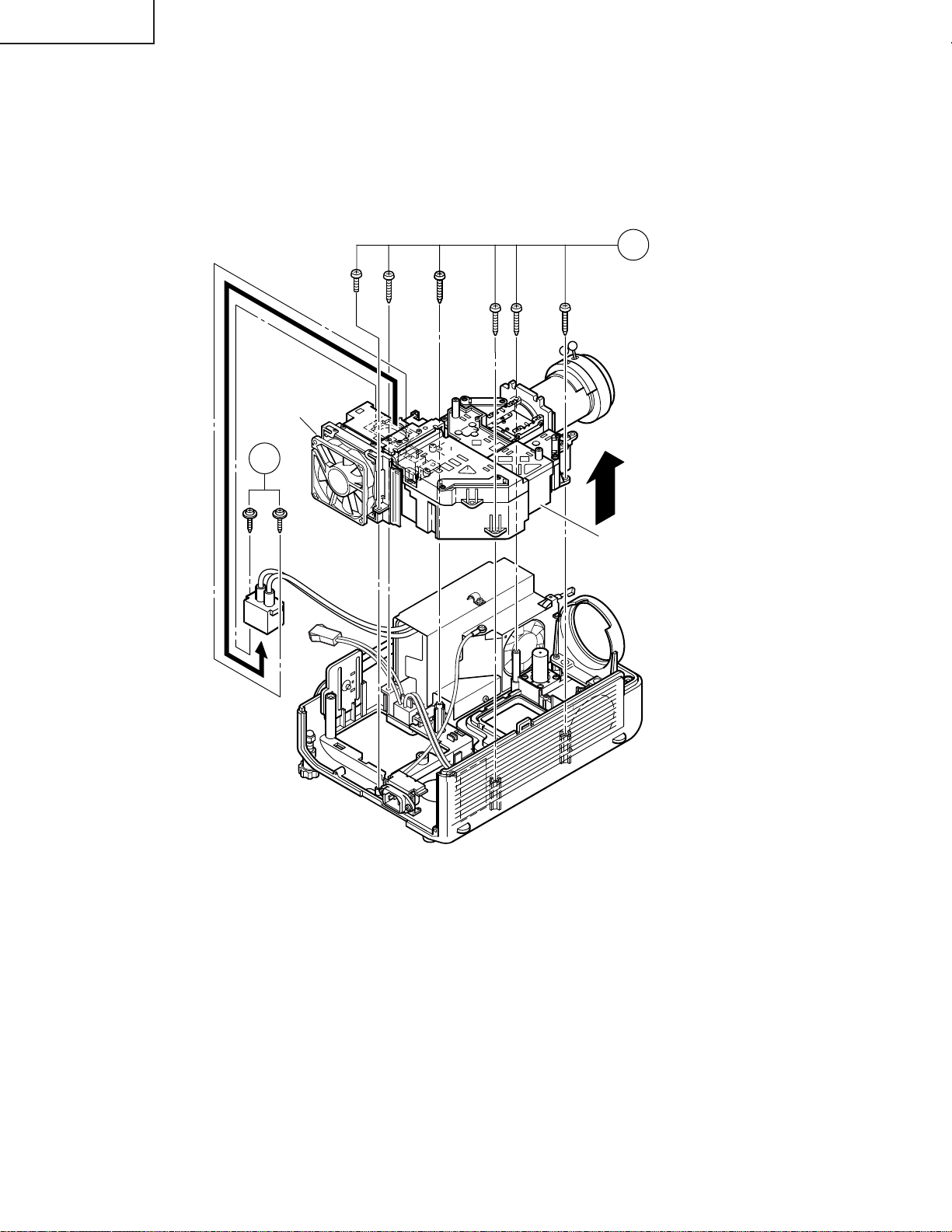

4.Removing the optical mechanism unit

4-1. Remove the six optical mechanism unit lock screws. Lift the unit off the position.

4-2. Remove the two lamp socket holder lock screws and take out the holder.

17

XG-C40XU/XE

6-1

6-3

(PA)

(BA)

(PA)

(FG)

AC power switch

(for Lamp replacement)

Inlet Unit

5-1

5-2

5-3

(FG)

(TP)

6-2

Power/Ballast Unit Ass'y

5.Removing the Power/Ballast unit assembly

5-1. Remove the Power/Ballast unit assembly lock screw.

5-2. Remove the (FG) lead lock screw.

5-3. Lift the Power/Ballast unit assembly off the position.

6.Removing the ballast unit and inlet unit

6-1. Disconnect the connector (PA) from the inlet unit. Take out the AC power switch.

6-2. Remove the Inlet unit lock screw.

6-3. Pull the inlet unit toward yourself off the position.

Note: Before installing the lamp cover, make sure the AC power switch is at the " " (OFF) position.

18

XG-C40XU/XE

'

'

'

'

I

+

RESIZE

AUTO

SYNC

ENLARGE

FREEZE

BLACK SCREEN

MENU

KEYSTONE

MUTE

VOLUME

ON

OFF

INPUT

ENTER

TEMP.

LAMP

POWER

ENTER ADJ." ADJ.|

B

GAMMA

UNDO

Problem

• Lamp has been used for over 1,900

hours.

• Lamp has been used for over 2,000

hours.

Possible Solution

• Purchase a replacement lamp unit

(lamp/cage module) of the current

type BQC-XGC40XU/1 from your

nearest Sharp Authorised LCD

Projector Dealer or Service Centre.

• Replace the lamp. If you wish, you

may have the lamp replaced at

your nearest Sharp Authorised

LCD Projector Dealer or Service

Centre.

Condition

The LAMP REPLACEMENT

indicator lights up red, and “LAMP”

and “ ” will flash in yellow in the

lower-left corner of the picture.

A significant deterioration of the

picture and colour quality occurs.

The power will automatically turn

off and the projector will enter

standby mode.

“LAMP” and “ ” will flash in red in

the lower-left corner of the picture,

and the power will turn off.

Lamp

The lamp in this projector operates for approximately 2,000 cumulative hours, depending on the usage environ-

ment. It is recommended that the lamp be replaced after 1,900 cumulative hours of use or when you notice a

significant deterioration of the picture and colour quality. The lamp usage time can be checked with the On-screen

Display.

CAUTION

• Intense light hazard. Do not attempt to look into the aperture and lens while the projector is operating.

• As the usage environment can vary significantly, the projector lamp may not operate for 2,000 hours.

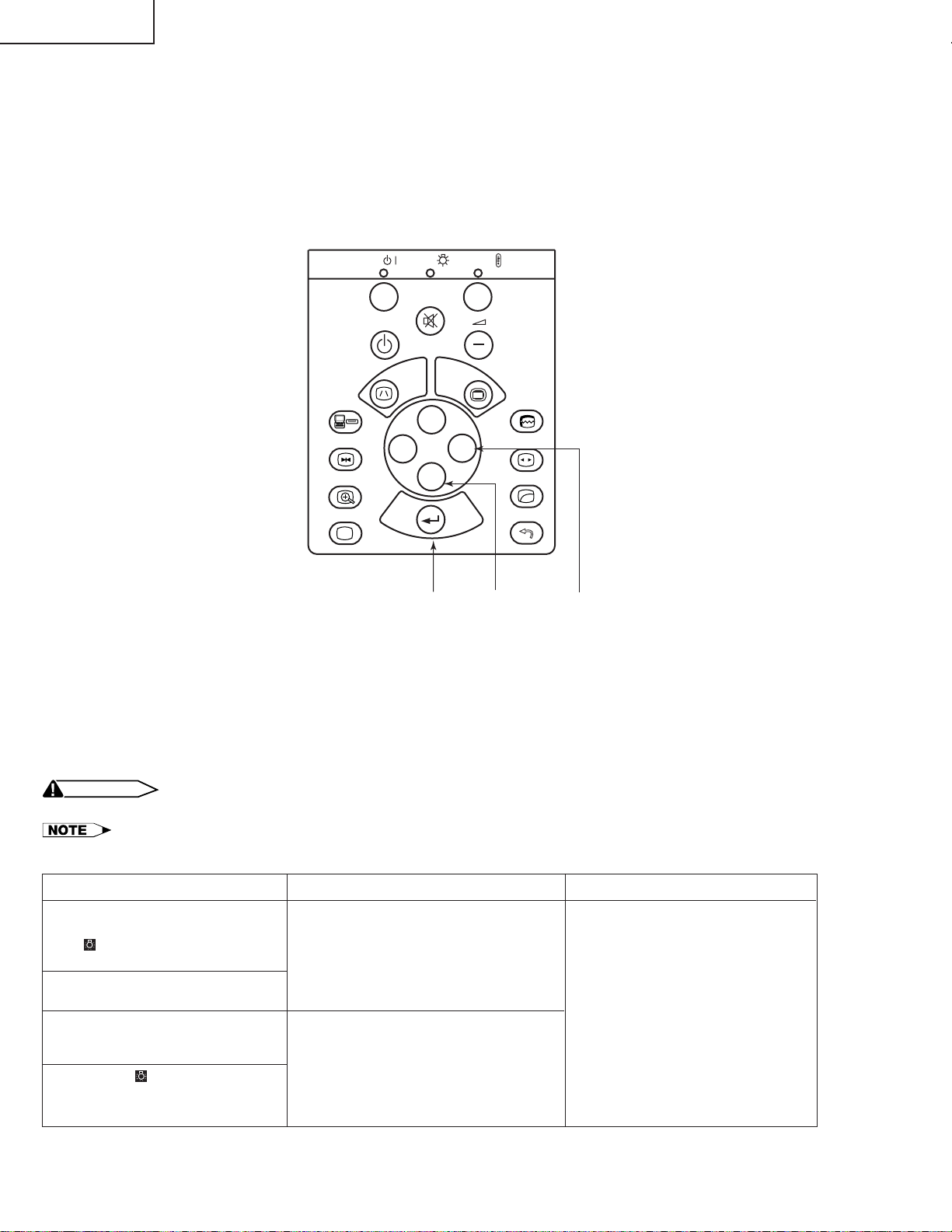

RESETTING THE TOTAL LAMP TIMER

When the lamp has been replaced, reset the total lamp timer in the following steps.

Resetting procedure

1. While holding down the “ENTER”, “ADJ."” and “ADJ.|” keys on the set at the same time, turn on the main

power switch (located side the AC inlet).

2. Now the total lamp timer is reset to zero. “000H” appears on the screen.

19

XG-C40XU/XE

B-LCD

G-LCD

GREEN

BLUE

BLUE

RED

R-LCD

AR coating

Dichroic coating

(B reflection)

Dichroic coating

(B reflection)

Porarizing film

Porarizing film

R-reflector

Dichroic coating

(R reflection)

Dichroic coating

(G transmission)

G reflector

Dichroic coating

Marking

Marking

(Bottom)

B/G reflector

Ag-coated mirror W

Ag-deposited

face

Fly-eye lens (outgoing light)

Fly-eye lens (incoming light)

DC lamp

(Light source)

Relay lens 1

Projection Lens

B reflector

B reflector

Cross dichroic prism

Incident polarizing plate B

emergent polarizing

plate B

Relay lens 3

Relay lens 2

emergent

polarizing plate G

emergent polarizing plate R

Condenser lens G

Fly-eye aperture

Condenser lens R

Dichroic coating (R transmission)

M3

M4/M6

RL3

CL2

RL2

CL3

RL1

M4/M6

M2

M5

M1

PBS(polarization

beam splitter)

CL1

UV-IR coating

UV-filter

UV-filter(0.8t)

THE OPTICAL UNIT OUTLINE

Layout of the optical system

Note: Layout for positioning the optical system.

20

XG-C40XU/XE

CONVERGENCE AND FOCUS ADJUSTMENT

» Start the convergence and focus adjustments with the top panel removed but the power

on. Use the remote control to adjust the image.

Take the following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the LCD panels with new ones. But until the focus has been completely readjusted, be careful not

to change the projection distance between the set and the screen, nor to move the projection lens focus

and zoom rings.

Note:

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE for example) may get out

of the focus range, or a long-distance image (300 WIDE for example) may come out of the focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

projection distance between the set and the screen, nor to move the projection lens focus and zoom rings.

3. If the projection distance has been changed or the projection lens readjusted, repeat the above steps 1 and

2.

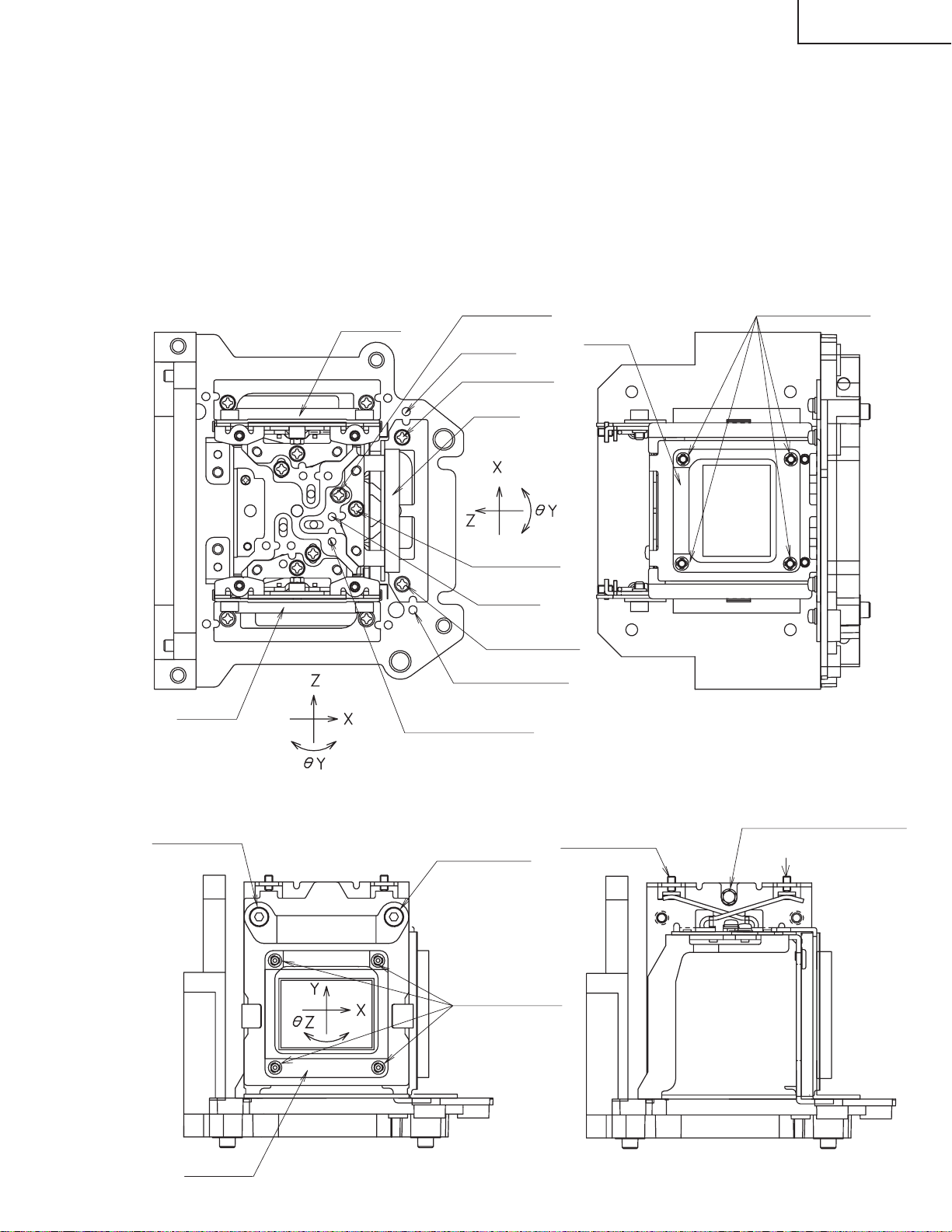

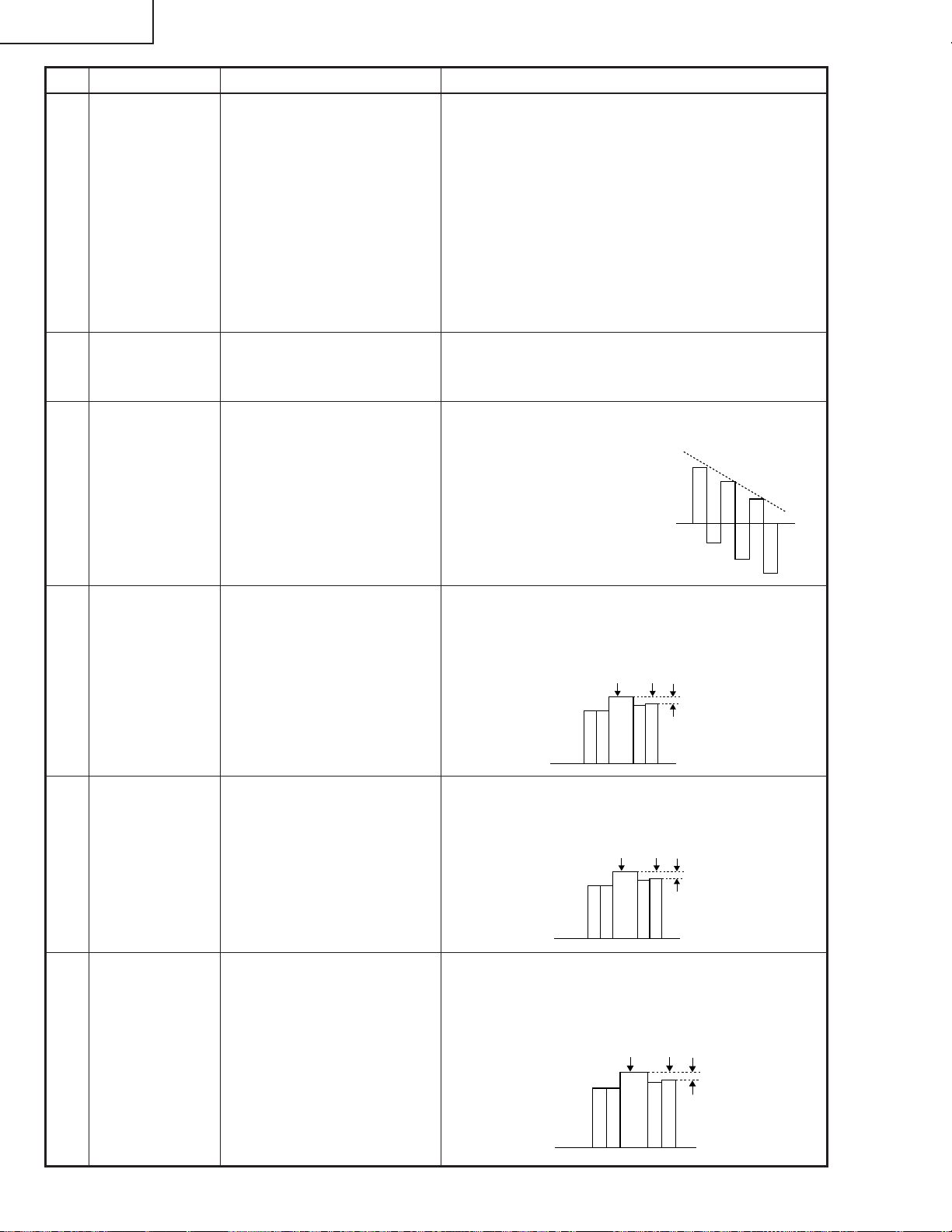

2. Focus adjustment

(A) Adjusting the G-LCD panel(Make this adjustment on the white-only screen.)

1. Adjustment in θX and Z directions .

Loosen the lock screw "a" and insert an eccentric screwdriver into the notch and hole "a". Turn the screwdriver

until the top, center and bottom on the screen get into focus. In adjusting this top-to-bottom focus, tighten

the lock screws "b" and "c" to fix the θY direction adjustment.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

2. Adjustment in θY direction

T emporarily tighten the lock screw "a" and loosen the lock screws "b" and "c". Insert the eccentric screwdriver

into the notch and hole "c" for adjusting in the θY direction on the top of the screen. Insert the eccentric

screwdriver into the notch and hole "b" for adjusting in the θY direction on the bottom of the screen.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Notes :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

(B) Adjusting the B-LCD panel (Do the same for the R-LCD panel.)

1. Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is

wider in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels,

roughly adjust the convergence first and then the focus.

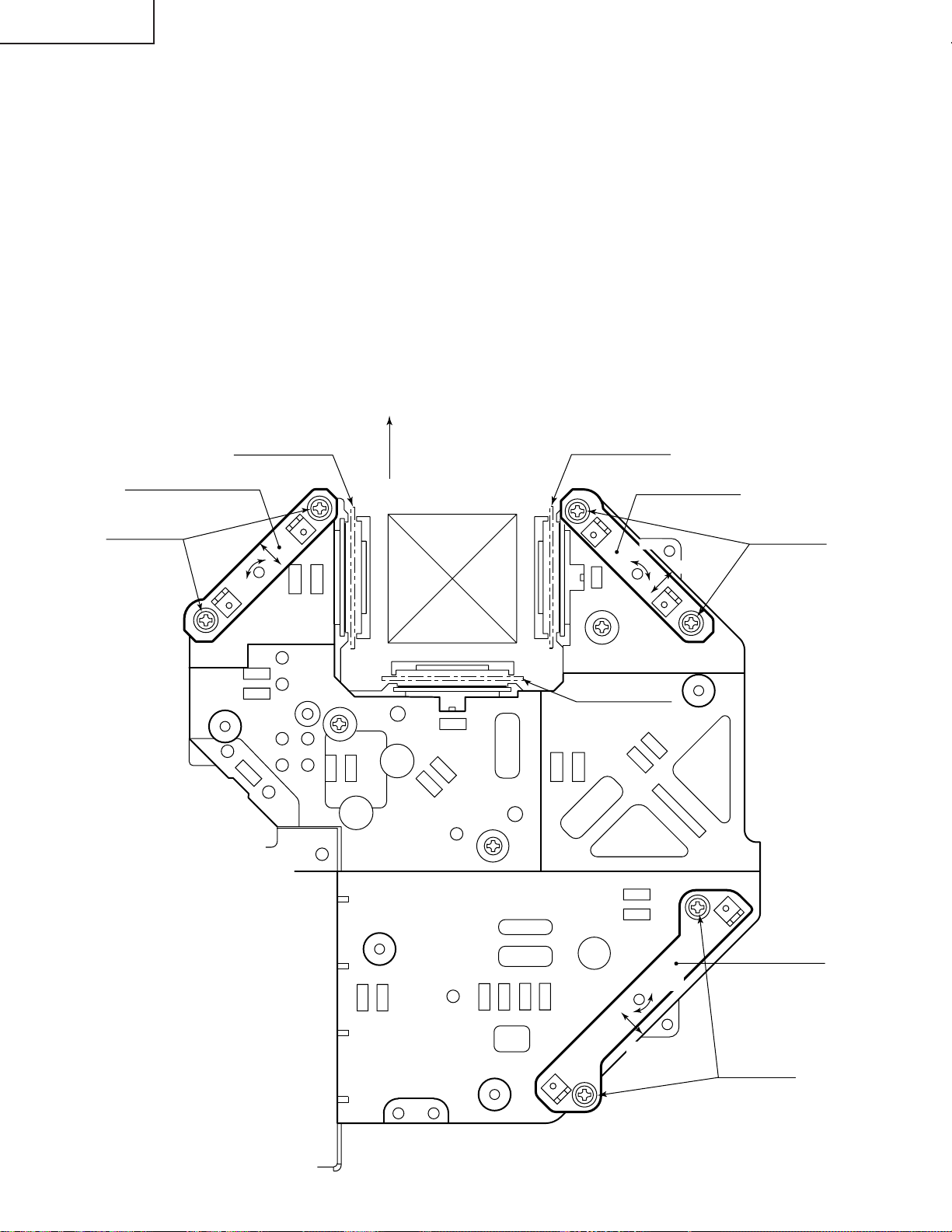

3. Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-LCD and the relevant colour.

1. Loosen the convergence lock screw "d".

2. Adjustment in Y and θZ directions

Put a hex wrench in the Y and θZ direction adjustment zone.

3. Adjustment in X direction

Put an eccentric cam adjusting wrench in the X direction adjustment zone.

21

XG-C40XU/XE

R-LCD

B-LCD

Lock screw "a"

Lock screw "c"

Notch and

hole "c"

Notch and

hole "b"

Lock screw "c"

G-LCD

G-LCD

Lock screw "b"

Notch and hole "c"

Notch and hole "a"

Lock screw "d"

Lock screw "d"

R·B-LCD panel

mounting screws

(four screws)

R·B-LCD

SIDE VIEW (from inside)

SIDE VIEW (from outside)

TOP VIEW SIDE VIEW

G-LCD panel

mounting screws

Eccentric cam

(Y direction adjustment)

Eccentric cam

(X direction adjustment)

Eccentric cam

(θZ direction adjustment)

(four screws)

4. With the G-LCD panel's screen center as refernce, adjust the R-LCD and B-LCD panels.

5. Finally tighten up the convergence lock screw "d".

Notes :

1 The eccentric cam is used for convergence adjustment.

This means that the cam's turning and the linear movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the cross-dichroic

prism is used for image formation. When the LCD panels all get into best focus, the images are almost

completely converged.

Convergence and Focus Adjustments Mechanism

22

XG-C40XU/XE

80

100

2

5

16

R2

50

CUT

2

2

92

5

7.5

0.5

min85

ø5

ø3.5

3.5

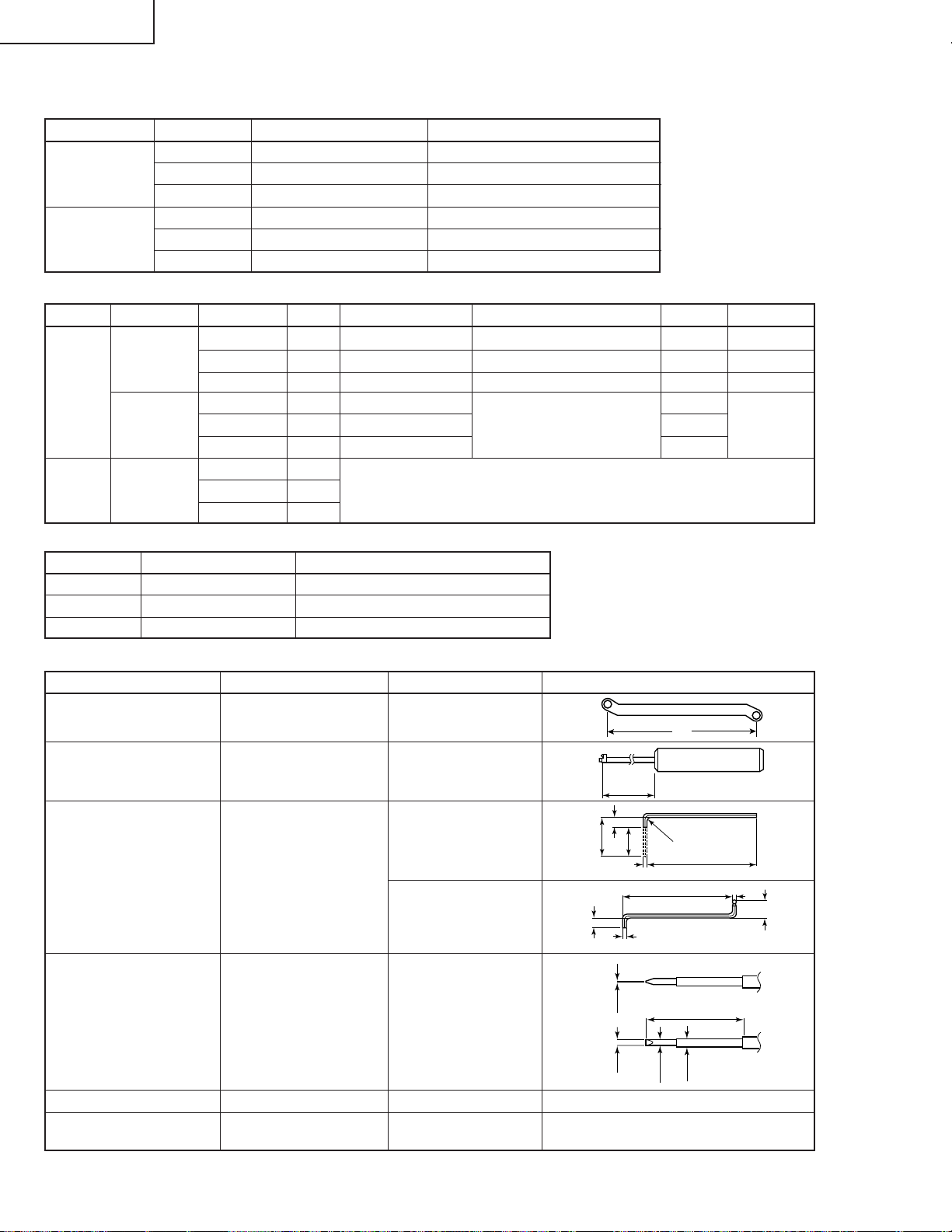

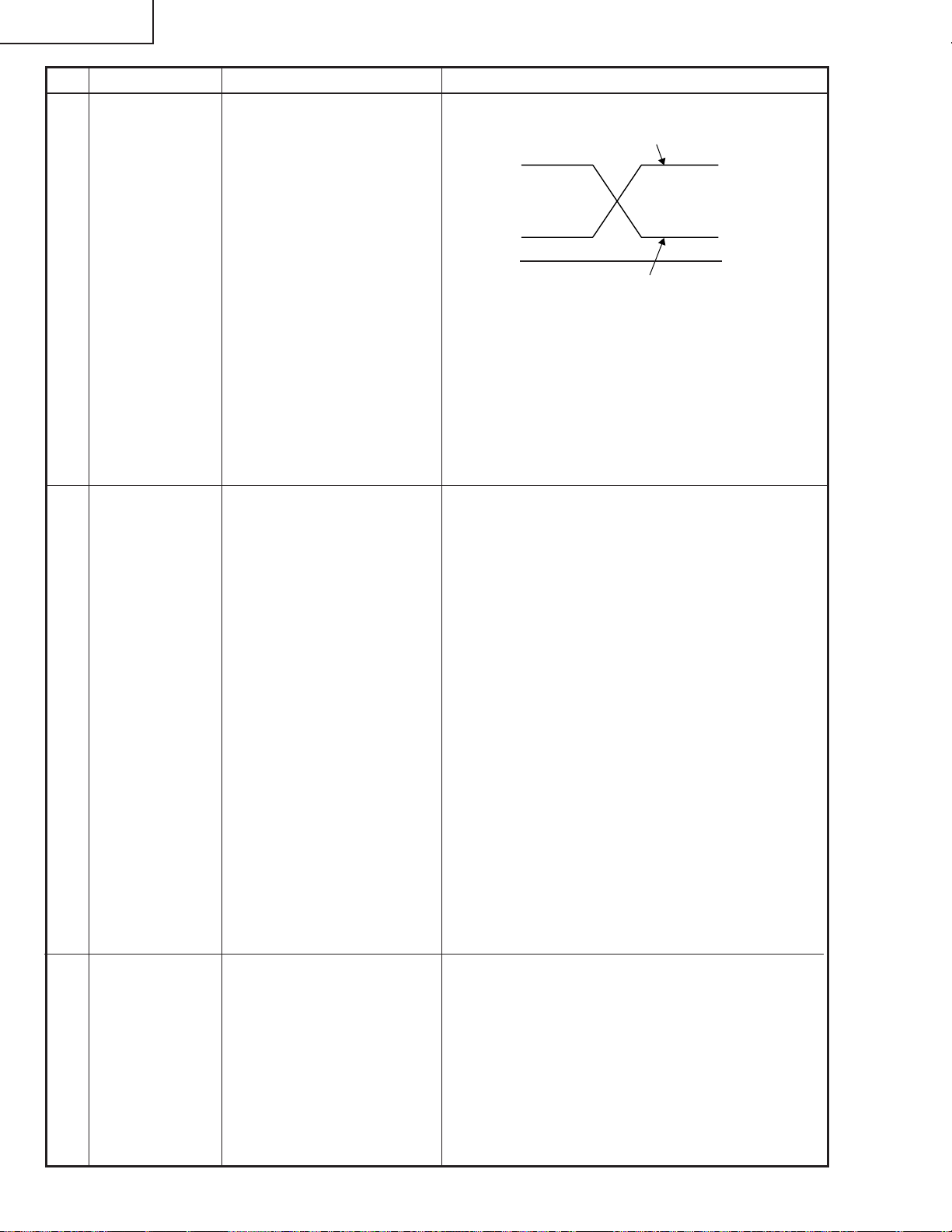

Convergence and Focus Adjustments at a Glance

Adjustment directions

Adjustment Direction Definition Direction of LCD panel

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the Optical Mechanism

Colour Adjustment Direction

Movement

Position Adjusting tool

Lock screw

Tightening tool

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colours Z direction ±0.8mm

Notch and hole "a" & "c"

Eccentric screwdriver, a, c

Focus θX direction ±1°

Notch and hole "a" & "c"

Bladed screwdriver a, c

θY direction ±1°

Notch and hole "b" & "c"

b, c

Z direction ±0.2mm

G colour Focus θX direction ±1° Same as for R and B colours

θY direction ±1°

Phillips

screwdriver,

*Hex wrench

Focus Adjustments the Other Way

Lock screw Position Related direction

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

Tool Specific or General Tool code Configuration

Eccentric cam

Specific 9DASPN-XGNV1U

adjusting wrench

Eccentric screwdriver Specific 9DADRiVER-NV4U

Hex wrench General (redesigned)

9EQLNC-XGNV1U

9EQLNC-XGNV4U

Bladed screwdriver General 9EQDRiVER-NV1B

Phillips screwdriver General — For M2.6 pan-head machine screw

*Hex wrench General —

1.27mm, preferably use a 70 mm or

longer screwdriver (with a handle).

23

XG-C40XU/XE

G-LCD

SIDE VIEW

G-LCD panel

mounting screws

Lock screw "d"

Lock screw "d"

R·B-LCD panel

mounting screws

R·B-LCD

SIDE VIEW (from inside)

2

2

1

Prism holder

Optical Mechanism Unit

Replacing the LCD panels

Detach the top panel and the optical mechanism unit in advance.

(1)Remove the four prism holder lock screws. Detach the prism holder from the optical mechanism unit.

(2)Remove the LCD panel lock screws (four each for the R-, G- and B-LCD panels). Detach the LCD panels from the

prism holder.

(3)Mount a new LCD panel in the reverse order of the above steps (1) and (2).

~ Readjust the convergence and focus. Note that the G-LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

24

XG-C40XU/XE

FRONT

M5 adjust lever

Lock screws

Lock screws

M4/M6

adjust lever

Lock screws

M1 adjust lever

Shielding plate G

slide

turn

turn

slide

turn

slide

Shielding plate R

Shielding plate B

Adjusting the optical axis of the mirrors (M1, M5 and M4/M6)

The optical axis must be readjusted if an eclipse happens with the R. G or B mirrors. Generally speaking,

this adjustment is needed when any of the internal optical components has been replaced.

Adjustment procedure required when any of the panels has been replaced or the convergence has been

adjusted

(1)Disconnect the flat cables of all the LCD panels.

(2)Let the lamp light up.

(3)To adjust the G mirror, shield the R and B mirrors with shielding plates (You can use a business card or the like to

block the light).

(4)Loosen the lock screw of the M1 adjust lever.

(5)Looking at the G image on the screen, turn or slide the M1 adjust lever until the eclipse on the screen disappears.

Tighten up the screw.

(6)To adjust the R mirror, shield the G and B mirrors and adjust the M5 adjust lever. For the B mirror , shield the R and

G mirrors and adjust the M6 adjust lever.

(Take the same steps 4 and 5 above.)

(7)Remove all the shielding plates to have a white image.

Make sure there is no eclipse.

25

XG-C40XU/XE

3.3Vp-p

(Adjust to 2.6V

DC for red and

blue.)

(Adjust to 3.3Vp-p

for green and blue.)

2.6V

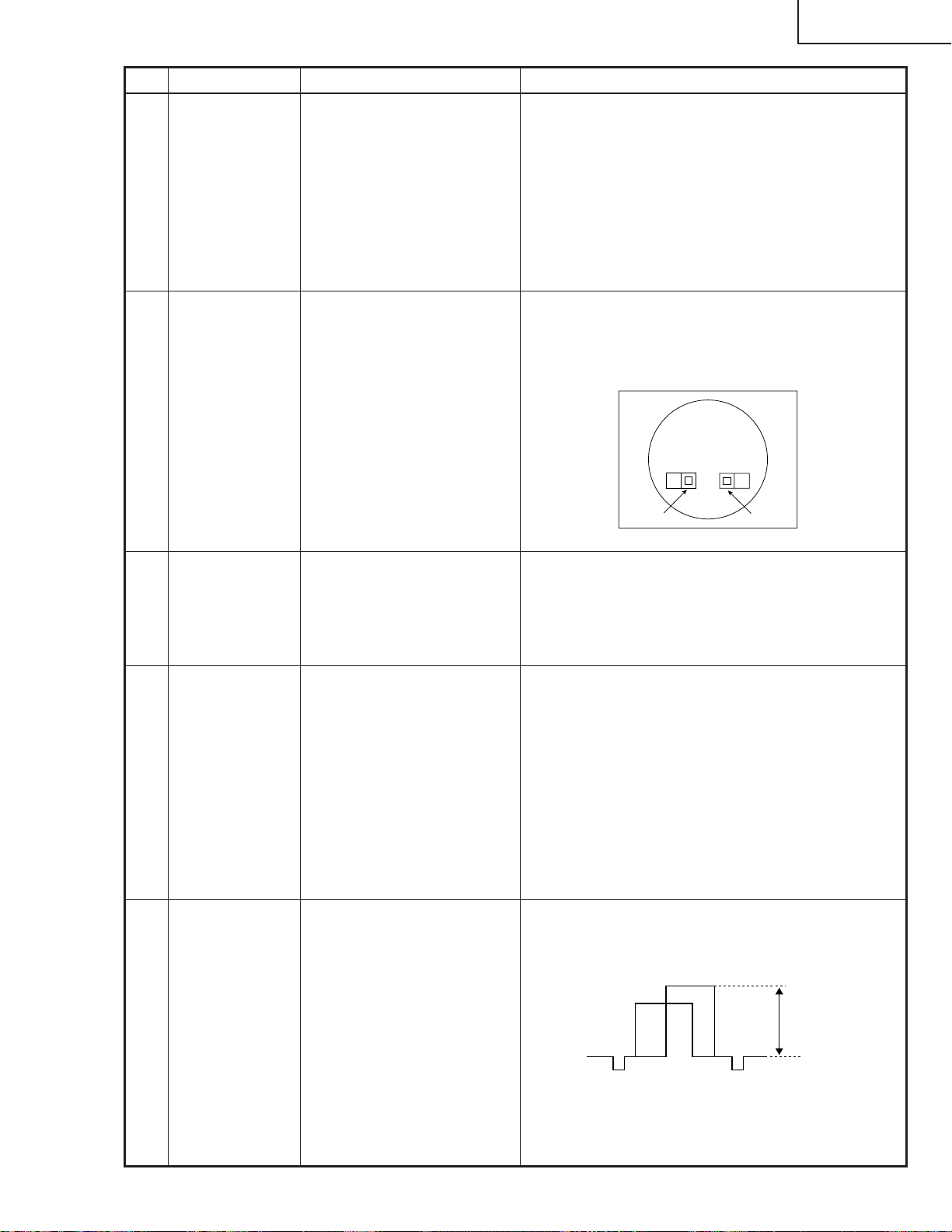

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (make

sure the lamp lights up) and

warm up the unit for 15 min-

utes.

» Make the following settings:

Press SW5101 to call up the process mode and

execute S2 in the SSS menu. Now the system,

with the PC board not included, is initialized. Do

not execute S1 because otherwise the PC board

will be initialized.

To adjust the PC board, follow the instruction in

"Adjusting the PC board". (See page 31)

2 3.3V power

supply

adjustment

1. Turn on the power.

2. Connect the digital voltme-

ter to TP1446.

» Adjust R1649 so that the voltmeter should read

3.43 ±0.03 Vp-p.

3 2.5V power

supply

adjustment

1. Turn on the power.

2. Connect the digital voltme-

ter to TP1447.

» Adjust R1652 so that the voltmeter should read

2.60 ±0.05 Vp-p.

4 R drive » Using the control switches or the remote controller

buttons, adjust the data so that the signal be-

comes bit-less (noise).

1. Feed the 100% red-only sig-

nal. Make the following

choice.

Group : A/D

Subject : R-D

5 B drive 1. Feed the 100% blue-only

signal. Make the following

choice.

Group : A/D

Subject : B-D

» Using the control switches or the remote controller

buttons, adjust the data so that the signal be-

comes bit-less (noise).

6 G drive 1. Feed the 100% green-only

signal. Make the following

choice.

Group : A/D

Subject : G-D

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes

bit-less (noise).

7 RGB 1 system

black level

signal amplitude

(odd-numbered)

1. Make the following choice:

Group : OUTPUT 1

Subject : G1-BLK

G1-GAIN

For red, choose the sub-

jects R1-BLK and R1-GAIN.

For blue, choose the sub-

jects B1-BLK and B1-GAIN.

2. Connect the oscilloscope to

TP1101 for red.

TP1201 for green

TP1301 for blue

» Choose the subject G1-GAIN and adjust the sig-

nal amplitude to 3.3 ±0.1 Vp-p using the control

switches or the remote controller buttons.

» Next,choose the subject G1-BLK and adjust the

white to white level to 2.6 ±0.1V DC.

» Adjust the signal's amplitude and white to white

level to 3.3 ± 0.1Vp-p and 2.6 ± 0.1V DC, respec-

tively, for red and blue.

26

XG-C40XU/XE

2.0V DC

6.2±0.2V DC

PSIG

GND

(Adjust with PSIG-H.)

(Adjust with PSIG-L.)

No. Adjusting point Adjusting conditions Adjusting procedure

8 P SIGNAL 1. Connect the oscilloscope to

TP1701 for red.

TP1702 for green

TP1703 for blue.

2. Make the following choice:

Group : OUTPUT 2

Subject : PSIG-H

: PSIG-L

» Adjust the PSIG waveform to the one shown below.

» For the green and blue colours, make sure their wave-

forms are similar to that of the red colour.

» Make sure the pin stripe of every 12 dot doesn't ap-

pear at 10 steps signal of side nays.

(Appearing white pin stripe or black one, adjust the

PSIG-H.)

9 Panel ghost

adjustment

1. Project the XGA60Hz ghost

test pattern (black charac-

ters in bold on the halftone

RGB background).

Group: OUTPUT3

2. GCK-PHASE adjustment

Make sure the setting is fixed

at 8 (initial value).

3. EN-WIDTH adjustment

Make sure the setting is fixed

at 8 (initial value).

4. ENR-PHASE adjustment (R-

LCD ghost adjustment)

5. ENG-PHASE adjustment

(G-LCD ghost adjustment)

6. ENB-PHASE adjustment (B-

LCD ghost adjustment)

» ENR-PHASE adjustment (R-LCD ghost adjustment)

1 Increase the setting until a ghost image (see

Note) becomes visible at the left of the back

characters on the R half-tone background.

2 Lower the setting point by point until the left-

hand ghost image (1 above) disappears.

3 Further lower the setting by one point.

» ENG-PHASE adjustment (G-LCD ghost adjust-

ment)

Adjust the G ghost image by following the same

procedures described under step 1 above.

» ENB-PHASE adjustment (B-LCD ghost adjust-

ment)

Adjust the B ghost image by following the same

procedures described under step 1 above.

Note: Left-hand ghost image: Characters are shown

double 12 dots left from the real characters.

Reference: This adjustment is made because the

EPSON LCD panel may have 1- or 2-

point differences due to lot-by-lot varia-

tions.

10 Sample-and-

hold pulse

phase

RCK-PHASE

GCK-PHASE

BCK-PHASE

1. Feed the XGA mode 75-Hz

black signal.

2. Make the following choice:

Group : OUTPUT 3

Subject : SH-PHASE

(Have the standard level at

2.)

Fix the RCK-, GCK- and

BCK-PHASE settings all to

8.

» Using the control switches or the remote controller

buttons, make sure that the “OUTPUT 3” charac-

ters are not blurry and there is no ghost image. If

such blur or ghost occurs, finely adjust the setting

in the range of 7~9.

27

XG-C40XU/XE

1

2

2.0Vp-p

No. Adjusting point Adjusting conditions Adjusting procedure

11 RGB counter-

voltage

adjustment

1. Feed the black-and-red

(25%) stripe signal (XGA).

2. Make the following choice:

Group : OUTPUT 3

Subject : RC (R)

and

Group : OUTPUT 3

Subject : RC-INV (R)

» Using the control switches or the remote controller

buttons, adjust the data in order to minimize the

flicker.

» Make the same adjustment for BC (B), GC (G),

RC-INV (B) and RC-INV (G).

» See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

12 RGB gradation

regeneration

adjustment

1. Feed the green-only SMPTE

pattern signal (XGA).

Group : OUTPUT 1

Subject : G1-BLK

» Adjust the G-BLK data until the gradation of the

portion 1 (95% and 100% white) shown below

can be slightly recognized. Make sure also that the

gradation of the portion 2 (0% and 5% black) is

visible.

13 RGB white

balance

1. Feed the 32-step gray scale

signal (XGA).

Group : OUTPUT 1

Subject : R1-BLK (R)

B1-BLK (B)

» Choose the subjects R1-BLK and B1-BLK and

adjust the black balance of the gradation.

14 Horizontal

center

1. Feed the NTSC monoscope

pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (4)

N443-DLY (0)

PAL-DLY (3)

SECAM-DLY (0)

Make sure the settings are

as above.

3. Group : VIDEO 1

Subject : NTSC-H

» Using the control switches or the remote controller

buttons, adjust the data to have the same

overscan.

15 Video picture

adjustment

1. Feed the split colour bar sig-

nal.

Group : VIDEO 1

Subject : PICTURE

2. Connect the oscilloscope

between pin (2) of P801 and

GND.

» Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.0 ±0.02 Vp-p.

28

XG-C40XU/XE

100% White Red

100% White Red

100% White Red

No. Adjusting point Adjusting conditions Adjusting procedure

16 Video

brightness

adjustment

1. Feed the baseband (split

colour bar) signal. (The ON-

AIR signal is not accepted

because of its too much

noise.)

Group : VIDEO 2

Subject :

VROS/VGOS/VBOS

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

» Using the control switches or the remote controller

buttons, adjust the setting until the black signal

becomes bit-less.

17 Video AGC 1.

Feed the split colour bar signal.

Group : VIDEO 1

Subject : AGC

» Using the control switches or the remote controller

buttons, adjust the setting until the white signal

becomes bit-less.

18 Tint 1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

pin (4) of P801.

» Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) wave-

form downhill straight.

» After adjusting, adjust the

value of TINT up 3 point.

19 NTSC colour

saturation level

1. Feed the split colour bar sig-

nal.

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.00 ±0.05 Vp-p.

(same as 100% white)

20 PAL colour

saturation level

1. Feed the PAL colour bar sig-

nal.

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.2 ±0.05 Vp-p.

21 SECAM colour

saturation level

1. Feed the SECAM colour bar

signal.

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

» Using the control switches or the remote controller

buttons, adjust the data to have a level difference

of 0.2 ±0.05 Vp-p between the 100% white portion

and the red portion.

29

XG-C40XU/XE

No. Adjusting point Adjusting conditions Adjusting procedure

22 Video input

panel signal

amplitude

adjustment

1. Feed the NTSC 10-step sig-

nal.

2. Select the following group

and subject.

Group: VIDEO2

Subject: R1-GAIN

B1-GAIN

3. Connect the oscilloscope to

TP1 101 (R) and TP1201 (G).

4. For the blue colour, con-

nect the oscilloscope to

TP1301 (B) and TP1201

(G).

» Select R1-GAIN and adjust the setting so that the

R and G signals have the same amplitude.

» For the blue colour, adjust the setting the same

way.

23 Video white

balance

1. Feed the NTSC monoscope

pattern signal

Group : VIDEO 2

Subject : R1-BLK

B1-BLK

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

24 DTV white

balance

1. Feed the monoscope pattern

signal.

2. Group: DTV

Subject: CR-OFFSET

CB-OFFSET

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

25 Setup 1. Group: VIDEO1

Subject: SET UP B

SET UP C

» Make sure the settings are 11 for SET UP B and 2

for SET UP C.

26 Automatic

colour correc-

tion

1. Using the colour correction

system (ccdc), apply auto-

matic colour correction.

» Make sure there is no noticeable colour irregularity

left on the screen.

27 Colour system

performance

check

1. Receive the colour bar sig-

nal.

» In the process mode and select L1. Check the col-

our and tint.

28 Video system

performance

check

1. Receive the monoscope pat-

tern signal.

» In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

29 Audio system

performance

check

» In the process mode nad select L3. Check the bass,

treble.

30

XG-C40XU/XE

S3 “Factory setting 3”(XG-C40XE)

S4 “Factory setting 4”(XG-C40XU)

No. Adjusting point Adjusting conditions Adjusting procedure

30 RGB

performance

check

1. Receive the RGB signal. » In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

31 Off-timer

performance

check

» In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down each

minute in 1 second, and turns off the set at “0”.

32 Thermistor

performance

check

1. Heat the thermistor using a

dryer.

» Make sure the “TEMP” is displayed.

33 Automatic

synchronization

1. Receive the PHASE check

pattern signal.

» Call the VGA/SVGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

34 Keystone

correction

performance

check

» Make sure the keystone correction functions well.

35 Factory settings » Make the following settings.

Process

adjustment

Remote controller setting

Loading...

Loading...