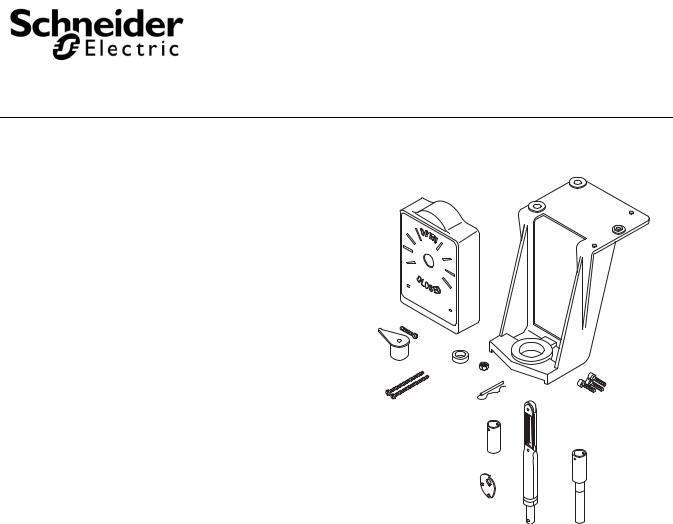

Schneider Electric AV-291, AV-293, AV-295, AV-296 Installation Instructions

AV-291, AV-293, AV-295, and

AV-296

Valve Linkage for

Hazardous Location Gear Train Actuators

General Instructions

Application

The AV-29x linkages are used to field assemble Schneider Electric gear train hazardous location actuators to VB-7xxx series or select VB-9xxx series valve bodies.

Features

• Die cast aluminum mounting bracket.

• Valve position indication provided as standard.

Applicable Literature

• EN-56-2 Apparatus for Use in Hazardous Locations,

F-18451

• MAx-305 & MAx-318 Series MAx-405 through MAx-419 Series, Two-Position Actuators General Instructions, F-06491

•MC-351, 421, 431, MC-4311 Three-Wire, Two Position Actuators General Instructions, F-08366

•MP-3xx and MP-4xx Series Reversible and Proportional Electric Actuators, F-15479

•Valve Products Catalog, F-27384

•EN-205 Water System Guidelines, F-26080

Printed in U.S.A. 4/10 |

© Copyright 2010 Schneider Electric All Rights Reserved. |

F-27441-2 |

SPECIFICATIONS

Required

Components

INSTALLATION

Inspection

Table-1 Model Chart.

Valve Linkage |

Description |

Stem Force |

|

Model Number |

Complete Linkages |

(lb.) |

|

AV-291 |

VB-7xxx 1/2” to 2” |

150 |

|

|

|

||

AV-293 |

300 |

||

|

|||

|

|

|

|

AV-295 |

VB-9xxx 2-1/2” to 3” bronze |

150 |

|

AV-296 |

VB-9313 2-1/2” to 4” cast iron flanged |

300 |

|

|

|

|

Temperature Restrictions

Verify that the fluid temperature of the media in the valve versus the ambient temperature at the actuator does not exceed the ratings shown in Table-2.

Table-2 Restrictions on Maximum Ambient Temperature for Actuators.

Maximum Temperature of Media in the Valve |

Maximum Ambient for Actuator |

|

(Check Rating of Valve) °F (°C) |

°F (°C) |

|

260 |

(126) |

136 (57) |

|

|

|

281 |

(138) |

125 (52) |

|

|

|

300 to 366 |

(149 to 185) |

100 (37) |

Close-off Pressure Rating

Close-off pressure ratings are listed in Table-3. Check the appropriate table to verify that the selected valve, valve linkage, and actuator provide adequate close-off pressure for your application.

The actuator with hazardous location housing, valve, and valve linkage should be purchased separately. See Table-3 for selections.

Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If undamaged, open the package and inspect the device for obvious damage. Return damaged products.

Requirements |

• |

Tools (not provided): |

|

|

|

– Appropriate wrenches for stem extensions, lock nuts, packing nuts, and brackets |

|

|

|

– |

Appropriate screwdriver for actuator mounting screws |

|

|

– |

TOOL-37, 1-5/8" open-ended wrench with a maximum thickness of 3/16" |

|

• |

Training: Installer must be a qualified, experienced technician |

|

Caution:

•Install the unit in accordance with the National Electric Code Article 500 and all applicable local codes.

•Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

•Install all two-way valves so that they close against the flow. An arrow on the valve body or a tag indicates the proper flow direction.

•Always install three-way mixing valves with two inlets and one outlet.

•Always install three-way diverting valves with one inlet and two outlets.

•The actuators can be mounted in any position above the centerline of the valve body. For steam applications where the ambient temperature approaches the limit of the actuator, the valve stem should be mounted 45° from vertical. When selecting a location, allow sufficient room for accessories and for service of the product.

2 |

© Copyright 2010 Schneider Electric All Rights Reserved. |

F-27441-2 |

Table-3 Linkage Selection and Valve Close-Off Pressure Ratings for VB-7xxx and VB-9x1x Valve Bodies.

|

|

|

|

|

|

TYPICAL ACTUATOR PART NUMBERSa |

|||

|

|

|

|

|

|

Spring Return |

No Normal |

|

No Normal Position |

|

|

|

|

|

|

|

Position |

|

|

|

|

|

|

|

|

MA8-318, MA8-318-500 |

MP6-421 |

|

MC6-351 |

|

|

|

|

|

|

MA8-418, MA8-418-500 |

|

|

MC6-421 |

|

|

|

|

|

|

MP6-361, MP6-367 |

|

|

MC6-431 |

|

|

|

|

|

|

MP6-371, MP6-377, MP6-379, |

|

|

MP6-381 |

|

|

|

|

|

|

MP6-465 MP7-4651 |

|

|

MP6-485 |

|

|

|

|

|

|

MP6-470, MP6-475, MP7-4751 |

|

|

MC7-4311 |

|

Minimum Torque/Travel Required |

50 lb.-in., 180° Rotation, |

|

|

175/220 lb.-in., 180° Rotation, |

||||

|

150 lb. Plunger |

|

|

300 lb. Plunger |

|||||

|

|

|

|

|

|

|

|

||

Linkage for 1/2" to 2” VB-7xxx Series Valves |

AV-291 |

|

|

AV-293 |

|||||

Linkage for 2-1/2" to 3" VB-9xxx Series Bronze Body |

AV-295 |

|

|

AV-296 |

|||||

|

|

|

|

Valves |

|

|

|

|

|

Linkage for 2-1/2" to 4" VB-9313 Cast Iron Body |

– |

|

|

|

|||||

|

|

|

|

Valves |

|

|

|

|

|

VALVE BODY INFORMATION |

|

|

CLOSE-OFF PRESSURE PSI (kPa) |

|

|||||

Valve Body |

Description |

P |

|

Size |

Cv |

|

|

|

|

Part Number |

|

Code |

|

|

|

|

|

|

|

VB-7213-0-4-P |

|

1 |

|

|

0.4 |

|

|

|

|

VB-7214-0-4-P |

|

|

|

|

|

|

|

|

|

|

2 |

|

|

1.3 |

|

|

|

|

|

VB-7215-0-4-P |

|

|

1/2" |

|

|

|

|

||

|

3 |

|

2.2 |

|

|

|

|

||

VB-7253-0-4-P |

|

|

|

250 (1724) |

|

|

|

||

VB-7273-0-4-P |

|

|

|

|

|

|

|

|

|

|

4 |

|

|

4.4 |

|

|

250 (1724) |

||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

3/4" |

5.5 |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

6 |

|

7.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

2-Way |

|

|

|

|

|

|

|

|

|

7 |

|

1" |

10 |

150 (1034) |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

8 |

|

14 |

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

9 |

|

1-1/4" |

20 |

90 (621) |

|

|

200 (1379) |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

1-1/2" |

28 |

65 (448) |

|

|

140 (965) |

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

2" |

40 |

35 (241) |

|

|

80 (552) |

VB-9213-0-4-P |

|

12 |

|

2-1/2" |

65 |

20 (137) |

|

|

50 (345) |

VB-9215-0-4-P |

|

|

|

|

|

|

|

|

|

|

13 |

|

3" |

85 |

12 (83) |

|

|

34 (234) |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

VB-7313-0-4-P |

|

2 |

|

1/2" |

2.2 |

250 (1724) |

|

|

|

VB-7314-0-4-P |

|

|

|

|

|

|

|

||

|

4 |

|

4.4 |

|

|

250 (1724) |

|||

VB-7315-0-4-P |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

6 |

|

3/4" |

7.5 |

220 (1517) |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

1" |

14 |

150 (1034) |

|

|

250 (1724) |

|

|

9 |

|

1-1/4" |

20 |

100 (689) |

|

|

200 (1379) |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

1-1/2" |

28 |

60 (414) |

|

|

140 (965) |

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

2" |

41 |

33 (228) |

|

|

80 (552) |

|

3-Way |

4 |

|

1/2” |

4.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

3/4” |

7.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB-7323-0-4-P |

|

8 |

|

1” |

15 |

250 (1724) |

|

|

250 (1724) |

|

9 |

|

1-1/4” |

20 |

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

1-1/2” |

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

2” |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VB-9313-0-4-P |

|

12 |

|

2-1/2" |

67 |

20 (137) |

|

|

50 (345) |

VB-9315-0-4-P |

|

|

|

|

|

|

|

|

|

|

13 |

|

3" |

91 |

12 (83) |

|

|

34 (234) |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

VB-9313-0-5-P |

3-Way |

12 |

|

2-1/2" |

74 |

20 (137) |

|

|

50 (345) |

|

125 lb. |

13 |

|

3" |

101 |

12 (83) |

|

|

34 (234) |

|

Flanged |

|

|

|

|

|

|

|

|

|

14 |

|

4" |

170 |

6 (41) |

|

|

17 (117) |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

a See Table-4 to set stem and cam position.

F-27441-2 |

© Copyright 2010 Schneider Electric All Rights Reserved. |

3 |

Loading...

Loading...